Vacuum ladle for aluminum electrolysis

A technology of vacuum ladle ladle and aluminum electrolysis, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of uncontrollable aluminum electrolyte suction, and achieve the goal of avoiding equipment damage accidents, reducing difficulty, and reducing loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

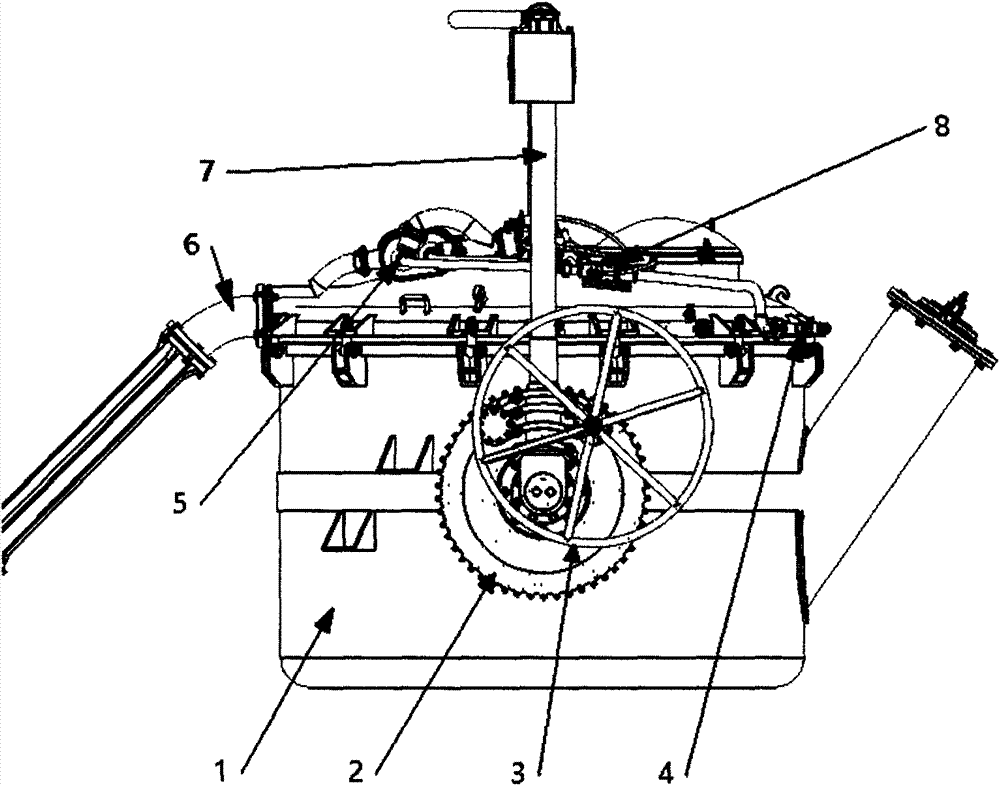

[0013] Below in conjunction with accompanying drawing, the present invention will be further described, as appended figure 1 As shown, the electrolyte discharge automatic control device 8 is installed in the vacuum discharge hole of the vacuum ladle, and the vacuum ladle rotary dumping device 2 is installed between the vacuum ladle boom 7 and the vacuum ladle body 1 . When working, turn on the compressed air switch 4, start the electrolyte discharge automatic control device 8, make the vacuum ladle generate pressure, and press the electrolyte out of the aluminum suction tube through the aluminum suction tube 6, and the electrolyte discharge automatic control device 8 automatically starts the vacuum device Ejector 5 starts to produce aluminum. The vacuum ladle rotating and dumping mechanical device 2 is installed between the ladle body 1 and the boom 7 to avoid equipment damage accidents during the lifting and transportation of the vacuum ladle.

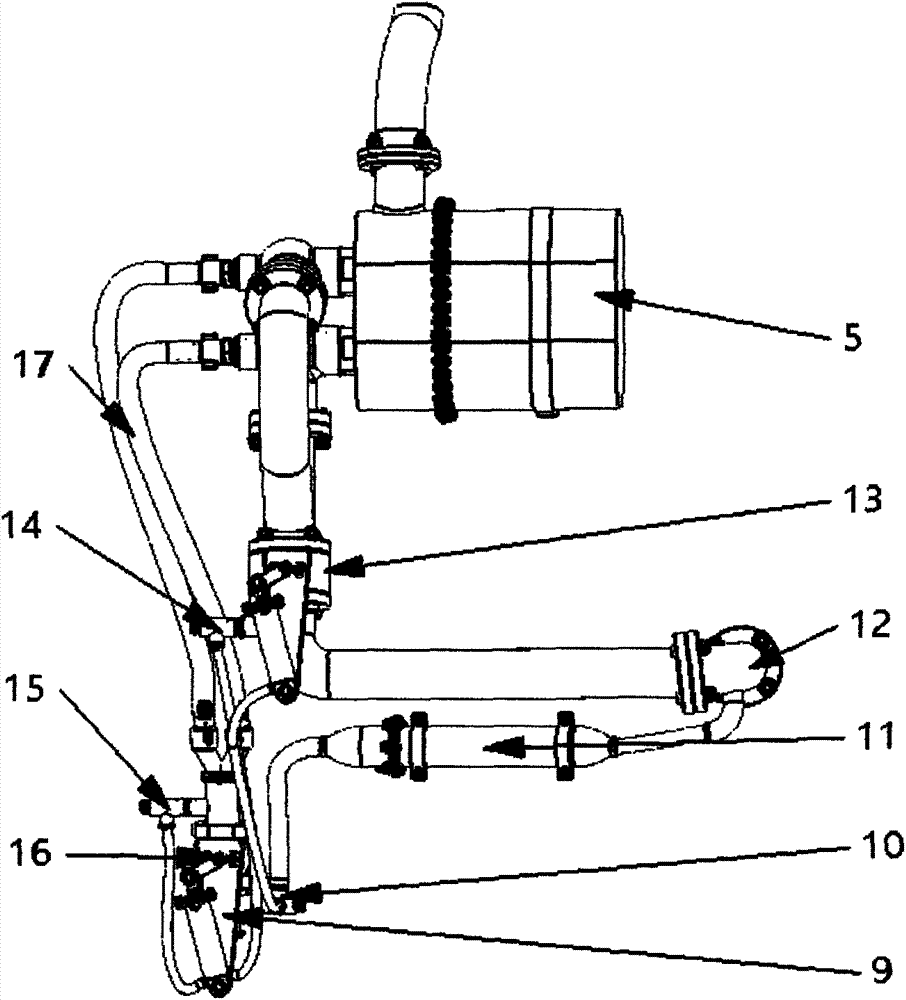

[0014] as attached figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com