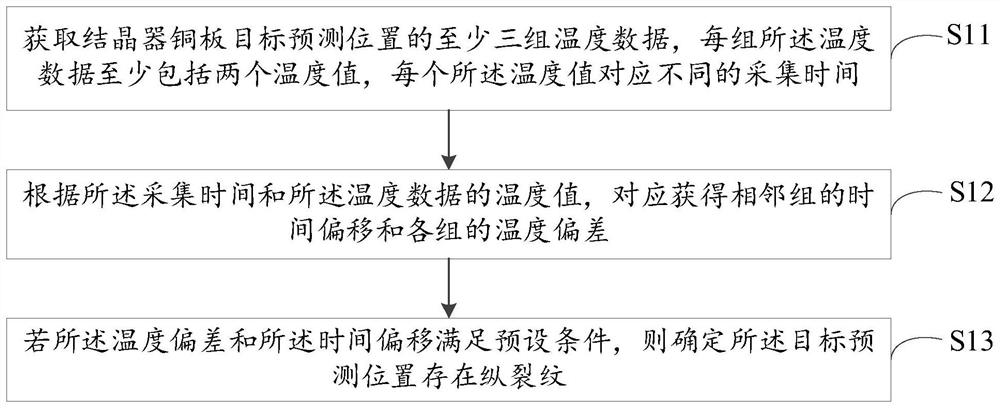

Method and device for predicting longitudinal crack of casting blank

A prediction method and longitudinal crack technology, applied in the field of steelmaking and continuous casting, can solve the problems of increasing the amount of casting billet cleaning, cracked steel leakage, jeopardizing production and product quality, etc., reducing the amount of cleaning and the incidence of longitudinal cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

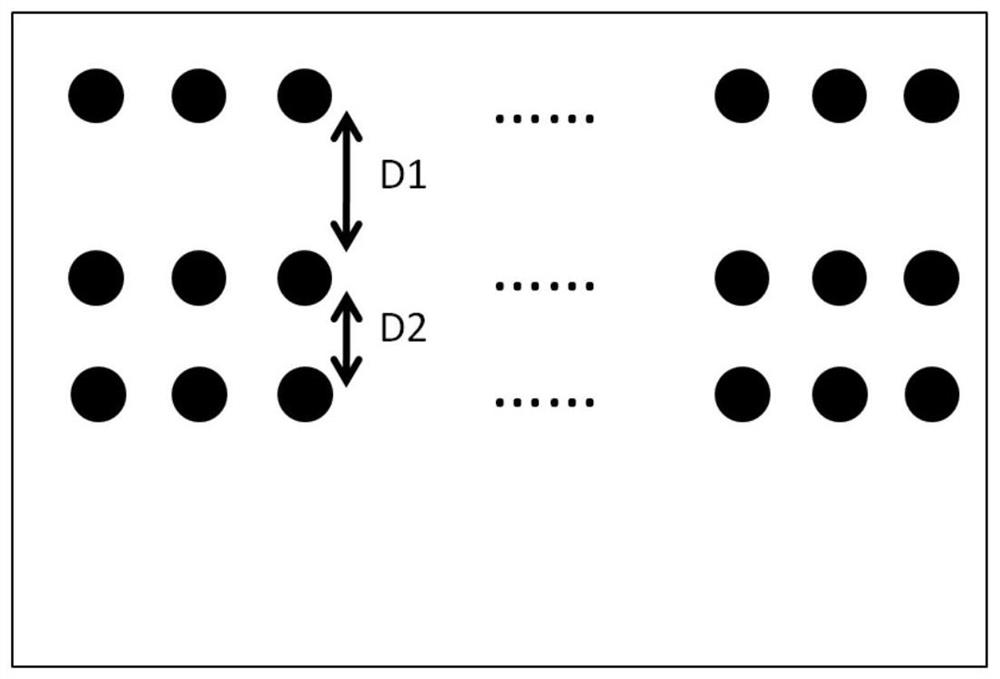

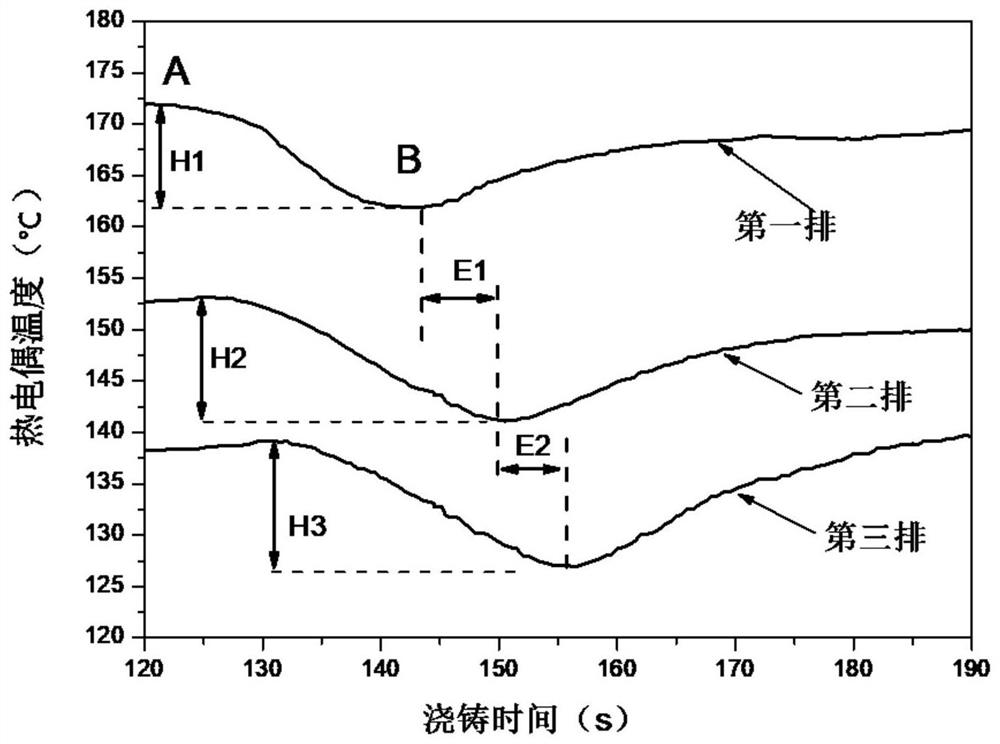

[0080] The carbon content in the billet is 0.09%, the thickness of the billet is 237mm, the width is 1200mm, and the pulling speed Vc is stably controlled at 1.4m / min. Install thermocouples on the wide and narrow sides of the copper plate of the mold. The thermocouples are installed at 111mm intervals in the thickness direction of the slab and 185mm in the width direction. The row spacing of the first row of thermocouples and the second row of thermocouples is 111mm. The row spacing of the second row of thermocouples and the third row of thermocouples is 185mm, with 9 rows of wide-face thermocouples and 2 rows of narrow-face thermocouples; both wide-face and narrow-face thermocouples are 6 rows. The copper plate temperature acquisition system collects the temperature measurement data of the thermocouples installed on the wide and narrow sides of the copper plate every 0.06s, and matches the pulling speed, reads and analyzes the temperature-time correspondence map every 70s; fin...

Embodiment 2

[0083] The carbon content in the slab is 0.10%, the slab thickness is 230mm, the width is 1200mm, and the pulling speed Vc is stably controlled at 1.5m / min. Thermocouples are installed on the wide and narrow sides of the mold copper plate, and the thermocouples are spaced in the slab thickness direction. 115mm installation, installation at 115mm intervals in the width direction of the slab, 11 rows of thermocouples in the width direction, 1 row of thermocouples in the thickness direction; 3 rows of thermocouples in the width direction and thickness direction. The copper plate temperature acquisition system measures the temperature data on the surface of the billet every 0.05s and matches the pulling speed, reads and analyzes the temperature-time correspondence map every 75s; finds out the temperature of all thermocouples in the first three rows within the predicted time T The maximum value of T max and the minimum value T min , calculate the difference between the maximum and...

Embodiment 3

[0086]The carbon content in the slab is 0.08%, the slab thickness is 237mm, the width is 1100mm, and the pulling speed Vc is stably controlled at 1.7m / min. Install thermocouples in the width direction and thickness direction of the mold copper plate respectively. The thermocouples are controlled at 111mm laterally and 185mm in the width direction. The spacing between the first row of thermocouples and the second row of thermocouples is 111mm. The row spacing between the row thermocouples and the third row thermocouples is 185mm, with 9 rows of wide-face thermocouples and 2 rows of narrow-face thermocouples; both wide-face and narrow-face thermocouples are 6 rows. The copper plate temperature acquisition system collects the temperature measurement data of the thermocouples installed on the wide and narrow sides of the copper plate every 0.06s, and matches the pulling speed, and reads and analyzes the temperature-time correspondence map every 85s; find out the T time period The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com