A kind of low-alloy high-strength steel plate for large-thickness boiler drum and its manufacturing method

A high-strength steel plate and a manufacturing method technology, which are applied to the low-alloy high-strength steel plate for large-thickness boiler drums and the manufacturing field thereof, can solve the problems of inconvenient control of cooling rate and inconsistent performance of steel plates, avoid repeated heat treatment, improve surface quality, The effect of improving manufacturability

Active Publication Date: 2016-06-01

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, in this invention, the steel plate is directly put into the water tank to accelerate cooling after normalizing. This method is inconvenient to control the cooling rate, and the steel plate is prone to produce abnormal structures, resulting in substandard performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

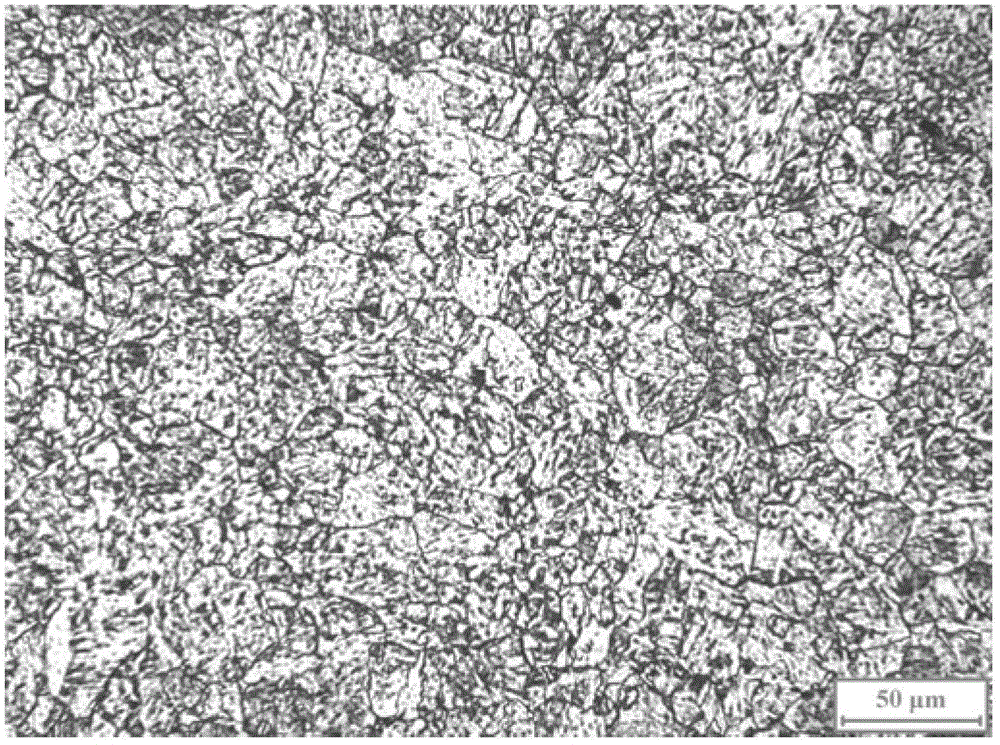

The invention relates to a low-alloy high-strength steel plate for a big-thickness boiler drum and a manufacturing method of the low-alloy high-strength steel plate. The manufacturing method comprises the following steps: (1) carrying out smelting, external refining and vacuum degassing treatment on the following components in percentage by weight: 0.135-0.17% of C, 0.15-0.50% of Si, 1.20-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 0.10-0.30% of Cr, 0.10-0.30% of Mo, 0.40-0.70% of Ni, 0.008-0.018% of Nb, 0.020-0.040% of Al, less than or equal to 0.05% of Cu, less than or equal to 0.006% of N, less than or equal to 0.003% of O, less than or equal to 0.00018% of H, 0.004-0.010% of Ti and the balance of Fe and unavoidable impurities, wherein Ti / N is less than or equal to 2.74; (2) casting; (3) carrying out steel ingot and cogging; (4) carrying out steel plate rolling and finishing; (5) carrying out normalizing, wherein the normalizing temperature of the steel plate is 900-940 DEG C, the temperature maintaining time is not less than 30 minutes after a core part of the steel plate is heated to 900-940 DEG C; (6) carrying out accelerated cooling to guarantee the cooling speed of the core part of the steel plate to be not less than 1 DEG C / second; (7) tempering at the temperature of 640-690 DEG C, and carrying out air cooling until reaching the room temperature after the steel plate is discharged out of a furnace.

Description

technical field [0001] The invention relates to a steel plate for a boiler drum and a manufacturing method thereof, in particular to a low-alloy high-strength steel plate for a large-thickness boiler drum and a manufacturing method thereof. 100mm~150mm. Background technique [0002] The overall structure of the boiler includes two parts: the boiler body and auxiliary equipment. The furnace, drum, burner, water wall superheater, economizer, air preheater, frame and furnace wall and other main components in the boiler constitute the core part of steam production, which is called the boiler body. The two most important components in the boiler body are the furnace and the drum. Among them, the main functions of the drum are: (1) connecting the heating surface pipes and pipelines, and installing water supply pipes and water vapor partitions inside the drum to form a stable water cycle; (2) designing a steam-water separation device inside the drum to Get dry and clean protecti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/48C22C38/58C22C33/04C21D8/02

Inventor 曾渝

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com