Raw material dissolving device and method for preparing porous inorganic material

A technology of inorganic materials and dissolving devices, applied in the direction of dissolution, dissolution, chemical instruments and methods, etc., can solve the problems of not being able to know the state of elements, not being able to deal with obstacles, and reducing the purity of inorganic salt raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

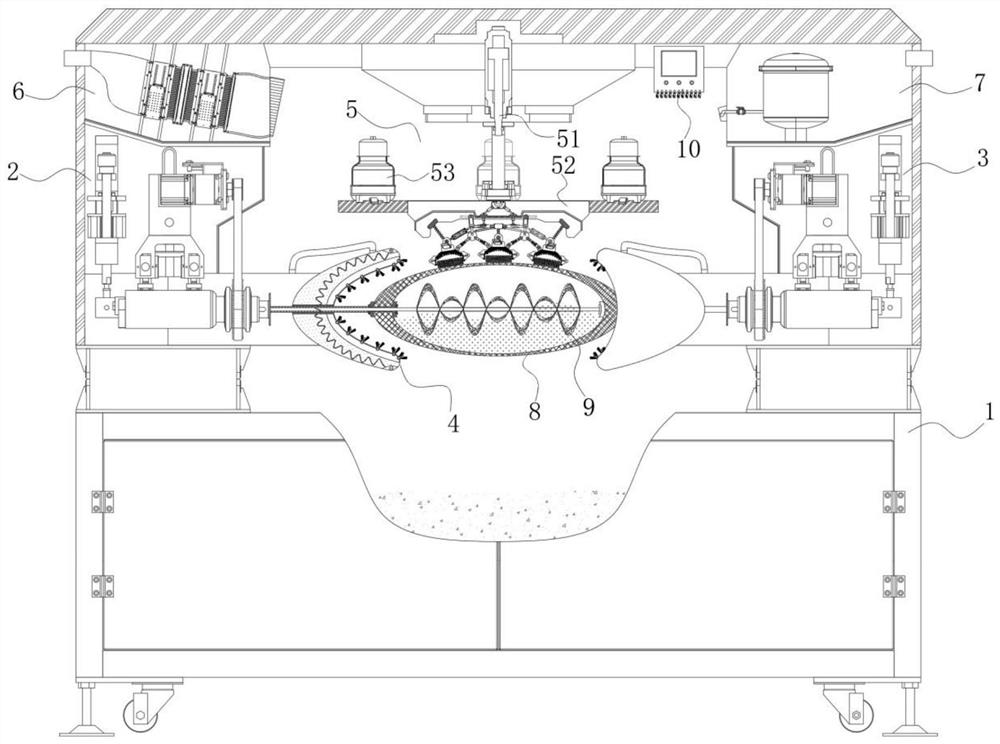

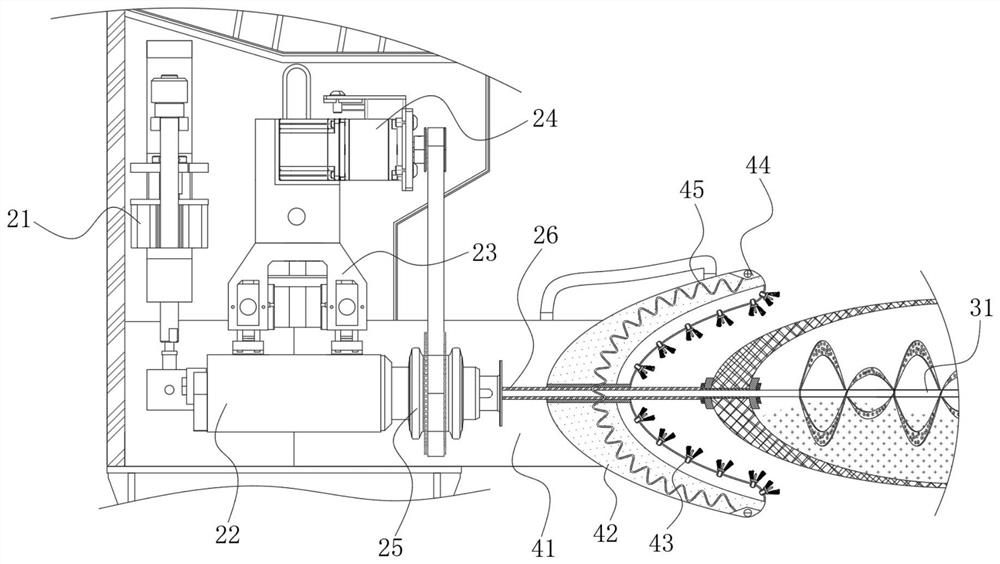

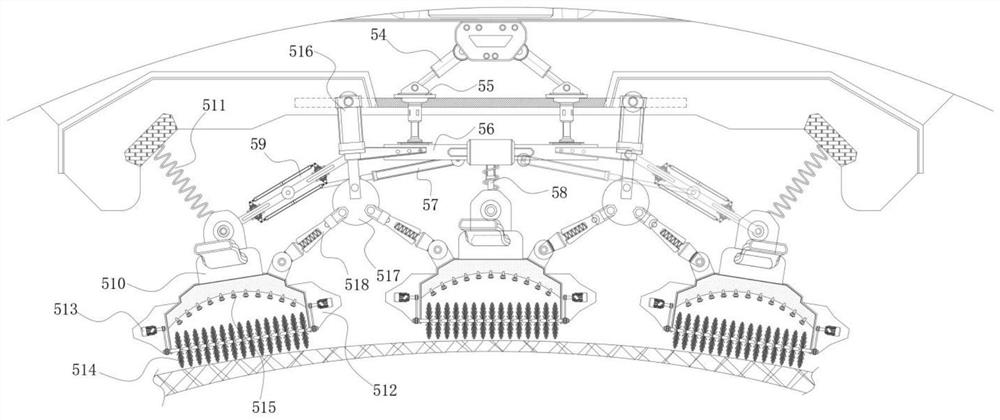

[0027] refer to figure 1, the present invention provides a technical solution: a raw material dissolving device for the preparation of porous inorganic materials, which includes a sealed cabinet 1, a left driving device 2, a right driving device 3, a spraying device 4, a cleaning device 5, a filter 6 and Pressure replenishing device 7, the upper and square cavities inside the sealed cabinet 1 are respectively set as a decomposition chamber and a collection chamber, a container 8 is arranged in the center of the decomposition chamber, and a stirring blade 9 is arranged inside the container 8, and the left The drive device 2 drives the container 8 to rotate along its transverse axis, the right drive device 3 drives the stirring blade 9 to rotate and stir inside the container, and the container 8 is equipped with a spraying device 4 on the left and right sides, and the container 8 A cleaning device 5 fixed on the central shell wall inside the sealed cabinet 1 is arranged above, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com