Parameter control method for vibrating table of continuous casting crystallizer

A technology of crystallizer vibration and continuous casting mold, which is applied in the field of parameter control of continuous casting mold vibration table, can solve the problems of increasing mold friction resistance, reducing mold slag consumption, and reducing lubricating performance, so as to improve metal Yield rate, reducing billet cleaning volume, and reducing the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method for controlling the vibration table parameters of the continuous casting mold of the present invention is mainly to establish a general method for determining and controlling the vibration parameters of the continuous casting mold for improving the surface quality of the continuous casting slab. The specific steps are:

[0019] 1. Construct an off-line vibration waveform trigger based on the waveform trigger model algorithm of the shaking table, and compile the crystallizer vibration waveform generation program.

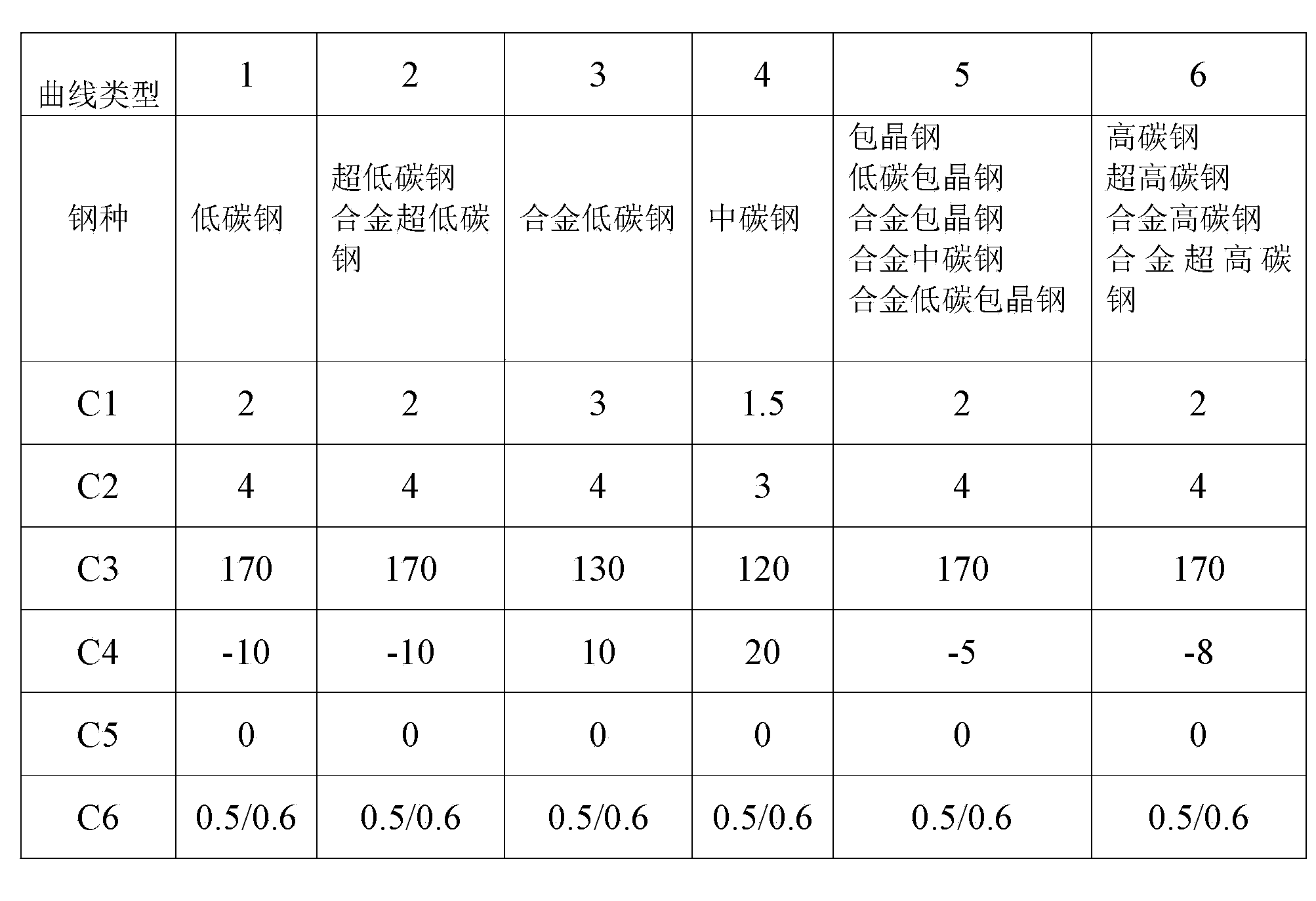

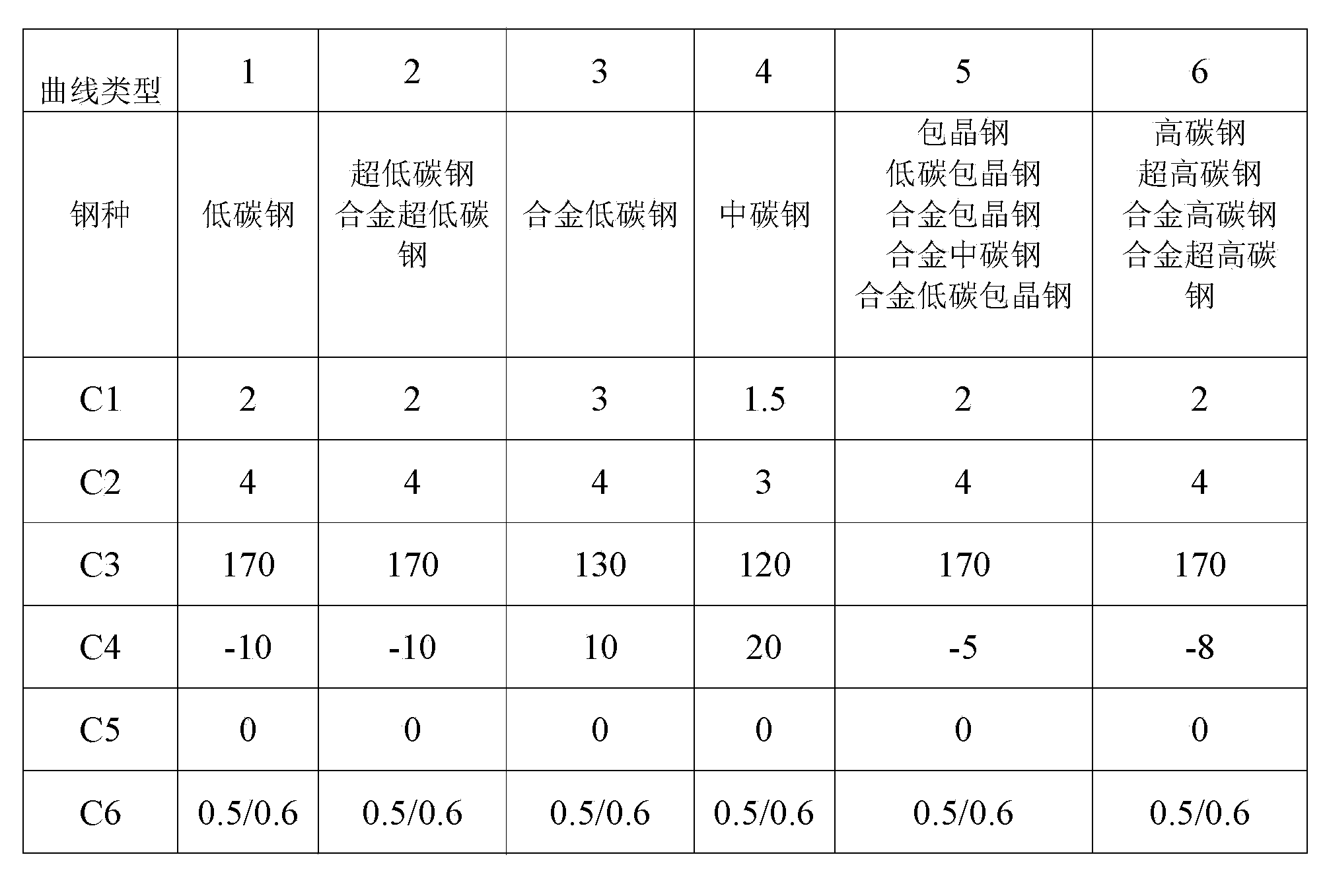

[0020] 2. Set the vibration parameters according to the steel type. The sinusoidal and non-sinusoidal vibration parameters are shown in Table 1.

[0021] Table 1 Sinusoidal and non-sinusoidal vibration parameters are shown in the table

[0022] In the table: C1 is the amplitude at zero casting speed, mm; C2 is the correction coefficient of amplitude to casting speed; C3 is the frequency at zero casting speed, Hz; C4 is the correction coefficient o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com