Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Reduce stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Warm-mixed asphalt additive and preparation method thereof

InactiveCN101602862AReduce stirringReduce the temperatureClimate change adaptationPaint thinnerChemistry

The invention discloses a warm-mixed asphalt additive and a preparation method thereof. The additive is prepared by the following steps: adding deionized water into prepared polyvinyl alcohol water solution, then adding rosin quaternary ammonium salt, aromatic quaternary ammonium salt emulsifier, aliphatic quaternary ammonium salt emulsifier and nonionic surfactant into the water solution in turn, stirring and dissolving the mixture, adding prepared polyacrylamide water solution and triethanolamine into the mixture, and mixing and stirring the mixture till the mixture is evenly dissolved so as to obtain a finished product. During application, when the temperature of the asphalt mixture reaches 110 to 130 DEG C, 5 percent of the diluent of the additive is added by the mass of asphalt in a spraying mode so as to realize the warm mixing technology of mixing and spreading the asphalt mixture; and test data show that various road indexes of the warm-mixed asphalt mixture are not lower than that of hot-mixed asphalt mixture under the condition that the mixing and molding temperature of the warm-mixed asphalt mixture is obviously reduced relative to the hot-mixed asphalt mixture.

Owner:TIANJIN UNIV

Method for cultivating Anguilla marmorata

InactiveCN102301973AReduce the chance of getting sickShort stayClimate change adaptationPisciculture and aquariaDiseaseFishery

The invention relates to a method for cultivating Anguilla marmorata. The method is applicable to the fishery. The invention discloses a method for improving the cultivation survival rate and growth speed of the Anguilla marmorata, namely a 'rest bed' is arranged for the Anguilla marmorata on one side of a pond, a layer of fishing net covers the 'rest bed', a food platform is positioned on one side of the 'rest bed', a sunshade shed is built above the 'rest bed', and a sunshade net covers the sunshade shed and is about 30cm away from the water surface. The area of the 'rest bed' can be 30 to 300 square meters, and 8 to 10 ten thousand fish is usually cultivated in each 300 square meters. A lifting device is arranged on the 'rest bed' so as to moderately adjust the height of the 'rest bed'; therefore, the aim that the 'rest bed' can be about 1 meter away from the water surface when the temperature of the water surface is overhigh or overlow in summer is fulfilled. In the method, the 'rest bed' which can be lifted is provided for the Anguilla marmorata during cultivation, so that the diseases can be reduced; and the survival rate is greatly improved, the growth speed is improved, the bait coefficient and cultivation cost are reduced, the quality of aquatic products is ensured, the environmental pollution is reduced, and the cultivation efficiency can also be improved.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

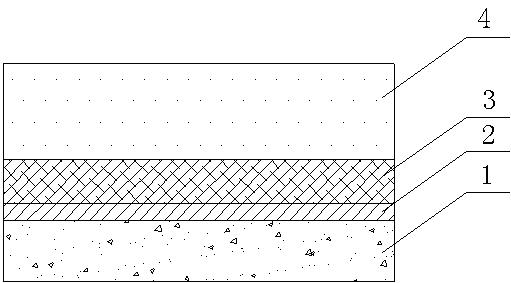

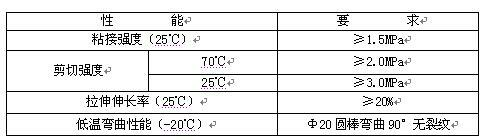

Pavement structure for cement concrete bridge deck and pavement method thereof

InactiveCN102002909AEfficient removalImprove interlayer adhesionBridge structural detailsEpoxyBridge deck

The invention relates to the technical field of traffic engineering, in particular to a pavement structure directly paved on a cement concrete bridge deck and a pavement method thereof. The pavement structure for the cement concrete bridge deck comprises a waterproof bonding layer, a stress absorption layer and a road surface layer, which are sequentially paved on the cement concrete bridge deck from bottom to top, wherein the waterproof bonding layer comprises a basalt gravel layer bonded on the cement concrete bridge deck through epoxy resin and a reactive waterproof binding agent layer coated on the basalt gravel layer. The invention also discloses a pavement method for the pavement structure. The pavement structure and the pavement method thereof enhance the bonding and shearing action between a pavement layer and a cement concrete slab, improve the using effect and service life of the pavement layer, reduce the temperature of mixing, transporting and paving, save energy and reduce environmental pollution; and the total thickness of the bridge deck pavement system is only 30 to 40 mm, so that the dead load of the bridge deck is greatly reduced, the pavement materials are saved and the construction cost is reduced.

Owner:CHONGQING JIAODA ROAD BRIDGE TECH RES

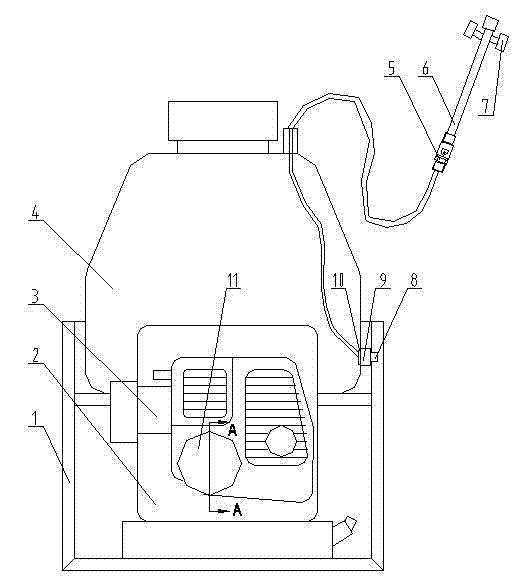

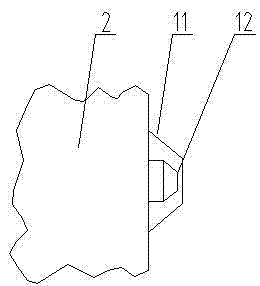

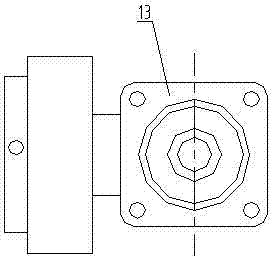

Six-freedom-degree wooden board paint spraying device for building construction

InactiveCN108031592AReduce stirringWell mixedSpraying apparatusArchitectural engineeringSpray nozzle

The invention discloses a six-freedom-degree wooden board paint spraying device for building construction. The six-freedom-degree wooden board paint spraying device for building construction comprisesa base plate. The upper side of the base plate is provided with a connection frame. The upper side of the connection frame is provided with first sliding grooves. A first sliding block is arranged ineach first sliding groove. The lower sides of the first sliding blocks are provided with first connection rods. The lower sides of the first connection rods are provided with a connection cover. Second lead screws are arranged at the left end and the right end in the connection cover. The second lead screws are provided with second sliding blocks. A third sliding groove is arranged between the second sliding blocks. Third sliding blocks are arranged at the left end and the right end in the third sliding groove. The lower sides of the third sliding blocks are provided with second connection rods. The lower sides of the second connection rods are provided with spray nozzles. The back ends of the inner sides of the spray nozzles are provided with connection hoses. A liquid drawing pipe is arranged inside the connection hoses. The lower end of the liquid drawing pipe is provided with a stirring cavity. Rotating shafts are arranged on the four corners inside the connection frame. Clampingblocks are arranged on the inner sides of the rotating shafts. By the adoption of the six-freedom-degree wooden board paint spraying device for building construction, the equipment can conveniently conduct six-freedom-degree paint spraying on the surface of a wooden board, the paint spraying quality of a formwork can be effectively guaranteed in this way, and the work efficiency of the equipment is improved.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

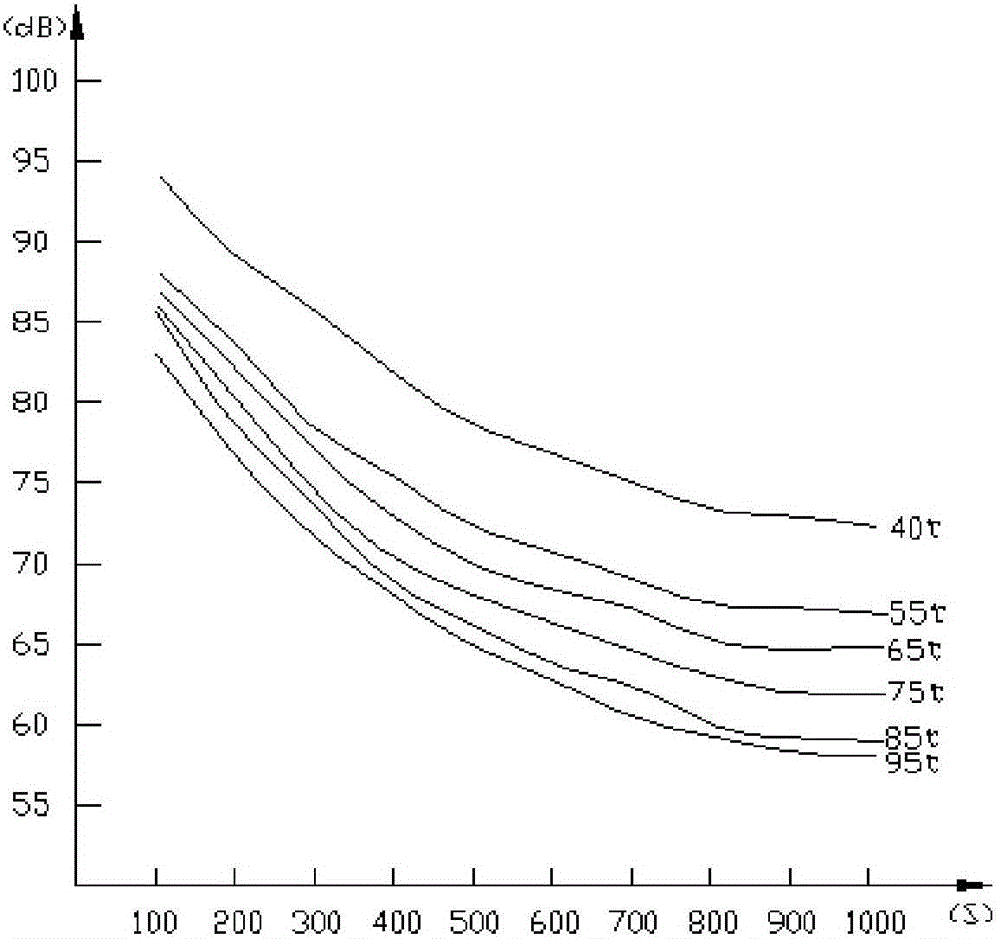

Low-noise milk-preparation method of soybean milk machine

InactiveCN105935247AReduce hardnessBad experienceBeverage vesselsDough shaping and cutting apparatusLow noiseElectricity

The invention relates to a low-noise milk-preparation method of soybean milk machine. A motor, a crushing cutter, a heating device and a cup body are provided. The control unit is electrically connected with the motor, and the heating device. The method at least comprises following phases: (1) a crushing stage: the motor drives the crushing cutter to rotate and crush water and material to milk and goes to the next phase; (2) a boiling phase: the heating device is used for heating milk till it is boiled. When the crushing phase begins, the temperature of liquid is larger than or equal to the pre-set crushing temperature. The pre-set crushing temperature is larger than or equal to 85 DEG C. Before the crushing phase, a heating pre-treatment phase is included. The heating pre-treatment phase lasts for 400 to 800 seconds. Therefore, noise can be effectively decreased and false boiling is avoided and reduced effectively.

Owner:JOYOUNG CO LTD

Method for microorganism-pelleting heap leaching of earthy oxide copper ores

InactiveCN101781705AIncrease throughputReduce ore washingProcess efficiency improvementThiobacillus ferrooxidansHydrometallurgy

The invention relates to a method for leaching earthy oxide copper ores, in particular to a method for microorganism-pelleting heap leaching, and belongs to the technical field of hydrometallurgy. The method is characterized in that: the earthy ores are directly screened, and fine ores with the granularity of 1.5mm are added with strain acid water and cement to prepare ore pellets with the diameter between 10 and 20 mm for heap leaching, wherein the mass concentration of sulphuric acid in the strain acid water is 3 to 10 percent, strains are mixed strains of Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, the mass ratio of the three is 4.0-5.5:2.5-3.5:1.5-2.5, the bacterial load ratio is 105 and 108 / ml, the cement amount is 15 to 30kg / ton of ores; and leachate in the leaching is sprayed for closed cycle production. The method has the advantages of low investment, low energy consumption, good leaching effect, and no discharge of closed cycle, solves the problem of leaching the low-grade earthy oxide copper ores (including sulphide and oxide blend ores) by microorganism heap leaching, and overcomes the defects of long flow and high cost of agitation leaching.

Owner:王宣明

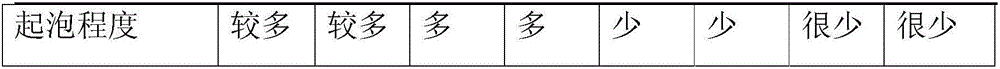

Intermittent feeding and mixing equipment of multiple kinds of feed for livestock husbandry

Owner:内蒙古德宇创新机械有限公司

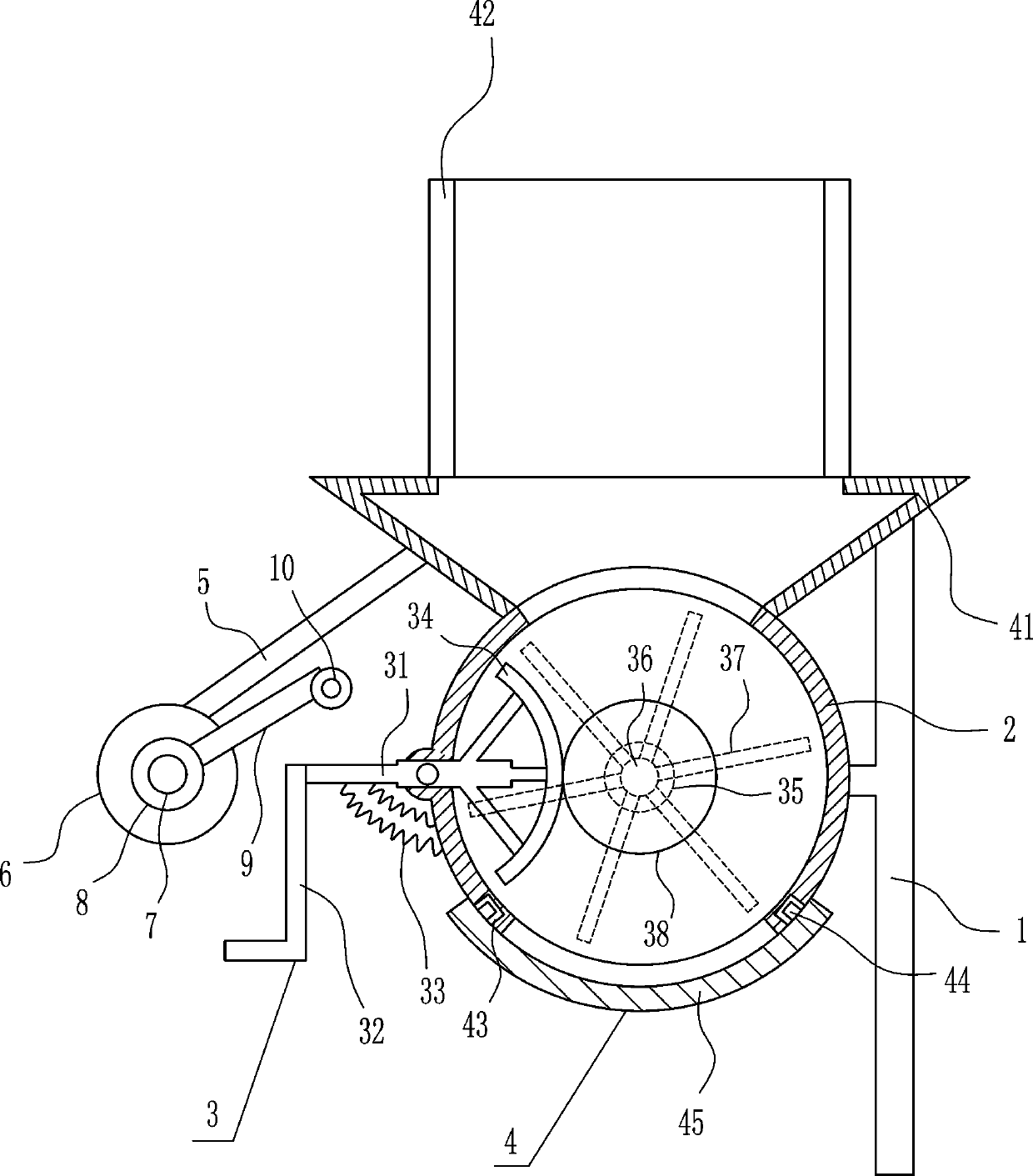

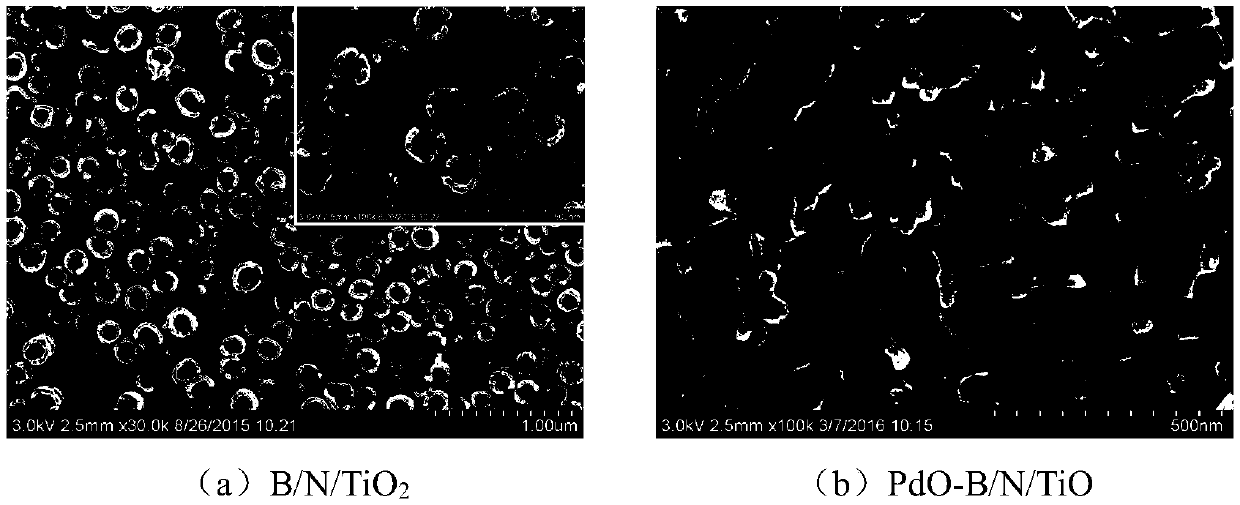

Integrated catalysis system based on TiO2 nanotube photocatalyst and degrading treatment method of integrated catalysis system

InactiveCN108675382ASolve the problem of low quantum efficiencyEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationTio2 nanotubeExternal bias

The invention discloses an integrated catalysis system based on a TiO2 nanotube photocatalyst. The TiO2 nanotube photocatalyst-based integrated catalysis system comprises TiO2 nanotubes, a visible light source or sunlight, an electrocatalysis device and an oxygenating pump, wherein the electrocatalysis device uses the TiO2 nanotubes as an anode and fibrous graphite felt as a cathode, and the anodeand the cathode are inserted into organic wastewater and are respectively connected to positive and negative electrodes of a voltage-stabilized power supply; the visible light source or sunlight correspondingly irradiates the anode; Fe<2+> is added into the organic wastewater; the oxygenating pump is positioned at the cathode. The invention further discloses a degrading treatment method of the integrated catalysis system based on the TiO2 nanotube photocatalyst. An external electric field environment is formed through application of external bias voltage to the TiO2 nanotubes so as to form acombination of TiO2 photocatalysis and electrocatalysis, and a Fenton reaction is further introduced to form the integrated catalysis system having a coupled and synergistic effect of a TiO2 nanotubevisible light catalysis reaction, an electrocatalytic reaction and the Fenton reaction, so that the degradation efficiency of toxic and refractory organic pollutants is greatly improved.

Owner:JINGDEZHEN CERAMIC INSTITUTE

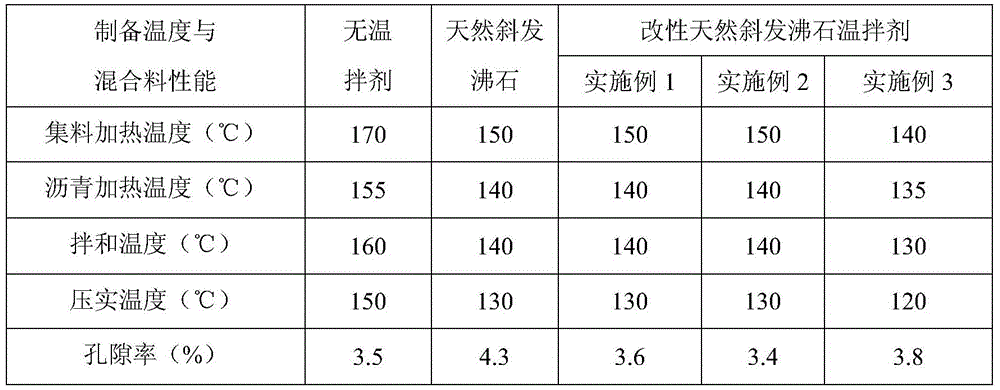

Modified natural zeolite warm mixing agent and preparation method thereof

InactiveCN105621914AReduce stirringReduce the temperatureClimate change adaptationWater contentZeolite

The invention belongs to the field of road construction materials, in particular relates to a modified natural zeolite warm mixing agent and a preparation method of the modified natural zeolite warm mixing agent. The modified natural zeolite warm mixing agent is prepared by carrying out alkaline solution treatment and fatty amine modification on natural zeolite. According to the modified natural zeolite warm mixing agent disclosed by the invention, the water content of the modified natural zeolite warm mixing agent is higher, so that the mixing and paving temperature of an asphalt mixture can be effectively reduced; a non-polar group of fatty amine in the modified natural zeolite warm mixing agent has very strong affinity with asphalt, and a polar group has very strong affinity with aggregate surfaces (particularly, acidic aggregates such as basalt), so that the interfacial free energy of the aggregates and the asphalt can be effectively reduced, the adhesion of the asphalt and the aggregates is improved, the water stability of the asphalt mixture is increased, and a water damage phenomenon of an asphalt pavement is effectively prevented from happening; raw materials of the modified natural zeolite warm mixing agent prepared by the invention are easy to obtain and low in cost, and the modified natural zeolite warm mixing agent is capable of obviously reducing the cost of a warm mixing asphalt mixture, and is beneficial for being widely applied.

Owner:WUHAN UNIV OF TECH

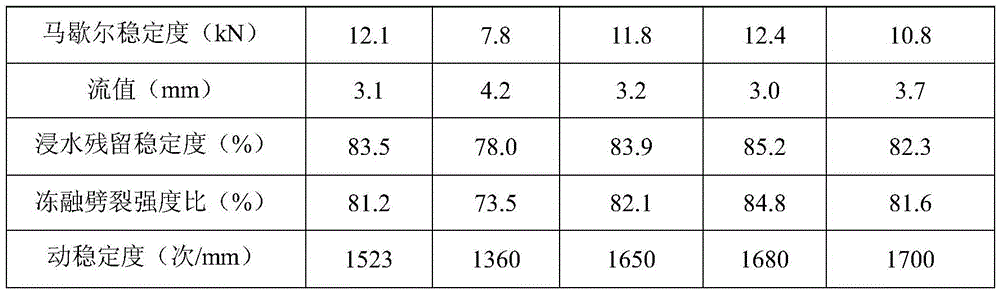

Device for separating ice and crystal

InactiveCN101129206AImprove separation efficiencyIncrease growth rateTea extractionOther dairy technologyEngineeringLiquid surfaces

The invention relates to a cryolite separating arrangement, which comprises a tank for putting the cryolite and the liquid mixture material, wherein the top of the tank is equipped with the surface agitator for making the liquid surface rotate, the surface agitator is the bifurcation shape, the tank is also equipped with the hollow cryolite collecting pipe, the cryolite collecting port of the cryolite collecting pipe is at the central position of the liquid surface rotating, and the discharge port of the cryolite vents to the exterior of the tank. The invention makes the cryolite move to the liquid surface rotating center of the cryolite collecting port naturally with the cryolite buoyance and centripetal force produced by mixing the liquid surface and discharge by the cryolite collecting pipe (that is also the center or centripetal discharging cryolite method), which not only saves the energy and improves the separation efficient, but also reduces the loss of solute and is fit for the concentration industry production by freezing.

Owner:陈锦权

Compounded edible fungus meat product and processing method thereof

The invention discloses a compounded edible fungus meat product and a processing method thereof. The method comprises the following steps: by taking fresh edible fungi and mauremys mutica as raw materials, firstly carrying out rinsing, color-protecting, slicing, precooking, salting, desalting and the like on the edible fungi so as to prepare a semi-product; carrying out rinsing, fishy smell removing, precooking, bone soup flavoring, cooling, slitting and the like on the mauremys mutica so as to prepare a semi-product; proportionally combining the semi-product of the edible fungi with the semi-product of the mauremys mutica, adding spices, seasonings and auxiliary materials and evenly mixing so as to obtain the compounded edible fungus meat product. The compounded edible fungus meat product has the advantages of being green and natural, reasonable in nutritional matching, excellent in flavor, good in taste, convenient to eat, long in shelf life and the like.

Owner:CHENGDU UNIV +1

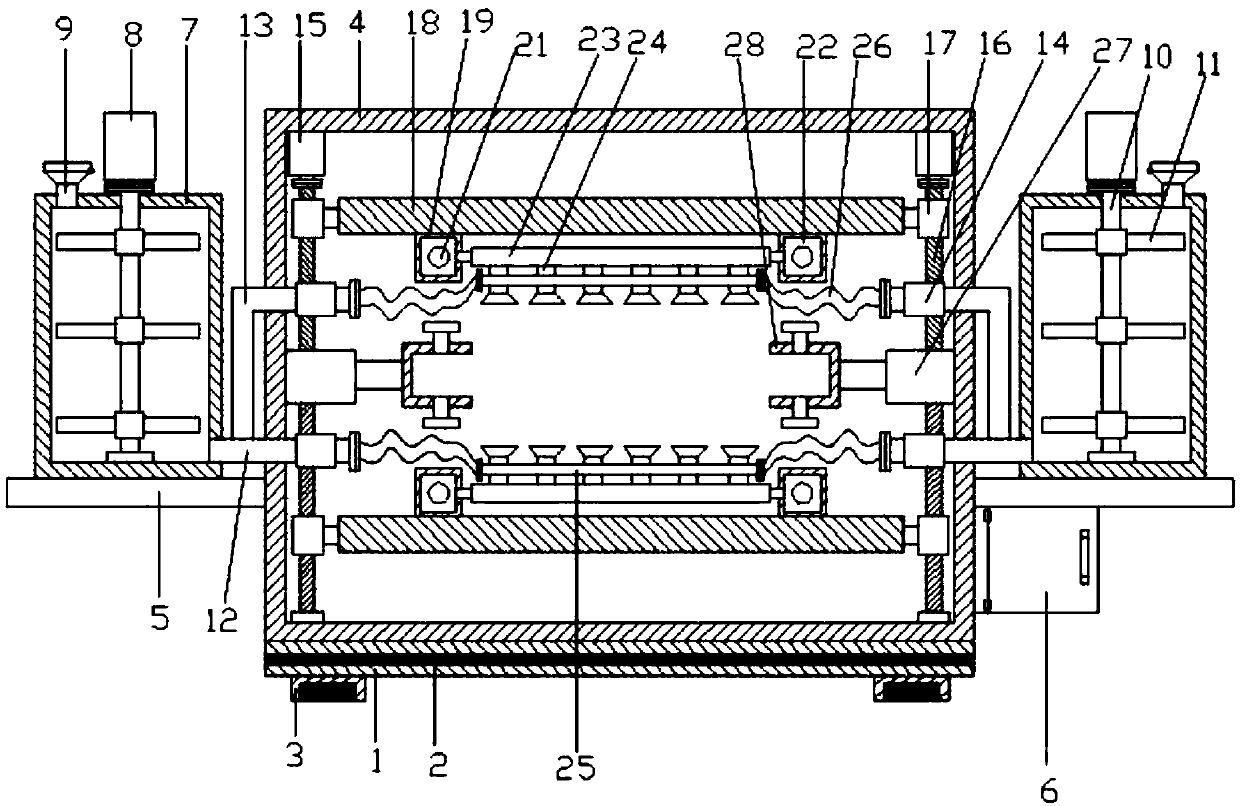

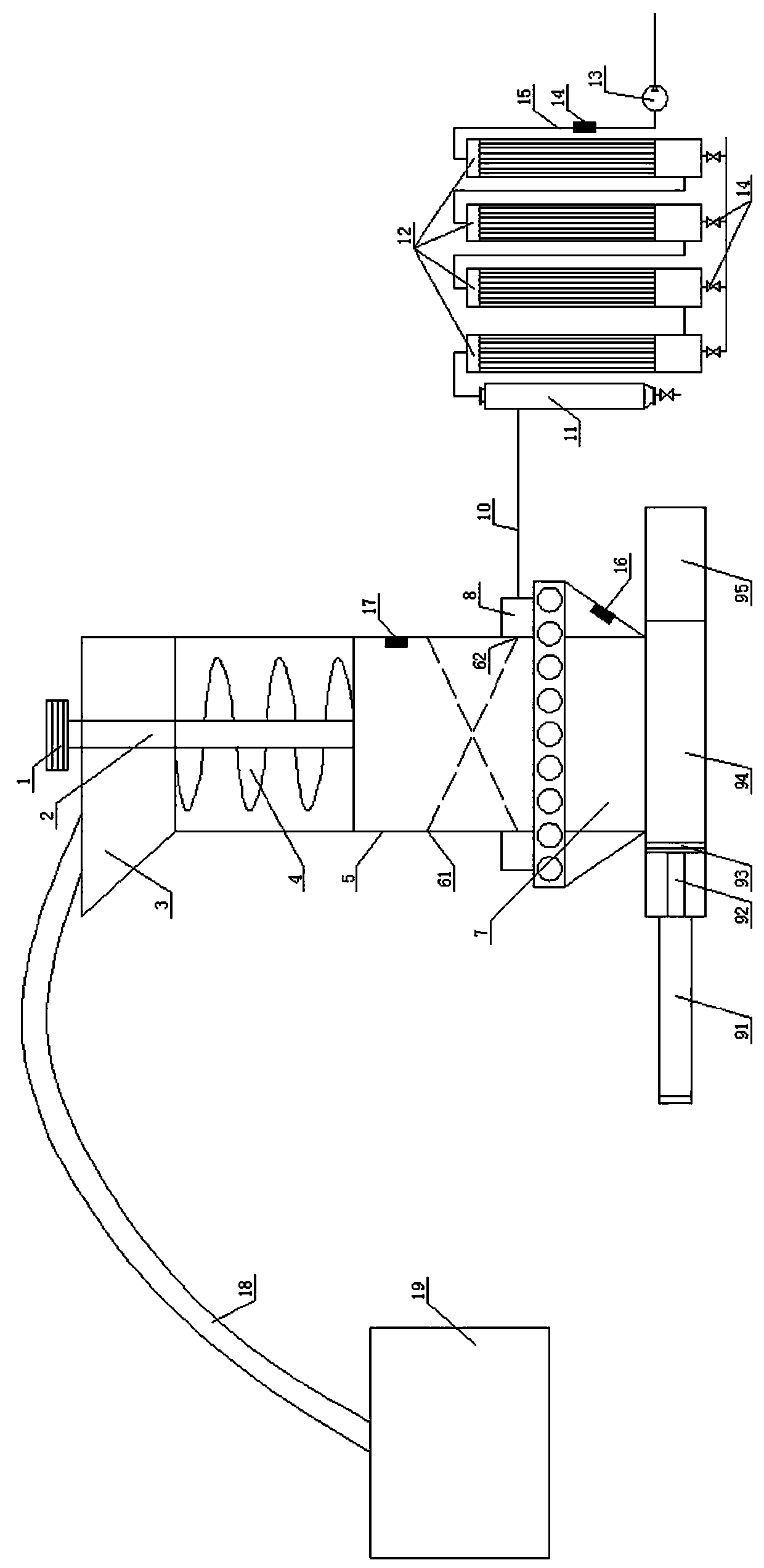

Sludge low temperature smoldering pyrolysis apparatus with automatic control and monitoring

ActiveCN110395865AReduce settingsReduce stirringSludge treatment by pyrolysisByproduct vaporizationAutomatic controlSlag

The invention discloses a sludge low temperature smoldering pyrolysis apparatus with automatic control and monitoring. The apparatus comprises control monitoring equipment, and one or more smolderingpyrolysis equipment, wherein the smoldering pyrolysis equipment comprises a pyrolysis furnace body and a sensing detection system, a closed feeder is arranged at the top of the pyrolysis furnace body,a slag discharge device is arranged at the bottom of the pyrolysis furnace body, and a carbon slag treatment device is equipped at a slag outlet of the slag discharge device; the bottom of the side wall of the pyrolysis furnace body is provided with a plurality of gas suction groups around the circumference, each gas suction group comprises a gas inlet and a gas outlet, the gas inlets are locatedabove the gas outlets, each gas inlet and the corresponding gas outlet are located at opposite side surfaces of the pyrolysis furnace body, an annular gas guiding pipe is arranged on the pyrolysis furnace body, each gas outlet communicates with the annular gas guiding pipe, and each gas inlet and each gas outlet are equipped with corresponding control valves; and a ventilation pipe is arranged onthe annular gas guiding pipe. According to the apparatus, the best smoldering effect is achieved, and monitoring of an operating state and a target position of each smoldering pyrolysis equipment isrealized by the control monitoring equipment.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Green low-carbon environment-friendly asphalt pavement structure

ActiveCN105926400AEmission reductionReduce stirringIn situ pavingsClimate change adaptationRoad surfaceLower face

The invention relates to a green low-carbon environment-friendly asphalt pavement structure. The green low-carbon environment-friendly asphalt pavement structure comprises an upper face layer made of a warm-mixed asphalt concrete material, a middle face layer made of modified asphalt concrete, a framework-compact type lower face layer made of a modified asphalt mixture and a road surface base layer made of asphalt stabilized macadam, all of which are sequentially laid on a cushion layer from top to bottom. Bonding layers are laid between the upper face layer made of the warm-mixed asphalt concrete material and the middle face layer made of the modified asphalt concrete and between the middle face layer made of the modified asphalt concrete and the framework-compact type lower face layer made of the modified asphalt mixture. Aggregate parts in the middle face layer made of the modified asphalt concrete, the framework-compact type lower face layer made of the modified asphalt mixture and the road surface base layer made of the asphalt stabilized macadam are replaced with construction garbage recycled aggregate. By the adoption of the green low-carbon environment-friendly asphalt pavement structure, construction garbage can be effectively used, and the structure is of great significance in the aspects of environment protection, resource thrift, aggregate type source increasing and the like.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

High efficiency soya-bean milk making method

InactiveCN105942853AIntegrity guaranteedImprove hydrophilic abilityBeverage vesselsMilk substitutesElectricityLiquid temperature

The invention relates to a high efficiency soya-bean milk making method. A motor, a crushing cutter, a heating device, an anti-overflow electrode, a control unit and a cup are provided; and the control unit is electrically connected to the motor, the heating device and the anti-overflow electrode. The high efficiency soya-bean milk making method at least includes the flowing stages: (1) a preheating stage: the heating device heats water and a material in the cup, and when the temperature of liquid is less than a first preset temperature, the control unit neglects an overflow signal detected by the anti-overflow electrode; (2) a crushing stage: the motor drives the crushing cutter to rotate so as to crush the water and the material into milk, and then the next stage starts; and (3) a boiling stage: the heating device heating the milk till the milk is well done. Compared with the prior art, the high efficiency soya-bean milk making method can allow the temperature of the liquid to rise continuously and stably, can avoid influence on the milk making period due to fake boiling, and then achieves high efficiency soya-bean milk making.

Owner:JOYOUNG CO LTD

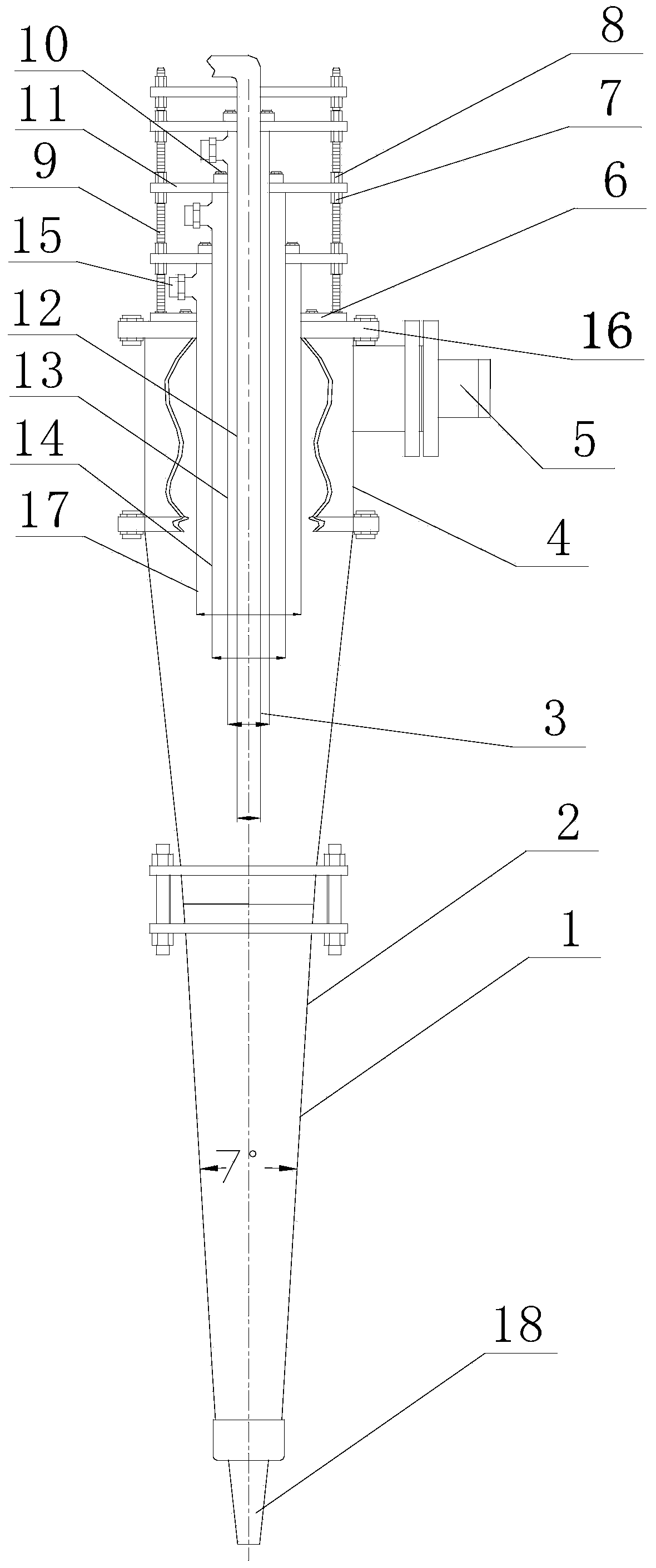

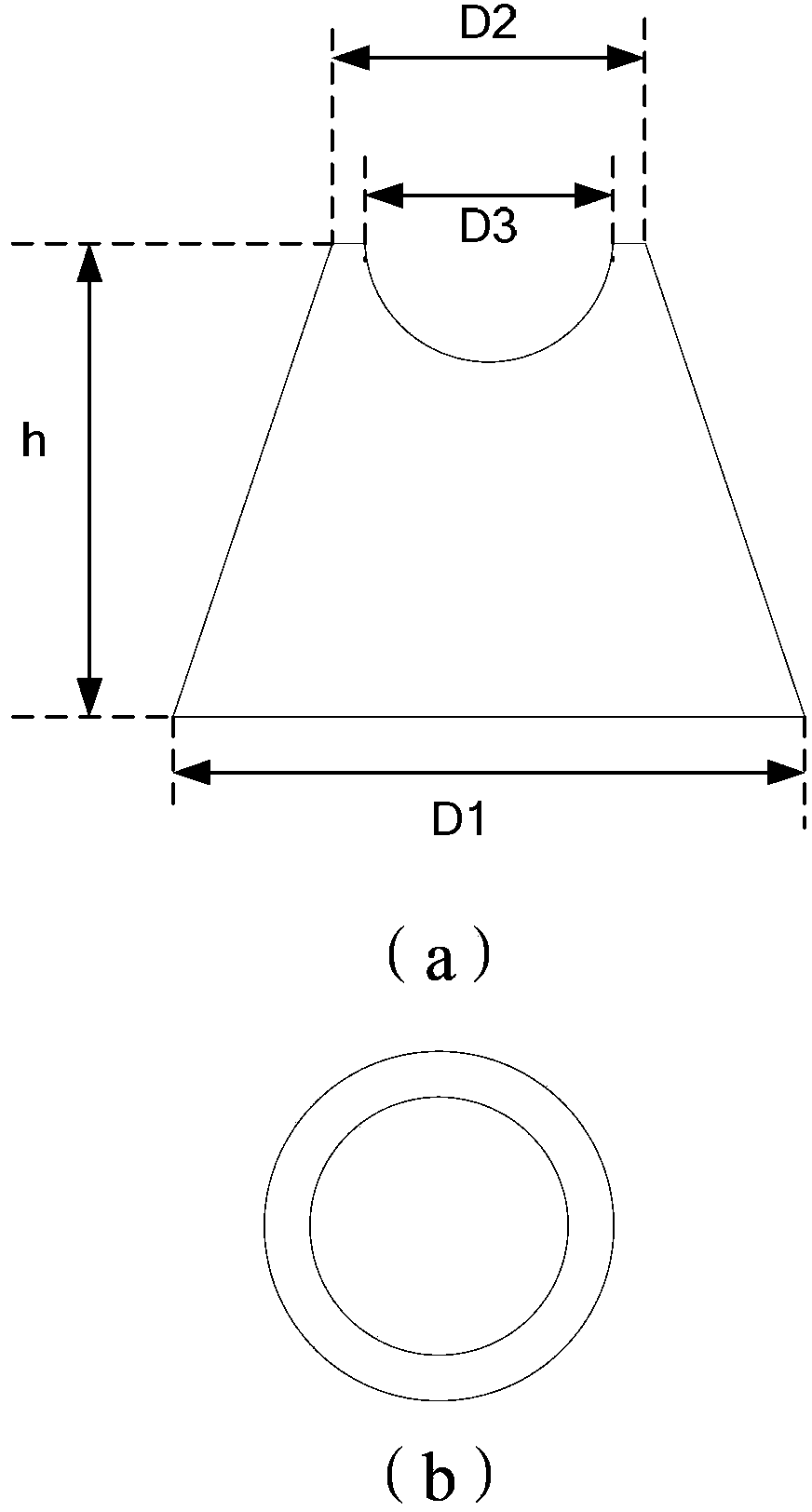

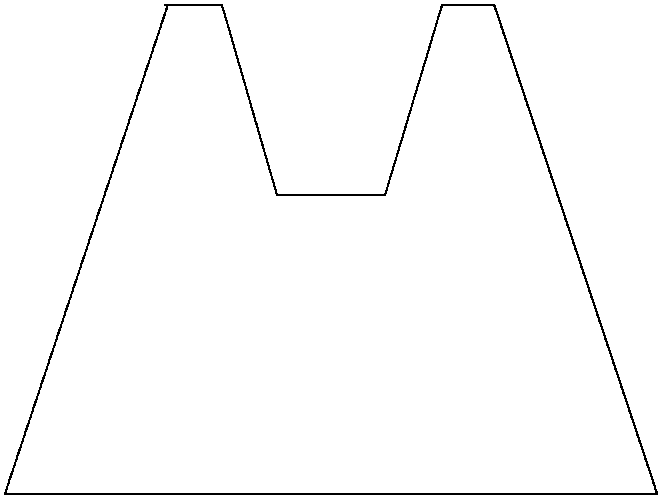

Single multi-stage type grading and sorting small-taper angle hydrocyclone

The invention relates to a single multi-stage type grading and sorting small-taper angle hydrocyclone belonging to the technical field of mineral grading equipment. The single multi-stage type grading and sorting small-taper angle hydrocyclone disclosed by the invention can realize multi-stage grading and sorting of materials of different particle sizes and different densities, and can effectively prevent the problem that coarse particles are mixed in an overflow product due to short-circuit current of a hydrocyclone. The single multi-stage type grading and sorting small-taper angle hydrocyclone comprises a cylinder body, wherein a feeding hole is formed in one side of a column body, a bottom flowing hole is formed in the bottom end of an inverted cone body, the taper angle of the inverted cone body is smaller than 15 degrees, the diameter of the column body is greater than 25mm; the single multi-stage type grading and sorting small-taper angle hydrocyclone is characterized in that more than two stages of overflow pipe of different lengths and different diameters are arranged at the top of the column body, all the stages of overflow pipes are sequentially coaxially arranged in a sleeving manner according to a small-to-large order; a cylinder body top cover is arranged at the top end of the column body, the column body is fixedly connected with the cylinder body top cover; overflow pipe top covers are arranged at top ends of all the stages of overflow pipes, center through holes are formed in the overflow pipe top covers, all the stages of overflow pipes are respectively fixed in the center through holes of all stages of overflow pipe top covers, and all stages of overflow pipe top covers are connected with the cylinder body top cover by virtue of lead screws and nuts.

Owner:LIAONING TECHNICAL UNIVERSITY

Landfill leachate efficient Fenton oxidation device

ActiveCN112390344ASimple structureIngenious ideaWater treatment compoundsContaminated groundwater/leachate treatmentPistonEngineering

A landfill leachate efficient Fenton oxidation device comprises a reaction tank, a motor is fixedly installed in the middle of the top side of the reaction tank, the lower end of a motor rotating shaft penetrates through the top wall of the reaction tank and is fixedly connected with the upper end of a telescopic shaft, and the lower end of the telescopic shaft is fixedly connected with the upperend of a screw of a reciprocating screw pair. The lower end of the screw of the reciprocating lead screw pair is rotationally connected with the middle of the top side of a piston plate through a bearing, the periphery of the piston plate is in sliding contact fit with the inner periphery of the reaction tank, and the bottom side of the piston plate is connected with the bottom of the reaction tank through a plurality of spring rods. Thelandfill leachate efficient Fenton oxidation device is simple in structure and ingenious in conception, sewage and an oxidizing agent are mixed more uniformlythrough the annular plates moving up and down, meanwhile, precipitates generated by reaction are collected between the two annular plates, the generated precipitates are automatically discharged through gravitational potential energy of the sewage, the cleaning difficulty of the reaction tank is reduced, market requirements can be met, and the reaction tank is suitable for popularization.

Owner:SHANDONG LONGANTAI ENVIRONMENTAL PROTECTION SCI TECH CO LTD

Bi-directional plank paint spraying equipment for building construction

The invention discloses bi-directional plank paint spraying equipment for building construction. The bi-directional plank paint spraying equipment comprises a bottom plate. The upper side of the bottom plate is provided with a connection frame. The lower ends of the left side and the right side of the connection frame are provided with supporting plates. The upper sides of the supporting plates are provided with stirring cavities. The inner sides of the stirring cavities are provided with liquid draining pipes, the upper sides of the liquid draining pipes are provided with first connection pipes, and telescopic rods are arranged between each liquid draining pipe and the corresponding first connection pipe. The inner side of each telescopic rod is provided with a clamping block. Second motors are arranged at four corners of the top end inside the connection frame. The lower sides of the second motors are provided with first lead screws. The upper end and the lower end of each first leadscrew are provided with first sliding blocks. Connection plates are arranged between the first sliding blocks. The left end and the right end of the inner side of each connection plate are provided with sliding grooves. A third motor is arranged on the rear side of each sliding groove. The front side of each third motor is provided with a second lead screw. Each second lead screw is provided witha second sliding block. Connection rods are arranged between the second sliding blocks. The inner sides of the connection rods are provided with spray heads. The front sides of the spray heads are provided with second connection pipes. The bi-directional plank paint spraying equipment for building construction can effectively and conveniently carry out rapid paint spraying, and in this way, the working efficiency of the equipment can be effectively improved.

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

Display panel and manufacturing method thereof

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

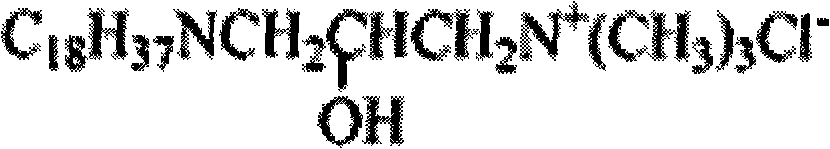

Zwitter-ion and nonionic composite asphalt warm-mixing agent and preparation method thereof

ActiveCN104559251AReduce high temperature viscosityImprove performanceClimate change adaptationBuilding insulationsHydrogenAsphalt

The invention discloses a zwitter-ion and nonionic composite asphalt warm-mixing agent and a preparation method thereof. The zwitter-ion and nonionic composite asphalt warm-mixing agent comprises in percentage by weight: 0.1-20% of zwitter-ion components, 0.1-20% of macromolecule nonionic components, 0.1-15% of low-molecular-weight nonionic components, 0.1-3% of acid catalysts and 42-99.6% of water. The preparation method comprises the following steps: the water is added into a container in the proportion, the temperature is controlled to range from 40 DEG C to 60 DEG C, the macromolecule nonionic components are added, a mixture is stirred for 0.5-2 hours at a constant temperature and then heated to 60-80 DEG C, the low-molecular-weight nonionic components and the zwitter-ion components are added in the proportion and are respectively stirred for 0.5-1 hours, the acid catalysts are added so that a pH (potential of hydrogen) can be adjusted to be 5-7, and the composite asphalt warm-mixing agent is obtained. The zwitter-ion and nonionic composite asphalt warm-mixing agent can effectively reduce high-temperature viscosity of the asphalt, improves the anti-peeling performance of the asphalt and stone and has the advantages of good compounding performance, stable performance, easiness of collection of the raw materials, low production cost, simple and convenient preparation method, wide application range and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-ionic asphalt warm mixing agent and preparation method thereof

The invention discloses a non-ionic asphalt warm mixing agent and a preparation method thereof. The non-ionic asphalt warm mixing agent comprises the following components in percentage by weight: 0.1-10 percent of a macromolecular component, 0.1-20 percent of a low-molecular component, 1-15 percent of inorganic micro powder and 55-98.8 percent of water. The preparation method comprises the following steps: adding water into a container according to the ratio, adding the macromolecular component, stirring for 0.5-2 hours at constant temperature, controlling the temperature to be 40-60 DEG C, then adding the low-molecular component and the inorganic micro powder according to the ratio, heating to 60-80 DEG C, and continuously stirring for 0.5-1 hour to obtain the non-ionic asphalt warm mixing agent. The non-ionic asphalt warm mixing agent disclosed by the invention can effectively reduce the high-temperature viscosity of asphalt and has the advantages of high dispersion property, stable performance, available raw material, low production cost, simple and convenient preparation method, wide application range and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Triploid Breeding Methods For Different Shrimp Species

InactiveUS20080115734A1Produced conveniently and efficientlyImprove the level ofClimate change adaptationPisciculture and aquariaHeat shockShrimp

This invention is about triploid breeding method for different shrimp species especially to the triploid production both in cold-warm water shrimp and tropical species, including the induction of MI triploid shrimp, the triploid induction methods for different shrimp and the development and utilization of revulsants for triploid shrimp. The triploid of cold-water shrimps were obtained by collecting the fertilized eggs and heat shock treatment; while the triploid induction of tropical shrimps were obtained with collection of the fertilized eggs, treatment of the revulsants or cold shock. The advantages of the invention are as follows: it has determined the optimal-inducing processes and methods for different species of shrimps, and led to the inducing rate increased distinctly; It also has determined the optimal-inducing methods for MI triploid shrimp, and led to the inducing rate increased distinctly without the destroy of eggs; The revulsants which led to high inducing efficiency in this invention are nontoxic, so the operation security and the safety to environment are improved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Low-pressure airflow atomizing sprayer

The invention discloses a low-pressure airflow atomizing sprayer which comprises a machine frame, a petrol engine, an air pump, a liquid medicine box and a spray lance, wherein the petrol engine and the liquid medicine box are mounted on the machine frame, and the spray lance is connected with the liquid medicine box. The low-pressure airflow atomizing sprayer is characterized in that a sewage outlet and a one-way air guide valve are arranged at the bottom of the liquid medicine box; a spray lance switch used for adjusting the spray outlet is mounted at a position of the spray lance, which is held by hand; a suction disc port is directly connected with an outlet of a liquid pipe port; the petrol engine is directly connected with the air pump; a hemispherical net membrane for secondary noise reduction and sound deadening is mounted at a smoke exhaust port of the petrol engine; and a plurality of atomizing spray heads are mounted on the spray lance. The low-pressure airflow atomizing sprayer has the characteristics of simple structure, easiness in manufacture, low cost, high efficiency and convenience in use, and can guarantee safety of people.

Owner:广西壮族自治区柳州市劲松机械制造有限公司

Phosphorus steel smelting method for a top-bottom combined blowing converter

ActiveCN105296703ARapid decarbonization and phosphorus conservationReduce stirringManufacturing convertersOxygen utilization rateSmelting process

The invention relates to a phosphorus steel smelting method for a top-bottom combined blowing converter. The method comprises the following steps that (1) the phosphorus content of molten iron is 0.08-0.12%, the oxygen supply pressure is 1-1.05 MPa, and the oxygen supply intensity is 3.5-3.8 m<3> / (t.min); (2) when converting is conducted for 1-3 min, and active lime and light burned dolomite are added; 1 min is delayed, and iron-containing material carbon balls are added; (3) an oxygen gun adopts a high-low-low gun position, and an automatic N / Ar switching mode is adopted for bottom blowing; (4) the nitrogen bottom-blowing mode is adopted for medium combined-blowing at the early stage and the medium stage, and the argon bottom blowing mode is adopted at the later stage of converting and 1-2 min before carbon catching; the converting final temperature is controlled within 1660-1680 DEG C, and the content of end point carbon is controlled within 0.04-0.06%; the content of end point phosphorus is controlled within 0.05-0.075%; and (5) the content of finished phosphorus is controlled within 0.06-0.09%. Compared with the prior art, the phosphorus steel smelting method has the beneficial effects that the converting time is shortened by improving the phosphorus steel smelting process for the top-bottom combined blowing converter, and the blowing converter can conduct decarbonization and phosphorus preservation rapidly; the oxygen utilization rate is increased, the smelting time is shortened, and the cost is reduced.

Owner:ANGANG STEEL CO LTD

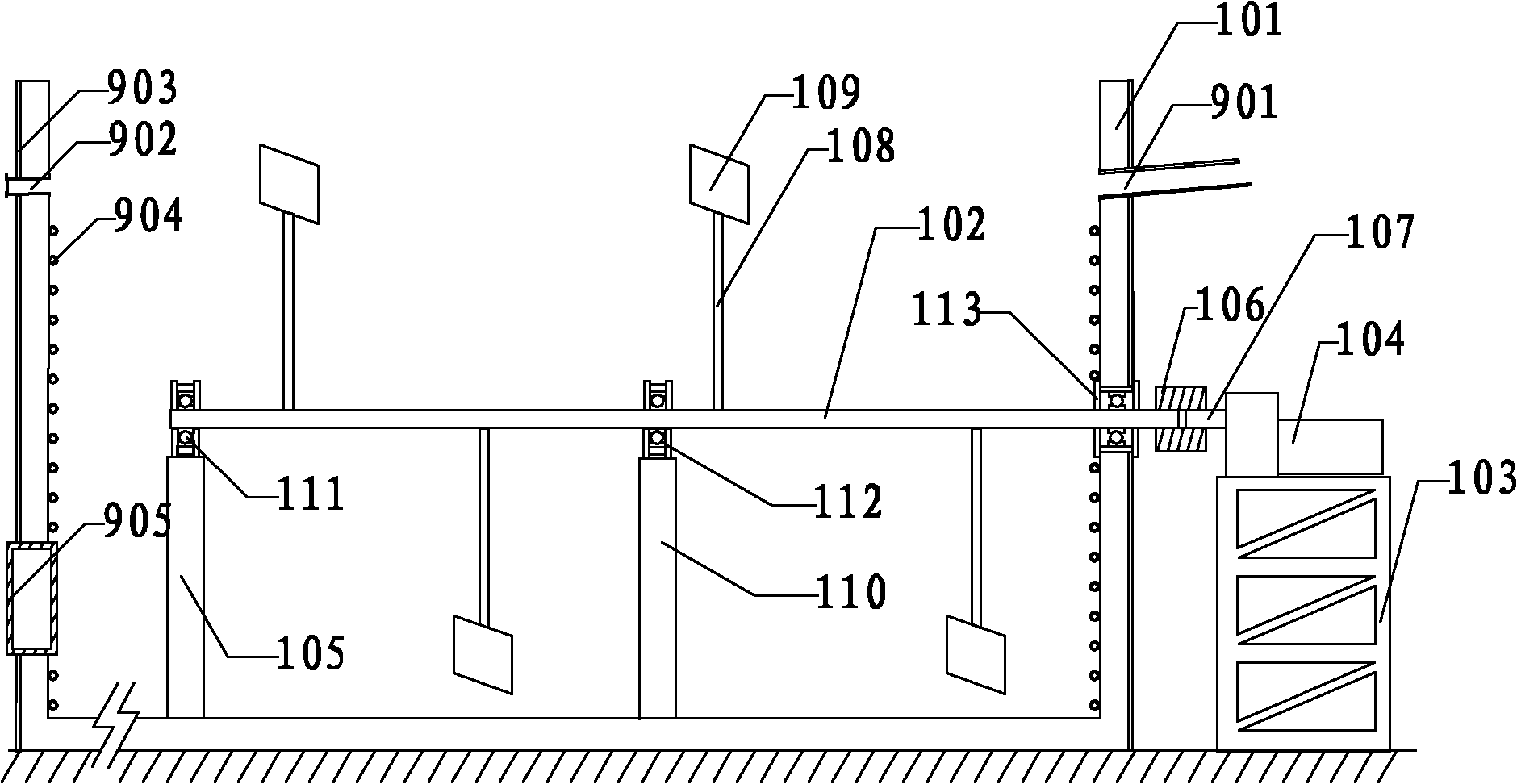

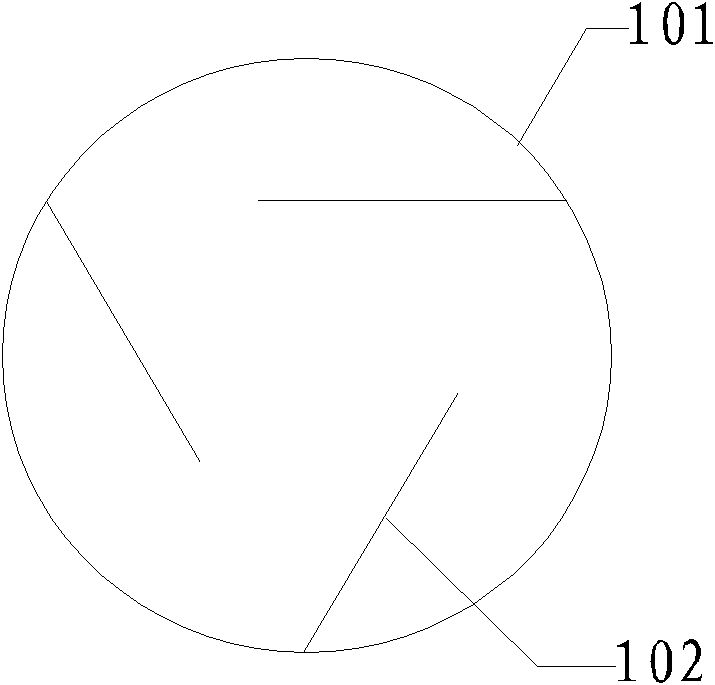

Waste smoldering combustion pyrolysis device with automatic controlling and monitoring function

ActiveCN110454792AMeet input requirementsAchieve firmnessIncinerator apparatusAutomatic controlCombustion

The invention discloses a waste smoldering combustion pyrolysis device with an automatic controlling and monitoring function. The waste smoldering combustion pyrolysis device comprises control monitoring equipment and one or more smoldering combustion pyrolysis equipment; each smoldering combustion pyrolysis equipment comprises a pyrolysis cylinder body and a sensing detection system, wherein an opening type feeding opening is formed in the top of the pyrolysis cylinder body, a vertically-arranged rotating shaft is rotationally connected in the opening type feeding opening through a supportingframe, the rotating shaft extends downwards to the lower part of the opening type feeding opening, and spiral extrusion blades are arranged on the part, at the lower part of the opening type feedingopening, of the rotating shaft; a slag discharging device is arranged at the bottom of the pyrolysis cylinder body; a plurality of gas suction sets are circumferentially arranged at the bottom of theside wall of the pyrolysis cylinder body, each gas suction set comprises an air inlet and an air outlet, an annular gas guide pipe is arranged in the pyrolysis cylinder body, and the air outlet is incommunication with the annular gas guide pipe; and a vent pipe is connected to the annular gas guide pipe, and the vent pipe is connected to a dust removal and cooling mechanism. The optimal smoldering combustion effect is achieved, and the running state and the target position of each smoldering combustion pyrolysis equipment can be realized through the control monitoring equipment.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Low-temperature and low-salt tank type circulating fermentation preparation method of thick broad-bean sauce

The invention provides a low-temperature and low-salt tank type circulating fermentation preparation method of thick broad-bean sauce. The method comprises the following steps: A, carrying pretreatment on broad beans; B, making broad bean koji; C, carrying out tank type fermentation on the broad bean koji: sending the broad bean koji into a fermentation tank, enabling the water content of the broad bean koji in the fermentation tank to be less than or equal to 50%, enabling the salt content of the broad bean koji to be 8-11%, controlling the temperature to be 15-20 DEG C, and carrying out fermentation; when fermentation is carried out for 13-15 days, adding 1-4 per thousand of lactobacillus powder for carrying out fermentation, continuously fermenting for 3-4 days, and then adding 1-4 per thousand of yeast powder for continuously fermenting; fermenting for 76-180 days in total so as to obtain the thick broad-bean sauce. The preparation method of the thick broad-bean sauce not only can meet the requirement for quality and avoid the external pollution in a making process, but also maintains the unique flavor of the traditional fermented bean sauce; the preparation method is less in land occupation and suitable for large-scale industrial production, and meets the market demand of Pixian bean sauce.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

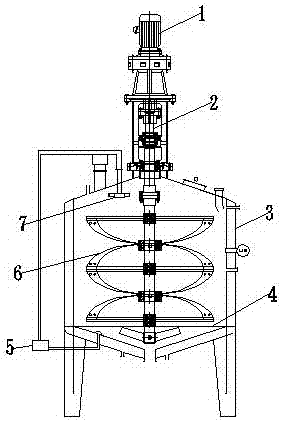

Dry-method anaerobic fermentation device

ActiveCN102643739AImprove efficiencyReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCoupling

The invention discloses a dry-method anaerobic fermentation device which comprises a fermentation tank, a first bracket, stirring shafts, a motor, a coupler, stirring arms and stirring paddles, wherein the first bracket is arranged on the outer side of the fermentation tank; the motor is arranged on the first bracket; stirring shaft holes are formed in the fermentation tank; the stirring shafts penetrate through the stirring shaft holes and are connected to the coupler; the coupler is connected onto the motor; one end of each stirring arm is connected onto each stirring shaft; and each stirring paddle is arranged at the other end of each stirring arm. The stirring shafts are averagely distributed on the cross section on the inner wall of the fermentation tank; and the stirring shafts and the fermentation tank deflect clockwise or anticlockwise for an angle of 15-45 degrees. According to the dry-method anaerobic fermentation device disclosed by the invention, the processing rate of materials is high, the fermentation effect is favorable and the problems of local acidification phenomenon and poor heating and heat transferring effects caused by poor stirring uniformity of the materials are solved; and meanwhile, the problems of scum on the upper layer, crusting prevention and the like are solved.

Owner:BEIJING ZISHENGLONG ENVIRONMENTAL TECH

Method for microorganism-pelleting heap leaching of earthy oxide copper ores

InactiveCN101781705BIncrease throughputReduce ore washingProcess efficiency improvementThiobacillus ferrooxidansIron(II) oxide

The invention relates to a method for leaching earthy oxide copper ores, in particular to a method for microorganism-pelleting heap leaching, and belongs to the technical field of hydrometallurgy. The method is characterized in that: the earthy ores are directly screened, and fine ores with the granularity of 1.5mm are added with strain acid water and cement to prepare ore pellets with the diameter between 10 and 20 mm for heap leaching, wherein the mass concentration of sulphuric acid in the strain acid water is 3 to 10 percent, strains are mixed strains of Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, the mass ratio of the three is 4.0-5.5:2.5-3.5:1.5-2.5, the bacterial load ratio is 105 and 108 / ml, the cement amount is 15 to 30kg / ton of ores; and leachate in the leaching is sprayed for closed cycle production. The method has the advantages of low investment, low energy consumption, good leaching effect, and no discharge of closed cycle, solvesthe problem of leaching the low-grade earthy oxide copper ores (including sulphide and oxide blend ores) by microorganism heap leaching, and overcomes the defects of long flow and high cost of agitation leaching.

Owner:王宣明

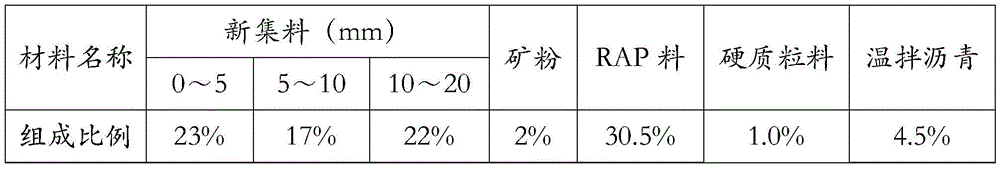

High-modulus asphalt paving material and preparation method thereof

ActiveCN105601175ATo achieve the role of energy saving and environmental protectionSolve the problem that the adsorption effect is not as good as ordinary asphaltSolid waste managementClimate change adaptationRoad surfaceHigh pressure

The present invention relates to asphalt paving material, and particularly to a high-modulus asphalt mixture and a preparation method thereof. The high-modulus asphalt mixture comprises the following raw materials by weight, 39-65% of a new aggregate, 1-5% of an ore powder, 28-52% of a RAP material, 0.4-1.2% of a hard pellet material, and 3-5% of warm mixing asphalt. The high-modulus asphalt mixture has high modulus, high compactness and durability.

Owner:厦门华特公路沥青技术有限公司

Warm mixing type track-resistant compound modification agent and preparation method thereof

ActiveCN106147249AProlonged viscosity at 60°CIncrease viscosity at 60°CClimate change adaptationBuilding insulationsActive agentOil sludge

The invention discloses a warm mixing type track-resistant compound modification agent and a preparation method thereof and belongs to the technical field of road asphalt. The warm mixing type track-resistant compound modification agent is prepared from a special warm mixing agent, a powdery solid, polyethylene wax, sulfur and hard asphalt according to a formula, wherein the special warm mixing agent is prepared from a fluorocarbon surfactant, alkyl glycoside and carlo amine, the powdery solid is a solid product separated after oily sludge is treated by adopting a sludge thermal-extraction dehydration process. The components in the warm mixing type track-resistant compound modification agent have a synergistic effect, the effect of additive synergism can be played, the mixing and forming temperatures of a warm mixing type asphalt mixed material prepared by applying the warm mixing type track-resistant compound modification agent are lower than 135 DEG C, the warm mixing type track-resistant compound modification agent has the advantages of obviously reducing the mixing and forming temperatures, and the properties of the mixed material are equivalent to the properties of warm mixing asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

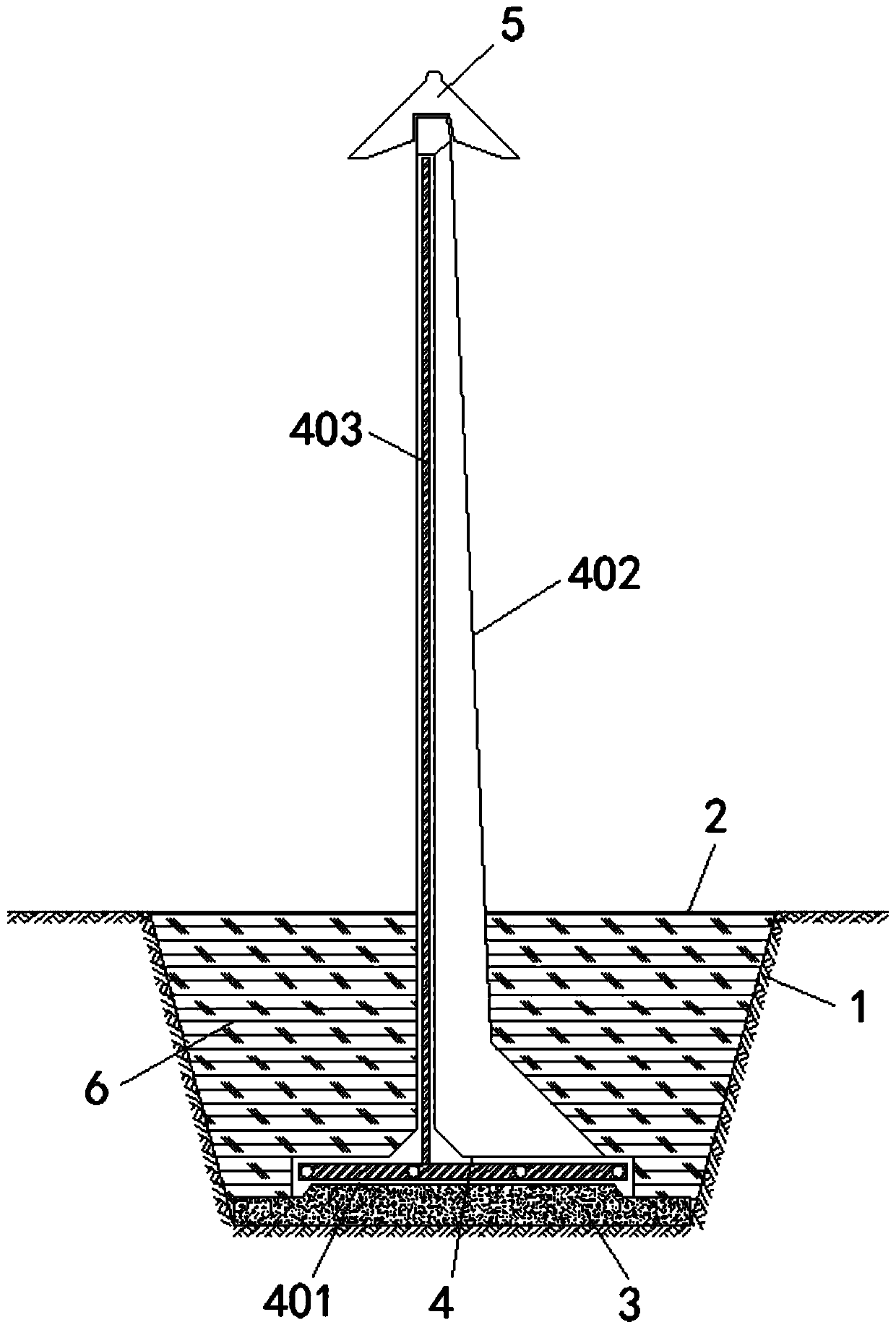

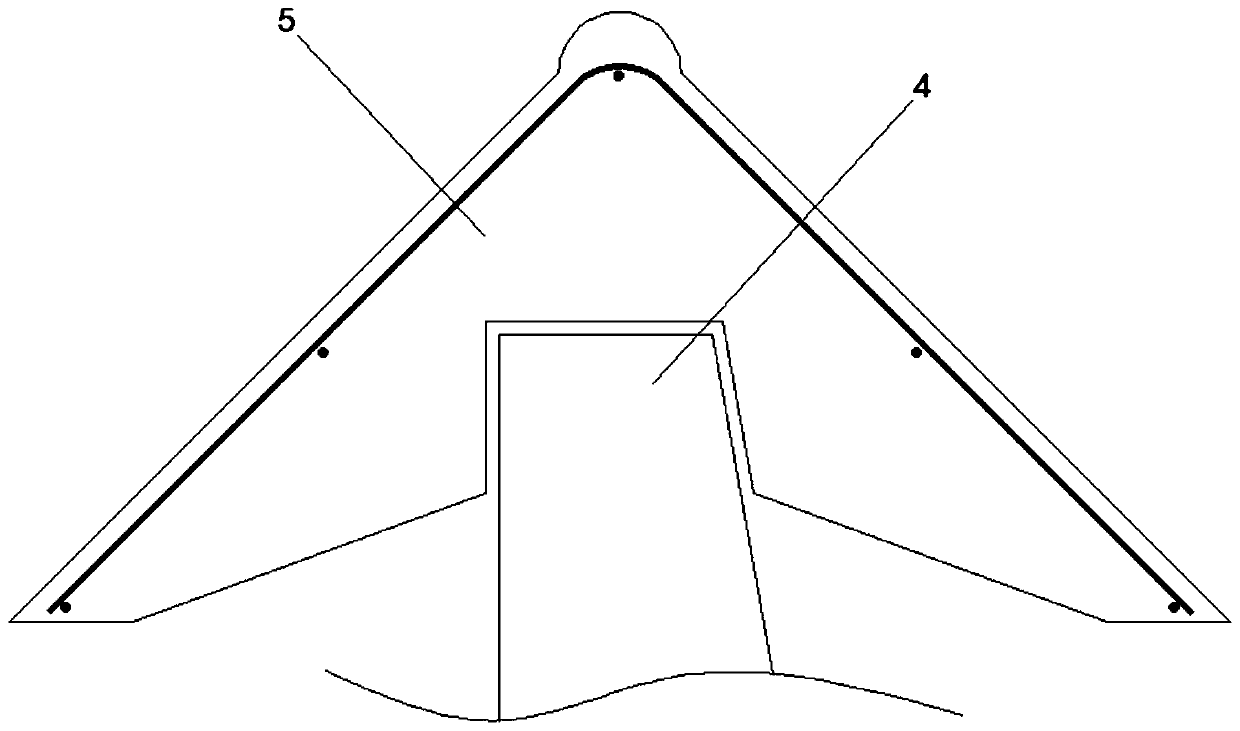

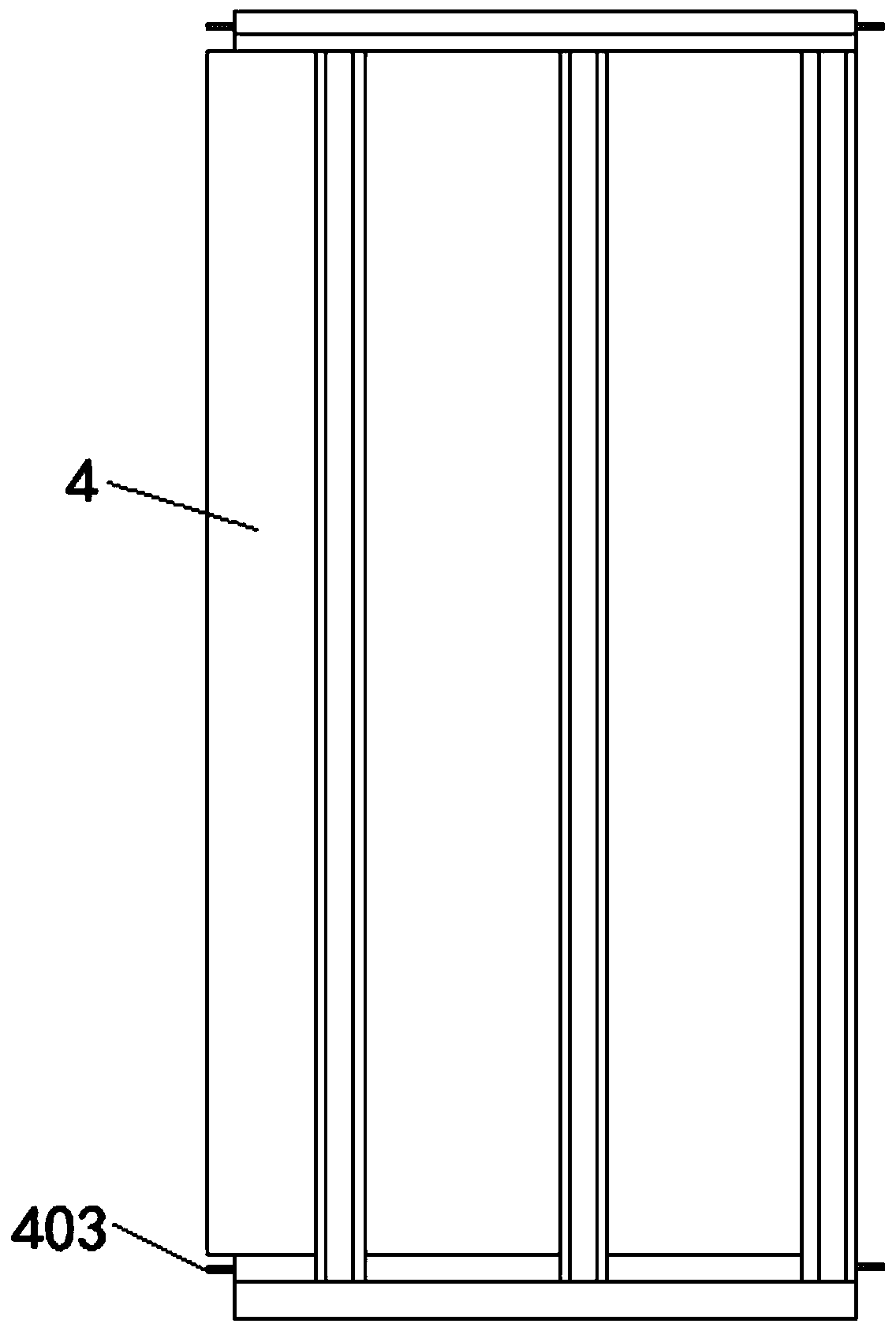

Integrated precast concrete wall

InactiveCN109779384AImprove aestheticsImprove the cultural atmosphereFencingEngineeringShock resistance

The invention relates to the technical field of buildings and discloses an integrated precast concrete wall. The concrete wall comprises an outdoor floor, a mounting foundation pit is formed in the top of the outdoor floor, a leveling layer is laid on the inner wall of the mounting foundation pit, a concrete enclosing wall body is movably mounted at the top of the leveling layer, a wall cap is clamped to the top of the concrete enclosing wall body, and soil is arranged in the mounting foundation pit. According to the integrated precast concrete wall, sheets, reinforcing ribs and reinforcing steel bars are subjected to one-time pouring of concrete in a factory in advance, and the steel bars are staggered horizontally and vertically, therefore the bearing capacity of the wall body is greatlyincreased. The wall body is made to be lighter and thinner under the condition that the normal using function is met, the using amount of building materials is effectively saved, the shock resistanceand the stability of the wall body are improved, the concrete enclosing wall body formed through pouring is transported to a construction site, then the tops of every two adjacent wall bodies are clamped through the corresponding wall caps, and the installation and construction efficiency is greatly improved.

Owner:游家良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com