Modified natural zeolite warm mixing agent and preparation method thereof

A natural zeolite and warm mix agent technology, applied in the direction of climate change adaptation, etc., can solve the problems that affect the popularization and application of zeolite warm asphalt mixture, reduce the ability of asphalt mixture to resist water damage, and the asphalt and aggregate are easy to peel off, etc. , to achieve the effect of improving water stability, reducing interfacial free energy, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

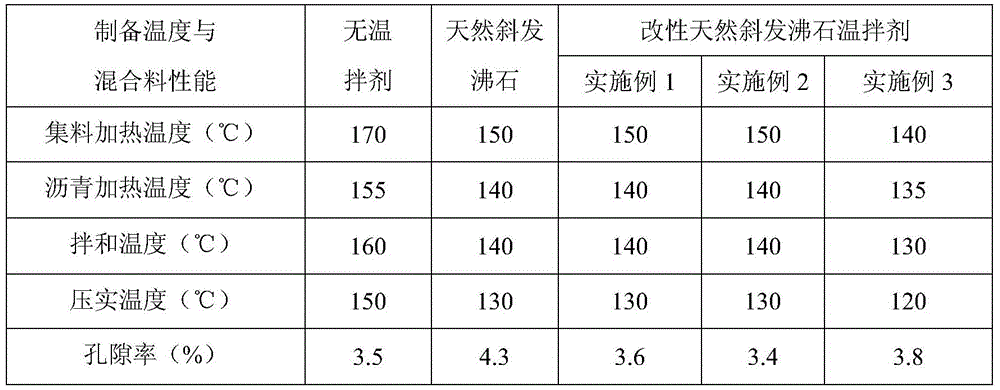

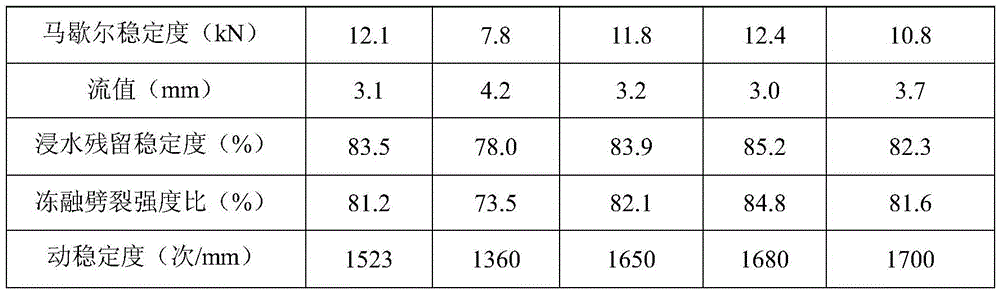

Embodiment 1

[0021] A modified natural zeolite warm mixing agent is prepared by the following method:

[0022] (1) Alkaline solution treatment: the raw material of natural zeolite is natural clinoptilolite, the fineness is 200 mesh; 30g of natural clinoptilolite is added to 100ml, 0.5mol / L sodium hydroxide alkali solution, mixed and stirred for 1h, and filtered to obtain Alkali-treated natural clinoptilolite;

[0023] (2) Fatty amine modification: Add 30 g of alkali-treated natural clinoptilolite to a 0.1 mol / L, 100 ml ethanol solution of stearylamine, mix and stir for 1 h, and filter the obtained solid components at a temperature of 80 ° C. Drying for 2 hours under the hood, the modified natural zeolite warm mixing agent was obtained.

[0024] The thermogravimetric (TG) test shows that the water content of natural clinoptilolite in this example is 9%, and the water content of the modified natural clinoptilolite warming agent after alkali treatment is 15%.

Embodiment 2

[0026] A modified natural zeolite warm mixing agent is prepared by the following method:

[0027] (1) Alkali solution treatment: natural zeolite raw material is natural clinoptilolite, fineness is 250 mesh; 25g natural clinoptilolite is added in the sodium hydroxide alkali solution of 100ml, 0.8mol / L, mix and stir 1.5h, filter Obtain alkali-treated natural clinoptilolite;

[0028] (2) Fatty amine modification: add 25g of alkali-treated natural clinoptilolite into 0.15mol / L, 100ml of octadecylamine ethanol solution, mix and stir for 0.5h, and filter the obtained solid component at 78°C Dry at low temperature for 3 hours to obtain the modified natural zeolite warm mixing agent.

[0029] The thermogravimetric (TG) test shows that the water content of natural clinoptilolite in this example is 9%, and the water content of the modified natural clinoptilolite warming agent after alkali treatment is 17%.

Embodiment 3

[0031] A modified natural zeolite warm mixing agent is prepared by the following method:

[0032] (1) Alkaline solution treatment: natural zeolite raw material is natural clinoptilolite, fineness is 300 mesh; 20g natural clinoptilolite is added in 100ml, 1.0mol / L sodium hydroxide alkali solution, mix and stir for 1.5h, filter Obtain alkali-treated natural clinoptilolite;

[0033] (2) Fatty amine modification: Add 20g of alkali-treated natural clinoptilolite into 0.2mol / L, 100ml of octadecylamine ethanol solution, mix and stir for 0.75h, and filter the obtained solid component at 75°C Dry at high temperature for 4 hours to obtain the modified natural zeolite warm mixing agent.

[0034] The thermogravimetric (TG) test shows that the water content of the natural clinoptilolite in this example is 9%, and the water content of the modified natural clinoptilolite warming agent after alkali treatment is 19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com