Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Reduce product rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

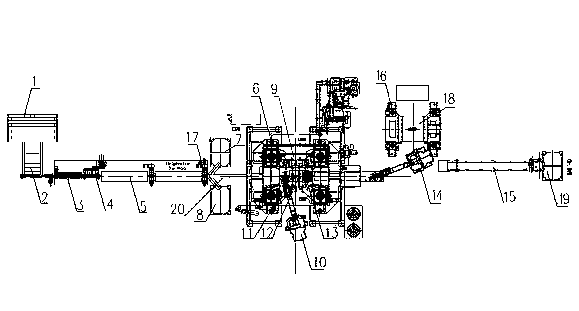

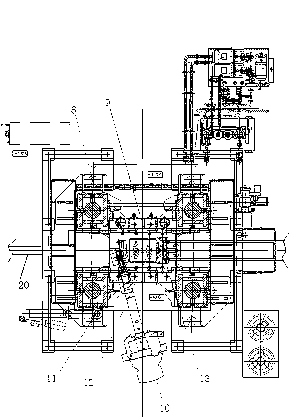

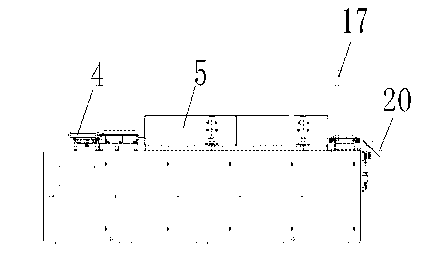

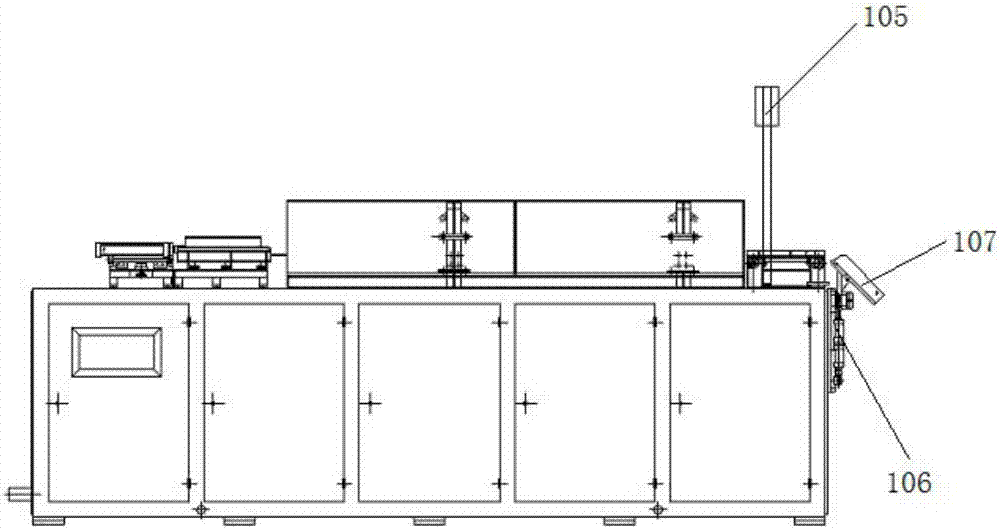

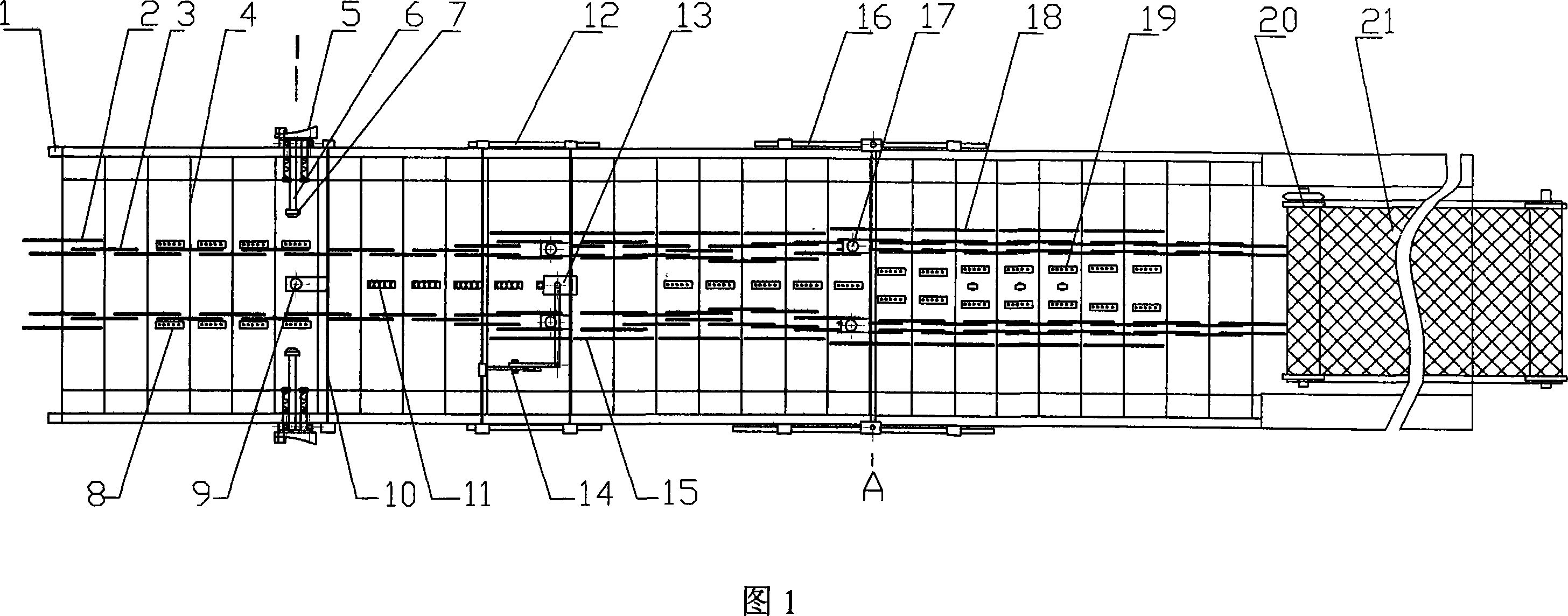

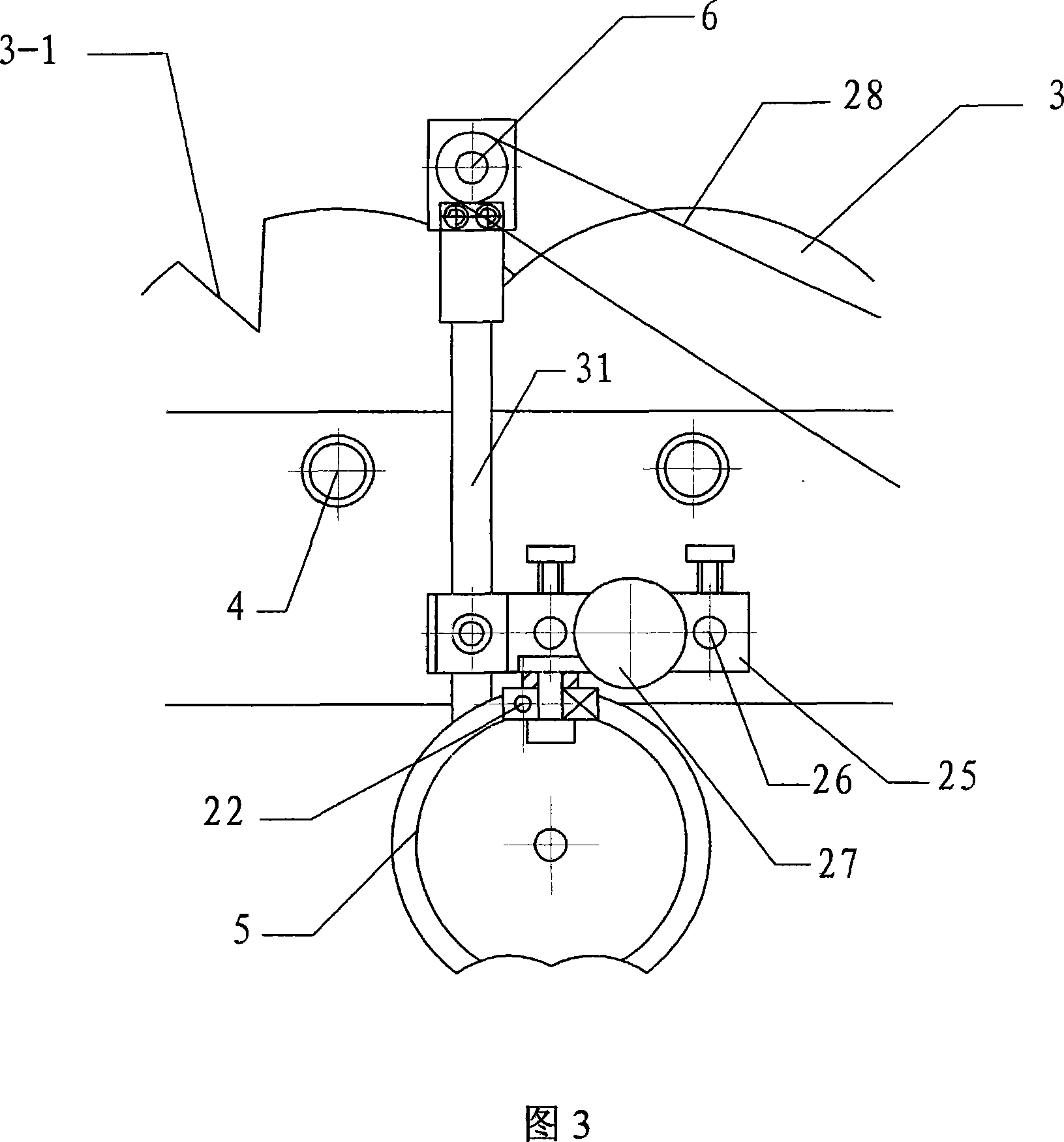

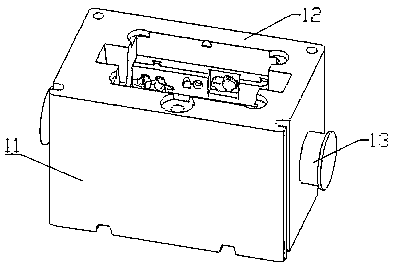

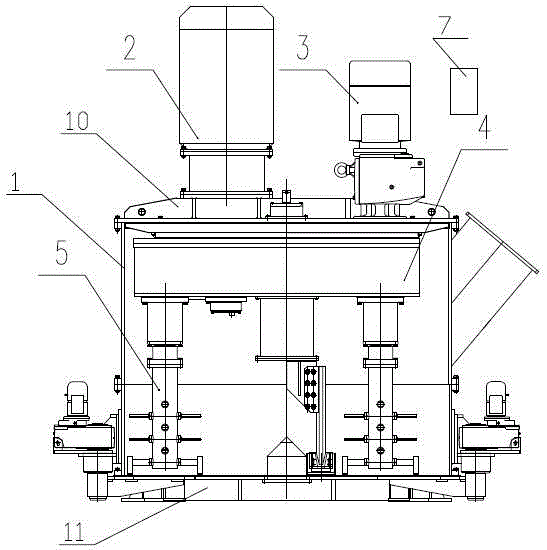

Production device and production technology for non-quenched and tempered steel forge piece automatic forging

InactiveCN103230997AEmission reductionImprove electricity efficiencyHandling devicesEngineeringUltimate tensile strength

The invention relates to the technical field of metal hot processing, in particular to the technical field of production device and production technology for non-quenched and tempered steel forge piece automatic forging. The device comprises a forging system, a feeding system and a discharging system, wherein the feeding system is arranged at the front end of the forging system, the discharging system is arranged at the rear end of the forging system, the forging system comprises an electric heating furnace connected with rear part of the feeding system, a forging pressing machine is connected with the rear part of the electric heating furnace, an edge trimmer is connected with the rear part of the discharging system, and the discharging system is connected with the rear part of the edge trimmer. According to the device provided by the invention, defects in the prior art is overcame, the full automatic line technology that the forge piece is heated once and is controlled by one worker is realized, is energy-saving and cost-reducing, labor saving, the outer surface and the inner quality of the forge piece is improved, and the service life is prolonged; as the mechanical property of each part of the forage is close to one anther, the forge piece quality and safety performance are improved, and the non quenched and tempered steel forging piece is high in tensile strength, fatigue strength and machinability.

Owner:ANHUI ANHUANG MACHINERY

Paper pouring channel tube for casting and shaping technique thereof

InactiveCN101508005AReduce pollutionSave energyFoundry mouldsPaper recyclingFiberResource utilization

The invention relates to a paper pouring channel pipe for forging, which is made of waste paper pulp, sintered filling materials, binding materials, reinforcing agent and moisture-proof agent materials. The new concepts and mechanisms completely different from the prior art are applied to the paper pouring channel pipe, namely the pouring channel pipe is not made of the prior used refractory materials such as pottery, porcelain and the like, and non-fireproof paper pulp fibers are taken as a main component which is added with the sintered filling materials and the like, carbonized and sintered under the using conditions of high temperature and oxygen deficiency to form a carbon sinter with high fire resistance degree and the paper pouring channel pipe which achieves the molten iron scouring resistance and fire resistance degree capable of meeting the current forging process requirements. The paper pouring channel pipe has the advantages of regenerative resource utilization, no forging, energy conservation, environment pollution reduction, socket joint, no sand leakage, convenient use, little dust during cutting, light weight, little resource consumption, no easy damage at normal temperature, crispness after high temperature treatment, easy stripping, easy cleaning, little hard solid waste after pouring, abrasion reduction of a sand regenerating device, improvement on the quality of regenerated sand, reduction on the defective index of forged pieces, no carburization problem for the forged pieces, and the like.

Owner:曹敏道

Method for producing tempered glass polarizing lens

ActiveCN101226255AIncrease production capacityImprove processing efficiencyPolarising elementsHigh volume manufacturingEngineering

The invention relates to a production method of toughened glass polarizing lens, belonging to the production method of spectacle lens. The inventive method comprises optically grinding a blank to reach demand arc degree and thickness, immersing into strengthen solution in batch to process chemical reinforcement, while the arc degree of front convex surface of the prepared back optical sheet is some larger than the back concave surface of the front optical sheet, heating and pressing the polarizing film into a polarizing curvature film with arc degrees, adhering the polarizing curvature film between the back concave surface of the front optical sheet and the front convex surface of the back optical sheet, removing foams, feeding into a constant-temperature solidifying furnace to be solidified in batch to prepare round lens blanks, edging and cutting the round lens blanks in the shape of mirror frame to obtain the shaped lens with triangle edge, uniformly coating adhesive on the triangle edges of the shaped lens to seal edges, laying horizontally and feeding into the constant-temperature solidifying furnace to be solidified in batch, clearing abundant adhesive materials on the edges after solidification, to obtain final product. The invention resolves the batch production problem of polarizing lens.

Owner:厦门思乐特科技有限公司

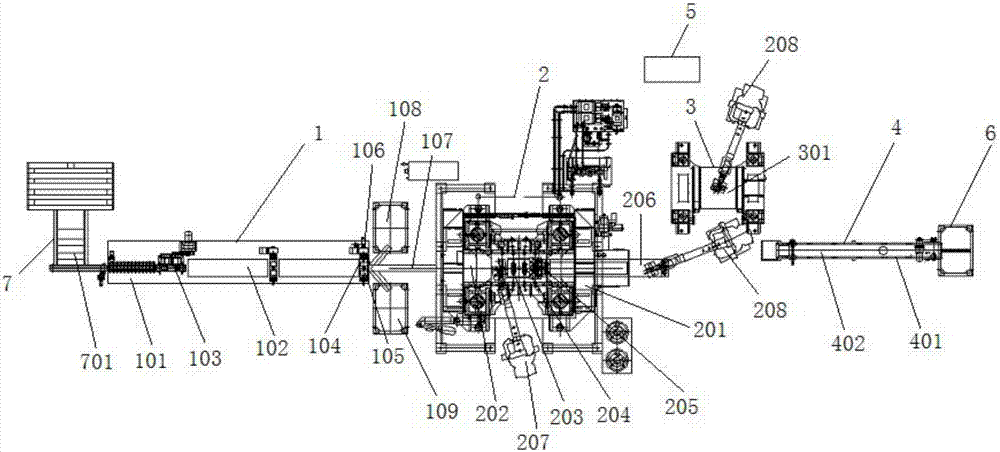

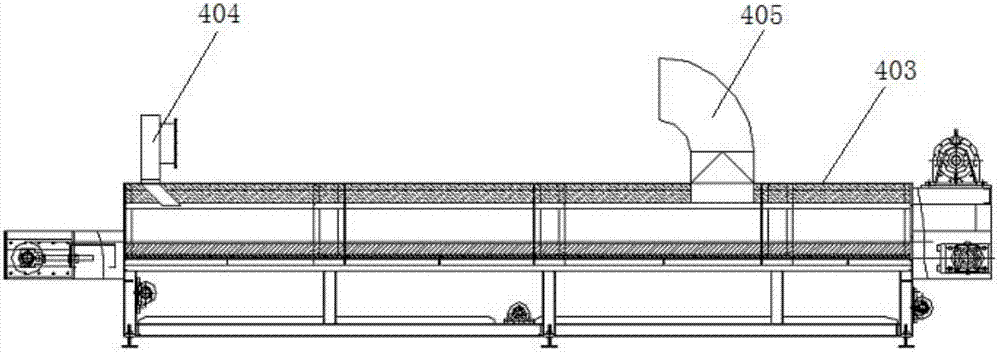

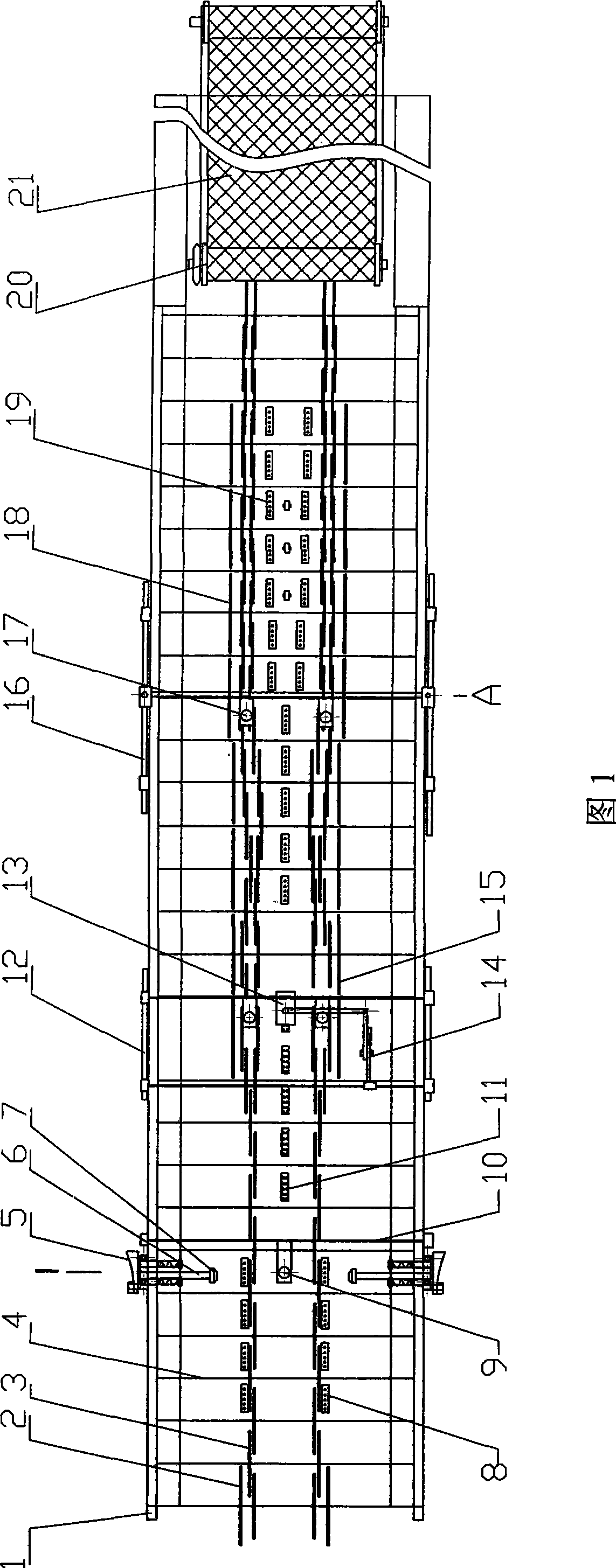

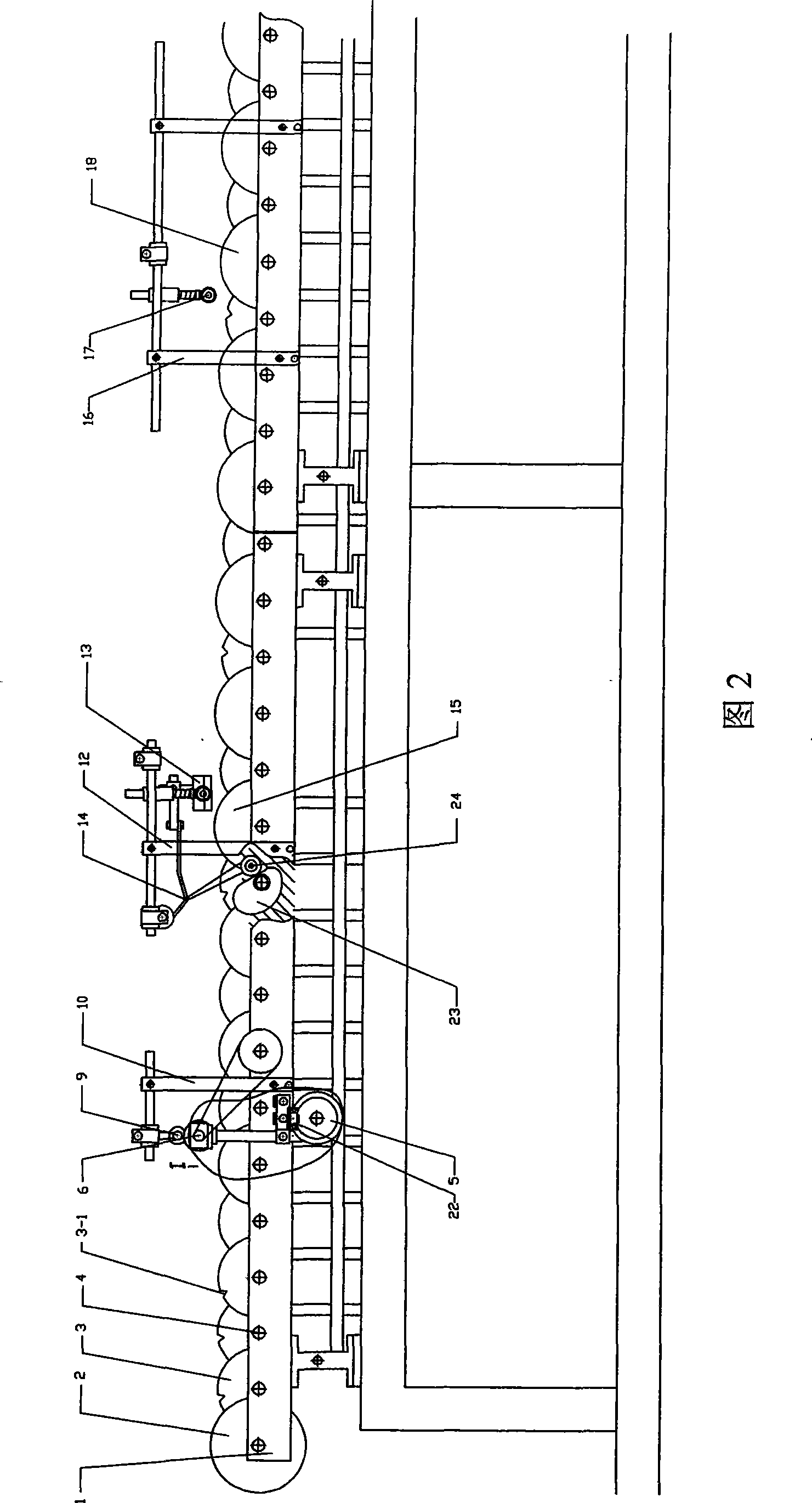

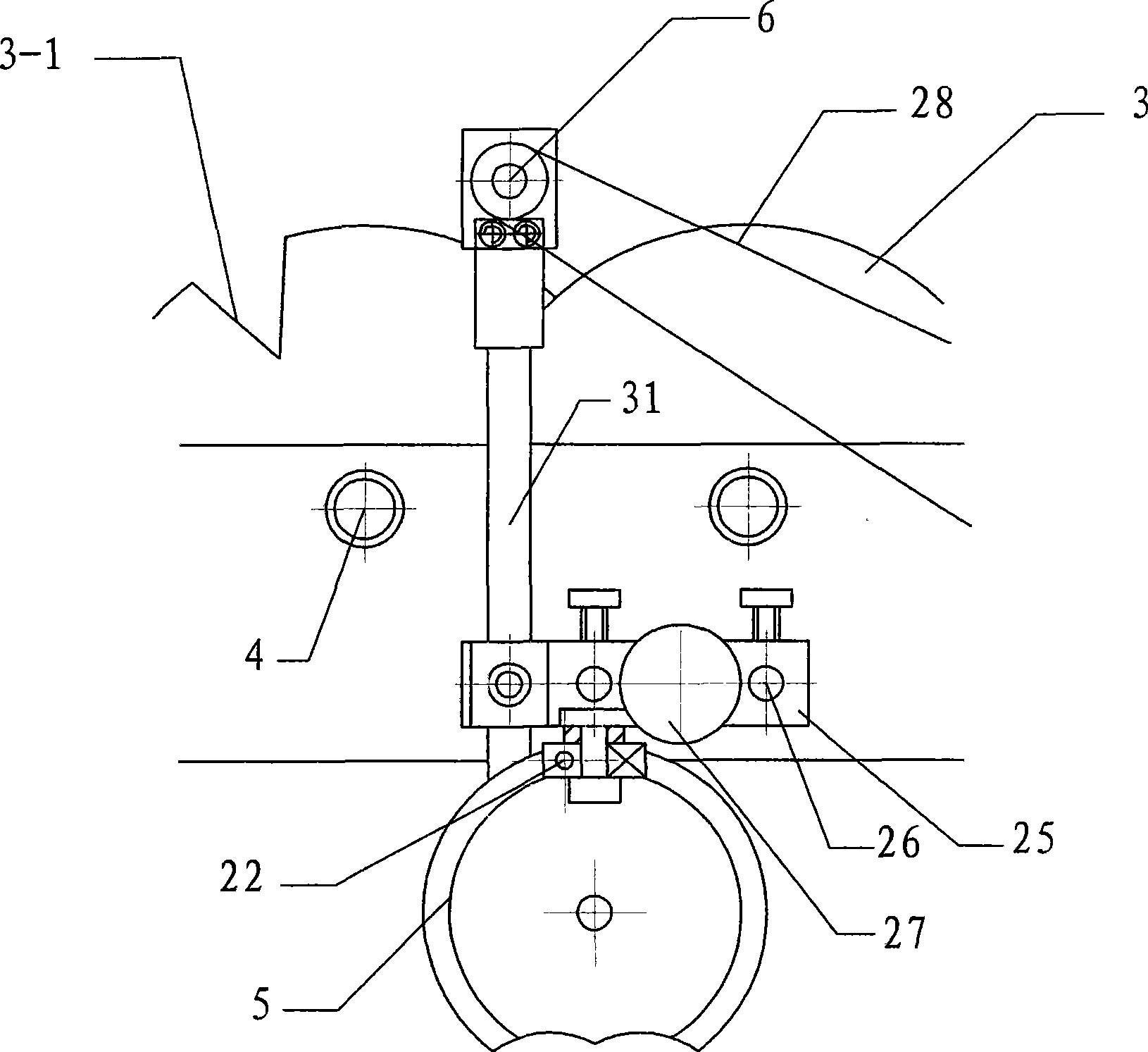

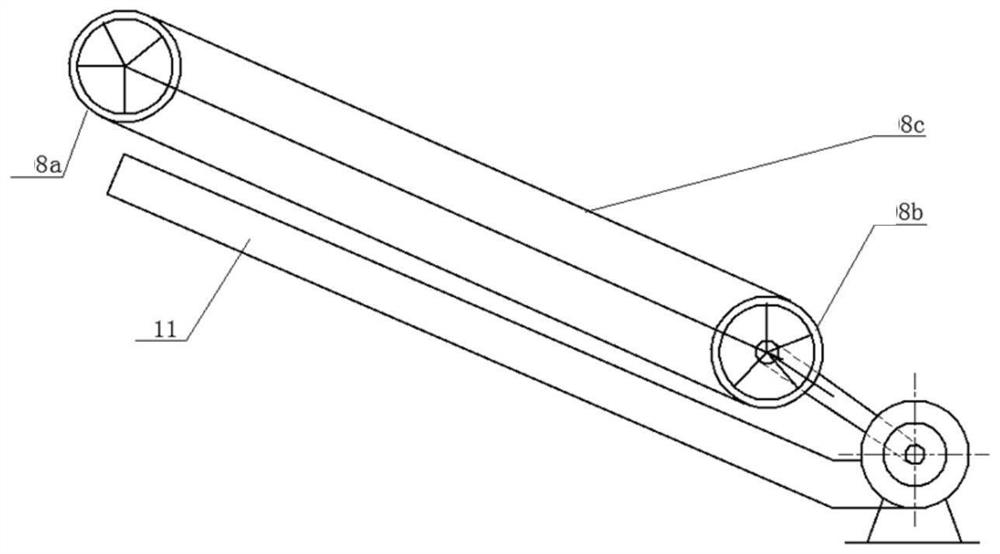

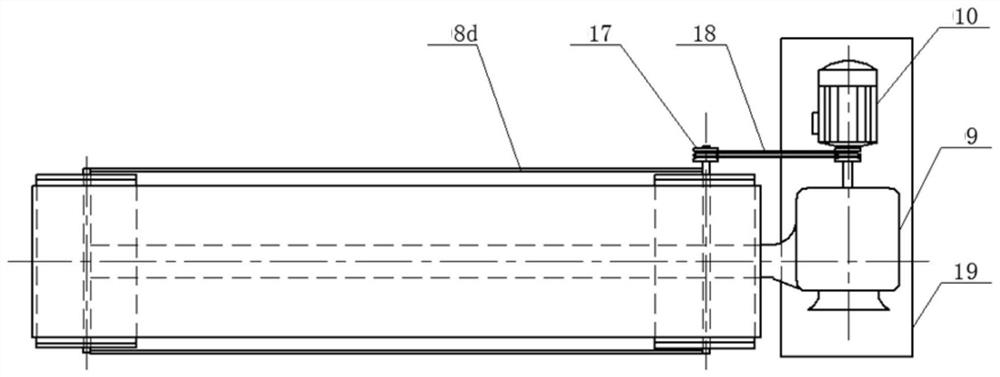

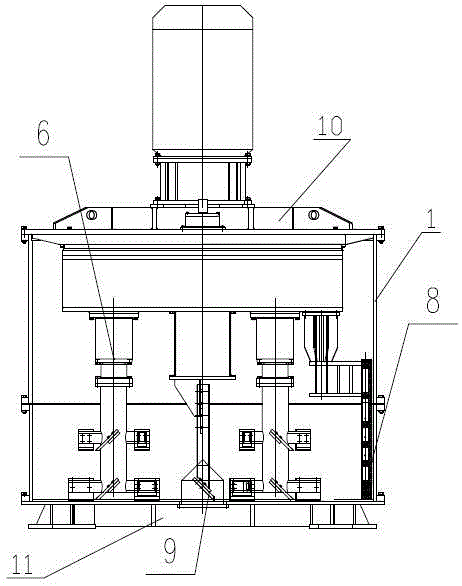

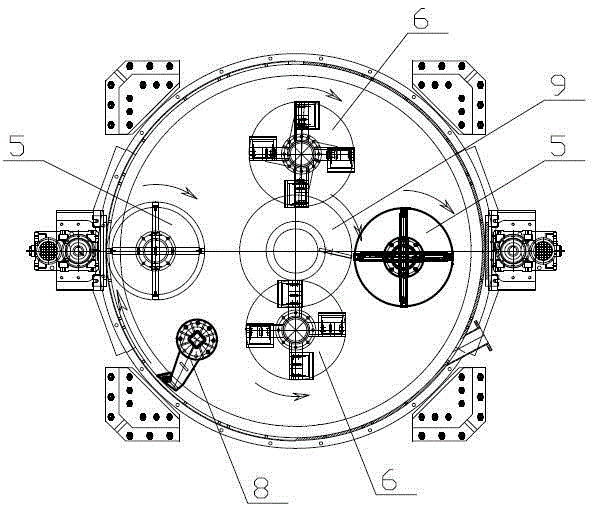

Full-automatic non-quenched-and-tempered steel forge piece production line

ActiveCN107442726AEmission reductionImprove electricity efficiencyForging/hammering/pressing machinesForging press drivesProduction linePunching

The invention discloses a full-automatic non-quenched-and-tempered steel forge piece production line. The production line comprises heating equipment, forging equipment, edge cutting and punching equipment, a cooling temperature control conveying chain, a finished product box and a programmable control system which are sequentially connected. According to the production line, a forge piece is heated at a time, continuous and automatic machining of multiple processes including upsetting, pre-forging molding, final forging molding, edge cutting, punching, heat treatment and the like is achieved, all machining processes need to be operated by one person, and the beneficial effects of being high in production efficiency and good in product quality are achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG +1

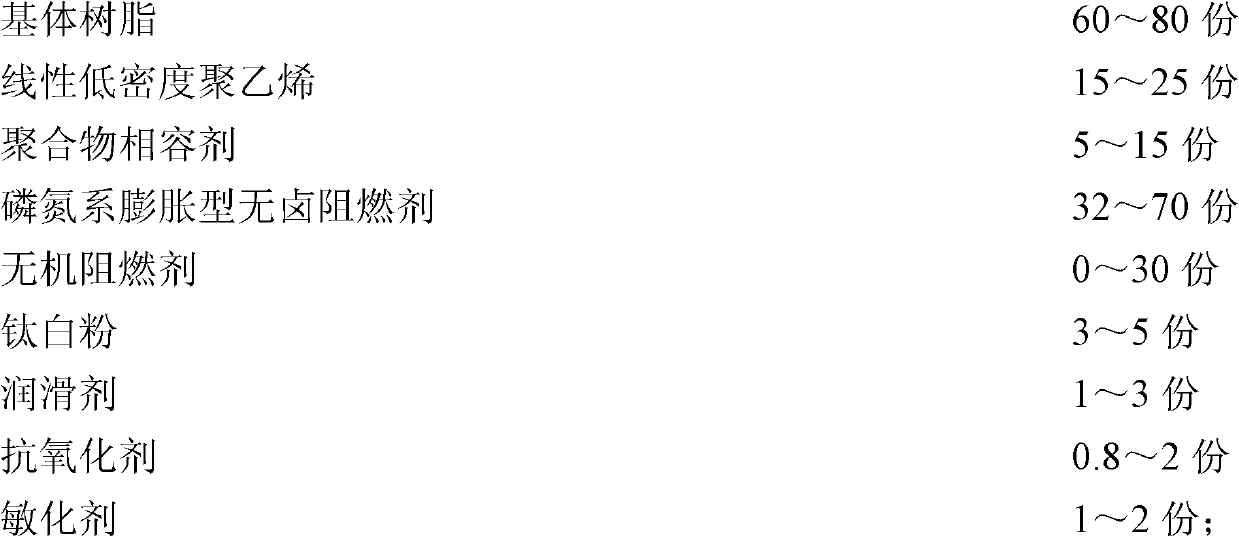

Oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation method and application thereof

The invention discloses an oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve and a preparation method thereof. The label sleeve consists of the following components in parts by weight: 60 to 80 parts of matrix resin, 15 to 25 parts of linear low-density polyethylene, 5 to 15 parts of polymer compatilizer, 32 to 70 parts of phosphorous nitrogen series expansible halogen-free flame retardant, 0 to 30 parts of inorganic flame retardant, 3 to 5 parts of titanium white powder, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant and 1 to 2 parts of sensitizer. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding with a double-screw extruder, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould, radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance and good oil resistance, produces little smoke, permanently preserves the label, and keeps good mechanical property, electric insulating performance and heat resistance.

Owner:广州凯恒科塑有限公司

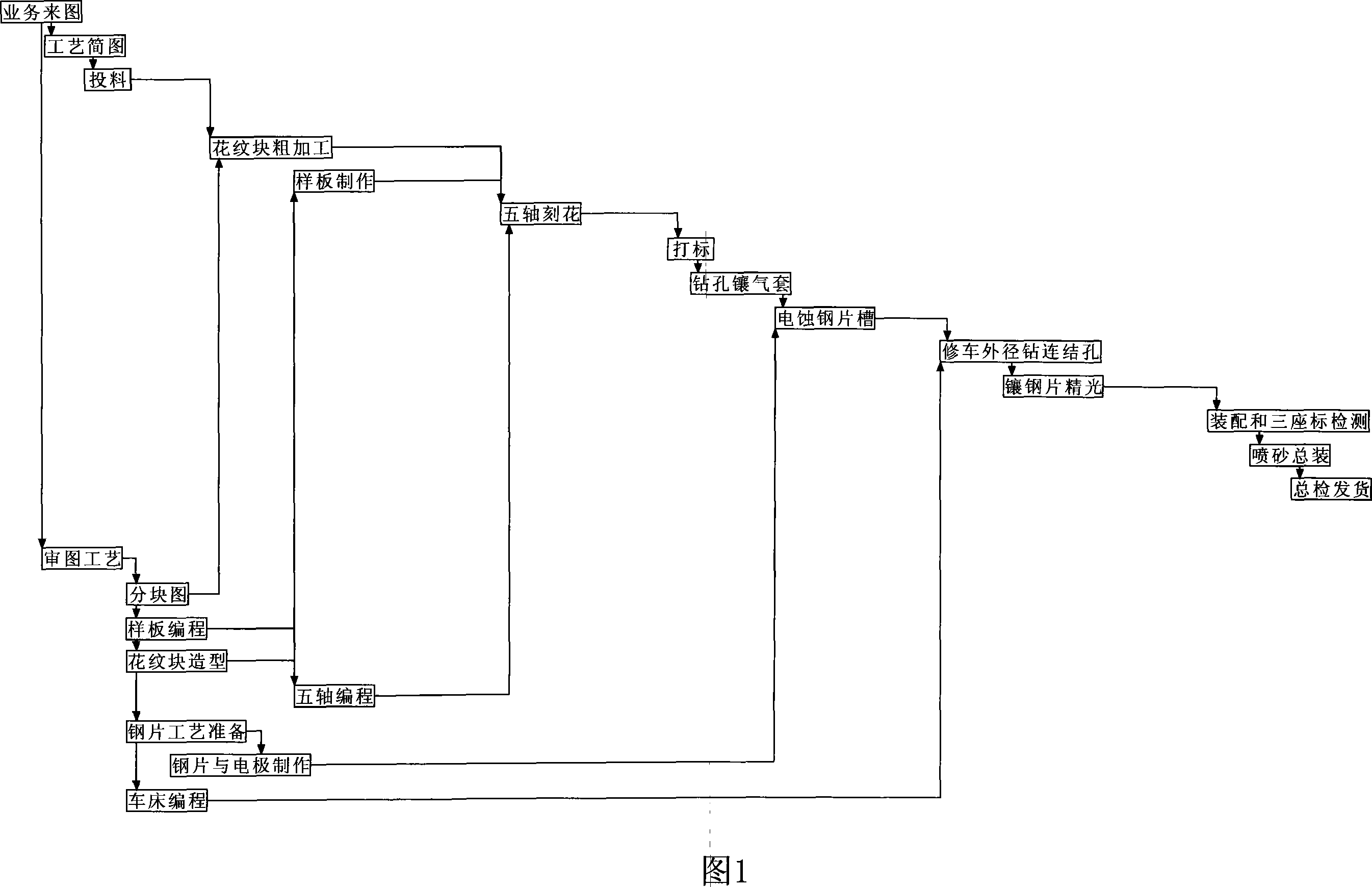

Tire mold high speed high precision parallel machining constitution method

InactiveCN101236416AShorten the design cycleReduce process preparation timeProgramme controlComputer controlNumerical controlEngineering

The invention relates to a high velocity and high precision constituting method for collaterally elaborating a tyre mould, comprising the following steps of a concurrence of designing and manufacture processing; a concurrence of designing and material purchasing; a concurrence of technology planning, rough machining and semifinishing; a concurrence of designing and numerical control process programming; and an elaboration for a single piece with high velocity and high precision. The high velocity and high precision constituting method for collaterally elaborating a tyre mould has the advantages of improving an elaborating precision of a product, shortening a delivery date for the mould and reducing the cost, and is suitable for collaterally elaborating the tyre mould with high velocity and high precision.

Owner:GREATOO INTELLIGENT EQUIP INC

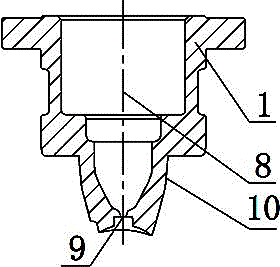

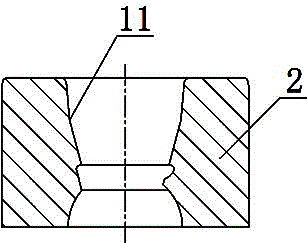

Method and equipment for producing cup of beaker

ActiveCN101050055AIncrease productivityGood lookingGlass reforming apparatusGlass productionCutting glassNeck parts

This invention provides method and apparatus for producing beaker. The method comprises: (1) cutting glass tube into 2.1-2.3 times of the height of beaker body, placing the cut glass tube on the transmission tray at the front end of the frame, moving by the channel on the transmission tray to the nozzle of the flaring device, heating both ends of the glass tube and flaring; (2) heating the middle part of the flared glass tube, pressing the middle part into bottle neck shape by a neck-pressing mold, cooling, heating the middle part again, and separating at the middle neck part by the force toward the two ends from the bottom pressure foot to obtain the bodies of two beakers; (3) pre-sealing the bottoms by the nozzle, sealing the bottoms, finishing, polishing, annealing, and outputting by a conveyer belt. The method has such advantages as high production efficiency, high product quality, and low raw material consumption.

Owner:YANCHENG HUAOU IND

Foamed brick cutting device for reducing rejection rate

InactiveCN104149180AAvoid no-go situationsReduced Power RequirementsCeramic shaping apparatusBrickEngineering

The invention relates to a foamed brick cutting device for reducing the rejection rate. The foamed brick cutting device comprises a track, a supporting plate on the track in a sliding mode, a foamed brick placed on the supporting board, a transverse cutting device and a vertical cutting device. A side scraping device used for scarping the two side faces of the foamed brick to be flat is arranged in front of the transverse cutting device and comprises a fifth fixing block, a sixth fixing block, a first scraping cutter and a second scraping cutter, the thickness of the first scraping cutter is gradually increased in the direction pointing to the output end of the foamed brick from the inlet end of the foamed brick, and the thickness of the second scraping cutter is gradually increased in the direction pointing to the output end of the foamed brick from the inlet end of the foamed brick. The first scraping cutter and the second scraping cutter of the side scraping device can scrape the two rugged sides of the foamed brick to be flat so that small building blocks on the two sides can conform to specifications, and the rejection rate is lowered. The first scraping cutter and the second scraping cutter scrape and cut the foamed brick gradually, the phenomenon that resistance borne by the foamed brick is too large, and the foamed brick cannot advance is avoided, and the requirement for the power of a motor for pushing the supporting plate is lowered.

Owner:宿迁市名扬建设工程有限公司

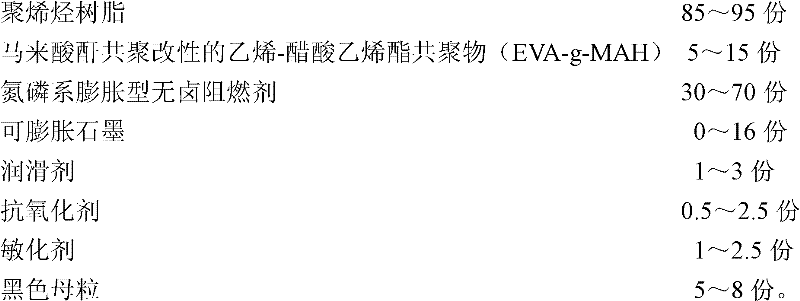

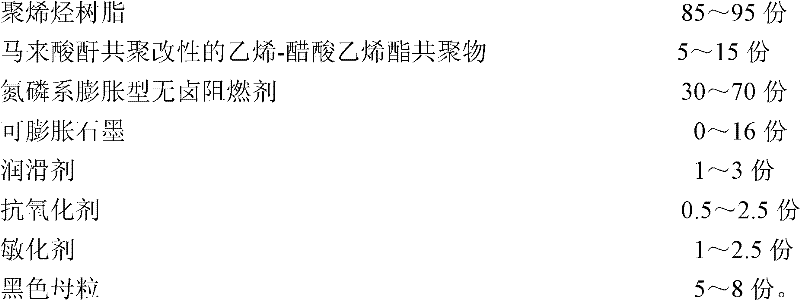

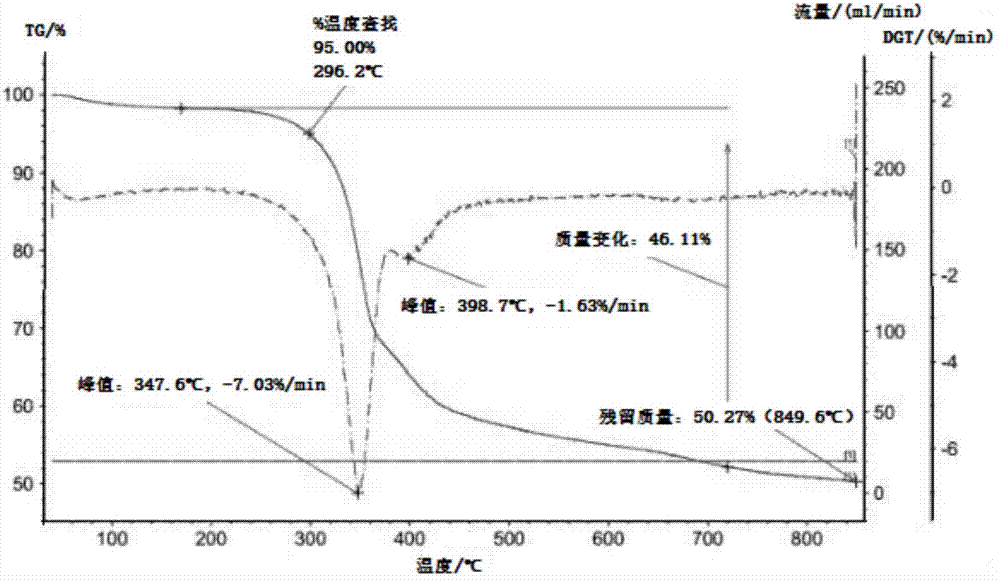

Low-smoke halogen-free phosphorus nitrogen expanding flame-retardant mold shrinkage sleeve and preparation method and application thereof

ActiveCN102432934AImprove qualityGood compatibilityInsulating bodiesConnection insulationCross-linkPolyolefin

The invention discloses a low-smoke halogen-free phosphorus nitrogen expanding flame-retardant mold shrinkage sleeve and a preparation method and application thereof. The low-smoke halogen-free phosphorus nitrogen expanding flame-retardant mold shrinkage sleeve contains 85 to 95 parts of polyolefin resin, 5 to 15 parts of maleic anhydride copolymerization modified ethylene-vinyl acetate copolymer, 30 to 70 parts of nitrogen phosphorus series expanded halogen-free flame retardant, 0 to 16 parts of expansible graphite, 1 to 3 parts of lubricating agent, 0.5 to 2.5 parts of antioxidant, 1 to 2.5parts of sensitizer and 5 to 8 parts of black master batch. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding the mixed raw materials at the temperature of between 100 and 160 DEG C by using a double-screw extruder, and performing wire drawing, air cooling and granulation; pressing the granules into a mold shrinkage sleeve, and performing irradiation, wherein the irradiation dose is 8 to 12Mrad; and expanding and drawing the irradiated and cross-linked mold shrinkage sleeve at the temperature of between 140 and 160 DEG C, cooling and setting, and thus obtaining the low-smoke halogen-free flame-retardant mold shrinkage sleeve. The preparation method is simple; and the obtained mold shrinkage sleeve has excellent flame-retardant performance, low smoke generating quantity and good mechanical property, electrical insulating property and heat resistance.

Owner:广州凯恒科塑有限公司

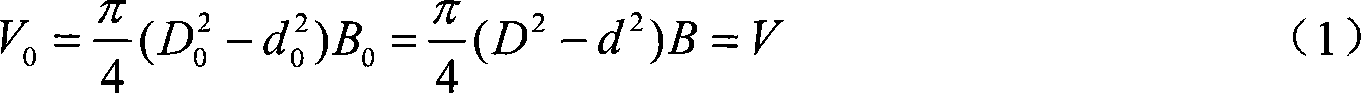

Ring weight online weighing and rolling deviation dispensing method

InactiveCN101053876AGeometric precision controlReduce product rateComputer controlRoll mill control devicesComputer control systemForge

The invention belongs to ring rolling processing field, specially relates to a method for online weighing the ring weight and distributing rolling deviation in a rolling process, characterized that the method comprises the following steps: 1). calculating actual relationship of external diameter and wall thickness during actual ring blank rolling process; 2). calculating actual ring blank weight error by online measuring wall thickness of the actual ring blank with specified external diameter at a specified time; 3). according to the actual ring blank weight error, calculating size error of actual ring forge piece; 4). according to geometric accuracy requirement of the rolling ring forge piece, online selecting one dimensional tolerance allocation plan as an instruction of a ring rolling computer-control system and online distributing dimensional tolerance of the ring forge piece to roll a corresponding ring forge piece. The invention is capable of effectively controlling geometric precision of rolling ring and reducing defective rate of the rolling ring.

Owner:WUHAN UNIV OF TECH

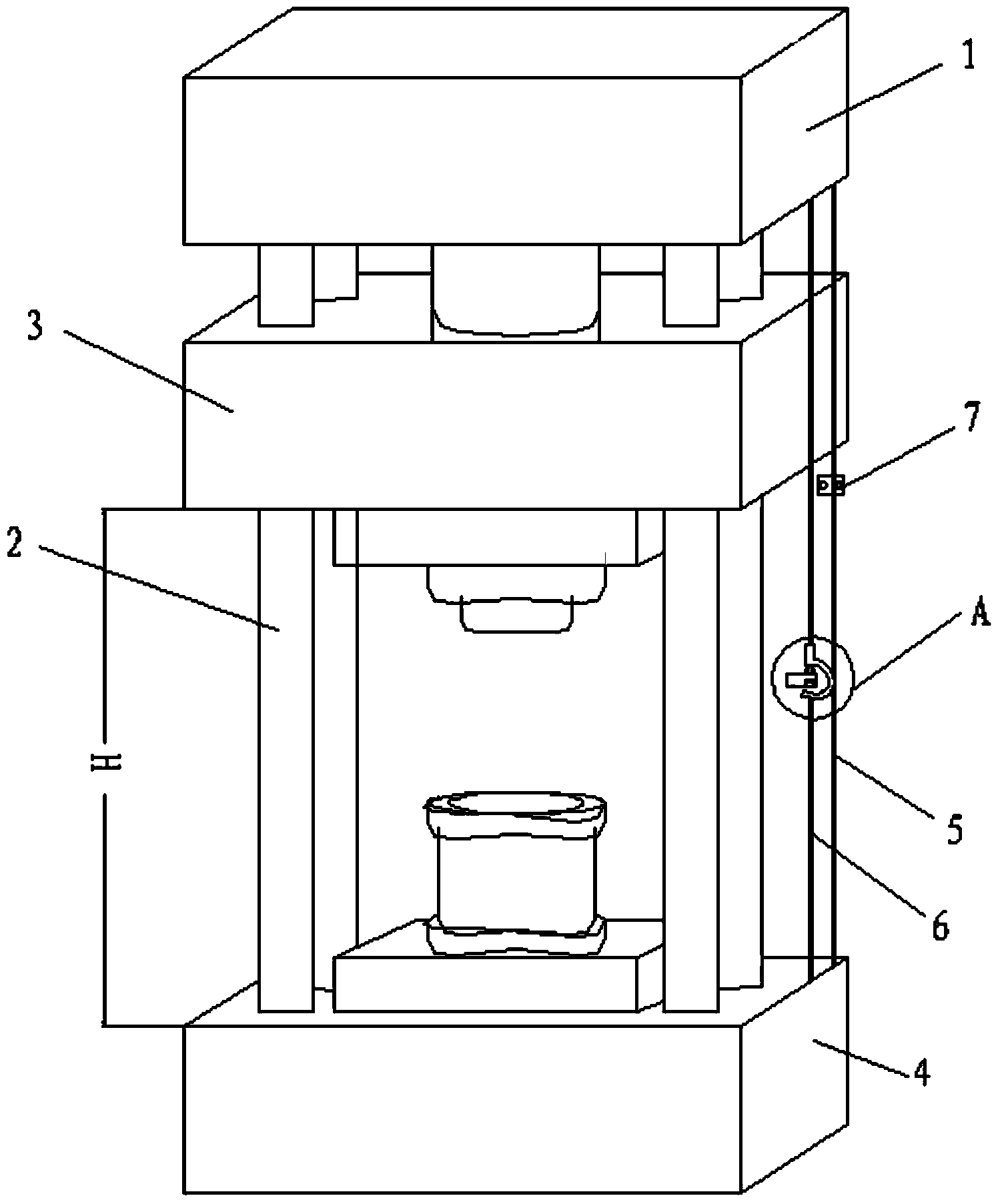

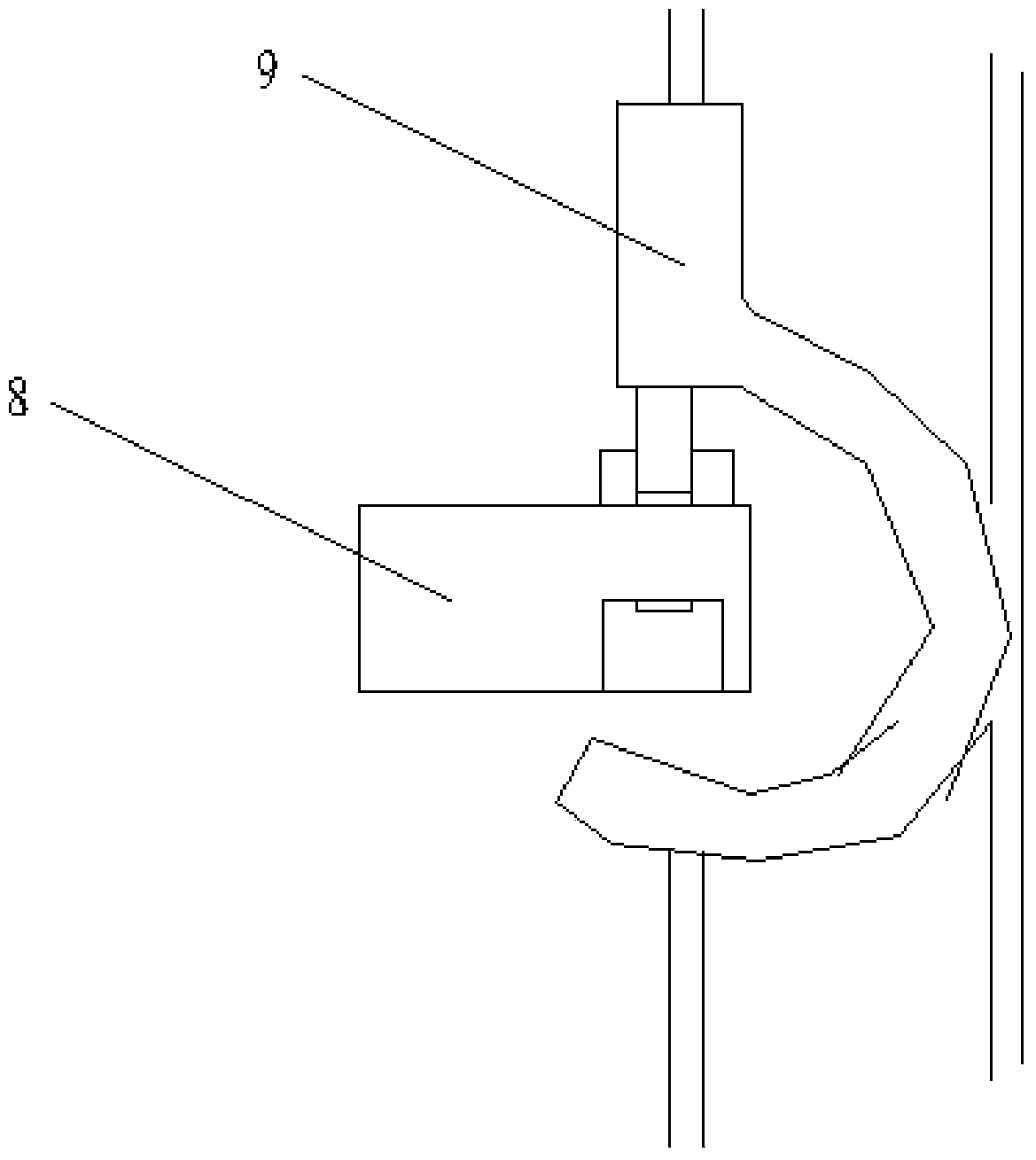

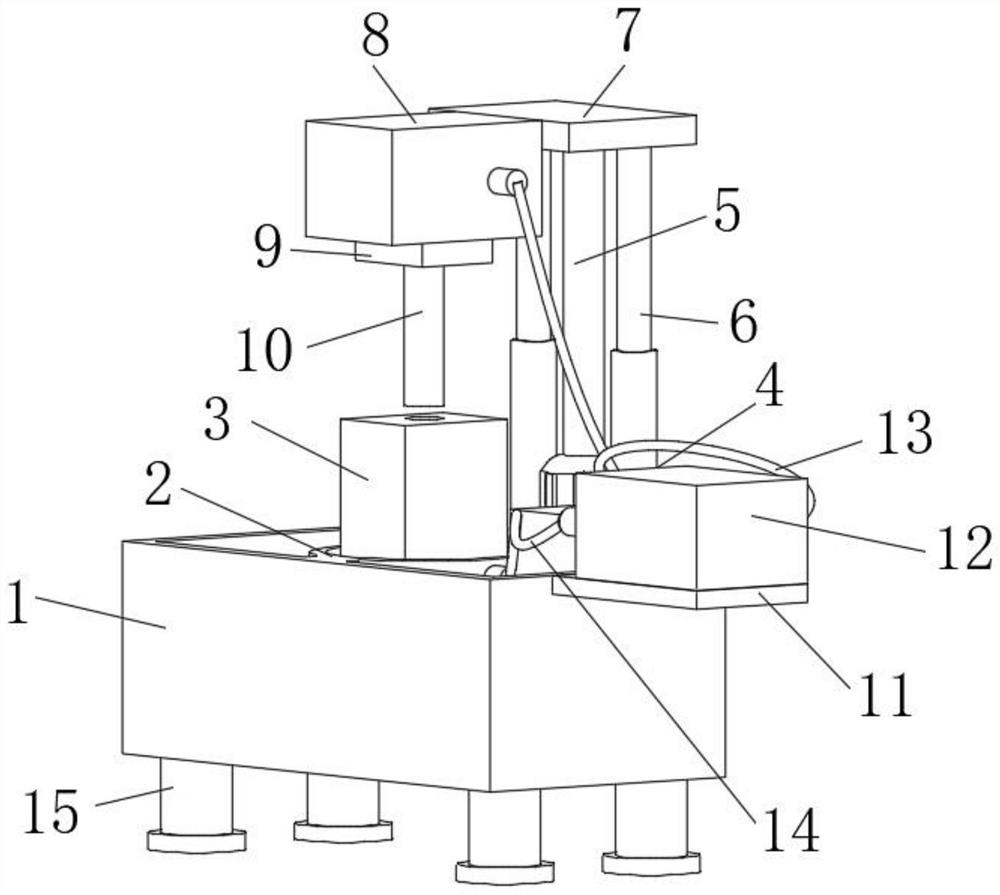

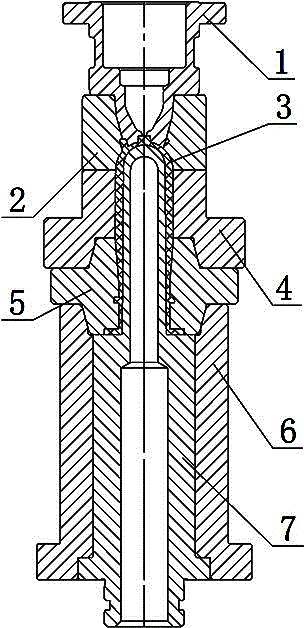

Fine adjustment device for stroke of hydraulic oil press

ActiveCN103752748AReduce the number of debuggingReduce the rejection rate of mold trialForging press drivesMicrometerEngineering

The invention provides a fine adjustment device for stroke of a hydraulic oil press. The fine adjustment device comprises a top plate, upright columns, a lower plate, an upper slider, a first slide groove, a second slide groove, a proximity switch, a limiting stopper and a micrometer. One end of each upright column is connected to the lower end of the top plate, the other end of each upright column is connected to the upper end of the lower plate; the upper slider is positioned below the top plate, through holes are formed in the upper slider, the upright columns penetrate the through holes, and the upper slider slides along the upright columns up and down via the through holes; the first slide groove and the second slide grooves are formed in positions between the top plate and the lower plate; the proximity switch is arranged on the first slide groove and moves along the first slide groove up and down; the limiting stopper is fixedly arranged on the second slide groove; the micrometer is mounted on the limiting stopper and is used for finely adjusting the limiting stopper up and down. The fine adjustment device has the advantages that adjustment and control on the stroke of the hydraulic oil press can be displayed via readable data of the micrometer, accordingly, accurate adjustment and control effects can be realized, debugging frequency can be effectively reduced in forging procedures, a die trial rejection rate can be reduced, the cost can be decreased, and the production efficiency can be improved.

Owner:江苏理研科技股份有限公司

High-temperature-resistant paper pouring pipe for producing metal casting and preparing method of high-temperature-resistant paper pouring pipe

ActiveCN106903300AImprove working environmentReduce weightMelt-holding vesselsFoundry mouldsFiberMullite

The invention discloses a high-temperature-resistant paper pouring pipe for producing metal casting. The high-temperature-resistant paper pouring pipe comprises, by weight, 60%-75% of old paper stock, 2%-5% of 200-400-mesh corundum fine powder, 13%-19% of 200-400-mesh mullite fine powder, 3%-5% of 200-400-mesh montmorillonite fine powder, 5%-10% of 200-400-mesh andalusite fine powder and 1%-2% of a paper fiber modified material. The invention further discloses a preparing method of the above high-temperature-resistant paper pouring pipe. The above ingredients are evenly mixed, a mixture is subject to mixing to obtain a blank, and an extrusion machine is used for preparing the blank into a blank pipe, and the blank pipe is dried to be subject to modified reacting.

Owner:ZHEJIANG UNIV

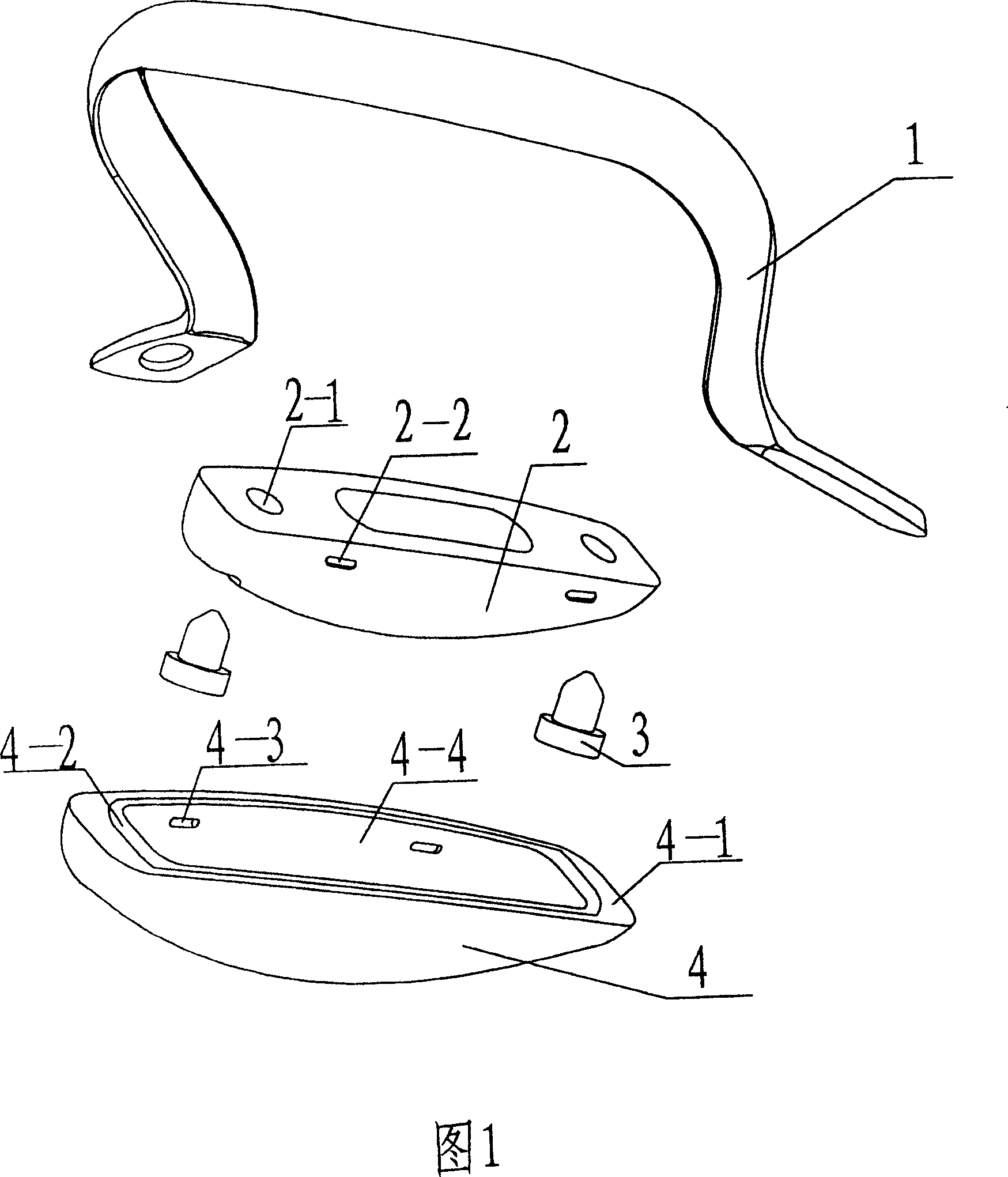

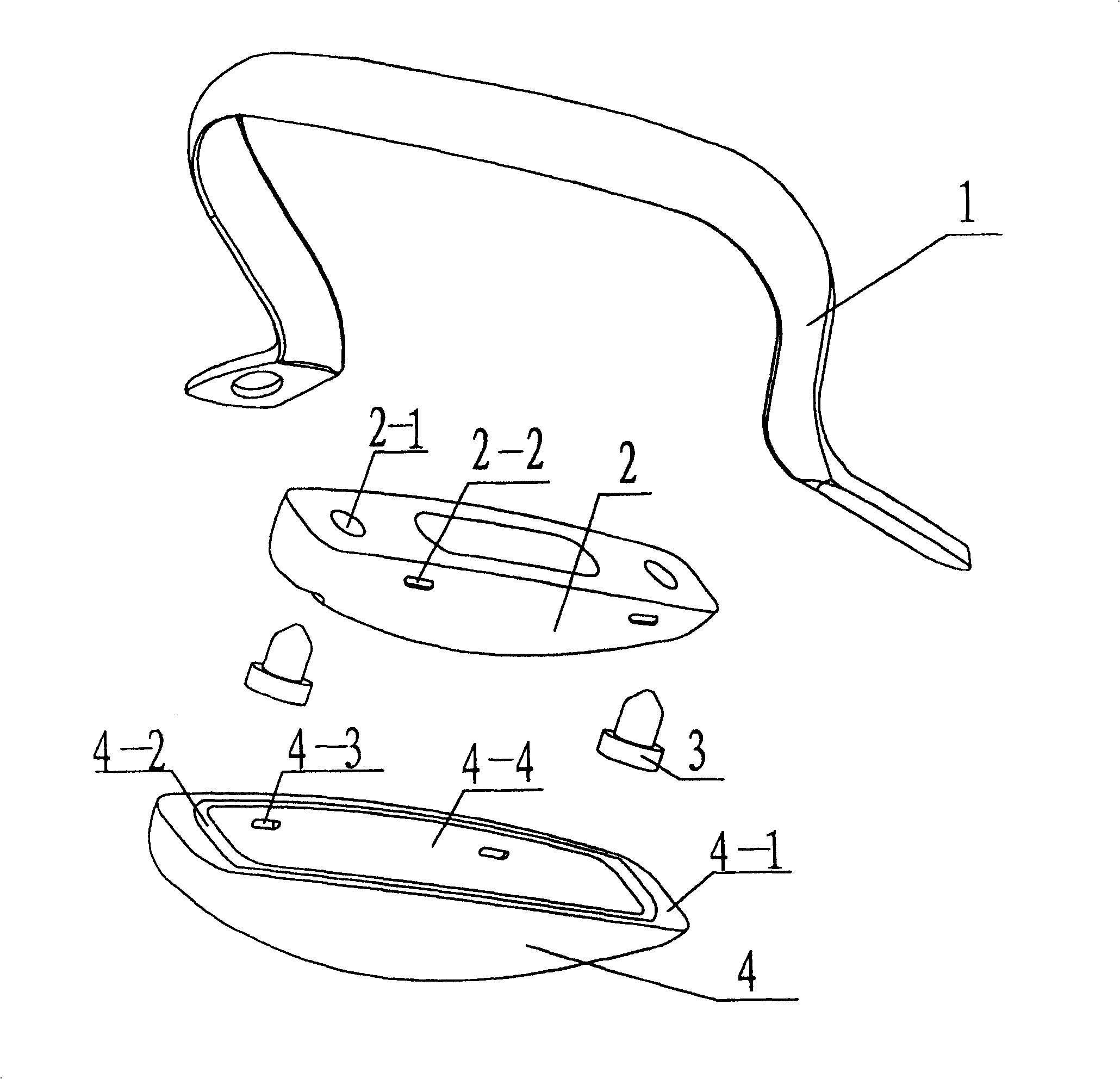

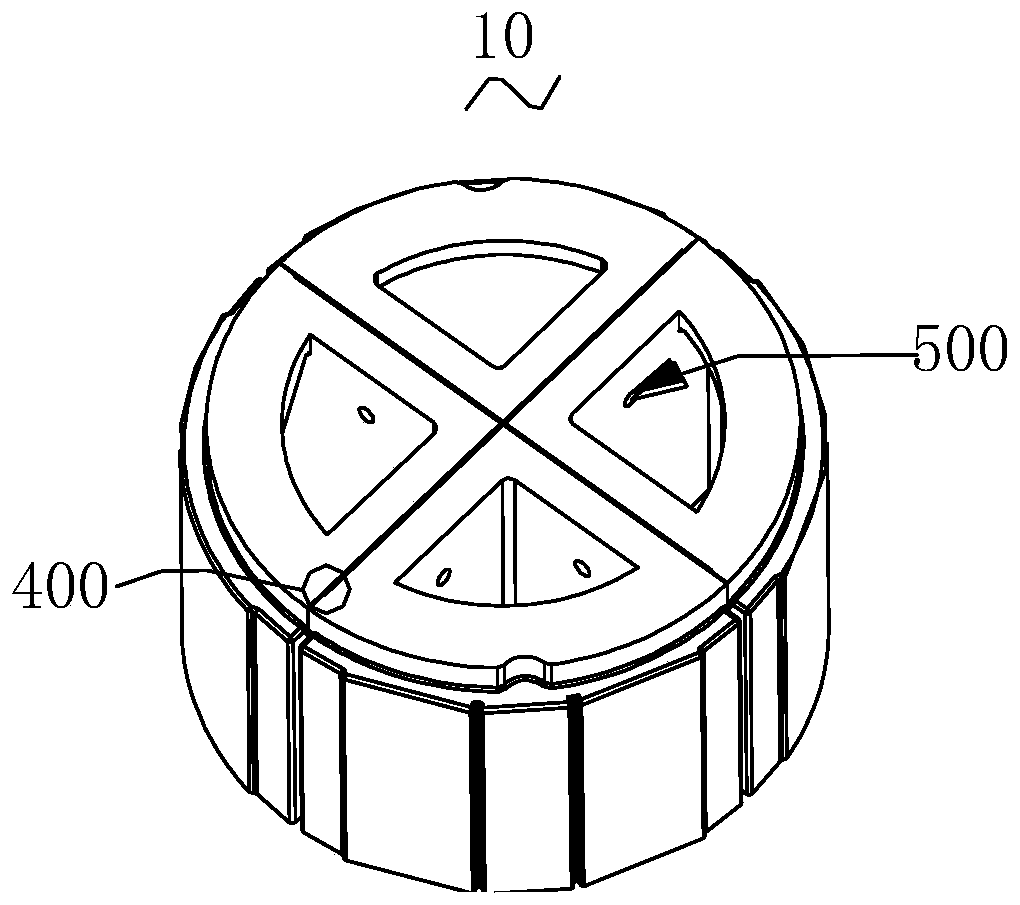

Combined ear for kitchenware and its production process

InactiveCN1931072AThe installation position is accurateReduce product rateKitchen equipmentBiomedical engineeringAudiology

The present invention discloses one kind of combined ear for kitchenware and its production process, and solves the technological problem of ensuring the accurate locating and connecting between the heat- isolating piece and the ear body. The metal ear body is once polished and this results in shortened technological process and raised production efficiency. The metal ear body is provided with hard non-metal connecting piece and double-layered composite non-metal heat isolating piece with hard inner layer and soft outer layer. The present invention is used mainly for kitchenware and may be also for other application.

Owner:陈健雄

Method and equipment for producing cup of beaker

ActiveCN101050055BIncrease productivityGood lookingGlass reforming apparatusGlass productionCutting glassNeck parts

This invention provides method and apparatus for producing beaker. The method comprises: (1) cutting glass tube into 2.1-2.3 times of the height of beaker body, placing the cut glass tube on the transmission tray at the front end of the frame, moving by the channel on the transmission tray to the nozzle of the flaring device, heating both ends of the glass tube and flaring; (2) heating the middlepart of the flared glass tube, pressing the middle part into bottle neck shape by a neck-pressing mold, cooling, heating the middle part again, and separating at the middle neck part by the force toward the two ends from the bottom pressure foot to obtain the bodies of two beakers; (3) pre-sealing the bottoms by the nozzle, sealing the bottoms, finishing, polishing, annealing, and outputting by aconveyer belt. The method has such advantages as high production efficiency, high product quality, and low raw material consumption.

Owner:YANCHENG HUAOU IND

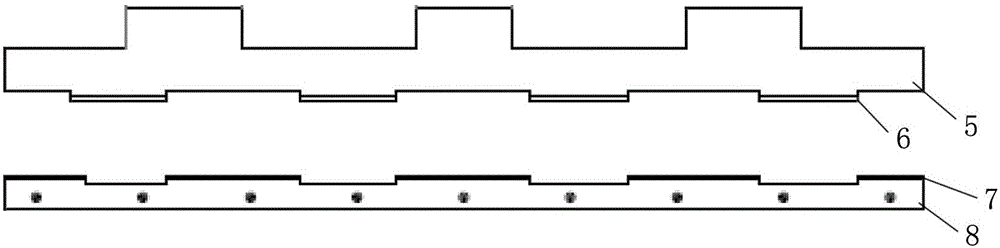

Roll-pressing narrow lap welding machine, welding process and moveable lining plates of roll-pressing narrow lap welding machine

ActiveCN106346159AMeet the needs of processing and productionLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNotching

The invention provides a roll-pressing narrow lap welding machine and moveable lining plates thereof. The welding machine comprises a machine body, an inlet side lining plate assembly and an outlet side lining plate assembly, wherein the inlet side lining plate assembly consists of a first fixed lining plate, a first moveable lining plate and a first connecting piece; the outlet side lining plate assembly consists of a second fixed lining plate, a second moveable lining plate and a second connecting piece; the first moveable lining plate and the second moveable lining plate are provided with opposite first and second connecting side parts and opposite first and second non-connecting side parts; concavo-convex notches are formed in the first non-connecting side part and the second non-connecting side part; the first connecting side part and the second connecting side part are moveably connected with one side part of the first fixed lining plate and one side part of the second fixed lining plate through the first connecting piece and the second connecting piece; and the other side part of the first fixed lining plate and the other side part of the second fixed lining plate are fixedly connected with the inlet side and the outlet side of the machine body. The roll-pressing narrow lap welding machine and the moveable lining plates thereof have the advantages that the fact that the roll-pressing narrow lap welding machine equipment meets the processing and production requirements of hot-dipped aluminum zinc plates can be effectively guaranteed; spare part cost, processing cycle and processing difficulty are reduced; and the outage failure times are reduced and the waste defective rate is reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Novel compound hardening agent used for casting industry

InactiveCN105458159AImprove yieldHigh dimensional accuracyFoundry mouldsFoundry coresAluminium chlorideInvestment casting

A novel compound hardening agent used for the casting industry comprises, by weight, 80-100 parts of crystallized aluminium chloride, 5-15 parts of ammonium chloride, 0.1-1 part of surface active agent, 0.1-1 part of dispersing agent and 0.1-1 part of air drying agent. During preparation of the crystallized aluminum chloride, aluminium hydroxide and waste hydrochloric acid are added to a reaction kettle according to the mole ratio of 1:1.02 to 1:1.15 to be subjected to a backflow reaction for 0.5-1.5 h, reaction liquid is filtered, evaporated, crystallized, centrifuged and separated, and then the crystallized aluminum chloride can be prepared. The crystallized aluminum chloride prepared according to the content and other components are stirred, mixed and compounded to form the novel compound hardening agent of water glass investment casting.

Owner:安徽东升精密铸钢件有限公司

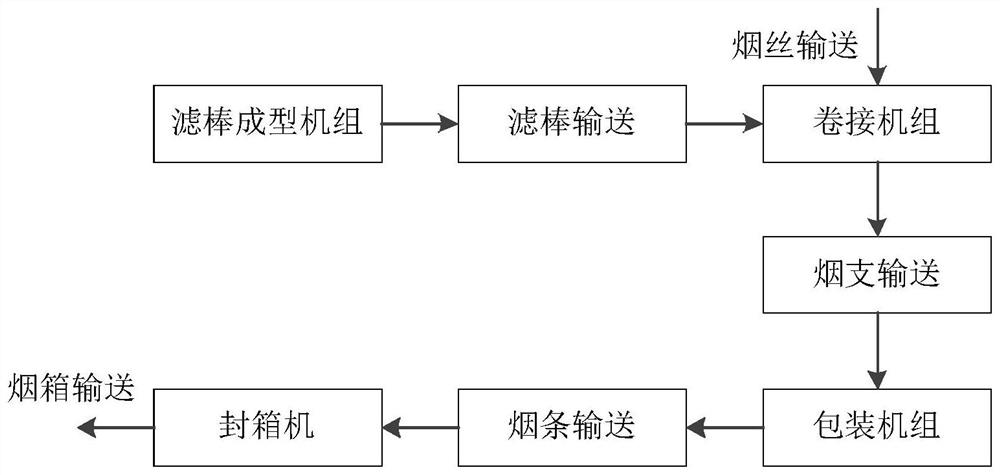

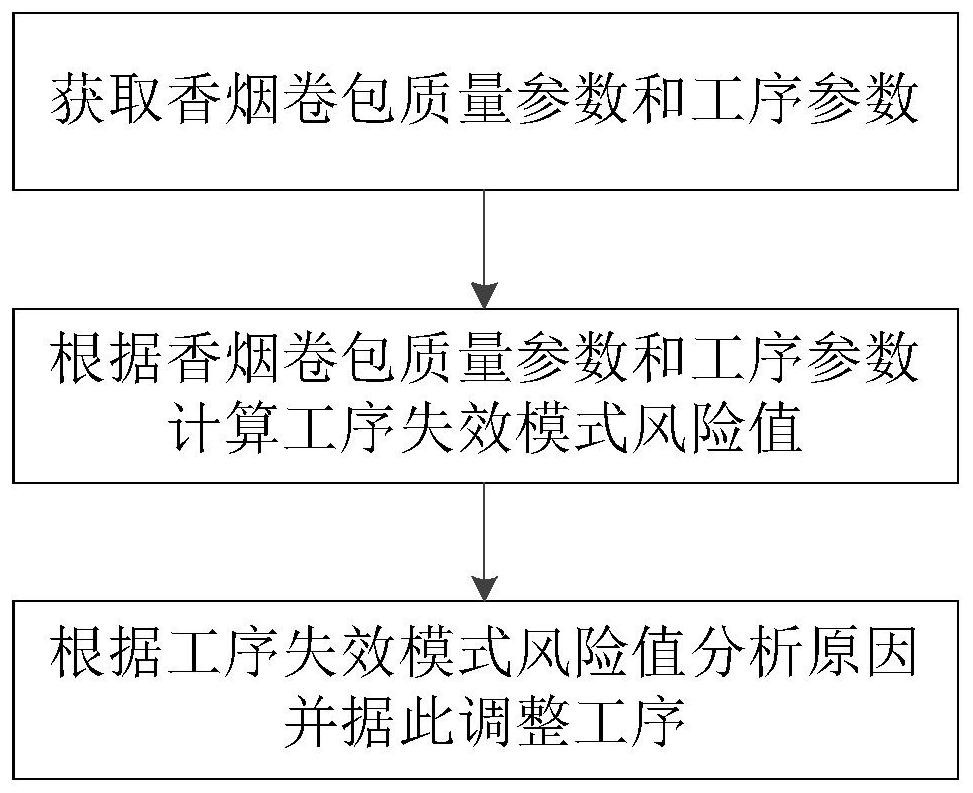

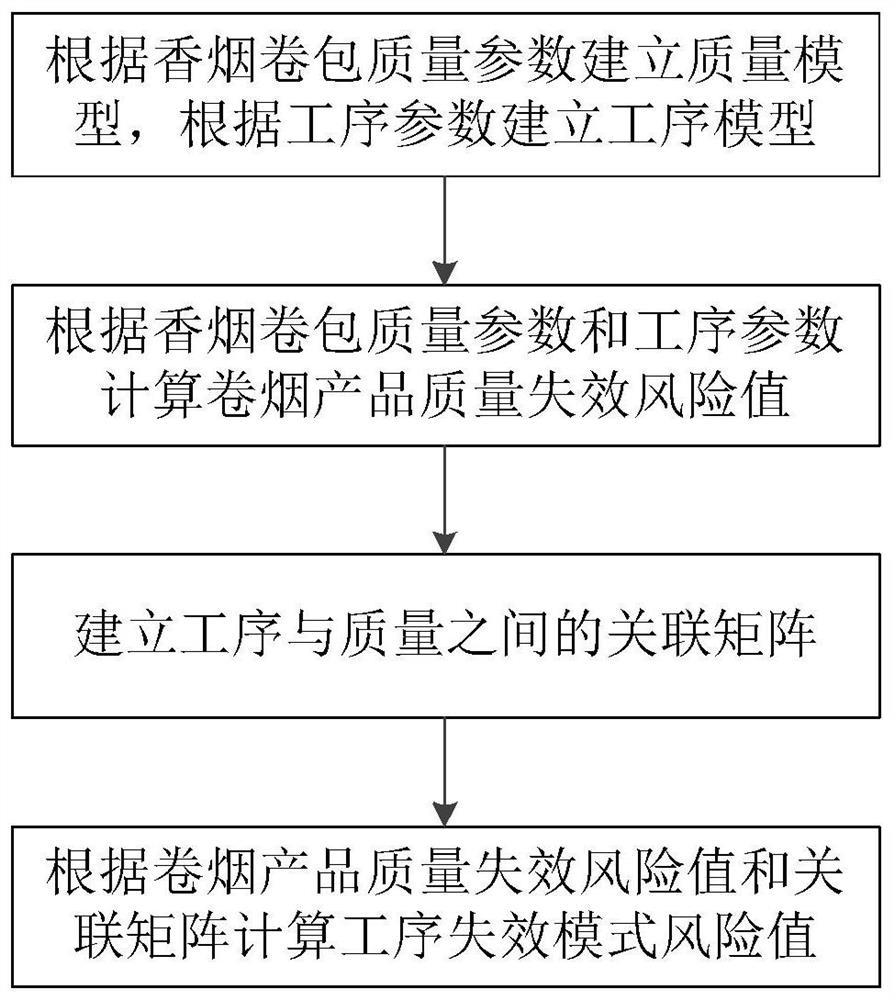

Cigarette packaging processing method, system and device

PendingCN111898880AReduce product rateImprove process capabilityResourcesManufacturing computing systemsProcess engineeringSystems engineering

The invention provides a cigarette packaging processing method, system and device. The method comprises the following steps of acquiring cigarette package quality parameters and procedure parameters;calculating a process failure mode risk value according to the cigarette package quality parameter and the process parameter; and analyzing reasons according to the process failure mode risk value andadjusting the process according to the reasons. The invention has the advantages that the quality failure mode risk can be converted into the process failure mode risk, the possible quality failure mode is analyzed and converted into the process risk, the risk of the process is recognized, the processing capacity of the process can be improved, and therefore the product rate of unqualified cigarettes is reduced.

Owner:NANJING SOARING CYBER REALITY INNOVATION CENT CO LTD

Paper pouring channel tube for casting and shaping technique thereof

InactiveCN101508005BReduce pollutionSave energyPaper recyclingFoundry mouldsFiberResource utilization

The invention relates to a paper pouring channel pipe for forging, which is made of waste paper pulp, sintered filling materials, binding materials, reinforcing agent and moisture-proof agent materials. The new concepts and mechanisms completely different from the prior art are applied to the paper pouring channel pipe, namely the pouring channel pipe is not made of the prior used refractory materials such as pottery, porcelain and the like, and non-fireproof paper pulp fibers are taken as a main component which is added with the sintered filling materials and the like, carbonized and sintered under the using conditions of high temperature and oxygen deficiency to form a carbon sinter with high fire resistance degree and the paper pouring channel pipe which achieves the molten iron scouring resistance and fire resistance degree capable of meeting the current forging process requirements. The paper pouring channel pipe has the advantages of regenerative resource utilization, no forging, energy conservation, environment pollution reduction, socket joint, no sand leakage, convenient use, little dust during cutting, light weight, little resource consumption, no easy damage at normal temperature, crispness after high temperature treatment, easy stripping, easy cleaning, little hard solid waste after pouring, abrasion reduction of a sand regenerating device, improvement on the quality of regenerated sand, reduction on the defective index of forged pieces, no carburization problem for the forged pieces, and the like.

Owner:曹敏道

Oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation method and application thereof

The invention discloses an oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve and a preparation method thereof. The label sleeve consists of the following components in parts by weight: 60 to 80 parts of matrix resin, 15 to 25 parts of linear low-density polyethylene, 5 to 15 parts of polymer compatilizer, 32 to 70 parts of phosphorous nitrogen series expansible halogen-free flame retardant, 0 to 30 parts of inorganic flame retardant, 3 to 5 parts of titanium white powder, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant and 1 to 2 parts of sensitizer. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding with a double-screw extruder, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould, radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance and good oil resistance, produces little smoke, permanently preserves the label, and keeps good mechanical property, electric insulating performance and heat resistance.

Owner:广州凯恒科塑有限公司

Combined ear for kitchenware and its production process

InactiveCN100450407CThe installation position is accurateReduce product rateKitchen equipmentMethods of productionMaterials science

The present invention discloses one kind of combined ear for kitchenware and its production process, and solves the technological problem of ensuring the accurate locating and connecting between the heat- isolating piece and the ear body. The metal ear body is once polished and this results in shortened technological process and raised production efficiency. The metal ear body is provided with hard non-metal connecting piece and double-layered composite non-metal heat isolating piece with hard inner layer and soft outer layer. The present invention is used mainly for kitchenware and may be also for other application.

Owner:陈健雄

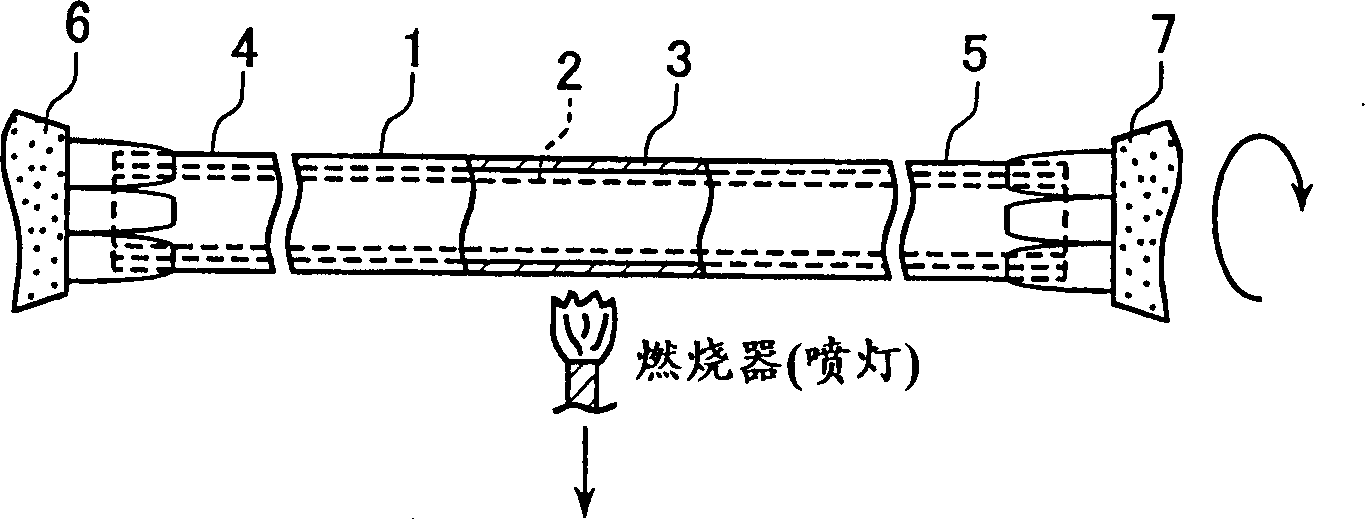

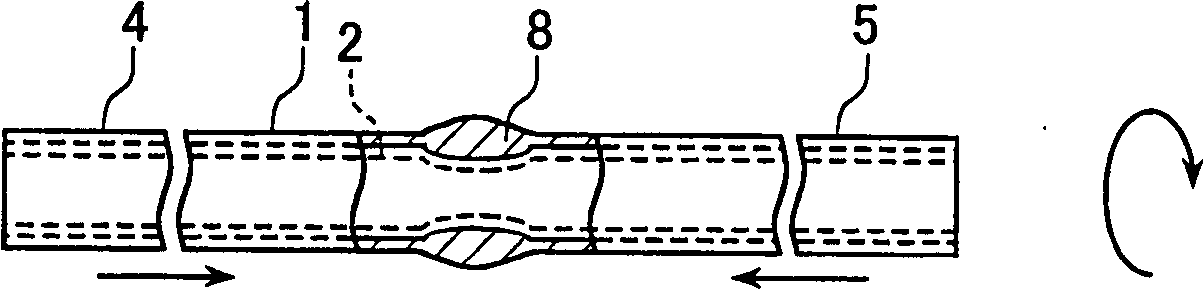

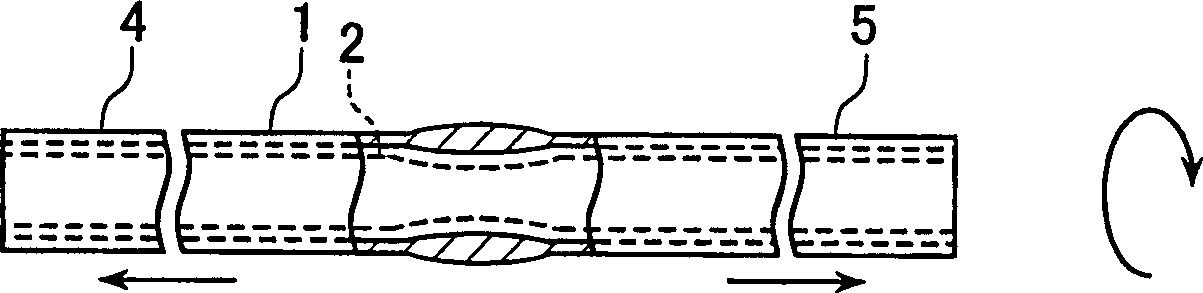

Manufacture of fluorescent lamp glass tubes

InactiveCN1231423CThicker and more uniformHigh mechanical strengthVessels or leading-in conductors manufactureGlass reforming apparatusEngineeringGlass aggregate

The present invention provides a method of manufacturing a fluorescent lamp having an arc tube formed by connecting a plurality of glass tubes. According to this method, a straight glass tube held at both ends is rotated, a portion of the glass tube to be cut is heated and softened, and the heated glass tube is moved in a direction toward the cut portion to form a glass aggregate in the area of the cut portion, and in the opposite direction. The glass tube is pulled apart in the direction and cut into two glass tubes with self-closing end walls. According to this method, the thickness of the end wall of the glass tube is thicker and more uniform compared with the conventional technology, and the mechanical strength is also improved. The rate of defective lamps due to cracks, leaks or damage in the end wall of the glass tube during the manufacturing process and distribution is thus reduced.

Owner:PANASONIC CORP

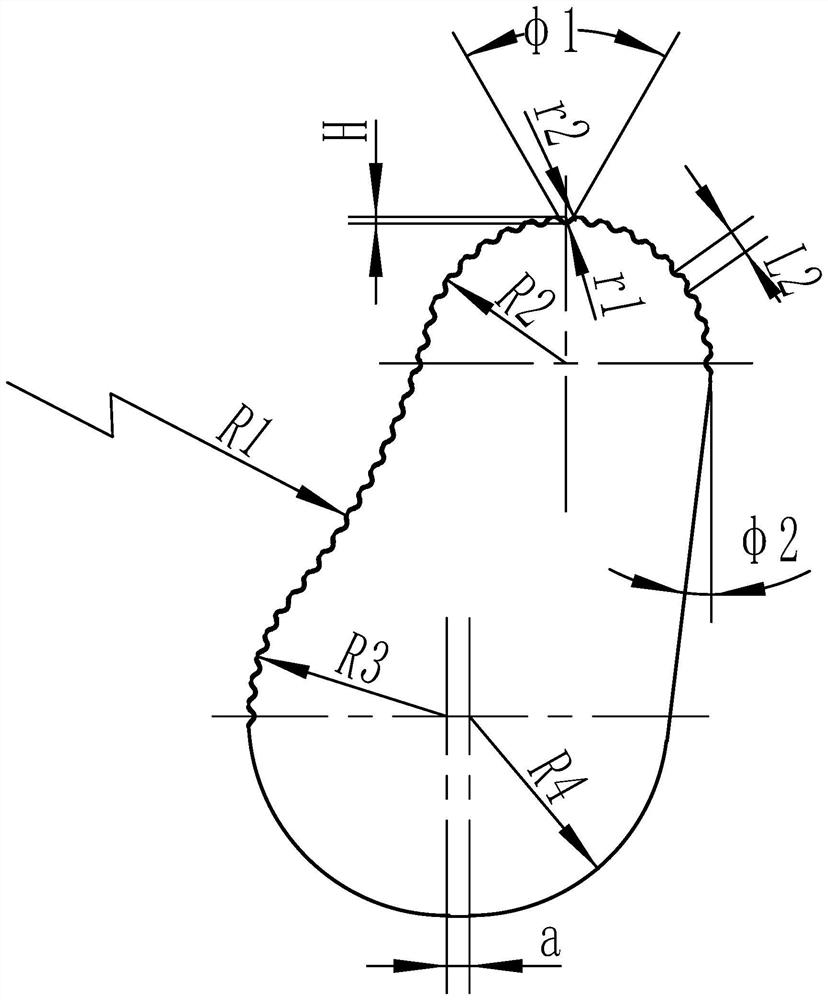

Special-shaped water-soluble salt core, manufacturing method and application thereof

PendingCN112427605AReduce casting scrap rateGuarantee process yieldFoundry mouldsMachines/enginesCombustion chamberEngineering

The invention relates to a special-shaped water-soluble salt core, a manufacturing method and application, and belongs to the technical field of internal combustion engine part manufacturing. The saltcore is annular, the section of the salt core is in a special shape, the section of the salt core comprises a top, a middle and a bottom, the top is close to the top face of a piston, and the top issemicircular. The bottom is in an arc shape, the two sides of the middle are respectively a straight line and an arc line, the arc line side of the middle is closest to a combustion chamber, and the outer side face of the top and the outer side face of the arc line side of the middle are provided with circular grooves. Through the special-shaped structural design of the salt core, the surface areaof the salt core is increased, after the salt core is dissolved by water, the surface area of an inner cooling oil cavity formed in the position, nearby the combustion chamber, of the head of the piston is increased, namely, the heat dissipation area is increased, after cooling oil enters the inner cooling oil cavity, rapid heat exchange between the cooling oil and an aluminum alloy of the head of the piston is achieved, and compared with a uniform-section inner cooling oil cavity, the heat exchange efficiency is improved by 5%-10%.

Owner:山东进化者新材料有限公司

Method for preventing shrinkage crack of casting

ActiveCN111195706ASolve crackingHigh strengthAdditive manufacturing apparatusFoundry mouldsCompressive strengthUltimate tensile strength

The invention relates to a method for preventing a shrinkage crack of a casting. The casting is produced by adopting sand mold casting, the method for preventing the shrinkage crack of the casting comprises the following steps that a strength technical standard of a sand mold is adjusted, and the strength technical standard comprises the sand mold tensile strength and the sand mold compressive strength; and a design structure of the sand mold is optimized, the sand mold is designed to be of a structure with a hollow inner cavity, and a plurality of reinforcing ribs are arranged in the hollow inner cavity. According to the method for preventing the shrinkage crack of the casting, the problems that the casting is prone to cracking and having size deviation during production can be effectively solved, so that the sand mold rejection rate of the casting is reduced, the research and development progress of a new product is accelerated, the research and development cost is reduced, and rapiddevelopment of a new product and a new technology is promoted.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

Mold rear support electrolytic machining method

PendingCN112427753ANovel processing methodReduce processing difficultyMachining electrodesMachining working media supply/regenerationPhysicsDrill hole

The invention relates to a mold rear support electrolytic machining method. The mold rear support electrolytic machining method comprises the steps that an electrode is prepared, specifically, the electrode matched with the diameter of an electrolytic tank is prepared; parts of electrolysis equipment are assembled, specifically, a placement supporting plate is connected to the upper portion in a water storage tank in a clamped mode through a clamping block, electrolyte is injected into the water storage tank, then a drilling machine and the placement supporting plate are electrified, and the electrode is fixed; a workpiece is placed, specifically, the electrolytic tank is enabled to correspond to an opening of an electrolyte conveying tank; the electrolyte is conveyed, specifically, the electrolyte in the water storage tank is pumped out through a water pumping pipe and conveyed into the electrolyte conveying tank through a water conveying pipe, so that the electrolyte makes contact with the inner wall of the electrolytic tank; and electrolytic machining is conducted, specifically, an electric telescopic rod contracts to drive a mounting plate to move downwards, the lower portion of the electrode is connected into the electrolytic tank in a penetrating and inserting mode, and the drilling machine drives the electrode to rotate to drill the electrolytic tank. According to the mold rear support electrolytic machining method, a mold rear support is machined through the electrolytic machining method, the machining time is short, operation is convenient and fast, the accuracy ishigh, and the cost is low.

Owner:周志容

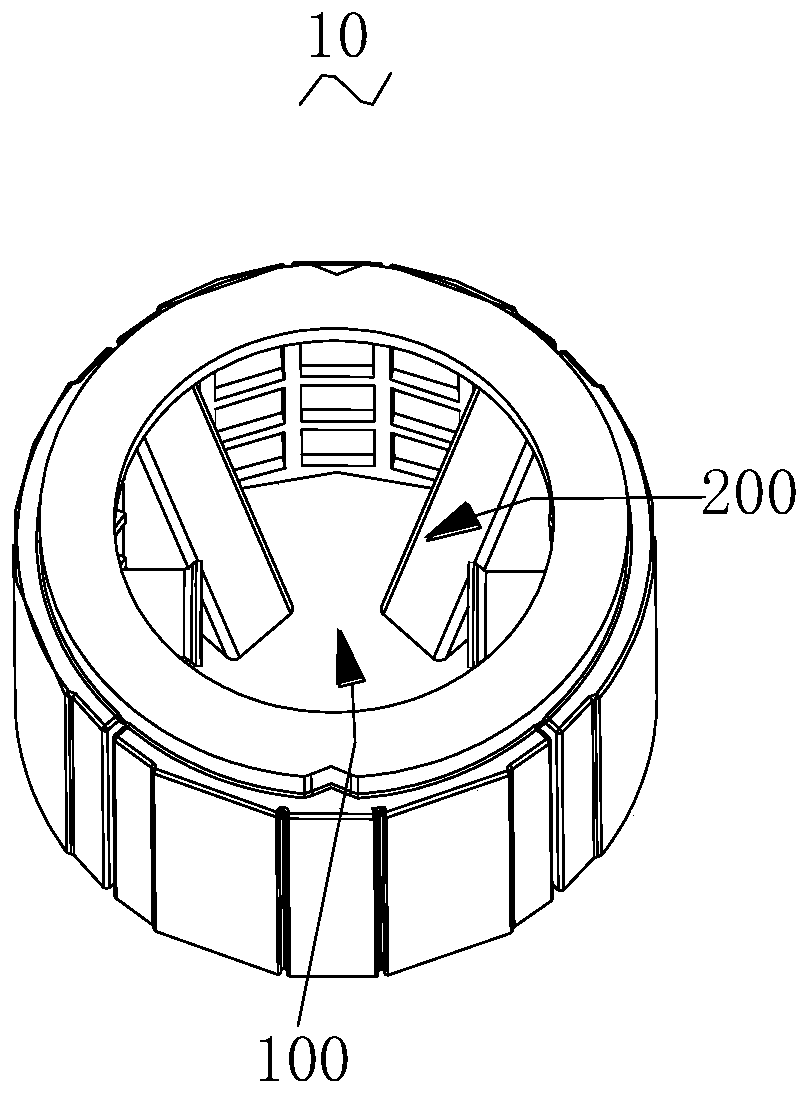

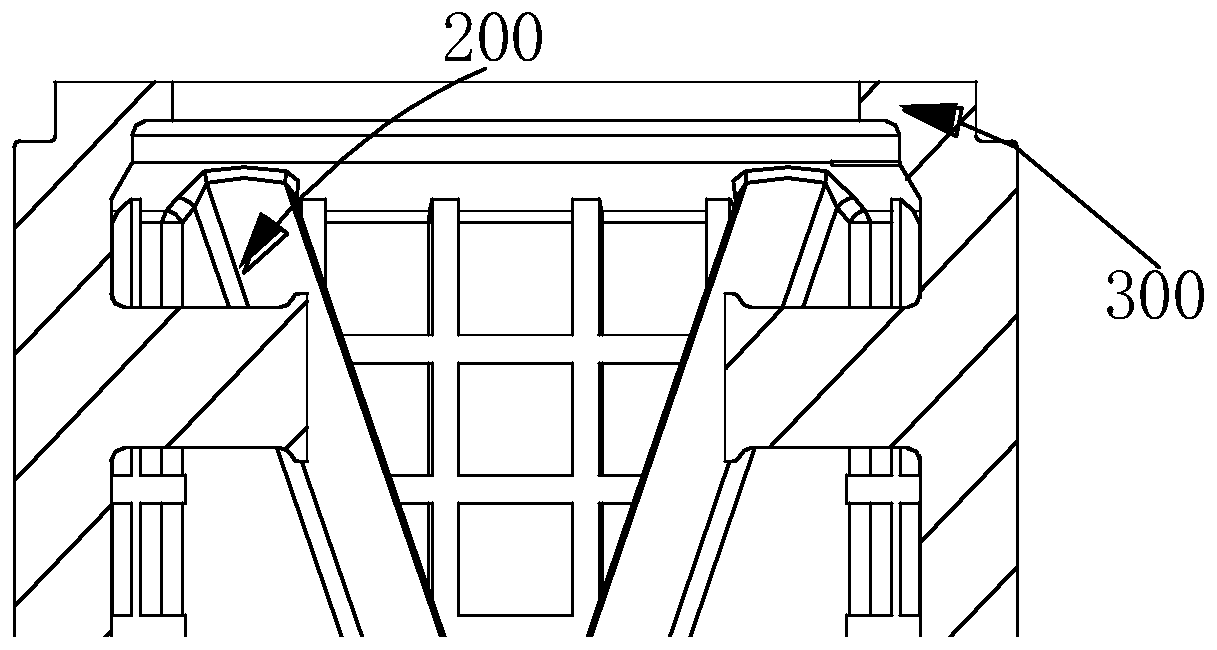

Integrated preform injection mould for PP large volume parenteral stationary ring

ActiveCN103350484BReduce labor intensityReduce manufacturing costLarge volume parenteralMaterials science

Owner:CHENGDU LIANYU PRECISION MACHINERY

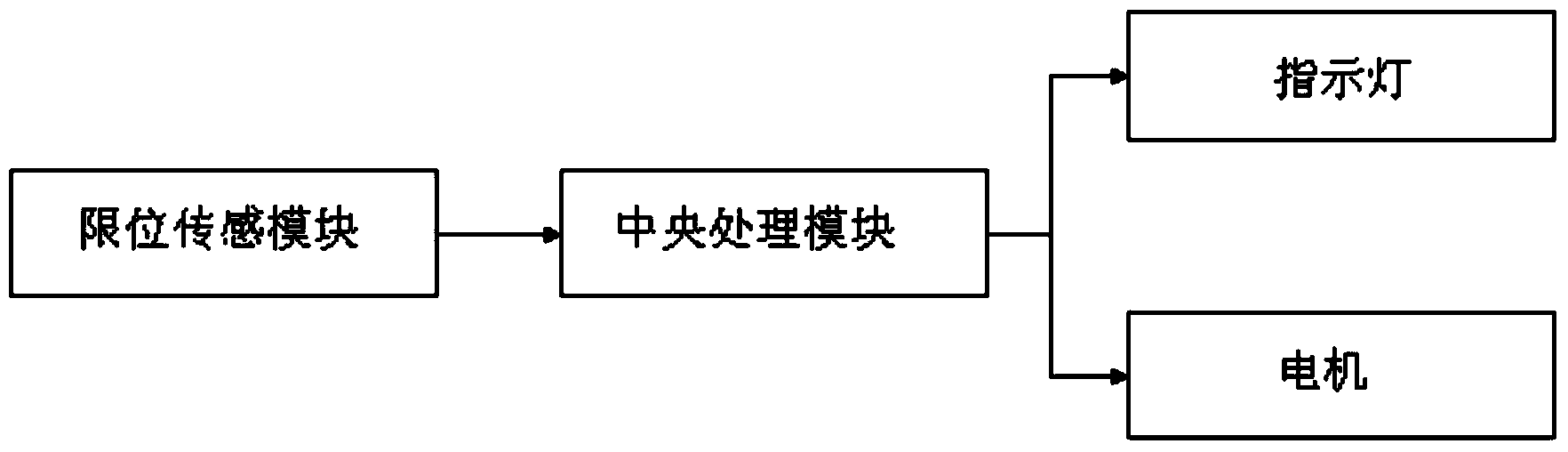

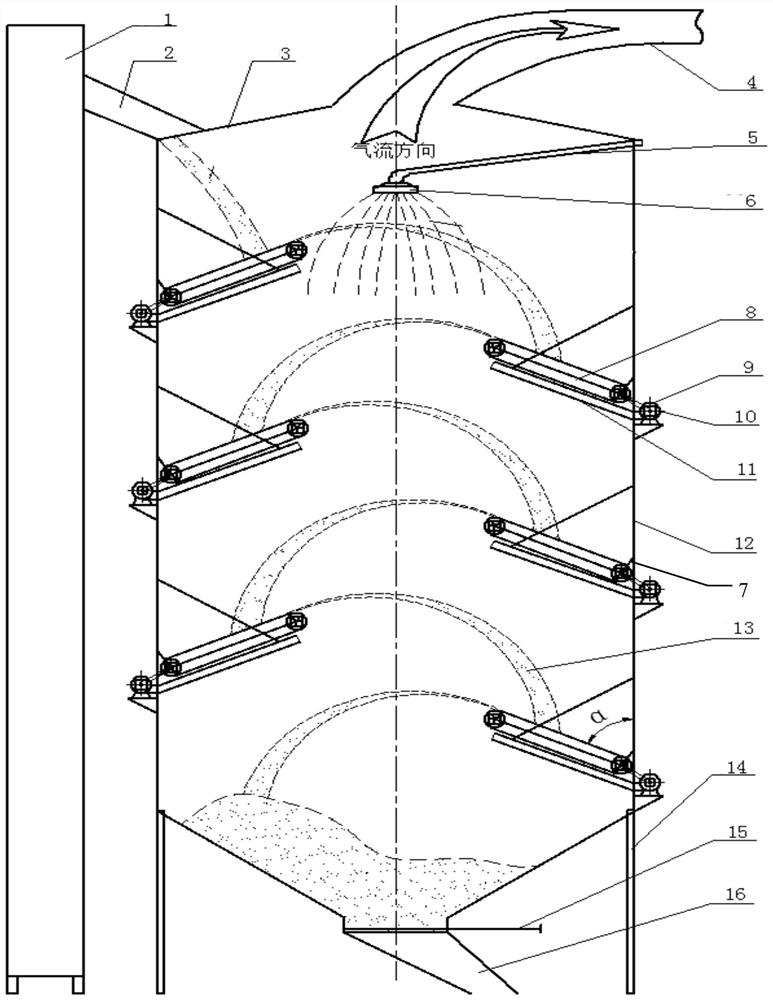

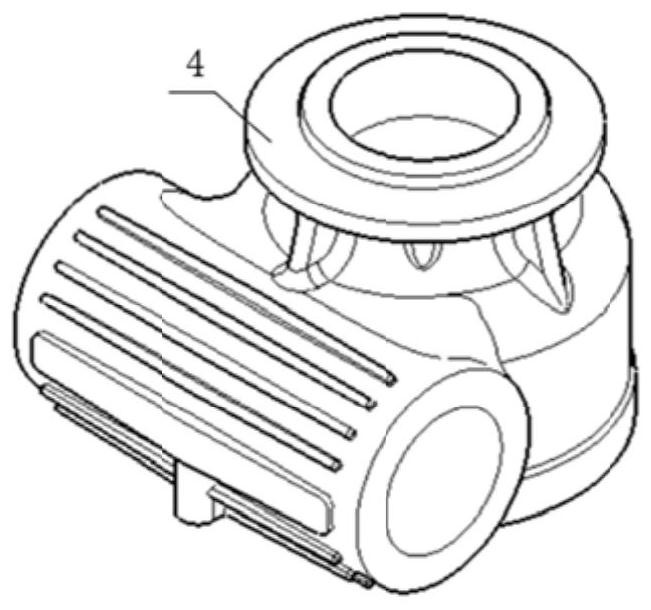

Multi-stage air-cooled molding sand cooling equipment and molding sand cooling method thereof

PendingCN113020539AImprove cooling efficiencyReduce product rateMould handling/dressing devicesElectric machineDust control

The invention discloses multi-stage air-cooled molding sand cooling equipment and a molding sand cooling method thereof. The multi-stage air-cooled molding sand cooling equipment comprises an elevator and a cooling sand bin, wherein a multi-stage cooling device, an air draft dust removal device and a spraying device are arranged in the cooling sand bin, the multi-stage cooling device comprises a plurality of cooling mechanisms, and the multiple cooling mechanisms are fixed to the two sides of the cooling sand bin from top to bottom and arranged in a crossed mode; each cooling mechanism comprises a sand raising machine, an air blowing pipe, an air blower and a driving motor, wherein the driving motors and the air blowers are fixed to the outer side of the cooling sand bin through mounting plates, the driving motors are connected with the sand raising machines through conveying belts, the sand raising machines are arranged in the cooling sand bin, the air blowers are connected with the air blowing pipes, and the air outlet ends of the air blowing pipes are arranged in the cooling sand bin. The multi-stage air-cooled molding sand cooling equipment and the molding sand cooling method thereof adopt the structure, and are suitable for a production environment with large production capacity, large molding sand circulation capacity and high circulation frequency, so that the molding sand cooling efficiency is greatly improved, and the waste and defective rate of castings is reduced.

Owner:河南旭锐合金新材料制造有限公司

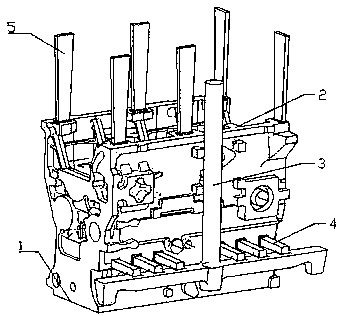

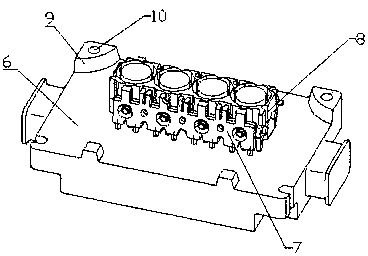

3D printing production method for automobile engine cylinder block

ActiveCN107127304BLow production costReduce manufacturing costFoundry mouldsFoundry coresSystems designCasting mold

The invention belongs to the manufacturing field of car engine cylinder body castings and particularly relates to a car engine cylinder body 3D printing production method. The method comprises the following steps that 1, a casting system is designed, wherein according to the design principle of the casting system, and a middle casting open type casting system is adopted; 2, a sand core is designed, wherein at first, a complete casting mold is drawn in three-dimensional software, and then core separating is carried out in three directions of a cylinder opening face, the top position of a water jacket and a flange face; 3, a core assembly modeling method is adopted, wherein separated cores are sequentially discharged, whole core assembling is carried out, and then casting is carried out. According to the method, by the adoption of the 3D printing technology, a set of core assembly modeling technologies applicable to such castings are designed, therefore, the casting rejection rate of the cylinder body castings and the difficulty of core assembly modeling are reduced, the purpose of producing high-quality and low-rejection-rate castings is achieved, the process control is simplified, the research and development cost of new products is reduced, and the trial-produce progress is accelerated.

Owner:NINGXIA KOCEL MOLD

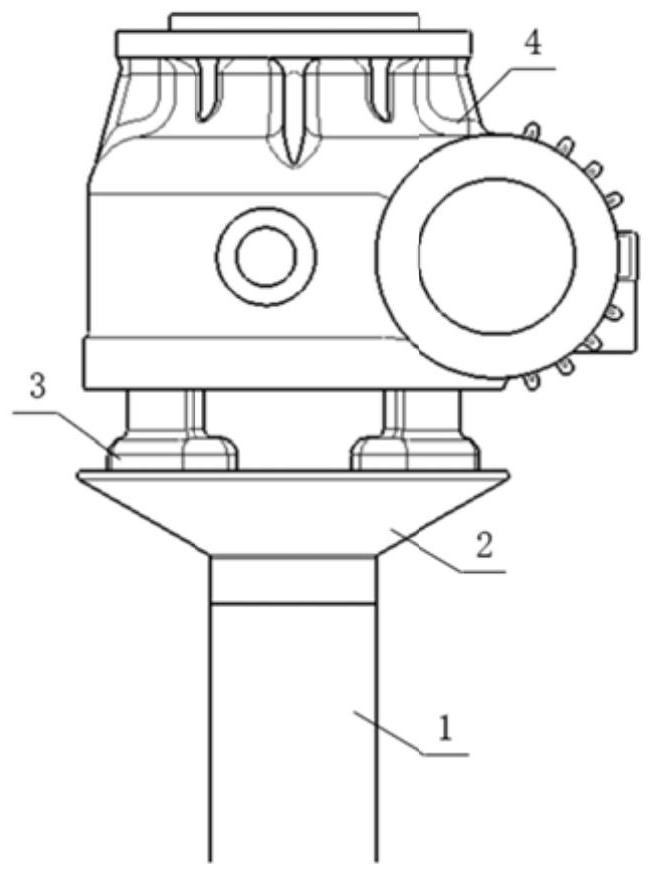

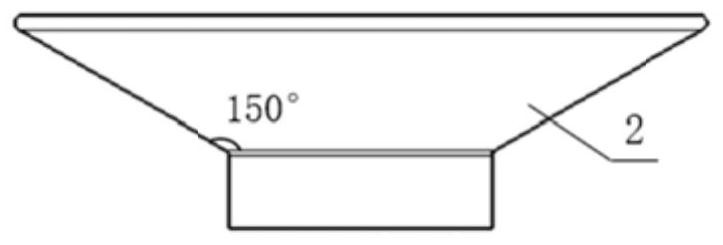

Claw-shaped circumferential equal-division type pouring system for aluminum alloy shell and pouring method of claw-shaped circumferential equal-division type pouring system

An aluminum alloy shell claw-shaped circumferential equant pouring system and a pouring method thereof are characterized in that the shapes and sizes of a riser tube, a cross gate and an ingate are reasonably set, impact of molten aluminum and a cavity wall is reduced, it is guaranteed that the casting mold filling process is stable and effective, solidification feeding is facilitated, and therefore the shrinkage porosity and shrinkage cavity defects in the casting production process are reduced, and the casting quality is improved. And the casting blank rejection rate is reduced. And the solidification time is greatly shortened by reducing the contact area of the flow gate and the bottom of the casting. The casting mold has high practicability, and the forming quality and production efficiency of castings can be effectively improved. And the device is simple in structure and easy to popularize.

Owner:NANJING UNIV OF TECH

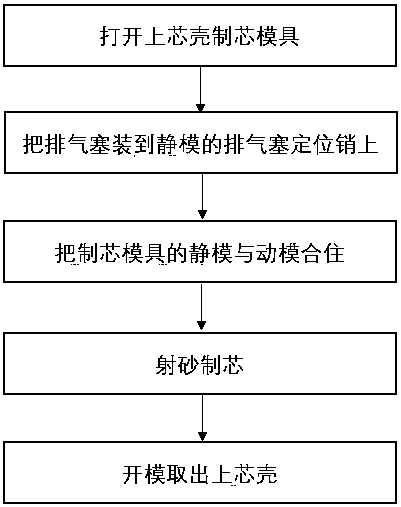

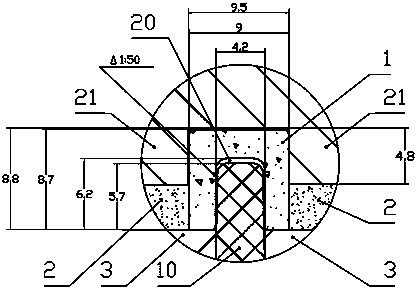

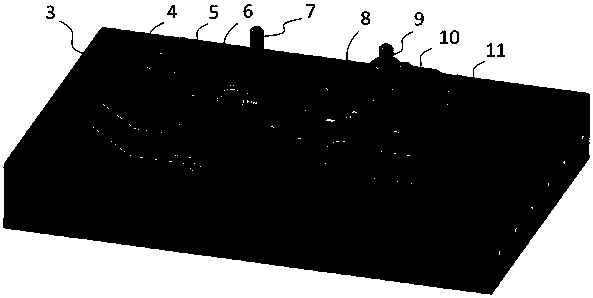

Installation method for venting plugs for casting

InactiveCN110405157AShorten takt timePrevent the phenomenon of easy falling offFoundry mouldsMoulding machinesRejection rateMaterials science

The invention discloses an installation method for venting plugs for casting. The venting plugs made from casting sand having sand particle sizes which are greater than the sand particle size of coresand for core making are used, and placed at corresponding positions in a die by virtue of an operation process of repairing each die by workers during production for a modelling line, and the ventingplugs are directly inlaid into the sand core in the process of core making, so that the previous operation method of needing to bond venting plugs one by one after core making is completed is avoided, the labor and glue water are saved, the core assembly rhythm is greatly shortened, and the bottleneck of capacity is broken through; and in addition, the previous phenomenon that the venting plugs are liable to separate off in a transfer process is further effectively prevented, so that the probability of sand entrance into a cavity is reduced, the sand-hole rejection rate of castings is lowered, and the product quality is effectively improved.

Owner:NANYANG FEILONG AUTOMOBILE PARTS CO LTD

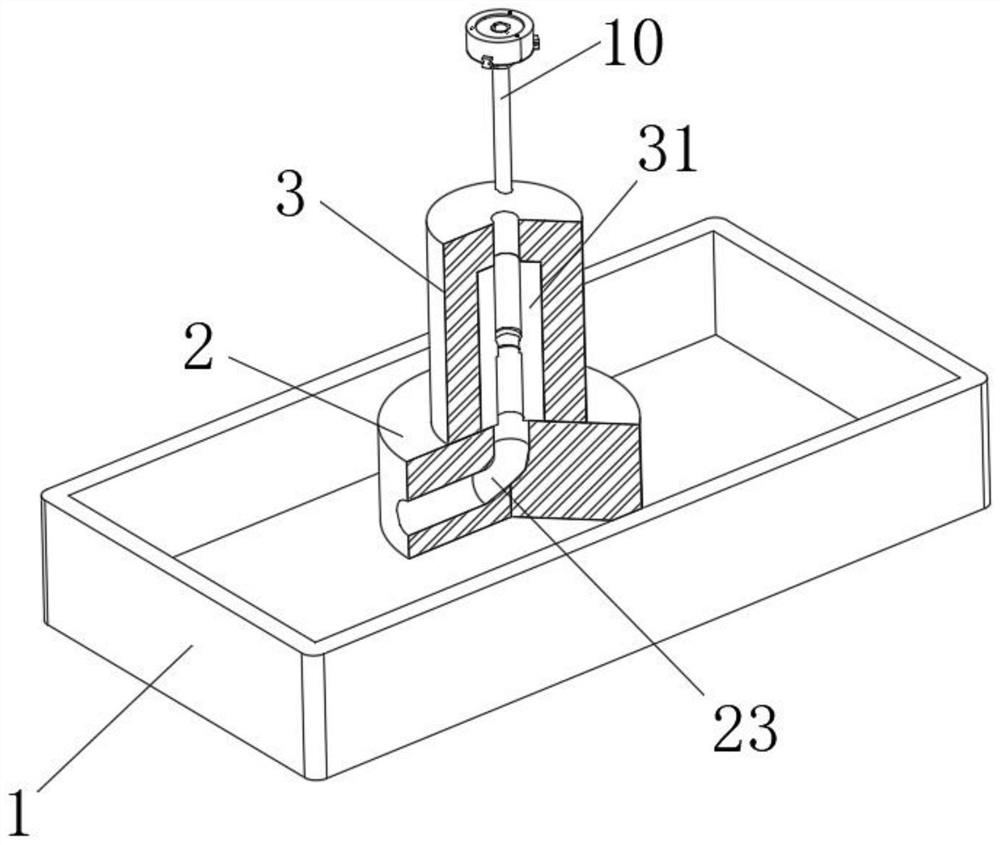

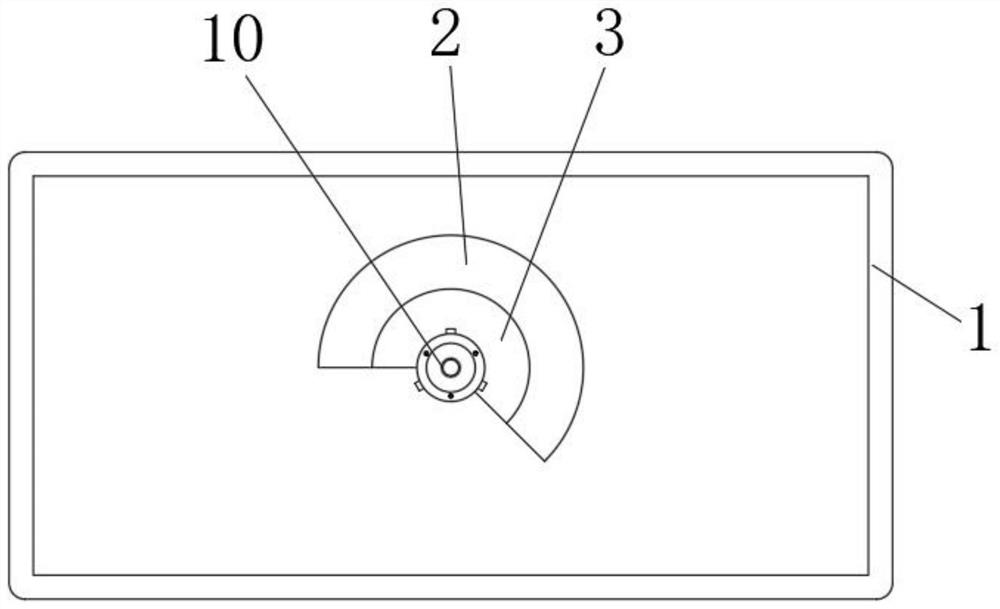

Multi-rotor frequency conversion sand mixer and sand mixing method

ActiveCN103949580BStir track overlap increasedHigh overlapMould handling/dressing devicesFrequency changerElectric machinery

The invention provides a multi-rotor frequency-changing sand mixer and a sand mixing method. Due to the application of a multi-rotor cutter, the overlapping degree of stirring tracks of a material is improved; meanwhile, due to the application of a frequency-changing rotor speed adjusting technology, the mixing process meet change of physical characteristic of mixed sand, that is, the mixing process can be more conductive to uniform coating of an auxiliary material (bentonite) on sand particles in the presence of water, so that the influence of small particles formed by the bentonite due to incomplete mixing on the mixing quality of casting sand can be avoided. A frequency changer is capable of automatically adjusting the frequency of a motor in a range of 50HZ-30HZ under the control of a rotation speed-time program which is determined by an industrial personal computer in advance. The multi-rotor frequency-changing sand mixer and the sand mixing method provided by the invention have the characteristics of uniformity in mixing the sand, high efficiency of mixing the sand and low energy consumption.

Owner:常州市通力机电设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com