Low-smoke halogen-free phosphorus nitrogen expanding flame-retardant mold shrinkage sleeve and preparation method and application thereof

A halogen-free, phosphorus-nitrogen, and intumescent flame-retardant technology, which is applied in the direction of insulators, connection insulation, etc., can solve problems such as unsatisfactory flame-retardant effects, reduced mechanical properties of materials, and environmental impact, so as to avoid the decline of mechanical properties and processing properties , excellent flame retardant performance and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

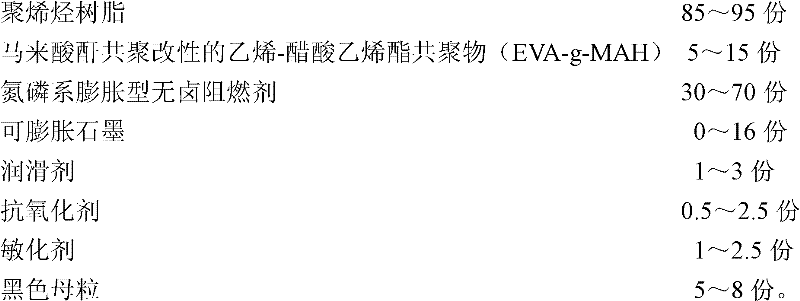

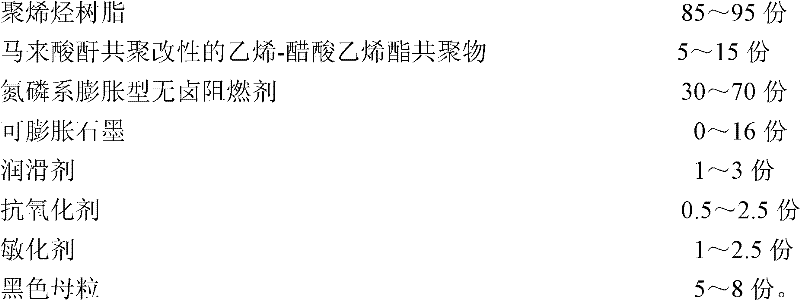

Method used

Image

Examples

Embodiment 1

[0042] Get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVAtane 2803) 40kg, ethylene-vinyl acetate copolymer (EVA, vinyl acetate content accounts for 14% mass, melt index is 3.5g / 10min, Japan Mitsui Group, brand is P1405) 40kg, linear low density polyethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W , melt index is 2g / 10min, density is 0.918g / cm 3) 5kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (grafting rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851) 15kg, Phosphorus nitrogen series intumescent flame retardant A (Co., Ltd. ADEKA, FP-2200) 43kg, polyethylene wax (Huiyang Yongqing Chemical Co., Ltd., Huizhou City) 3kg, 0.5kg antioxidant 1010, thiodipropionic acid di(ten 4) 2kg of ester, 2.5kg of trimethylolpropane triacrylate and 8kg of black masterbatch are ad...

Embodiment 2

[0045] Get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVAtane 2803) 40kg, ethylene-vinyl acetate copolymer (EVA, vinyl acetate content accounts for 14% mass, melt index is 3.5g / 10min, Japan Mitsui Group, brand is P1405) 40kg, linear low density polyethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W , melt index is 2g / 10min, density is 0.918g / cm 3 ) 5kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (grafting rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851) 15kg, Phosphorus-nitrogen series intumescent flame retardant A (Co., Ltd. ADEKA, FP-2200) 34kg, expandable graphite (average particle size 400 mesh, average particle size is 150ml / g, Qingdao Tianhe Graphite Co., Ltd.) 10kg, polyethylene Wax 3kg, 0.5kg antioxidant 1010, di(tetradecyl) thiodipropionate 2kg, trimet...

Embodiment 3

[0048] Get ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 28% quality, and melt index is 4.5g / 10min, French Atofina company, trade mark is EVAtane 2803) 50kg, ethylene-vinyl acetate copolymer Thing (EVA, the content of vinyl acetate accounts for 14% quality, and melt index is 3.5g / 10min, Japan's Mitsui Group, trade mark is P1405) 40kg, maleic anhydride functional group graft ethylene-vinyl acetate copolymer (grafting rate 1.2%, the melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., the trade mark is JCP-851) 10kg, phosphorus nitrogen series intumescent flame retardant B (Persaifur (Qingyuan) Phosphorus Chemical Co., Ltd. , EPFR-100D) 67kg, zinc stearate (ZnSt) 1kg, 0.25kg antioxidant 1076, dilauryl thiodipropionate 0.25kg, triallyl isocyanate 1kg and black masterbatch 5kg, add to the high-speed mixer , high-speed stirring for 8 minutes, the temperature of the material is controlled within the range of 80 ° C; then the above m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com