Multi-stage air-cooled molding sand cooling equipment and molding sand cooling method thereof

A technology of sand cooling and multi-stage air, which is applied to casting molding equipment, metal processing equipment, and machinery for cleaning/processing mold materials, etc. It can solve the problems of small internal space of equipment, limited cooling capacity, and high molding sand temperature. Effect of improving cooling efficiency and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

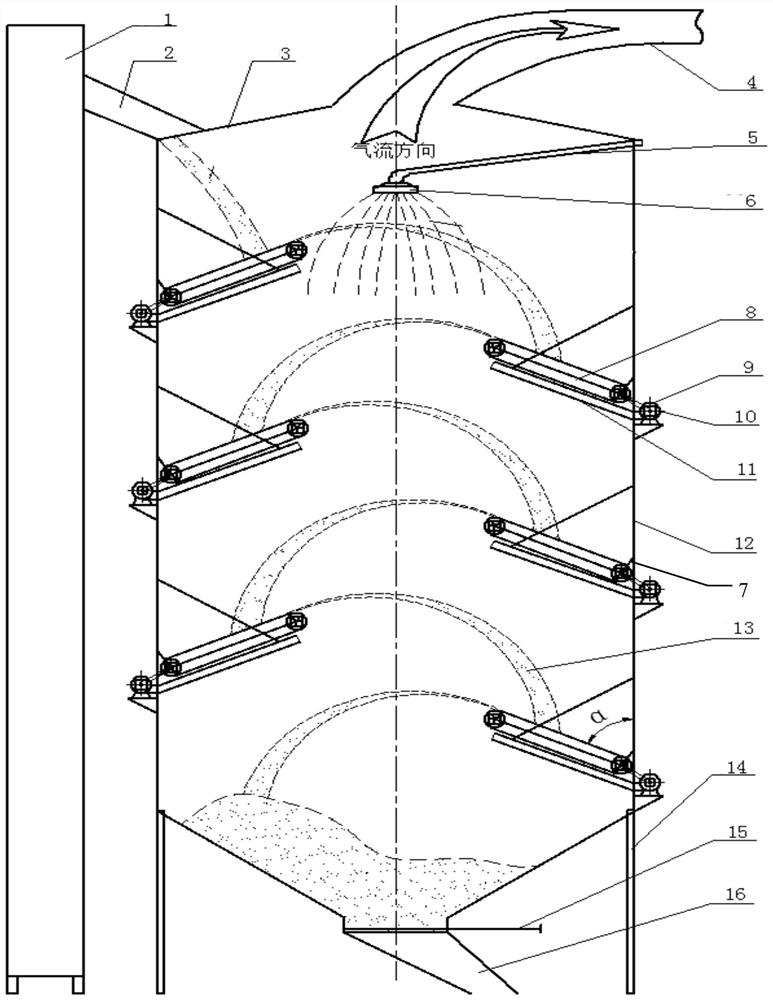

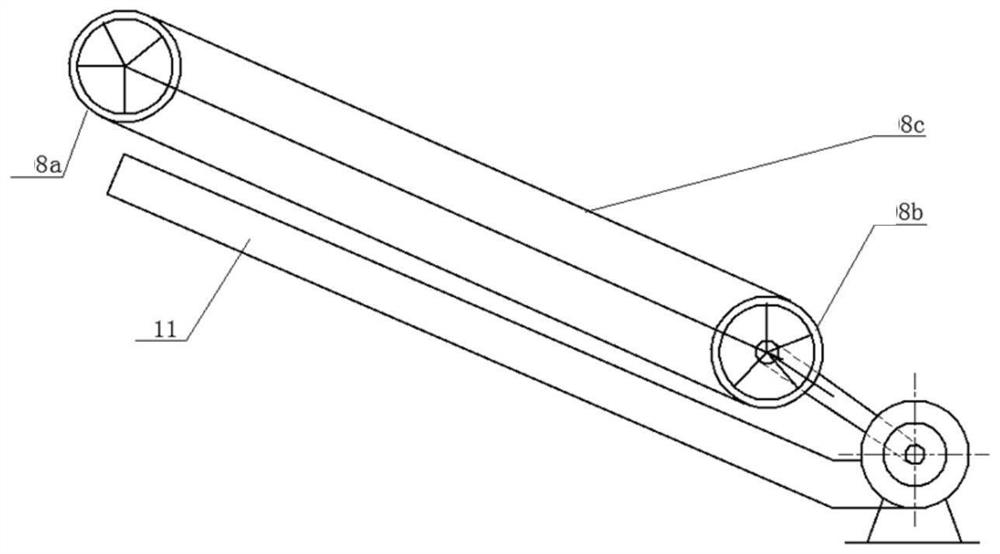

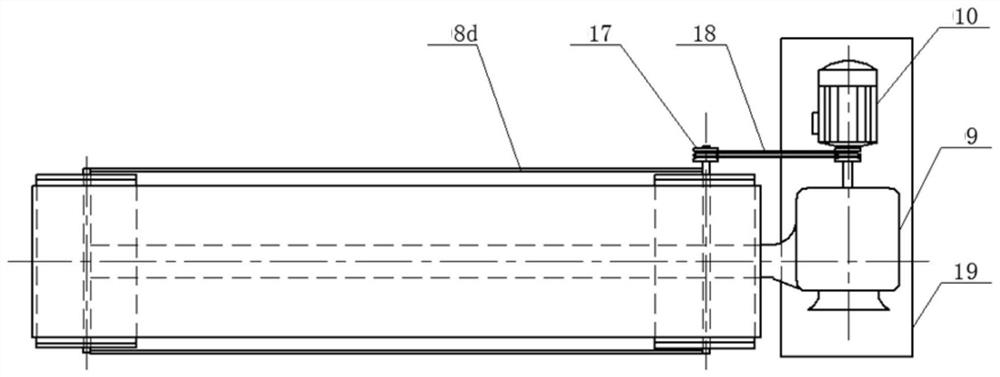

[0023] figure 1 It is a structural schematic diagram of a multi-stage air-cooled molding sand cooling equipment of the present invention, figure 2 It is a side view of the cooling mechanism of the present invention, image 3 It is a top view of the cooling mechanism of the present invention. As shown in the figure, a multi-stage air-cooled molding sand cooling device includes an elevator 1 and a cooling sand storehouse 12. The lower hopper 2 on the top of the cooling sand storehouse 12 is connected to the top of the elevator 1. The high-temperature molding sand is transported to the top of the cooling sand storehouse 12 . The bottom of the cooling sand storage 12 is fixed with sand storage legs 14, sand discharge gates 15 and sand outlet pipes 16. The cooled molding sand falls to the bottom of the molding sand cooling storage 12 and is transported to the next sand processing through the sand outlet pipe 16. process. The speed at which the molding sand is sent out from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com