Combined ear for kitchenware and its production process

A combined type, cooking utensil ear technology, which is applied in household utensils, kitchen utensils, applications, etc., can solve problems such as complex process flow, damage, and difficult cleaning, and achieve the effects of shortening process flow, good bonding effect, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

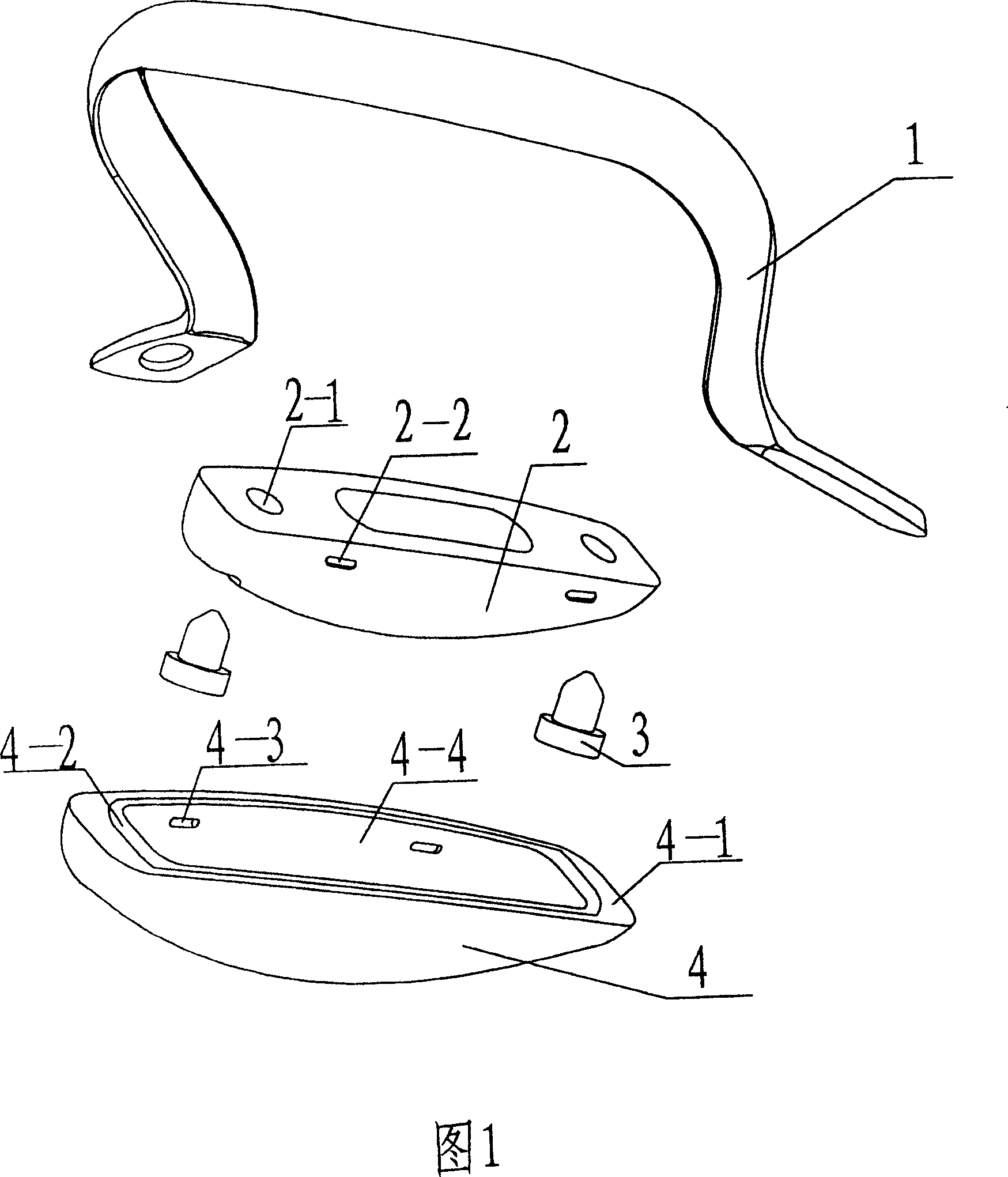

[0022] Referring to FIG. 1 , an embodiment of the present invention is a combined cooker ear, which is composed of a metal ear body 1 , a hard non-metal connector 2 , a metal pin 3 , and a double-layer composite non-metal heat insulating member 4 . The metal ear body 1 is punched from stainless steel shaped wire rod or sheet, with installation holes on both sides, and 1-3 hard non-metallic connectors 2 can be assembled under the middle section, depending on the length of the ear body, this embodiment adopts 1 A hard non-metallic connector 2. The hard non-metallic connector 2 is made of nylon material, with two levels of through holes 2-1 at both ends and two convex buckles 2-2 on both sides, and the nylon connector 2 is accurately positioned by the clamp Below the middle section of the stainless steel ear body 1, a stainless steel pin 3 is inserted from the two-stage through hole 2-1 and matched with the corresponding small through hole in the stainless steel ear body 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com