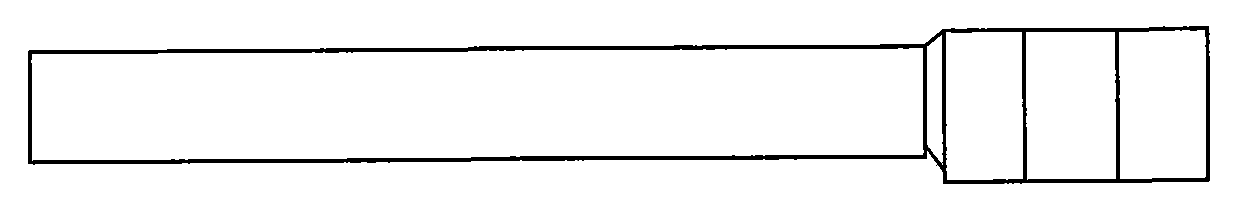

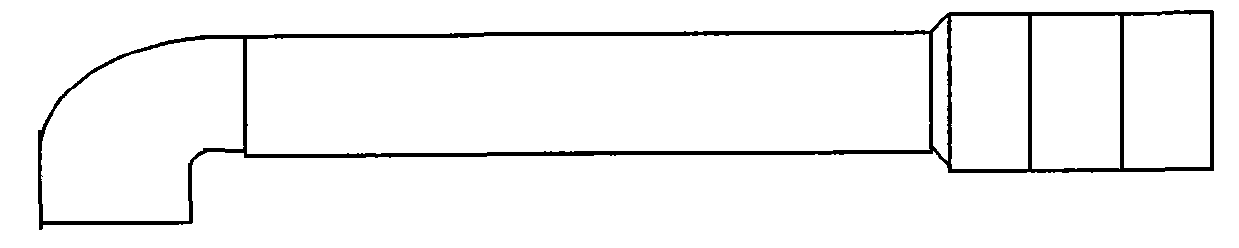

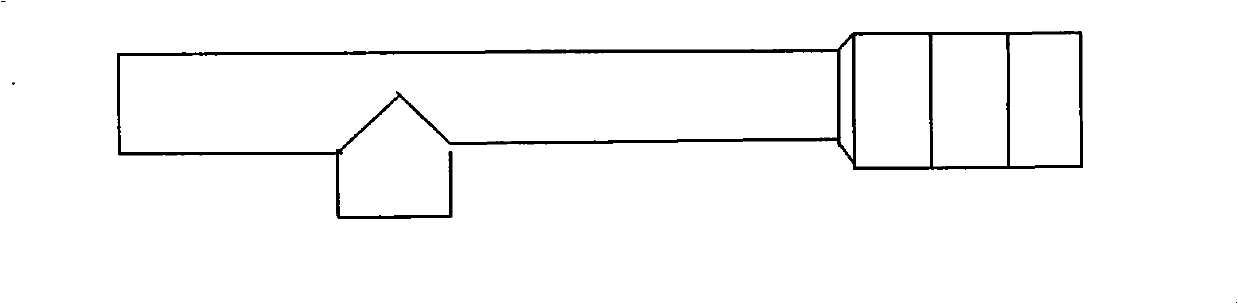

Paper pouring channel tube for casting and shaping technique thereof

A molding process and sprue tube technology, which is applied to casting molding equipment, casting molds, papermaking, etc., to achieve the effects of reducing scrap rate, convenient use, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] a. Collect all kinds of waste printed matter or / and waste cardboard, add water and water at a weight ratio of 1:25 to the disintegrator to prepare pulp, then put it into the pulp tank, and adjust the pulp concentration to 4% ;

[0056] b. Preparation of sinterable filling materials and bonding materials,

[0057] White Clay or Kaolin 80%,

[0058] Bentonite 20%,

[0059] Add white clay or kaolin, and bentonite to the mixer in turn according to the above ratio, mix well and set aside;

[0060] c. Weigh the above prepared pulp, sinterable filling material, bonding material, reinforcing agent, and moisture-proof agent material: instant sodium silicate or water glass according to the following proportions, gradually add them to the slurry tank and stir evenly, and then use a pump to Pump the pulp into the quantitative box and circulate it to maintain the liquid level and concentration in the pulp box;

[0061]Waste paper pulp 82%,

[0062] Sinterable filler material, b...

Embodiment 2

[0068] a. Collect all kinds of waste printed matter or / and waste cardboard, add water and water at a weight ratio of 1:25 to the disintegrator to prepare pulp, then put it into the pulp tank, and adjust the pulp concentration to 4% ;

[0069] b. Preparation of sinterable filling materials and bonding materials,

[0070] Clay or casting clay 78%,

[0071] Bentonite 18%,

[0072] High alumina fine powder 4%,

[0073] Add clay or casting clay, bentonite and high alumina micropowder into the mixer in sequence according to the above ratio, mix well and set aside;

[0074] c. Weigh the pulp prepared above, sinterable filling material, bonding material and reinforcing agent, moisture-proof agent material: instant sodium silicate or water glass according to the above ratio, gradually add and stir evenly, and then use a pump to pump the pulp into the quantitative box, and make it circulate to maintain the liquid level and concentration in the pulp box;

[0075] Waste paper pulp 77...

Embodiment 3

[0082] a. Collect all kinds of waste printed matter or / and waste cardboard, add water and water at a weight ratio of 1:25 to the disintegrator to prepare pulp, then put it into the pulp tank, and adjust the pulp concentration to 4% ;

[0083] b. Preparation of sinterable filling materials and bonding materials,

[0084] White Clay or Kaolin 80%,

[0085] Bentonite 20%,

[0086] Add white clay or kaolin and bentonite to the mixer in turn according to the above ratio, mix well and set aside;

[0087] c. Weigh the prepared pulp, sinterable filling material and bonding material according to the following proportions, gradually add them to the slurry tank and stir evenly, then use a pump to pump the pulp into the quantitative box and circulate it to keep the pulp box The liquid level and concentration in the

[0088] Waste paper pulp 83%,

[0089] Sinterable filler material, bonding material 15%,

[0090] Silicone-based silicone waterproofing agent is not added temporarily, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com