Roll-pressing narrow lap welding machine, welding process and moveable lining plates of roll-pressing narrow lap welding machine

A lap welding and liner technology, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of damage to the short plate of the shear belt and tail, unreasonable structure, and speed reduction of the galvanizing unit, etc., to achieve The effect of reducing the number of shutdown failures, shortening the processing cycle, and reducing the rate of scrap and defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the rolling narrow lap welding machine and welding process and its movable liner of the present invention will be described in detail with reference to exemplary embodiments.

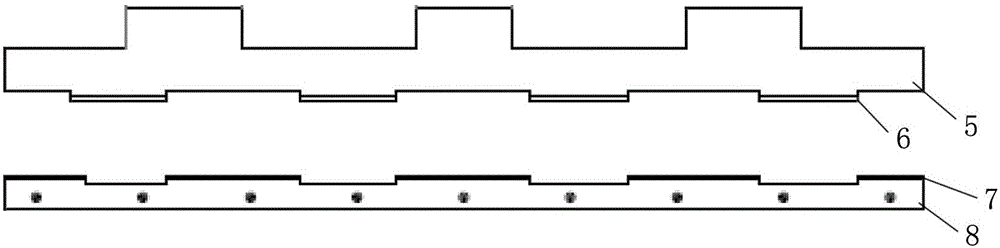

[0021] figure 1 A schematic structural view of an inlet side liner assembly of an exemplary embodiment of the present invention is shown. figure 2 show figure 1 The schematic diagram of the overall assembly. image 3 A schematic structural view of an outlet-side liner assembly according to an exemplary embodiment of the present invention is shown. Figure 4 show image 3 The schematic diagram of the overall assembly.

[0022] Such as Figures 1 to 4 As shown, in an exemplary embodiment of the present invention, the movable liner of the rolling narrow lap welder includes an inlet side liner assembly and an outlet side liner assembly.

[0023] Such as figure 1 with 2 As shown, the inlet side liner assembly is composed of the first fixed liner 4 , the first movable liner 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com