Special-shaped water-soluble salt core, manufacturing method and application thereof

A technology of water-soluble salt and production method, applied in the direction of cores, manufacturing tools, mechanical equipment, etc., can solve the problem that the piston ring groove and the combustion chamber have a large thermal influence, the heat cannot be quickly taken away by the cooling oil, and the inner cooling oil cavity is cooled. The effect is limited and other problems, to achieve the effect of ensuring the yield of the process, reducing the scrap rate of casting, and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

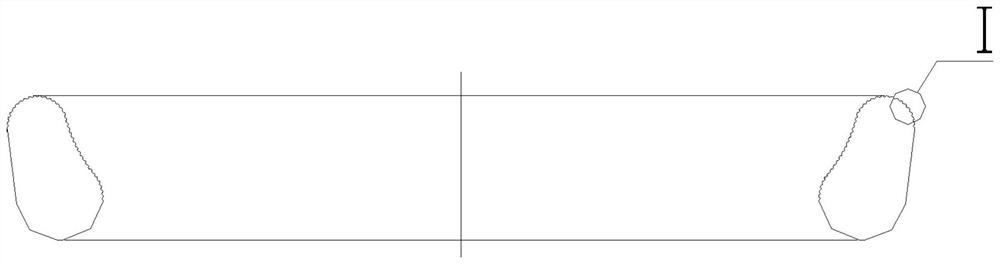

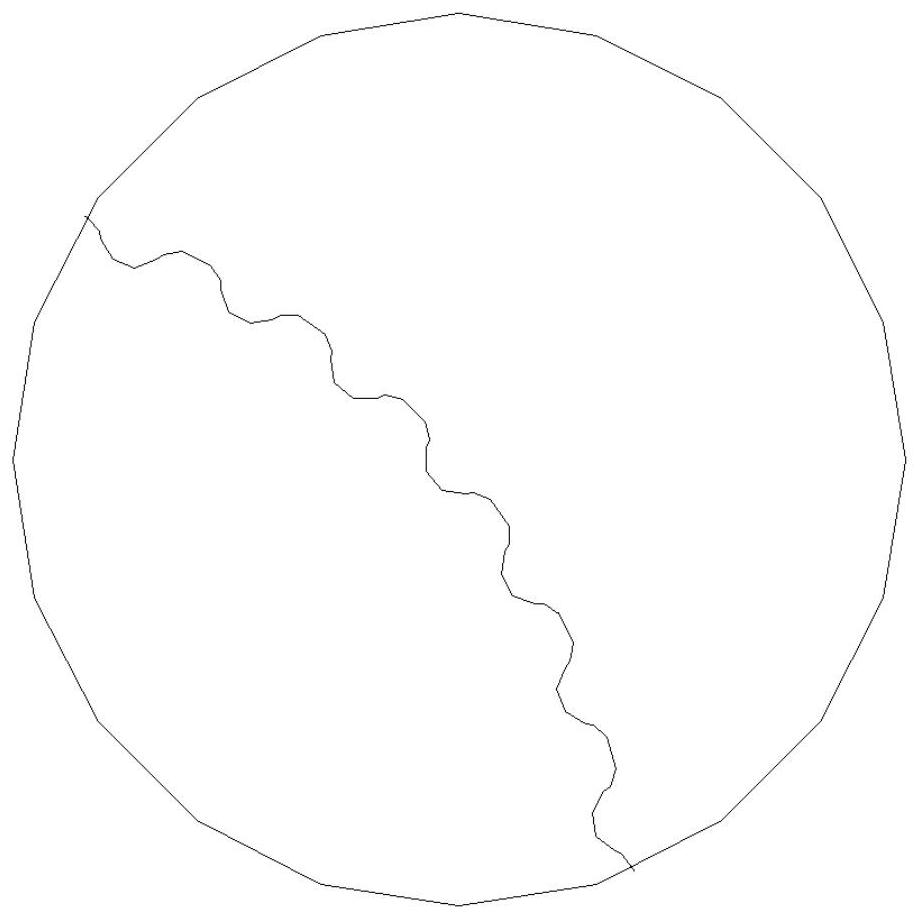

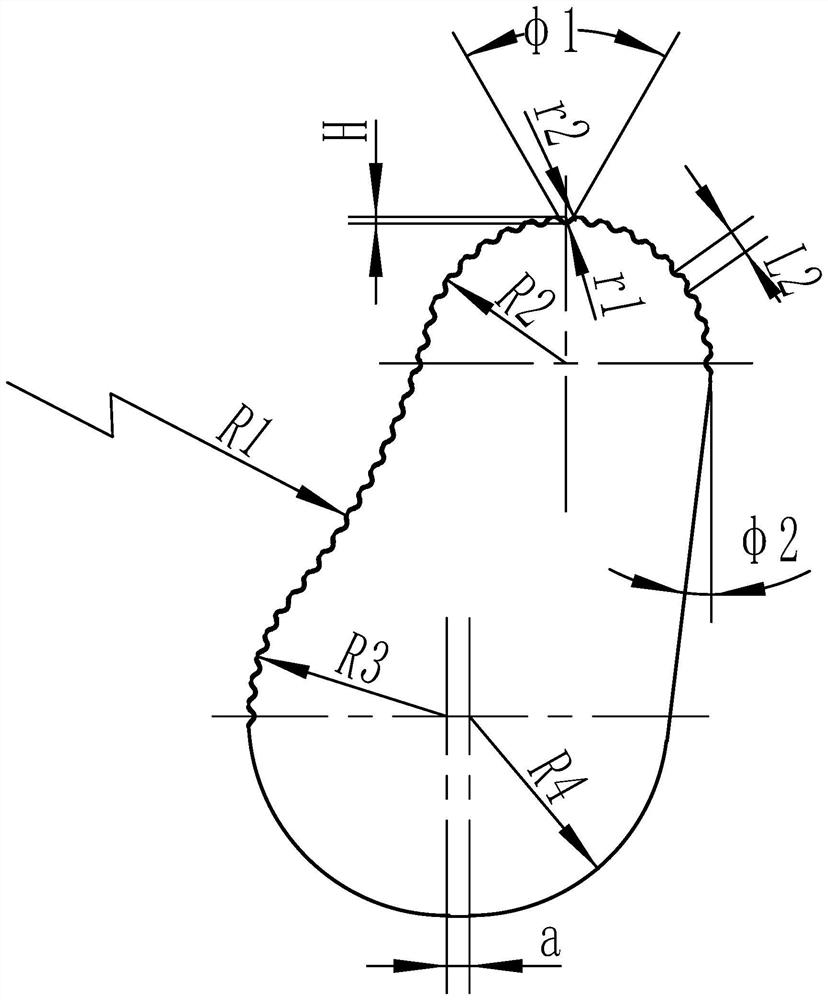

[0055] A special-shaped water-soluble salt core, the salt core is circular, the cross-section of the salt core is special-shaped, the cross-section of the salt core includes the top, middle, and bottom, the top is close to the top surface of the piston, the top is semicircular; the bottom is arc-shaped, and the middle The two sides are straight lines and arcs respectively, and the arc side in the middle is closest to the combustion chamber.

[0056] There are circular grooves on the outer surface of the top and the outer surface of the arc side in the middle, and a plurality of circular grooves are arranged to form a corrugated surface. An annular groove is also formed in the inner cooling oil passage made of this salt core. The arrangement position of the annular groove in the inner cooling oil passage of the piston is close to the ring of the piston, the top of the piston, the throat, and the fillet at the bottom of the combustion chamber. The heat dissipation area of the ...

Embodiment 2

[0061] A method for making a special-shaped water-soluble salt core, comprising the following steps:

[0062] (1) Raw material ratio

[0063] The special salt for salt core making and water glass are mixed according to the ratio of salt 97%+water glass 3%; the salt and water glass are evenly mixed and then sieved (40-100 mesh) to prevent uneven salt particles. It is not conducive to the pressing and forming of salt core;

[0064] (2) suppression

[0065] Salt core compression specific pressure (pressure per unit area): 125-160MPa;

[0066] System pressure calculation formula: P 系统 A 系统 =P 盐 A 盐

[0067] In the formula: P 系统 is the system pressure, adjusted according to different varieties, A 系统 is the jacking cylinder area, and the equipment fixes this parameter as a fixed value, P 盐 is the specific pressure for pressing the salt core, that is, 125-160MPa, A 盐 is the projected area of the salt core, and the value is different for different models;

[0068] (3) De...

Embodiment 3

[0084] An application of the special-shaped water-soluble salt core described in Embodiment 1 in a piston, including a piston, as shown in the figure, a combustion chamber is provided on the top of the piston, the bottom of the combustion chamber is arc-shaped, and an insert ring is provided on the side of the piston to burn A cooling oil passage is provided in the piston on the side of the chamber, and the cross-section of the cooling oil passage is the same as that of the special-shaped water-soluble salt core.

[0085] The distance between the tangent surface of the cooling oil passage on the side of the combustion chamber and the tangent surface of the combustion chamber is L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com