Microstructure Prediction Method of Cast Cylinder Head Based on Rough Set and Neural Network

A neural network, BP neural network technology, applied in the direction of neural learning method, biological neural network model, prediction, etc., can solve the problems of reducing the input dimension of neural network, reducing the rate of metal consumables and casting rejects, and speeding up the training speed and prediction accuracy, reduced metal consumables rate, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

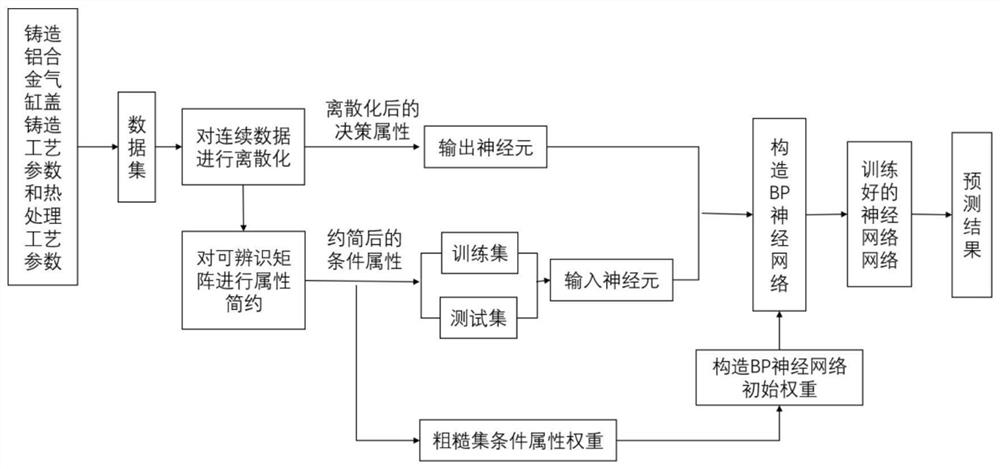

[0038] A method for predicting the microstructure of cast cylinder heads based on rough sets and neural networks. The prediction process is as follows: figure 1 shown, including the following steps:

[0039] Step 1, obtaining the microstructure information database of the cast aluminum alloy cylinder head material;

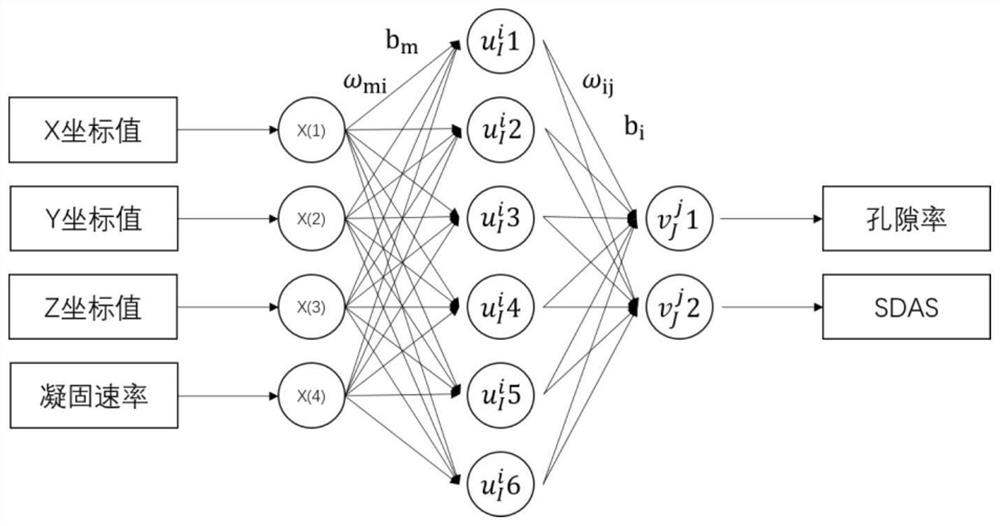

[0040] The casting process parameters and heat treatment parameters of the selected cast aluminum alloy cylinder head are provided by the foundry, and the microstructural parameters of the cylinder head are obtained from laboratory scanning microscope and electron microscope measurements. The test samples were taken from different positions of the low-pressure cast aluminum alloy cylinder head, and the position coordinate values x, y, z were taken; the selected casting and heat treatment process parameters were: sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com