Lost foam casting method of cylinder of single cylinder diesel engine

A diesel engine and lost foam technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as insurmountable, and achieve the effect of solving carbon slag problems, improving casting quality, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

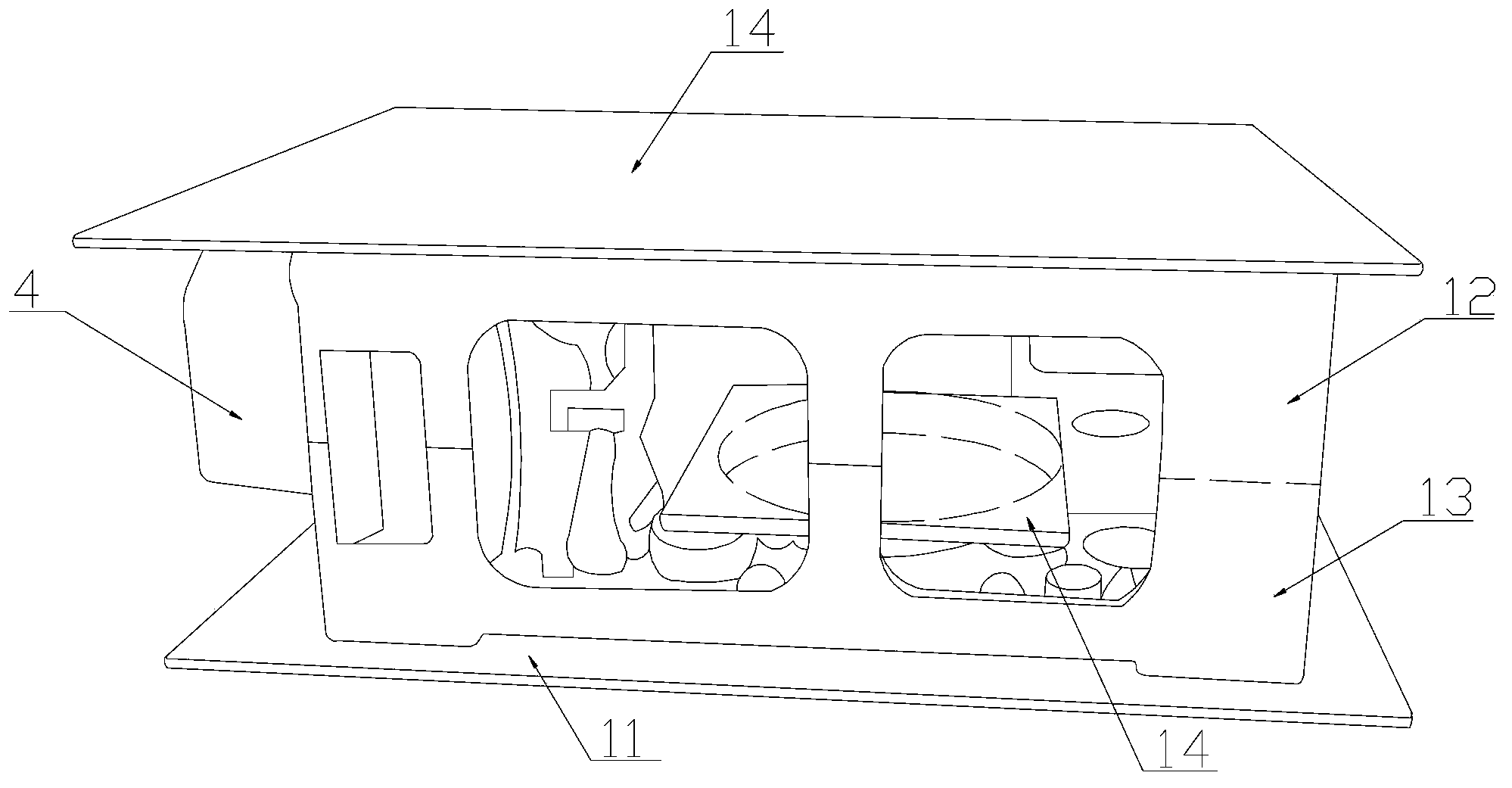

Embodiment 1

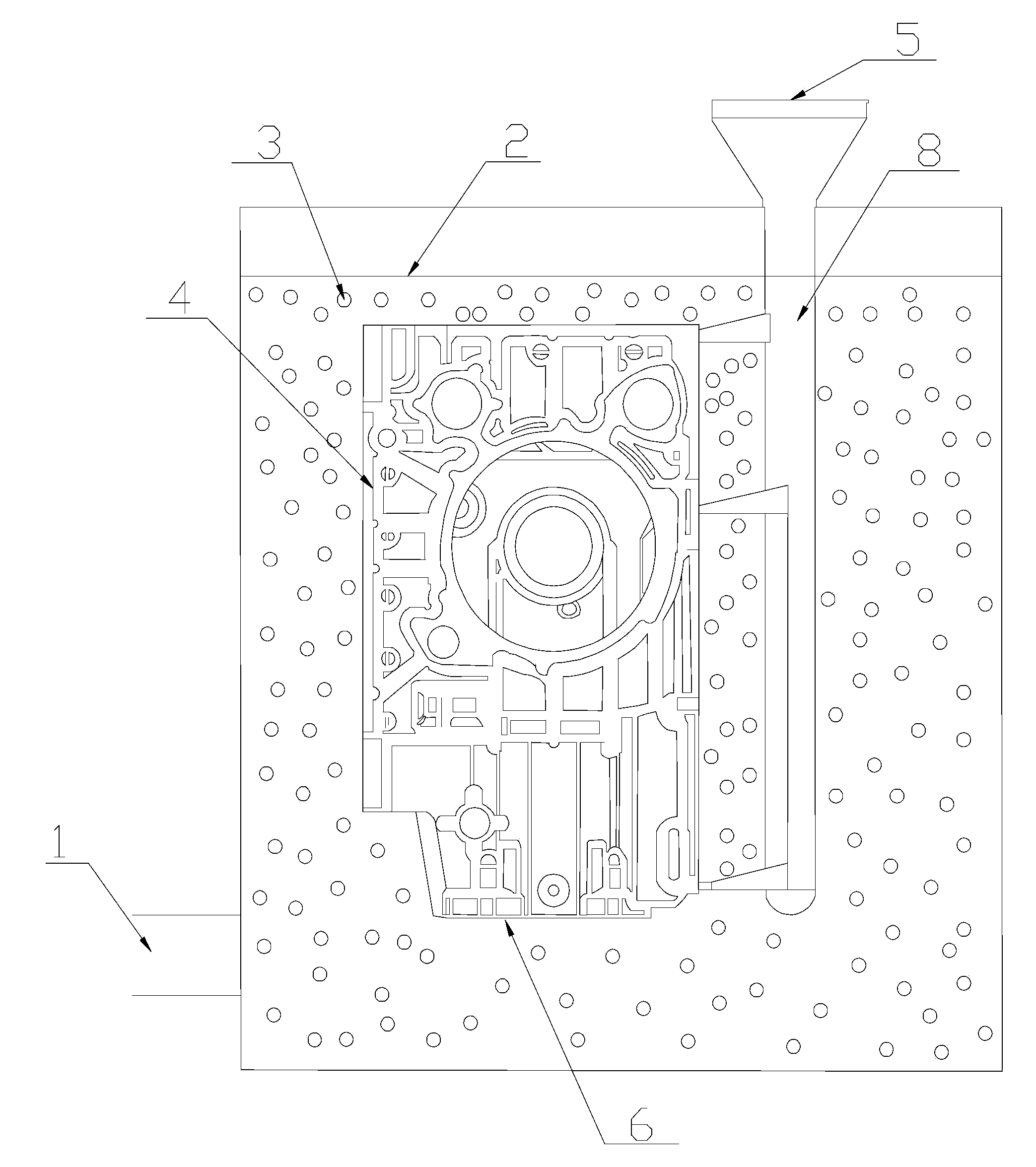

[0034] like figure 2 As shown, the lost foam white mold 4 of the cylinder block of a single-cylinder diesel engine is placed in a three-dimensional vibrating sand box with the bottom molding sand 3, the cylinder head face 6 faces downward, and two lost foam white molds are connected to a casting system white mold 8 4. The lost foam white mold 4 is inclined laterally, the inclination angle 7 is 15°, the thickness of the molding sand 3 on the top of the cylinder is 12cm, the gate 5 is 4cm higher than the plane of the molding sand 3, the surface of the molding sand 3 is covered with a layer of plastic film 2, and the surface of the molding sand 3 is covered with a layer of plastic film 2 The surface is covered with 3cm-thick molding sand 3 and the gate 5 is exposed. The sand box is in a closed state. The sand box is connected to the vacuum system through the vacuum interface 1 at the bottom. The cylinder lost foam white mold 4 is inclined laterally at 15° to reduce the flow resis...

Embodiment 2

[0036] like image 3As shown, the lost foam white mold 4 of the cylinder block of a single-cylinder diesel engine is placed in a three-dimensional vibrating sand box with the bottom layer of molding sand 3, the cylinder head face 6 faces downward, and a lost foam white mold 8 of a casting system is connected to it 4. The thickness of the molding sand 3 on the top of the cylinder is 13cm, the gate 5 is 5cm higher than the plane of the molding sand 3, the surface of the molding sand 3 is covered with a layer of plastic film 2, and the surface of the film 2 is covered with 4cm thick molding sand 3 and the gate 5 is exposed, the sand box In the closed state, the flask is connected to the vacuum system via the vacuum docking port 1 at its bottom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com