Method for macrosegregation numerical simulation of casting

A technology of numerical simulation and macrosegregation, which is applied in electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of low precision and long calculation time of macrosegregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

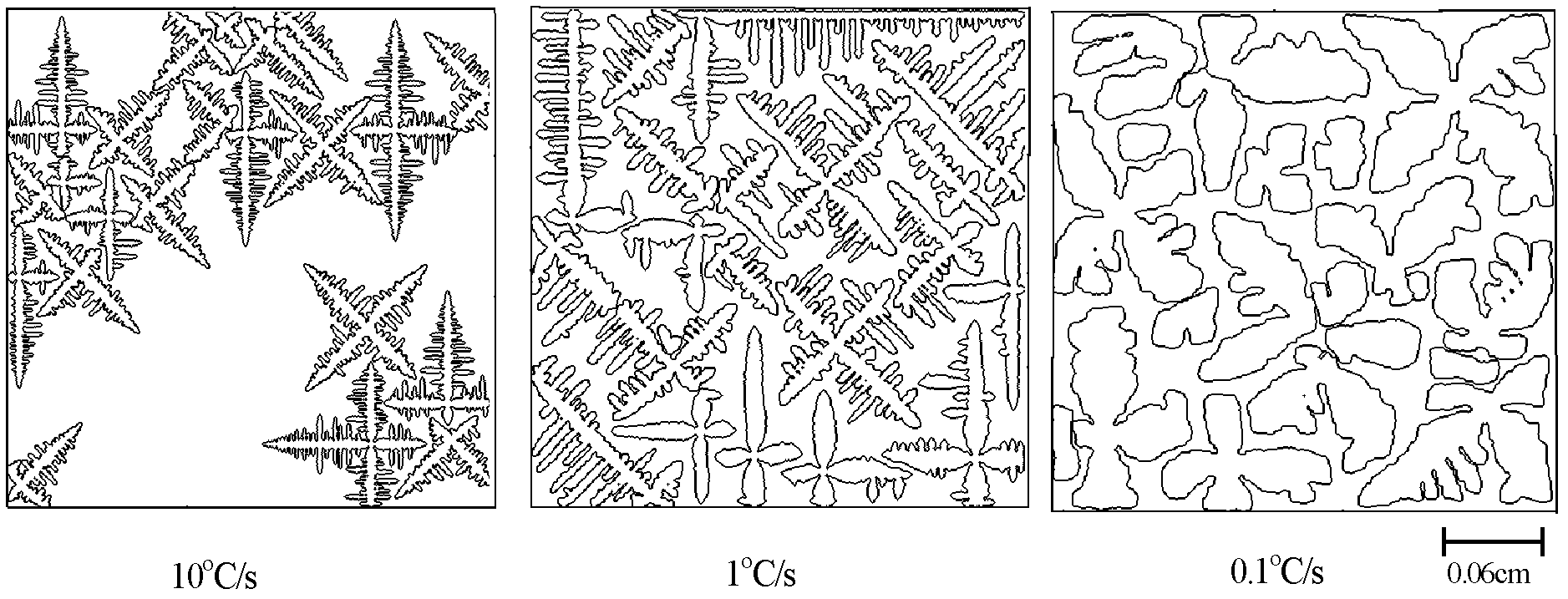

[0058] Specific embodiment one: the method for numerical simulation of casting macrosegregation of the present embodiment, described method comprises the following steps:

[0059] Step 1, subdividing the dendrite growth calculation domain into micro-scale grids, and dividing it into n×m grids; the calculation domain is a rectangle, and the area of the calculation domain (X meters × Y meters) and the number of grid divisions Choose to meet Grid area Δy·Δx≤25×10 -12 (rice) 2 ;

[0060] Step 2. Determine the maximum nucleation density NU max and the maximum nucleation undercooling ΔT max ;

[0061] Step 2 (1), under a solidification time t, based on the Gaussian continuous nucleation distribution principle, the hyperbolic cosine function is used to calculate the number of nucleation particles MU(t) in the microscopic scale calculation domain:

[0062] ΔT ( t ) = T l ...

specific Embodiment approach 2

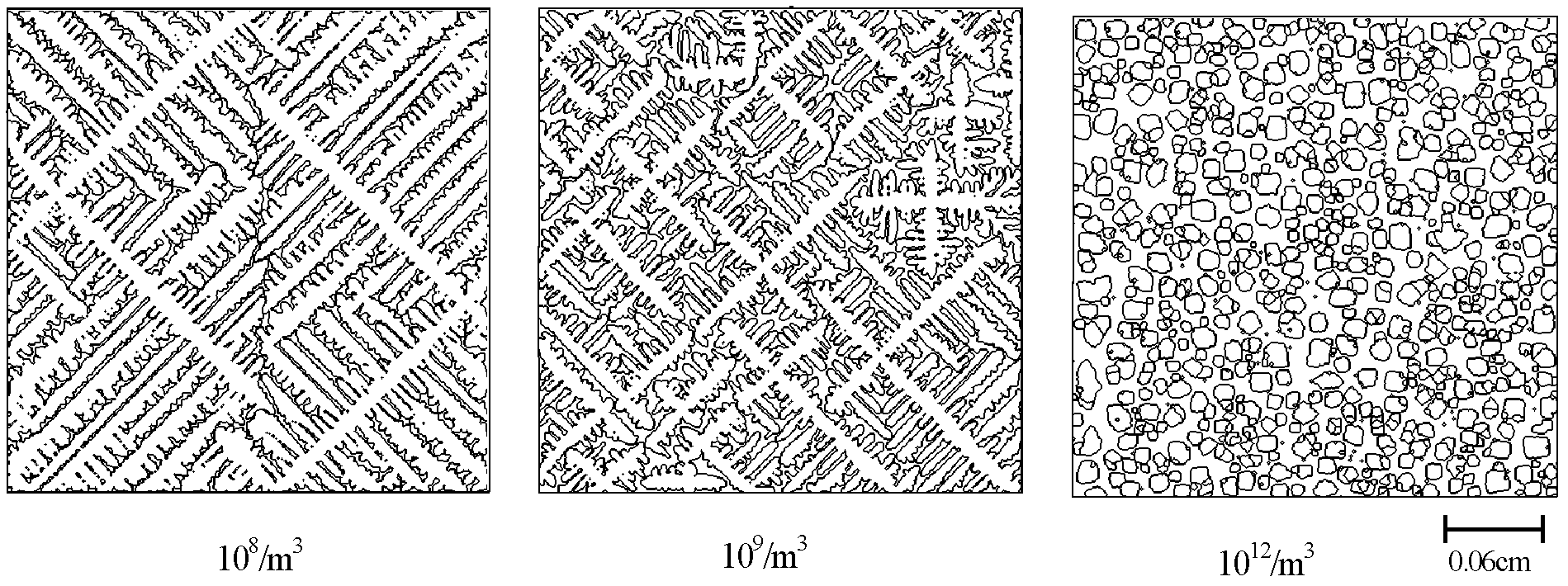

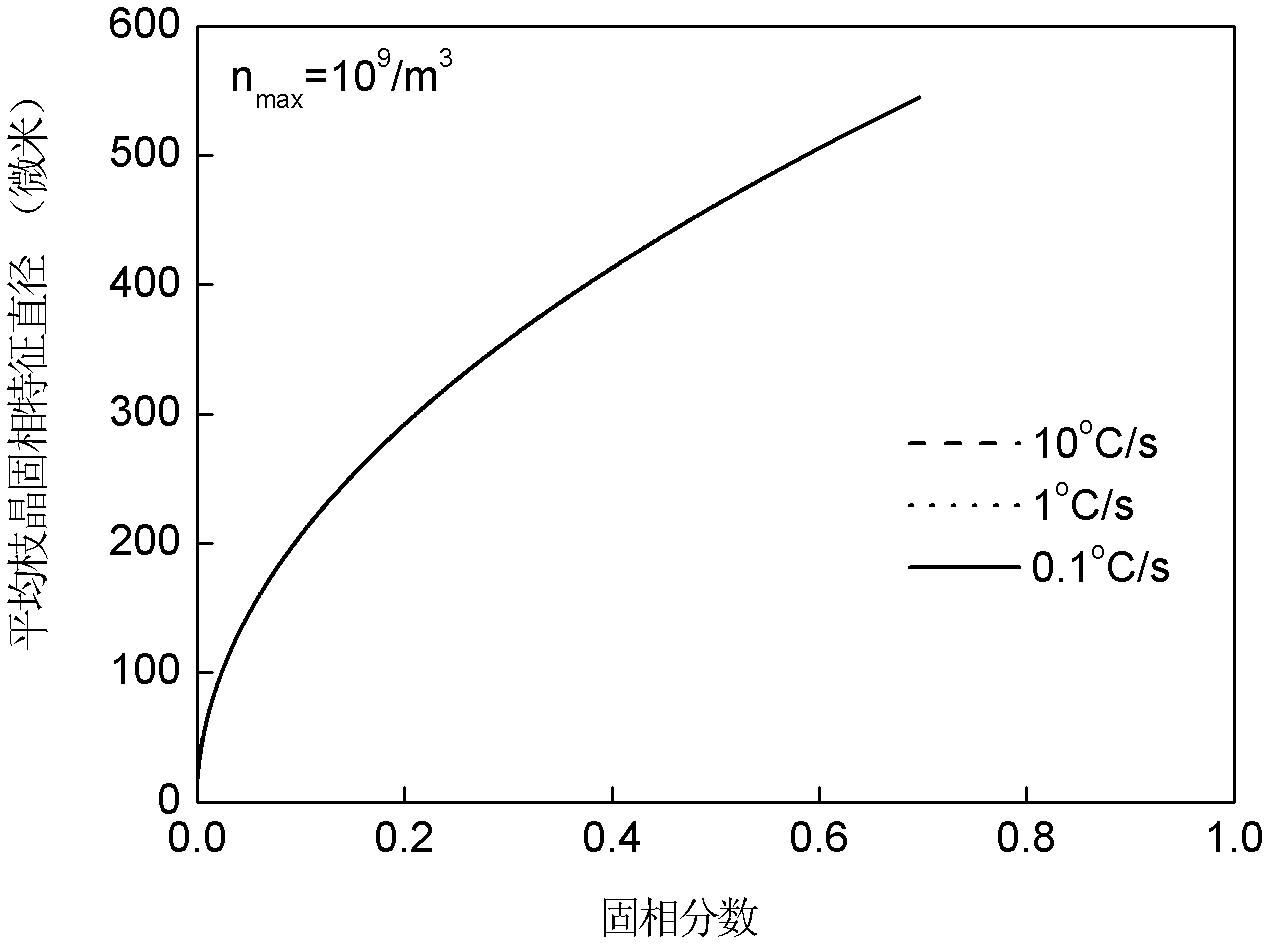

[0107] Specific embodiment two: the calculation of the mushy zone permeability model described in the step eight of the present embodiment adopts two methods, and a kind of calculation method is based on the maximum nucleation density 10 9 / m 3 For the corresponding solid phase fraction-average dendrite solid phase characteristic diameter curve, a calculation method is based on the classical mixing theory, and a set of data closest to the experiment is selected for the calculated results. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0108] Specific embodiment three: in the step 4 of the present embodiment, set (Bn×Bm) grids as columnar crystal growth grids, and (An×Am-Bn×Bm) grids as equiaxed crystal growth grids; step Determine the data file Nuclei.dat corresponding to the reading of the casting in the fifth step; in the ninth step, the maximum nucleation density of columnar crystals LNU max and equiaxed maximum nucleation density ENU max , the permeability calculation of the mushy zone in the crystal growth zone is based on the maximum nucleation density LNU max The corresponding solid phase fraction-average dendrite solid phase characteristic diameter curve, the permeability calculation of the mushy zone in the equiaxed crystal growth zone is based on the maximum nucleation density ENU max The corresponding solid phase fraction-average dendrite solid phase characteristic diameter curve, this step is to simulate the formation of macrosegregation when the microstructure evolves during solidification, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com