Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Realize harmless discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

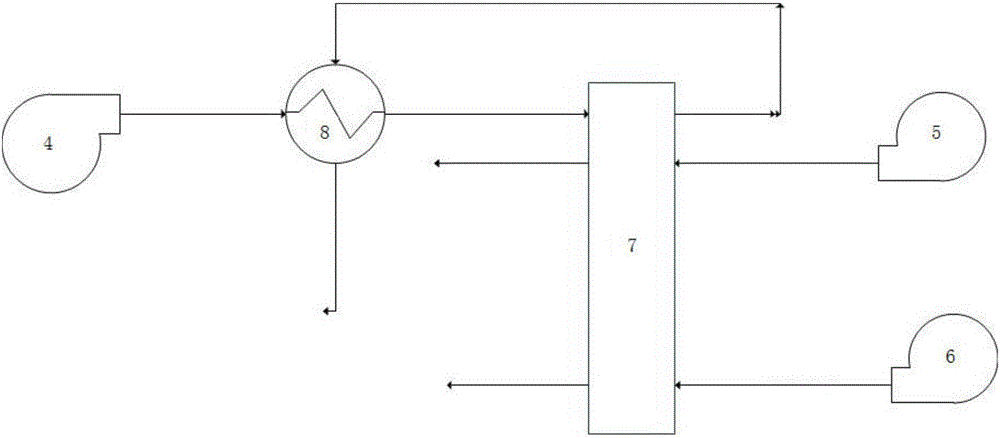

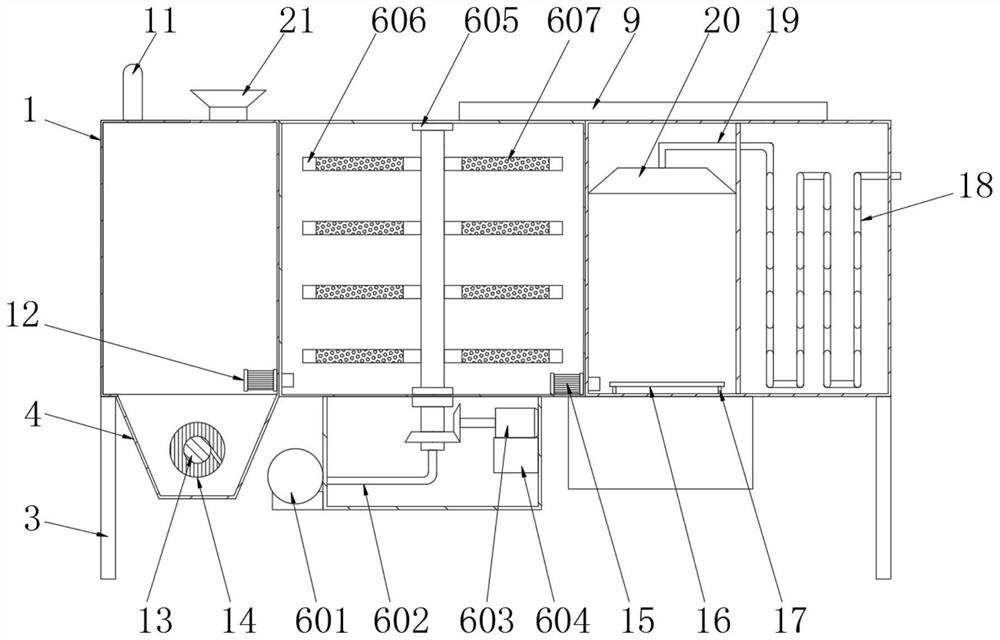

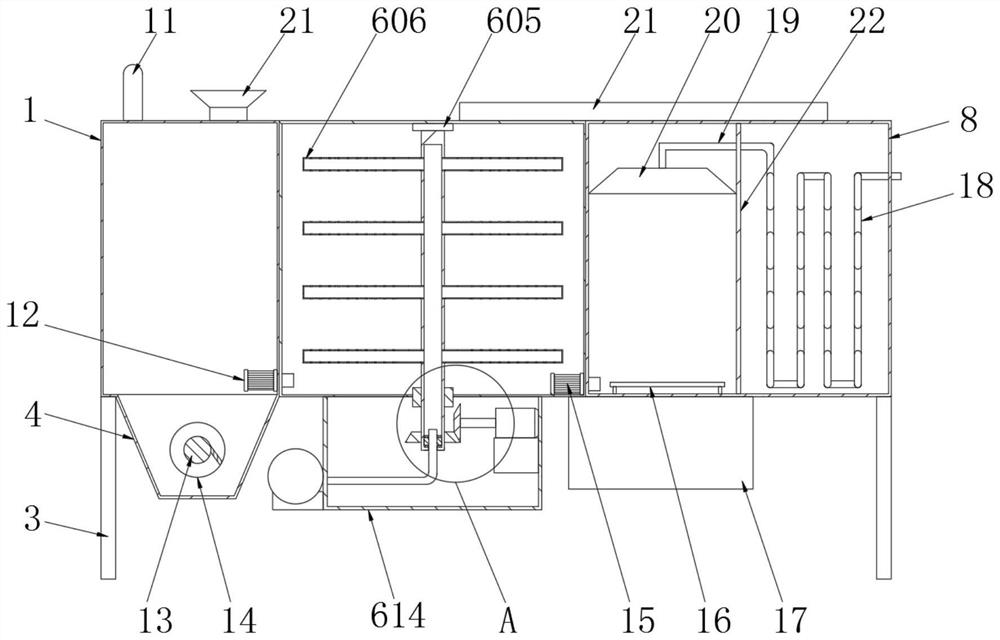

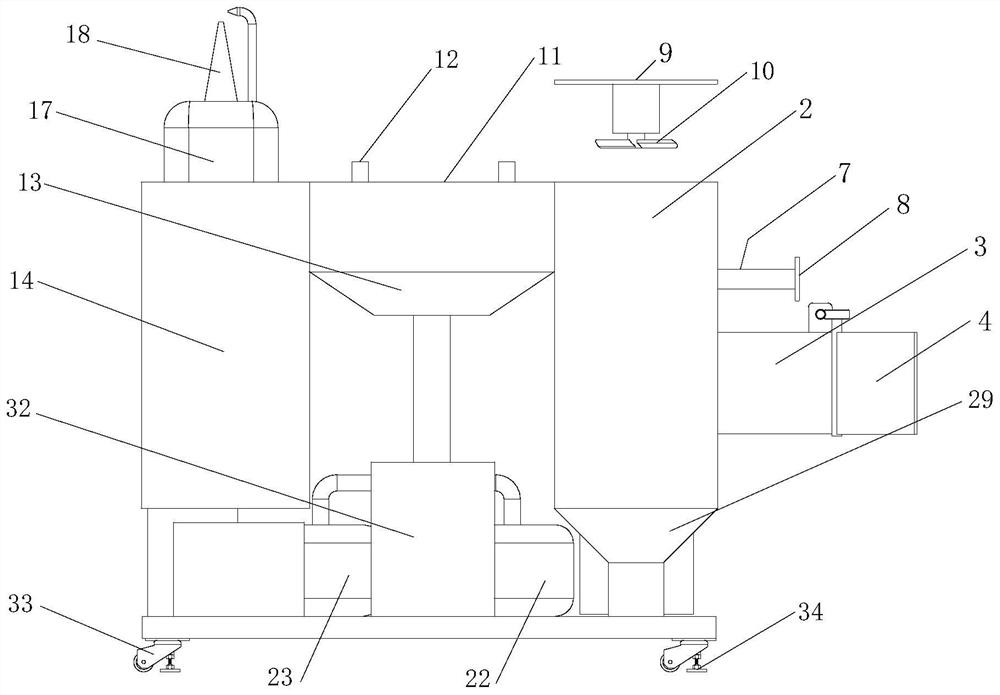

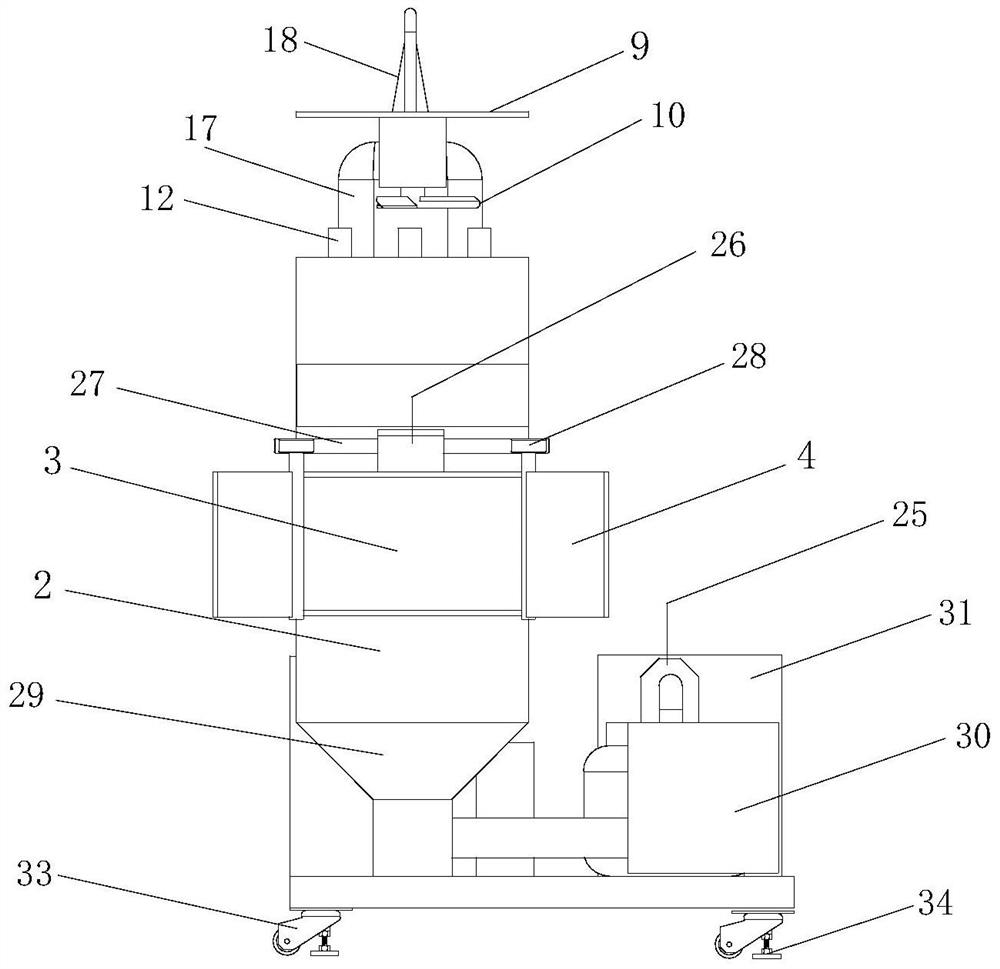

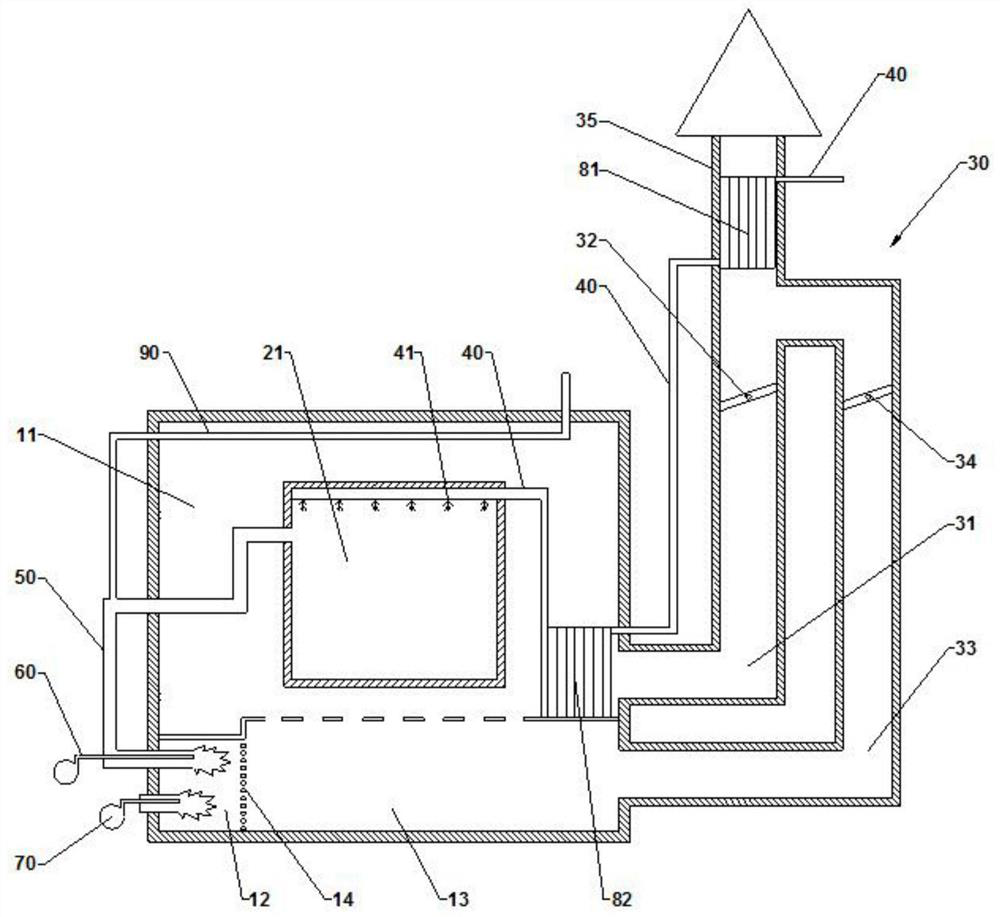

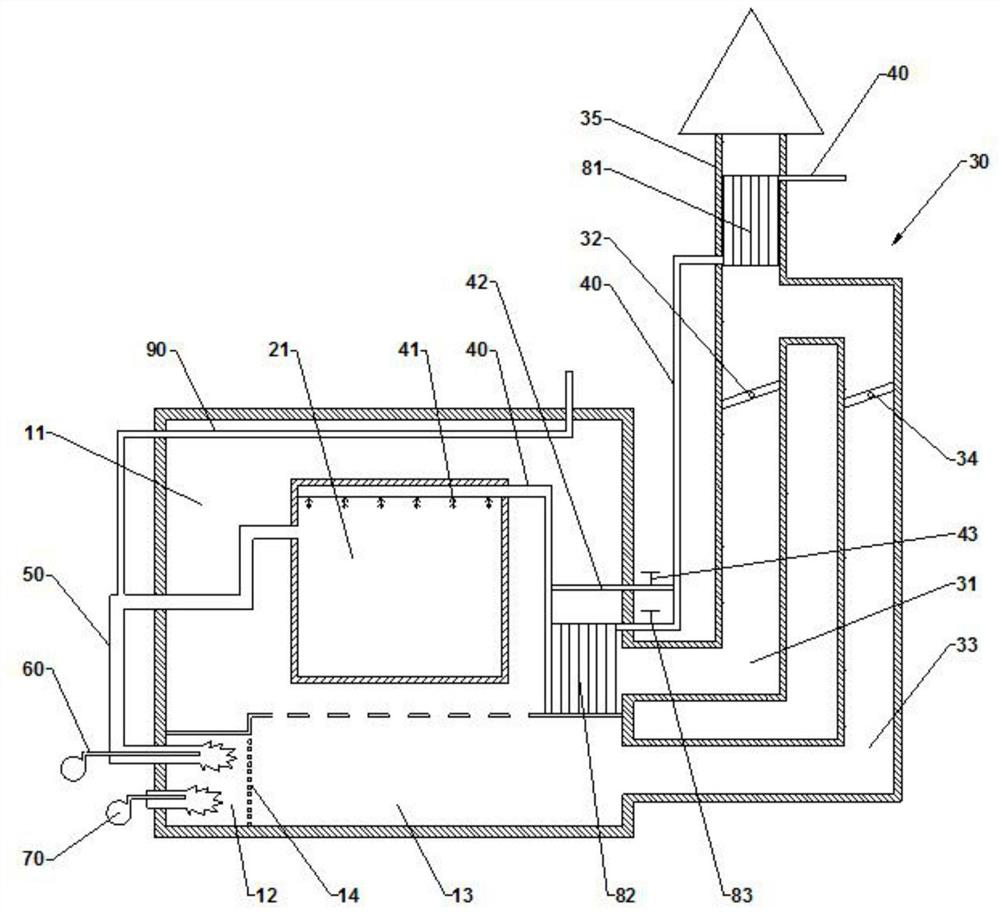

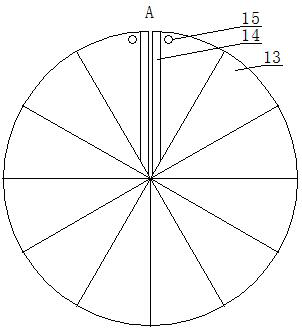

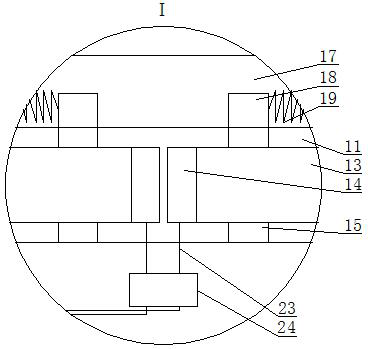

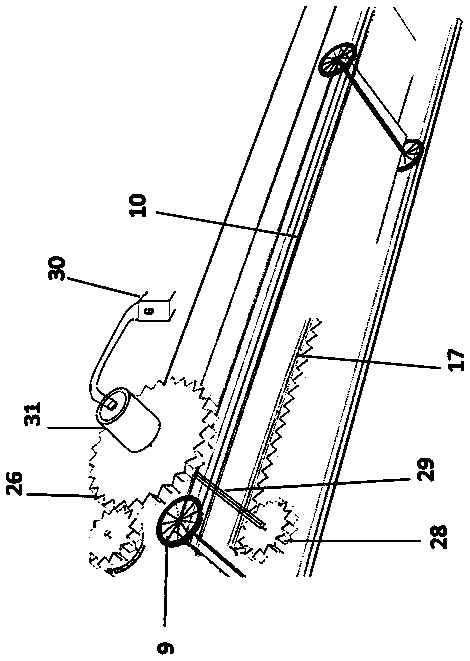

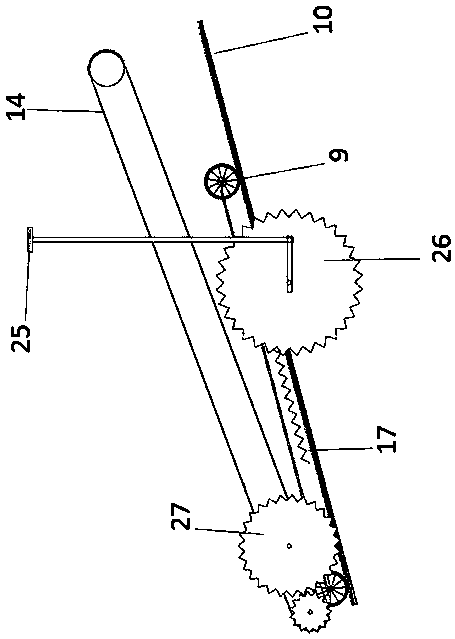

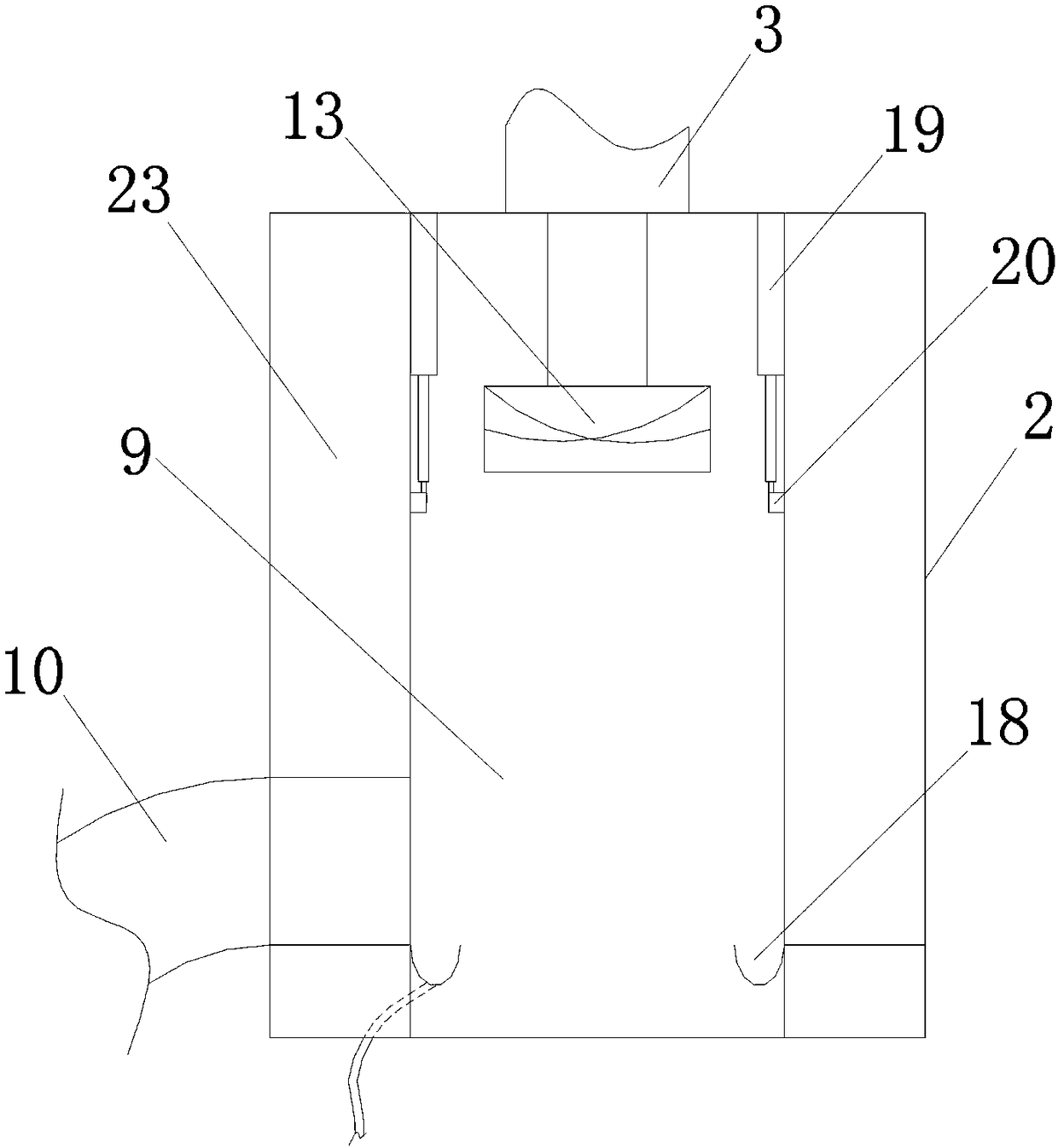

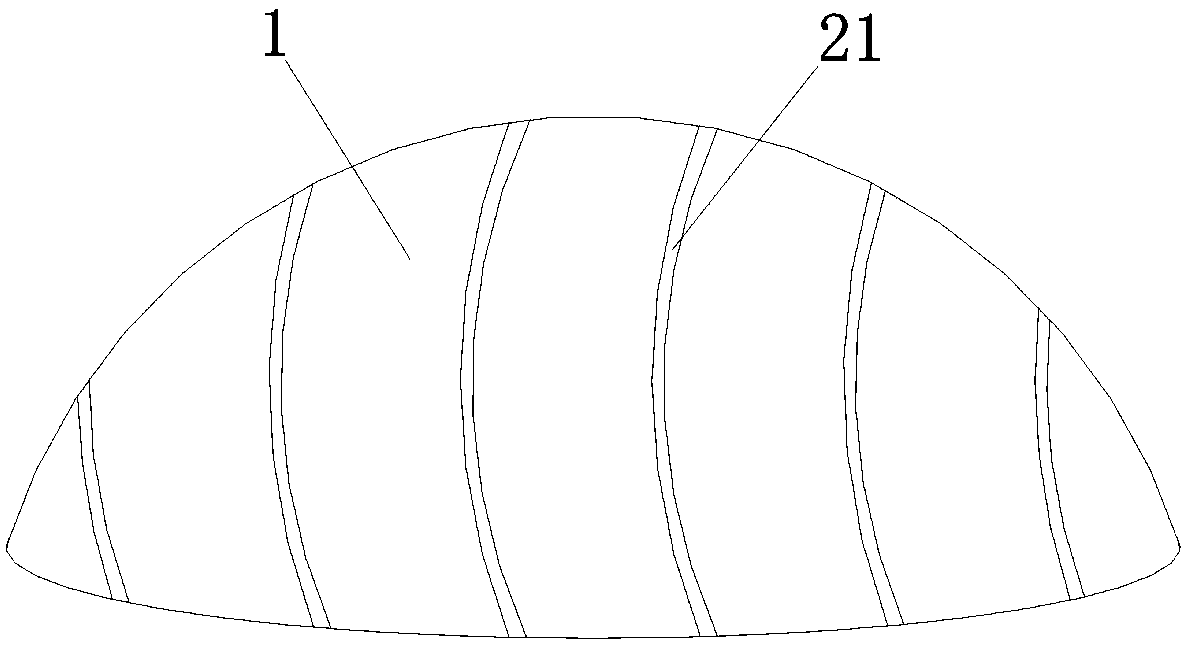

Sludge incineration treatment system

InactiveCN105198185AEmission reductionRealize harmless dischargeSludge treatment by de-watering/drying/thickeningEngineeringTreatment system

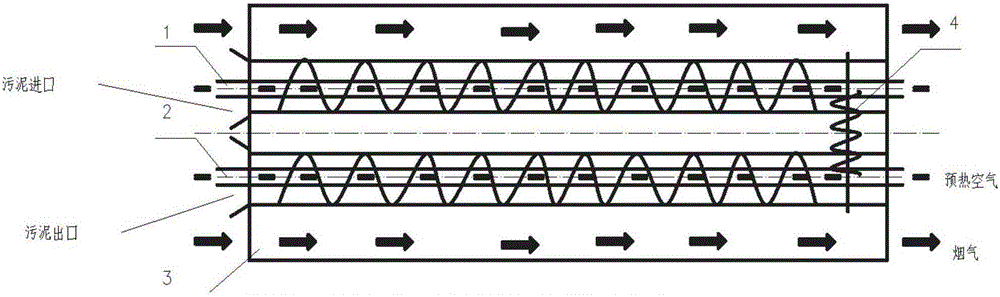

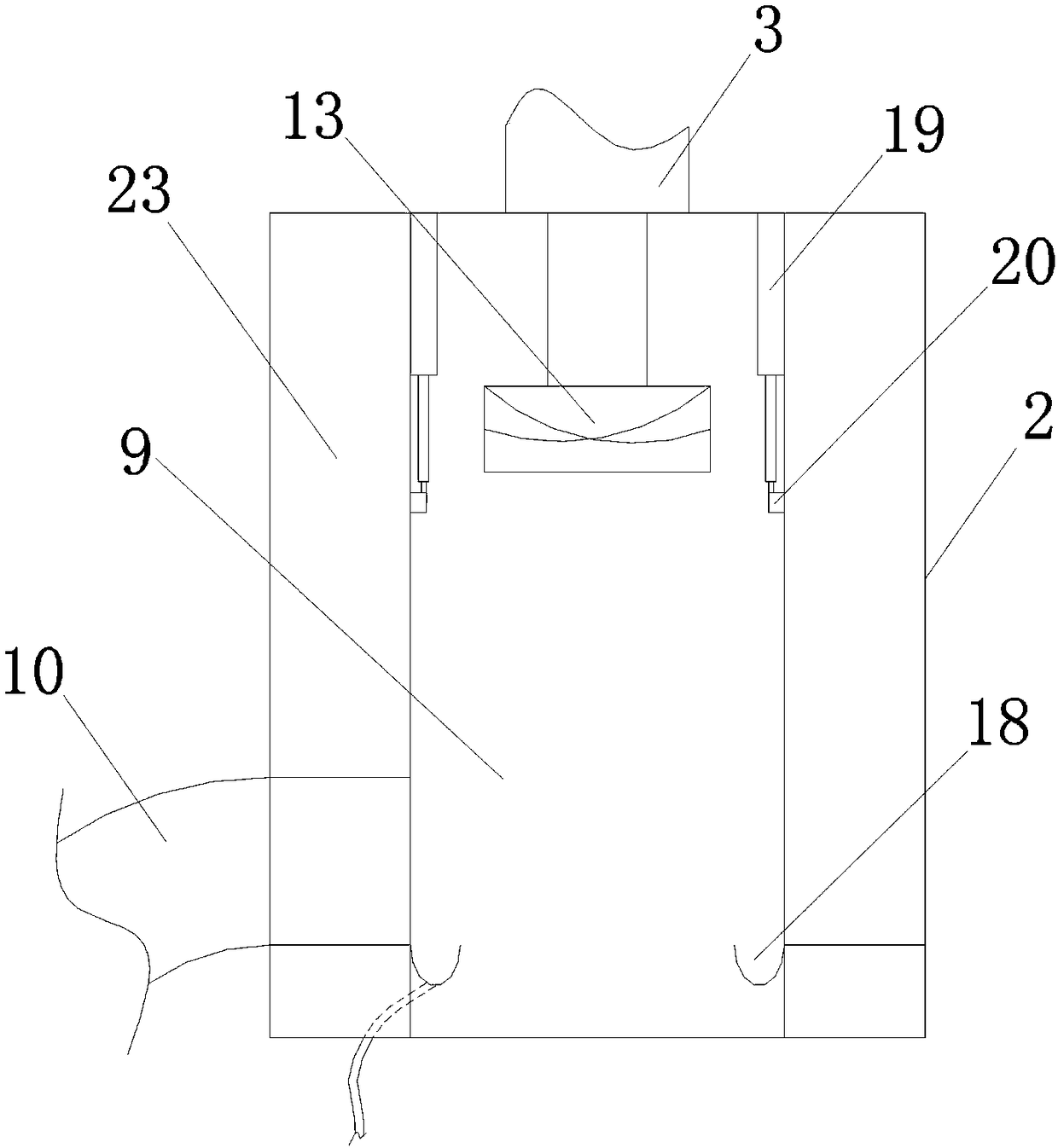

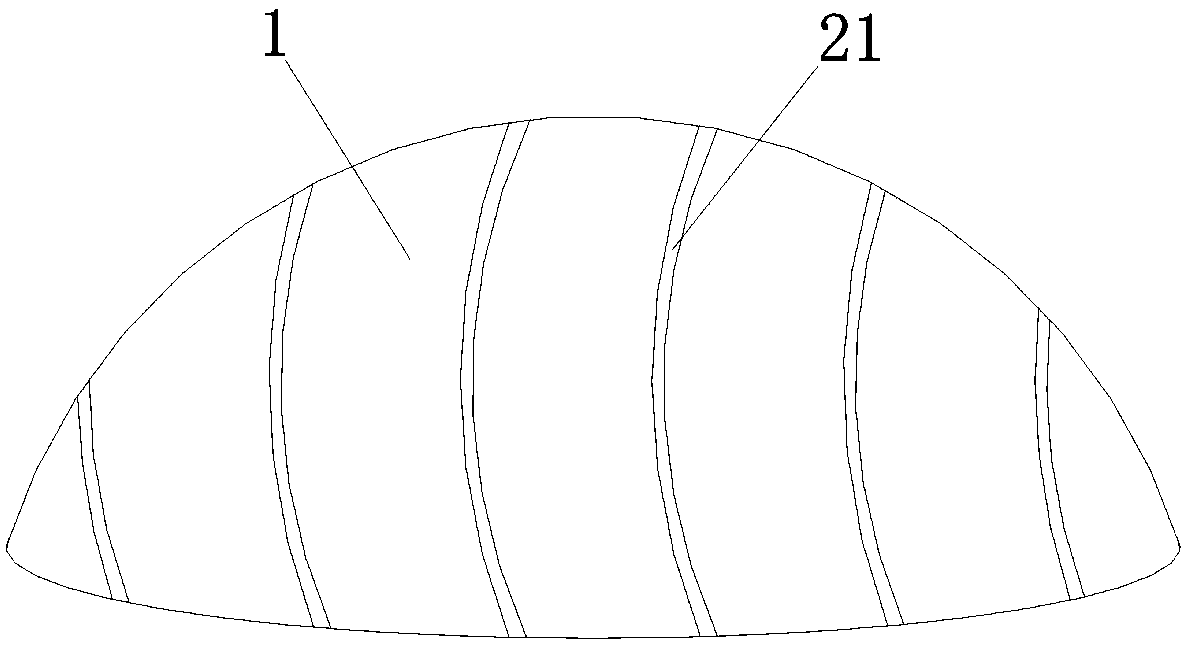

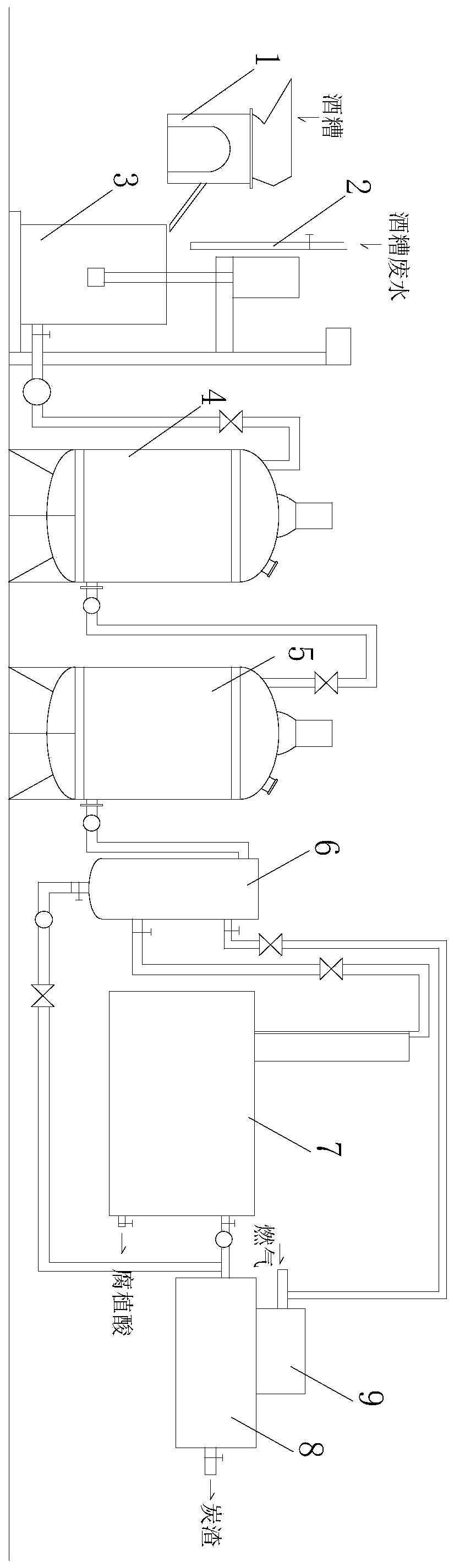

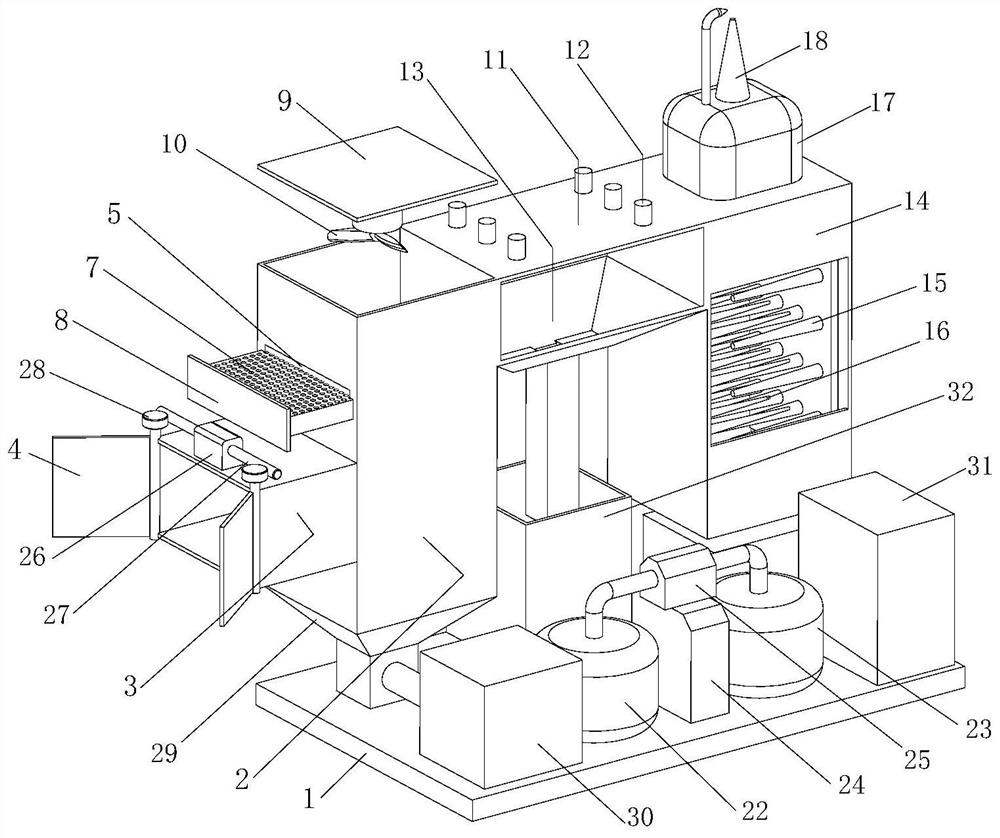

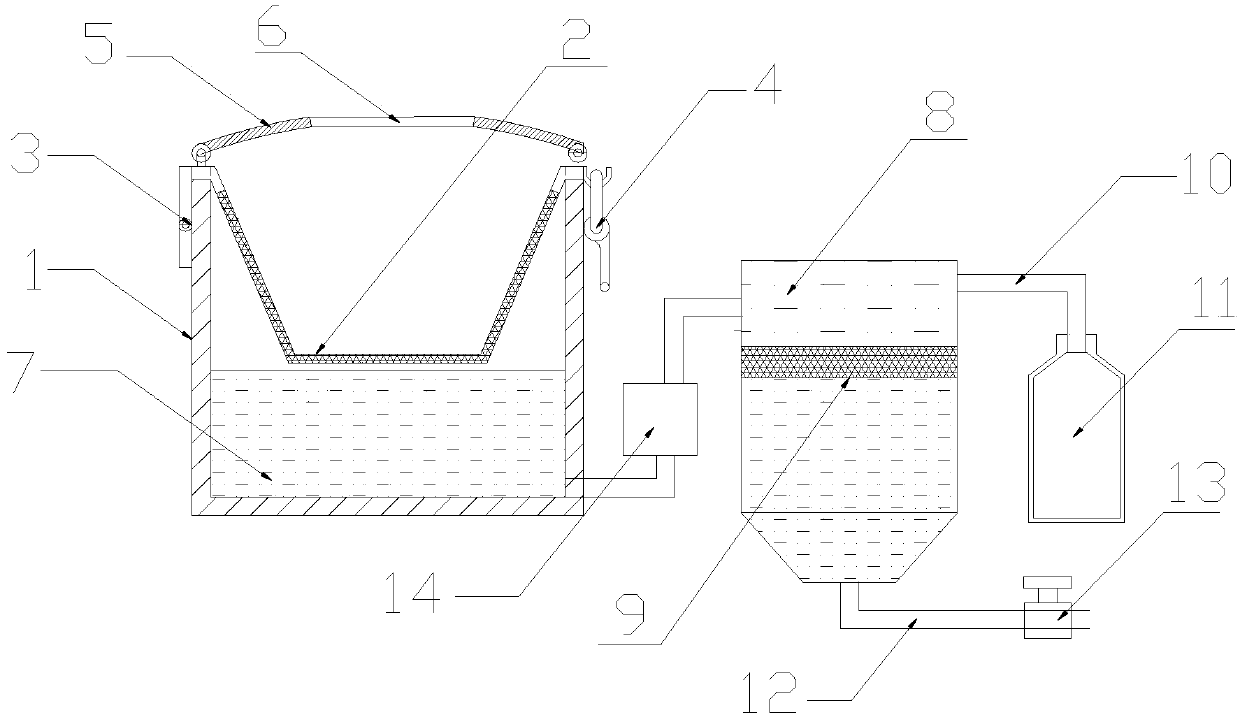

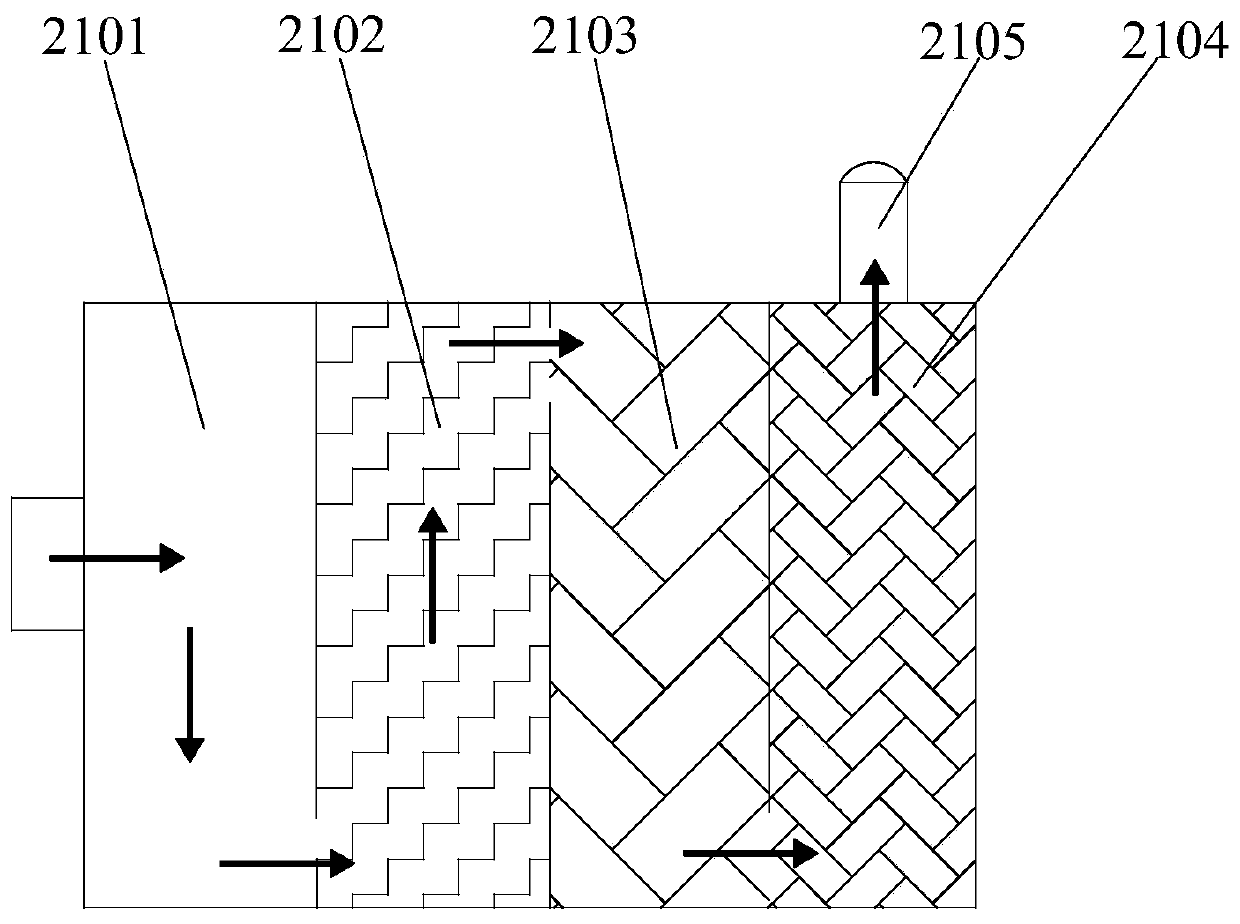

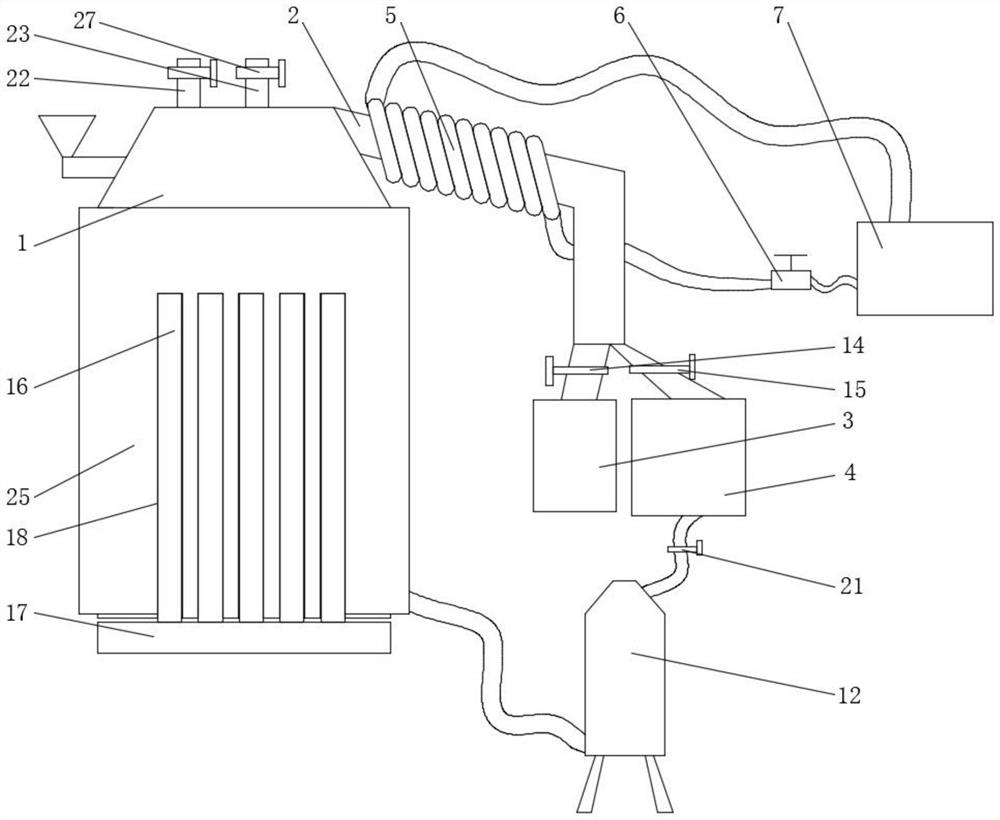

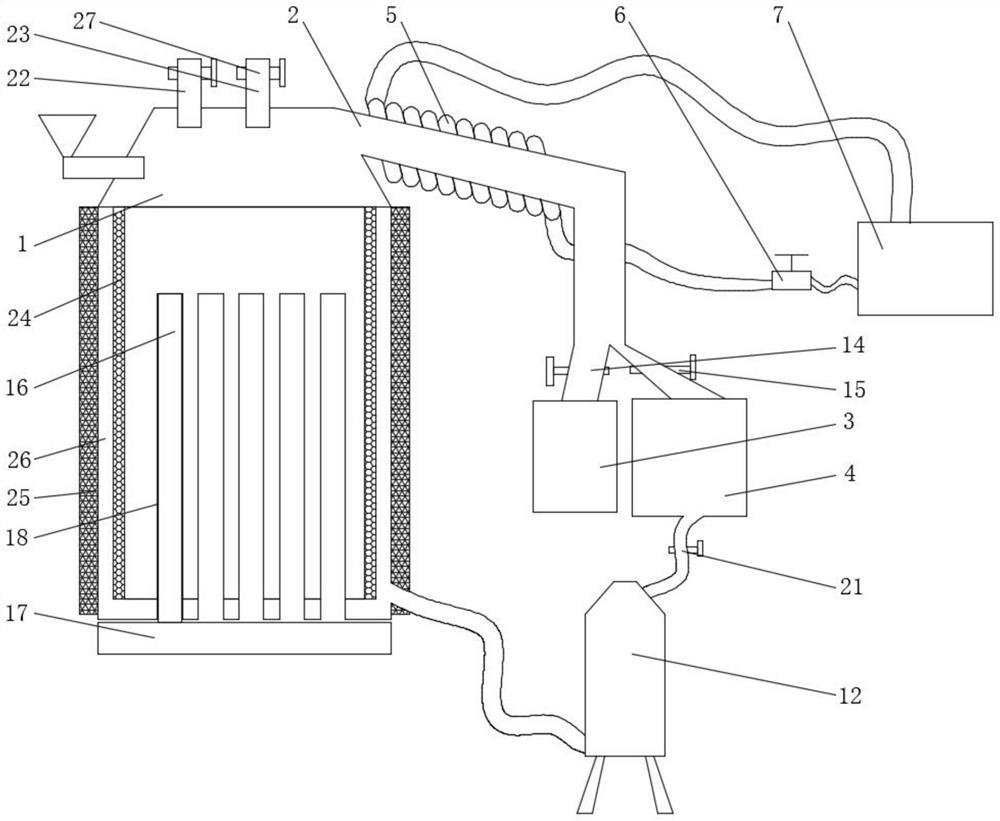

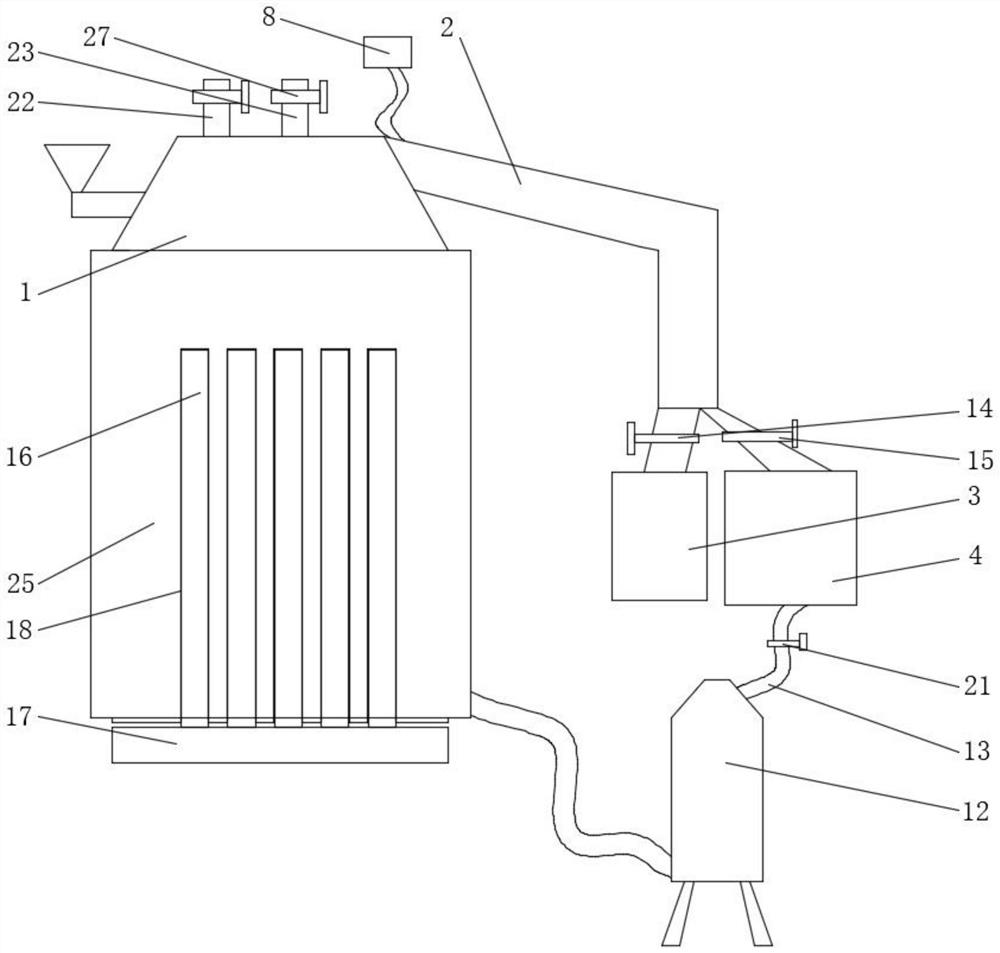

The invention relates to a sludge incineration treatment system which comprises a sludge purification treatment device, a gas-liquid separation device, a tail gas purification device, a drying device, a blower and an induced draft fan. The sludge incineration treatment system is characterized in that the drying device and the tail gas purification device respectively comprise an inner layer and an outer layer, smoke generated by the sludge purification treatment device enters the outer layer of the drying device, so as to indirectly dry sludge, and the smoke which enters the outer layer of the drying device enters the outer layer of the tail gas purification device from an outlet of the outer layer of the drying device; hot air generated by the sludge purification treatment device enters the inner layer of the tail gas purification device for preheating, preheated air enters the inner layer of the drying device from an outlet of the inner layer of the tail gas purification device, so as to directly dry the sludge, and the preheated air enters the gas-liquid separation device from an outlet of the inner layer of the drying device and is blown in the sludge purification treatment device by the blower for burning.

Owner:WEIMING BIOLOGY ENVIRONMENT TECH GRP

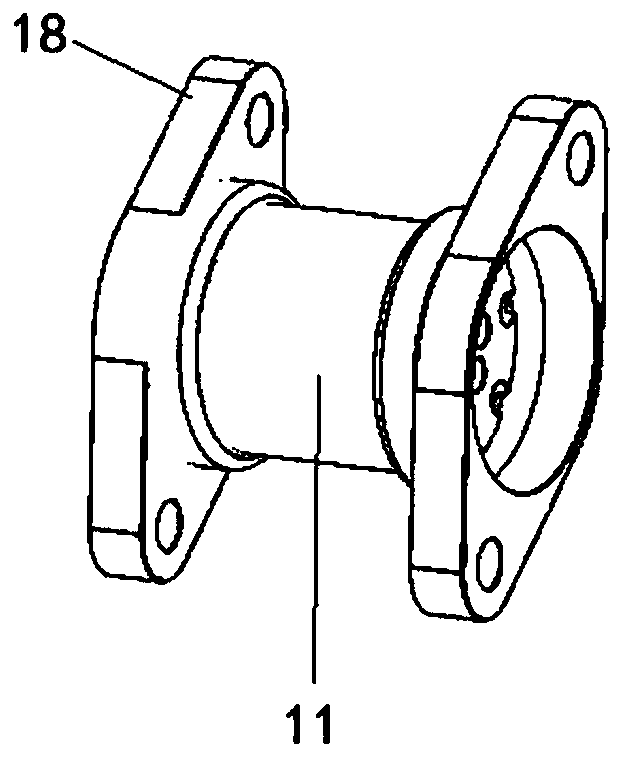

High temperature high pressure acoustic emission electrochemistry simulation experiment apparatus capable of loading stress

InactiveCN103226091AConvenient researchAffect accuracyMaterial analysis using acoustic emission techniquesWeather/light/corrosion resistanceAcoustic emissionEngineering

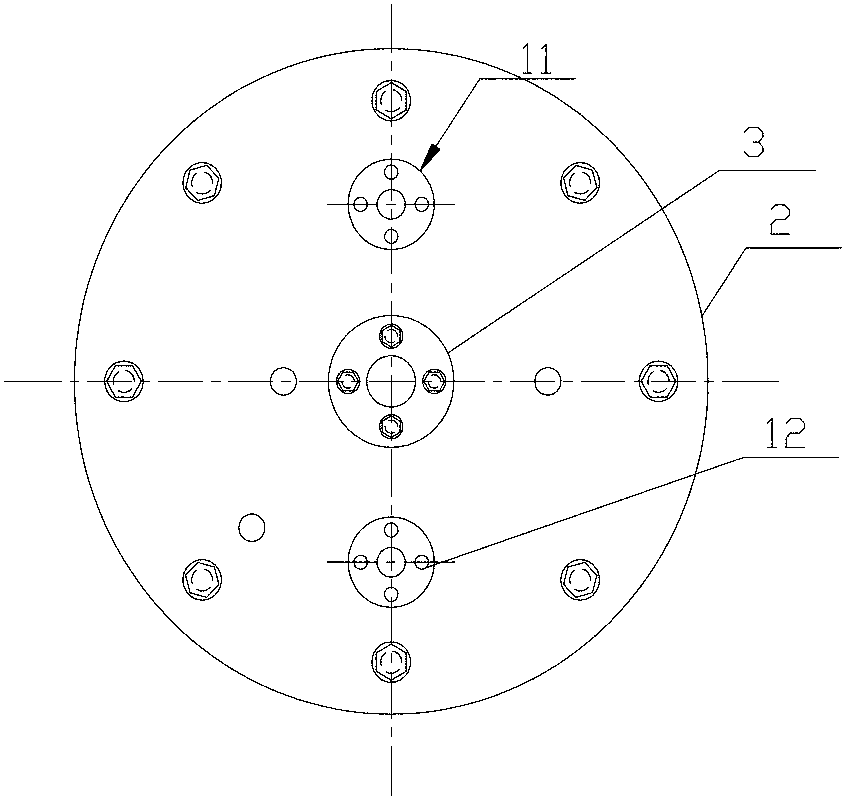

The invention provides a high temperature high pressure acoustic emission electrochemistry simulation experiment apparatus capable of loading stress. The apparatus comprises: a pressure kettle, wherein the pressure kettle is provided with an inner cavity, and a specimen is arranged inside the inner cavity; stretching test systems installed on both ends of the specimen, wherein the tension test system stretches the specimen, tests and obtains tension and a strain signal of the specimen; a solution circulation inflation system connected with the inner cavity of the pressure kettle and provided for providing a solution required by an experiment for the pressure kettle; acoustic emission probes arranged on both ends of the specimen and provided for testing an acoustic signal of the specimen; an electrochemistry test system connected with the specimen and the pressure kettle, and provided for applying polarization current on the specimen to carry out polarization, testing and obtaining an electrochemistry signal; and a data collector for collecting the simultaneously measured strain signal, the electrochemistry signal and the acoustic emission signal. With the present invention, controllable pressurizing, controllable heating and controllable inflation can be performed, and an actual working condition of the on-site material is well simulated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Integrated kitchen of offshore platform

ActiveCN104481173AStandardized processingOrderly and efficient diningSpecial buildingSmall buildingsFiltrationProgrammable logic controller

The invention relates to an integrated kitchen of an offshore platform. The integrated kitchen of the offshore platform comprises kitchen electric devices, an electric system, an exhaust system, a water supply and drainage system and an illuminating system. The layout of each electric device, a working table and a cleaning pool of the kitchen is divided to a plurality of function areas according to the function, each electric device, the exhaust system and the illuminating system in the kitchen are integrally controlled by a programmable logic controller (PLC), the cooking fume of the kitchen is discharged after processed by a smoke purification device, the kitchen wastewater is discharged before the oil-water separation or multiple filtration treatment, and the garbage of the kitchen is processed by a garbage processing device. The integrated kitchen is capable of standardizing the typical layout and standard configuration of the integrated kitchen of the offshore platform, finally forming an advanced, systematic and effective technical manual of the integrated kitchen of the offshore platform, and filling up the domestic blank.

Owner:CNOOC ENERGY TECH & SERVICES

Recycling method of aluminum ash

The invention discloses a recycling method of aluminum ash. The recycling method includes: grinding industrial secondary aluminum ash for 0.5-5h, and sieving with a 40-mesh screen to obtain aluminum ash micropowder; well mixing, by weight, 25-65 parts of aluminum ash micropowder, 20-35 parts of SiO2, 10-30 parts of CaO, 4-12 parts of TiO2, 5-12 parts of MgO and 0-5 parts of colorant; and putting in a melting furnace for melting treatment to obtain melt after melting; pouring the melt into a die, cooling-molding to obtain a glassy-state block, and thermally treating the glassy-state block to obtain a microcrystalline glass material. By the recycling method, the microcrystalline glass material stable in structure can be made of the aluminum ash, so that the defect of being prone to generating toxic and harmful volatile matters when existing wet methods are used to extract useful ingredients in the aluminum ash is overcome effectively, and harmless treatment and recycling of the aluminumash are realized.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Method for treating wastewater after ore leaching and ore closing of ionic rare earth ore

InactiveCN112456620ARealize harmless dischargeEnable recyclingCalcium/strontium/barium chloridesWater contaminantsAluminium chlorideMining engineering

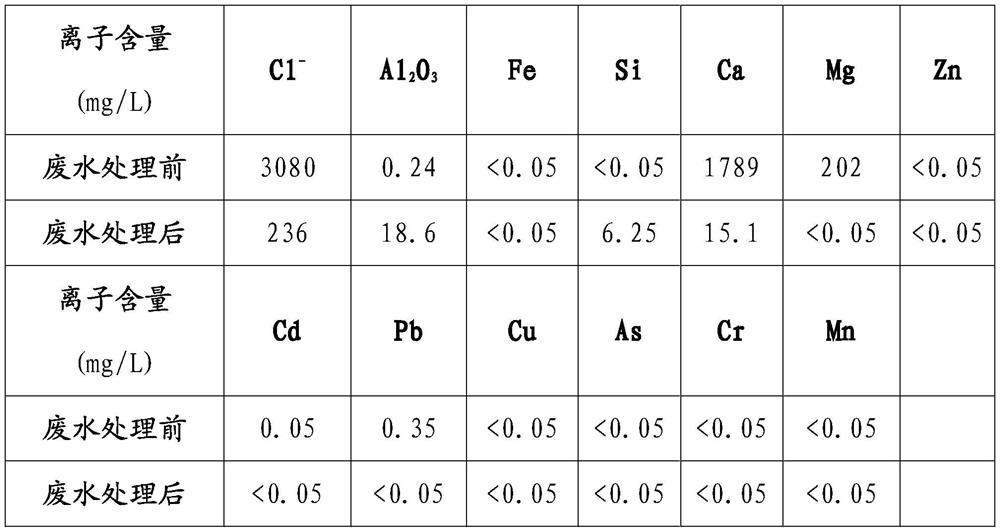

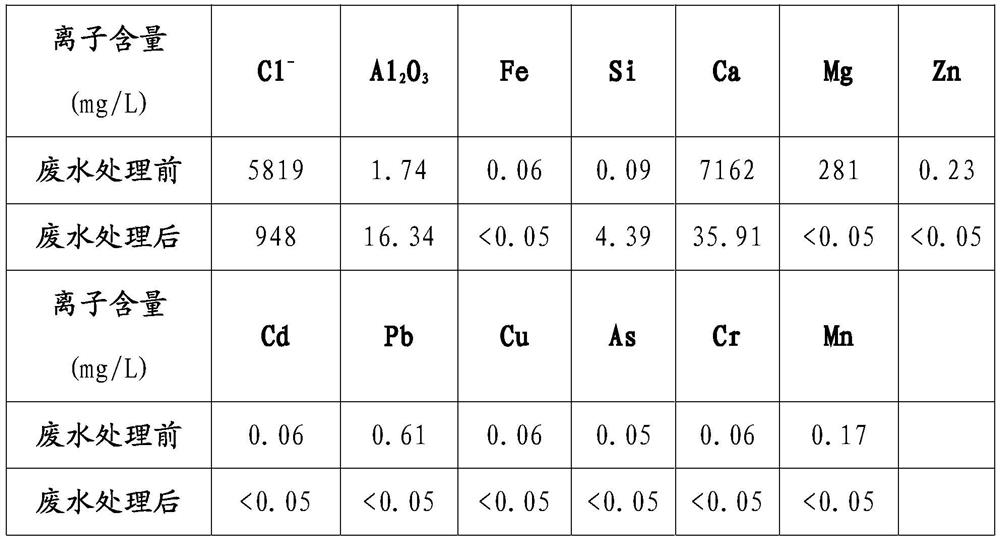

The invention discloses a method for treating wastewater after ore leaching and ore closing of ionic rare earth ores. The method comprises the following steps: S1, taking ore leaching tail liquid, precipitation supernatant and product water washing liquid generated in an ore leaching process of ionic rare earth ores as raw materials, and determining the concentrations of rare earth ions, chlorineions, calcium ions and aluminum ions and the concentrations of other non-rare earth ions and heavy metal ions in the wastewater; S2, adding lime and sodium metaaluminate into the wastewater until themass ratio of Ca<2+> to Al<3+> to Cl<-> in the wastewater is (9-12):(1.5-2):1, stirring for reaction, and filtering; and S3, filtering to obtain a Fremys salt precipitate, and decomposing with hydrochloric acid to obtain a solution containing calcium chloride and aluminum chloride. According to the method, calcium salt, aluminum salt and chlorine ions in closed ore waste water are converted into Fremys salts to achieve recycling of an ore leaching agent while the content of the chlorine ions and the content of heavy metal Zn, Cd, Pb, Cu, As, Cr and Mn in the wastewater are reduced to achieve the harmless discharge of the wastewater, and the mining area environment influence after ore closing is small, so that efficient and environment-friendly extraction of ionic rare earth can be achieved.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD +2

Supercritical water oxidation treatment system for high-salt high-chlorine organic wastewater

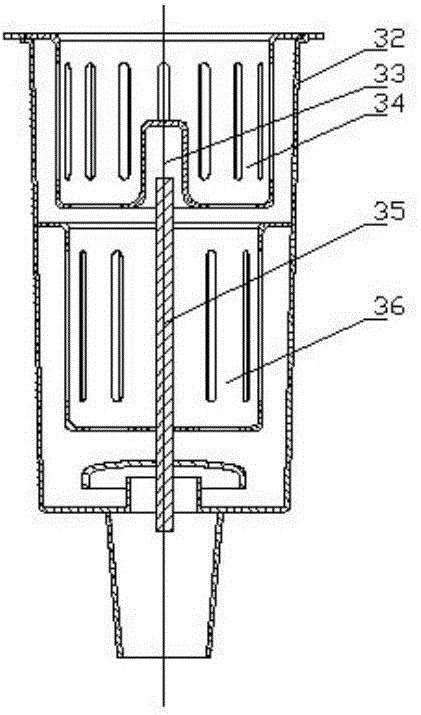

InactiveCN102249461BPrevent jam frequencyJam frequency avoidanceWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSolubilityCyclone

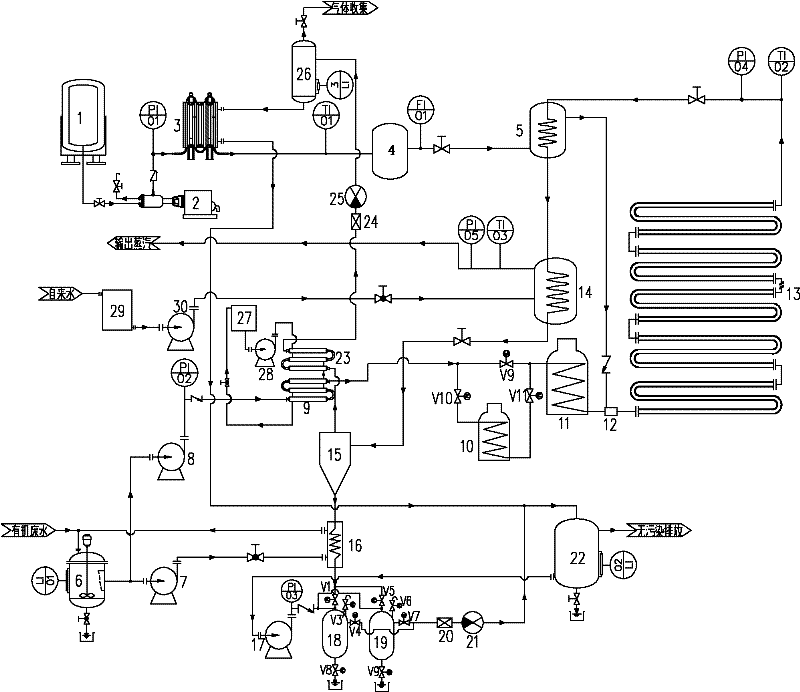

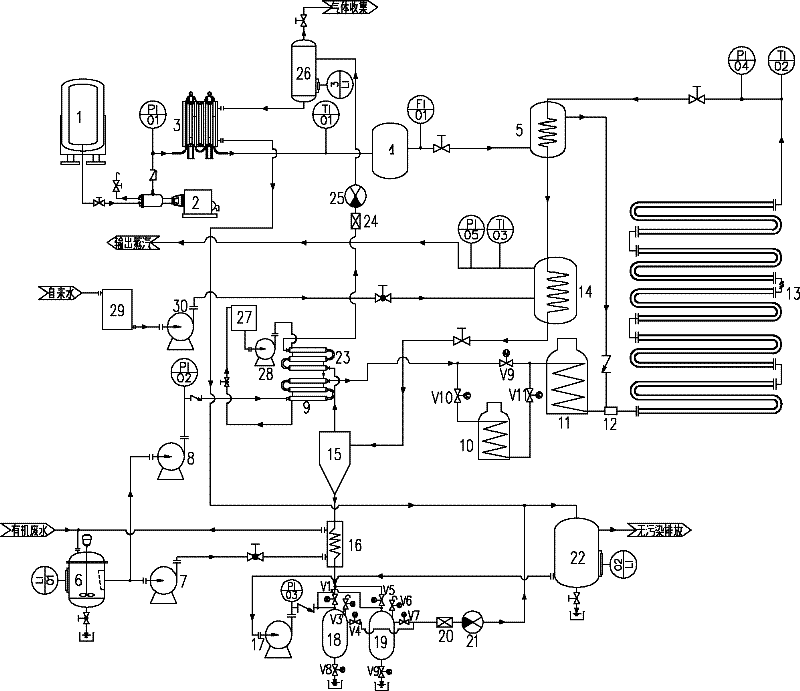

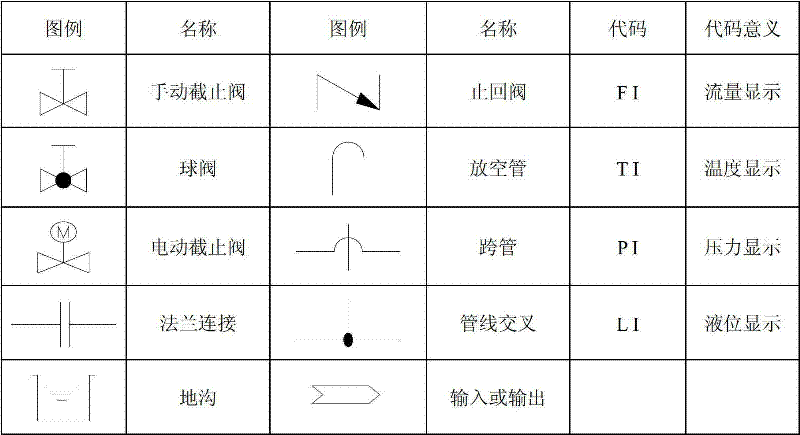

The invention discloses a supercritical water oxidation treatment system for high-salt high-chlorine organic wastewater. Heat of reacted fluid is partially recovered by a second heat exchanger to preheat feedstock, and the heat of fluid passing through a reactor is recovered by steam generated by a steam generator, so that the system investment and operating cost are effectively reduced; a hydraulic cyclone, a first salt storage tank, a second salt storage tank, first and second pipeline filters and a high pressure filling pump are arranged, the pressure reduction requirement of the treatmentsystem can be met, the blockage frequency of the first and second pipeline filters is reduced, and insoluble salt can be continuously removed and discharged; meanwhile, the flow rate of the fluid in the system is controlled to be 1-2m / s, the deposition and blockage of the insoluble salt and soluble salt separated out under the supercritical water condition are further effectively reduced. In addition, equipment and conveying pipelines, which are contacted with the high-salt high-chlorine organic wastewater in the system, are made of composite tubes, the corrosion of the system can be effectively reduced and the equipment investment cost is reduced.

Owner:XI AN JIAOTONG UNIV +1

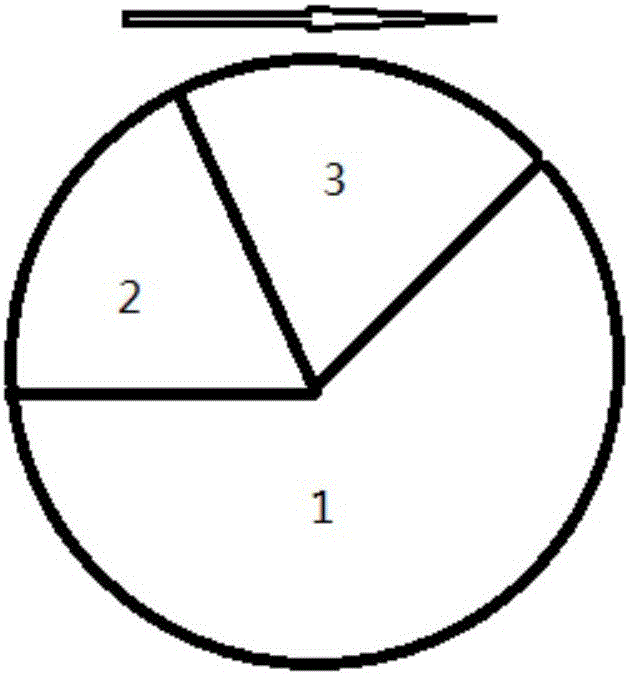

Method for treating organic waste gases by utilizing rotary wheel

InactiveCN105833720ALow costAchieve degradationGas treatmentDispersed particle separationFiberSorbent

The invention discloses a method for treating organic waste gas by using a runner, comprising: step 1, a runner loaded with an adsorbent and a catalyst contacts and adsorbs the organic waste gas; step 2, applies high-temperature gas to the adsorbed runner, and Under the action of the catalyst, the attachment on the adsorbent is oxidized and decomposed; step 3, applying room temperature or low temperature gas to the runner after oxidative decomposition of organic matter to cool down; step 4, repeating steps 1 to 3 to complete the treatment of organic waste gas. The runner uses ceramic fiber or polymer fiber as a base material to make a support layer, and the surface of the support layer is coated with the adsorbent and catalyst. The invention realizes the degradation and harmless discharge of organic matter, utilizes the high temperature generated by the catalytic reaction to effectively remove some difficult-to-desorb substances in the adsorbent, and regenerates the adsorbent on the runner well.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Method for dehydrating viscous waste by vacuum coupled physicochemical strengthening and device

InactiveCN109678319AStrong water absorptionImprove dehydration abilitySludge treatment by de-watering/drying/thickeningWater contaminantsBound waterPhosphoric acid

The invention discloses a method for dehydrating viscous waste by vacuum coupled physicochemical strengthening. The method comprises steps as follows: the viscous waste is prepared to form slurry withhigh water content firstly and is kept at certain temperature; phosphoric acid is formed by the aid of added auxiliary materials, and bound water and heavy metals are separated from viscous waste particles by the aid of phosphoric acid; phosphoric acid and the heavy metals are subjected to a reaction, and soluble metal salts are generated; the treated viscous waste is dehydrated by an improved dehydration device, finally, the harmless viscous waste with low water content is obtained, water obtained by dehydration is treated by ion exchange resin, and phosphoric acid is recovered. The problemsof low dehydration efficiency and high heavy metal content of a traditional viscous waste treatment mode are solved; the treated viscous waste can realize harmless discharge and recycling.

Owner:KUNMING UNIV OF SCI & TECH

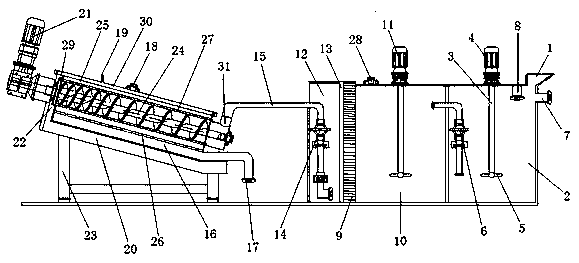

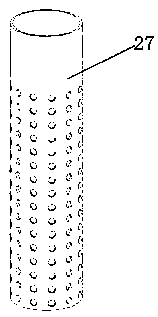

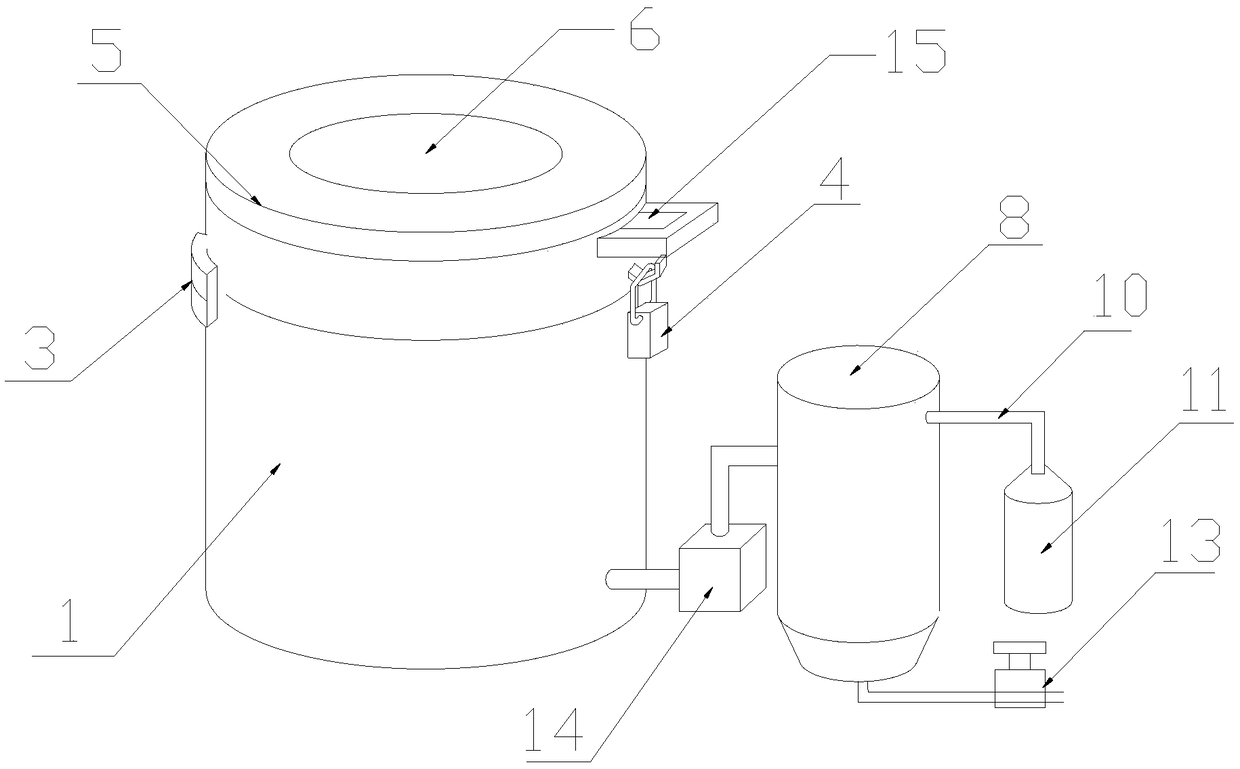

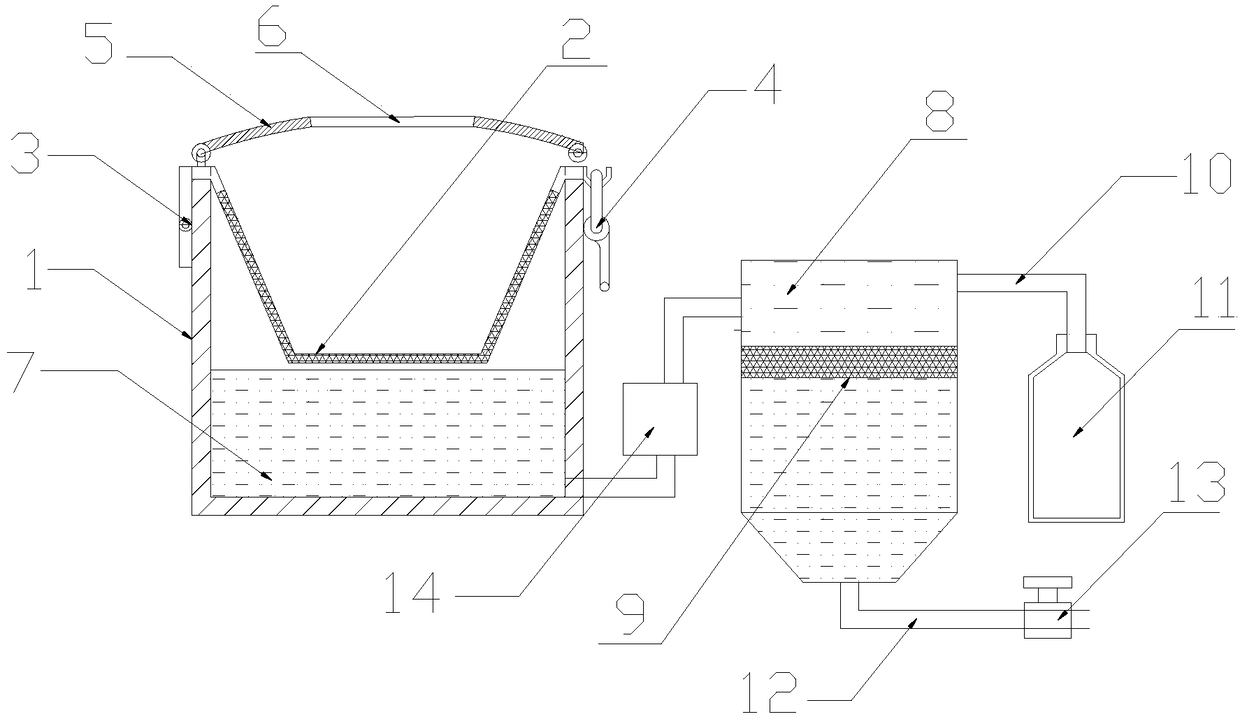

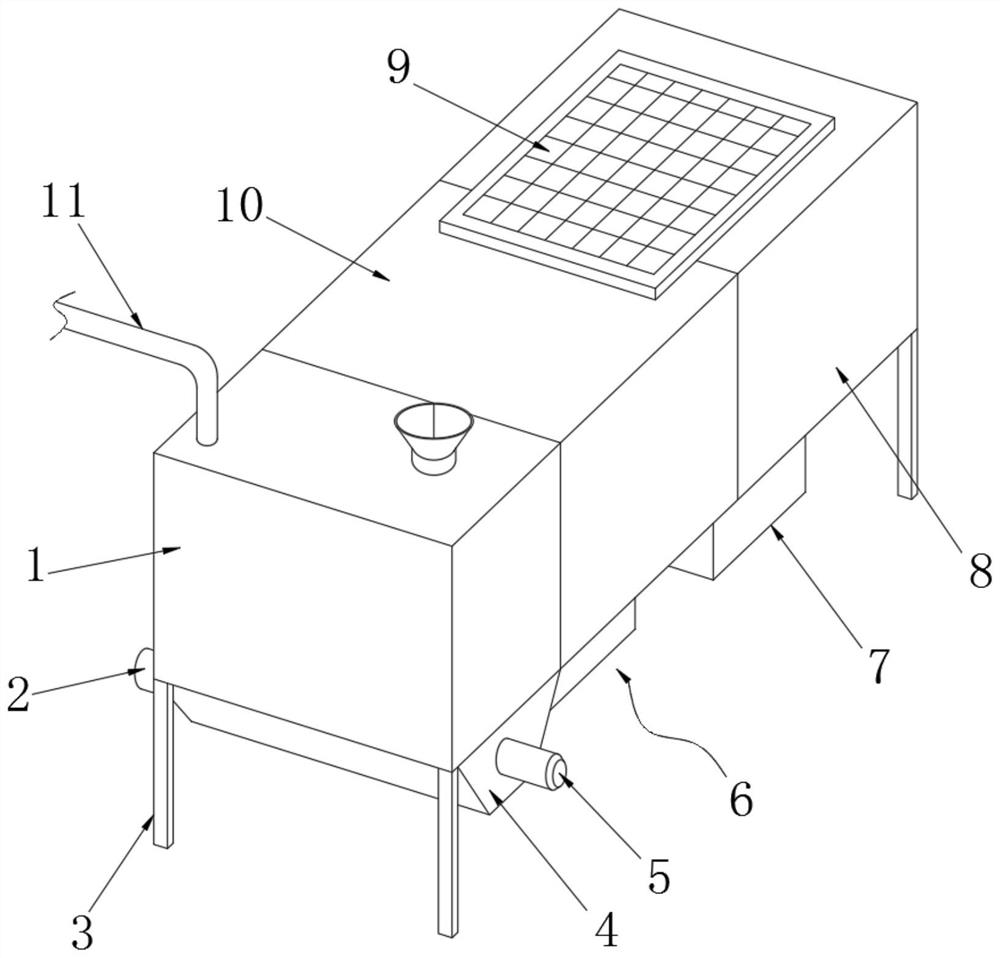

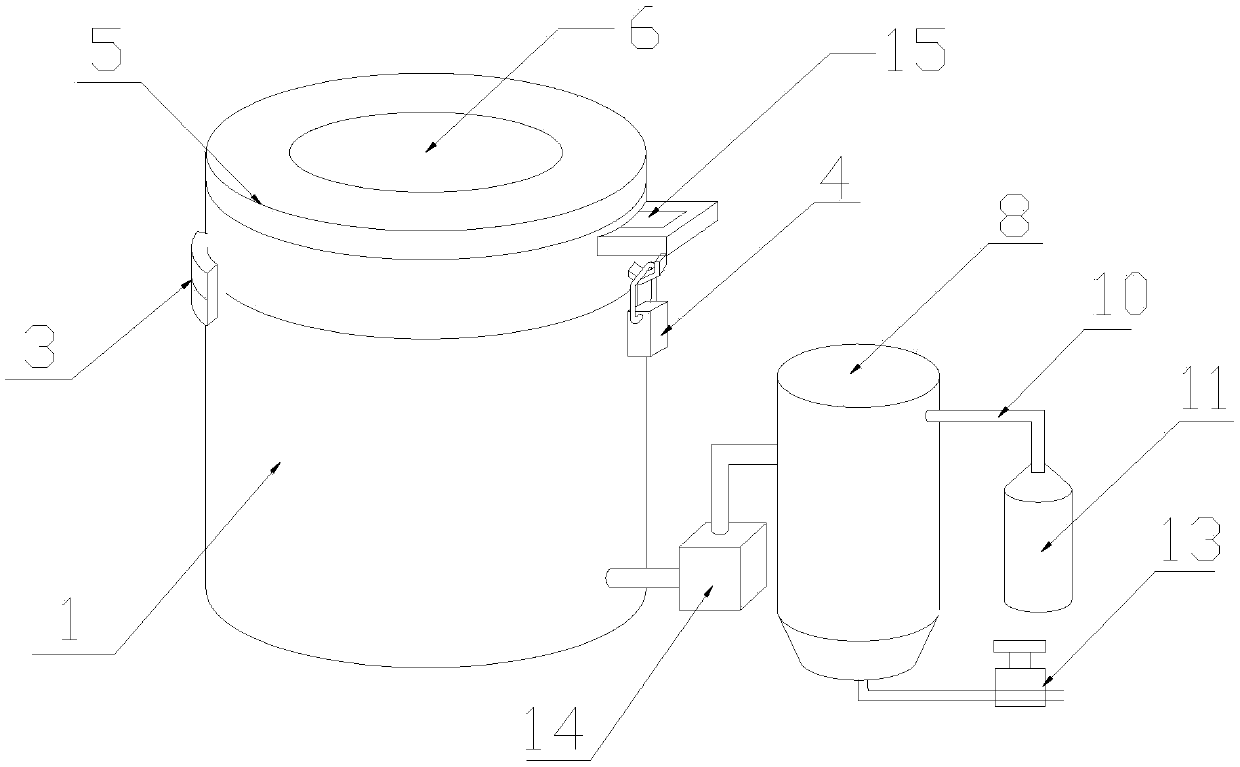

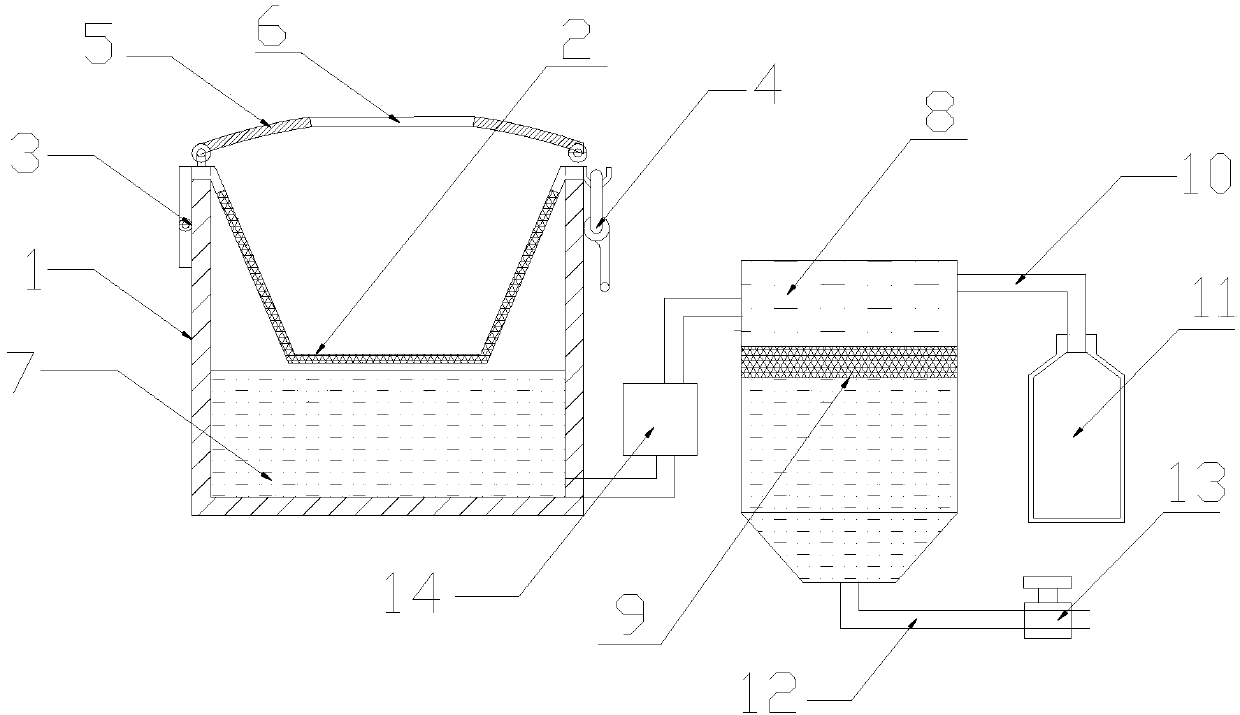

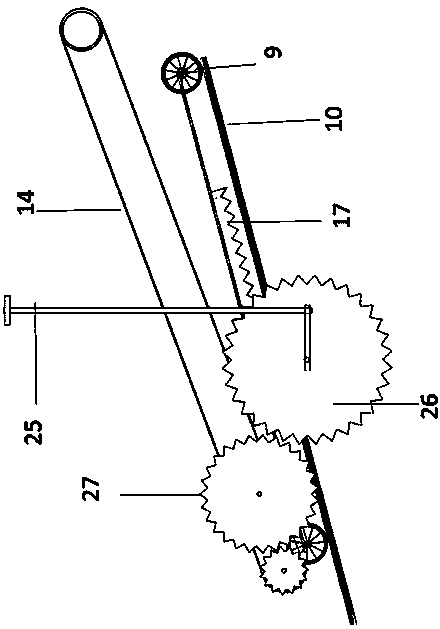

Environment-friendly and energy-saving hogwash separation mechanism

InactiveCN108706758ASolve the problem that the swill cannot be harmlessly treatedRealize harmless dischargeFatty/oily/floating substances removal devicesTreatment involving filtrationWater dischargePulp and paper industry

The invention discloses an environment-friendly and energy-saving hogwash separation mechanism. A cylinder is used as a device main body; the top end of the device main body is connected with a filtering net basket through a hinge and solids and liquid in hogwash are separated; the separated solids are poured into a recycling vehicle to be intensively treated under the overturning of the filteringnet basket; an oil-water mixed solution separated at the bottom end of the device main body is conveyed into an oil-water separation tank; the oil-water separation tank is internally provided with afiltering net layer for further separating oil and water; separated oil at the top end of the oil-water separation tank enters a recycling oil bucket and is stored; separated water is discharged intoa sewer through a water discharging pipe and a valve, so that harmless emission of the hogwash is realized, and the problem that an existing hogwash treatment device in a catering industry cannot be used for carrying out harmless treatment on the hogwash is solved; the environment-friendly and energy-saving hogwash separation mechanism has very good practical value.

Owner:朗瀚智能装备(江苏)有限公司

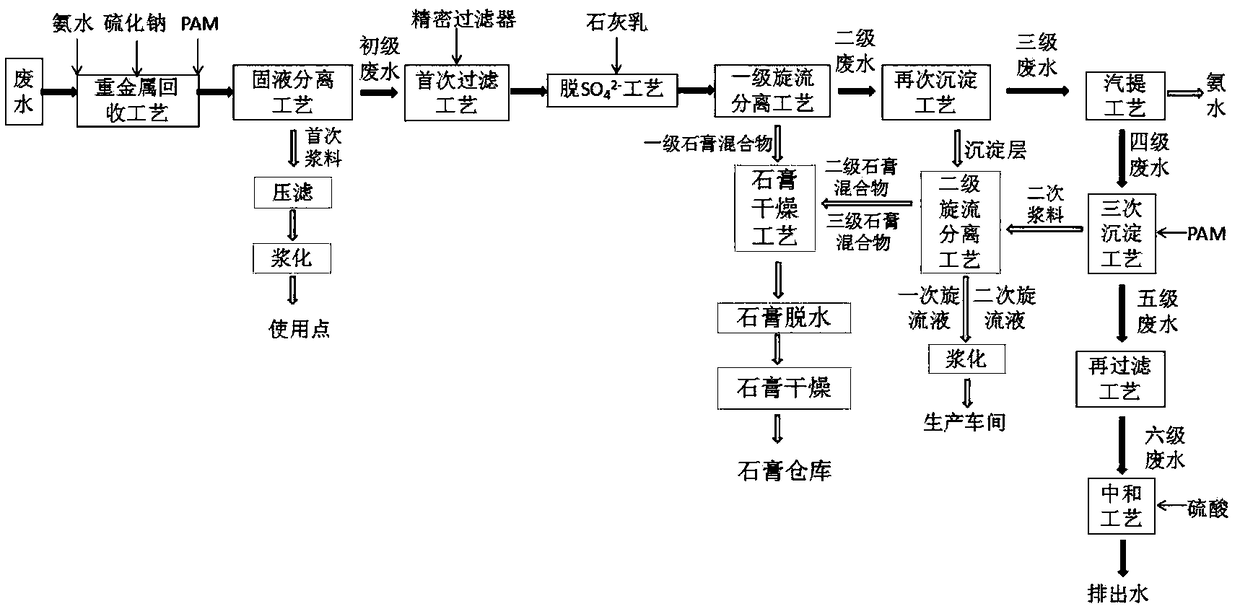

Cyclic treatment process for wastewater containing cobalt-nickel heavy metal ions

InactiveCN108928985AReduce concentrationRealize recyclingWater/sewage treatment by centrifugal separationWater contaminantsFiltrationManganese

The invention provides a cyclic treatment process for wastewater containing cobalt-nickel heavy metal ions, belonging to the field of treatment of heavy metal wastewater. The cyclic treatment processcomprises the following steps: heavy metal recovery; solid-liquid separation; primary filtration; removal of SO4<2->; first-stage cyclone separation; gypsum drying; re-precipitation; stripping; ternary precipitation; re-filtration; and neutralization. According to the invention, ammonia water is used in the replacement of NaOH, so the production cost of enterprises and the salt content of discharged water are reduced; the heavy metals cobalt and nickel are reused; ammonia is recycled; profits are produced as gypsum is sold; and up-to-standard discharge of the wastewater is realized. Since a precision filtration process and other processes are additionally carried out and processes like multiple precipitation and multiple filtration are carried out for deep recovery of heavy metals such ascobalt, nickel and manganese, the discharged wastewater has lower salt content and lower concentration of heavy metal ions, and the recycling of heavy metal ions and the harmless discharge of the wastewater are realized. After treatment of the wastewater with the cyclic treatment process, the concentrations of NH<4+>, Co<2+>, Ni<2+> and SO4<2-> in the wastewater are lower than 27.32 g / L, 55.49 mg / L, 60-65 mg / L and 103.62 g / L, respectively and are reduced to 15 mg / L, 1 mg / L, 1 mg / L and almost zero.

Owner:JINGMEN GEM NEW MATERIAL

Breeding wastewater treatment device

PendingCN114455654AReduce the content of harmful substancesReduce consumptionGeneral water supply conservationWater aerationHazardous substanceEngineering

The invention discloses an aquaculture wastewater treatment device which comprises a settling tank, an aeration tank is mounted on one side of the settling tank, an evaporation tank is fixedly connected to one side of the aeration tank, an aeration stirring mechanism is mounted in the center of the bottom of the aeration tank, a storage battery is mounted on one side of the bottom of the evaporation tank, and a fixing pin is fixedly connected to one side of the bottom surface in the evaporation tank. An electric heating pipe is installed at the top of the fixing pin, a partition plate is arranged in the center of the interior of the evaporation box, and a collecting cover is installed on the upper middle portion of the interior of the evaporation box, the equipment is high in integration degree and small in size, through chemical precipitation, aeration treatment and distillation treatment, the content of harmful substances in waste water is greatly reduced, harmless discharge of the waste water is achieved, and environmental protection is achieved. The solar panel is used for generating power for distillation, so that the energy consumption is reduced, and the aeration stirring mechanism is mounted, so that continuous stirring of the stirring rod and the stirring shaft is realized while aeration is performed, and the aeration efficiency is favorably improved.

Owner:益阳创辉农业机械装备有限公司

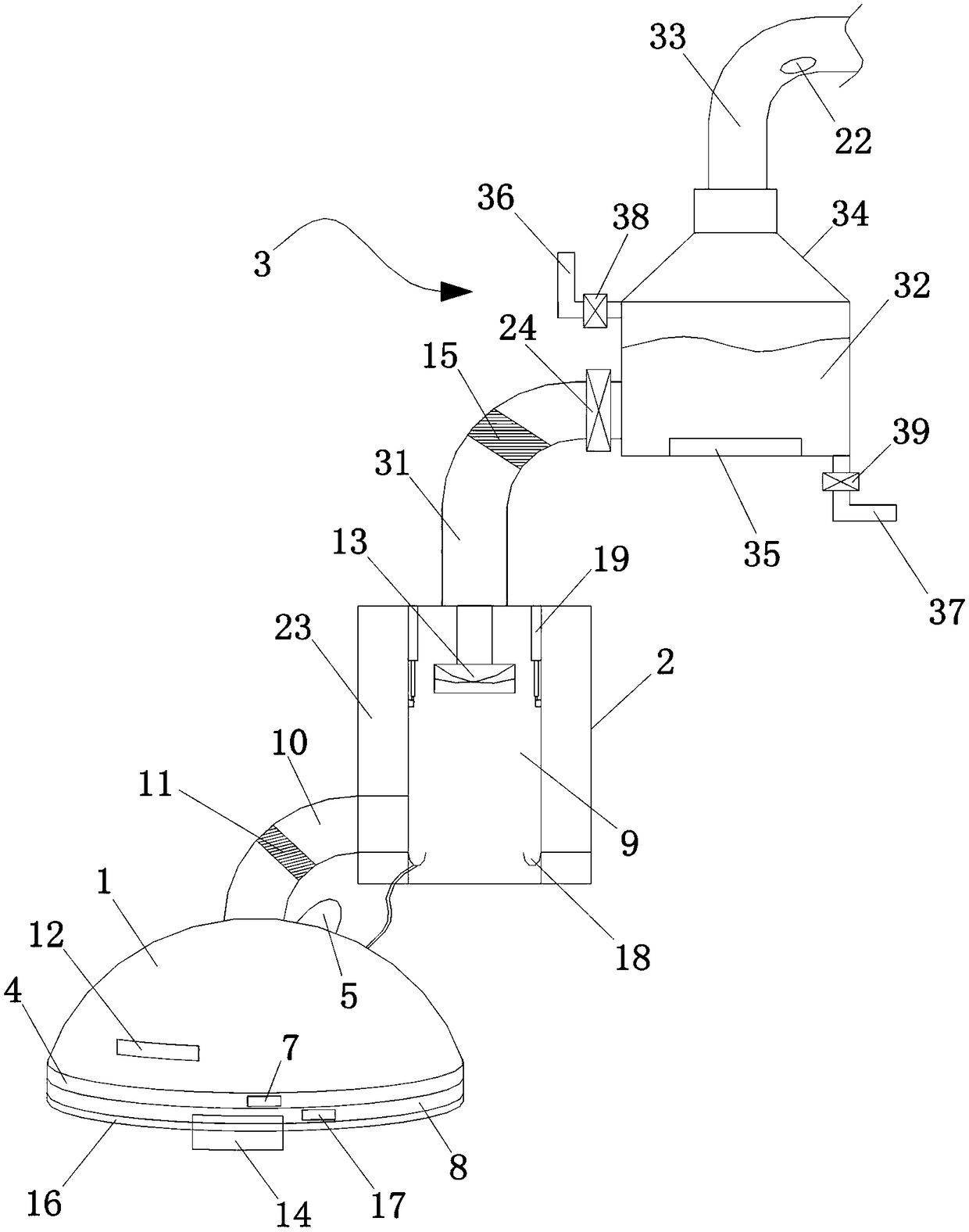

Harmless discharge range hood

InactiveCN108344013AEasy to cleanEfficient collectionDomestic stoves or rangesLighting and heating apparatusDischarge efficiencyElectromagnetic valve

The invention discloses a harmless discharge range hood. The problems that in the prior art, oil fume dirt is liable to adhere to the inner walls of oil fume separation pipes, then the waste discharging efficiency is lowered, oil fume mixtures coagulate on oil fume suction hoods, cleaning is troublesome, and discharged waste gas contains fume and pollutes the atmosphere environment are solved. Theharmless discharge range hood comprises an oil fume suction hood body, an oil fume separation box body, a waste gas discharging device, a flange, a microprocessor, an audible and visual alarm, a smoke concentration sensor, a flange oil collection groove, an oil fume extraction pipe, an oil fume separation pipe, a negative pressure fan, an oil fume separation fan, an electric push rod, an oil pushing tool, a separation pipe oil collection groove, a waste oil collection box, a first waste gas discharging pipe, a purification pool, a second waste gas discharging pipe, a purification pool cover,a water inlet and outlet pipe and a water inlet and outlet electromagnetic valve. Oil fume dirt on the inner wall of the oil fume separation pipe can be effectively removed, little oil fume mixtures coagulated on the bottom face of the oil fume suction hood can be collected, the operation intensity of users is relieved, meanwhile, discharged waste gas can be completely purified, and waste gas harmless discharging is achieved.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

Harmless resourceful treatment system for vinasse waste and method for producing humic acid

PendingCN110394357AImprove economySolve the problem of environmental pollutionSolid waste disposalHumic acidEngineering

The invention discloses a harmless resourceful treatment system for vinasse waste. The system comprises a vinasse waste conveyer belt, a vinasse waste delivery pipe and a treatment device, wherein thetreatment device consists of a crusher, a homogenizer, an anaerobic fermentation tank, an aerobic fermentation tank, a multiphase separator, an extraction and separation device and a carbonization device; the homogenizer is used for delivering the mixed and emulsified materials to the anaerobic fermentation tank through a connection pipe; the liquid outlet of the aerobic fermentation tank is communicated with the feeding port of the multiphase separator through a connection pipe; and intermediate carbon generated by the extraction and separation device via extraction is delivered into the carbonization device through a connection pipe. Compared with the prior art, the system carries out harmless treatment and resourceful utilization on the vinasse waste in the wineries, thereby thoroughlyrealizing harmless discharging of the vinasse waste after the treatment and discharging no harmful substances in the treatment process. According to the system, the sludge is recycled to produce high-value humic acid products and biochar raw materials, thereby greatly improving the economy and solving the environment pollution problems of the sludge factories.

Owner:SI CHUAN RUI YUAN ENERGY & ENVIRONMENT TECH

Treatment method of methyl mercaptan odor

InactiveCN110681253AAvoid secondary pollutionAchieve emissionsGas treatmentDispersed particle separationEnvironmental chemistrySodium hydroxide

The invention discloses a method for treating methyl mercaptan odor. The method comprises the following steps: chlorine dioxide oxidation reaction, liquid separation treatment, UV efficient photolysispurification reaction, ultraviolet synergistic chlorine dioxide advanced oxidation reaction and sodium hydroxide chemical absorption reaction. The method has the advantages that through the chlorinedioxide oxidation reaction, the UV efficient photolysis purification reaction and the ultraviolet synergistic chlorine dioxide advanced oxidation reaction, namely a series of reactions, the methyl mercaptan odor can be thoroughly removed; the sodium hydroxide chemical absorption reaction can be used for absorbing other harmful gases generated in the process of removing the methyl mercaptan odor, so that the secondary pollution can be avoided, and finally, the harmless emission can be realized.

Owner:江苏绿塔环境工程有限公司

Industrial harmful waste gas treatment and recovery equipment based on atmospheric pollution prevention and control

PendingCN111715060ANo secondary pollutionEasy to handleHuman health protectionGas treatmentEnvironmental engineeringAtmospheric pollution

The invention discloses industrial harmful waste gas treatment and recovery equipment based on atmospheric pollution control, and belongs to the field of industrial harmful waste gas treatment. The industrial harmful waste gas treatment and recovery equipment based on atmospheric pollution control comprises an equipment bottom plate, a dust treatment cavity, a washing cavity and a low-temperatureplasma cavity, wherein the dust treatment cavity, the washing cavity and the low-temperature plasma cavity are fixedly mounted on the top surface of the equipment bottom plate in sequence from one endto the other end, one side of the bottom end of the dust treatment cavity communicates with an air inlet pipeline, air inlet adjusting plates are hinged to the two sides of the air inlet pipeline through rotating shafts, a maintenance opening is formed in the middle of the dust treatment cavity, rail grooves are symmetrically formed in the two sides of the maintenance opening, and dust filteringnets are movably embedded and fixed in the two rail grooves. Dust in industrial waste gas is well filtered through the dust treatment cavity, the dust is scraped into a dust collecting hopper througha scraper plate and finally absorbed by a dust collector, and harmless emission of the dust is achieved.

Owner:沈锋良

Environment-friendly and energy-saving swill separation treatment device for catering

InactiveCN109879455ASolve the problem that the swill cannot be harmlessly treatedRealize harmless dischargeMultistage water/sewage treatmentPulp and paper industrySewerage

The invention discloses an environment-friendly and energy-saving swill separation treatment device for catering. A cylinder is arranged as a device main body; the top end of the device main body is connected with a filter screen basket through a hinge to separate solid from liquid in swill; separated solid is poured into a recycling vehicle for centralized treatment under the overturning of a filter screen basket valve; at the bottom end of the device main body, separated oil-water mixed liquid is conveyed into an oil-water separation tank; a filter screen layer is arranged in the oil-water separation tank and is used for further separating oil from water; at the top end of the oil-water separation tank, the separated oil enters a recovery oil drum to be stored, and the separated water isdischarged into a sewer through a drain pipe and a valve, so that harmless discharge of swill is realized, the problem that swill cannot be harmlessly treated by an existing swill treatment device inthe catering industry is solved, and the swill separation treatment device has a very good practical value.

Owner:西安佳纳环保科技有限公司

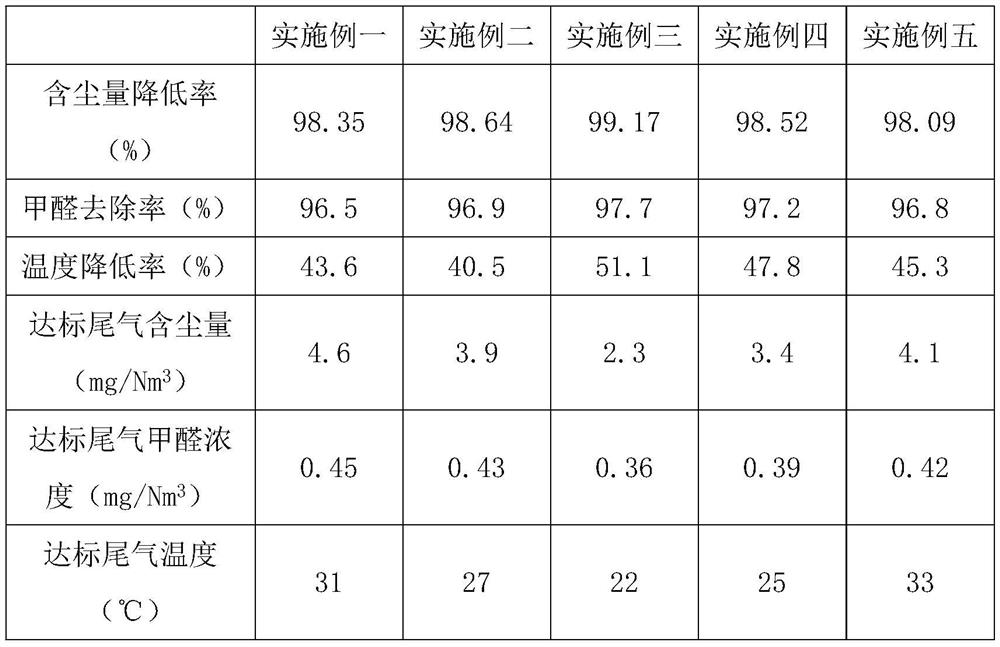

MDF tail gas up-to-standard emission process

PendingCN113731120AReduce processing energy consumptionHigh catalytic efficiencyWater/sewage treatment by centrifugal separationGas treatmentActivated carbonPtru catalyst

The invention belongs to the technical field of artificial board manufacturing tail gas treatment, particularly relates to an MDF tail gas up-to-standard emission process, and solves the problems of high dust content, high temperature, high formaldehyde content and the like due to the fact that tail gas components are not controlled during MDF tail gas emission in the prior art. The process comprises the following steps: spraying and condensing MDF tail gas discharged from production to obtain spraying liquid; adding an activated carbon supported catalyst into the spray liquid for catalytic reaction, and performing centrifugal separation to obtain a treatment liquid and a precipitate; and roasting the precipitate to regenerate and recover the activated carbon. According to the invention, low-temperature water spraying and condensation treatment are adopted, so that the MDF tail gas discharged during production is changed into room-temperature spraying liquid, the catalytic treatment of subsequent procedures is facilitated, the catalytic efficiency of a catalyst is improved, the service life of the catalyst is prolonged, and the treatment energy consumption of the MDF tail gas is reduced.

Owner:佳诺威集团(河南)新材料有限公司

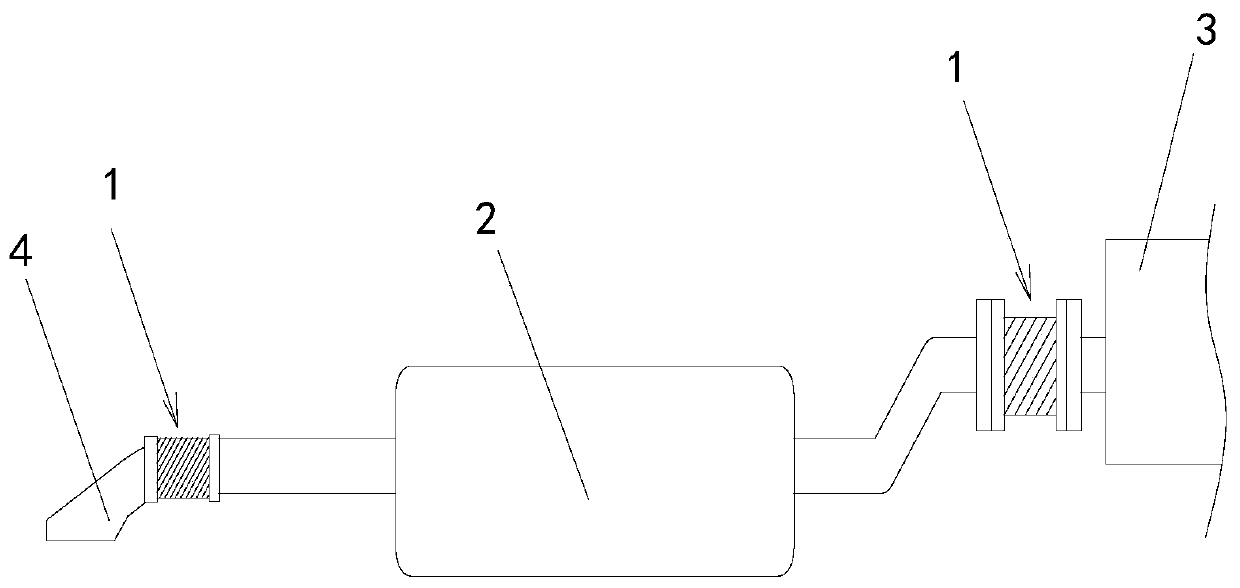

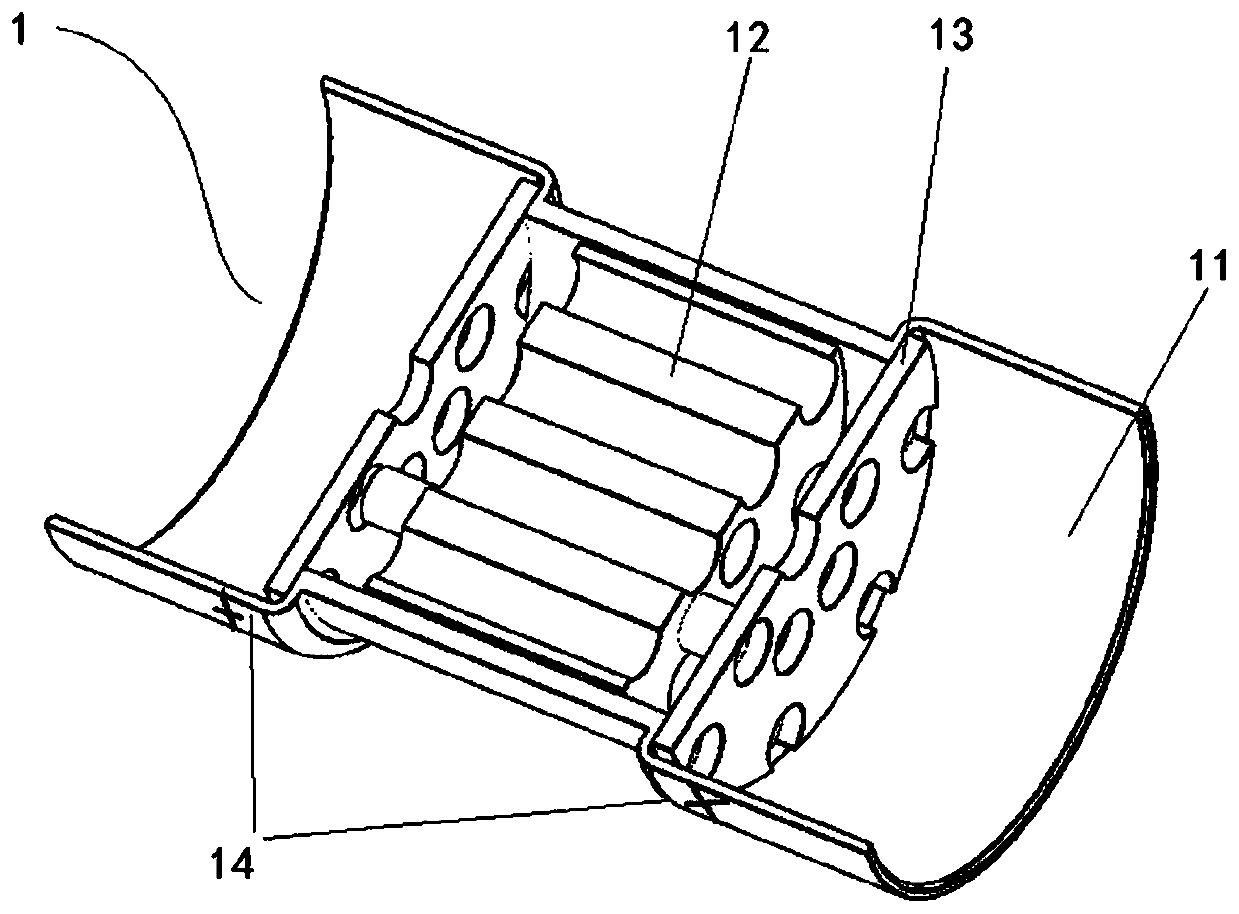

Automobile tail gas cleaner device

PendingCN111075545ARealize harmless dischargeReduce effluxExhaust apparatusSilencing apparatusFiltrationProcess engineering

The invention relates to an automobile tail gas cleaner device. The device comprises two tail gas purifiers and a silencer connected between the two tail gas purifiers; and each tail gas purifier comprises a purifier shell and a filter block arranged in the purifier shell, wherein the filter block is a Cu-Ca-based consolidated type filter block, and the filter block is in a honeycomb mesh structure. According to the device, compared with the prior art, the silencer and the tail gas purifiers are connected in series at intervals, so that the high conversion rate filtration of tail gas is completed while silencing effect is realized, and the harmless discharge of the automobile tail gas is realized; and the tail gas purifiers have the functions of ash discharge and drainage, so that the discharge of ash in the tail gas is obviously reduced, and the influence, on the reaction, from the accumulated ash and accumulated water after filtration is avoided.

Owner:HUNAN LAIMU ELECTRONICS

Organic solid waste treatment method and device

PendingCN112094661AAchieve anaerobic continuous pyrolysisRealize harmless dischargeCoke ovensCombustion chamberWaste treatment

The invention belongs to the technical field of waste treatment and provides an organic solid waste treatment method and treatment device. The treatment method comprises the steps that organic solid waste is indirectly heated through an external heat source, the organic solid waste is directly heated through superheated steam, and continuous anaerobic pyrolysis of the organic solid waste is achieved; then the mixed gas formed by pyrolysis gas generated by pyrolysis of the organic solid waste and superheated steam is subjected to high-temperature gasification combustion, the superheated steam serves as a reactant to participate in the high-temperature gasification combustion process, and the high temperature means that the temperature is higher than or equal to 800 DEG C. The treatment device comprises a heating chamber, a pyrolysis chamber, a superheated steam supply pipe, a combustion chamber, an exhaust pipe, a discharge device, a pyrolysis gas burner and an auxiliary fuel burner. According to the method, harmless and resourceful treatment of the organic solid waste can be achieved, and the method can also be used for recycling high-value resources of the original size from the waste. The whole device is simple in structure, easy to maintain and low in treatment cost.

Owner:王小钉

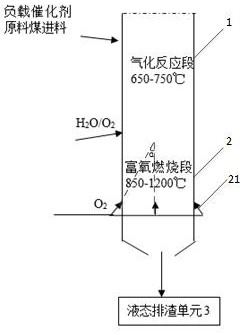

Fluidized bed gasification furnace and gasification process

ActiveCN112480969ARealize harmless dischargeImprove economyGasification processes detailsGranular/pulverulent flues gasificationSlagProcess engineering

The invention provides a fluidized bed gasification furnace and a gasification process. The fluidized bed gasification furnace comprises a gasification reaction section and an oxygen-enriched combustion section which are sequentially communicated from top to bottom. A catalyst-loaded feed coal inlet and a gasifying agent inlet are respectively formed in the upper part and the lower part of the wall surface of the gasification reaction section; a plurality of oxygen nozzles are formed in the wall surface of the oxygen-enriched combustion section, are obliquely arranged upwards along the wall surface and are communicated with an oxygen inlet of the oxygen-enriched combustion section, and oxygen is conveyed to the oxygen-enriched combustion section in a rotational flow manner, so that ash slag generated by the gasification reaction section and oxygen are subjected to a combustion reaction; a large amount of heat is released and a high-temperature area is formed, so that the ash slag containing the catalyst is molten into a liquid state at a high temperature, and the liquid ash slag descends along the inner wall to be discharged out of the gasification furnace. Coal with low ash melting point can be effectively catalyzed and gasified, the coal adaptability is greatly improved, and harmless discharge of ash slag is realized at the same time.

Owner:ENN SCI & TECH DEV

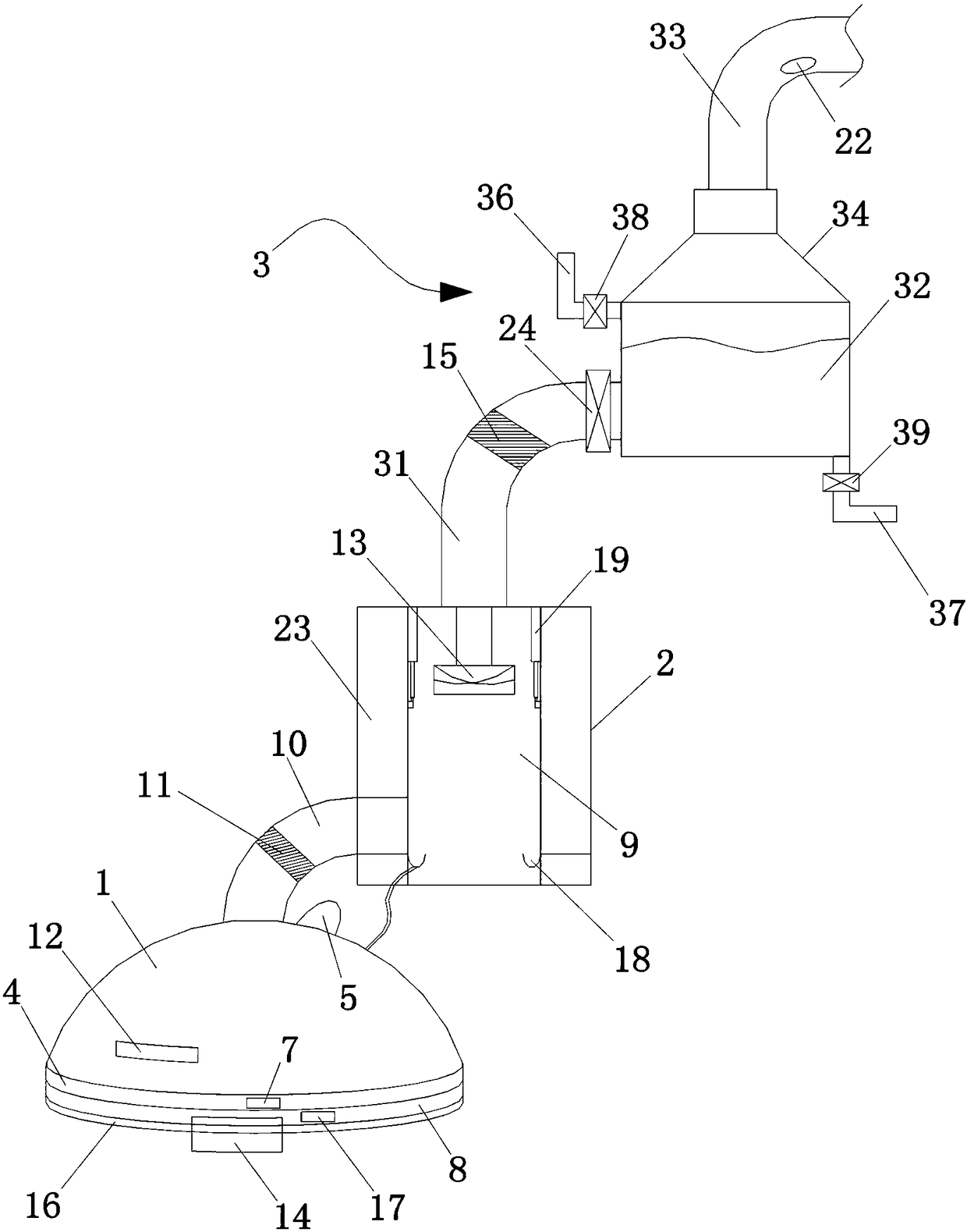

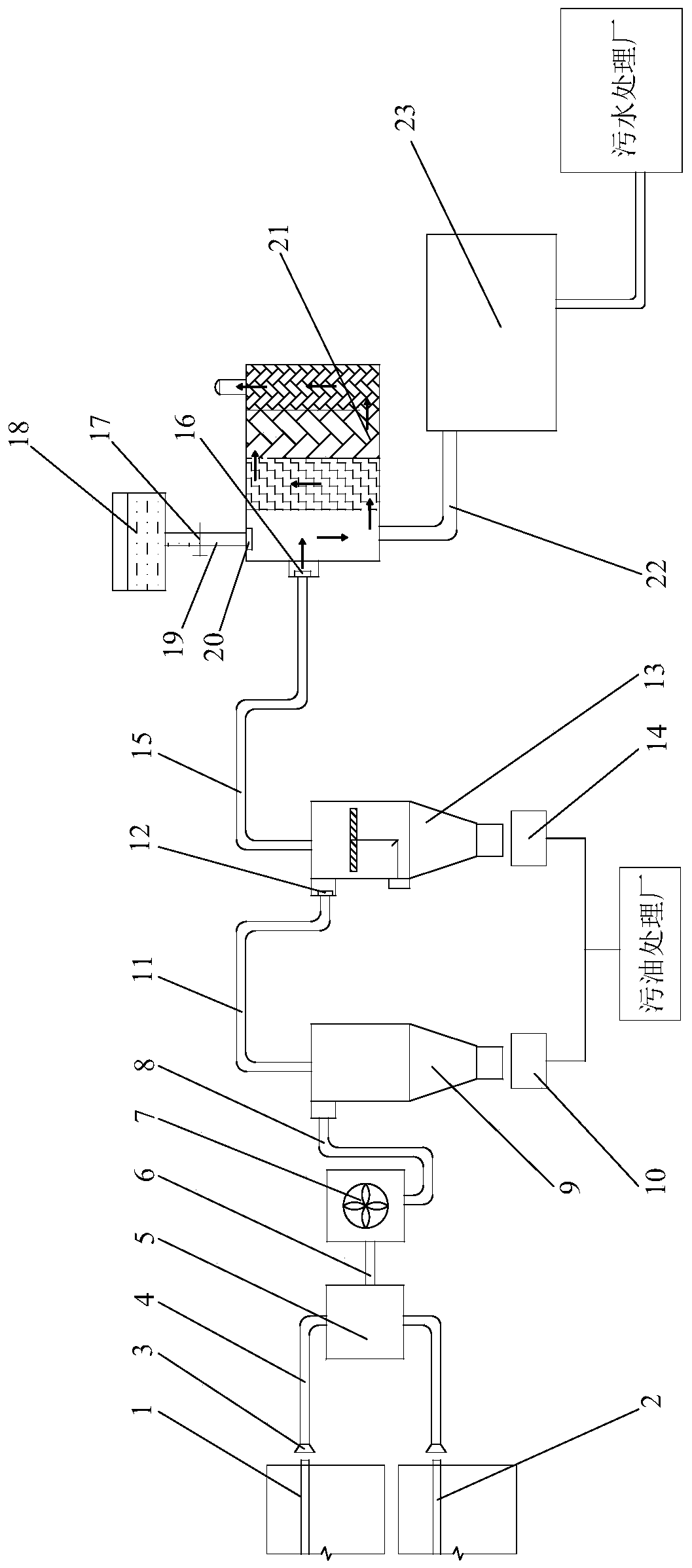

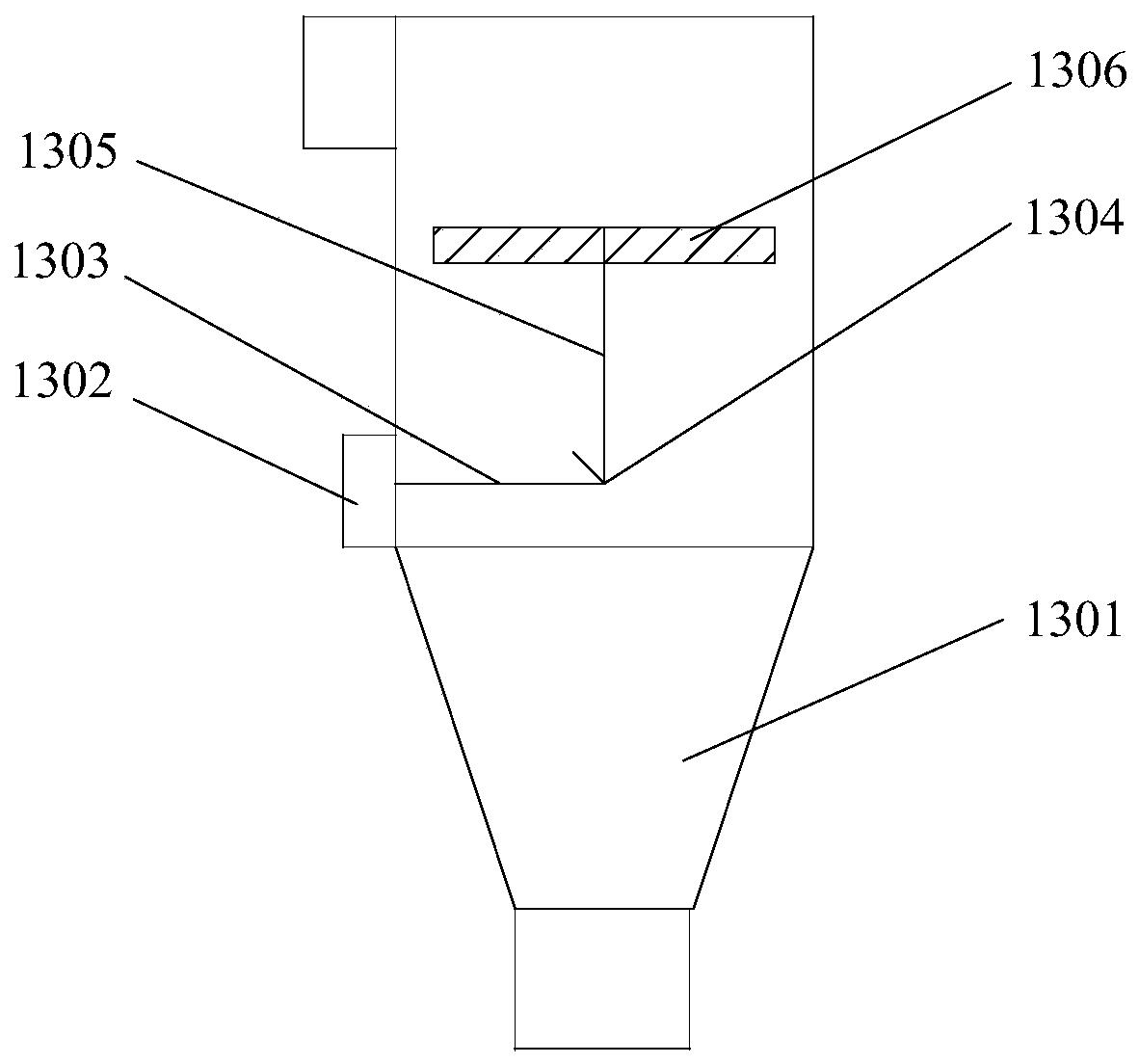

Comprehensive treatment system capable of realizing stage filtering for kitchen lampblack

PendingCN109780605AAchieve separationRealize harmless dischargeDomestic stoves or rangesLighting and heating apparatusSewageProduct gas

The invention provides a comprehensive treatment system capable of realizing stage filtering for kitchen lampblack. The comprehensive treatment system capable of realizing the stage filtering for thekitchen lampblack is used for a residential district, and comprises a fan, a primary separation device, a secondary separation device and a gas filtering device which are sequentially arranged, wherein the fan is used for conveying the kitchen lampblack to the primary separation device; the primary separation device is used for separating oil drops in the kitchen lampblack to obtain a primary separated substance; the secondary separation device is used for separating oil mist in the primary separated substance to obtain a secondary separated substance; and a gas separation device is used for removing impurities and peculiar smell of the secondary separated substance to obtain a tertiary separated substance. The comprehensive treatment system capable of realizing the stage filtering furthercomprises a spray device, wherein the spray device is arranged at the top of the gas filtering device. The comprehensive treatment system capable of realizing the stage filtering is capable of realizing that the kitchen lampblack is treated to achieve the national gas emission standards; and the separated dirty oil can be concentratedly conveyed to a dirty oil plant to be treated, the generated sewage can be concentratedly conveyed to a sewage plant to be treated, and concentrated collection for the dirty oil and the sewage is realized separately, and pollution is reduced.

Owner:刘骏旻

Temperature change carbonization device and method for organic matter

PendingCN114214081ARealize savingsRealize harmless dischargeSpecial form destructive distillationStationary retortsTemperature controlCarbonization

The invention discloses an organic matter temperature change carbonization device and method, and relates to the field of organic matter treatment.The device comprises a carbonization treatment barrel, a temperature control assembly used for controlling the treatment temperature in the carbonization treatment barrel, a flow guide pipe, a cooling assembly, a water collection chamber and a gas collection chamber; the method comprises the following steps: S1, controlling the temperature in a carbonization treatment barrel to be a first temperature, and performing high-temperature dehydration on to-be-treated organic matters; s2, controlling the temperature in the carbonization treatment barrel to be a second temperature; s3, controlling the temperature in the carbonization treatment barrel to be a third temperature, and carrying out carbonization treatment on the pre-carbonized organic matters; organic materials to be treated enter the carbonization treatment barrel, the temperature control assembly controls the temperature, the time and the like of the organic materials in the barrel, smooth transition of the organic materials from the dehydration stage to the drying stage to the carbonization stage is achieved, and the carbonization efficiency is improved; the water vapor generated in the carbonization process is collected and recycled, and the collected waste gas is heated and combusted, so that harmless emission and energy conservation and effectiveness are realized.

Owner:上海巧松嘉悦科技有限公司

High-efficiency and low-energy tailings dry discharge process

InactiveCN101734809BLow running costReduce security risksWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentMicroparticlePollution

The invention relates to a mine tailings water treatment method, in particular to tailings dry discharge and tailings water treatment process with high efficiency and low energy consumption. The technical scheme includes the following processes: primary sewage concentration process, coarse particle dehydration process, medium particle dehydration process, sewage secondary concentration process, fine particle dehydration process, micro particle concentration and dehydration process. The advantages and application effects of the present invention: greatly reduce the operating cost of the concentrator, and reduce the tailings treatment cost from 10 yuan per ton of mineral powder to 2 yuan; realize the completely closed operation of tailings sewage and waste water reuse or harmless discharge , save water resources, thoroughly solve the pollution of tailings sewage to the surrounding environment and groundwater; completely ban tailings ponds, and reduce mine safety hazards.

Owner:吴爱华

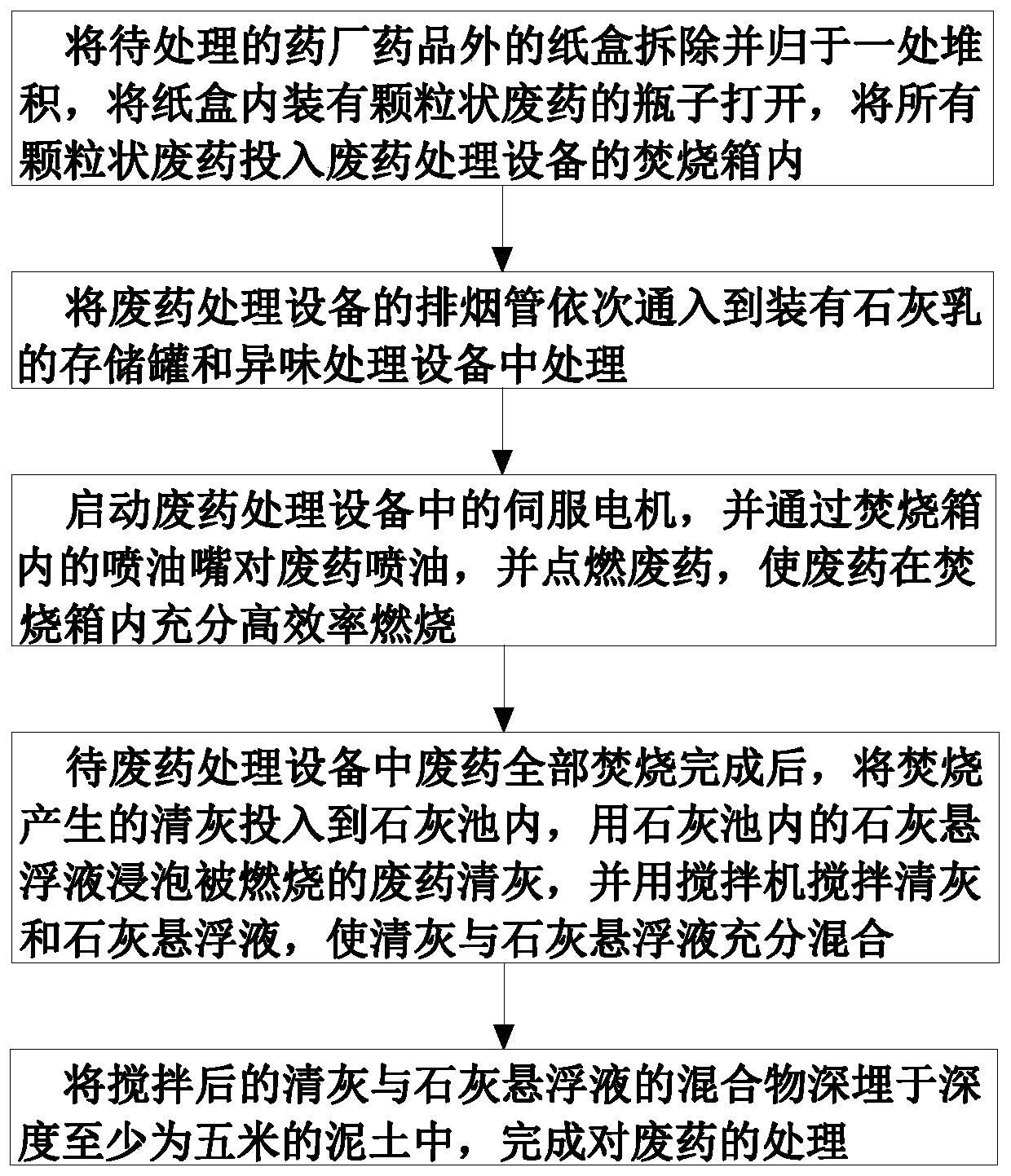

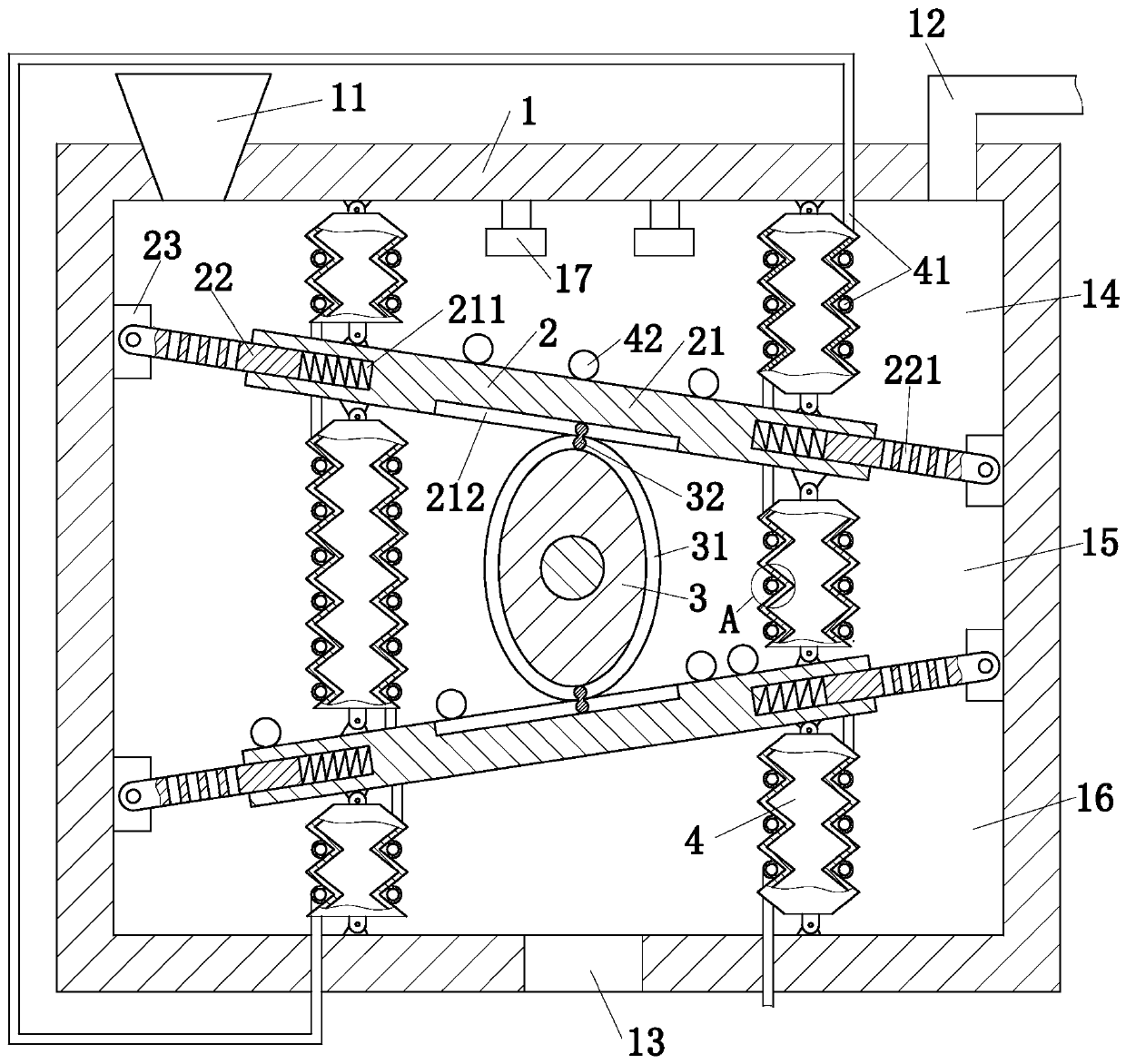

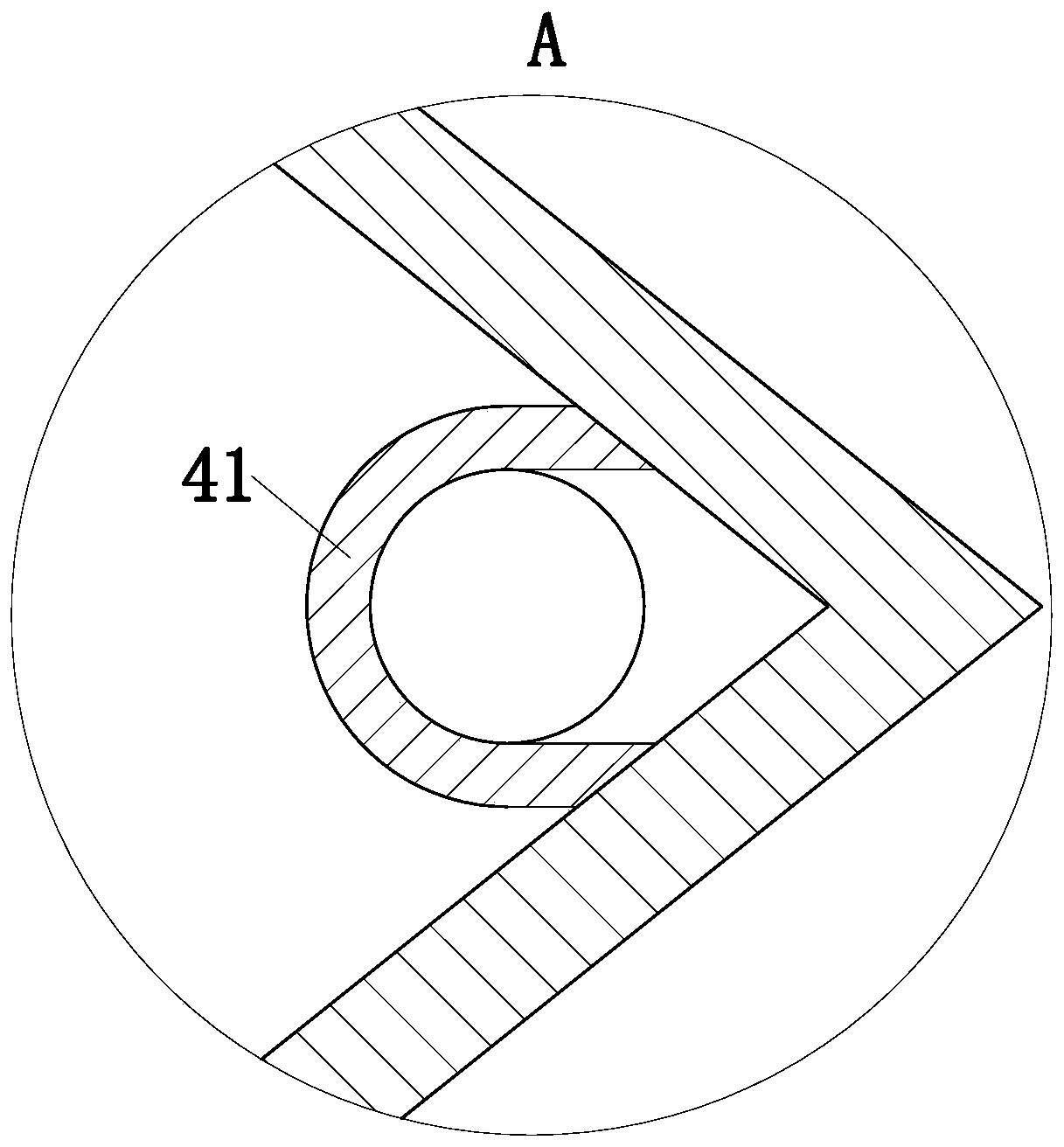

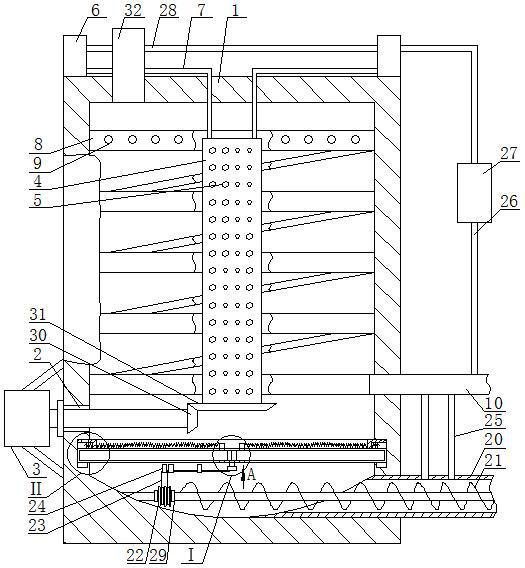

A kind of pharmaceutical factory waste drug treatment method

ActiveCN109737428BAvoid pollutionRealize harmless dischargeIncinerator apparatusThermodynamicsPharmaceutical drug

Owner:NANCHANG BAIYUN PHARMA

A combined physical and chemical activation device for biocoke

A combined physical and chemical activation device for biocoke, comprising an activation box, gas storage tanks are fixedly installed on both sides of the top surface of the activation box, and the inside of the bottom of the gas storage tank is respectively fixedly connected to one end of a first air pipe, and the other end of the first air pipe is connected to Pass through the top surface of the activation box, the inner wall of the activation box is fixedly connected to the outer circumference of the spiral tube, and several air holes are evenly opened on the top of the inner wall of the spiral tube. One end of the second air pipe is fixedly connected, and the other end of the second air pipe passes through the activation box. An annular groove is provided on the lower part of the inner wall of the activation box, and a circle of chute is provided on the bottom surface of the annular groove. The present invention can heat the activation box by arranging the spiral pipe in the activation box, reduce the heat loss in the activation box, and facilitate the activation process to be carried out under a suitable temperature condition. Temperature, can save energy, more energy-saving and environmental protection.

Owner:南京洐而立科技有限公司

Household toilet and domestic waste treatment system

ActiveCN104146646BImprove pumping capacityEnhanced suction functionSolid waste disposalBathroom accessoriesPipingUrine

The water-free toilet and domestic garbage treatment system provided by the invention relates to the field of sanitary toilet and domestic garbage treatment, and is composed of a collection and transportation system, a biological treatment system, and a waste gas discharge system. Wherein the collection and conveying system includes a toilet, a movable belt conveying mechanism, a conveying room, a waste exhaust pipe, a composting room, a liquid storage tank, etc.; The fermentation area, the vermiculture area, and the vermicompost accumulation area are composed of different functional areas; the exhaust gas discharge system includes a composting room, waste exhaust and air extraction pipes, a conveying room, an exhaust air duct, and a toilet. The beneficial effect of the present invention is that, through the above-mentioned system established, the toilet does not need water, is clean and odorless, separates and collects urine, and transports, collects, and uses biological treatment of solid organic domestic waste such as feces; saves water resources, and is highly efficient. Transformation and utilization of domestic waste, reducing the spread of diseases.

Owner:秦立 +1

Harmless discharge range hood based on ultrasonic generator for efficiency improving

InactiveCN108344014AEasy to cleanEfficient collectionDomestic stoves or rangesLighting and heating apparatusDischarge efficiencyAtmospheric air

The invention discloses a harmless discharge range hood based on an ultrasonic generator for efficiency improving. The problems that in the prior art, oil fume dirt is liable to adhere to the inner walls of oil fume separation pipes, then the waste discharging efficiency is lowered, discharged waste gas contains fume and pollutes the atmosphere environment, and the fume purification efficiency islow are solved. The harmless discharge range hood comprises an oil fume suction hood body, an oil fume separation box body, a waste gas discharging device, a flange, a microprocessor, an audible and visual alarm, a smoke concentration sensor, a flange oil collection groove, an oil fume extraction pipe, an oil fume separation pipe, a negative pressure fan, an oil fume separation fan, an electric push rod, an oil pushing tool, a separation pipe oil collection groove, a waste oil collection box, a first waste gas discharging pipe, a purification pool, a second waste gas discharging pipe, a purification pool cover, the ultrasonic generator, a water inlet and outlet pipe and a water inlet and outlet electromagnetic valve. Oil fume dirt on the inner wall of the oil fume separation pipe can be effectively removed, oil fume mixtures on the bottom face of the oil fume suction hood can be collected, the operation intensity of users is relieved, meanwhile, discharged waste gas can be completely purified, waste gas harmless discharging is achieved, and the fume purification efficiency is high.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

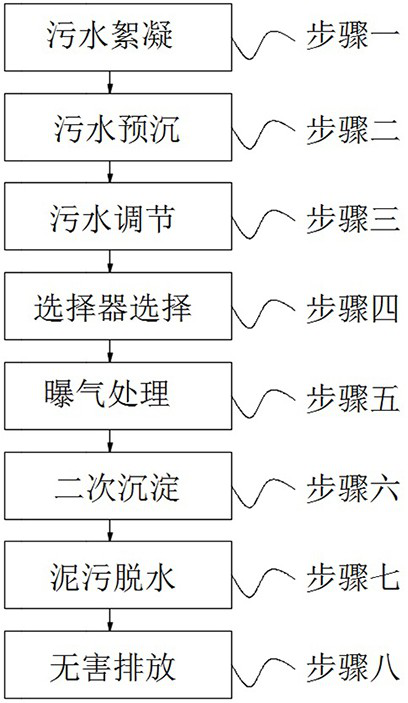

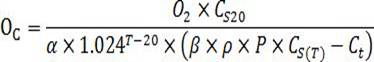

Aeration system activated carbon adsorption biological oxidation process

PendingCN114538701AImprove processing efficiencyRealize harmless dischargeTreatment involving filtrationWater/sewage treatment by neutralisationActivated carbonSewage

The invention discloses an aeration system activated carbon adsorption biological oxidation process. The process comprises the following steps: step 1, sewage flocculation; step 2, sewage pre-sedimentation; step 3, sewage regulation; step 4, selecting by a selector; step 5, aeration treatment; step 6, secondary precipitation; step 7, sludge dehydration; step 8, harmless discharge; the COD (Chemical Oxygen Demand) in the treated sewage is 45mg / l, the suspended solids are 8mg / l, the ammonia nitrogen is 2mg / l, the total nitrogen is 5mg / l, the total phosphorus is 0.2 mg / l and the chromaticity is 4 times and is smaller than GB3544-2008 < Discharge Standard of Water Pollutants for Pulping and Papermaking Industry >, harmless discharge of the sewage is realized, the oxygen demand is automatically detected through the arrangement of an intelligent aeration energy-saving control system, the aeration quantity matched with the oxygen demand is timely adjusted according to the oxygen demand, and the sewage treatment efficiency is improved. The energy consumption of the aeration system is saved by 9.5%, a facility for inputting a PAC biological carrier is additionally arranged in the aeration tank, activated carbon adsorption and biological oxidation are combined for treatment, and the purification function of the activated sludge process of the aeration tank is improved.

Owner:JIANGSU LEE & MAN PAPER MFG

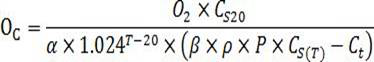

A kind of sludge recycling method

ActiveCN106365398BRealize recycling of resourcesReduce carbonizationSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCarbonizationOrganic content

The invention discloses a sludge recycling method which comprises the following specific steps: 1, fermenting, namely feeding sludge with the moisture content of more than 80% and the organic content of more than 50% into an upflow anaerobic sludge blanket, and performing anaerobic fermentation on the sludge; 2, separating, namely performing three-phase separation on the sludge, obtaining sludge, water and biogas, and directly discharging the water through overflow; 3, drying and carbonizing, namely feeding the obtained solid sludge into a carbonization furnace, drying at a temperature of 120 DEG C for an hour, heating to the temperature of 550 DEG C for carbonizing, wherein the carbonization time is 1.5 hours; 4, activating, namely adding ZnCl2 into the carbonized sludge for activating, thereby obtaining activated carbon; 5, purifying, namely introducing the biogas into the activated carbon, purifying, thereby obtaining the natural gas. According to the method disclosed by the invention, sludge resource recycling is really realized, harmless discharge is achieved, 60m<3> biogas can be produced from the sludge per tonnage, and the produced activated carbon and natural gas have obvious economic benefits.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

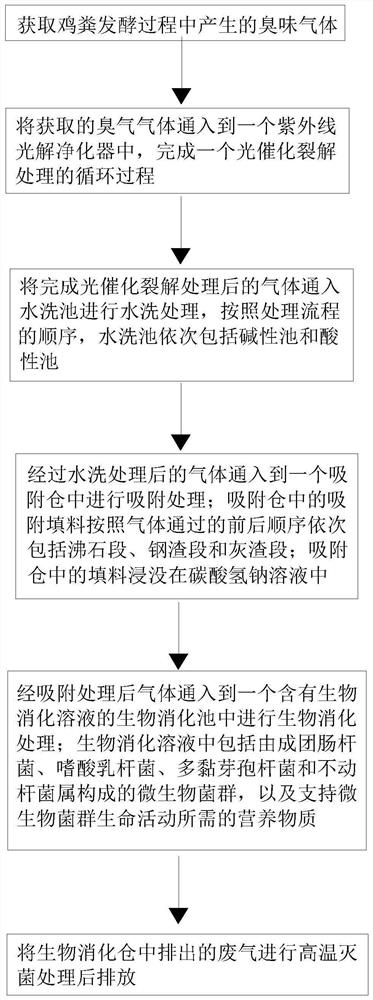

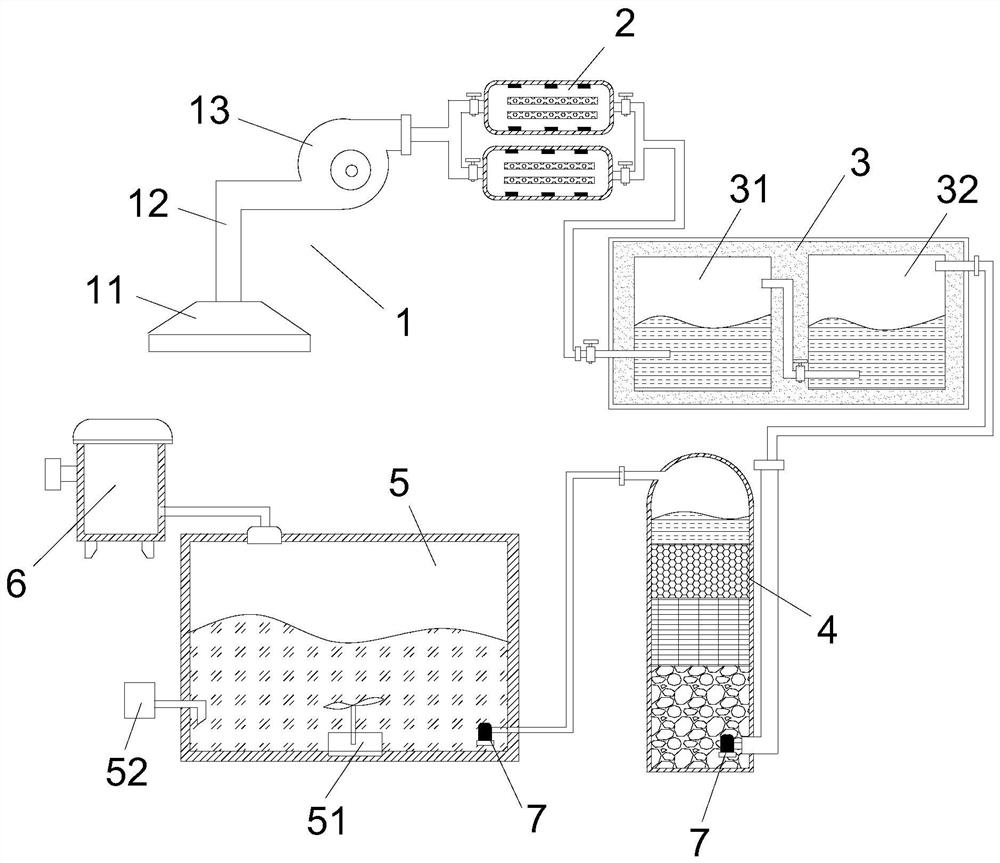

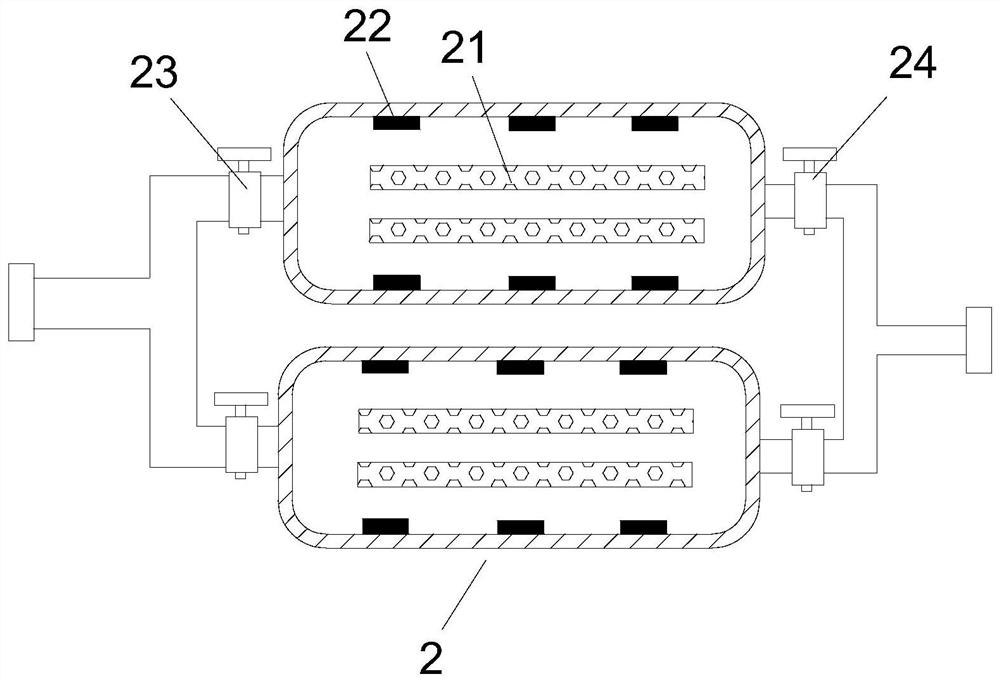

Biological treatment process for odor generated by chicken manure recycling

PendingCN113634102AFully processedRealize harmless dischargeGas treatmentDispersed particle separationDigestion TreatmentEnvironmental engineering

The invention relates to the field of biological environmental protection, in particular to a biological treatment process for odor generated by chicken manure recycling. The biological treatment process comprises the following steps of: (1) acquiring odor gas generated in a chicken manure fermentation process; (2) introducing the obtained odor gas into an ultraviolet photolysis purifier to complete a cyclic process of photocatalytic cracking treatment; (3) introducing the gas subjected to photocatalytic cracking treatment into a water washing tank for water washing treatment; (4) introducing the gas subjected to water washing treatment into an adsorption bin for adsorption treatment; (5) introducing the gas subjected to adsorption treatment into a biological digestion tank containing a biological digestion solution for biological digestion treatment; and (6) performing high-temperature sterilization treatment on the waste gas discharged from the biological digestion bin, and then discharging the waste gas. The problem that an existing composting field deodorization technology is not thorough in deodorization effect, can hardly deal with a scene with large-flow odor gas and low in treatment efficiency is solved.

Owner:安徽坤健生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com