A kind of sludge recycling method

A sludge recycling and sludge technology, applied in sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of low resource recycling rate and high energy consumption, reduce investment and production energy consumption, reduce The effect of carbonization and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

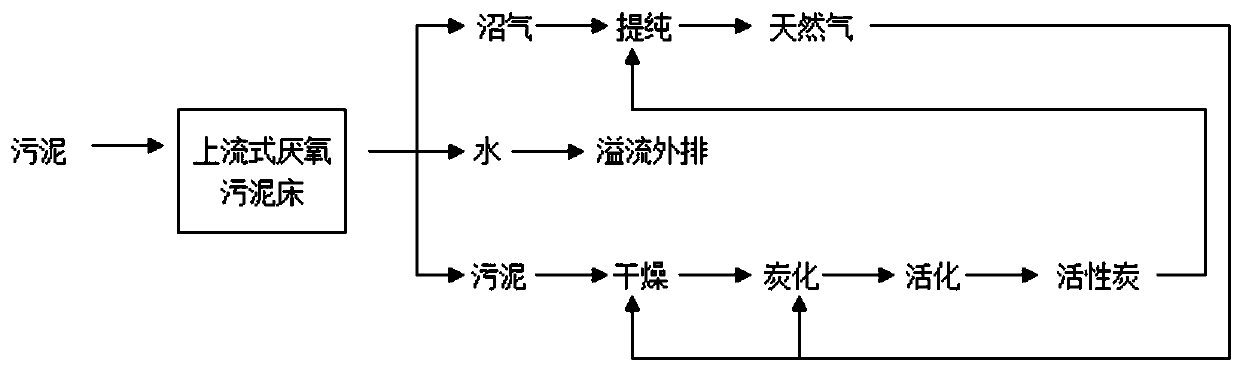

[0020] The invention provides a method for sludge recycling, the specific process is as follows figure 1 shown, including the following steps:

[0021] Step 1. Fermentation: Sludge with a moisture content of 83% and an organic matter content of 64% is sent to an upflow anaerobic sludge bed. The sludge bed is divided into sludge inlet area, reaction fermentation area, three-phase separation area, The air chamber, sedimentation area, supernatant overflow tank and outlet pipe are directly treated by the USAB method, and the sludge is anaerobically fermented, and the organic matter in the sludge is used to generate biogas;

[0022] Step 2. Separation: After 6 days of fermentation, the sludge is subjected to three-phase separation, solid sludge is obtained in the sedimentation area, liquid water is obtained in the supernatant overflow tank, biogas is obtained in the gas chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com