Cyclic treatment process for wastewater containing cobalt-nickel heavy metal ions

A technology for heavy metal ion and recycling treatment, applied in centrifugal separation of water/sewage treatment, multi-stage water treatment, water/sewage treatment and other directions, can solve the problems of low concentration of heavy metal ions, high NaOH cost, low salt content in wastewater, etc. Achieve low concentration of heavy metal ions, reduce processing burden, and low salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

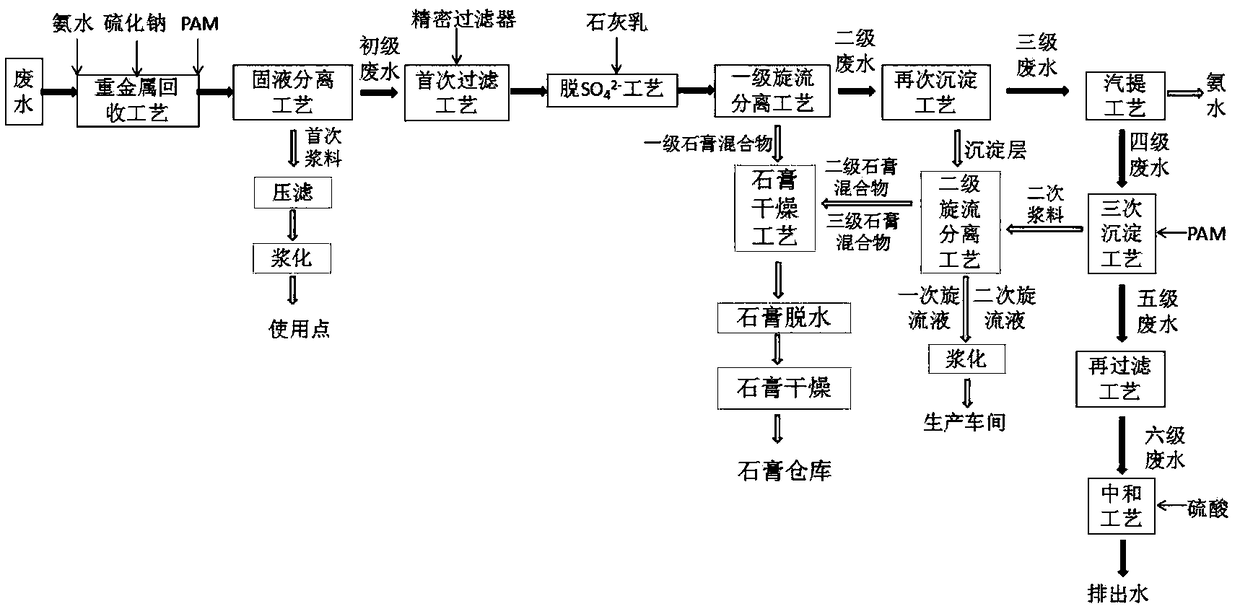

[0024] A recycling process for wastewater containing cobalt and nickel heavy metal ions, including heavy metal recovery process, solid-liquid separation process, primary filtration process, SO removal 4 2- process, primary cyclone separation process, gypsum drying process, re-precipitation process, secondary cyclone separation process, stripping process, tertiary precipitation process, refiltration process, neutralization process;

[0025] The heavy metal recovery process includes: 1. adding ammonia water to the raffinate; 2. continuing to add sodium sulfide to the above-mentioned treatment solution to obtain CoS and NiS precipitates; 3. adding PAM flocculant to make the above-mentioned precipitates aggregate to form Alum flower cloudy liquid;

[0026] The solid-liquid separation process refers to the muddy water separation of the alum flower turbid liquid to form the first slurry and primary wastewater. The first slurry is sent to the point of use after the press filter proc...

Embodiment 2

[0042] Optimum embodiment: a recycling treatment process for wastewater containing cobalt and nickel heavy metal ions, including heavy metal recovery process, solid-liquid separation process, primary filtration process, SO removal 4 2- process, gypsum drying process, primary cyclone separation process, secondary precipitation process, secondary cyclone separation process, stripping process, tertiary precipitation process, refiltration process, neutralization process;

[0043] The heavy metal recovery process includes: 1. Add ammonia water to the raffinate, adjust the pH of the raffinate to 7-8, and adjust the dosage of ammonia water through a pH meter. This step is mainly used to adjust the pH; 2. Then add sodium sulfide , to precipitate heavy metals to obtain precipitates such as CoS and NiS; 3. Add PAM non-ionic polymer flocculant to make the above-mentioned precipitates gather to form alum flower turbid liquid; the ammonia water is 30% concentration grade industrial ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com