Method for dehydrating viscous waste by vacuum coupled physicochemical strengthening and device

A physicochemical, viscous technology, applied in chemical instruments and methods, dewatering/drying/concentrating sludge treatment, water pollutants, etc., can solve the problems of viscous waste with high viscosity, high moisture content and difficult dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

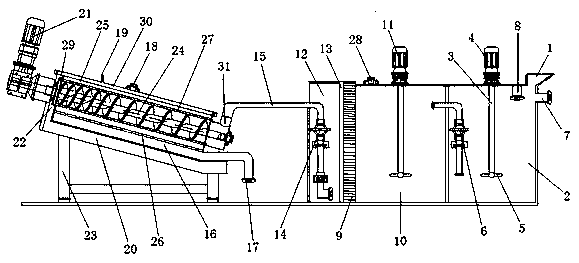

[0048] Embodiment 1: The processing object of this embodiment is the cow feces produced by a dairy cow breeding factory, its moisture content is 85%, and its density is 1t / m 3 ,Specifically:

[0049] Make 3 tons of fresh cow dung into a slurry with a moisture content of 95%, and the temperature of the slurry is 40°C, and add auxiliary material P to the slurry 2 o 5 , stirring reaction 4h, P 2 o 5 The amount of addition is 40% of the mass of viscous waste (1.2 tons), and the P 2 o 5 Mix well with viscous waste, P 2 o 5 The heated interstitial water reacts to generate phosphoric acid. Phosphoric acid is corrosive to sticky waste particles, causing the bound water on the surface of molecules or inside the sticky waste to detach, and at the same time, the heavy metals in the particles are detached, realizing the combination of bound water, interstitial water and heavy metals. For the separation of waste particles, heavy metals exist in the slurry in a combined state; becaus...

Embodiment 2

[0053] Embodiment 2: the processing object of this embodiment: the chicken excrement that certain chicken breeding factory produces, and its moisture content is 75%, and density is 1.25t / m 3 ,Methods as below:

[0054] (1) Make viscous waste into a slurry with a water content of 95%, and the temperature of the slurry is 30°C, and add auxiliary material P to the slurry 2 o 5 ,P 2 o 5 The amount of addition is 25% of the mass of the viscous waste, and the reaction is stirred for 3 hours to realize the separation of bound water, interstitial water, and heavy metals from the viscous waste particles. The heavy metals exist in the slurry in a combined state; Add conditioner in remaining waste, the add-on of iron salt conditioner ferric chloride is 0.5% of the viscous waste quality, the add-on of aluminum salt conditioner alum is 0.05% of viscous waste quality; 2% of the mass of viscous waste; the amount of diatomaceous earth added is 0.1% of the mass of viscous waste. After stir...

Embodiment 3

[0058] Embodiment 3: The processing object of this embodiment: the dewatered sludge produced by a certain urban sewage treatment plant, its moisture content is 90%, and its density is 1.07t / m 3 ,Methods as below:

[0059] (1) Make viscous waste into a slurry with a water content of 92%, and the temperature of the slurry is 50°C, and add auxiliary material P to the slurry 2 o 5 ,P 2 o 5 The amount added is 10% of the mass of the viscous waste, and the reaction is stirred for 2 hours to realize the separation of bound water, interstitial water, and heavy metals from the viscous waste particles. The heavy metals exist in the slurry in a combined state; Add conditioner in remaining waste, the add-on of iron salt conditioner ferrous sulfate hydrate is 1% of viscous waste quality, the add-on of aluminum salt conditioner aluminum chloride is 1% of viscous waste quality; The amount of added is 0.05% of the mass of viscous waste; the amount of fly ash added is 1% of the mass of vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com