Supercritical water oxidation treatment system for high-salt high-chlorine organic wastewater

A technology of supercritical water oxidation and organic wastewater, applied in the direction of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of reducing system investment and operating costs, clogging, equipment and Pipeline corrosion and other problems to achieve the effect of avoiding clogging frequency, avoiding salt deposition, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

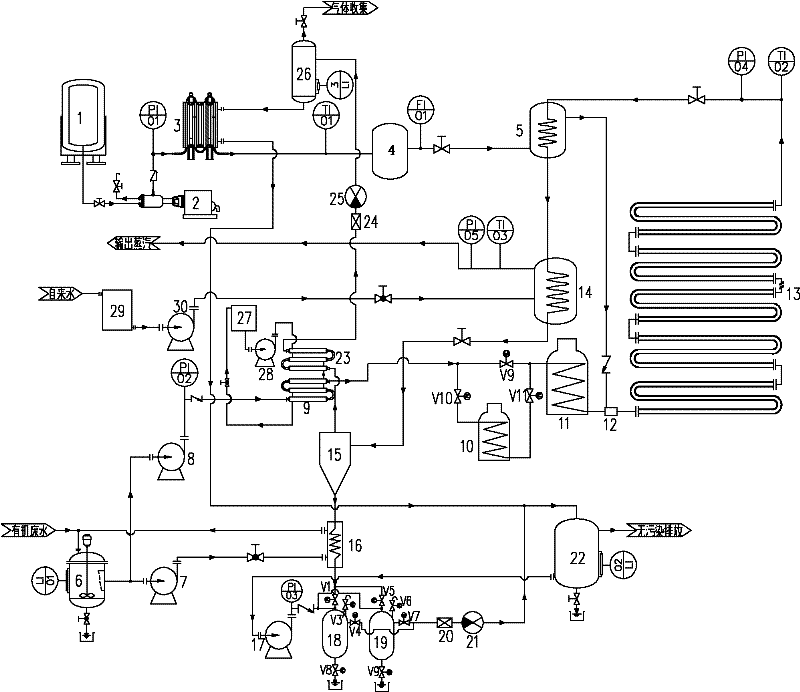

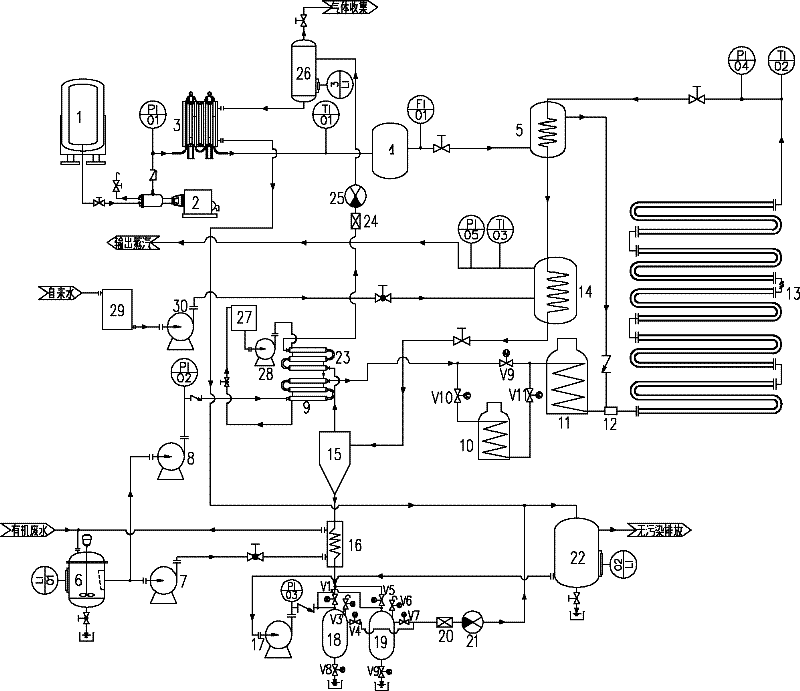

[0029] refer to figure 1 As shown, the connection mode of equipment in the supercritical water oxidation treatment system for high-salt and high-chlorine organic wastewater is as follows:

[0030] The outlet of the cryogenic liquid storage tank 1 is connected to the inlet of the cryogenic liquid oxygen pump 2, the outlet of the cryogenic liquid oxygen pump 2 is connected to the inlet of the shell side of the hot water bath vaporizer 3, and the outlet of the shell side of the hot water bath vaporizer 3 The end is connected with the inlet end of the buffer tank 4, the outlet end of the buffer tank 4 is connected with the inlet end of the shell side of the oxygen preheater 5, and the outlet end of the shell side of the oxygen preheater 5 is connected with an inlet port of the mixer 12. The inlet end of the storage tank 6 is connected to the organic wastewater feed pipeline, the outlet end of the storage tank 6 is connected to the inlet end of the high-pressure material pump 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com