Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Quick dip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

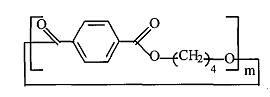

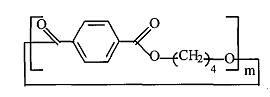

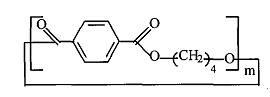

Resin membrane melt impregnation forming method of fiber reinforced PBT composite material

ActiveCN102555234ASimplify the production processReduce manufacturing costPolymer chemistryPolyethylene terephthalate

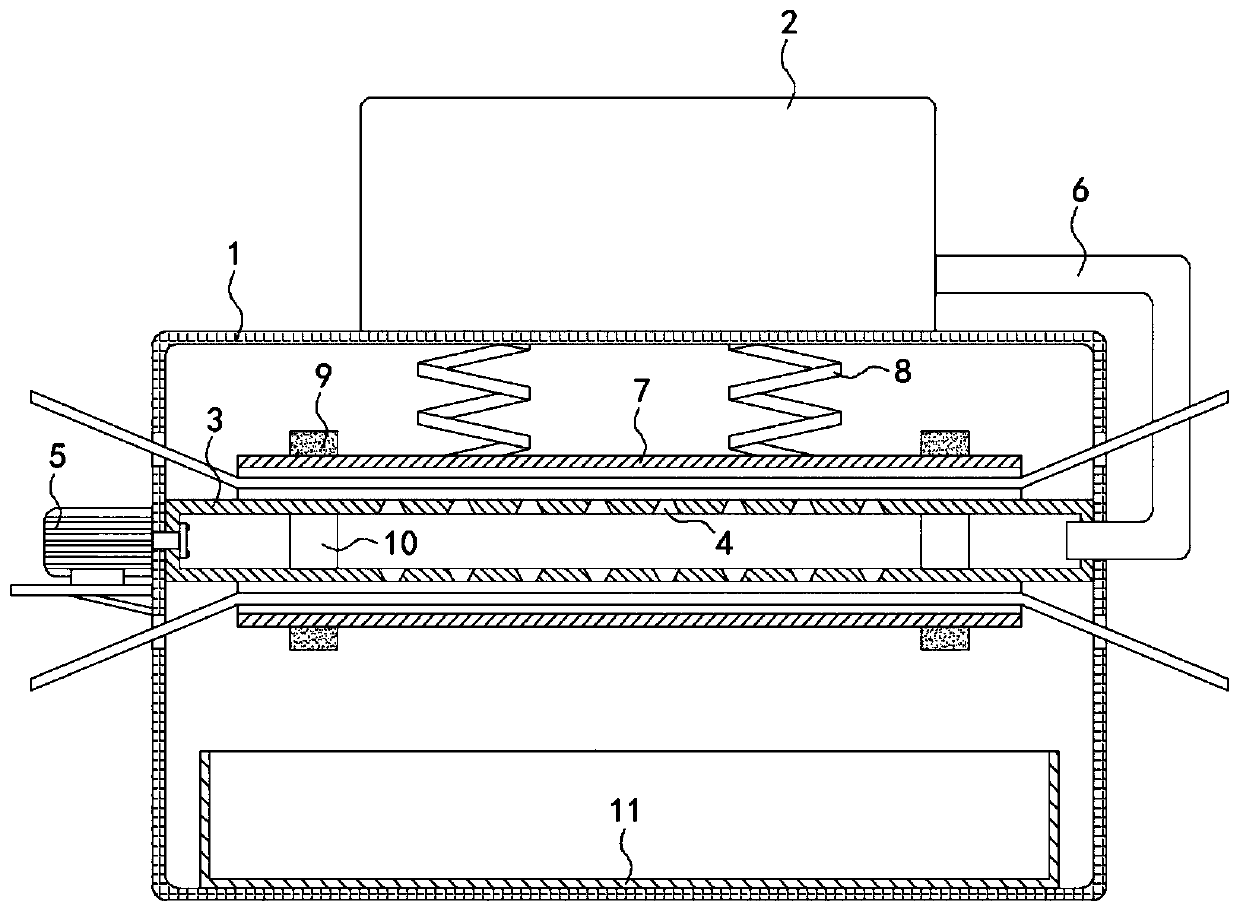

The invention discloses a resin membrane melt impregnation forming method of a fiber reinforced polyethylene terephthalate (PBT) composite material, comprising the following steps: 1) processing to form a cyclic butylenes terephthalate(CBT) resin membrane with the thickness of 15-700 mu m; 2) successively placing a demolding cloth, the CBT resin membrane, a fiber reinforced material and a demolding cloth on a mold; 3) heating up the assembly obtained by the step 2) to 180-225 DEG C under vacuum and preserving the heat for 5 min-6 h to melt the CBT resin in the CBT resin membrane and completely impregnate the fiber reinforced material, simultaneously polymerizing the CBT resin into PBT with high molecular weight, cooling, and then demolding. According to the invention, the forming method has no need to prepare a prepreg, the forming process can be realized at the temperature which is lower than the PBT melting temperature, the process is simple and easy to operate, the efficiency is high, and large members can be formed. The invention is beneficial for popularization and application.

Owner:中材科技(邯郸)风电叶片有限公司

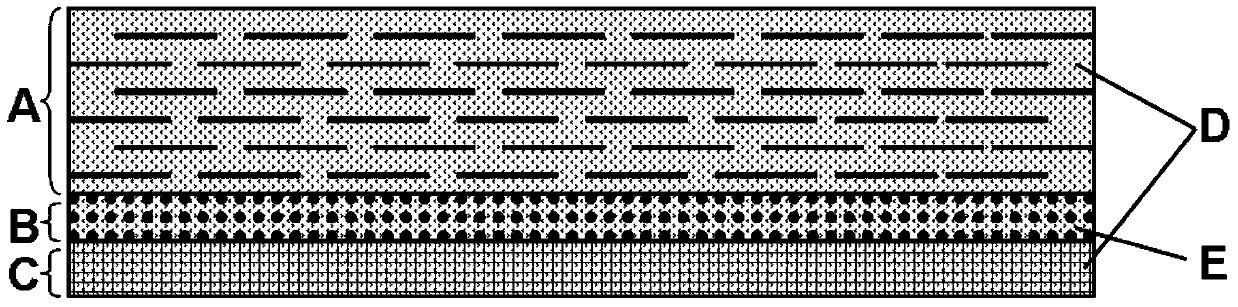

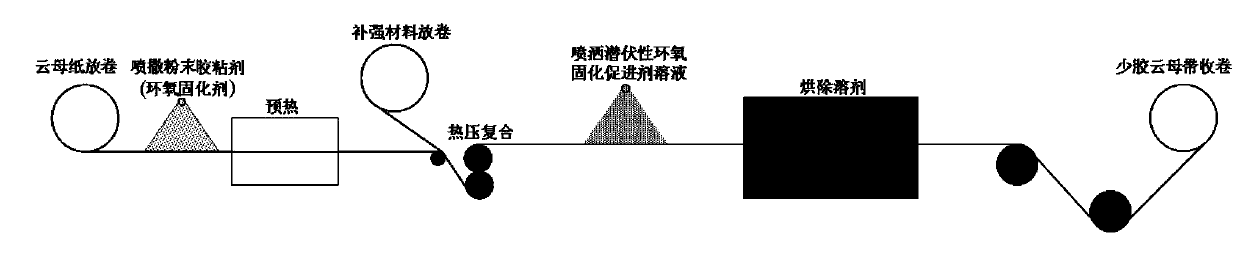

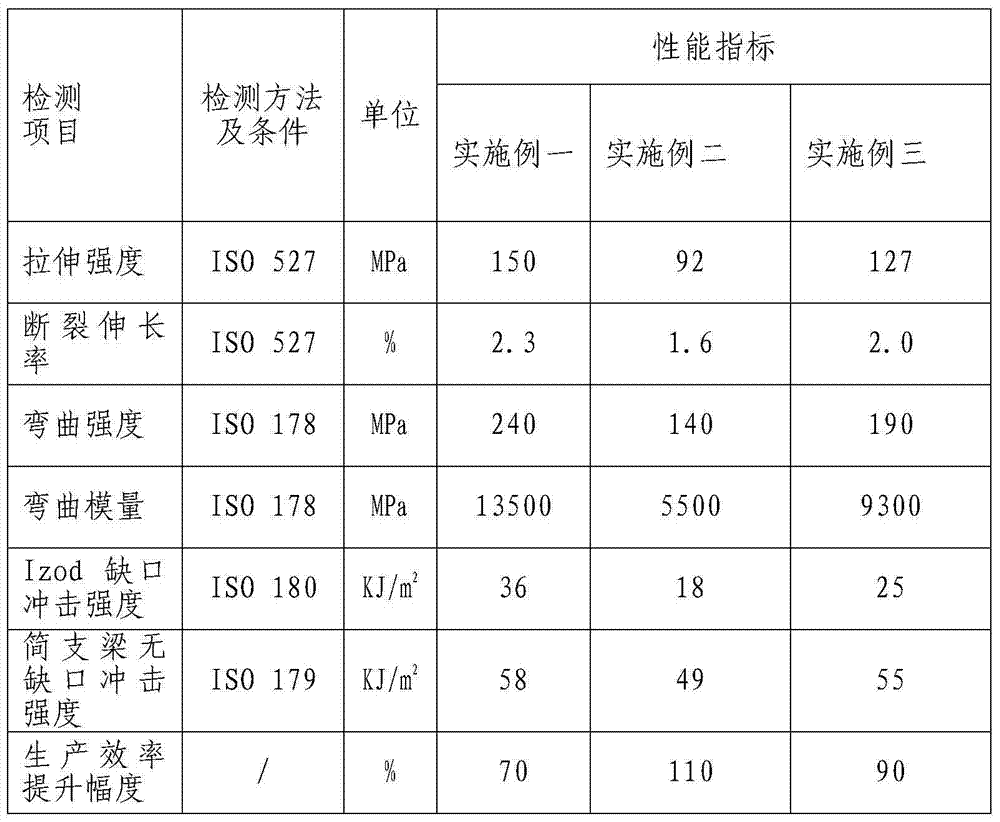

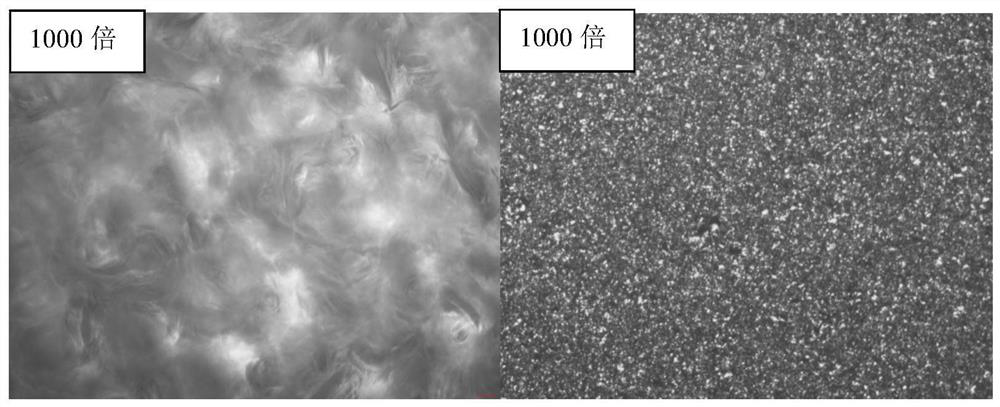

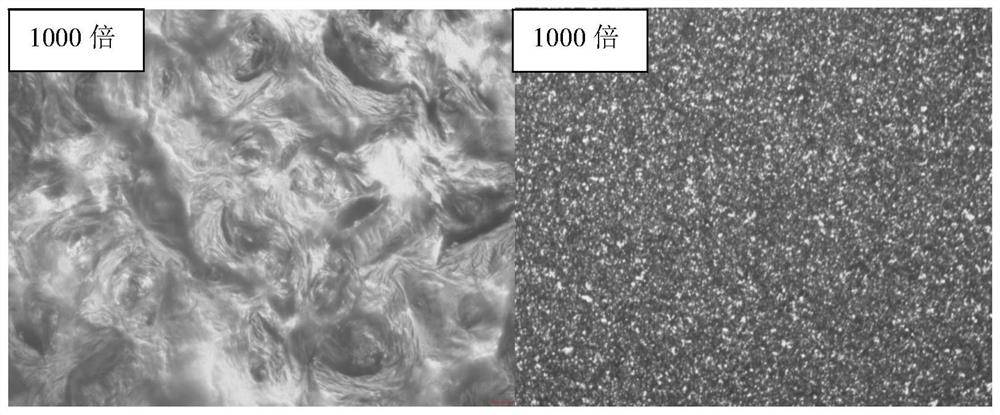

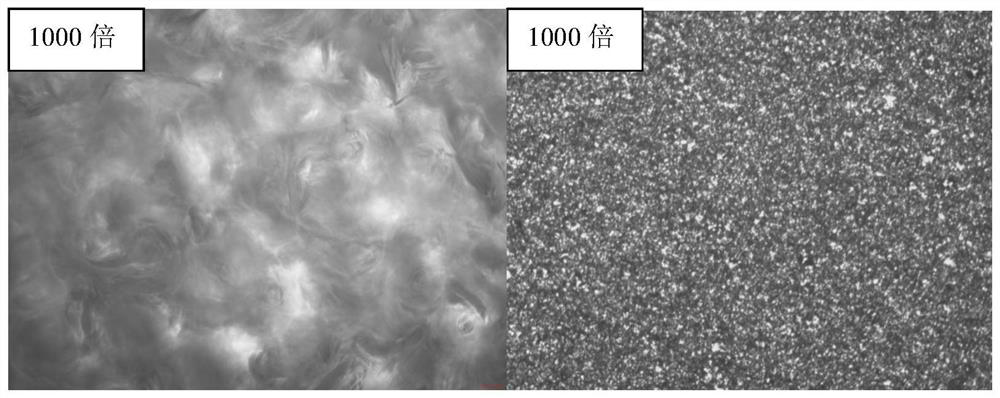

Mica tape, high in ventilation performance and with little glue, suitable for pure epoxy VPI insulating resin and preparation method thereof

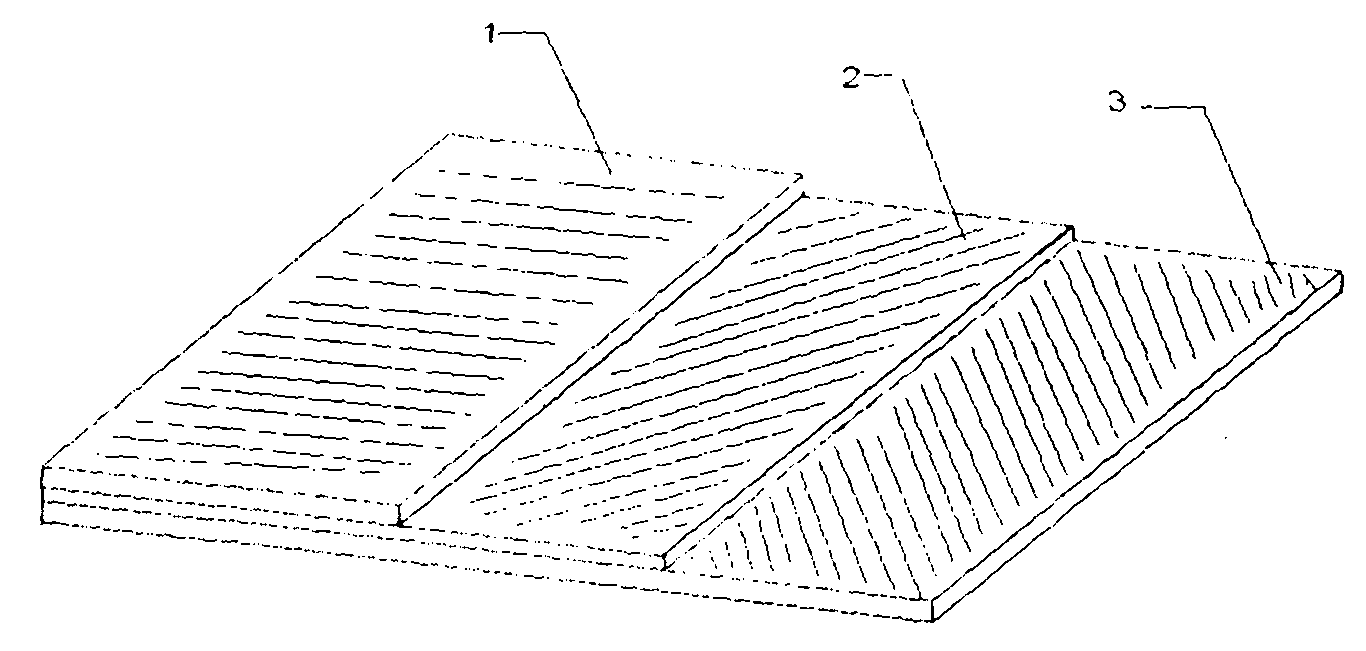

The invention relates to mica tape, high in ventilation performance and with little glue, suitable for pure epoxy VPI insulating resin and a preparation method thereof. The mica tape comprises a mica paper layer, a reinforcing material layer, and an adhesive agent layer. The adhesive agent layer is composed of powder adhesion agents distributed, in a point shape, on the interface of the mica paper layer and the interface of the reinforcing layer. A large number of pore channels exist between powder adhesion agents distributed in the point shape. The powder adhesion agents are epoxy hardeners. The mica tape high in ventilation performance and with little glue further comprises latent epoxy curing accelerators distributed in the mica paper layer, the reinforcing material layer and the pore channels. No chemical reaction of the epoxy hardeners and the latent epoxy curing accelerators occurs under 110 DEG C, and the the epoxy hardeners and the latent epoxy curing accelerators can not dissolve and enter the pure epoxy VPI insulating resin in the VPI dipping paint process. The mica tape with little glue expands the utilization range of the epoxy resin as electric insulting materials, greatly reduces the requirements of the epoxy VPI insulation resin for dipping paint equipment and technologies, reduces energy consumption, and saves utilization cost.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Long glass fiber reinforced polypropylene material adopting foaming technique and preparation method thereof

The invention relates to a material and a preparation method thereof, and particularly relates to a long glass fiber reinforced polypropylene material adopting a foaming technique and a preparation method thereof, belonging to the technical field of materials. The long glass fiber reinforced polypropylene material comprises the following components by mass percent: 30-75wt% of polypropylene, 20-60wt% of long glass fiber, 0.5-5wt% of chemical foaming agent and 1-5wt% of compatibilizer. The viscosity of the resin is further reduced by adopting a micro-foaming technology, meanwhile, the chance that a glass fiber strong dispersing device reduces or avoids direct contact of a glass fiber bundle and a roller or a convex part is reduced, the damage to the glass fiber is reduced, and the traction resistance of a material bar is reduced. The long glass fiber reinforced polypropylene material has the beneficial effects that the product performance, quality stability and production efficiency are improved when the impregnation effect on the glass fiber caused by polypropylene resin is ensured.

Owner:NANJING JULONG SCI&TECH CO LTD

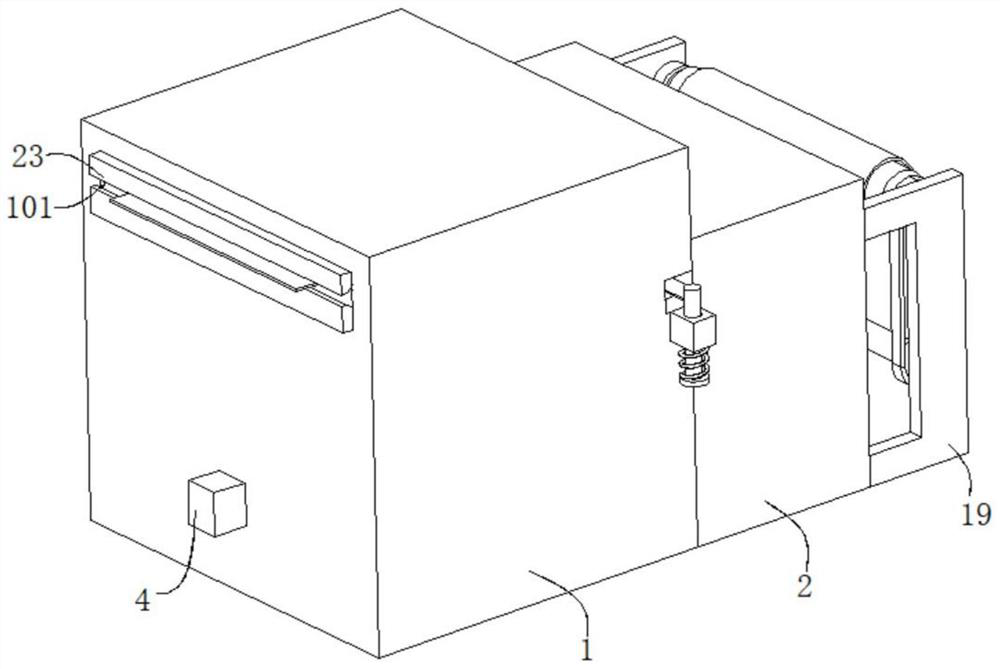

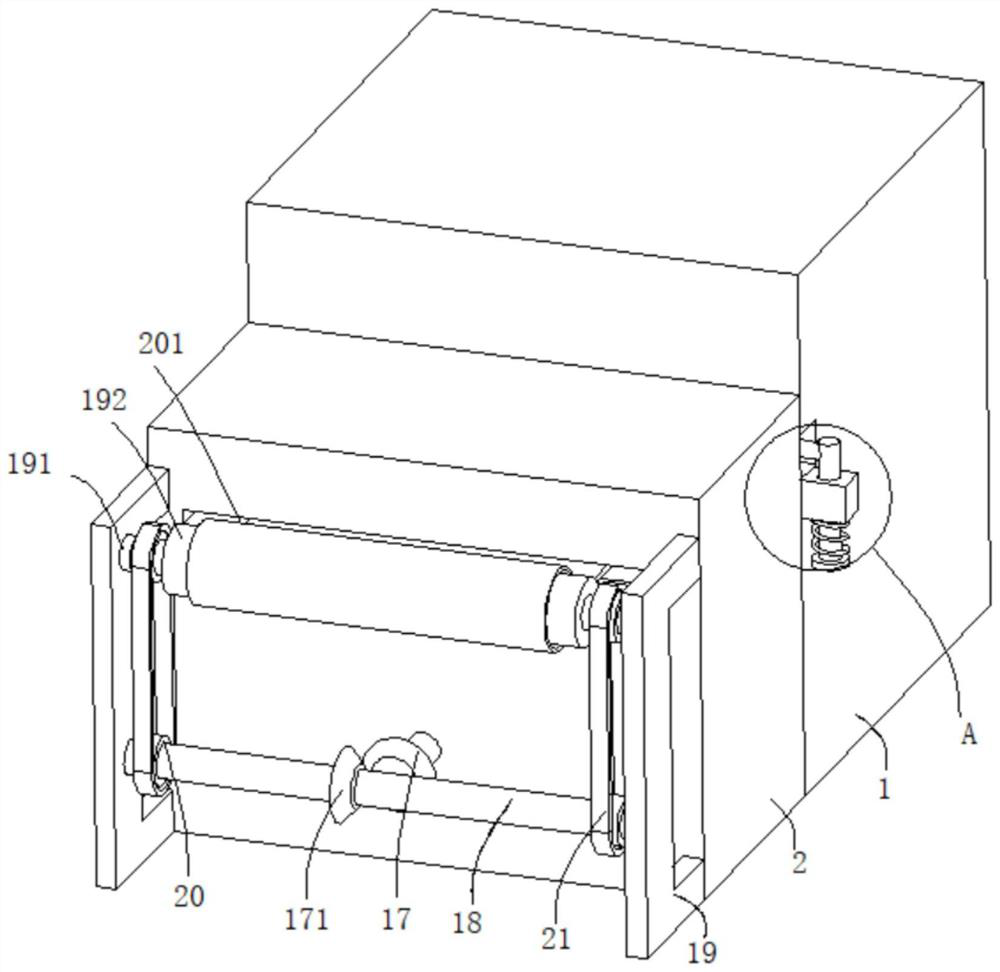

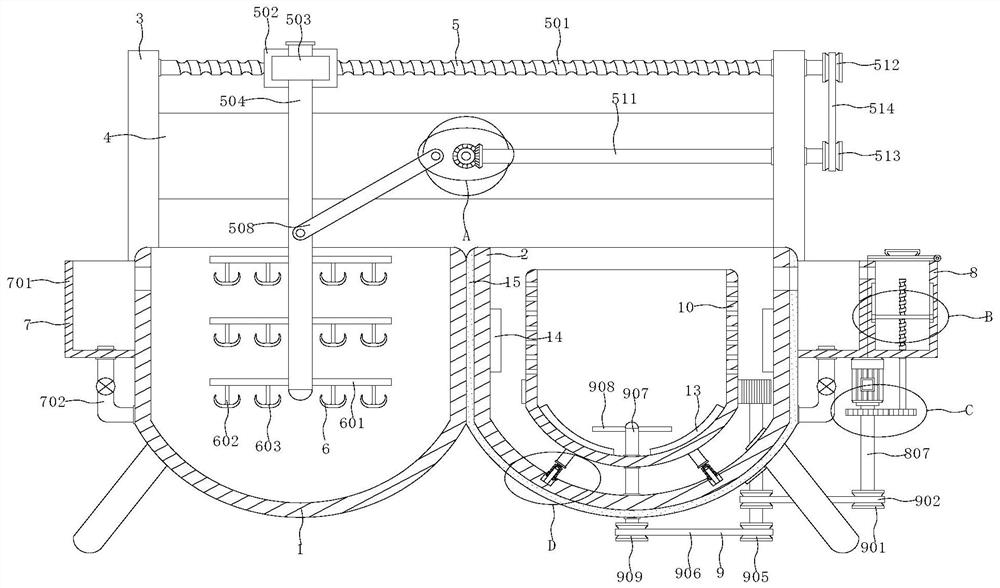

Cloth soaking, printing and dyeing device and using method thereof

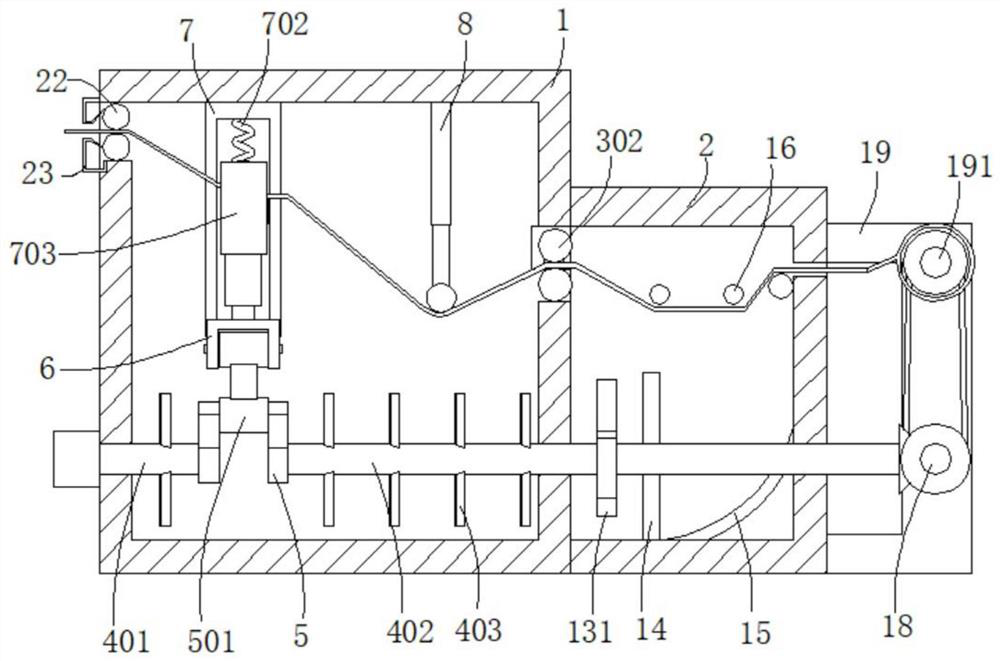

InactiveCN111826854AFast realization of printing and dyeingAvoid uneven printing and dyeingMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsMechanical engineeringDyeing

The invention discloses a cloth soaking, printing and dyeing device and a using method of the cloth soaking, printing and dyeing device, and belongs to the technical field of printing and dyeing. Thecloth soaking, printing and dyeing device comprises a dye box and a drying box, a through hole is connected between the dye box and the drying box, the dye box communicates with the drying box, a feeding hole is formed in the outer wall of the dye box, a discharge hole is formed in the outer wall of the drying box, the outer wall of the dye box is connected with a motor, the output end of the motor is connected with a first rotating shaft, the first rotating shaft is rotationally connected to the inner wall of the dye box, a second rotating shaft is rotationally connected to the inner wall ofthe dye box through a bearing, stirring blades are connected to the outer walls of the first rotating shaft and the second rotating shaft, cams are connected to the ends, away from the inner wall of the dye box, of the first rotating shaft and the second rotating shaft, and a connecting piece is fixedly connected between the two cams. With the technical scheme, the dye immersion into cloth can beaccelerated, so that the printing and dyeing efficiency is improved, meanwhile, the cloth can be rapidly dried, thus the situation that printing and dyeing are uneven after the cloth is rolled up is avoided, and the printing and dyeing effect of the cloth can be guaranteed.

Owner:浙江七色彩虹科技有限公司

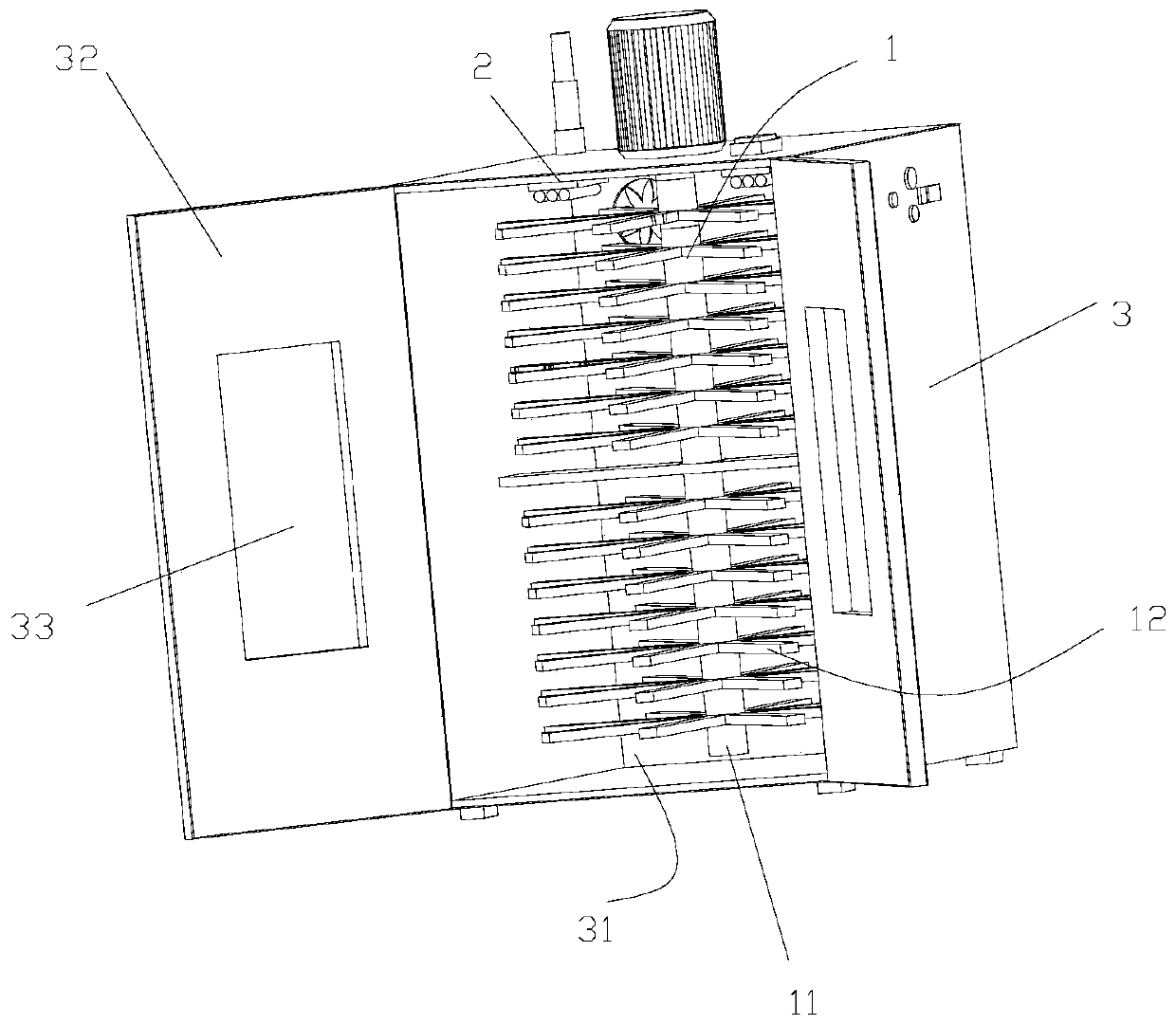

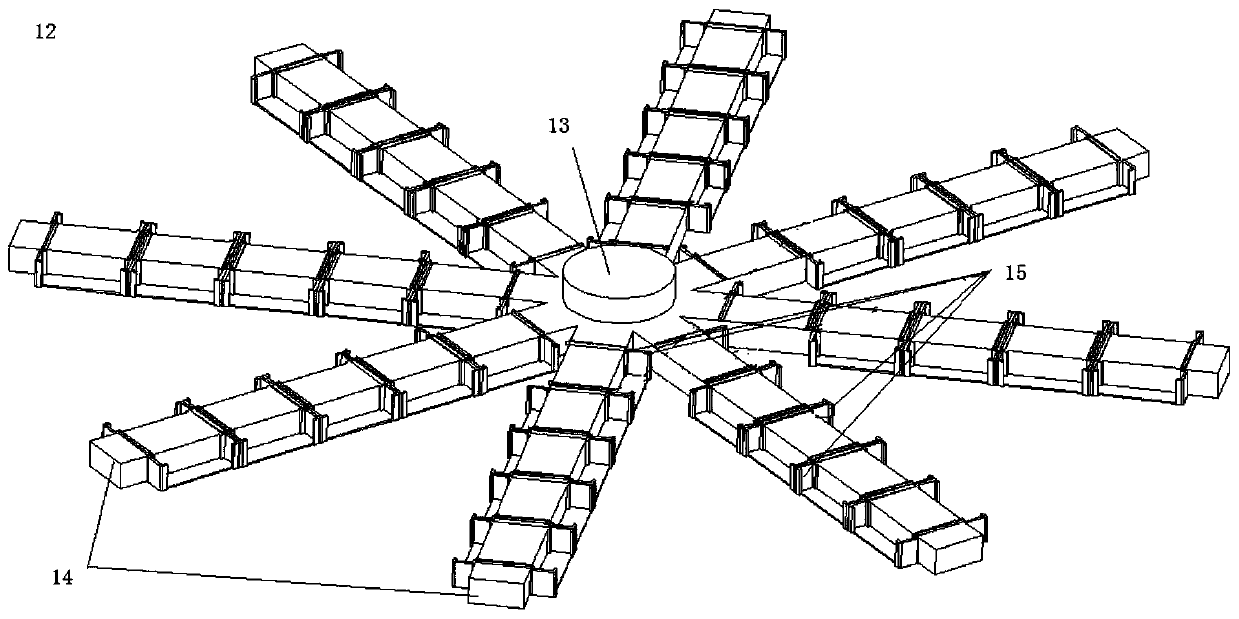

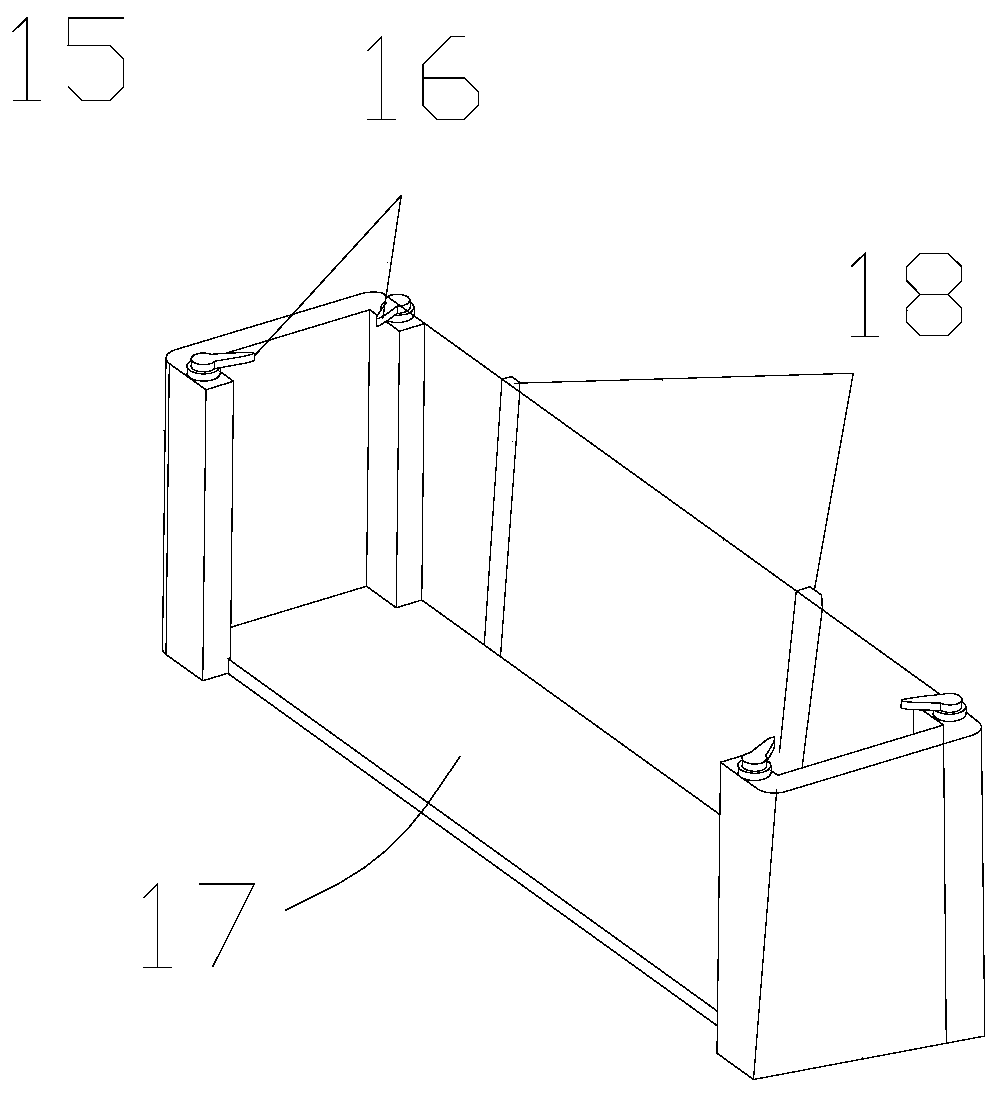

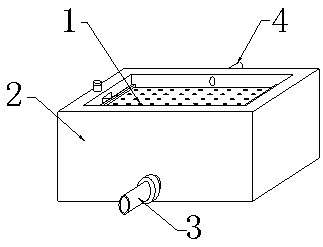

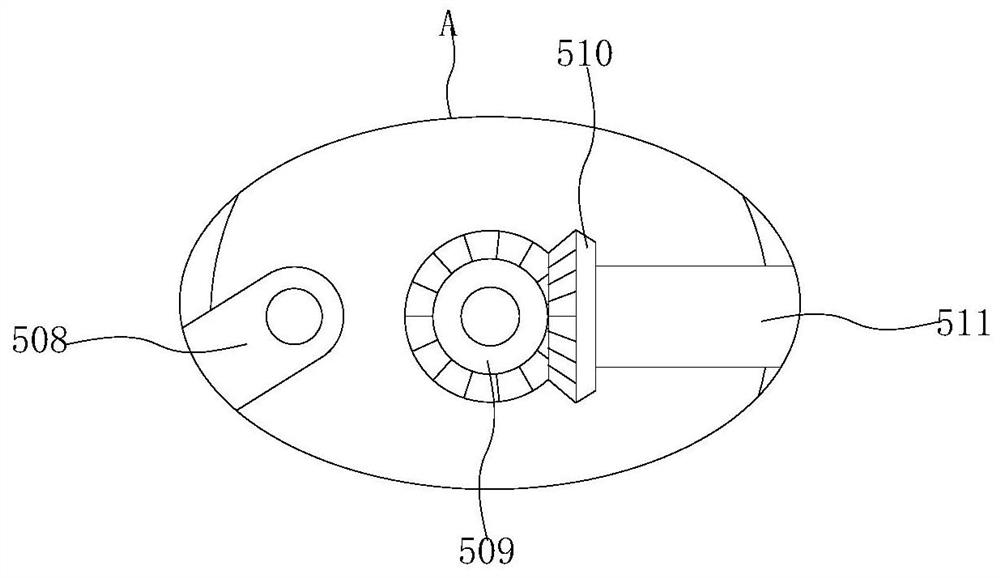

Device for assisting battery infiltration

ActiveCN110649321AQuick dipFully infiltratedFinal product manufactureSecondary cells manufactureThermodynamicsElectrical battery

The invention relates to the technical field of battery infiltration equipment and particularly relates to a device for assisting battery infiltration. The device comprises a rotating unit, a heatingunit and a shell with a cavity, wherein the rotating unit is rotatably mounted on the shell and is provided with an extending part extending into the cavity, the extending part is arranged to be capable of installing and driving a plurality of batteries filled with the electrolyte to rotate, and the heating unit is arranged on the shell and is arranged to be capable of heating the chamber so as toenable the batteries accommodated in the chamber to reach the infiltration temperature. The device is advantaged in that the rotating unit and the heating unit are arranged, so the battery injected with the electrolyte can be infiltrated in a rotating mode at the infiltration temperature, the infiltration time is remarkably shortened, secondary electrolyte injection is not needed, and infiltration efficiency is obviously improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Low-temperature oil-heat bamboo modifying processing method

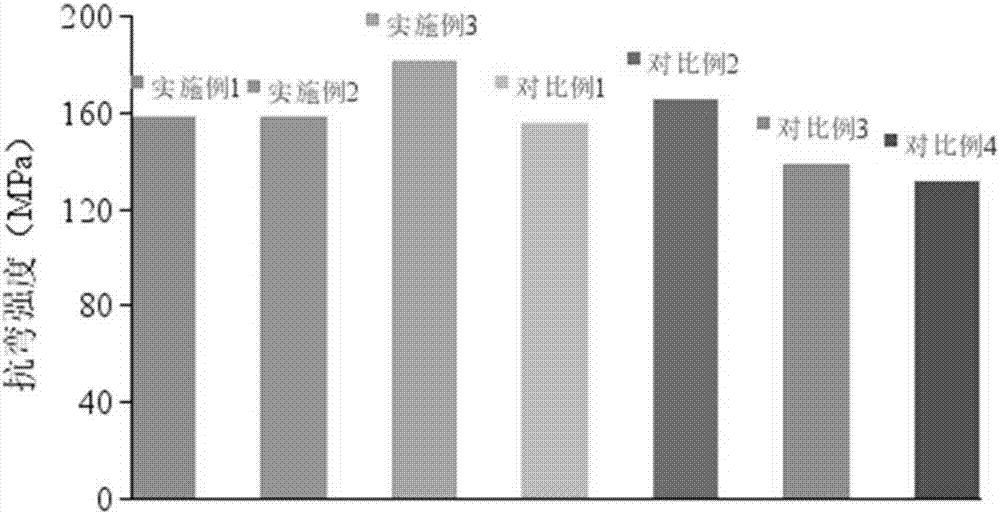

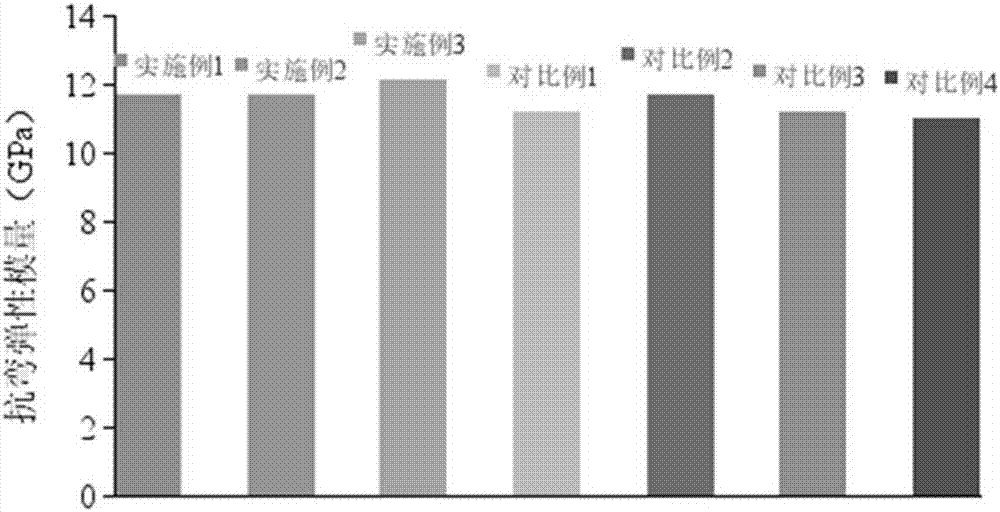

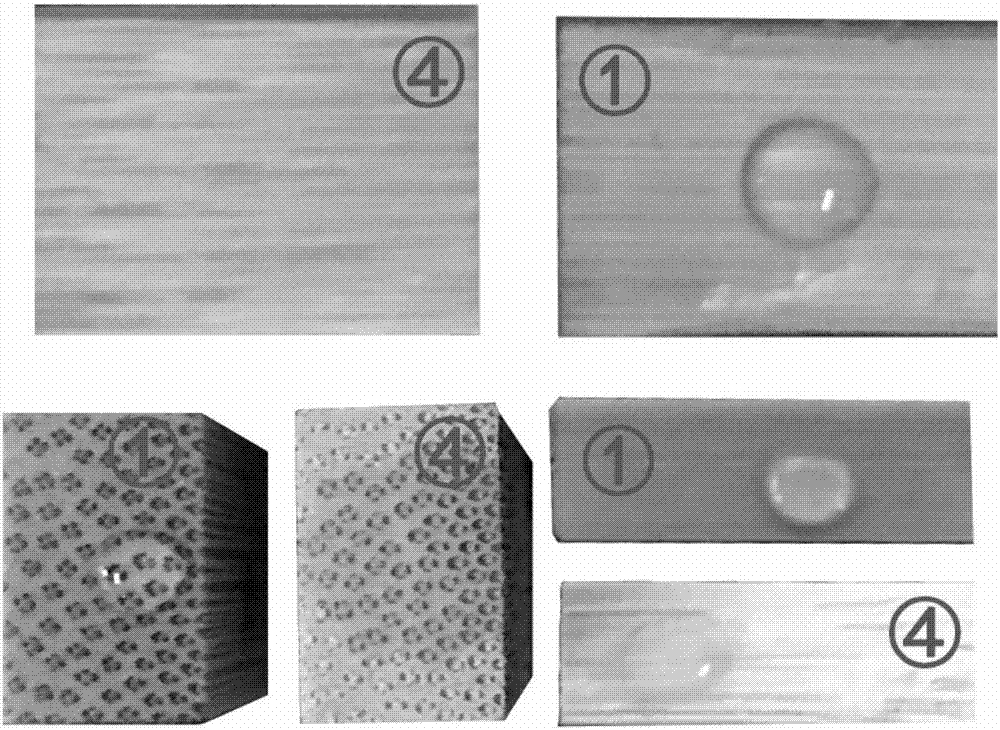

ActiveCN107443518AGood dimensional stabilityQuick dipWood treatment detailsReed/straw treatmentApplication areasMechanical property

The invention discloses a low-temperature oil-heat bamboo modifying processing method. By means of the method, the mechanical property of bamboo can be improved, the waterproof effect of the bamboo can be better, the anti-corrosive durability is improved, and therefore the application field of the bamboo is widened. The method comprises the following steps of (1) drying the bamboo, (2) adding a coupling agent into oil for preparing an oil solution, (3) heating the oil solution, (4) immersing the bamboo into constant-temperature heated oil for treatment, (5) conducting surface treatment and (6) conducting end-capping treatment. The dimensional stability of the bamboo treated according to the method is improved, the anti-corrosion, mold-proof and waterproof properties of products are improved, and the mechanical property does not decline. After the cross section of the bamboo is subjected to end-capping treatment, the loss of a modifying agent can be effectively reduced, and the protecting effect is more lasting.

Owner:INT CENT FOR BAMBOO & RATTAN

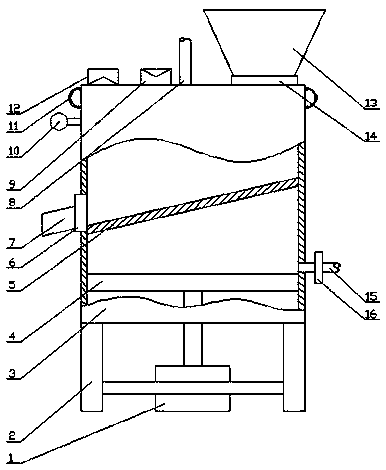

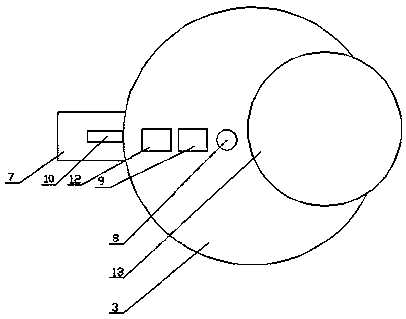

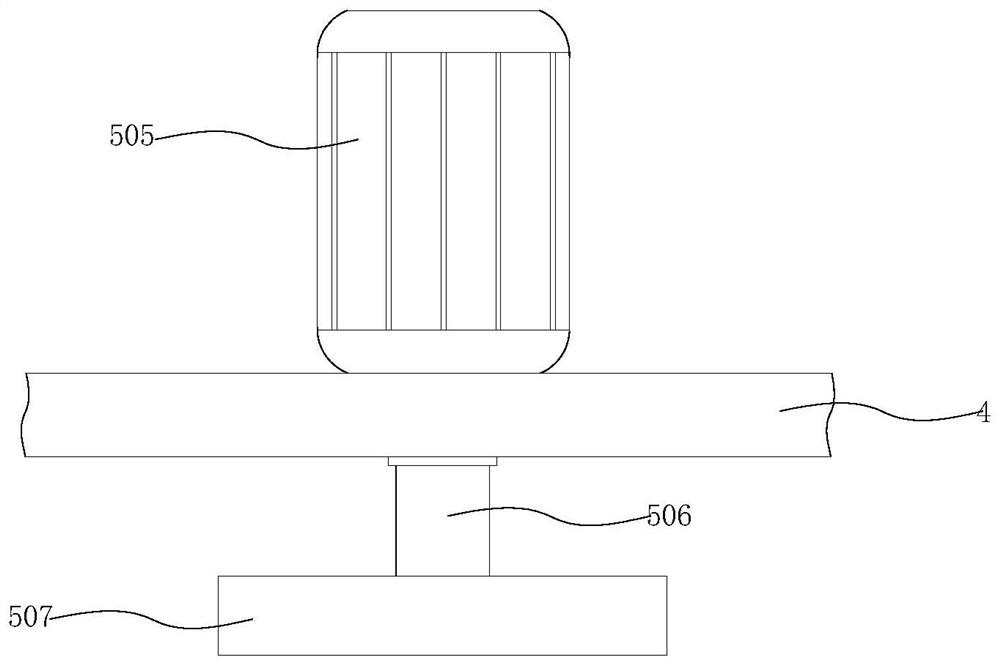

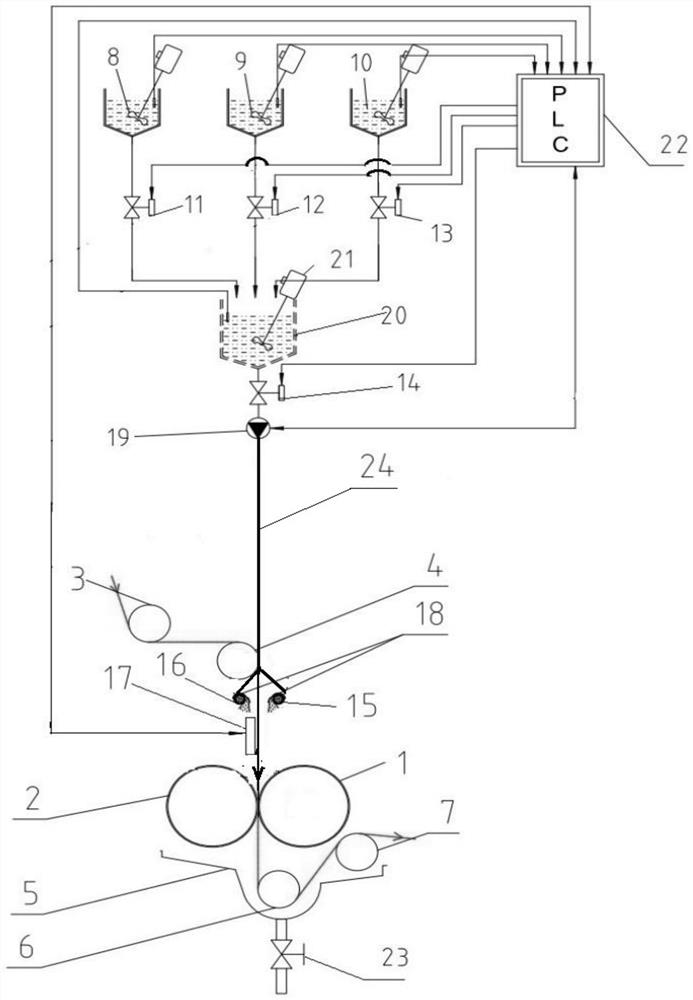

High-performance cotton thread moistening device for textile production

InactiveCN110592843AImprove work efficiencyFast processTextile treatment machine arrangementsTextile treatment with treating outlet contectElectric machineryFuel tank

The invention belongs to the field of textiles, and particularly relates to a high-performance cotton thread moistening device for textile production. The device comprises a box body, an oil storage tank is fixedly connected to the upper end of the box body, a horizontally arranged rotating inner pipe is rotationally connected to the inner side wall of the box body, multiple through oil outlet holes are formed in the side wall of the rotating inner pipe, a motor is fixedly installed on the side wall of the box body, an output shaft of the motor penetrates through the box body and is coaxiallyand fixedly connected with the rotating inner pipe, an oil outlet pipe is fixedly communicated with the side wall of the oil storage tank, the lower end of the oil outlet pipe sequentially penetratesthrough the box body and the rotating inner pipe and is rotationally connected with the rotating inner pipe, and a movable outer pipe sleeves the rotating inner pipe. Accordingly, by means of relativerotation of the rotating inner pipe and the movable outer pipe, cotton threads can be rubbed, and meanwhile the movable outer pipe periodically shakes in the rotating inner pipe to extrude the cottonthreads so that silicon oil can immerse into the cotton threads rapidly; the thread moistening effect is better, and the efficiency is high.

Owner:任晓倩

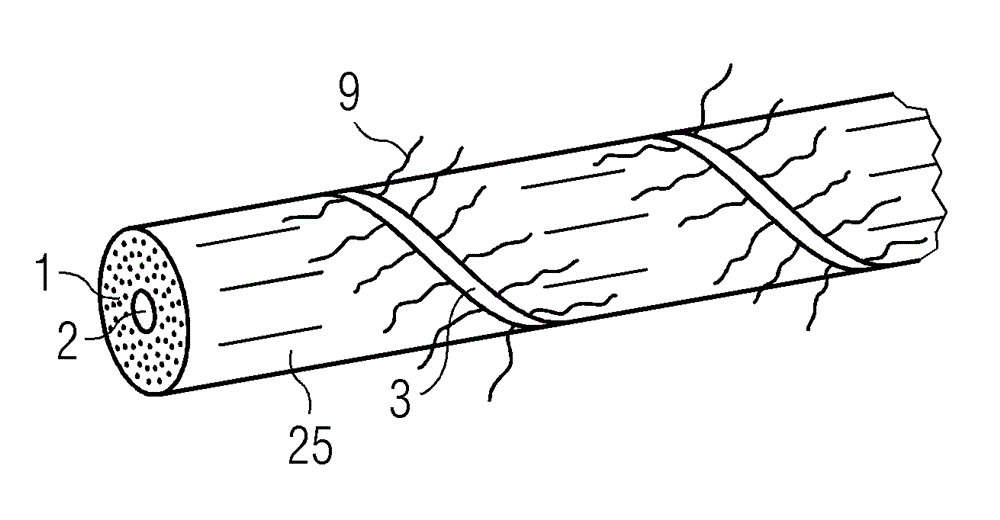

Bundle of roving yarns, method of manufacturing a bundle of roving yarns and method for manufacturing a work piece

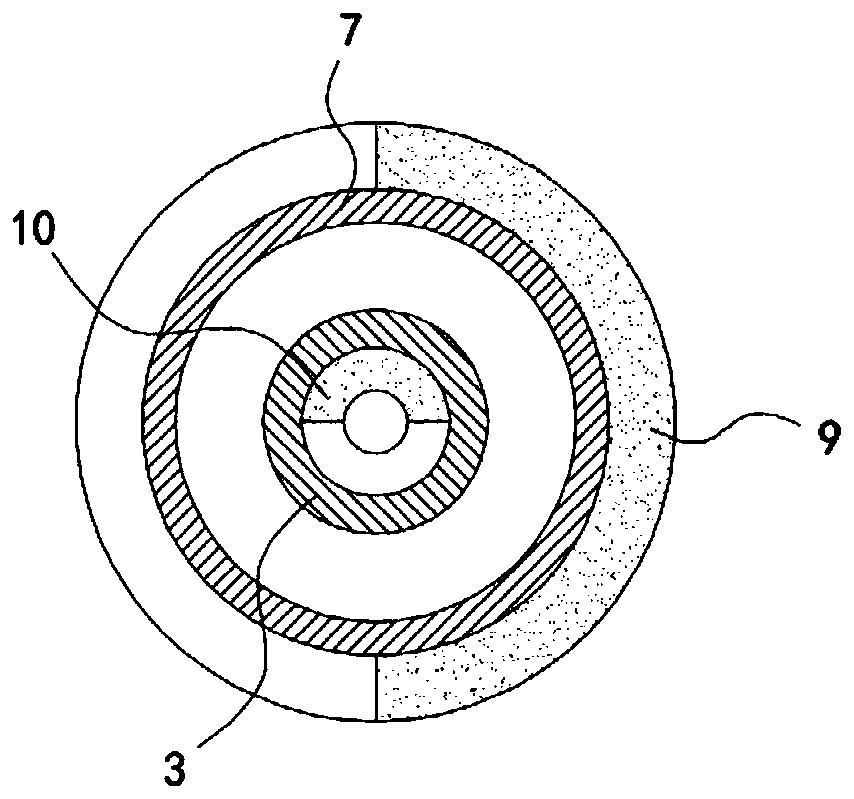

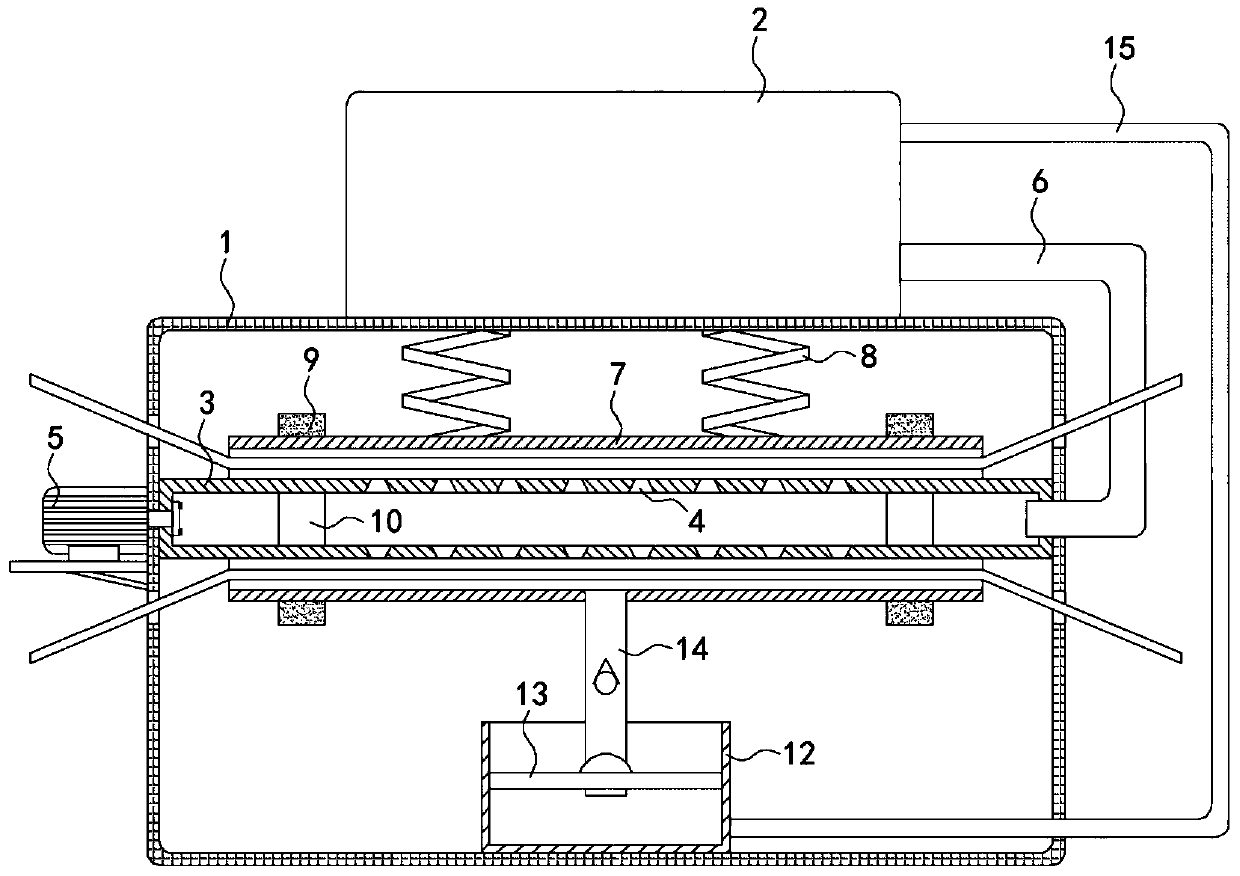

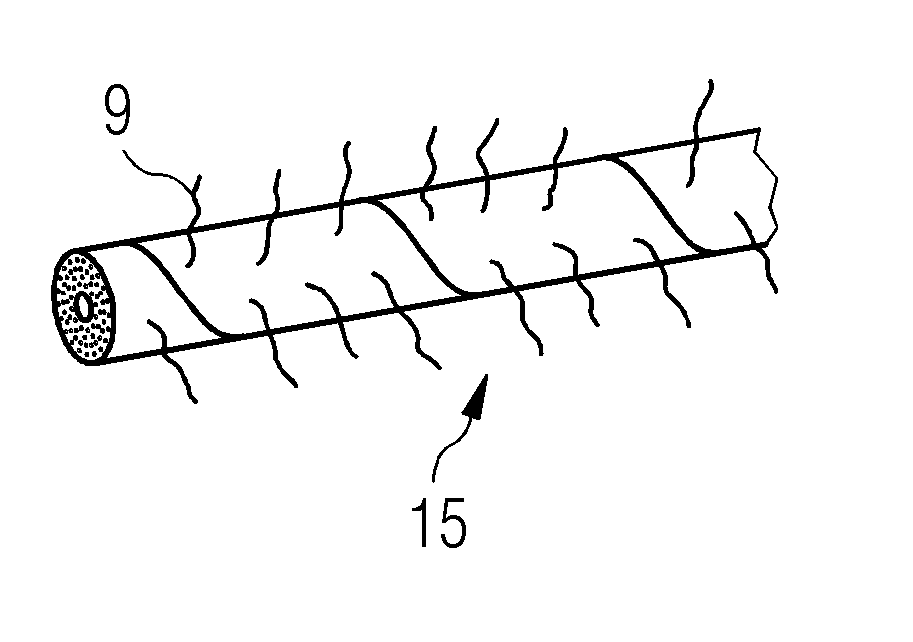

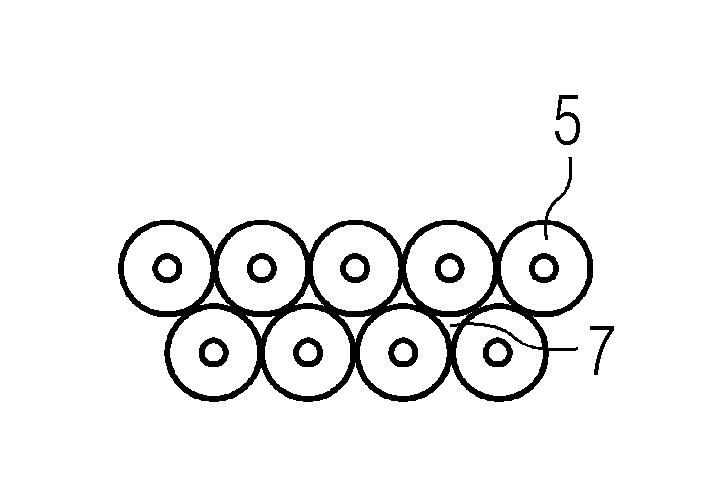

A method of manufacturing a bundle (5) of roving yarns (1) is described. The method is characterised in assembling a number of roving yarns (1) of longitudinal unidirectional fibres and an additional component (2, 36) in a bundle (5). For example, at least one resin distribution means (2) or a thermoplastic material (36) can be placed as the additional component (2, 36) in the bundle (5).

Owner:SIEMENS AG

Microwave dip dyeing method for willow twigs

ActiveCN106956336AReduce rigidityImprove fixation effectRadiation/waves wood treatmentWood treatment detailsFiberMicrowave

The invention discloses a microwave dip dyeing method for willow twigs. The microwave dip dyeing method comprises the following steps: firstly, stewing the willow twigs; secondly enabling the stewed willow twigs to be subjected to alkali-H2O2 one-bath boiling; finally, enabling the materials obtained in the second step to be subjected to pretreatment by a chitosan acid solution; components like xylogen in the willow twigs are degraded, so that the rigidity of the willow twig structures is reduced, and the willow twigs are prevented from cracking under the mechanical force action and a thermal action; chitosan is added to play a certain modifying effect on willow twig fibers, the dye fixation is higher; besides, an anti-cracking dyeing auxiliary is added into the dye, the dyeing power of the dye on the surfaces of the willow twigs is improved, a protective film is formed on the surfaces of the willow twigs, a continuous, flatted and smooth coloring film is formed, the dye can quickly immerse into the willow twig fibers by microwave treatment, and an everlasting and stable dyeing effect is achieved.

Owner:霍邱县淮美奇工艺品有限公司

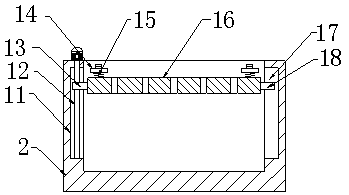

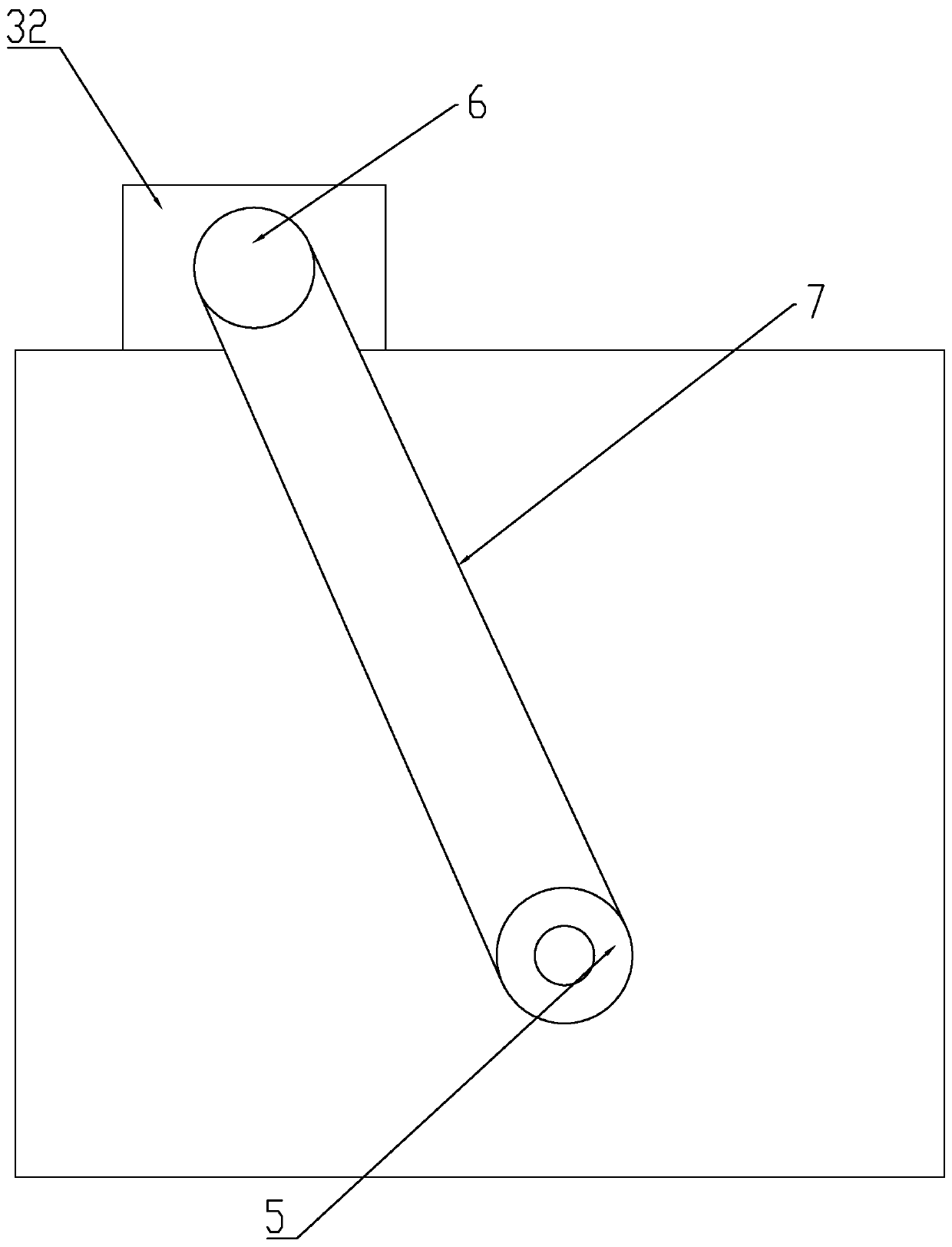

Silk soaking device

InactiveCN108754934AReasonable structurePracticalTextile treatment machine arrangementsTextile treatment carriersEngineering

Owner:ANHUI LIANFENG SILK MAKING

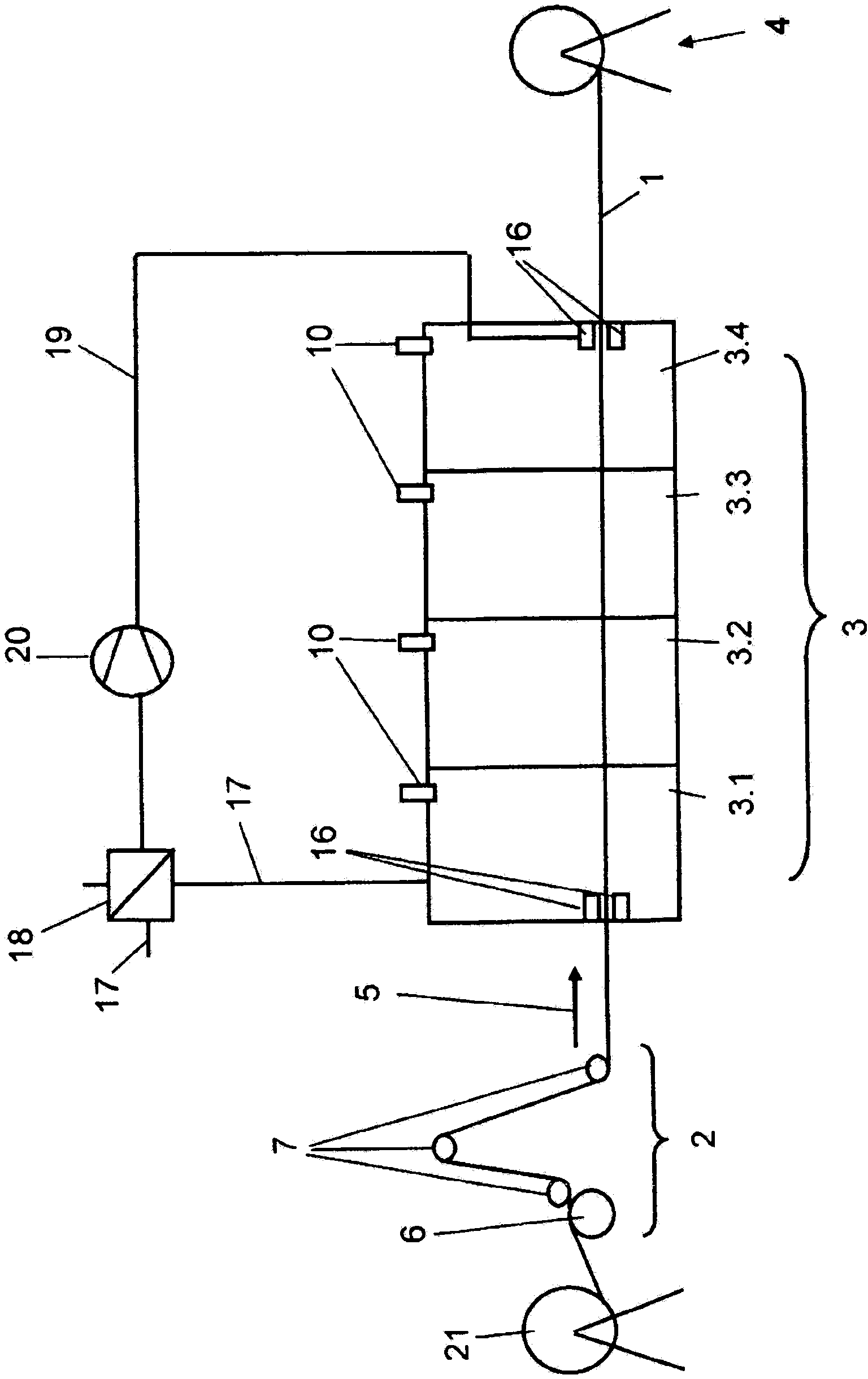

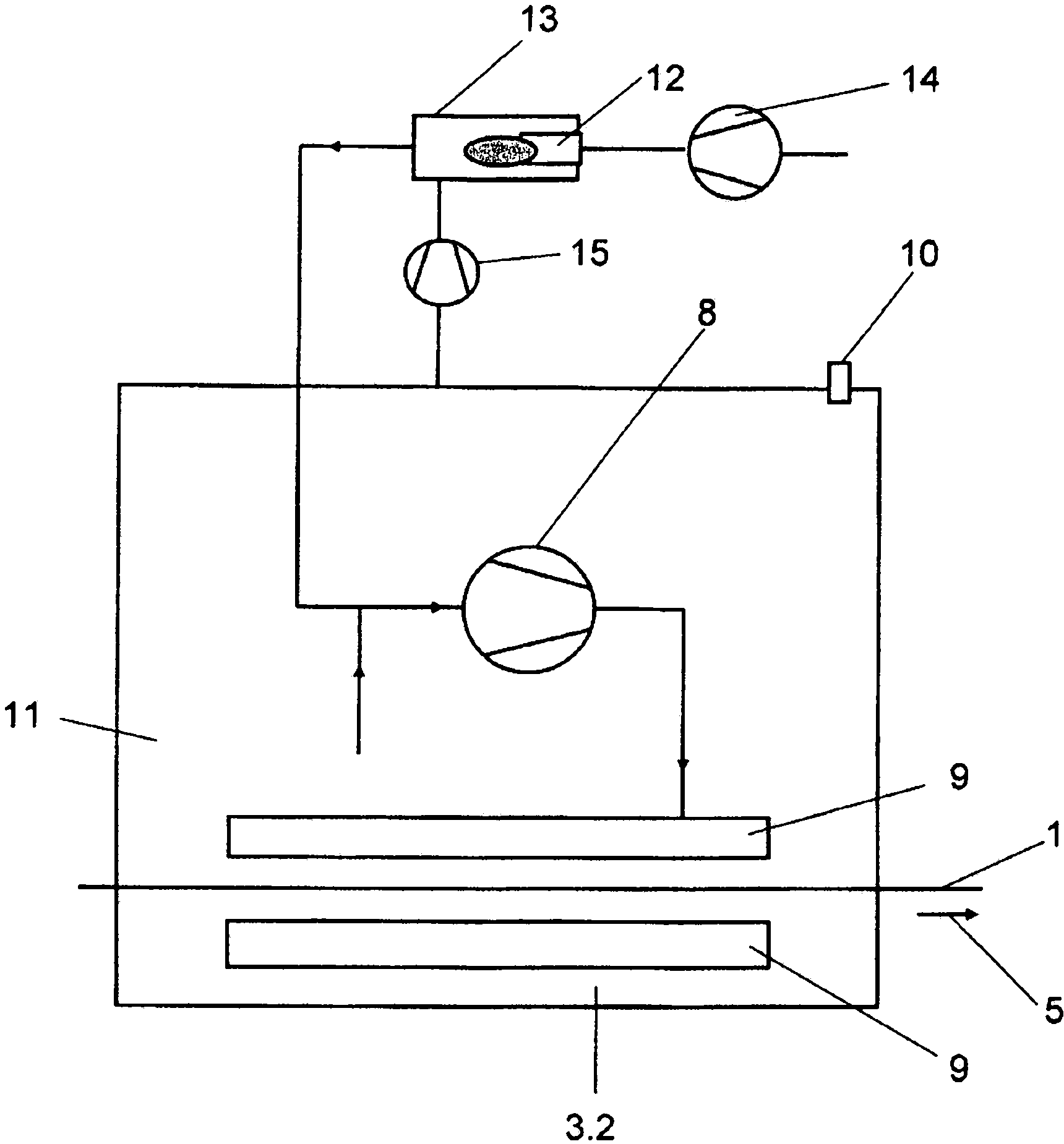

Method and system for impregnating and drying a continuous paper web

InactiveCN103370589APrevent crosslinkingPrevent inflowNon-fibrous pulp additionSpecial paperPulp and paper industryMelamine

The invention relates to a method for impregnating and drying a continuous paper web (1) by means of a urea resin dissolved in water, and to a corresponding system. Such paper webs (1) are employed for example as furniture foil or floor laminate, wherein in the known art melamine resin is used exclusively for bonding to a substrate. This is relatively expensive. Therefore the object of the invention is to create a method in which the paper web (1) which is impregnated by means of urea resin can be bonded to the substrate with a high degree of operational reliability. Said object is achieved in that the temperature of the paper web (1) is determined separately in each of the drying zones (3.1, 3.2, 3.3, 3.4), that for each of the drying zones (3.1, 3.2, 3.3, 3.4) an amount and / or a temperature of the circulating air are regulated so that the maximum temperature of the paper web (1) is 99° C., and that exhaust air is extracted from a first one of the drying zones (3.1, 3.2, 3.3, 3.4) and fresh air is supplied to a last one of the drying zones (3.1, 3.2, 3.3, 3.4).

Owner:VITS TECH

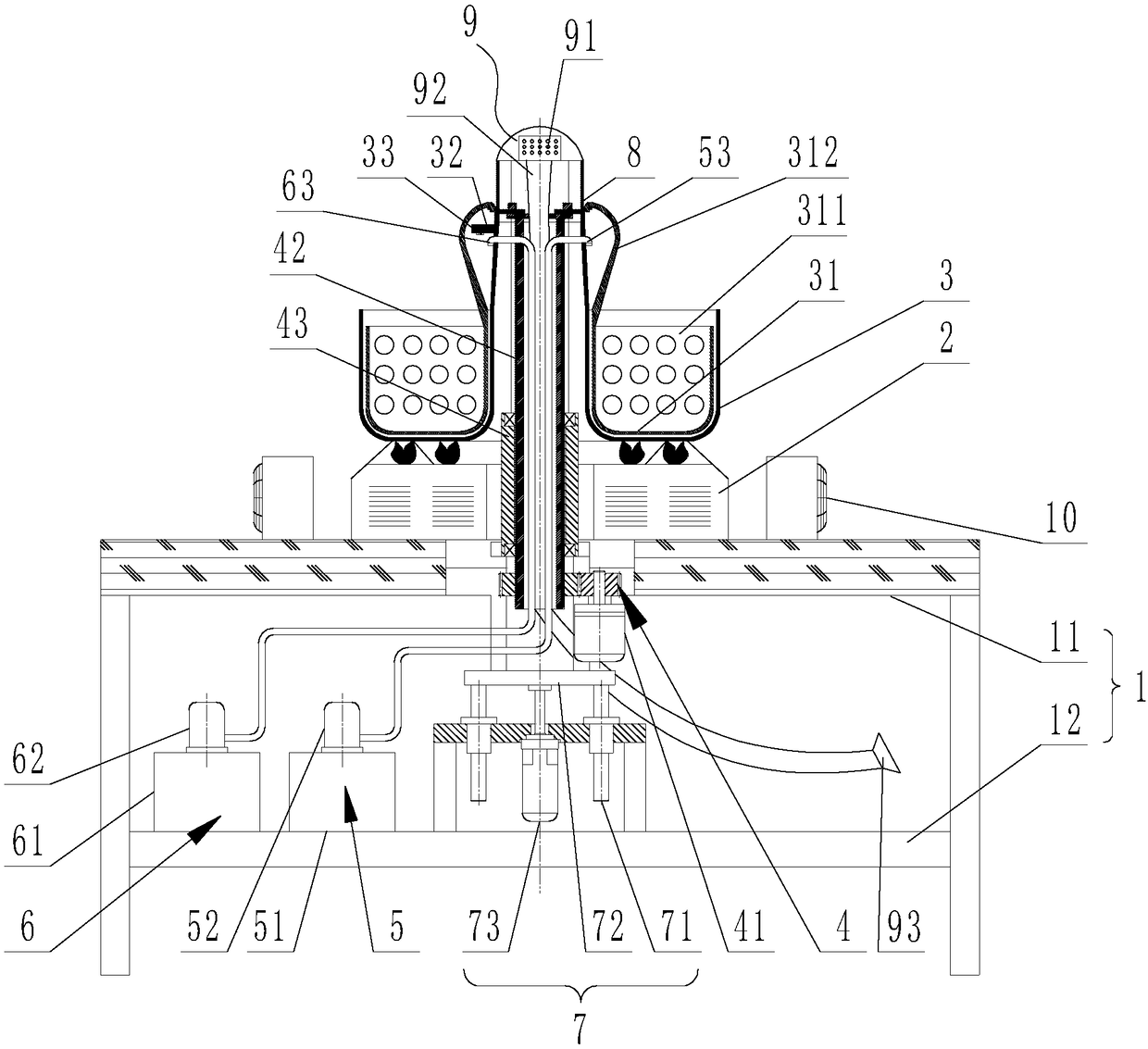

Barrier-free soup-adding hot pot

InactiveCN108903588AConvenient diningLarge dining areaCooking insertsCooking vessel constructionsFuel tankFood material

The invention provides a barrier-free soup-adding hot pot, and relates to an intelligent hot pot. The intelligent hot pot comprises a table body, a heating device, a pot body, a rotating mechanism, anautomatic oil tank system, an automatic soup system, a lifting mechanism, an upper cover body and the like, wherein the table body comprises a table panel and a bottom plate; the center of the tablepanel is hollowed-out; the heating device is mounted at the hollowed-out position; the pot body is placed on the heating device; the heating device and the pot body are annular; the automatic oil tanksystem and the automatic soup system are mounted on the bottom plate; and the output end of the automatic oil tank system successively penetrates through the hollowed-out position of the table panel,the central hole of the heating device and the pot wall of the inner side of the pot body and extends to the position above a cavity of the pot body. Soup and edible oil can be added automatically, the space of the table body does not need to be occupied, the hot pot does not hinders diners, splashing can further be prevented when soup and water are added, the barrier-free soup-adding hot pot hasthe characteristics of convenience in cleaning, simplicity and attractiveness, convenience in isolation of a seasoning from food materials, stirring and clamping are facilitated, food is convenient to find, lampblack is small, degree of automation is high, the hot pot is convenient to use, and the like, and the barrier-free soup-adding hot pot is easy to popularize and use.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

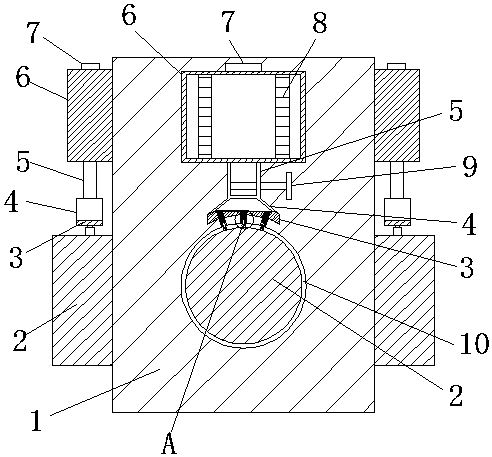

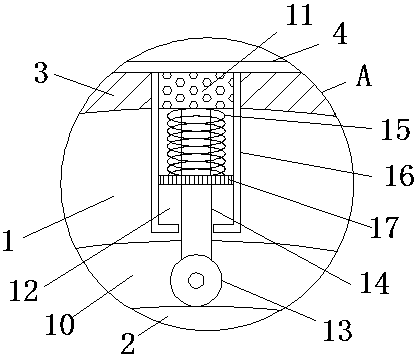

Silkworm cocoon soaking device for spinning

ActiveCN105970301AIncrease or decrease pressureQuick dipSilk filament obtainingWater resourcesSoaking Procedure

The invention relates to the field of spinning, in particular to a silkworm cocoon soaking device for spinning. The silkworm cocoon soaking device for spinning can improve silkworm cocoon water absorbing efficiency, shorten soaking time and save soaking water, and waste of water resources is avoided. The device structurally comprises a cylinder of a cylindrical hollow structure. A piston head is supported at the bottom in the cylinder through an electric hydraulic jack, the electric hydraulic jack penetrates through the bottom of the cylinder, the piston head is of a disc structure and placed horizontally, and the outer ring of the piston head is attached to the inner wall of the cylinder. A grid is supported in the middle of the inner wall of the cylinder, is of a grid structure and is obliquely arranged. A discharge hopper is supported on the outer side wall of the cylinder through a discharge door, the discharge hopper is communicated with the inside of the cylinder through the discharge door and is flush with the lower end of the grid, and the discharge hopper is of a U-type tank structure. The silkworm cocoon soaking device for spinning is high in use efficiency, low in use cost and suitable for the spinning silkworm cocoon soaking procedure.

Owner:SUZHOU DONGZHAN DOWN GARMENTS

Semiconductor cleaning agent and preparation method thereof

InactiveCN112592771AMeet production needsReduce pollutionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsOrganic solventActive agent

The invention discloses a semiconductor cleaning agent and a preparation method thereof, and belongs to the technical field of semiconductor cleaning. The semiconductor cleaning agent comprises the following components in parts by mass: 2-5 parts of a nonionic surfactant, 9-12 parts of an anionic surfactant and 3-6 parts of an organic solvent. The semiconductor cleaning agent prepared by the preparation method of the semiconductor cleaning agent has excellent dispersing performance and tolerance to abrasives, metal ions and the like on the surface of a silicon wafer, the cleaned surface is uniform, smooth and clean, the production requirements of customers are well met, and meanwhile, the pollution to the environment is reduced.

Owner:德锡化学(山东)有限公司

Coaxial reversing box

The invention discloses a coaxial reversing box. The coaxial reversing box comprises a box body. Rotating cavities are correspondingly formed in the front face and the left and right side walls of thebox body. A rotating shaft is rotationally connected in each rotating cavity. Lubricating devices are correspondingly arranged on the front face and the left and right side walls of the box body. According to the coaxial reversing box, when the box body is connected with a power source to drive the rotating shafts to rotate, valves are turned on to enable lubricating oil in oil tanks to flow intohoppers through oil inlet pipes, and slight vibration occurs to the box body in the rotating process of the rotating shafts, so that the lubricating oil is accelerated to soak into oil absorption sponge faster, and the lubricating oil slowly flows into pulleys along the side walls of guide rods through the oil absorption sponge; and when the rotating shafts drive the pulleys to rotate together, the surfaces of the rotating shafts are uniformly coated with the lubricating oil, so that the surfaces of the rotating shafts are wetter and smoother, the friction force between the rotating shafts and the inner walls of the rotating cavities is reduced, the rotating shafts can rotate more smoothly, and the working efficiency is improved.

Owner:YANCHENG PUCI MACHINERY CO LTD

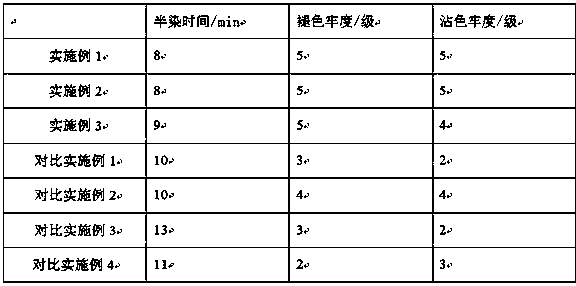

Pure cotton active salt-free dyeing solution, dyed pure cotton shell fabric using same and technology

The invention belongs to the technical field of textile finishing processing, and specifically relates to a pure cotton active salt-free dyeing solution, a dyed pure cotton shell fabric using the purecotton active salt-free dyeing solution and a technology. The pure cotton active salt-free dyeing solution comprises the following components in concentrations: 0.5 to 80 g / L of active dye, an alkaline agent whose using amount is 55% to 65% of that of the active dye and is not lower than 9 g / L, NaOH whose using amount is 2.5% to 3.5% of that of the active dye and is not lower than 0.6 g / L, and the balance is water; the active dye is one or more of active yellow O, active red R and active blue B; the alkaline agent is SFA-01. The dyeing solution has good permeability for the pure cotton shellfabric, and can be used for dyeing under the condition without salt acceleration; the dyed pure cotton shell fabric is stable in quality, excellent in color fastness, colorful and plump in yarn-dyed weaving and excellent in comprehensive performance; according to the technology dyed by using the dyeing solution, surface dyeing can be removed effectively, the color fastness and washing fastness ofthe shell fabric are promoted, the COD value of wastewater discharge is reduced, and the technology is environmentally friendly and good in economic benefit.

Owner:鲁丰织染有限公司

Method for performing normal-temperature rapid dip dyeing on seaweed non-woven fabric and enhancing ultraviolet resistance

ActiveCN106049101AImprove hydrophobicitySmall particle sizeLiquid/gas/vapor removalDyeing processUltraviolet lightsNonwoven fabric

The invention relates to a method for performing normal-temperature rapid dip dyeing on a seaweed non-woven fabric and enhancing ultraviolet resistance, in particular to a method for utilizing a copper phthalocyanine pigment to perform rapid dip dyeing on the seaweed non-woven fabric and enhance ultraviolet resistance, and belongs to the technical field of spinning dyeing and printing. According to the method, cationic surfactant cetyltrimethylammonium chloride is utilized to prepare the small copper phthalocyanine pigment stably dispersed in water, the normal-temperature rapid dip dyeing of the seaweed non-woven fabric is achieved, the ultraviolet light transmittance can be remarkably lowered, the ultraviolet protection factor (UPF) of the non-woven fabric is improved remarkably, and thus the ultraviolet resistance of the seaweed non-woven fabric can be enhanced obviously.

Owner:QINGDAO UNIV

A silkworm cocoon soaking device for textile

ActiveCN105970301BIncrease or decrease pressureQuick dipSilk filament obtainingWater resourcesSoaking Procedure

Owner:SUZHOU DONGZHAN DOWN GARMENTS

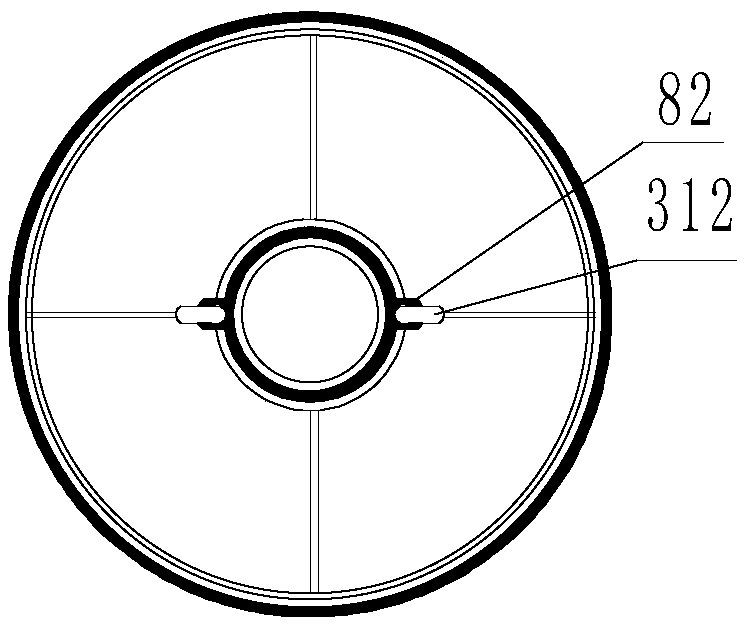

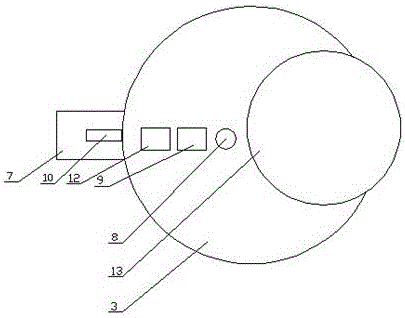

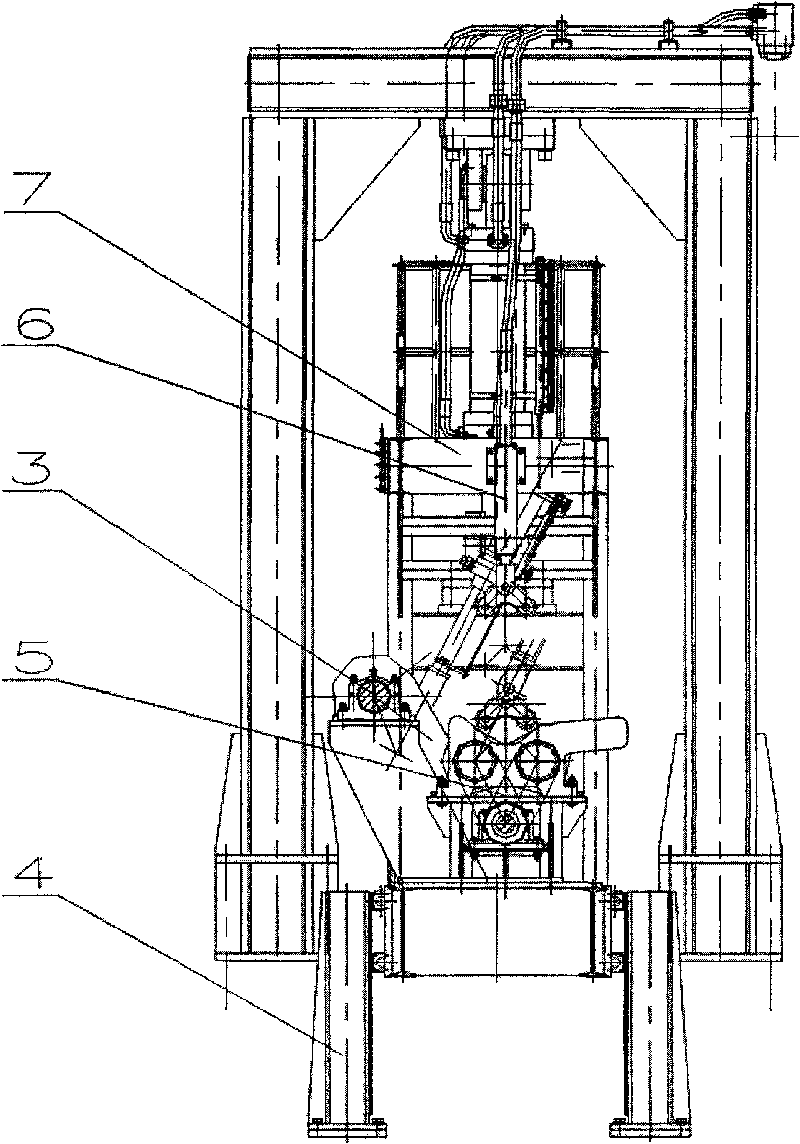

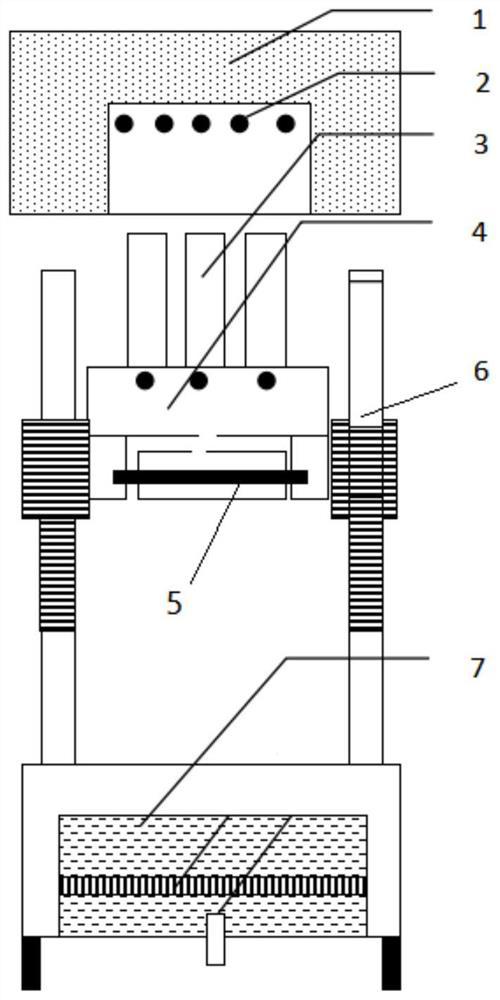

Rotation lifting mechanism in steel tube quenching device and steel tube quenching method

InactiveCN101109039BHigh speed rotationQuick dipFurnace typesHeat treatment process controlQuenchingSteel tube

The invention relates to a rotation lifting mechanism of a steel pipe quenching unit and a steel pipe quenching method. The steel pipe quenching method is that when the heated steel pipe is placed ona rotation supporting wheel, the rotation supporting wheel rotates at a speed lower than 10 rotations per minute to 15 rotations per minute; a compaction device distributed along the steel pipe direction closely presses the steel pipe; the rotation supporting wheel drives the steel pipe to rotate at a speed faster than 45 rotations per minute to 120 rotations per minute, and drives a frame beam 7to move downwards at a speed of 150 mm per second to 400 mm per second driven by a left lift cylinder 1 and a right lift cylinder 9 at the same time; the steel pipe is dipped into quenching medium ofa quenching tank, at this time, the inner spraying liquid flushes liquid to the internal of the steel pipe by an inner spraying nozzle always aiming to mouth of the steel pipe and the steel pipe innerwall quenching is carried out; until the temperature of the steel pipe is lower than 300 DEG C., the frame beam 7 is driven by both the left lift cylinder 1 and the right lift cylinder 9 and is lifted, at the same time, the compaction device is opened and a feeding overturn board 3 is turned to the material outlet location from a material receiping location to convey the steel pipe to an inclinedbench.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

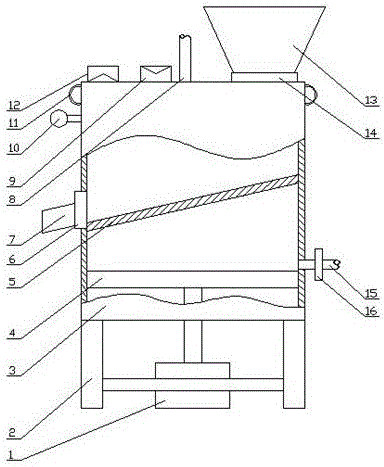

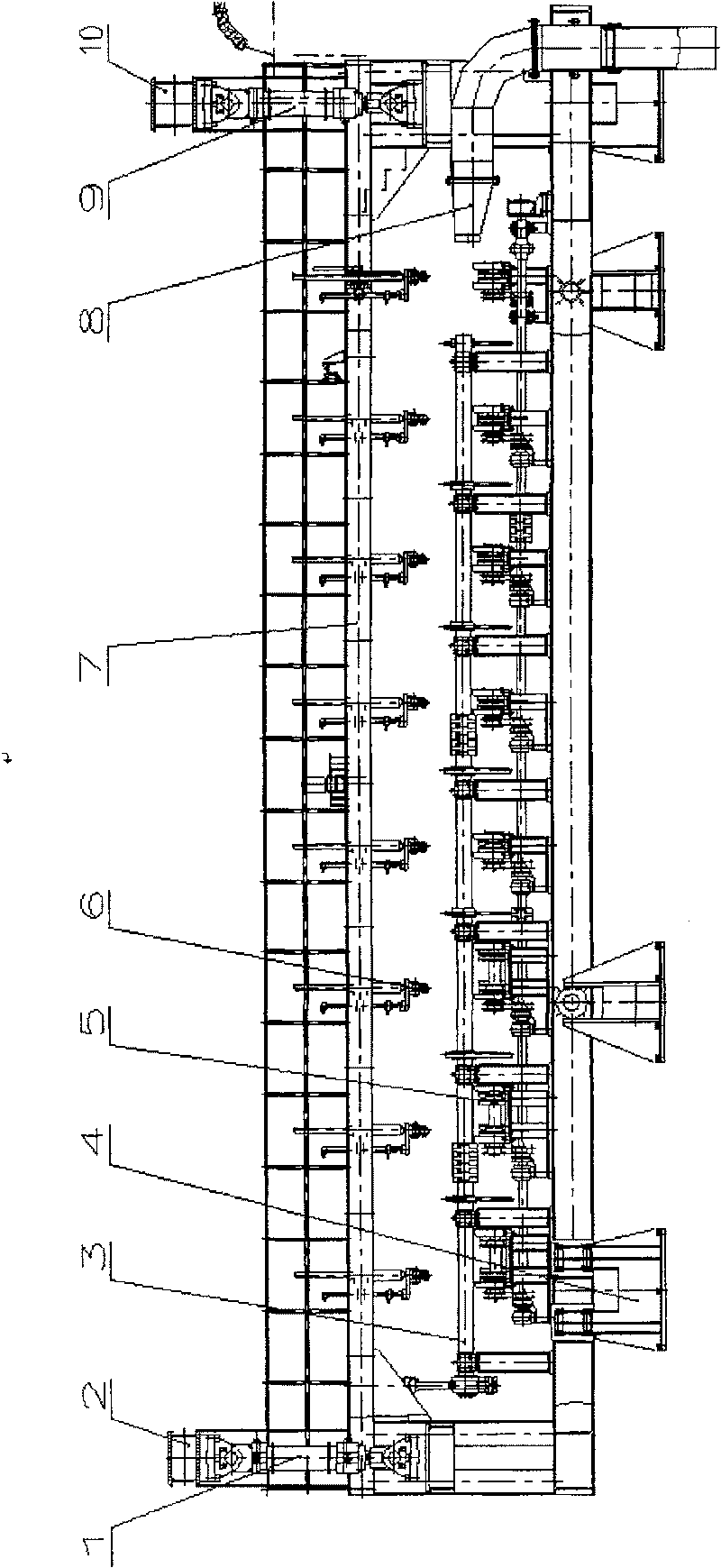

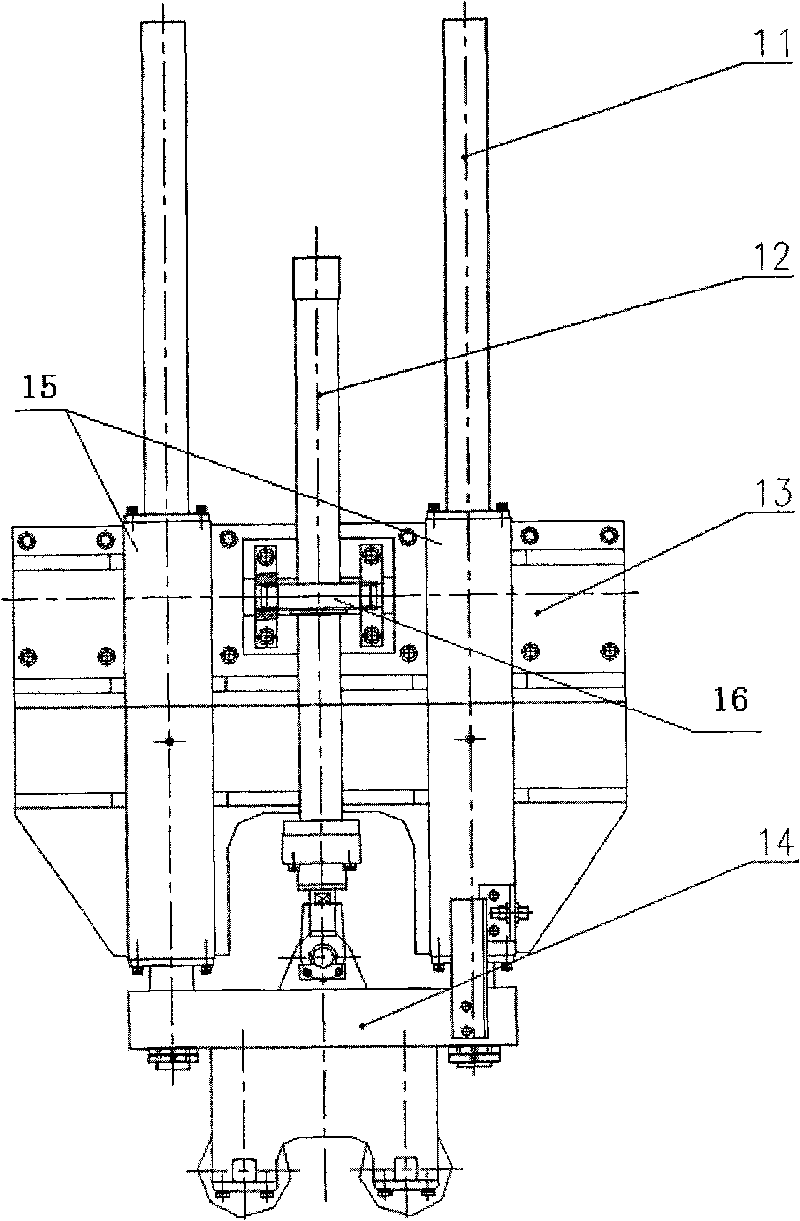

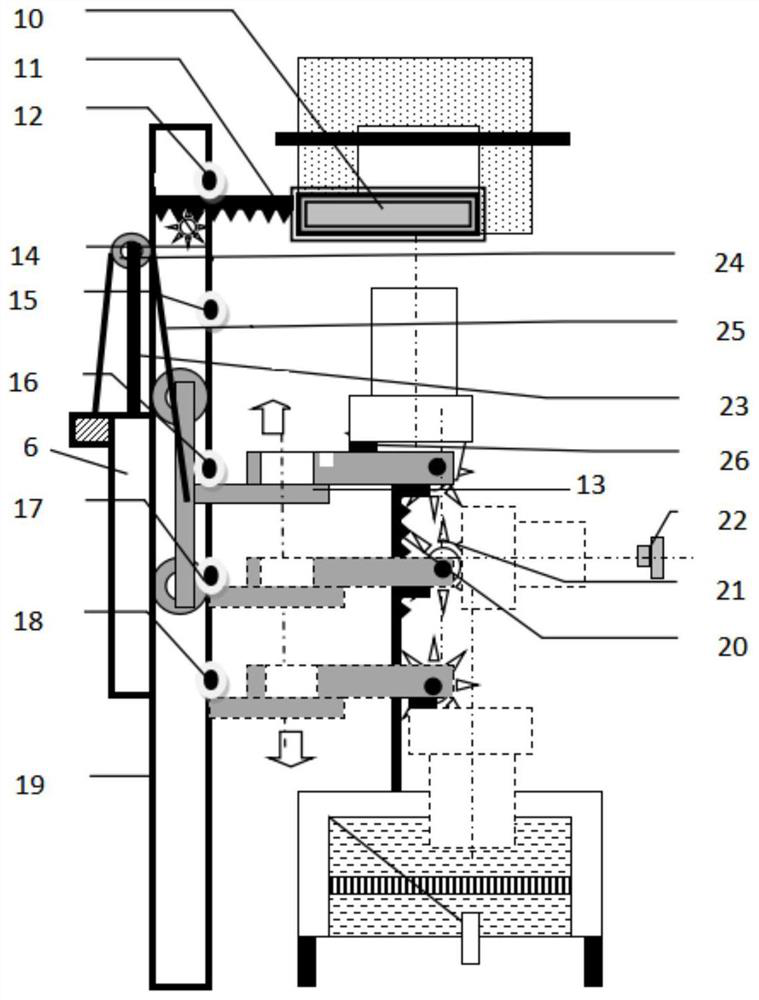

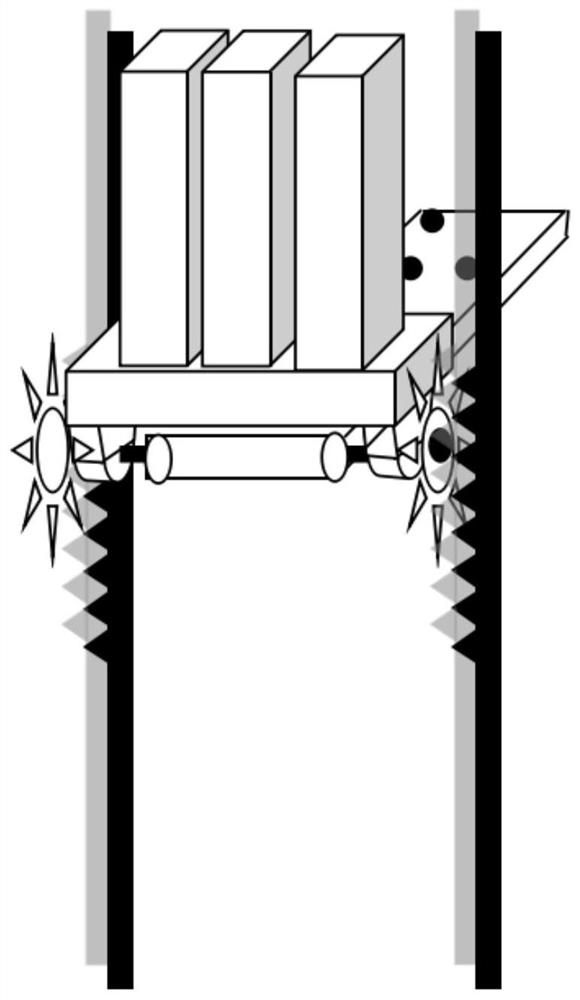

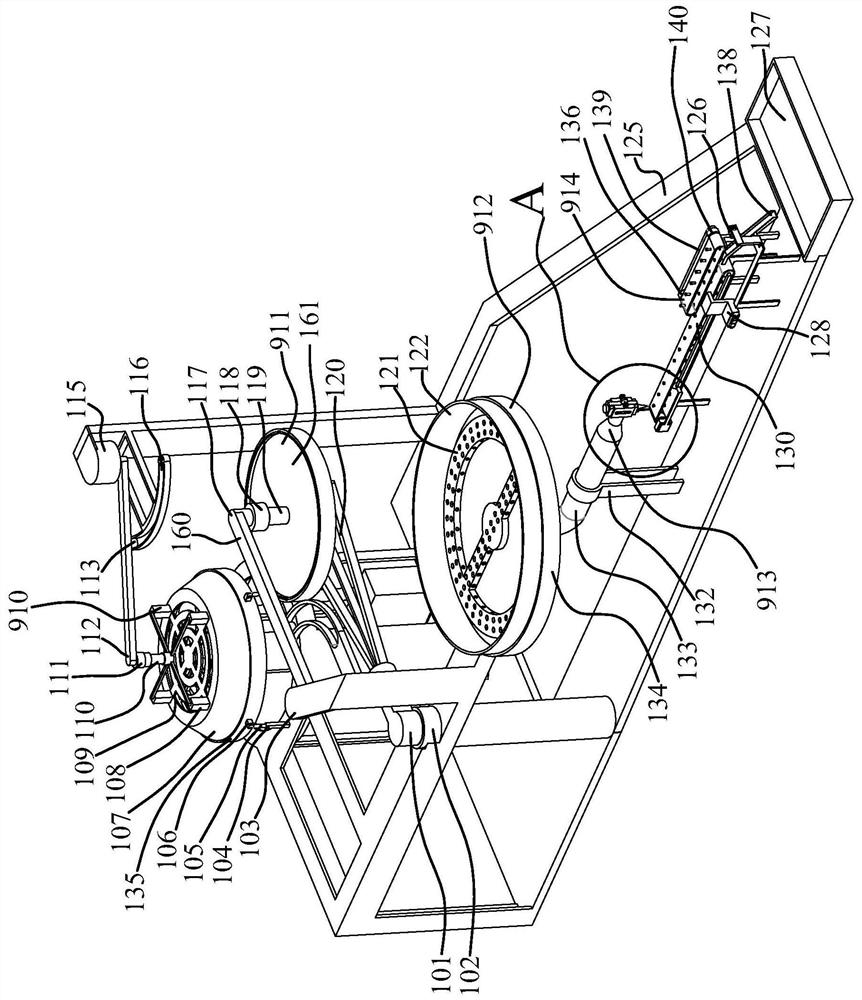

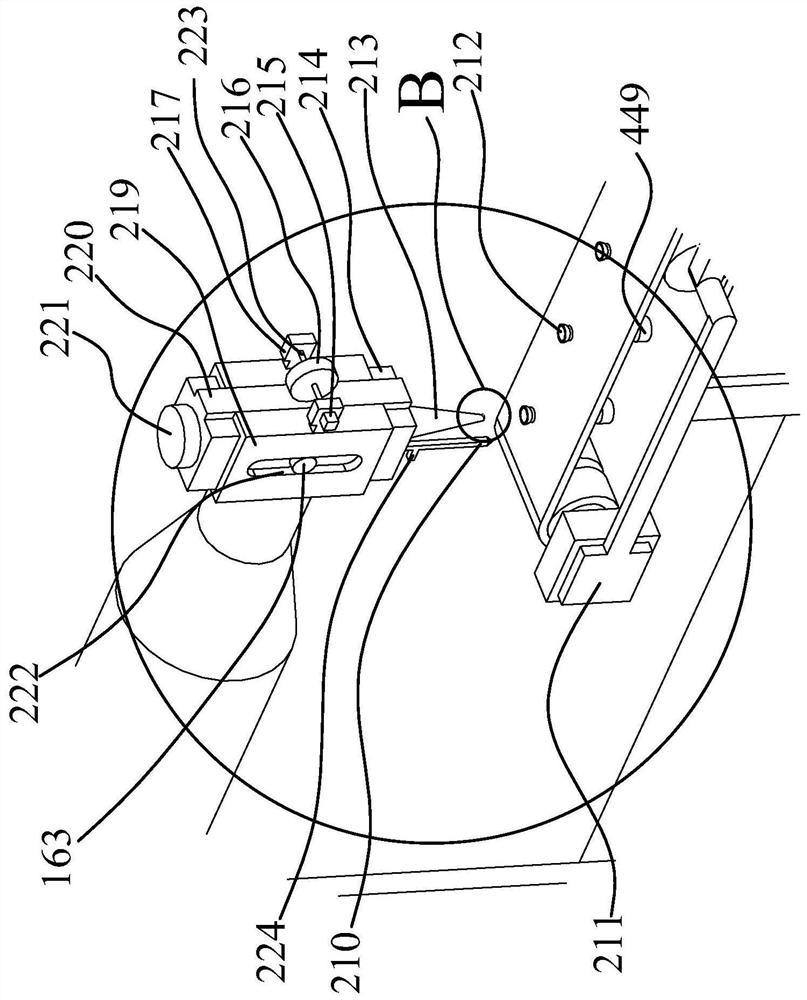

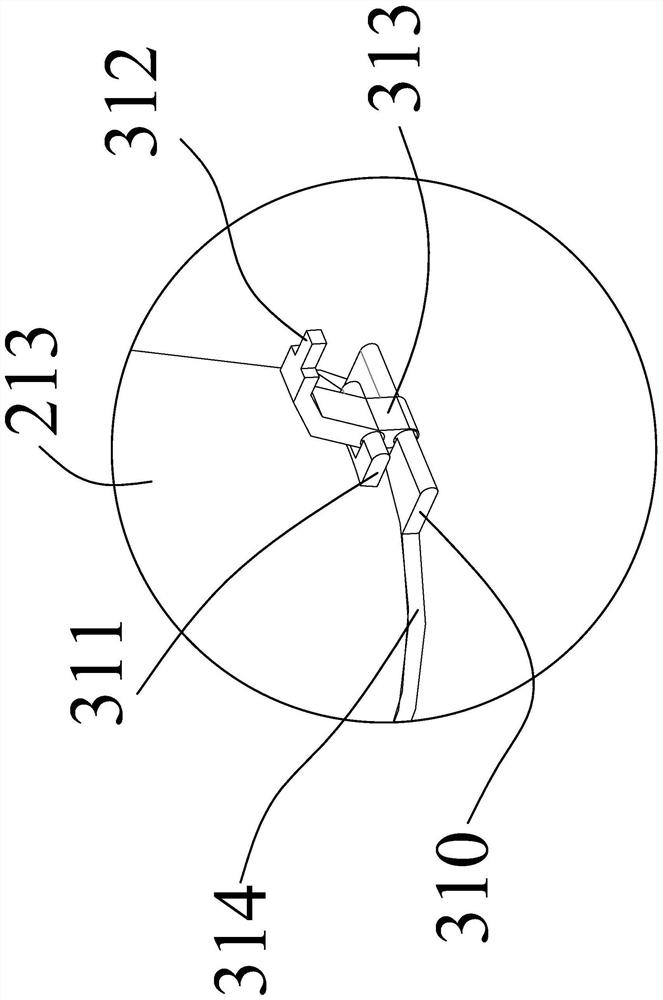

Automatic lifting and overturning mechanism for refractory material thermal shock test device

PendingCN112484496AQuick dipMeet the needs of "quick cooling"Charge manipulationFurnace typesGear wheelMechanics

The invention relates to an automatic lifting and overturning mechanism for a refractory material thermal shock test device. The automatic lifting and overturning mechanism comprises an automatic lifting system and an automatic overturning system, wherein a lifter adopted by the automatic lifting system is of a piston-movable pulley chain wheel-chain type combined structure; the up-down movement speed and the stroke of a test sample are two times of those of a common lifting mechanism, and the heated test sample can be rapidly immersed into a water cooling tank, so that the quenching requirements of test standards are met; the automatic overturning system adopts a combined mechanism composed of an eccentric rotary shaft on the back surface of a test sample clamping device, overturning gears at two sides of the test sample clamping device, an overturning rack on a rack and the like, so that the test sample can be automatically overturned in an up-down movement process, the test sample can be put into a furnace / discharged from the furnace in a manner that the end face of the test sample is upward and the test sample can be put into water / discharged from the furnace in a manner thatthe end face of the test sample is downward, and an extra test sample overturning driving mechanism is not needed; and the automatic lifting and overturning mechanism provided by the invention can realize full automation through a positioning control system and manual intervention / operation is not needed.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Efficient fish net dyeing technology

The invention discloses an efficient fish net dyeing technology. The technology is simple, convenient to implement, uniform in dyeing, efficient in coloring and high in drying firmness; a fish net iscarded into bundles, then, gradient heating ultrasound and cold water ultrasound operations are performed, internal fiber inside the fish net is preliminarily softened, the tenacity of the fish net isenhanced, and preparation is made for follow-up uniform dyeing; dyeing auxiliaries are used for processing the fish net, microwave radiation is performed, water inside the fiber of the fish net in ahigh-strength microwave field is rapidly heated and vaporized, the fiber ventilation rate is increased, and therefore a novel fluid channel is formed, and the internal surface area of the fish net isincreased; accordingly, the dyeing auxiliaries can be rapidly soaked into the fish net; due to the effect of the dyeing auxiliaries, bacteria are killed, the original color of the fish net is removed,and the fish net dyeing efficiency and color saturation are improved.

Owner:CHAOHU LOTUS FISHING NET

Integrated manufacturing equipment for aerogel heat preservation felt

InactiveCN110318182AReduce volatilityIncrease profitLiquid/gas/vapor removalTextile treatment machine arrangementsPhysical hard workEngineering

The invention relates to integrated manufacturing equipment for aerogel heat preservation felt. The equipment comprises an aerogel spraying sealing bin, a drying bin and a conveying device, an aerogelspraying assembly is arranged in the aerogel spraying sealing bin, and the conveying device comprises a conveying belt and a motor; the motor is located at the top of the aerogel spraying sealing bin, the motor is fixedly connected with the aerogel spraying sealing bin, and the aerogel spraying assembly further internally comprises an air negative pressure assembly; a cooling bin is seamlessly connected between the aerogel spraying sealing bin and the drying bin, and the conveying belt penetrates through the aerogel spraying sealing bin, the cooling bin and the drying bin. The integrated manufacturing equipment has the advantages that the working efficiency is high, the floor space of the equipment is small, the wage and labor cost is reduced, the physical labor of master workers is lowered, and the pollution of the solution to the air is small.

Owner:常州玛特利尔干燥工程有限公司

Method for improving dyeing efficiency of fishing net

The invention discloses a method for improving the dyeing efficiency of a fishing net, the method has high dyeing efficiency and low half-dyeing time, and the fading fastness and the staining fastnessof the dyed fishing net are effectively improved. By use of steam to treat the fishing net under high temperature and high pressure and low temperature and vacuum, internal gaps of the fishing net can be fully opened, dye molecules immerse quickly, the half-dyeing time of the fishing net can be reduced, the staining fastness and dyeing efficiency can be improved, and the existence of castor oil can make the surface of the fishing net soaked, prolongs the residence time of the dye molecules and improves the dyeing fastness; nano diatomite can enter the internal gaps of the fishing net to firmly lock the dye molecules to make the fishing net not easy to fade so as to improve the fading fastness and the use effect of the fishing net; finally a chitosan solution is used to spray the fishing net and form a film protective layer on the surface of the fishing net, can improve the fading fastness of the fishing net, makes the fishing net smooth and prevents fluffing.

Owner:CHAOHU YULANG FISHING GEAR CO LTD

Machining method of low-temperature oil heat modified bamboo

InactiveCN108621267AGood dimensional stabilityQuick dipCane mechanical workingHeating timeHeating temperature

The invention discloses a machining method of low-temperature oil heat modified bamboo. The method comprises following steps of firstly, bamboo drying, wherein the bamboo is dried until the water containing rate ranges from 5 to 12%; secondly, solution preparation, wherein under the temperature environment being 30 to 150 DEG C, a coupling agent is added into oil, and sufficient stirring is carried out until complete mixing is achieved; thirdly, solution heating, wherein the prepared oil mixed solution is heated, and is heated to 100 to 180 DEG C; fourthly, treatment, wherein the bamboo is completely immersed in constant-temperature hot oil, and heating treatment is carried out for 0.5 to 3 h; fifthly, surface treatment, wherein the bamboo is taken out, a surface remaining oil solution iswiped up, then, the bamboo is put into a drying, disinfecting and carbonizing machine, the heating temperature of the drying, disinfecting and carbonizing machine ranges from 160 to 190 DEG C, the heating time ranges from 2 to 4 hours, bamboo chip and bamboo filament powder is carbonized, and the carbonizing degree ranges from 5 to 30%.

Owner:朱昆鹏

Anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment

The invention discloses an anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment, and relates to the technical field of micro-arc oxidation treatment. The anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment comprises a liquid-plating tank, wherein a heat preservation layer is arranged fixedly to the outer wall of the liquid-plating tank in a sleeving manner; a cleaning tank is fixedly mounted to the outer wall of the other side of the heat preservation layer; support plates are fixedly connected to the outer surfaces of the tops of the cleaning tank and the liquid-plating tank; a back plate is fixedly connected to the adjacent side walls of the two groups of support plates; and a conveying mechanism is arranged on the back plate. According to the anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment disclosed by the invention, through cooperative application of a long threaded rod sliding plate, a sliding rod sleeve, a sliding rod, a servo motor, a short rotary rod, a rotary disc, a connecting rod, a first bevel gear, a second bevel gear, a long rotary rod, a first belt pulley, a second belt pulley and a first belt, workpieces can be quickly cleaned, and the cleaned workpieces can be quickly soaked into hard-chromium plating solutions.

Owner:成都文亿辉科技有限公司

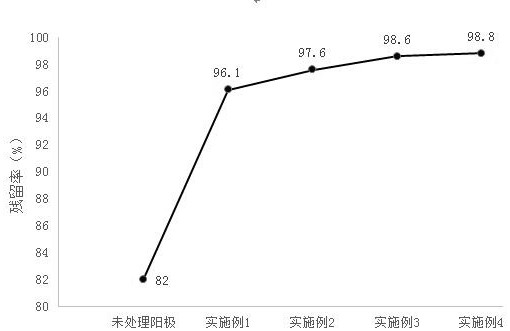

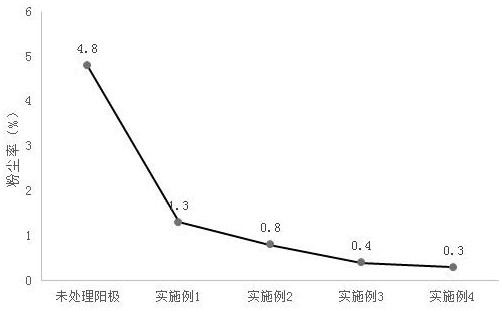

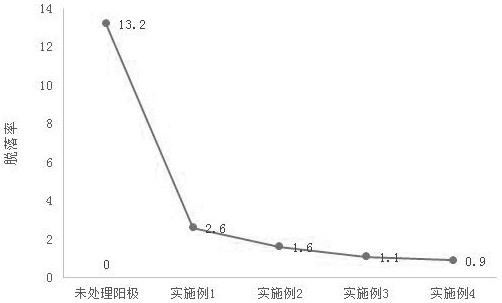

Formula of efficient silicon-boron system impregnant as well as preparation and application processes of efficient silicon-boron system impregnant

The invention discloses a silicon-boron system impregnant, which is a solution prepared by blending 0.001%-10% of a silicon-based substance, 0.001%-10% of a boron-based substance, less than or equal to 10% of an auxiliary agent and 80%-99% of water according to a certain proportion. The auxiliary agent is a thickening agent, and the use amount of the thickening agent is adjusted according to actual requirements, so that the viscosity of the impregnant is controlled to be 0.01-10 Pa.s. The impregnant is organized and actively enters pores in the anode in a mode of first negative pressure and then positive pressure, is dried at a low temperature, and forms a compact silicon-boron anti-oxidation film on the inner cavity wall of an anode carbon block in a high-temperature environment during electrolysis, and has certain bonding strength, the silicon-based substance in the impregnant enhances the oxidation resistance of the carbon anode by improving the adhesion of a boron oxide film and the carbon anode, invalid oxidation in pore channels of the anode carbon block can be effectively prevented, the air reactivity is reduced, and a silicon-boron-carbon system forms a stable net-shaped structure in pores of the anode carbon block, so that slag falling is effectively prevented.

Owner:湖南国发控股有限公司

A kind of Cordyceps pharmaceutical equipment

The invention discloses a kind of Cordyceps pharmaceutical equipment, the structure of which comprises a main frame, the front end of the main frame is fixed with a cleaning module for cleaning the Cordyceps, and the right end of the cleaning module is fixed with a container for drying and grinding the Cordyceps into powder. Putting module, the lower side of the holding module is equipped with a filling module for filling the powder, and the right side of the filling module is installed with a synthetic module for finally packaging the pills. The cleaning module includes a cylinder. This equipment passes through the cleaning module, The crushing module, holding module, pouring module, and synthesis module realize the cleaning, grinding, filling of pills, and pill packaging. Compared with traditional processing equipment for Cordyceps, this equipment reduces manpower and improves work efficiency. There is a better use of value.

Owner:江西天元药业有限公司

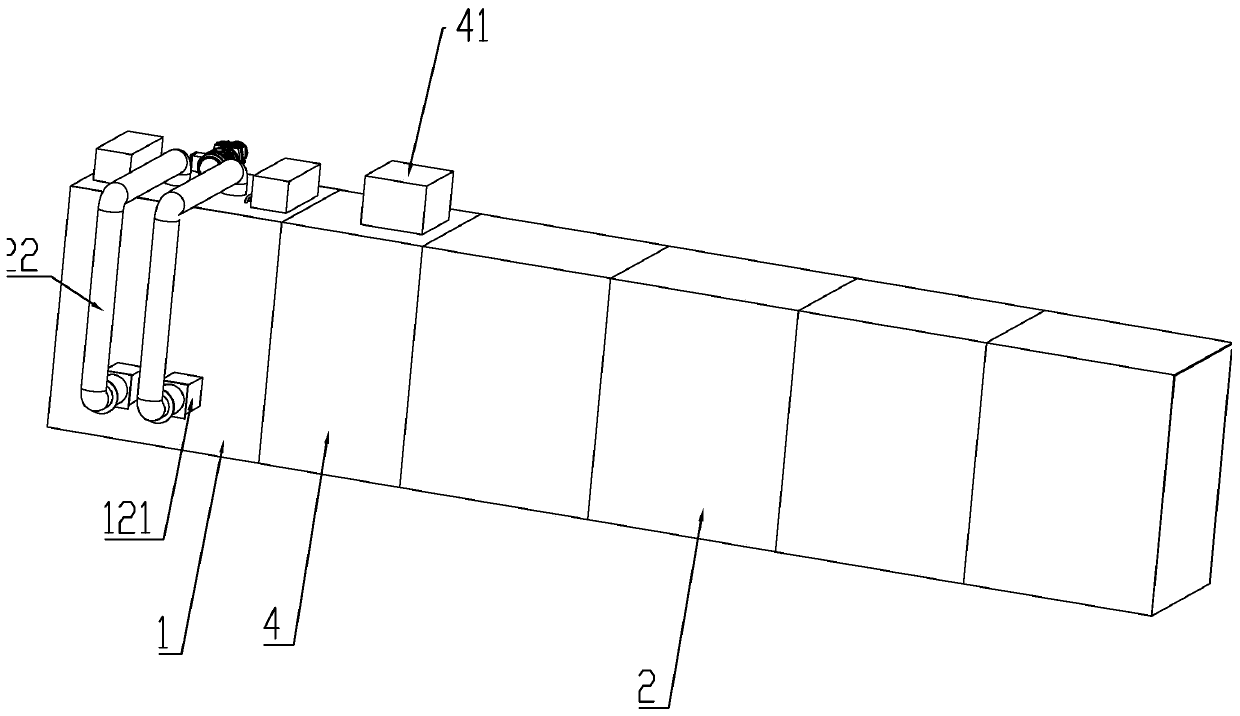

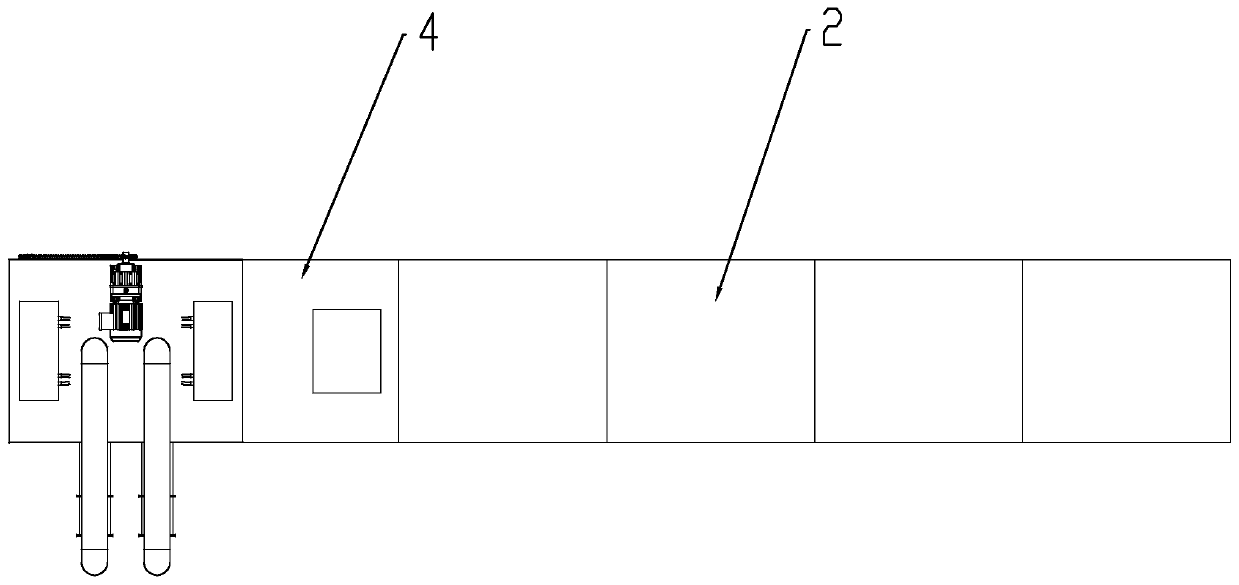

Low-liquor-ratio continuous dyeing device and dyeing method thereof

PendingCN114150449AEasy to switchImprove work efficiencyFibre treatmentHeating/cooling textile fabricsLaundry washing machineProcess engineering

The invention belongs to the technical field of textile dyeing, and particularly relates to a low-liquor-ratio continuous dyeing device. Comprising a rubber driving roller, a rubber driven roller, a cloth feeding guide roller, a spreading roller, a stainless steel bottom groove, a bottom guide roller, a cloth discharging guide roller, a first working liquid barrel, a second working liquid barrel, a water barrel, a first automatic valve, a second automatic valve, a water barrel valve, a proportional valve, a first liquid supplementing conveyor, a second liquid supplementing conveyor, a liquid level control inductive head, a liquid supplementing pump and a mixer. And an electric stirrer and a liquid outlet valve. The invention further provides a low-liquor-ratio continuous dyeing method which comprises the following steps: putting the cloth into a washing machine, filling a washing tank with clear water, and the like. According to the technical scheme provided by the invention, the technical problems of huge waste, difficulty in switching dyeing devices, waste of cylinder washing and material changing time and the like during dyeing replacement are solved.

Owner:博格曼(江苏)纺织科技有限公司

A method for wicker dipping and dyeing by microwave

ActiveCN106956336BReduce rigidityImprove fixation effectRadiation/waves wood treatmentWood treatment detailsFiberMicrowave

The invention discloses a microwave dip dyeing method for willow twigs. The microwave dip dyeing method comprises the following steps: firstly, stewing the willow twigs; secondly enabling the stewed willow twigs to be subjected to alkali-H2O2 one-bath boiling; finally, enabling the materials obtained in the second step to be subjected to pretreatment by a chitosan acid solution; components like xylogen in the willow twigs are degraded, so that the rigidity of the willow twig structures is reduced, and the willow twigs are prevented from cracking under the mechanical force action and a thermal action; chitosan is added to play a certain modifying effect on willow twig fibers, the dye fixation is higher; besides, an anti-cracking dyeing auxiliary is added into the dye, the dyeing power of the dye on the surfaces of the willow twigs is improved, a protective film is formed on the surfaces of the willow twigs, a continuous, flatted and smooth coloring film is formed, the dye can quickly immerse into the willow twig fibers by microwave treatment, and an everlasting and stable dyeing effect is achieved.

Owner:霍邱县淮美奇工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com