Integrated manufacturing equipment for aerogel heat preservation felt

An aerogel and thermal insulation felt technology is applied in the field of integrated aerogel thermal insulation felt production equipment, which can solve the problems of increasing environmental pollution, low work efficiency, increasing physical labor of employees, and large equipment footprint. The effect of reducing physical labor, improving utilization, and increasing drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

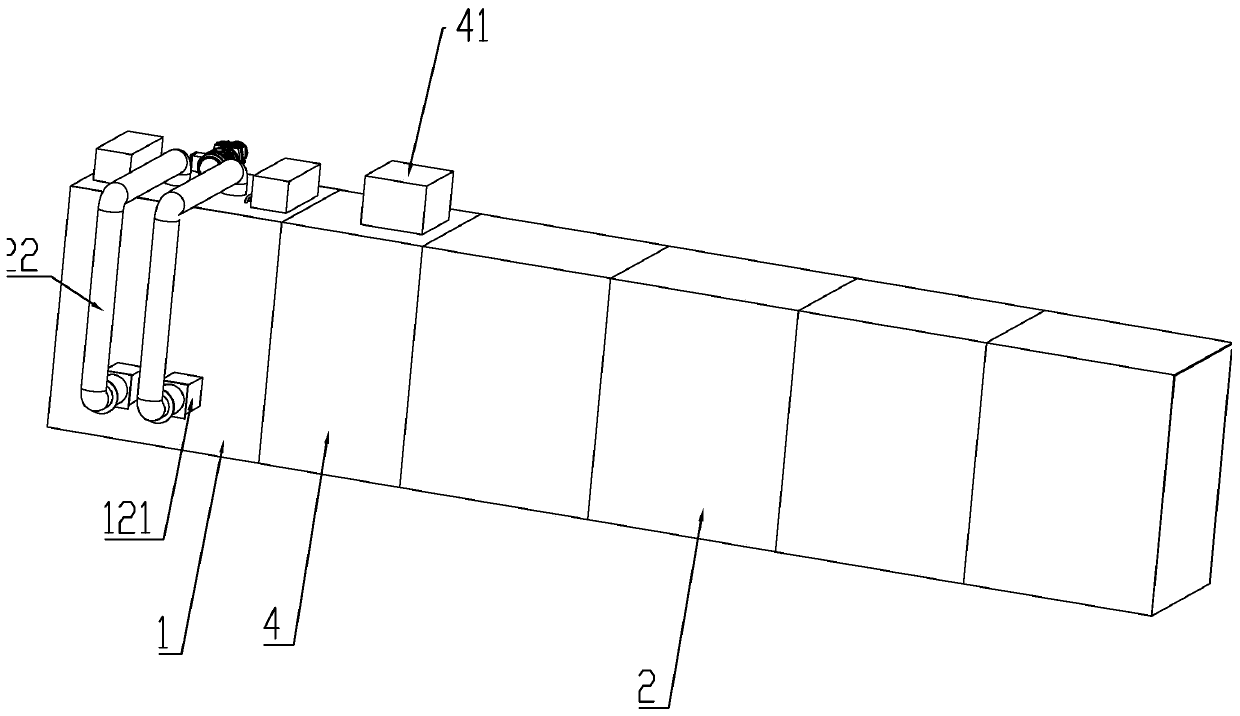

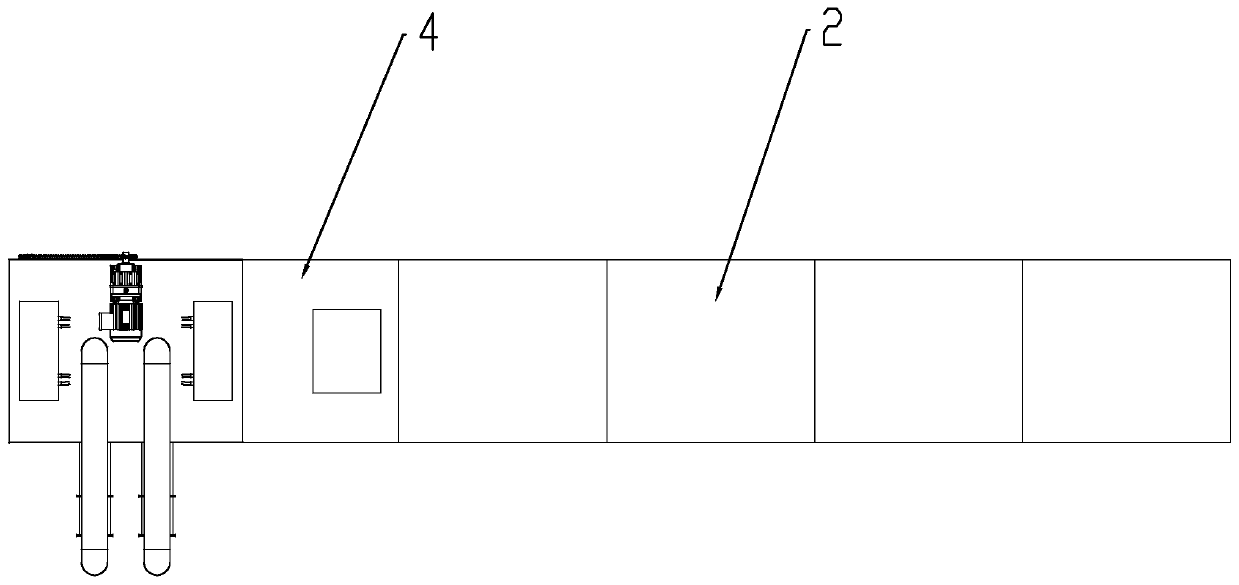

[0035] refer to figure 1 , figure 2 , which is a kind of integrated airgel insulation blanket manufacturing equipment disclosed by the present invention, including a glue-sprayed sealing cabin 1, which is connected with a cooling cabin 4 and a drying cabin 2 in sequence after the glue-spraying sealing cabin 1, and the glue-spraying sealing cabin 1 A fan 121 is fixedly connected with bolts on one side, and the air outlet flange of the fan 121 is connected with an air outlet pipe 122. A fan 41 is fixedly connected to the top of the cooling cabin 4 by bolts against the glue-spraying sealing cabin 1 , and the working end of the fan 41 extends to the inside of the cooling cabin 4 .

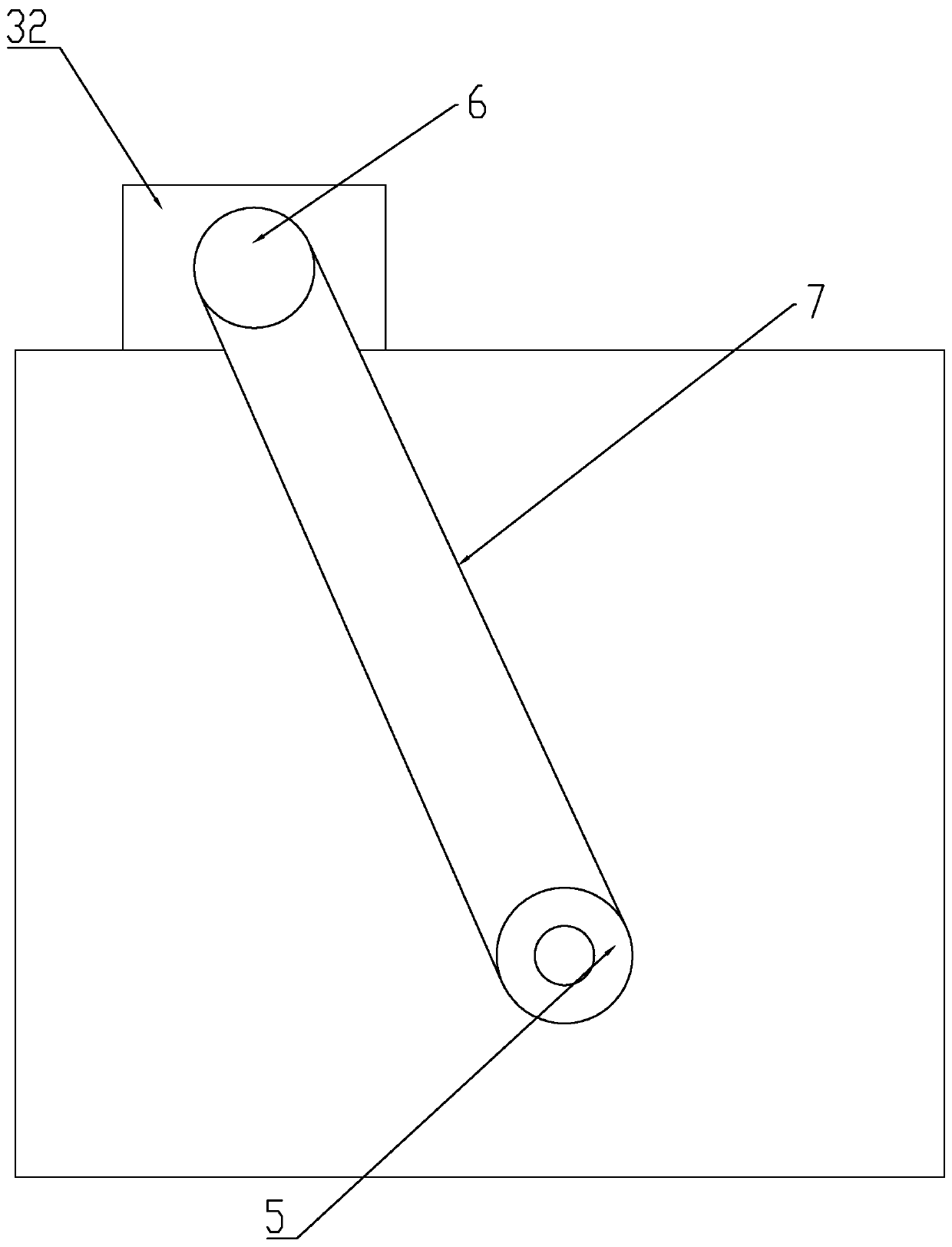

[0036] Such as image 3 As shown, three rotating rods 32 are welded inside the glue spraying sealing cabin 1, and the outer side of the rotating rod 32 is movably sleeved with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com