Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Promote solubilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

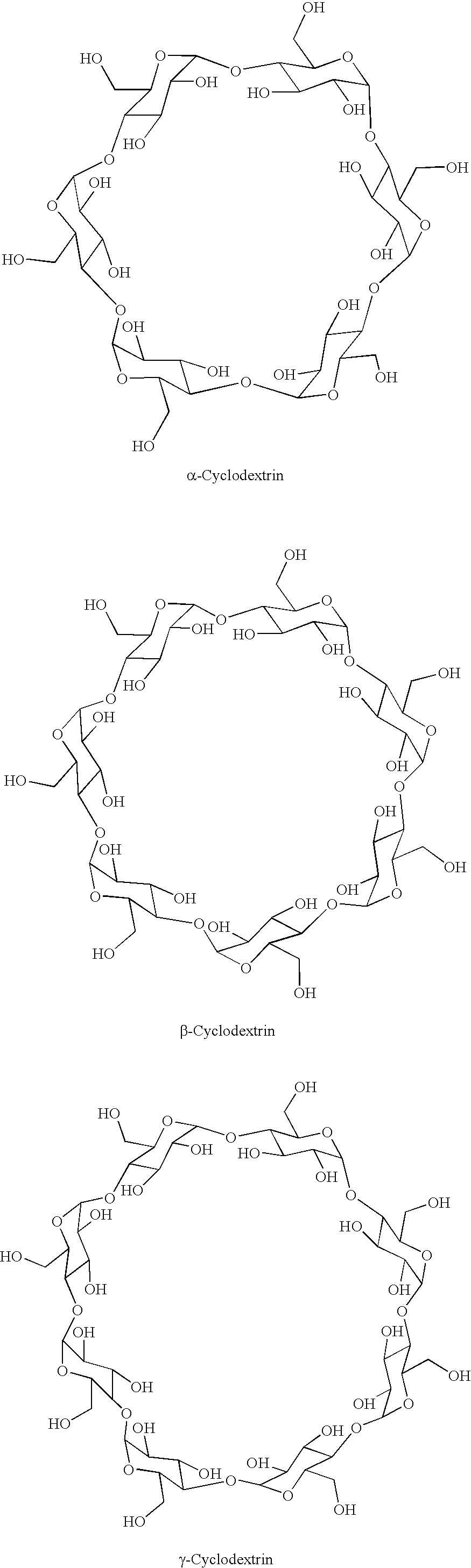

Targeting conjugates comprising active agents encapsulated in cyclodextrin-containing polymers

InactiveUS20100226987A1Reduce solubilityImprove solubilityBiocidePowder deliveryActive agentCyclodextrin

A targeting conjugate is provided comprising an active agent, one or more residues of a cyclodextrin (CD)-containing polymer and a biorecognition molecule. The polymer is preferably a peptide or a polypeptide comprising at least one amino acid residue containing a functional side group to which at least one of the CD residues is linked covalently; the biorecognition molecule is covalently bonded directly or via a spacer to the polymer backbone of the CD-containing polymer; and the active agent is noncovalently encapsulated within the cavity of the cyclodextrin residues and / or entrapped within the polymer matrix of the CD-containing polymer.

Owner:CAPSUTECH

All Purpose Cleaning Compositions

InactiveUS20100093581A1Fine foamCut skinOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsHydrocarbon solventsAdjuvant

An environmentally friendly, human safe, aqueous-based cleaning composition which can be formulated for cleaning a variety of substrates comprises an alkyl polyglycoside nonionic surfactant, and an alkyl amphocarboxylate surfactant. The composition is free of hydrocarbon solvents, contains a minimal amount of organic polar solvents, and contains naturally derived adjuvants such as chelating agents, fragrances, and buffers.

Owner:RUBI ROSE

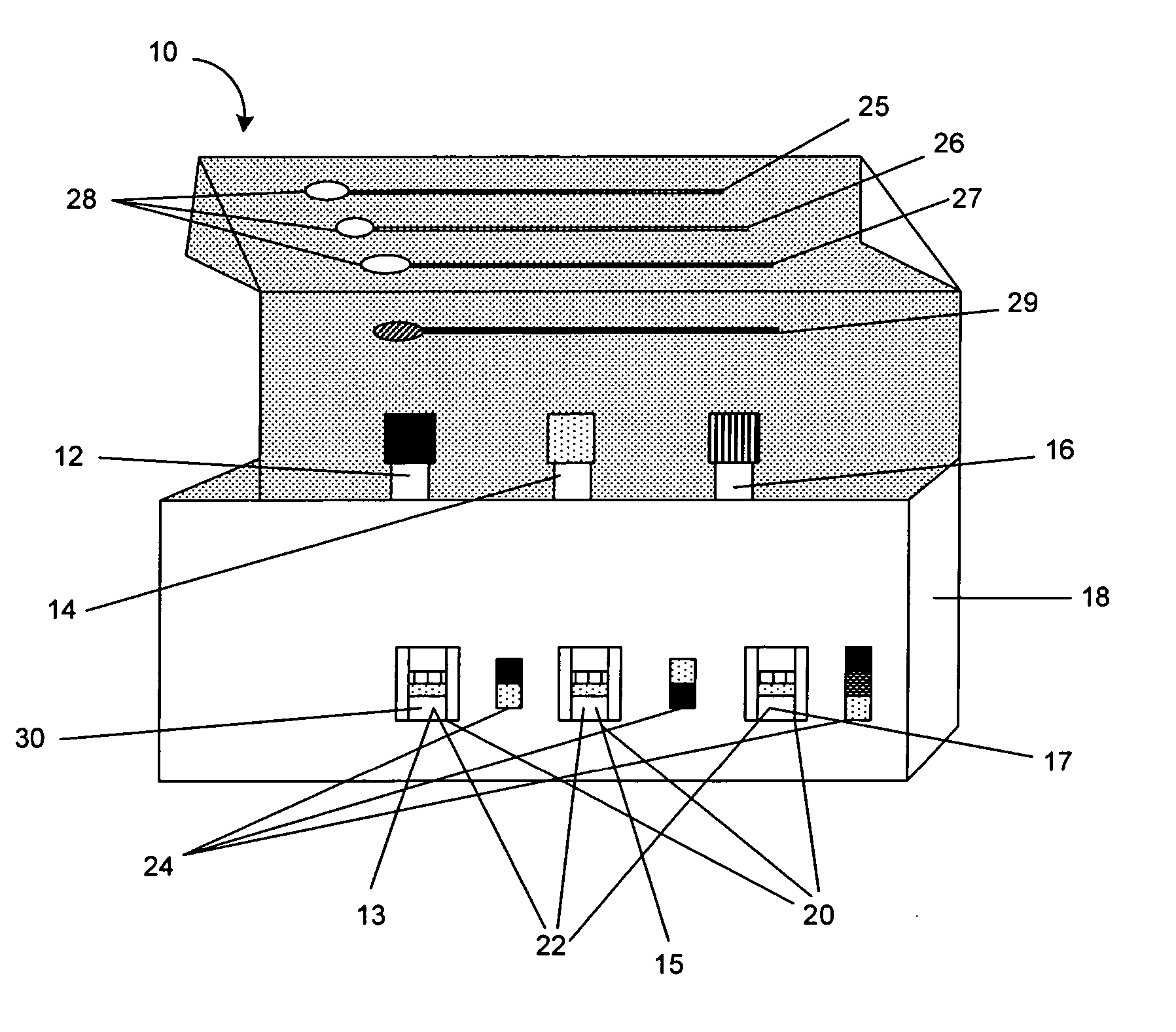

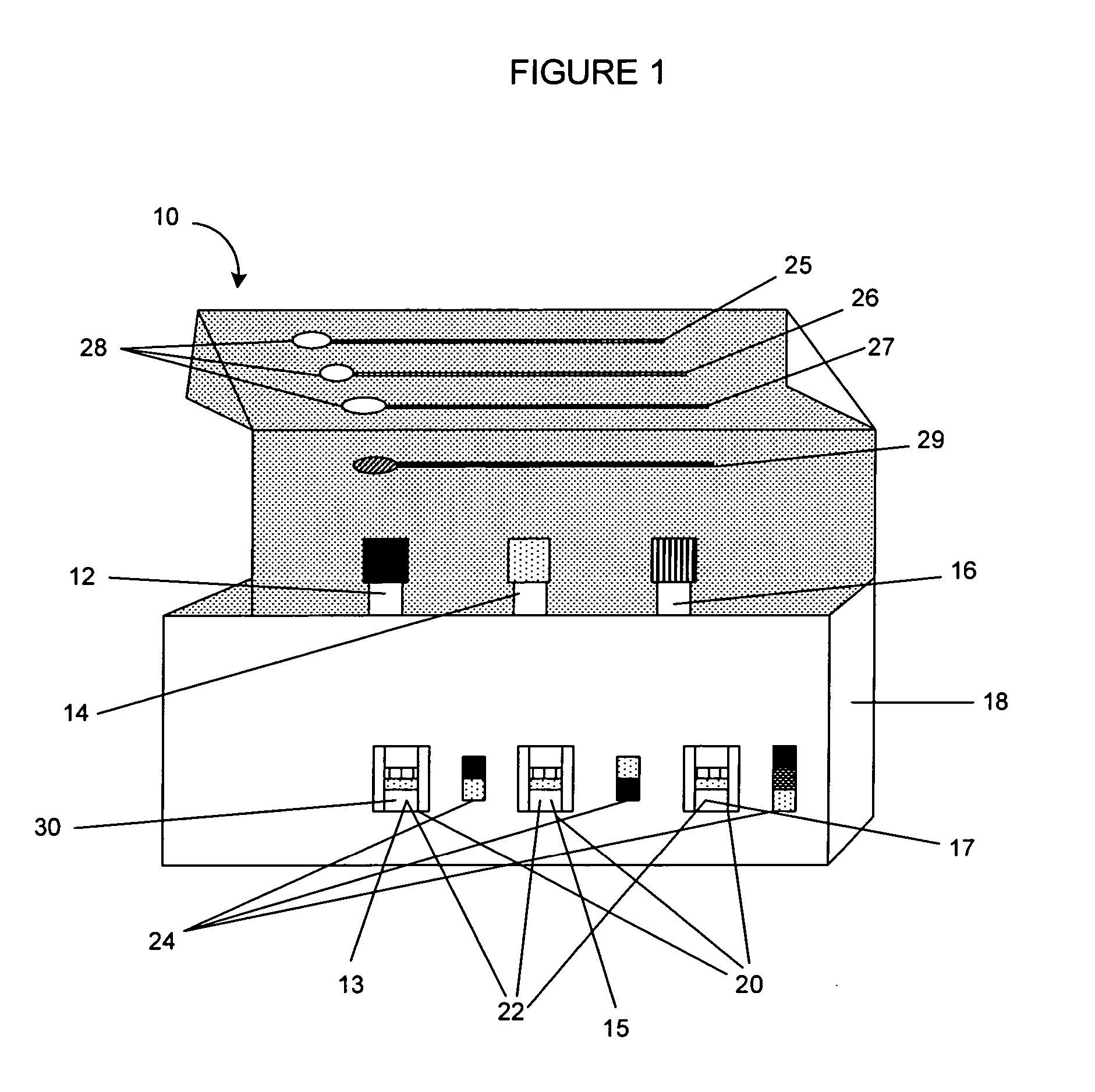

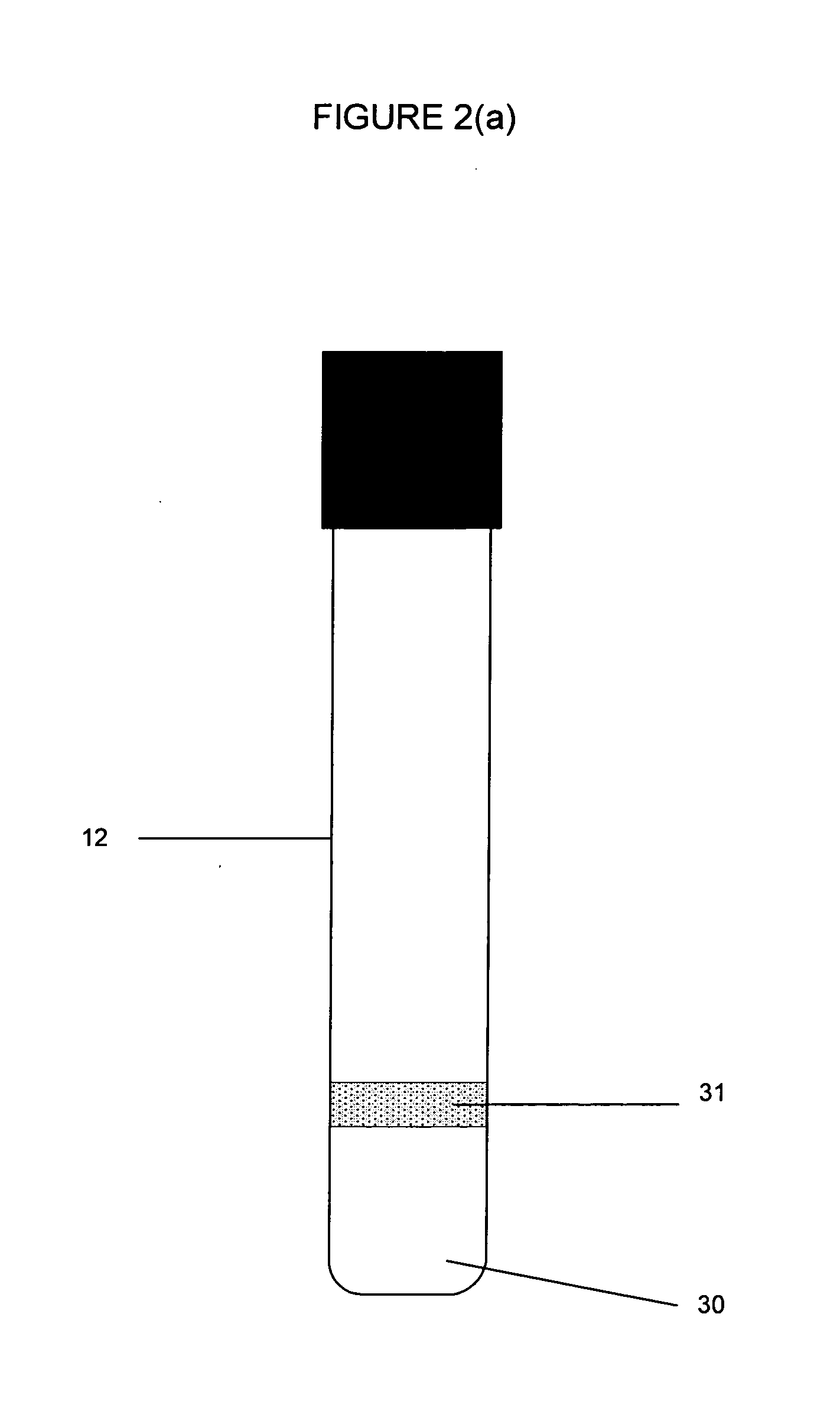

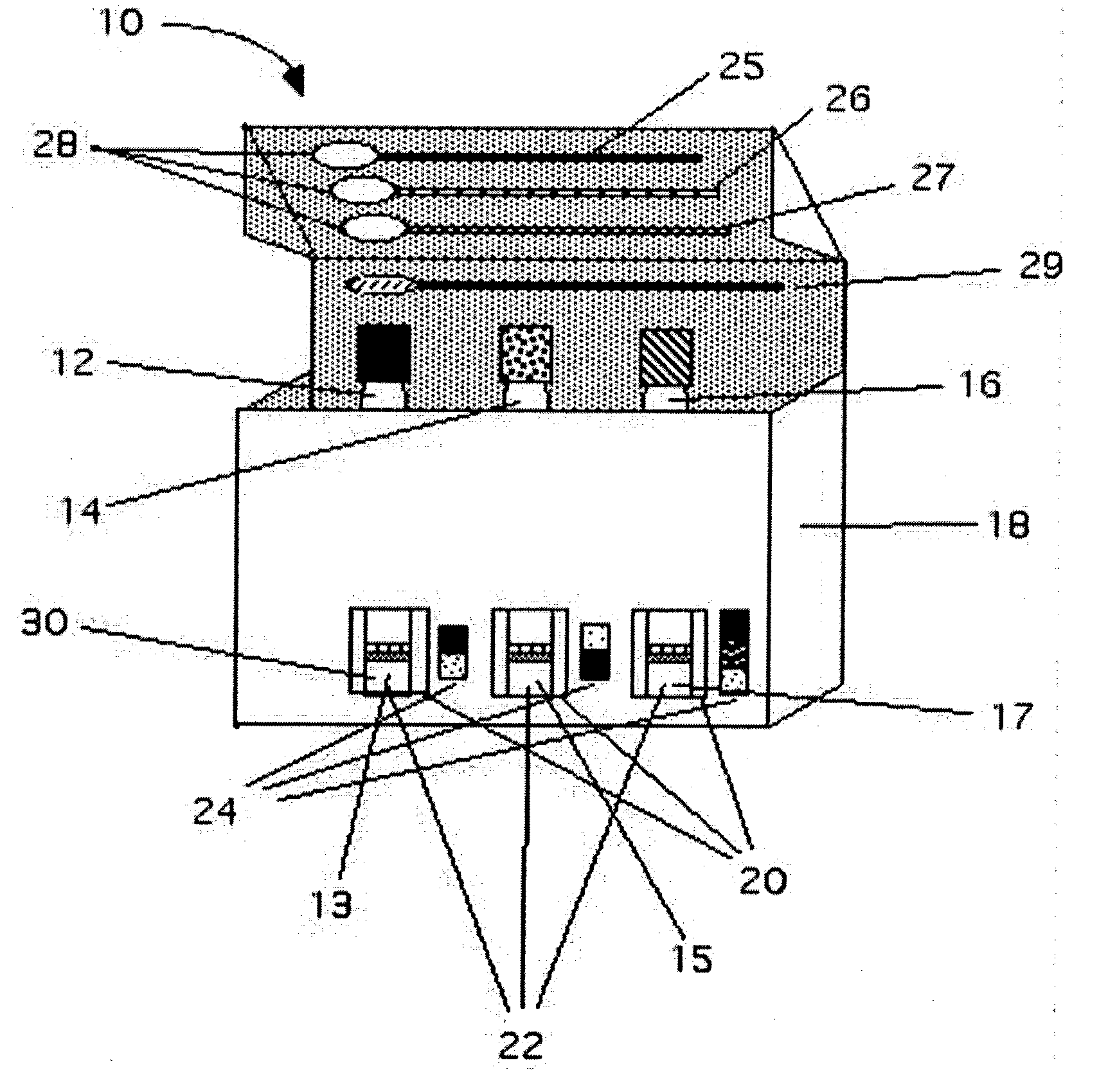

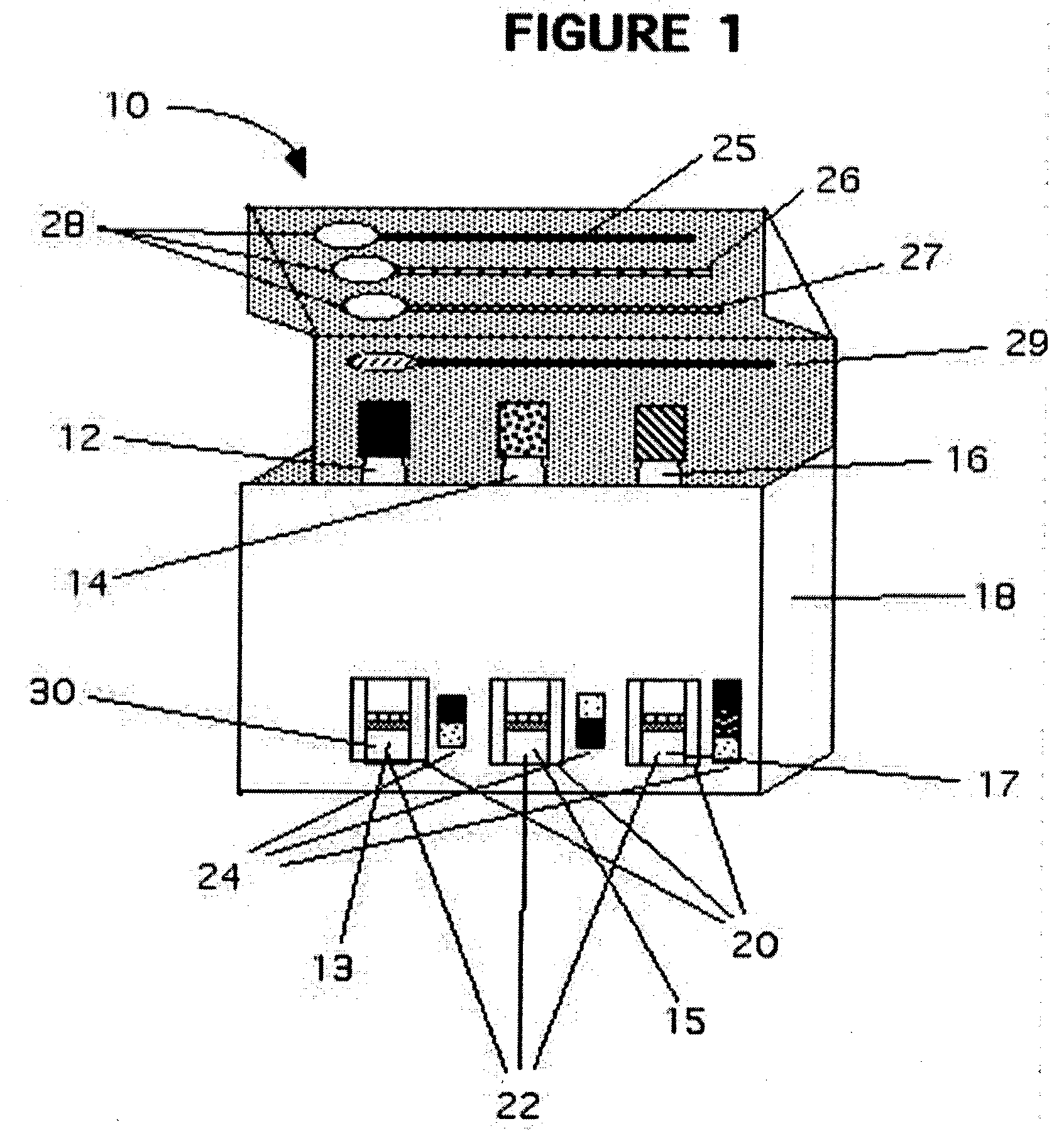

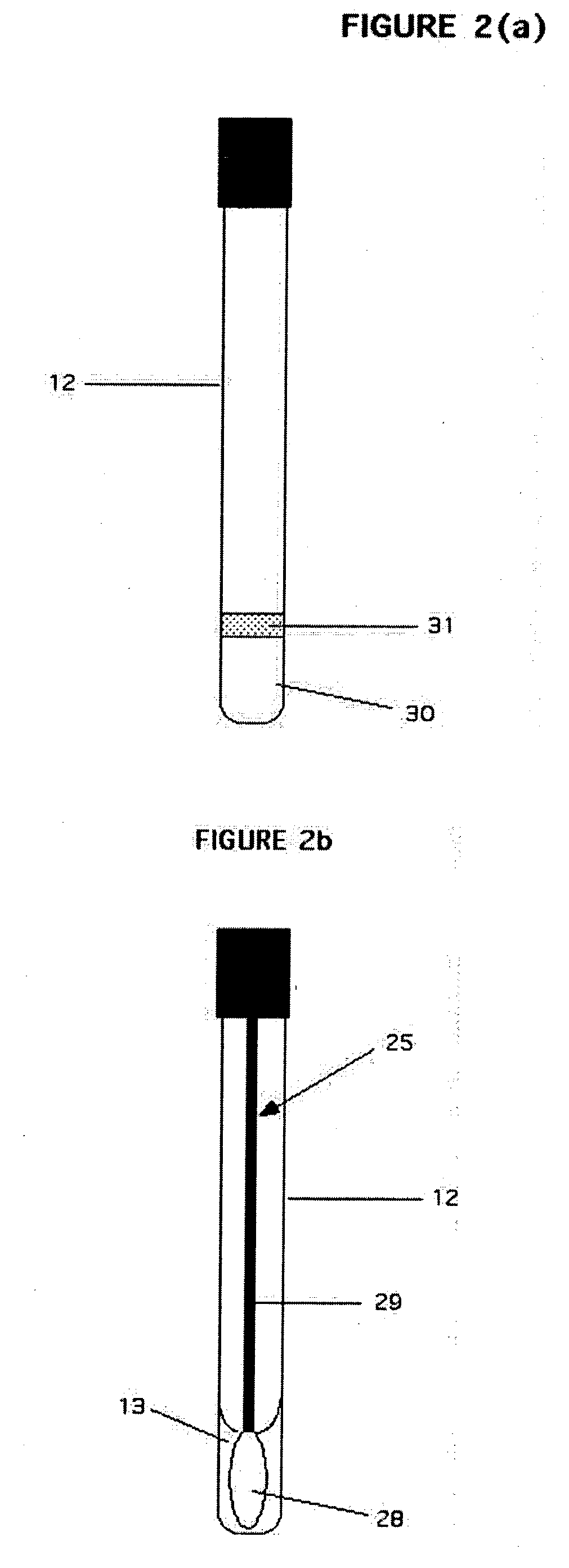

Rapid assay, method and system for detecting biowarfare agents

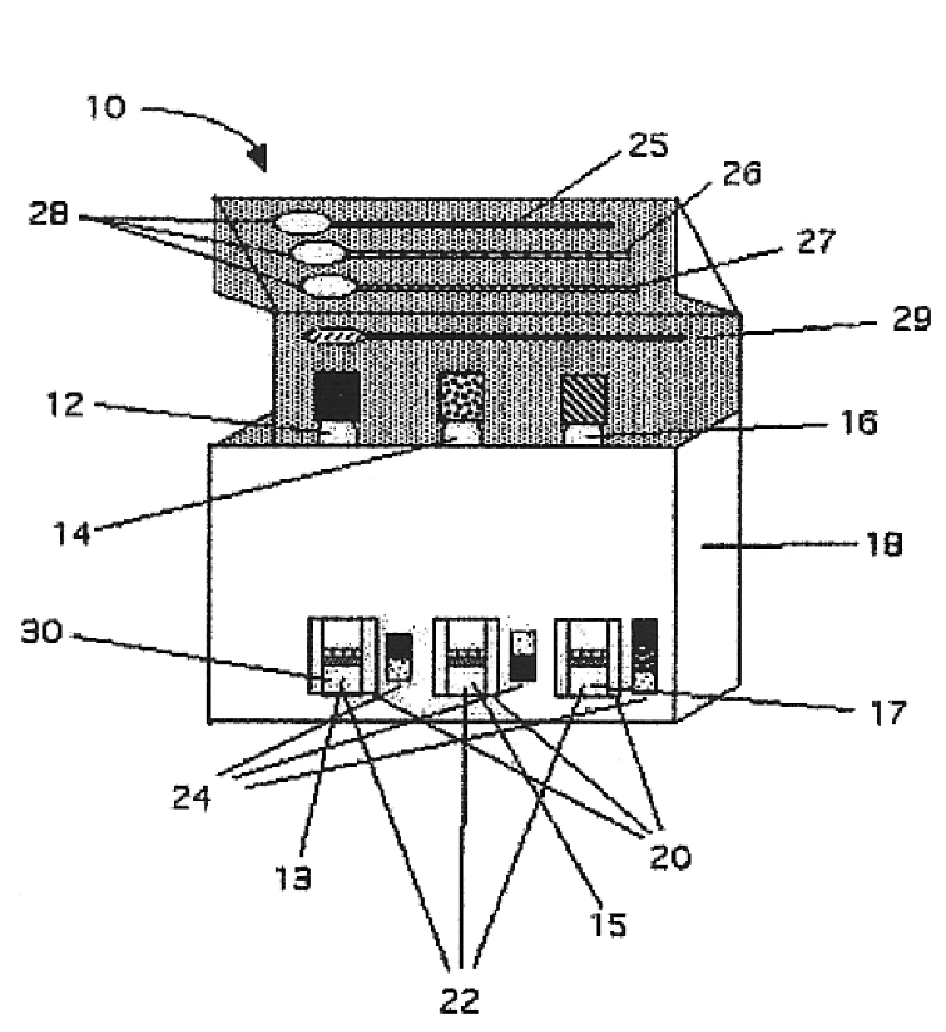

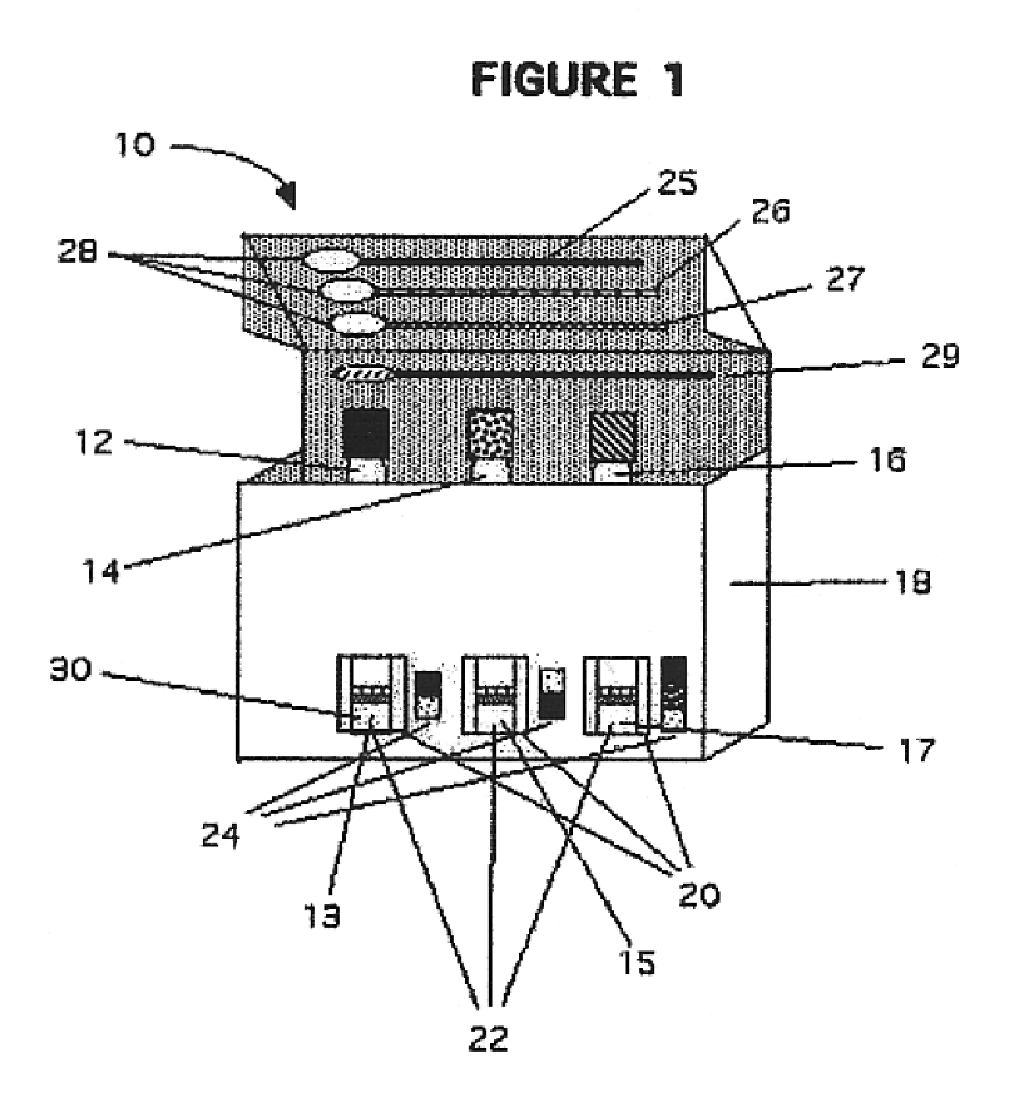

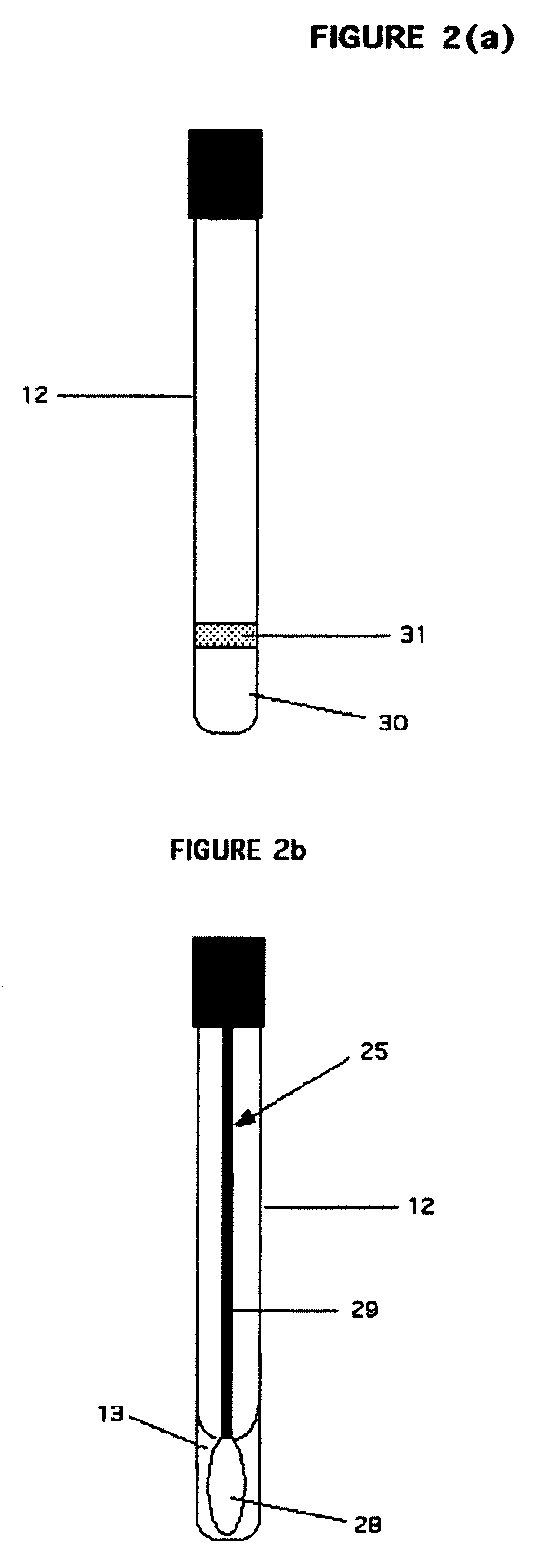

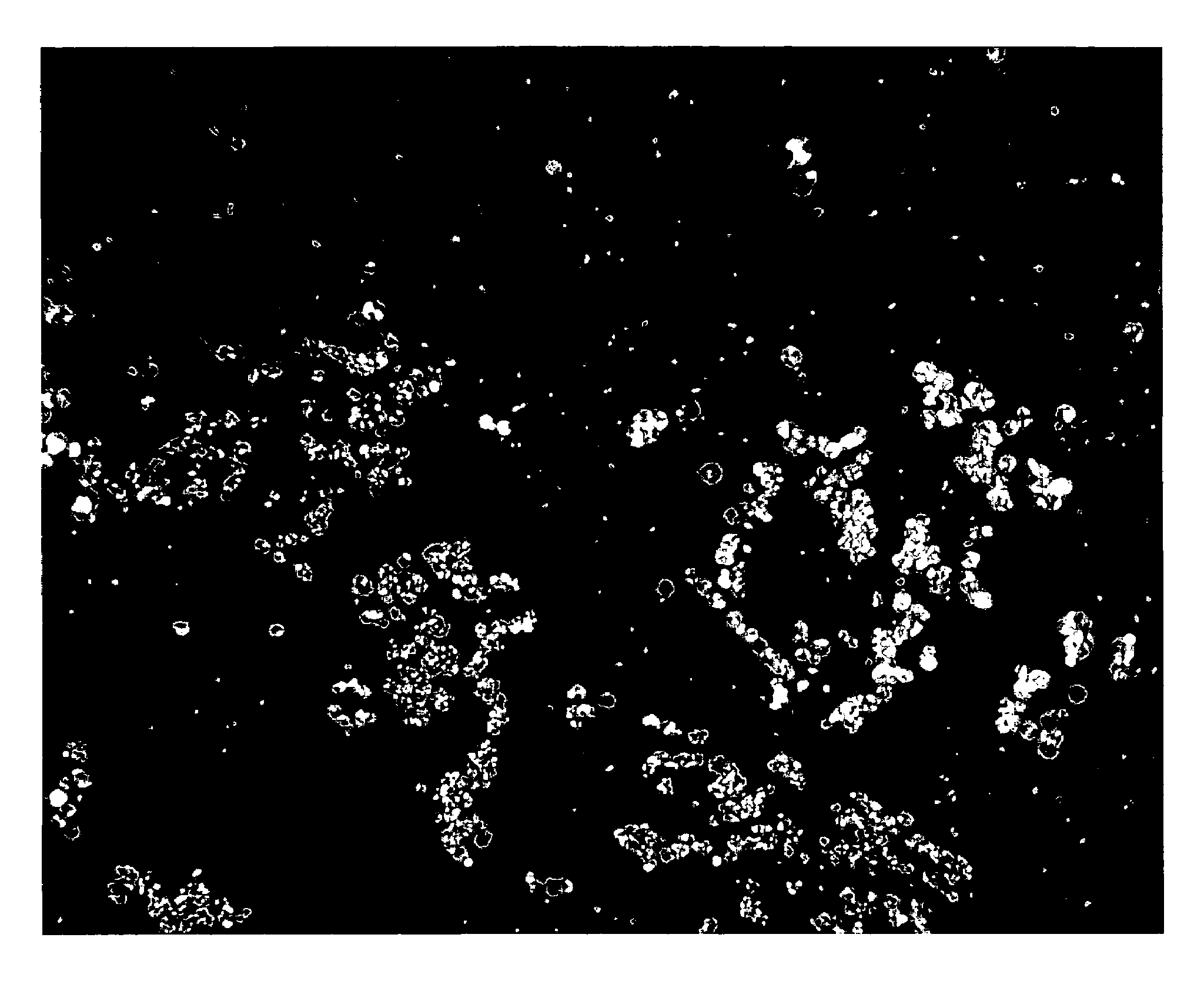

InactiveUS20050238535A1Promote solubilizationAnalysis using chemical indicatorsBurette/pipette supportsTest proteinSugar

Provided herein are methods for preliminary analysis of suspect samples, which can be used in triaging possible contaminated sites (e.g., sites contaminated or thought to be contaminated by biowarfare agents). In some embodiments, the methods involve testing for the presence of protein in the suspect sample; optionally, the sample can also be tested for the presence of sugar, and / or for pH determination. Specific embodiment methods are carried out in tubes or other reaction vessels, others are carried out in a pad format, and still others are carried out in a test strip format. Kits for carrying out the described methods are also provided.

Owner:20 20 GENESYSTEMS INC

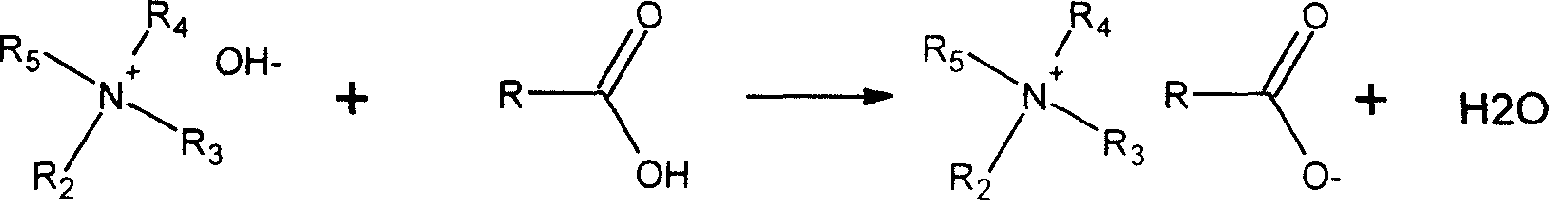

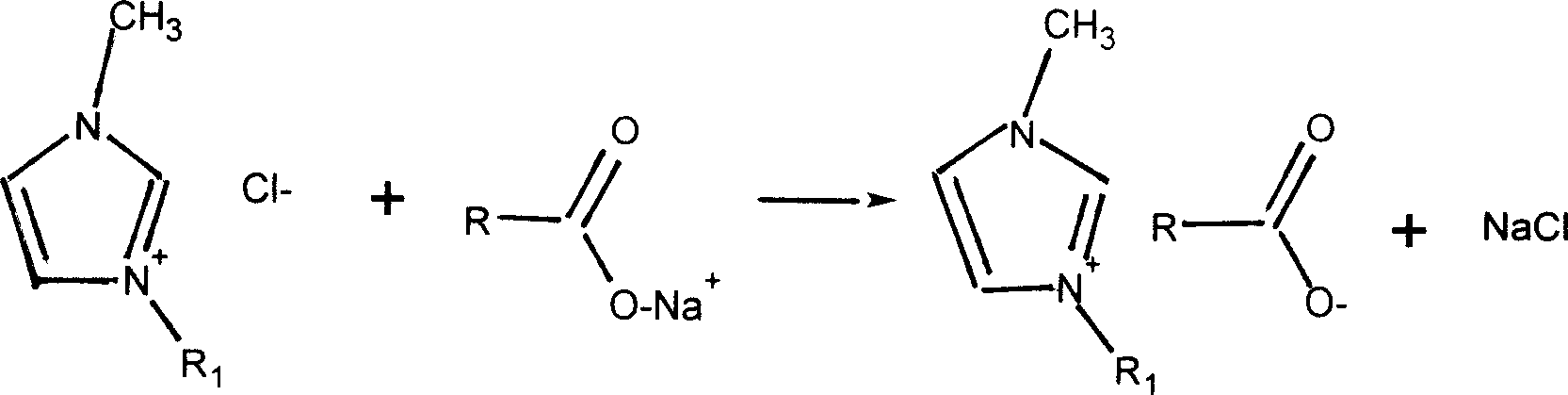

Non-toxic ionic liquid, preparation method and its application

InactiveCN1651089AWide range of liquid phaseGood thermal stabilityPharmaceutical non-active ingredientsSolventWater soluble

A non-toxic ionic liquid used as the solvent, cosolvent, or surfactant for increasing the water-solubility of the medicines difficult to dissolve in water features that its cation is alkylimidazole salt with short carbon chain or quaternary ammonium salt.

Owner:HEBEI NORMAL UNIV

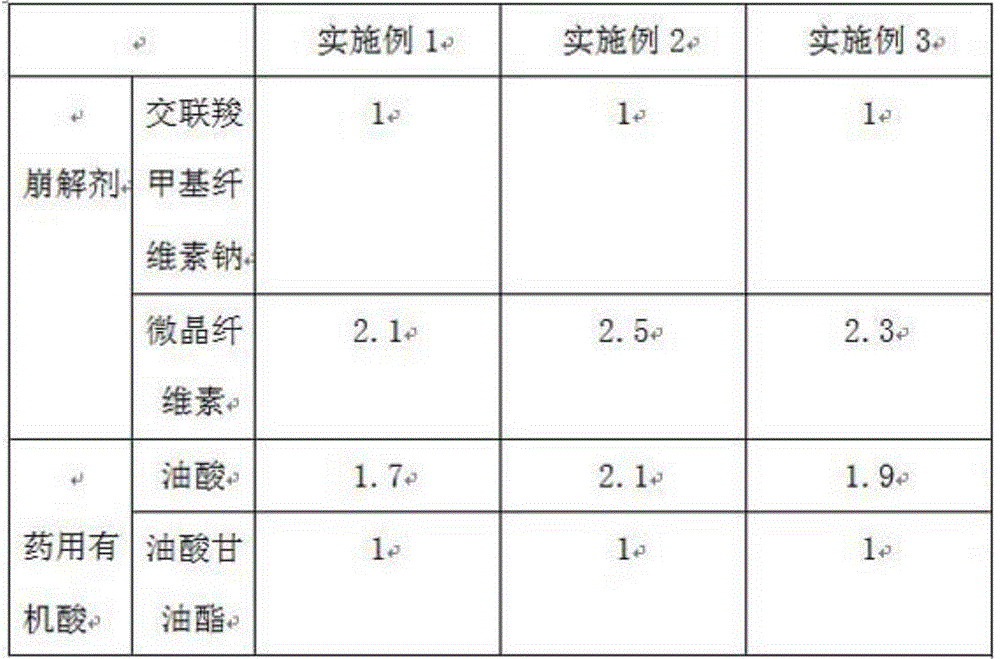

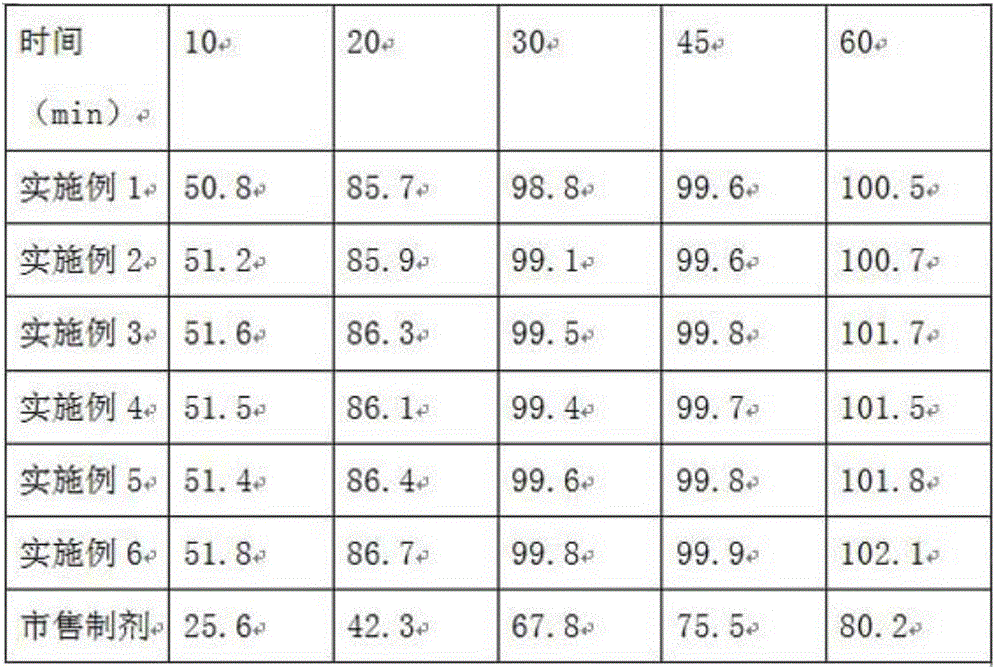

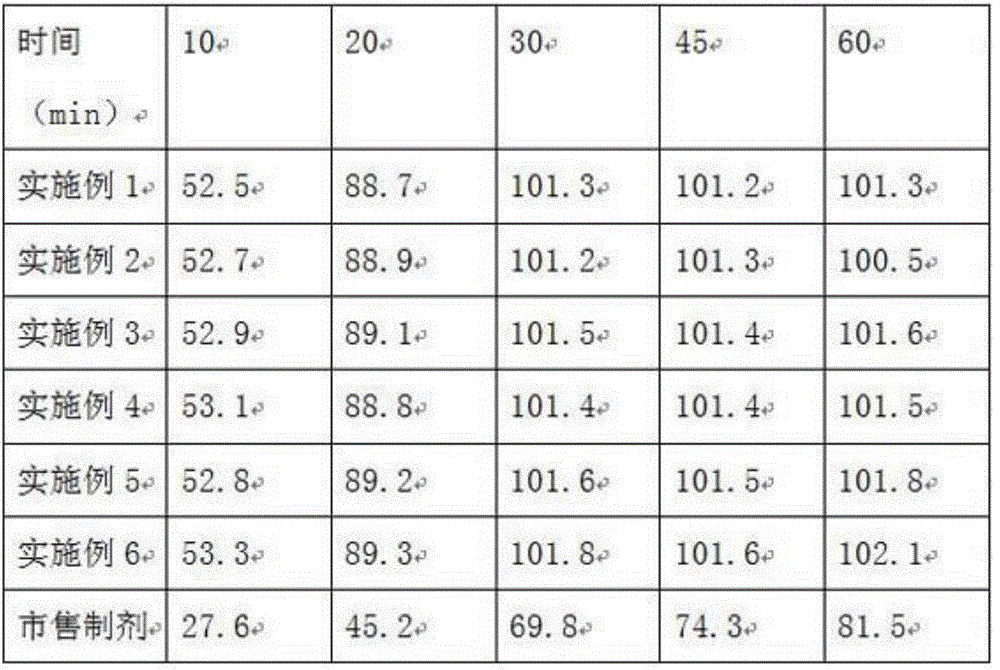

Pharmaceutical composition containing ibrutinib

InactiveCN106619643AGood solubilityGood compatibilityOrganic active ingredientsPharmaceutical non-active ingredientsDrugOrganic acid

The invention relates to a pharmaceutical composition containing ibrutinib. The pharmaceutical composition is prepared from, by weight, 13-15 parts of ibrutinib, 30-50 parts of solvent, 20-30 parts of solubilizer, 8-12 parts of filler, 6-10 parts of disintegrant and 21-26 parts of officinal organic acid, wherein the solvent is glycerolformal, and the officinal organic acid is a mixture of oleic acid and glyceryl monooleate based on the mass ratio of (1.7-2.1):1. The pharmaceutical composition containing ibrutinib has the advantages that compared with traditional pharmaceutical compositions, the variety of the solvent in the formula is changed, glycerolformal which is high in safety performance serves as the solvent with dosage unlimited, and multiple medicines are soluble in glycerolformal; meanwhile, due to the fact that the officinal organic acid is a mixture of oleic acid and glyceryl monooleate, the pharmaceutical composition containing ibrutinib is more stable and simpler than traditional pharmaceutical compositions adopting single officinal organic acid.

Owner:ABA CHEM SHANGHAI

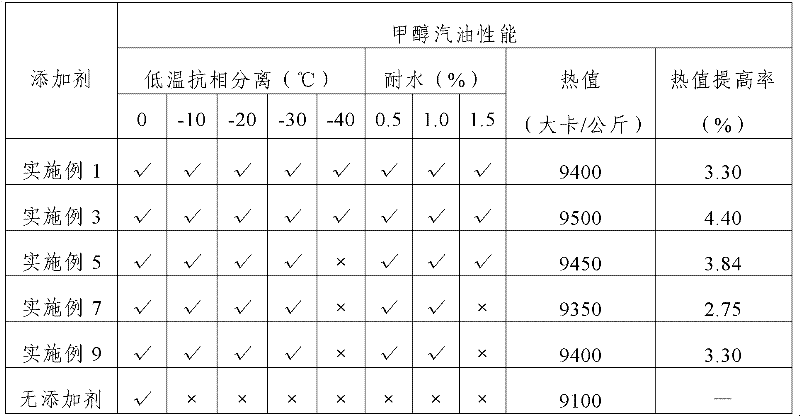

Additive for improving resisting phase separation performance and heat value of methanol gasoline

InactiveCN102344837AImprove oilinessReduce fuel consumptionLiquid carbonaceous fuelsAmyl acetateN-Butyl Alcohol

The invention discloses an additive for improving resisting phase separation performance and a heat value of methanol gasoline. The additive consists of the following raw materials in percentage by weight: 35-45 percent of aliphatic alcohol, 10-20 percent of aliphatic ether, 15-30 percent of aliphatic ester, 5-15 percent of aliphatic acid, 1-5 percent of aliphatic amine and 0.1-3 percent of emulsifier OP, wherein the aliphatic alcohol is one or more of isopropyl alcohol, n-propanol, n-amyl alcohol, isoamyl alcohol and n-butyl alcohol; the aliphatic ether is one or more of ethylene glycol methyl ether, ethylene glycol ethyl ether and ethylene glycol butyl ether; the aliphatic ester is one or more of butyl acetate, n-amyl acetate and isoamyl acetate; the aliphatic acid is oleic acid and / or naphthenic acid; the aliphatic amine is dimethylamine and / or diethylamine; and the emulsifier OP is emulsifier OP-15 and / or emulsifier OP-20. The methanol gasoline in which the additive is added has superior low-temperature resisting phase separation and water resisting phase separation performances and an obviously improved heat value.

Owner:西安祺祥能源科技发展有限公司

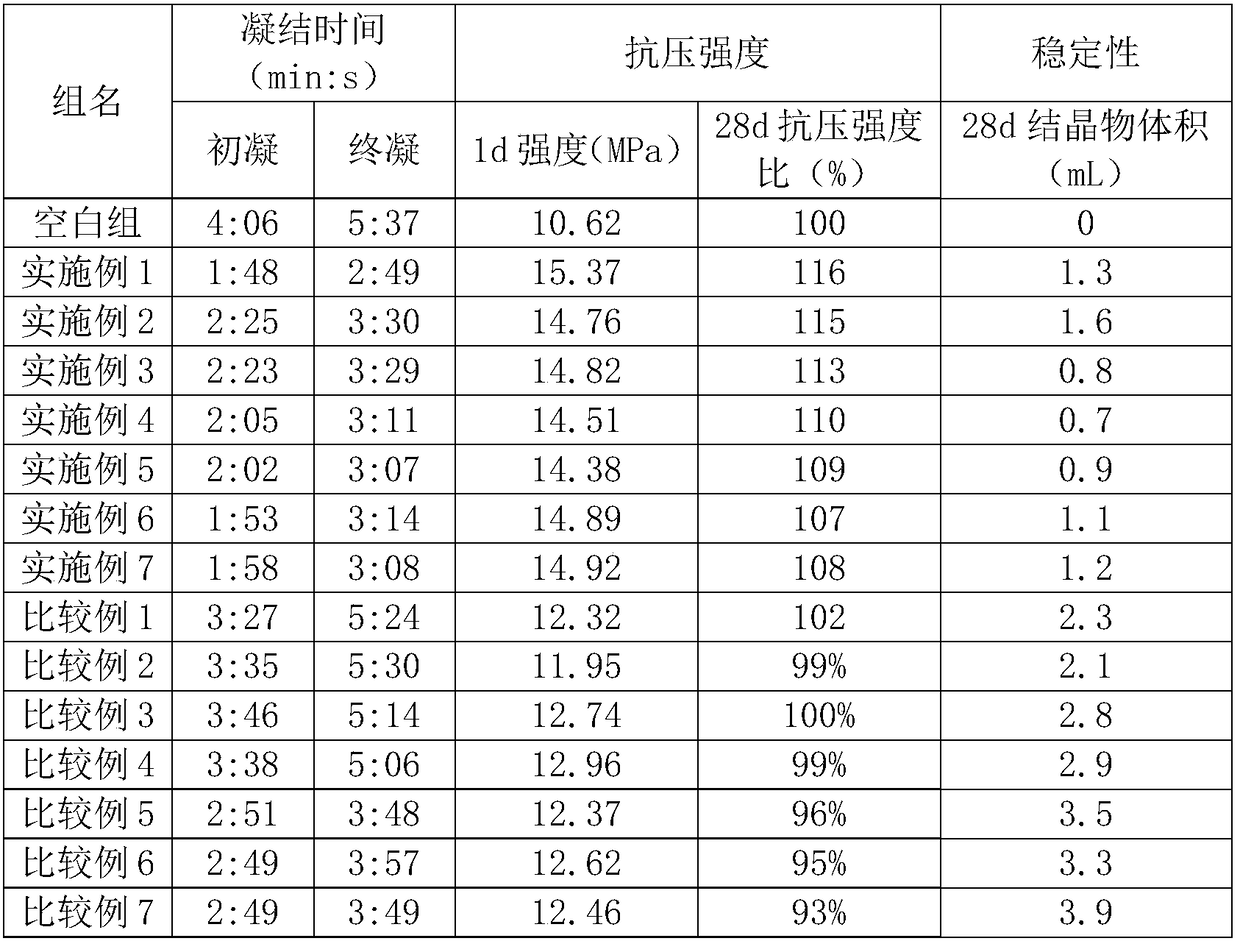

Alkali-free liquid accelerator and preparation method thereof

The invention discloses an alkali-free liquid accelerator and a preparation method thereof. The alkali-free liquid accelerator is prepared from, by weight, 45%-55% of aluminum sulfate, 1%-5% of aluminum hydroxide, 1%-5% of phosphoric acid, 1%-3% of diethanol amine, 1%-3% of glycollic acid, 0.5%-2% of sepiolite mineral powder, 0.5%-2% of bisphenol condensation compound and the balance deionized water. The preparation method of the alkali-free liquid accelerator comprises the steps that the aluminum hydroxide and the aluminum sulfate are successively dissolved, the bisphenol condensation compound and the sepiolite mineral powder are added to complete viscosity improvement, and finally residual components are added to complete organic compounding. The bisphenol condensation compound and the sepiolite mineral powder are added into the alkali-free liquid accelerator, its tiny granules and thin and short fibers are evenly dispersed in the solution to form a crosslinking net-like structure, the crystallizing resistance of sulfate radicals and aluminum ions is greatly improved, water molecules and aluminum sulfate difficultly produce crystallization and sedimentation and good solubilizingand stabilizing effects are achieved. The concrete setting time is effectively shortened by the glycollic acid and the diethanol amine, and the early strength of concrete is improved.

Owner:武汉优城科技有限公司

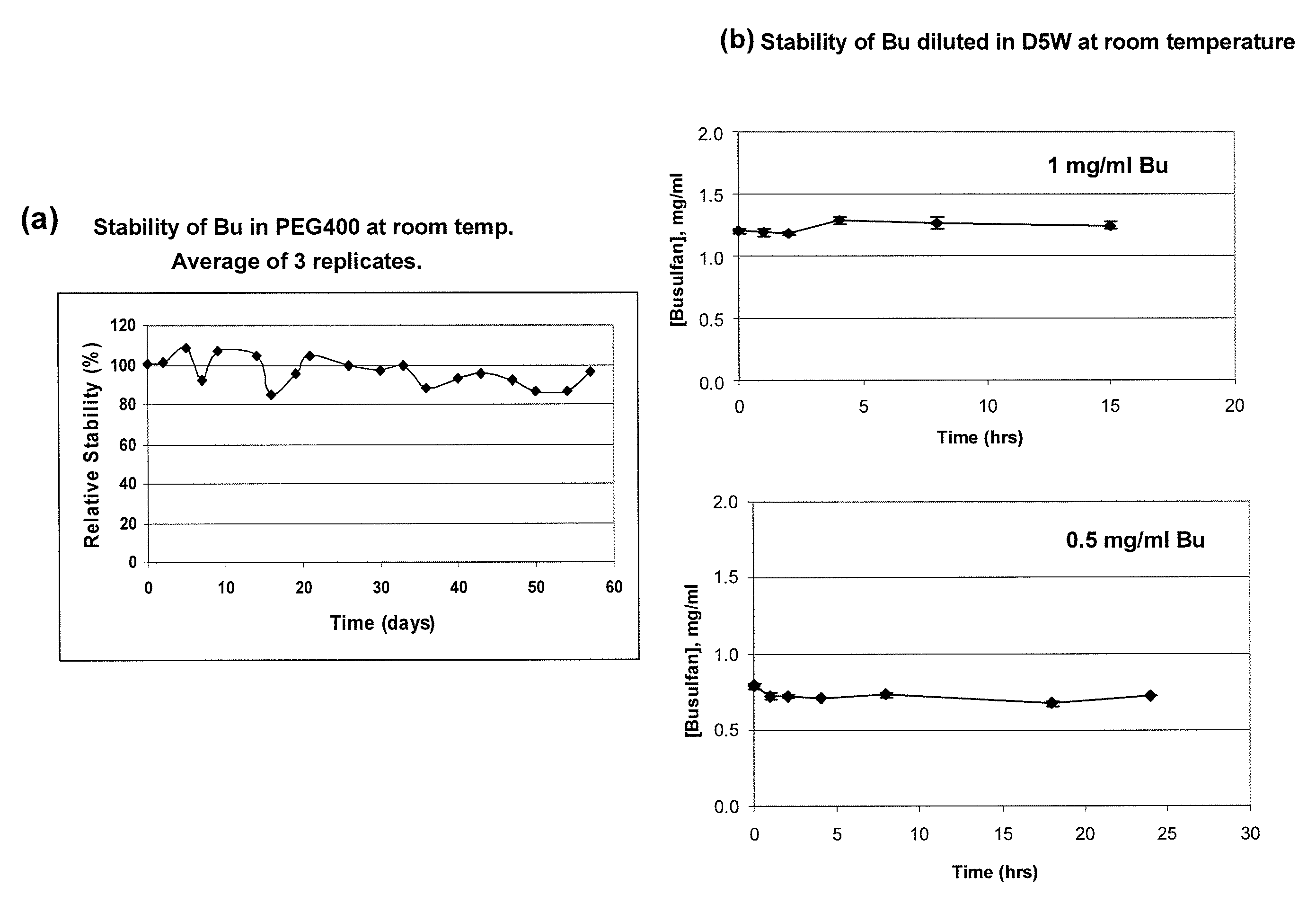

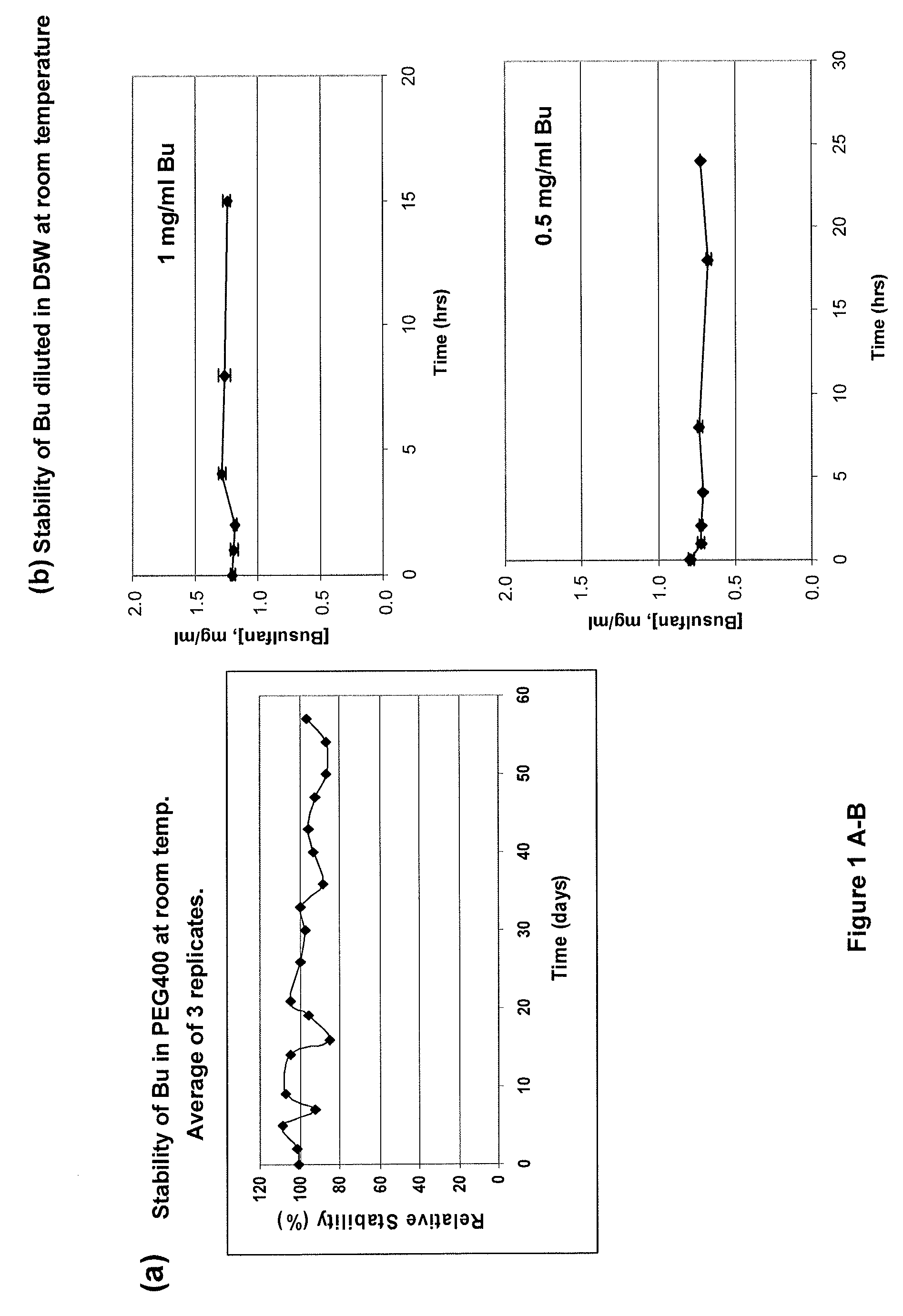

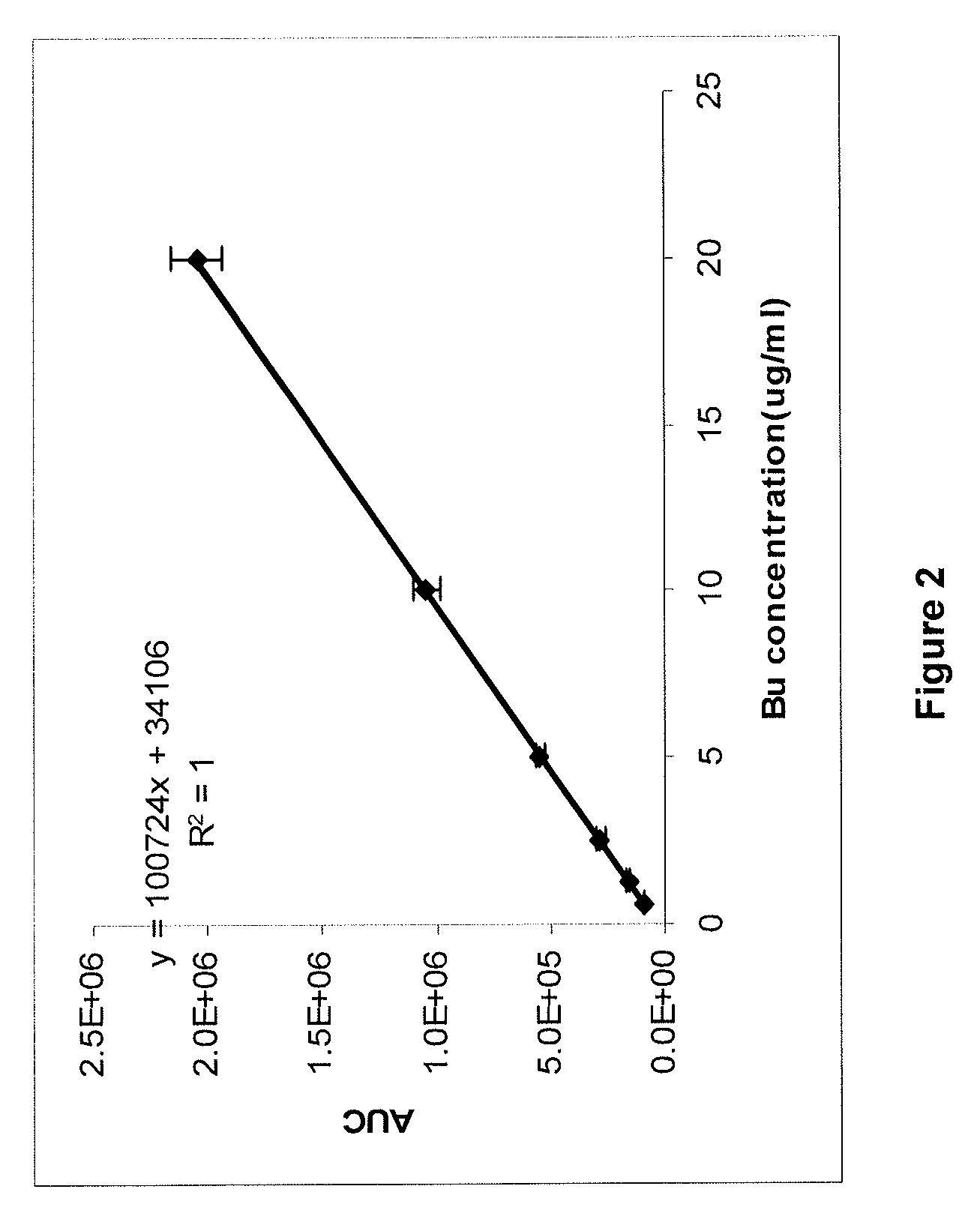

Parenteral formulations of lipophilic pharmaceutical agents and methods for preparing and using the same

ActiveUS9364433B2Improve solubility and stabilityPromote solubilizationAntibacterial agentsBiocideOrganic solventAutoimmune disease

Owner:GREENJAY THERAPEUTICS INC

Method for preparing compounded collecting agent of vegetable fatty acid diethanolamide ester soap

The invention relates to a method for preparing a compounded collecting agent of vegetable fatty acid diethanolamide ester soap. The method comprises the following steps of: 1) performing amide esterification reaction on fatty acid with an iodine value of 85 to 135 and diethanolamine, performing saponification reaction on an obtained reaction product and 30 mass percent of sodium hydroxide solution, and thus obtaining fatty acid diethanolamine and a fatty acid soap mixture thereof; 2) performing the saponification reaction on raw materials such as the fatty acid with the iodine value of 120 to 135 and sodium hydroxide or sodium carbonate, and thus obtaining fatty acid soap; and 3) mixing the fatty acid diethanolamine and the fatty acid soap mixture thereof obtained in the step 1) with the fatty acid soap obtained in the step 2) to obtain fatty acid diethanolamide ester soap, compounding a surfactant into the fatty acid diethanolamide ester soap, and thus obtaining the compounded collecting agent of the vegetable fatty acid diethanolamide ester soap. By adoption of the method, phosphorus selectivity is obviously improved, flotation temperature is reduced, floatation efficiency is high, and the raw materials are easy to purchase and low in cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

Rapid assay, method and system for detecting biowarfare agents

InactiveUS6770485B2Promote solubilizationAnalysis using chemical indicatorsChemical analysis using titrationSugarBiology

Provided herein are methods for preliminary analysis of suspect samples, which can be used in triaging possible contaminated sites (e.g., sites contaminated or thought to be contaminated by biowarfare agents). In some embodiments, the methods involve testing for the presence of protein in the suspect sample; optionally, the sample can also be tested for the presence of sugar, and / or for pH determination. Specific embodiment methods are carried out in tubes or other reaction vessels, others are carried out in a pad format, and still others are carried out in a test strip format. Kits for carrying out the described methods are also provided.

Owner:20 20 GENESYSTEMS INC

Delayed coking process for producing free-flowing coke using polymeric additives

InactiveUS7658838B2Low viscosityPromote solubilizationThermal non-catalytic crackingCombustible gas coke oven heatingMaterials sciencePolymer

A delayed coking process for making substantially free-flowing coke, preferably shot coke. A coker feedstock, such as a vacuum residuum, is heated in a heating zone to coking temperatures then conducted to a coking zone wherein volatiles are collected overhead and coke is formed. At least one polymeric additive is added to the feedstock prior to it being heated in the heating zone, prior to its being conducted to the coking zone, or both.

Owner:EXXON RES & ENG CO

Non-corrosive heavy oil dirt remover and preparation method thereof

ActiveCN102533477AGood emulsificationGood decontamination effectSurface-active non-soap compounds and soap mixture detergentsSodium metasilicatePotassium hydroxide

The invention provides a non-corrosive heavy oil dirt remover and a preparation method thereof. The remover comprises fatty alcohol-polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene (7) ether, alkyl polyglucoside, sodium polyacrylate, 2-methyl-2,4-pentanediol, sodium hydroxide, potassium hydroxide, sodium metasilicate, monoethanol amine, essence and deionized water. The non-corrosive heavy oil dirt remover, provided by the invention, has the advantages of strong oil dirt removing capacity, environmental friendliness, and free corrosion about materials of metal, plastic, glass and the like in use.

Owner:北京兴谷绿伞科技有限公司

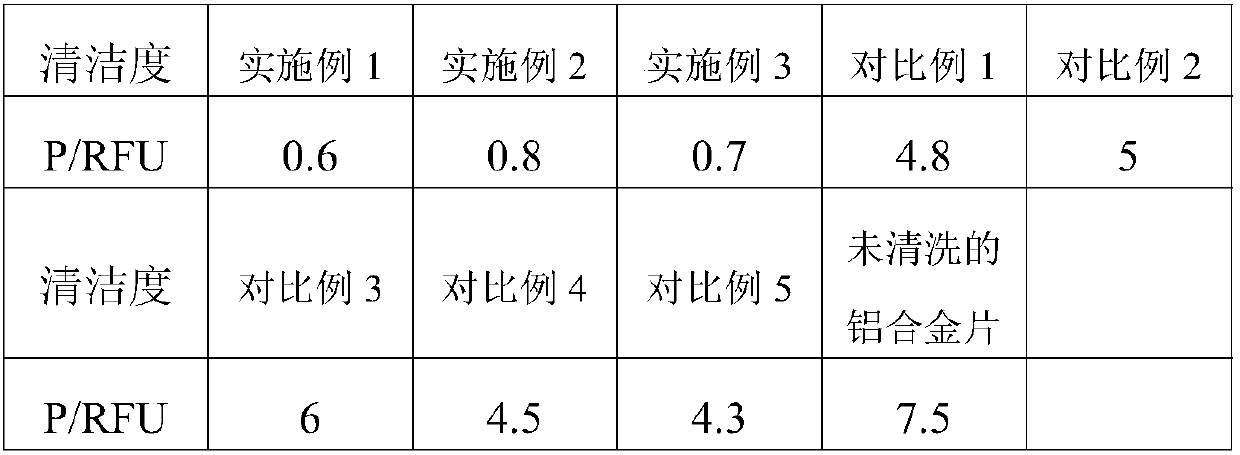

High performance cold rolling stack scouring agent and preparation method

InactiveCN101338514AAdsorptiveHas the ability to solubilizeFibre treatmentHigh concentrationOrganic acid

The invention provides a high-performance cold pad-batch scouring agent and its preparation method, which is characterized in that its structure molecular formula is CH-O(EO)n(PO)m-H, and it has the following formulation: 1mol of R(R')CH-O(EO)n(PO)m-H, 1-1.2mol of maleic anhydride, 0.05-1% of catalyst-composite organic acid by weight, 1-1.2mol of anhydrous sodium sulfite; the preparation method comprises an esterification reaction comprising adding low carbon alcohol EO / PO polyether, maleic anhydride and catalyst into a reactor, stirring and heating in nitrogen, timely sampling and measuring acid value until reaction termination; and a sulphonation reaction comprising reacting the resultant of the esterification reaction with sodium sulfite solution, adding nitrogen, stirring and heating to temperature of 40-85 DEG C until reaction termination when sulphonation rate variation is less than 0.5% per hour. The scouring agent of the invention can be resistant to high-concentration alkali liquor, make scouring and bleaching liquor permeate quickly, has good emulsification and dispersion ability, and good ability to adsorb or solubilize decomposed reaction product, thereby the scoured and bleached cloth acquires good capillary effect and whiteness.

Owner:金东辉

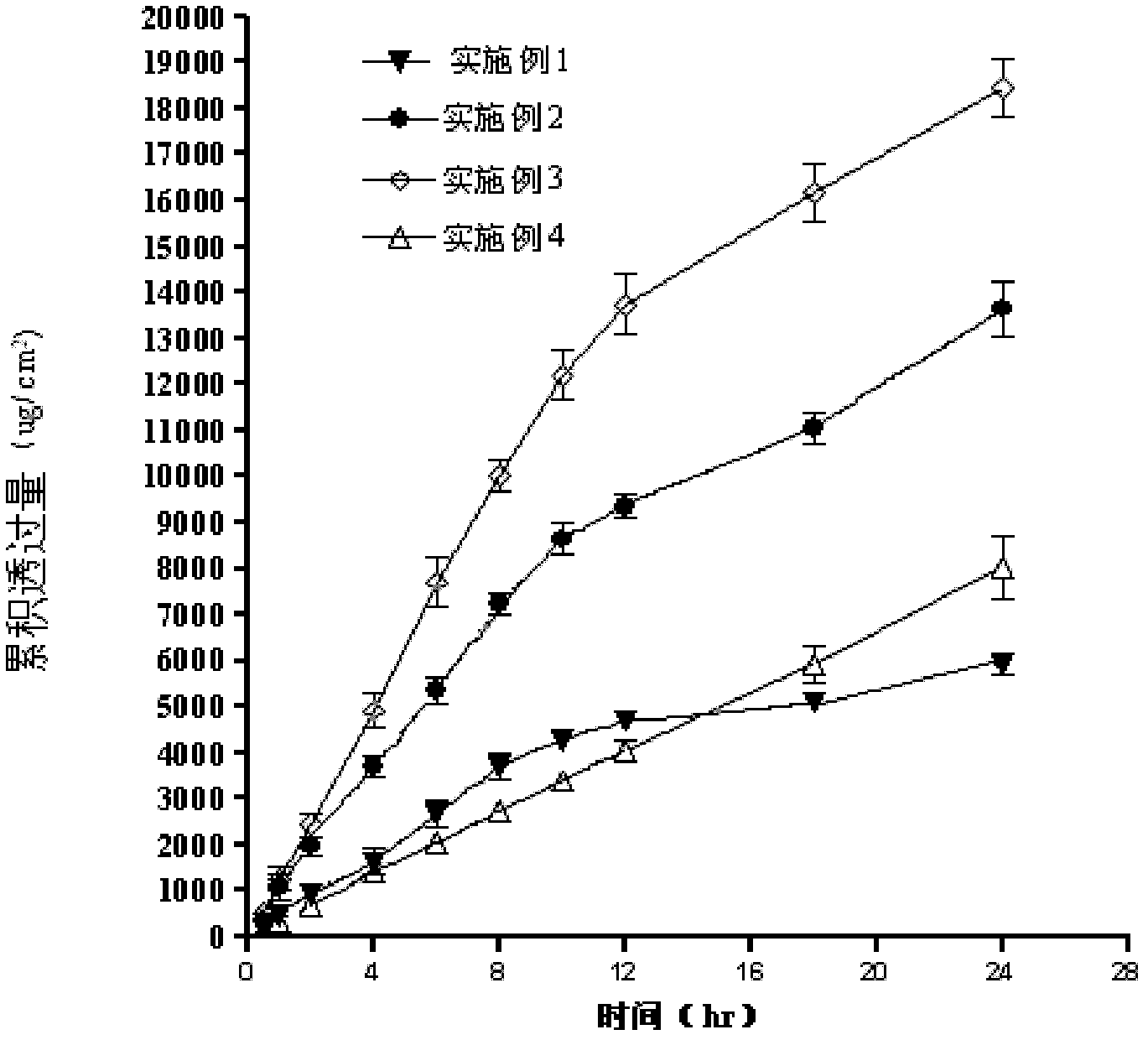

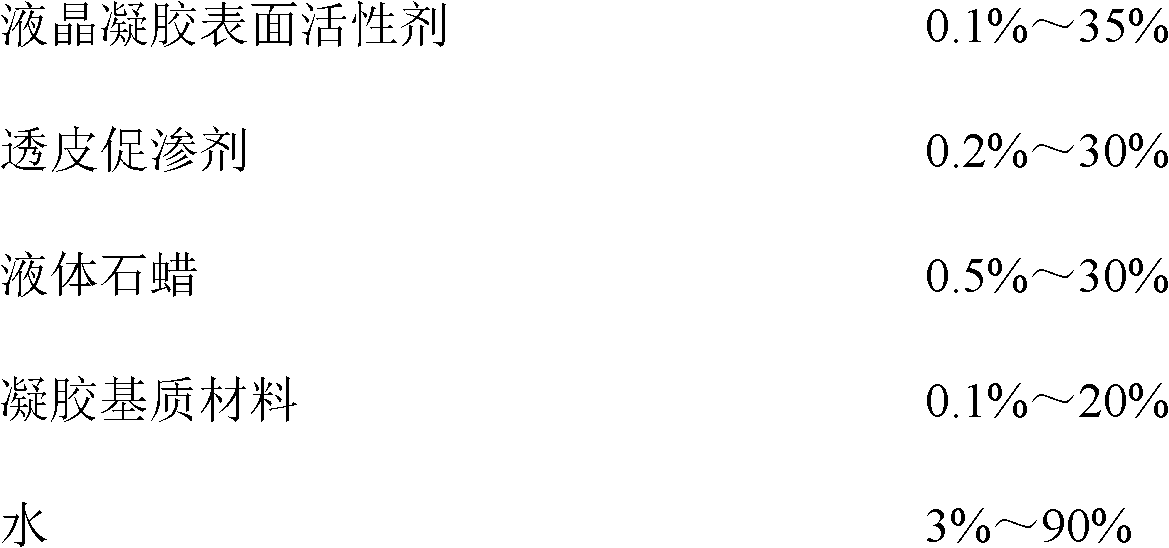

Active substance-contained gel composite based on multilayer liquid crystal framework and method for producing same

ActiveCN102614109AIncrease concentrationImprove stabilityNervous disorderPharmaceutical delivery mechanismChemistryLiquid crystal

The invention discloses an active substance-contained gel composite based on a multilayer liquid crystal framework and a method for producing the same, wherein the gel composite comprises the following components in percentage by weight: 0.1-35% of liquid crystal gel surfactant, 0.2-30% of permeable skin penetration enhancer, 0.5-30% of liquid paraffin, 0.1-20% of gel host material, 3-90% of water, 0.1-15% of active substance and 3-90% of ethanol solution. The active substance-contained gel composite based on the multilayer liquid crystal framework not only has better efficiency, but also can reduce the medicine taking frequency, so the compliance of a user is increased; and meanwhile, a permeable skin way avoids the first-pass effect after the medicine is orally taken and then passes by gastrointestinal tract and liver, so higher bioavailability is obtained.

Owner:SHANGHAI MODERN PHARMA ENG INVESTIGATION CENT +1

Production technology of anti-static fabric

ActiveCN110396753AImprove anti-static performanceIncreased durabilityBiochemical fibre treatmentSingeingPolyesterEscherichia coli

The invention discloses a production technology of an anti-static fabric. An electric conduction wire and a polyester cotton yarn are double-twisted to obtain a conductive yarn, the conductive yarn iswoven at intervals to obtain an anti-static gray fabric, and through singeing, shape setting and dyeing, the dyed gray fabric is obtained; through anti-static after-finishing of an anti-static finishing solution, two-time soaking and two-time rolling, the anti-static gray fabric is obtained; finally, through antibacterial anti-mite finishing of an antibacterial anti-mite finishing agent, two-timesoaking and two-time rolling, the anti-static fabric is obtained. The prepared anti-static fabric has good anti-static performance, can achieve moisture absorption and air permeation, has antibacterial and anti-mite performance and is good in comfort and particularly suitable for being used as a fabric of outdoor sports wear and climbing wear. The point-to-point resistance of the anti-static fabric reaches 2.8*1,010 omega, the rate of resisting staphylococcus aureus reaches 89.7%, the rate of resisting escherichia coli reaches 86.8%, the rate of resisting candida albicans reaches 73.6%, the water absorption rate reaches 106%, and the amount of water vapor transmission reaches 8,125 g / m<2>.24 h.

Owner:保定澳森制衣股份有限公司

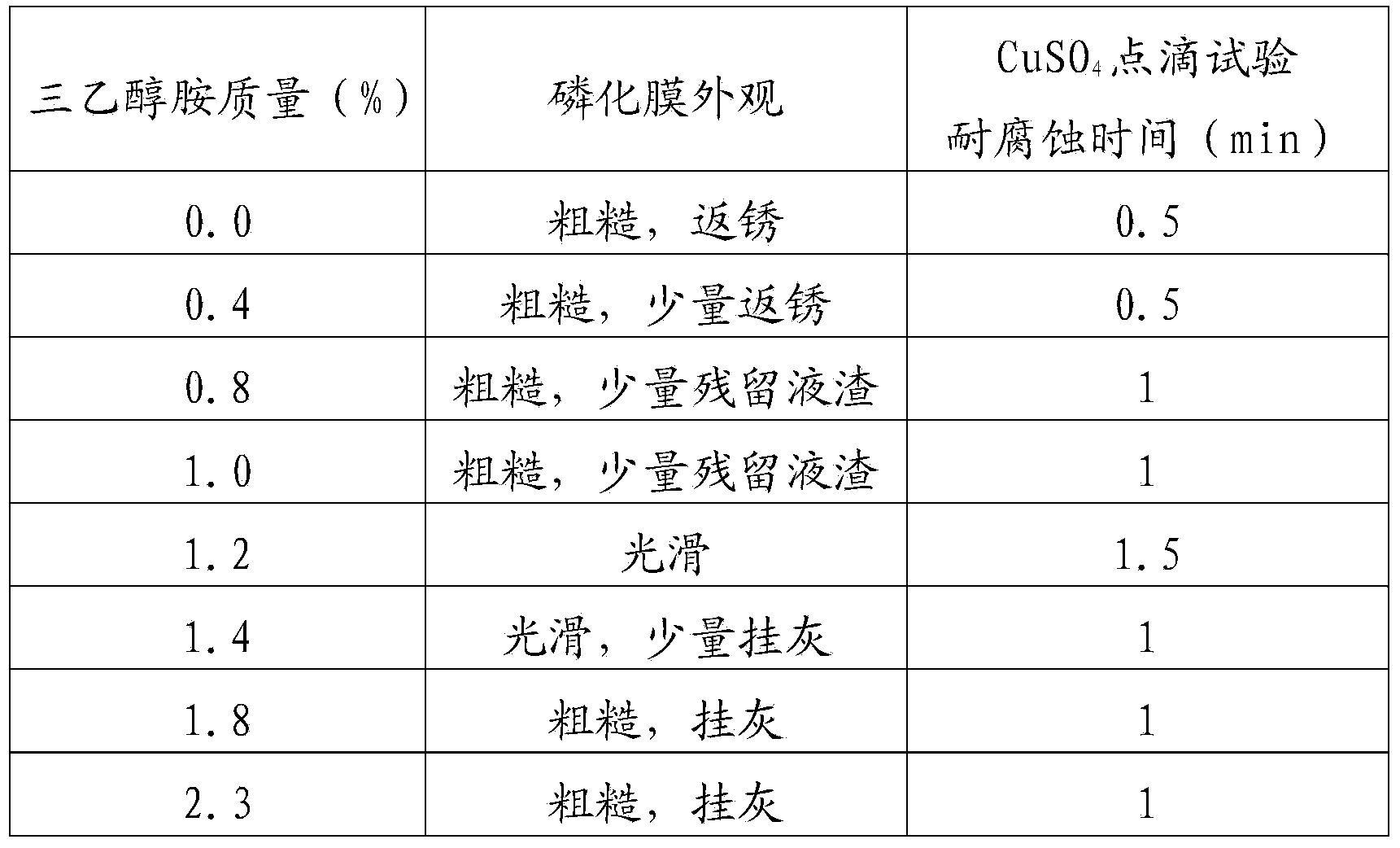

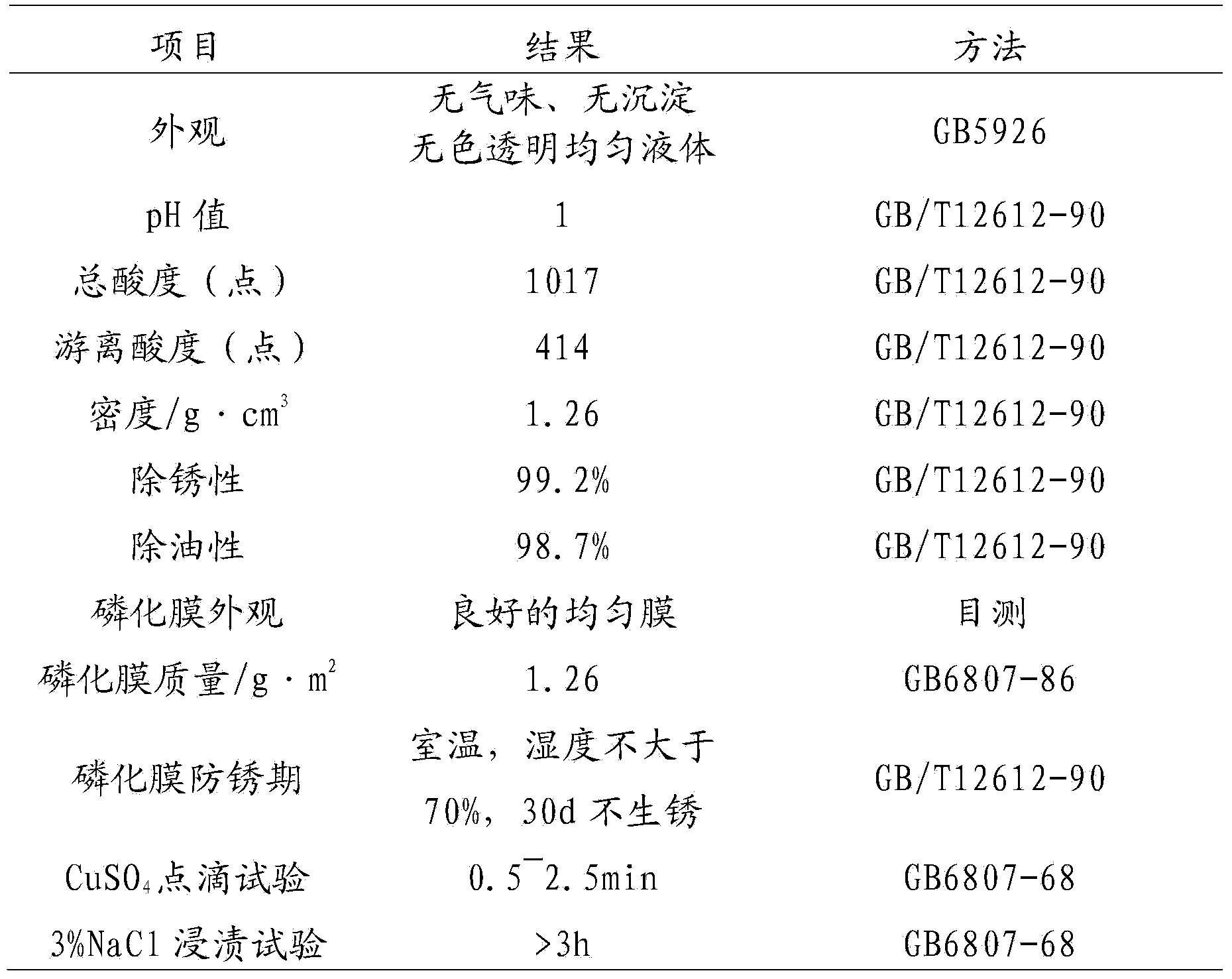

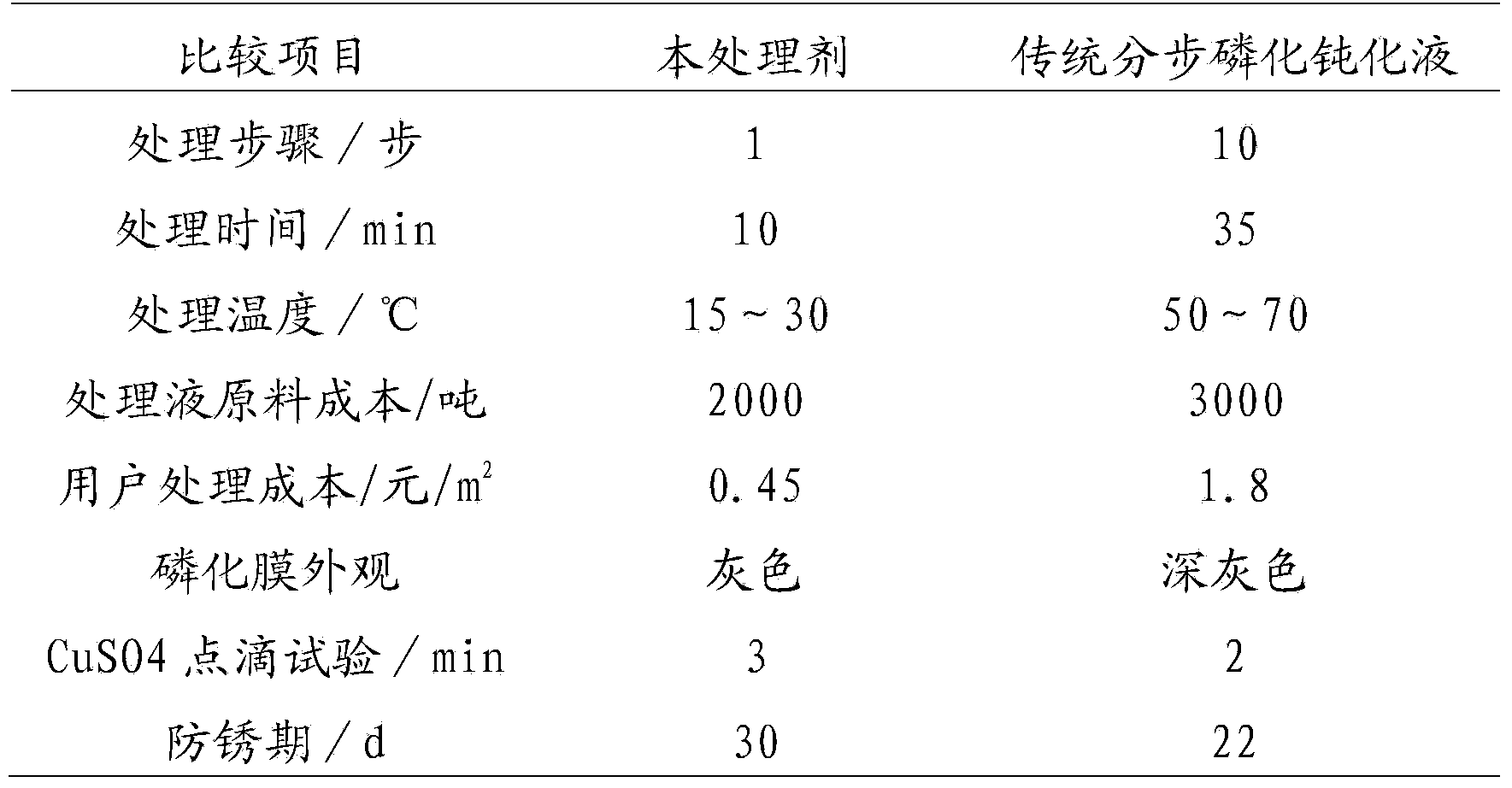

Comprehensive treatment agent and use method thereof

InactiveCN103436872AAvoid time costReduce processing costsMetallic material coating processesThioureaPhosphate

The present invention relates to a comprehensive treatment agent, which comprises, by mass, 25.0-30.0% of phosphoric acid, 1.0-3.0% of zinc oxide, 0.1-0.5% of sodium molybdate, 4.0-7.0% of zinc dihydrogen phosphate, 0.3-1.2% of potassium chlorate, 0.3-1.2% of a surfactant, 0.0-2.3% of triethanolamine, 0.8-2.3% of citric acid, 0.1-0.3% of thiourea, and 58.0-62.6% of water. According to the present invention, the treatment agent can be recycled, a treatment cost is low, and pollution on the environment can not be generated.

Owner:谢俊磊

High efficiency and no pollution industrial cleaning agent and its application

InactiveCN102242029AImprove solubilityCorrosion will notSurface-active non-soap compounds and soap mixture detergentsCleaning using liquidsPtru catalystActive agent

The invention discloses a high efficiency and no pollution industrial cleaning agent and its application. The formula of the cleaning agent comprises 80% - 93% of mixed ester solvent, 2% - 5% of nonionic surfactant, 3% - 10% of sodium carbonate and 2% - 10% of sodium silicate. The preparation method comprises the following steps: adding the mixed ester solvent at first, simultaneously adding a nonionic surfactant, sodium carbonate and sodium silicate and then stirring by manual or a machine for 15 - 20 minutes to obtain the high efficiency and no pollution industrial cleaning agent of the present invention. The high efficiency and no pollution industrial cleaning agent of the present invention is suitable for cleaning a oil circuit system which takes an operation medium as an oil product in equipment, and especially suitable for cleaning petrochemical apparatus, as well as on-line cleaning or stopping to disassembly and clean the oil circuit system of all industrial equipments such asa compressor. The cleaning agent of the invention has no influence to the equipment system, product quality and catalyst performance.

Owner:SHANGHAI DYNAMIC TECH

Method for preparation of vegetable fatty acid and citric alkyl ester saponin compounded collecting agent

The invention relates to a compound collecting agent for flotation of phosphorus ores, in particular to a method for preparation of a vegetable fatty acid and citric alkyl ester saponin compounded collecting agent. The method includes the steps: 1) subjecting alkyl alcohol and citric acid to esterification reaction to obtain a reaction product which is a citric alkyl ester surfactant; 2) adding vegetable fatty acid with iodine value being 135 into the citric alkyl ester surfactant obtained at the step 1), heating and well mixing; 3) adding the mixture obtained at the step 2) to sodium hydroxide solution to realize saponification, and well mixing to obtain the vegetable fatty acid and citric alkyl ester saponin compounded collecting agent. The method has the advantages that by utilization of the vegetable fatty acid and citric alkyl ester saponin compounded collecting agent, phosphorus selectivity is evidently improved, flotation temperature is lowered, and flotation efficiency is improved; in addition, easiness in purchase of raw materials, low cost, simple production lines, safety in production process and avoidance of irritating odors are realized, ore dressing cost is reduced, and defects in the prior art are overcome.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Delayed coking process for producing free-flowing coke using low molecular weight aromatic additives

InactiveUS7645375B2Low viscosityPromote solubilizationThermal non-catalytic crackingCoking carbonaceous materialsMaterials science

A delayed coking process for making substantially free-flowing coke, preferably shot coke. A coker feedstock, such as a vacuum residuum, is heated in a heating zone to coking temperatures then conducted to a coking zone wherein volatiles are collected overhead and coke is formed. A low molecular weight additive is added to the feedstock prior to it being heated in the heating zone, prior to its being conducted to the coking zone, or both.

Owner:EXXON RES & ENG CO

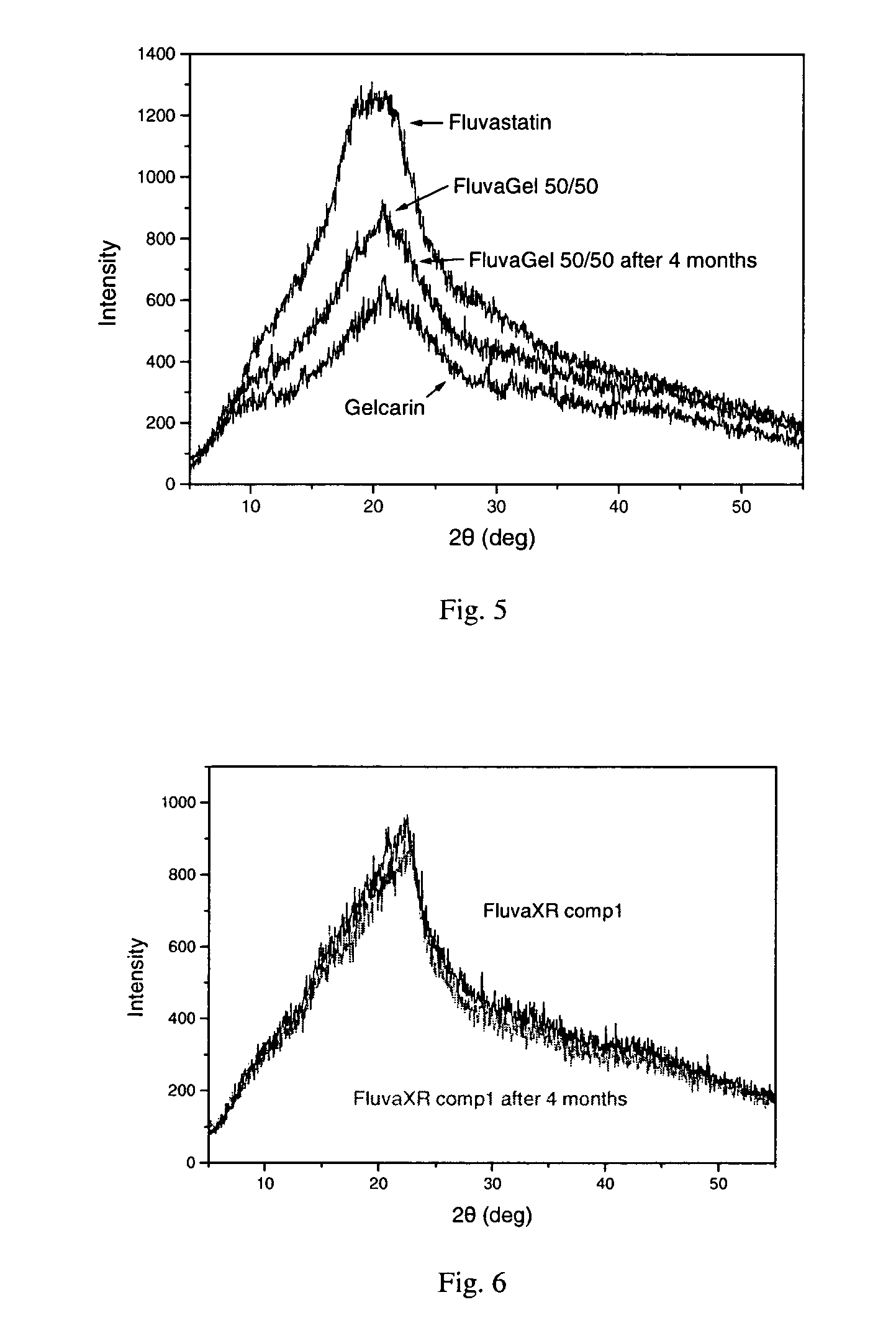

Pharmaceutical formulation containing an hmg-coa reductase inhibitor and method for the preparation thereof

InactiveUS20100137400A1Improve bioavailabilityLow production costBiocideOrganic chemistryHMG-CoA reductaseSulfation

The present invention relates to improved pharmaceutical formulation for oral administration comprising a therapeutically effective quantity of an HMG-CoA reductase inhibitor, and more particularly Fluvastatin, Atorvastatin or salts thereof in combination with a linear sulphated polysaccharide such as Carrageenan and a method for the preparation thereof.

Owner:PHARMATHEN

Steel and iron chemical oil removing powder and preparing and using methods thereof

Steel and iron chemical oil removing powder comprises, by weight, 5-10 g of sodium hydroxide, 40-50 g of sodium carbonate, 0.5-1 g of EDTA disodium, 8-10 g of sodium tripolyphosphate, 1-2 g of a washing assisting agent, 20-30 g of a metal protecting agent and 5.5-8.5 g of a surface active agent. A preparing method of the oil removing powder includes the following steps that sodium hydroxide, sodium bicarbonate, EDTA disodium and sodium tripolyphosphate are mixed and stirred uniformly so that A powder can be obtained; and the washing assisting agent, the metal protecting agent and the surface active agent are added into the A powder at a time, and after uniform stirring is performed, the finished oil removing powder can be obtained. A using method of the oil removing powder includes the following steps that warm water is added in a cleaning tank, and temperature is 40-70 DEG C; and 4-8% of the oil removing powder is added into the warm water and is stirred till complete dissolving is achieved. The surface of steel and iron cleaned through the oil removing powder is free of a visible oil film or oil spots, meanwhile, the using amount of the oil removing powder is small, and the steel and iron chemical oil removing powder is economical, non-toxic and environment-friendly.

Owner:江门市濠成化工科技有限公司

Preparation process of functional soybean protein concentrate

InactiveCN101617736AImprove water holding capacityIncrease elasticityVegetable proteins working-upSolubilityDry weight

The invention relates to a preparation process of functional soybean protein concentrate. The preparation process comprises the following steps: (1) putting soybean protein concentrate curd which is prepared by an alcohol extraction process or soybean protein concentrate which is sold on markets and screened by a 80-mesh screen in a dissolving tank; adding 6-15 times of water to mix and stir for 10-20 minutes while controlling water temperature at 50-60 DEG C; (2) using sodium hydroxide to adjust the pH value of the protein liquid to 7.0-8.0 and stirring the protein liquid for 10-20 minutes; (3) using a feeding pump to pump the protein liquid in an ultra-high temperature sterilizer so that the temperature reaches 120-155 DEG C, processing the protein liquid for 1-240 seconds and setting the temperature of a liquid outlet at 40-80 DEG C; (4) pumping the protein liquid in a spray drying tower for spraying and drying; (5) heating phospholipid at different processing stages, wherein the addition of the phospholipid is 0.1-1 percent of the dry weight of protein, and the HLB value of the phospholipid is 4-10; and (6) together adding sucrose ester and / or amber acid direactive glyceride and the phospholipid to the protein liquid, wherein the additions are respectively 0.1-0.5 percent of the dry weight of the protein. The invention remarkably improves the dissolvability of products, achieves the NSI of 50-80 percent and the haloduric index of 30-80 and has light color, mild flavor and good oil and moisture retention.

Owner:天津实发中科百奥工业生物技术有限公司

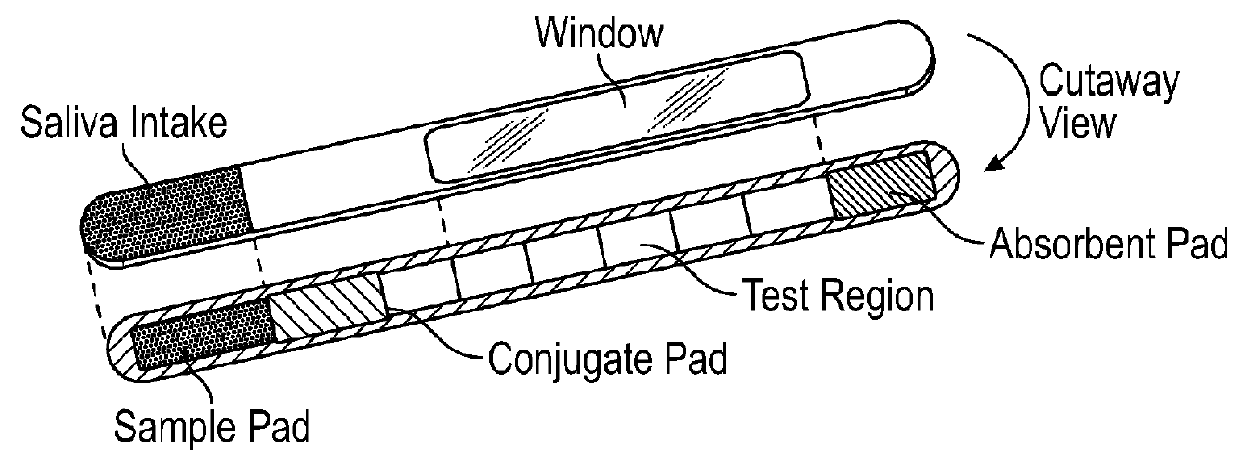

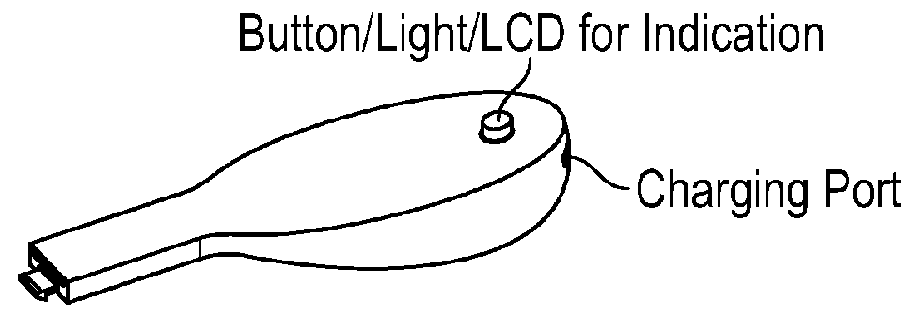

A test device for detecting an analyte in a saliva sample and method of use

InactiveUS20180106799A1Promote solubilizationImprove liquiditySurgeryVaccination/ovulation diagnosticsTherapy monitoringObstetrics

In some aspects, the present disclosure relates to a lateral flow test device, a kit or an instrument comprising the test device, and a method of using the test device, kit, or instrument for quantitatively detecting an analyte in a saliva sample, e.g., a saliva sample from a subject, for example, for assessing hormone(s), ovulation, pregnancy, and / or fertility for a user, e.g., hormonal, ovulation, pregnancy, fertility status, time window, trend, or therapy monitoring or guidance for the user.

Owner:BLUDIAGNOSTICS INC

Method for reinforced combined repairing of polycyclic aromatic hydrocarbon contaminated soil

InactiveCN106734187AImprove bioavailabilityEnvironmentally friendlyContaminated soil reclamationLand levelingContaminated soils

The invention discloses a method for reinforced combined repairing of polycyclic aromatic hydrocarbon contaminated soil, and relates to a method for repairing contaminated soil. The method comprises the following processes of field investigation, land leveling, culture activation, medicament preparing and field in-situ repairing operation. In the field in-situ repairing operation, prepared lignin and a prepared rhamnolipid solution are applied into to-be-repaired soil according to the regulated concentration, the soil is sufficiently mixed, 500 mL of plant growth-promoting bacteria liquid and 500 mL of efficient degrading bacteria liquid are evenly sprayed to the to-be-repaired soil every square meter, sufficient uniform mixing is conducted again, and rape seeds are sown; and later management is conducted, quality detection is conducted, the above steps can be repeatedly conducted continuously if polycyclic aromatic hydrocarbon left in the soil does not reach the repairing expectation till the content of the polycyclic aromatic hydrocarbon in the soil reaches the soil environment safety standard. A biology enhancer is applied for activating soil pollutants, plants are induced for enhancing the microbial activity, large-area application can be achieved, environment friendliness is achieved, enrichment of the polycyclic aromatic hydrocarbon through oilseed rapes cannot be promoted, and the application prospect is wide.

Owner:SHENYANG UNIV

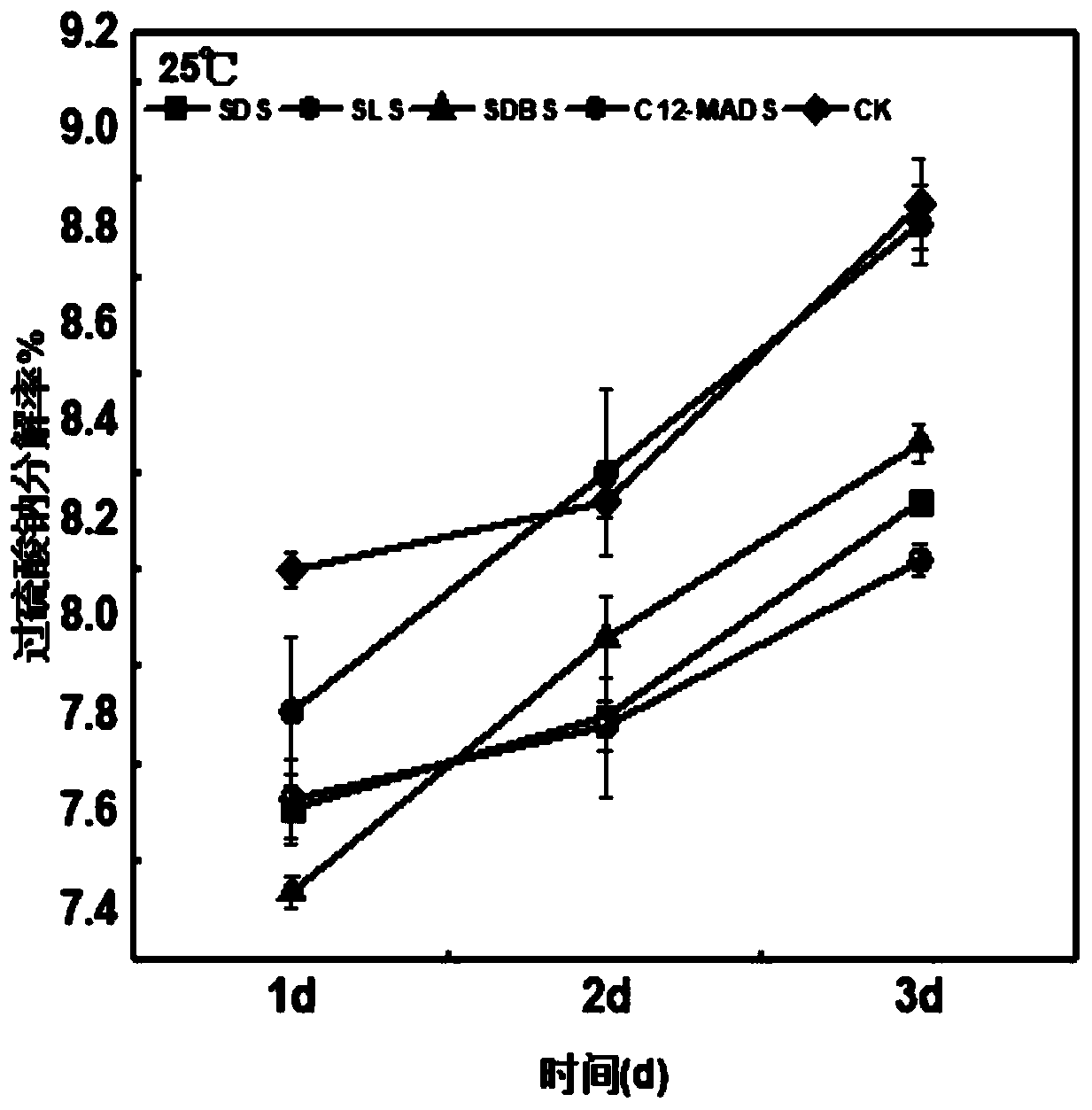

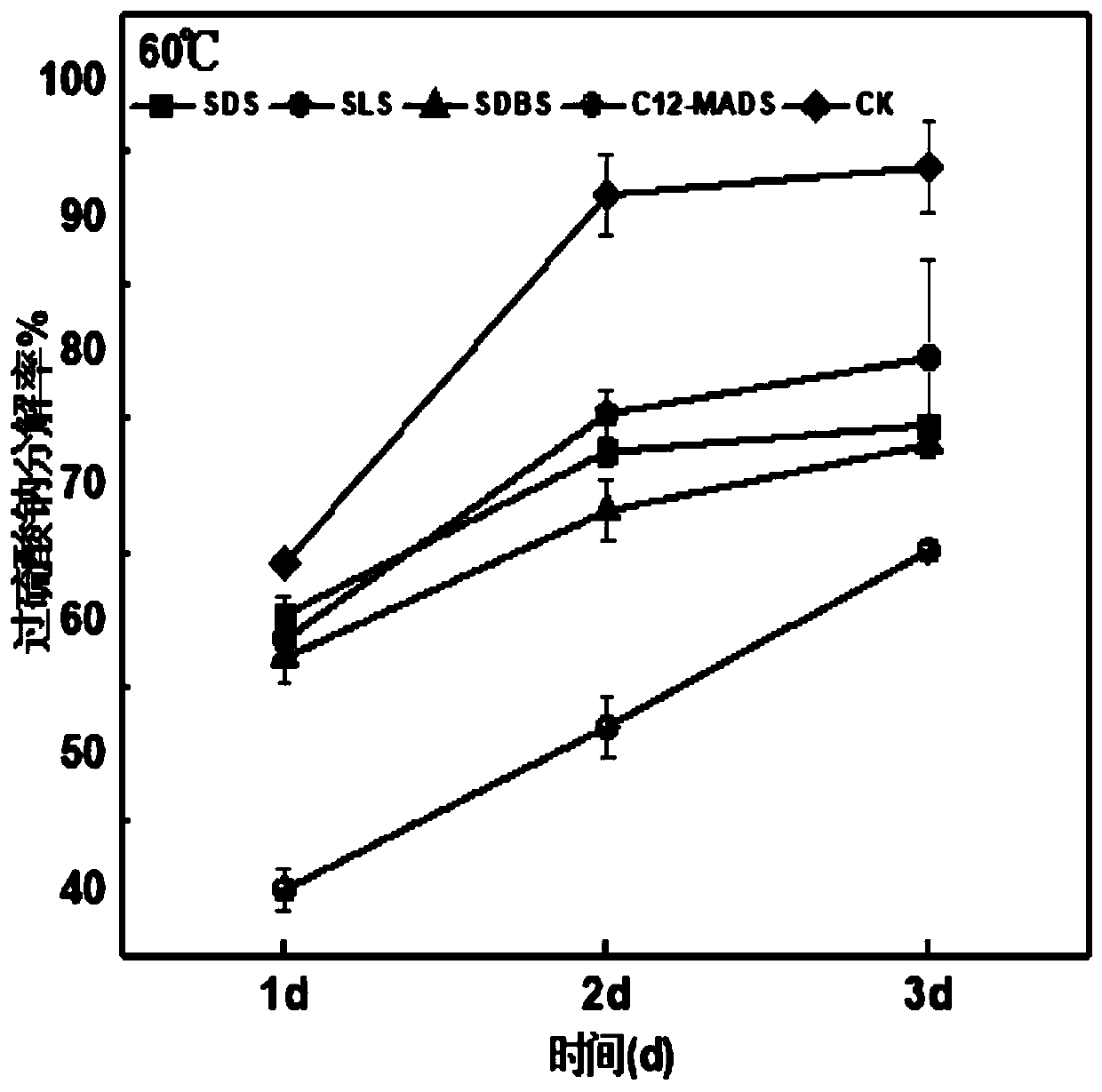

Method for repairing organochlorine pesticide-polluted soil through microwave-enhanced sodium percarbonate

InactiveCN106623382AFast degradationImprove efficiencyContaminated soil reclamationSodium carbonateChemistry

The invention belongs to the technical field of organic polluted soil repairing engineering and discloses a method for repairing organochlorine pesticide-polluted soil through microwave-enhanced sodium percarbonate. The method comprises the steps of mixing the organochlorine pesticide-polluted soil into a mud-state soil mixture solution at a certain liquid-solid ratio, feeding a certain amount of surfactant, sodium percarbonate, sodium citrate and ferrous sulfate and carrying out microwave treatment and standing, wherein the degradation rate of an organochlorine pesticide in the soil can reach over 85%. The method has the advantages of being high in treatment efficiency, low in oxidant consumption, simple in process condition and low in operation requirements, and is suitable for the repairing of the organochlorine pesticide-polluted soil.

Owner:CHANGZHOU UNIV

Oil removal powder for metal surface and preparation method thereof

The invention provides an oil removal powder for a metal surface. The oil removal powder comprises the following raw materials of, by weight, 20-30 g of sodium carbonate, 5-10 g of borax, 0.5-1 g of EDTA disodium, 8-10 g of washing assistant, 40-50 g of a metal protective agent and 2.5-7.5 g of a surfactant, wherein the surfactant comprises at least one of an anionic surfactant and a nonionic surfactant; the anionic surfactant is sodium alcohol ether sulphate; the nonionic surfactant comprises at least one of nonylphenol polyoxyethylene ether and fatty acid methyl ester ethoxylate; and the washing assistant is sodium citrate. A preparation method comprises the following steps of mixing sodium carbonate, borax and EDTA disodium, and carrying out uniform stirring so as to obtain a powder A;mixing the washing assistant and the metal protective agent, and carrying out uniform stirring so as to obtain a powder B; mixing the powder A and the powder B, adding the surfactant, and carrying outuniform stirring so as to obtain the finished product oil removal powder. The oil removal powder is high in oil removal capability and has good wetting, solubilizing and emulsification capabilities.

Owner:江门市濠成化工科技有限公司

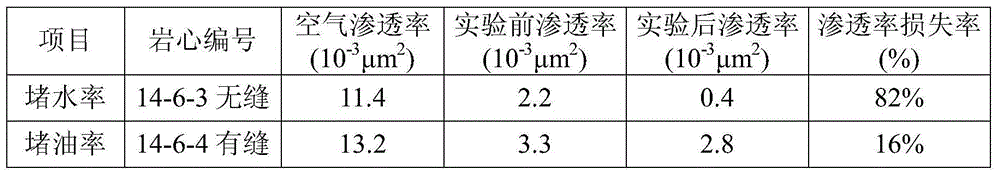

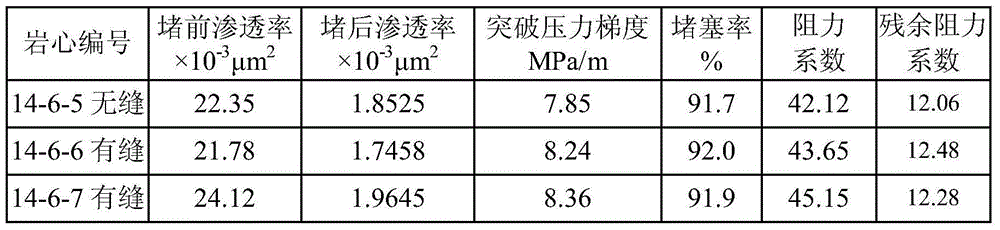

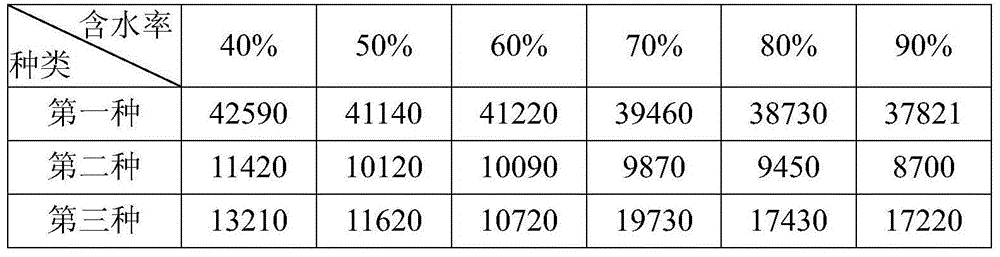

Activating agent for water plugging and water-plugging thickened oil activating agent prepared from same

ActiveCN104830295ALow irritationReduce total usageDrilling compositionSealing/packingOperational safetyFatty alcohol

The invention provides an activating agent for water plugging, and a water-plugging thickened oil activating agent prepared from the same. The water-plugging thickened oil activating agent is formed by mixing the activating agent for the water plugging and thickened oil, wherein the activating agent for the water plugging comprises a main agent and auxiliaries, and the main agent comprises a higher fatty alcohol-polyoxyethylene ether sulfate anionic surfactant and an imidazoline zwitterionic surfactant. The invention further provides a method for performing oil well water plugging by utilizing the water-plugging thickened oil activating agent. The water-plugging thickened oil activating agent has the advantages that the environment is low in toxicity and pollution-free, the field operation process is simple, the compatibility with a stratum is good, the selective water plugging performance is high, and the water-plugging thickened oil activating agent is suitable for thickened oil and super heavy oil deposits; furthermore, the use amount of the raw materials is small, the cost is low, no toxicity exists, nonvolatility and nonflammability are achieved, the operation is safe, no clean water or deionized water needed is needed for blending, and the problem that crude oil is emulsified on the ground and therefore cannot be injected into the stratum is avoided during field construction.

Owner:PETROCHINA CO LTD

Rapid assay, method and system for detecting biowarfare agents

InactiveUS20030180961A1Promote solubilizationReduce the possibilityAnalysis using chemical indicatorsChemical analysis using titrationSugarBiology

Provided herein are methods for preliminary analysis of suspect samples, which can be used in triaging possible contaminated sites (e.g., sites contaminated or thought to be contaminated by biowarfare agents). In some embodiments, the methods involve testing for the presence of protein in the suspect sample; optionally, the sample can also be tested for the presence of sugar, and / or for pH determination. Specific embodiment methods are carried out in tubes or other reaction vessels, others are carried out in a pad format, and still others are carried out in a test strip format. Kits for carrying out the described methods are also provided.

Owner:20 20 GENESYSTEMS INC

Method for repairing organic matter contaminated soil with reinforced persulfate

PendingCN110814006AIncrease profitIncreased persistenceContaminated soil reclamationSoil sciencePersulfate

The invention discloses a method for repairing organic matter contaminated soil with a reinforced persulfate. According to the method, repairing is carried out through adding a specific kind of surfactant and a persulfate into the organic matter contaminated soil and reacting. Through combined application of the specific surfactant and the persulfate, the surfactant has a good stabilizing effect on thermal activation of the persulfate, rapid decomposition of the persulfate can be avoided, and the continuous action effect of the persulfate is improved; meanwhile, through the solubilizing effectof the surfactant, the solubility of organic pollutants in the soil is increased, so that the organic pollutants are eluted from the soil, and the degradation efficiency of the organic pollutants inthe soil is improved.

Owner:JINAN UNIVERSITY +1

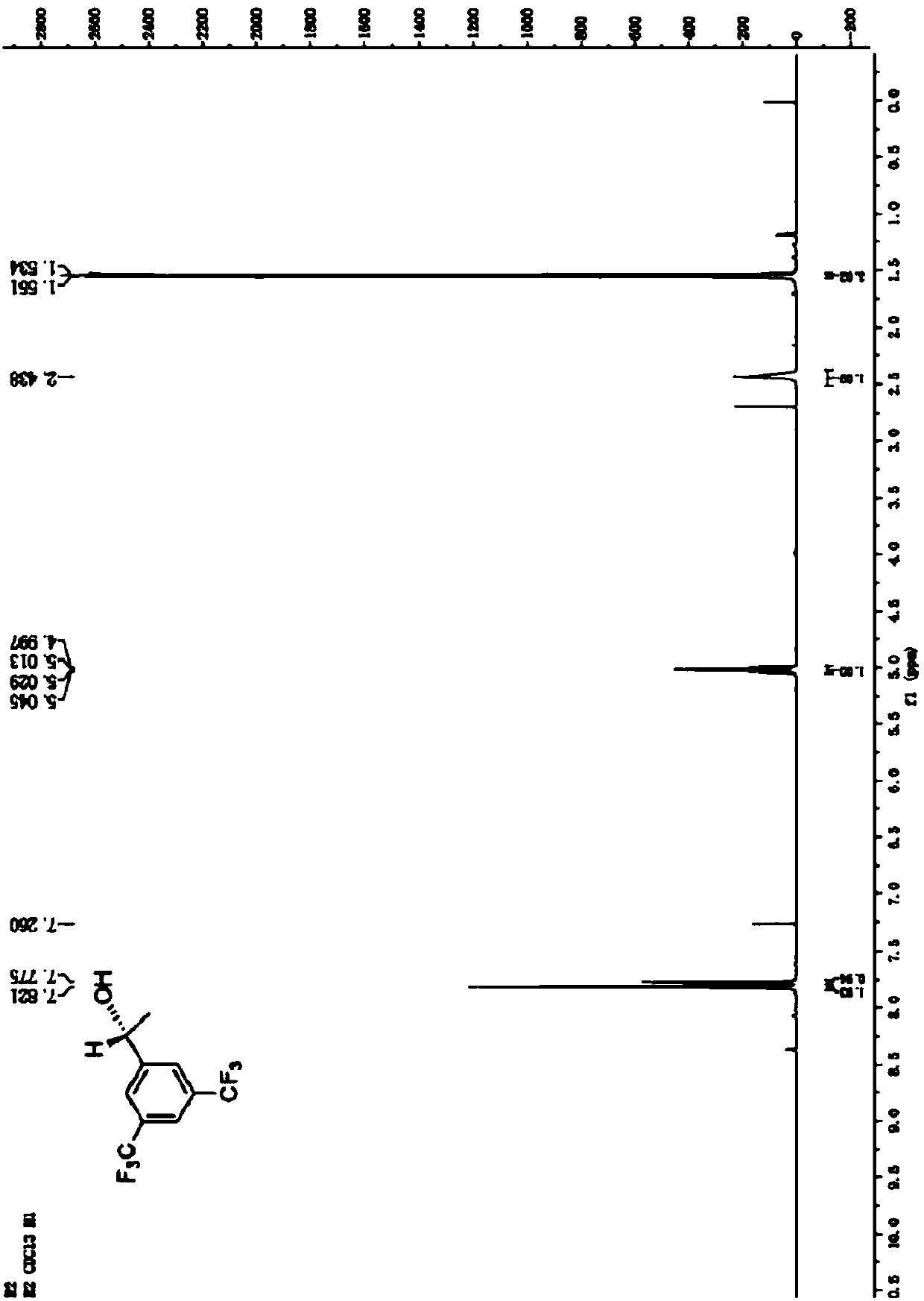

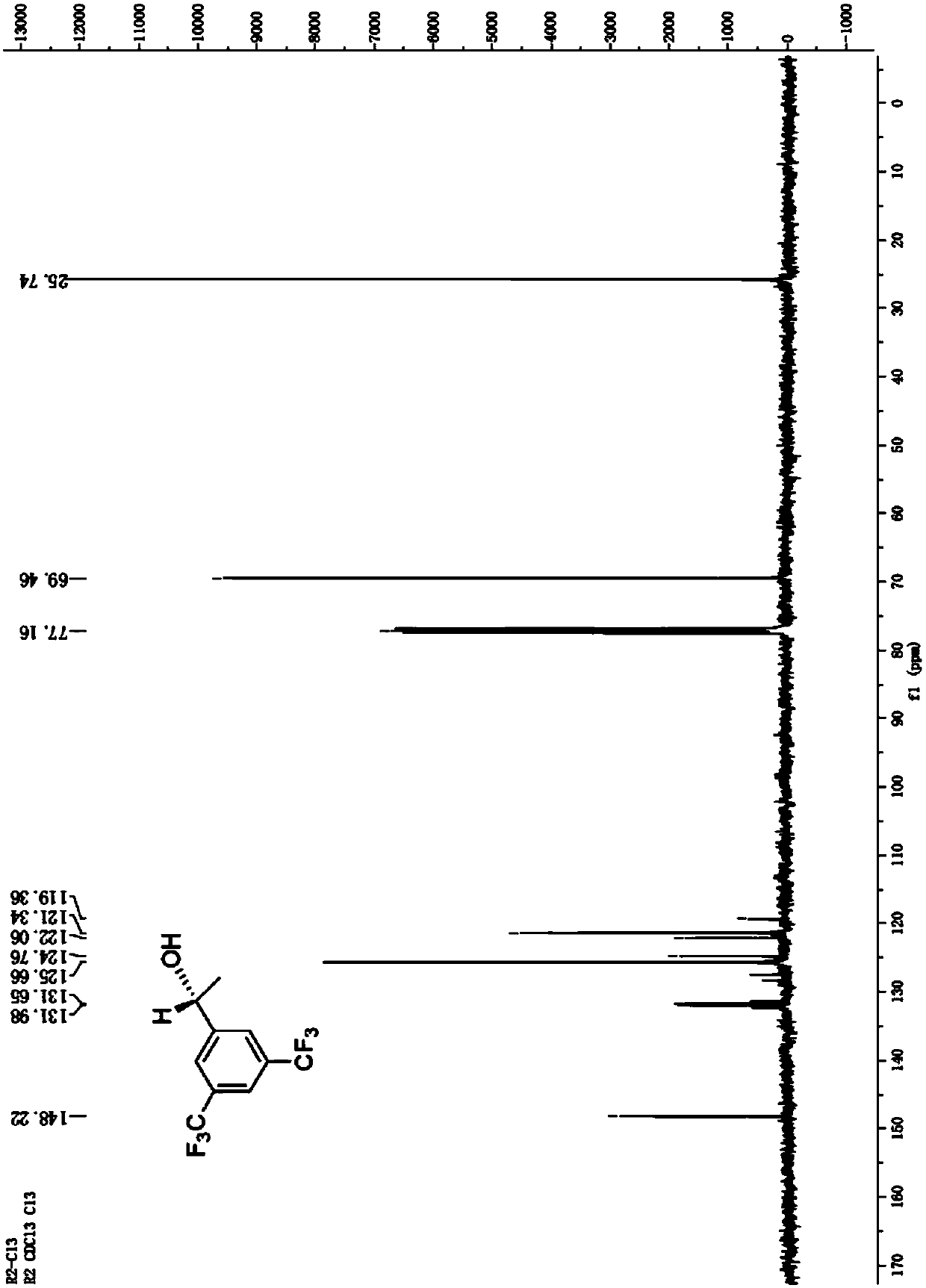

Method for preparing (R)-3,5-bis(trifluoromethyl)phenethyl alcohol in ionic liquid-containing cosolvent medium

ActiveCN104212841AImprove solubilityImprove permeabilityMicroorganism based processesFermentationSolubilityCell membrane

The invention provides a method for preparing (R)-3,5-bis(trifluoromethyl)phenethyl alcohol in an ionic liquid-containing cosolvent system. The method is characterized in that an ionic liquid is added to a reaction system during asymmetric reduction of 3,5-bis(trifluoromethyl)acetophenone by use of genetically engineered recombinant bacteria; the permeability of the cytomembrane is improved and a substrate is solubilized so that the solubility of the substrate can be effectively improved and the inhibition effect of the substrate and the product on the reaction can be reduced; as a result, the substrate concentration and the reaction efficiency of the reaction are improved; the substrate concentration of the reaction is increased to 1200mM from 50mM; besides, when the substrate concentration is 1200mM, the yield is increased to 93.8% from 70.4% of water phase reduction; the yield is increased by 33.2%; the ee value is greater than 99%.

Owner:南陵县建设投资有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com