Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Prolonged initial setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

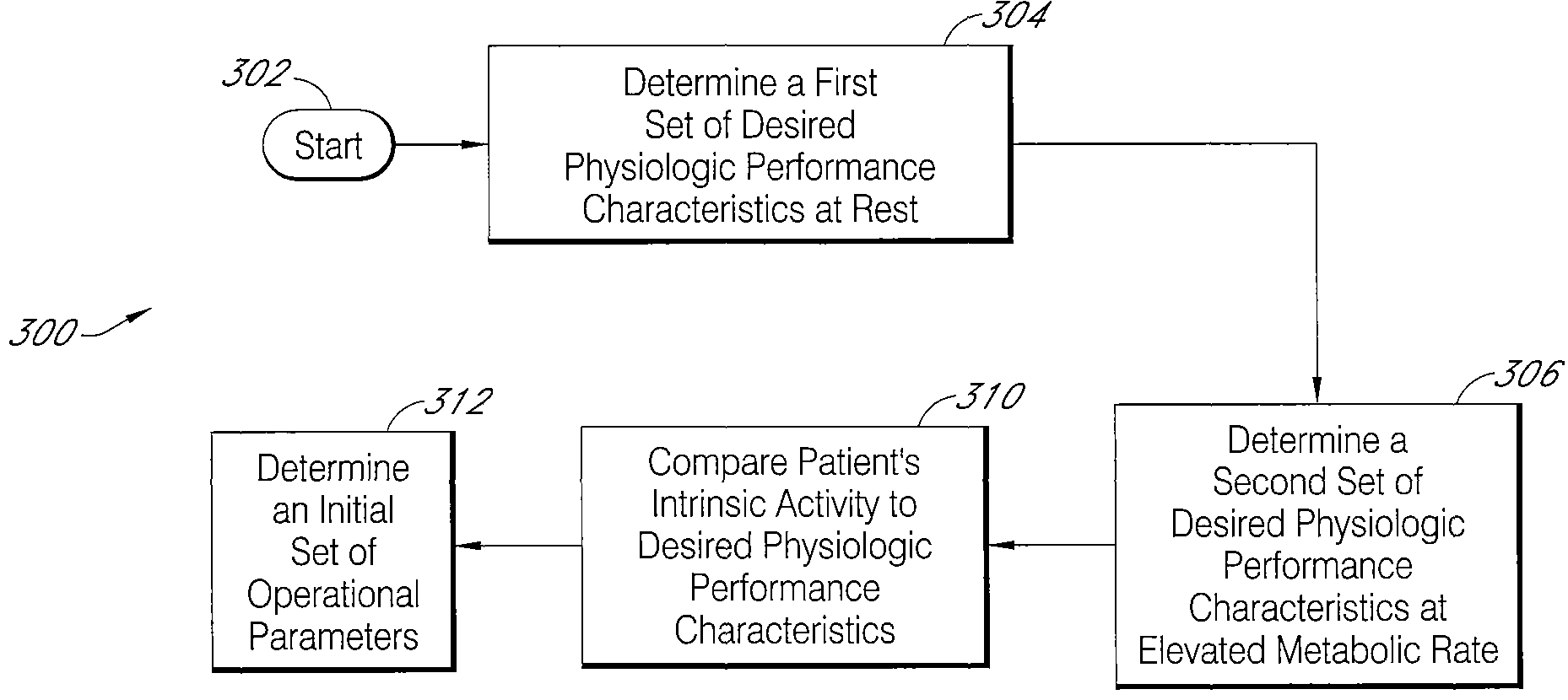

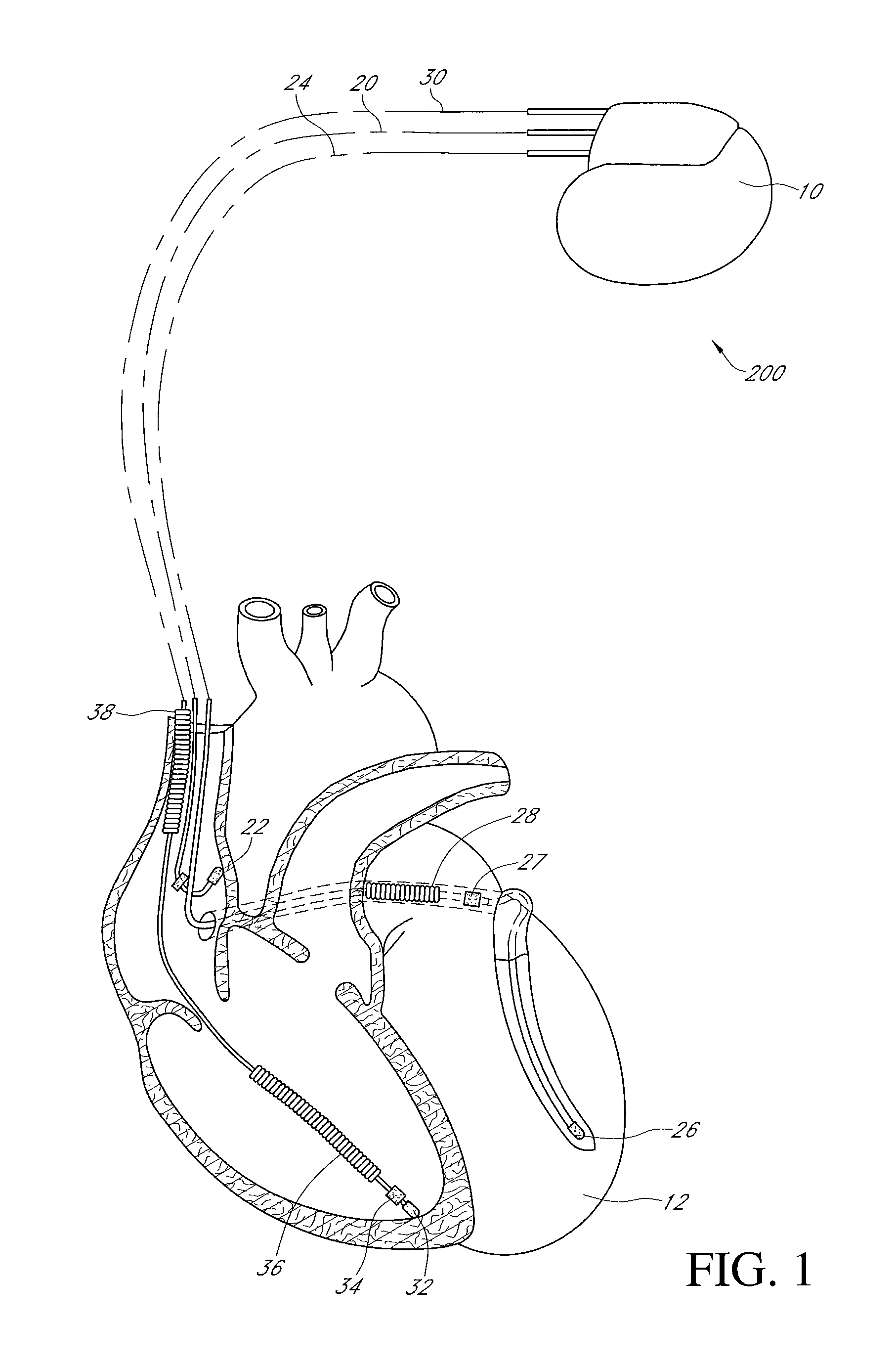

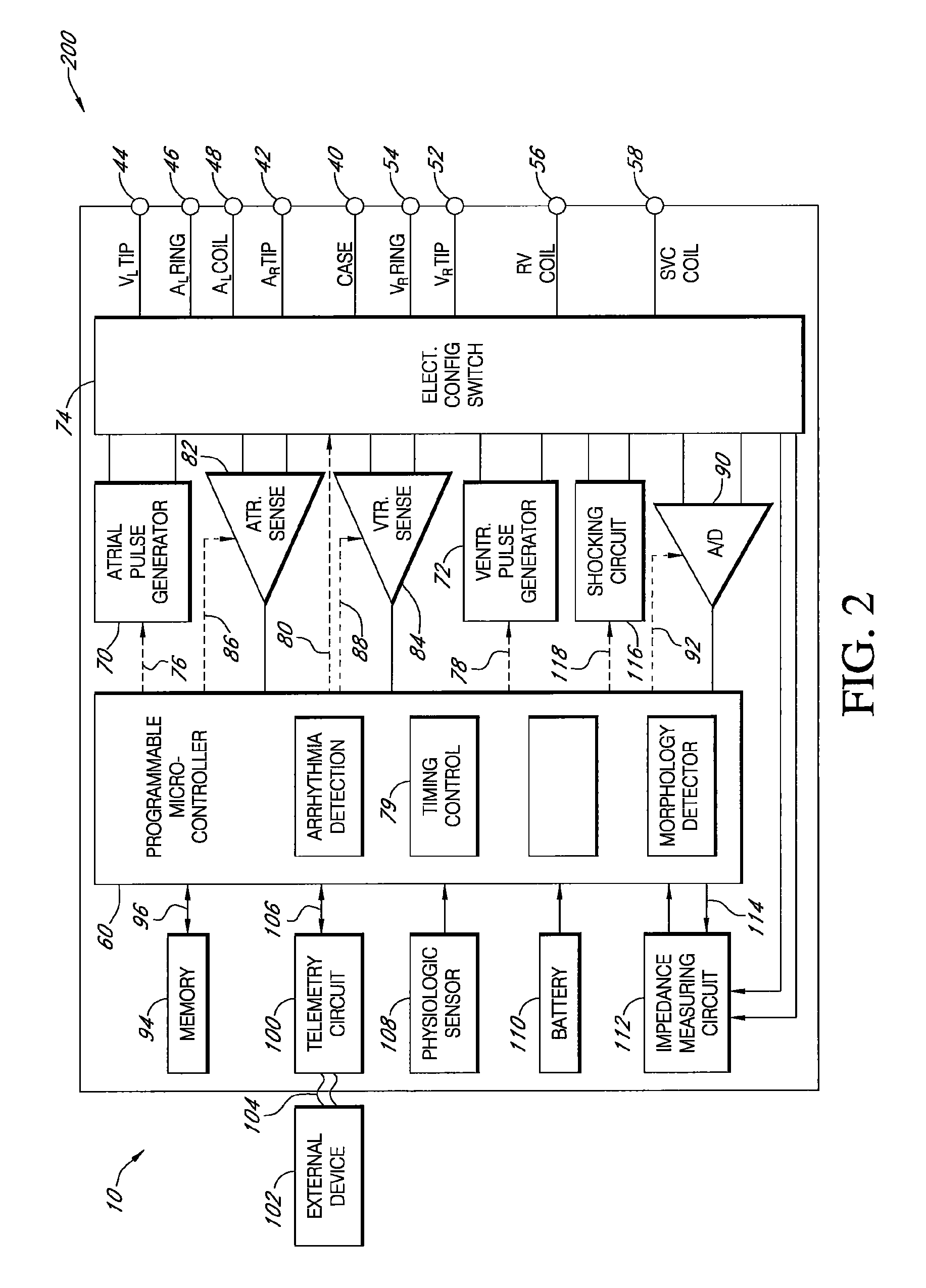

Closed loop programming for individual adjustment of electro-mechanical synchrony

InactiveUS7751889B1Prolonged initial settingImprove performanceElectrocardiographySurgeryThird partyMedicine

An implantable therapy system including implantable stimulation and control components. The implantable components operate under a set of variable parameters that can be adjusted for improved performance for an individual patient. The implantable components are adapted to self-evaluate the patients physiologic performance and autonomously adjust an existing set of parameters to improve performance throughout an implantation period without requiring intervention of a clinician, for example with a physicians programmer. The implantable components can compare a patient's exhibited activity to a desired template of that activity to determine when adjustments are indicated. The template can be based on observations of one or more third parties exhibiting normal activity. The implantable components can adjust the operating parameters to improve synchrony of multiple heart chambers and / or to increase a peak contractility.

Owner:PACESETTER INC

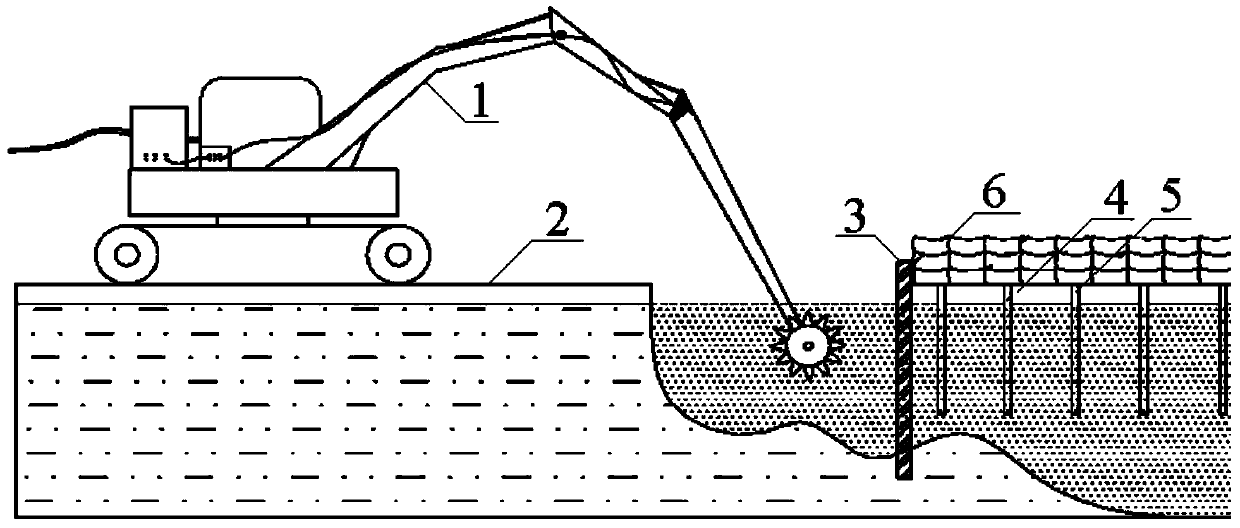

High-efficiency curing method for soft soil site with high moisture content

The invention belongs to the technical field of environment rock-soil engineering and discloses a high-efficiency curing method for a soft soil site with high moisture content. The high-efficiency curing method comprises an in situ chemical curing step and a preloading drainage step; the in situ chemical curing step comprises investigating sites, determining physical and chemical indexes such as depth, area, moisture content, organic matter content, liquid plastic limit and salt content of the soft soil site; blending a curing agent, determining the types, adding ratio, and initial and final setting time of the curing agent based on the physical and chemical indexes; blocking the site, and building partition walls for site blocking in the soft soil site; carrying out chemical curing construction, and uniformly mixing the blended curing agent with to-be-cured soft soil; carrying out preloading drainage construction according to three construction modes of vacuum preloading or surchargepreloading or vacuum surcharge preloading; unloading and repairing the site; after preloading time reaches 28 days, swabbing off drained water from the upper surface layer of curing blocks, unloadingand injecting cement slurry into a drain board for secondary repair and reinforcement by adopting a high-pressure grouting pump.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

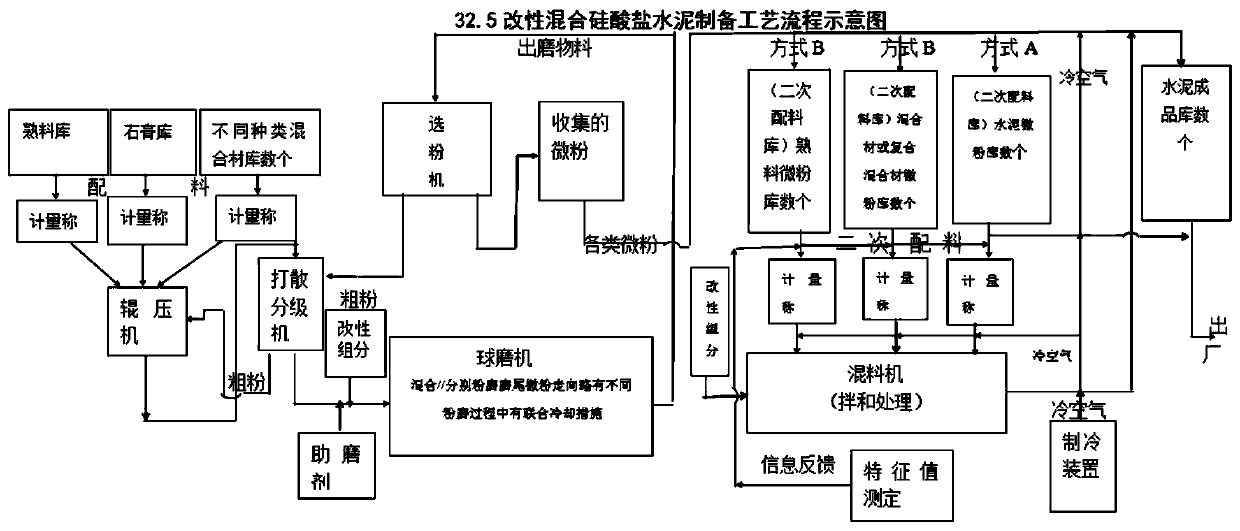

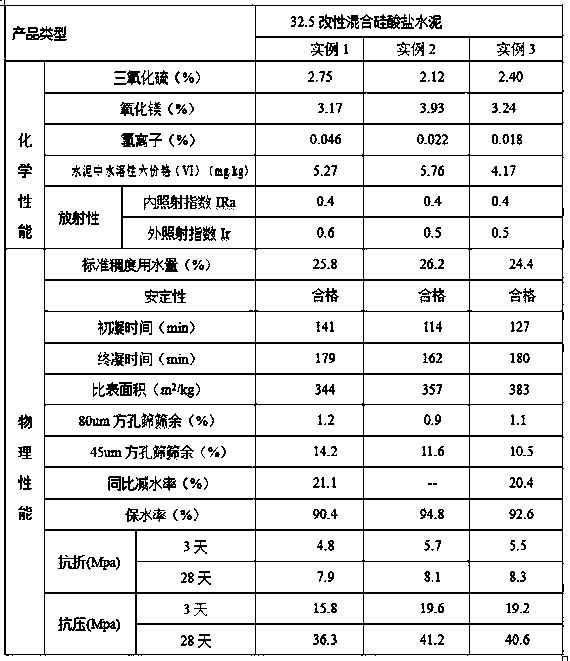

32.5 modified mixed Portland cement and preparation method thereof

The invention discloses a 32.5 modified mixed Portland cement and a preparation method thereof. The cement comprises, by mass, 45.0-68.0% of Portland cement clinker and gypsum, 5.0-25.0% of limestone,0-0.5% of a grinding aid and 0.02-5.5% of a modifying component, and also includes 5.0-45.0% of one or more of granulated blast furnace slag, granulated blast furnace slag powder, a vulcanic ash mixture and a fly ash-containing active or non-active mixture, and 8.0% or below of other incorporation-allowed waste slag. The raw materials have wide sources, and the preparation method is not complicated, relates to the fields of comprehensive utilization of cement, concrete, mortar and solid wastes, and meets the conditions of the process for preparing the cement product containing the modifyingcomponent. The cement improves the homogeneity, the workability, the durability and other performances of concrete and mortar prepared from the cement, increases the construction efficiency, and facilitates of comprehensive utilization of resources, energy saving and emission reduction.

Owner:程菲 +1

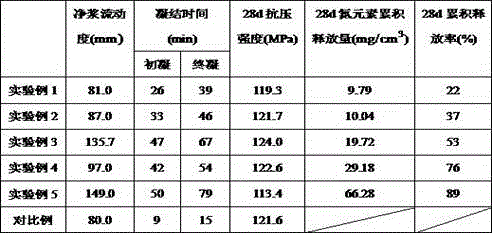

Retarder applicable to sulphate aluminum cement

The invention discloses retarder applicable to sulphate aluminum cement. The retarder is composed of, by weight, 7-60 parts of carbamide, 3-11 parts of sodium lignin sulfonate, 2-7 parts of dinaphthyl methane disulfonic acid sodium, 2-5 parts of water reducing agent and 30-70 parts of vermiculite. By means of the retarder, the coagulation speed of the sulphate aluminum cement can be effectively reduced, the flowability of sulphate aluminum cement slurry can be remarkably improved, and the water demand in the sulphate aluminum cement mixing process can be reduced. The carbamide is added into the retarder, the coagulation time of the sulphate aluminum cement can be prolonged, nitrogen nutrient elements required by the plant growth can be further released slowly after the cement slurry is hardened, and the nitrogen nutrient elements are supplied to plants in porous plant-growing concrete for meeting the plant growth requirements.

Owner:UNIV OF JINAN

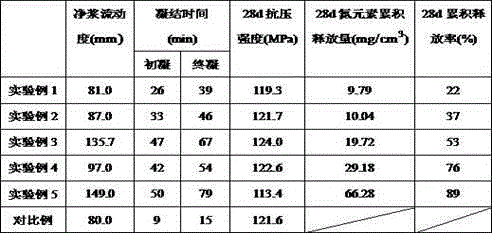

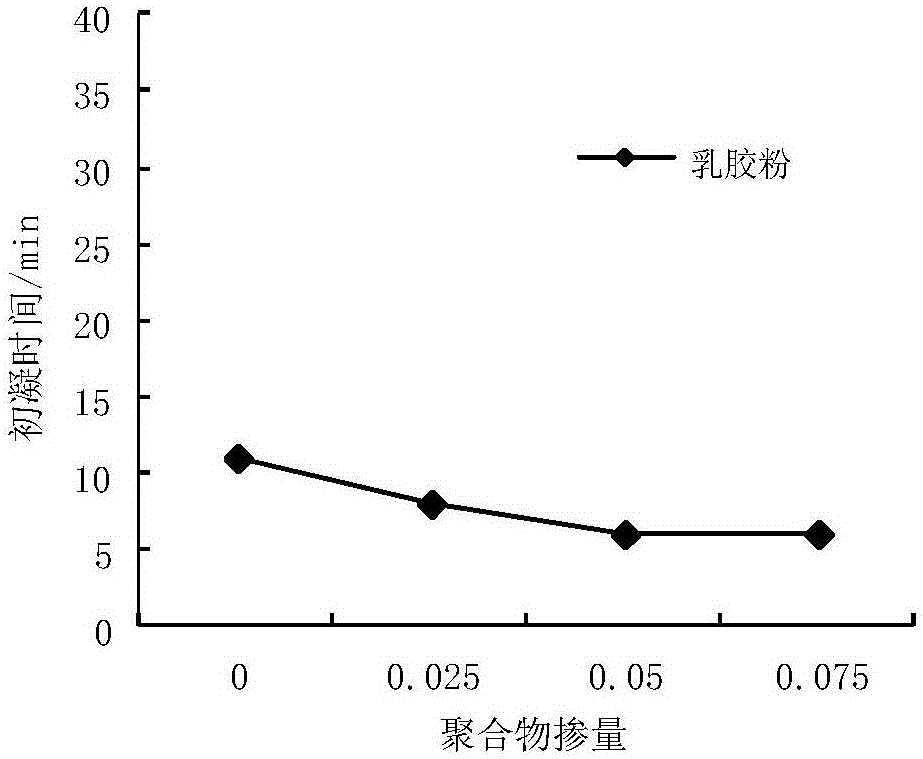

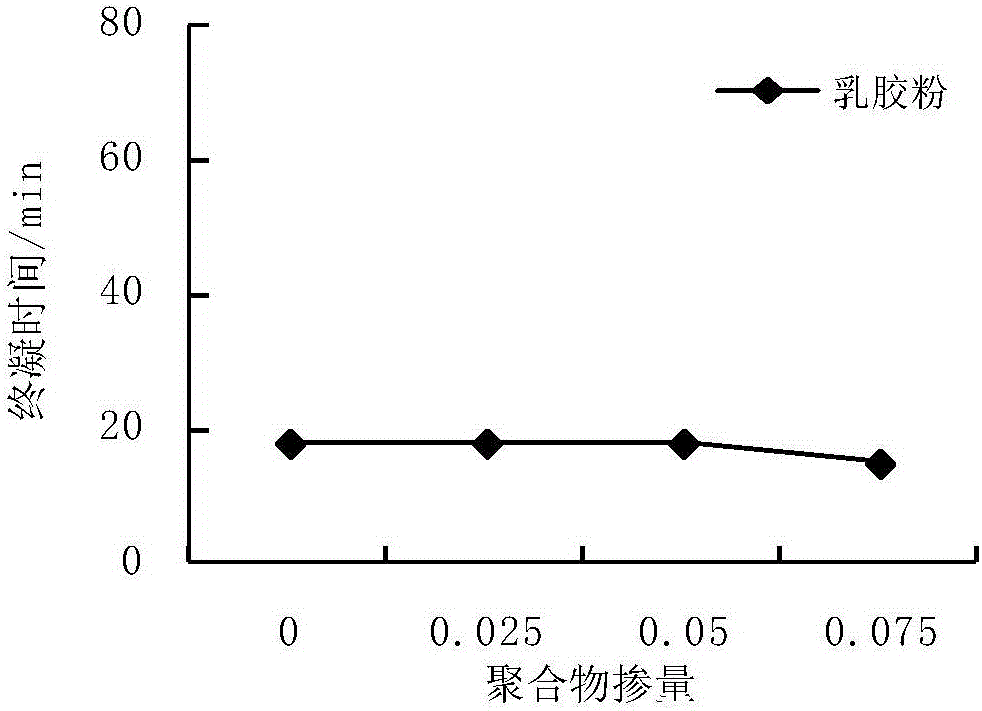

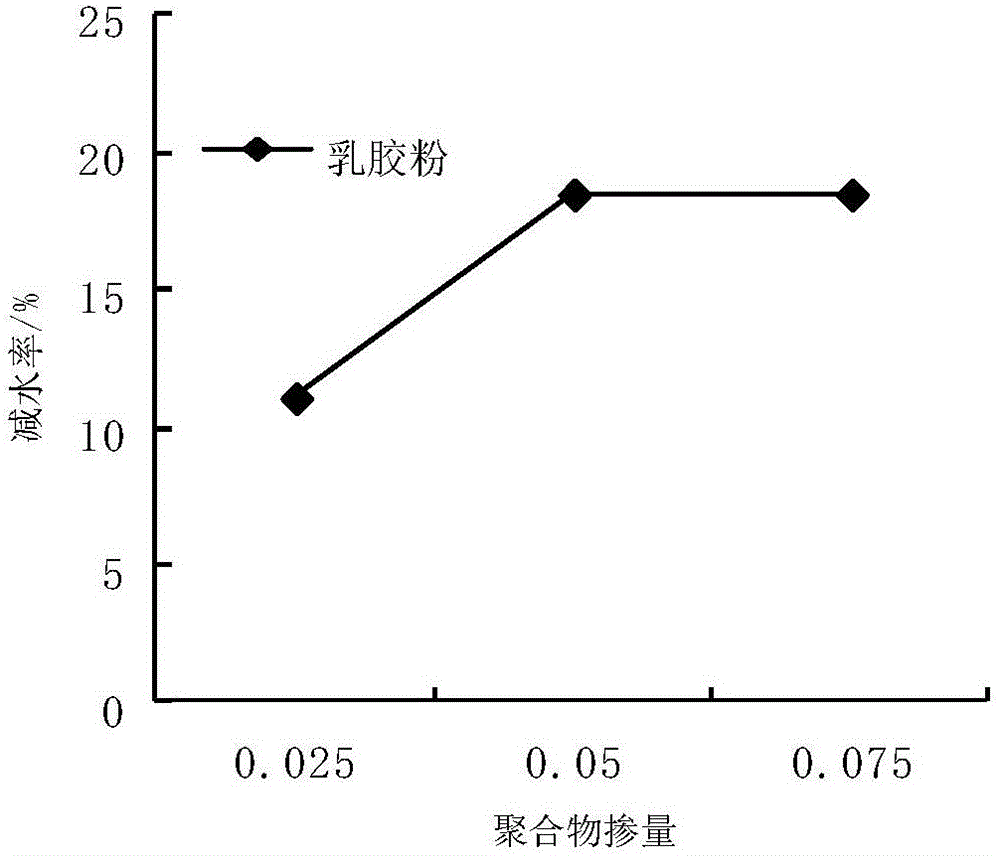

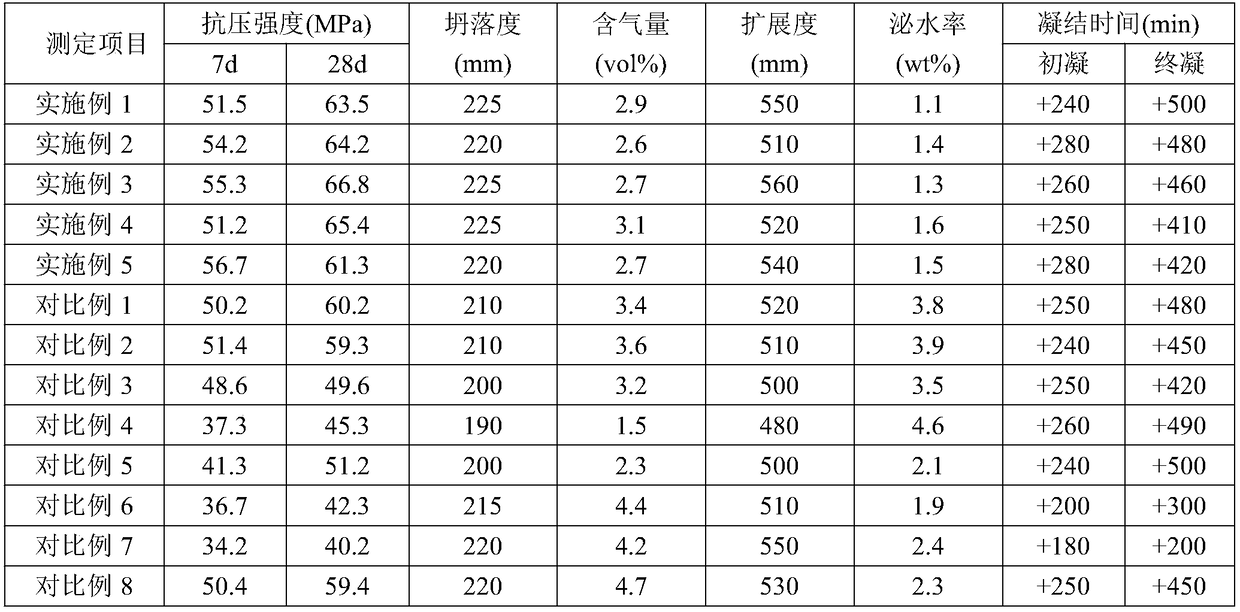

Modified cement slurry for rapidly repairing concrete

ActiveCN105130314AIncreased durabilityIncreased folding ratioSolid waste managementCement slurryChloride ion penetration

The invention discloses a modified cement slurry for rapidly repairing concrete, comprising following components in weight ratio: 30-70% of cement, 15-55% of aggregates, 12-15% of fly ash, 2.5-7.5% of latex powder, 0.25-5.5% of early strength admixture, and 0.25-1% of antifoaming agent. The modified cement slurry also comprises an expanding agent by weight of 0-2.5% of total weight and a thickening agent by weight of 0-2.5% of total weight. The modified cement slurry for rapidly repairing concrete can quicken the initial set of the cement slurry, promote water reducing rate of mortar, reduce unit weight of the newly-stirred mortar, and obviously promote flexural compression ratio, binding intensity and chloride ion penetration resistance of slurry, and the durability of concrete after rapidly repairing.

Owner:SHANGHAI LIYANG ROAD REINFORCEMENT TECH

Compound admixture for bare concrete and bare concrete

ActiveCN108275941AImprove liquidityProlong the interval between initial setting and final settingTetramethylureaEther

The invention relates to a compound admixture for bare concrete and the bare concrete, belonging to the technical field of concrete materials. The compound admixture for the bare concrete is preparedfrom a polycarboxylate copolymer, an anionic surfactant, a nonionic surfactant, an activator, a buffer solution, sodium gluconate, polyoxyethylene polyoxypropylene ether, tetramethylurea, polyethyleneglycol and water. The bare concrete is prepared by mixing the compound admixture for the bare concrete, cement, fly ash, sand, stones and water. After being mixed with the concrete, the compound admixture for the bare concrete can improve the fluidity without increasing the bleeding rate of the concrete, and prolongs the time interval between initial setting and final setting, thus enabling the concrete to have the advantages of being low in bleeding rate, high in fluidity and long in time interval between initial setting and final setting.

Owner:龙南恒沣建材有限公司

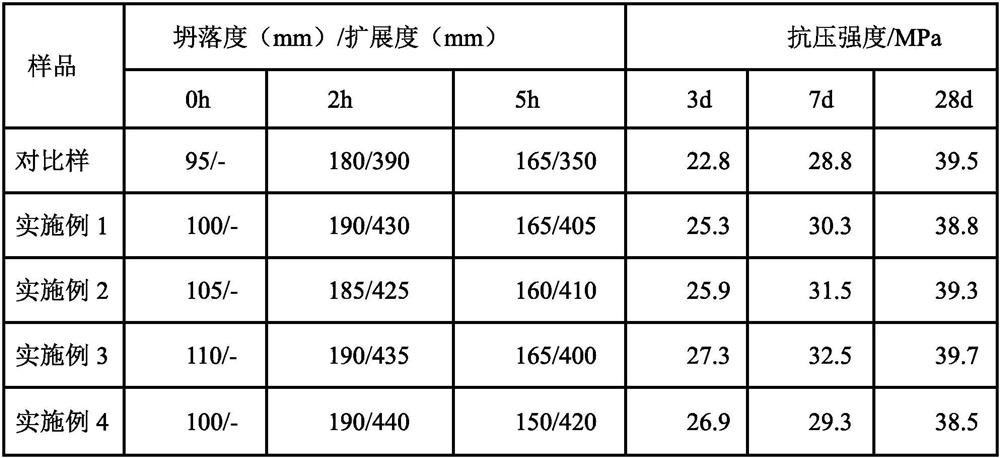

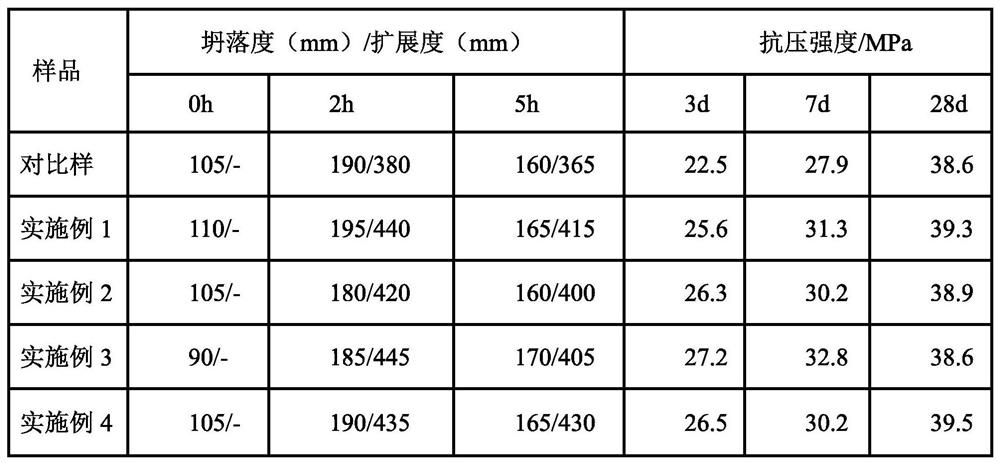

Preparation method of delayed coagulation type ester polycarboxylate water reducing agent

The invention discloses a preparation method of a delayed coagulation type ester polycarboxylate water reducing agent. The preparation method comprises the following steps: (1) preparing an esterification monomer; (2) performing a copolymerization reaction; and (3) performing a neutralization reaction. The preparation method utilizes a saccharide compound and crotonic acid to prepare the esterification monomer, and has the advantages of low costs and simple and convenient operation; the prepared saccharide esterification product participates in the next step of the copolymerization reaction, so that the main chain of the polycarboxylate water reducing agent has a polyhydroxy structure, and the prepared polycarboxylate water reducing agent has a better delayed coagulation effect, effectively prolongs the initial setting and final setting time of cement, and can reduce negative effects caused by using a retarder; and the polyhydroxy structure of the saccharide compound enables the polycarboxylatewater reducing agent to have better slump loss resistance, so that the pumping construction of concrete in summer is facilitated.

Owner:KZJ NEW MATERIALS GROUP CO LTD

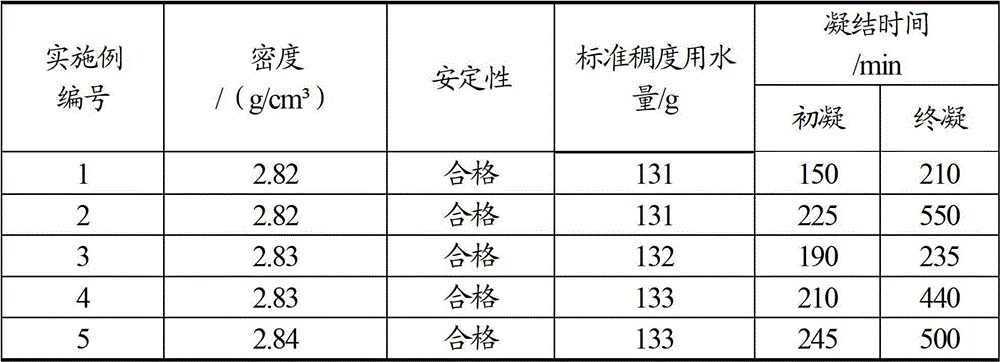

Phosphorus slag super-sulfate cement and preparation method thereof

The invention discloses super-sulfate cement and a preparation method thereof, in particular to phosphorus slag super-sulfate cement and a preparation method thereof. The phosphorus slag super-sulfate cement comprises the following components by weight portions: 30-50 portions of electric furnace phosphorus slag, 25-50 portions of slag, 10-20 portions of plaster, 1-10 portions of auxiliary materials and 1-10 portions of alkaline composition, wherein the auxiliary materials are admixtures of active CaO, active Al2O3 and active SiO2, and the alkaline composition is at least one of cement clinker and calcium hydroxide. The preparation cost of the super-sulfate cement can be effectively reduced, and the phosphorus slag super-sulfate cement fully utilizes the phosphorus slag resource with rich sources. Meanwhile, the setting and hardening speed of the phosphorus slag super-sulfate cement is high, and the initial setting and final setting time and the mechanical property conform to the requirement of GB175-2007 on P.O42.5 ordinary portland cement.

Owner:重庆中建西部建设有限公司

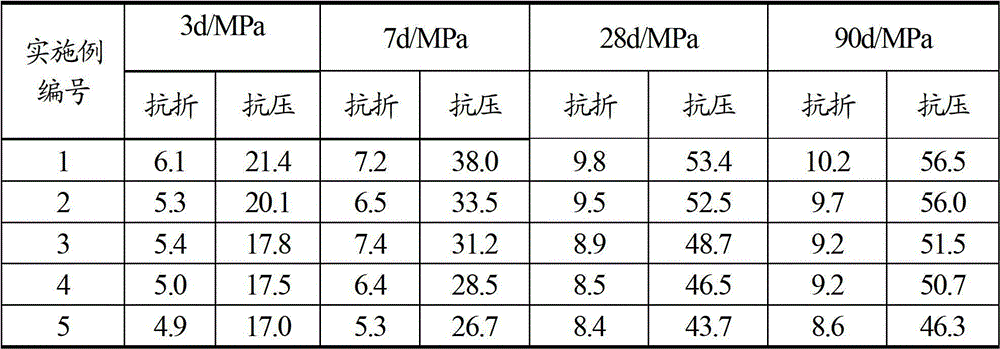

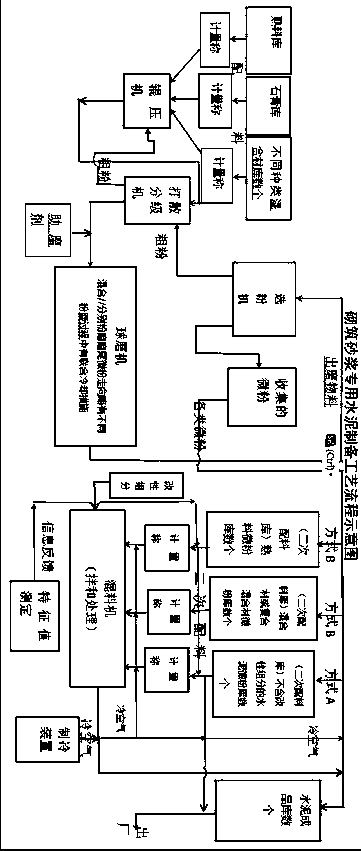

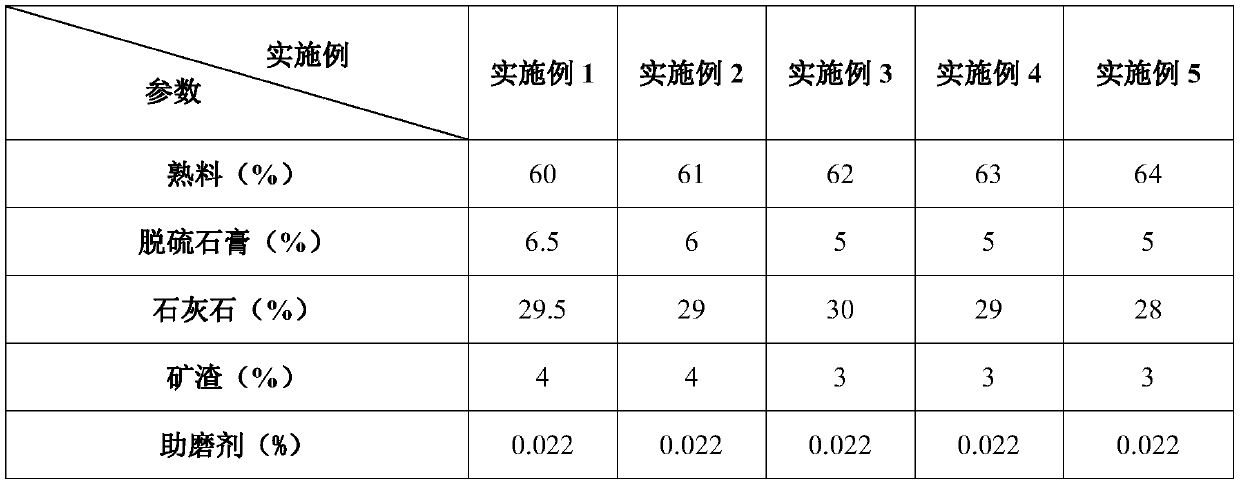

Special cement for masonry mortar and preparation method thereof

ActiveCN109851259APromoting energy saving, consumption reduction, emission reduction and waste utilizationSimple preparation processCement productionSlagCement mortar

A special cement for masonry mortar comprises the following raw materials in proportion: clinker, gypsum, limestone, grinding aid and modifying component, and also comprises one or more of active or inactive mixtures including granulated blast furnace slag, granulated blast furnace slag powder, pozzolanic mixture and fly ash and other waste slag is allowed to replace the active mixture. The invention also discloses a preparation method of a special cement for masonry mortar, and a secondary batching mixing and homogenizing system is adopted in the design. The method has a wide source of raw materials and relates to the field of cement mortar. The homogeneity of cementitious material system in mortar is improved and the properties and construction efficiency of mortar are improved without adding admixtures and additives when the special cement for masonry mortar is used to prepare masonry mortar.

Owner:王紫娴 +1

Hydration heat inhibition type concrete expanding agent and preparation method thereof

ActiveCN109231866AThe hydration temperature peak of the net slurry is reducedProlonged initial settingSlagGypsum

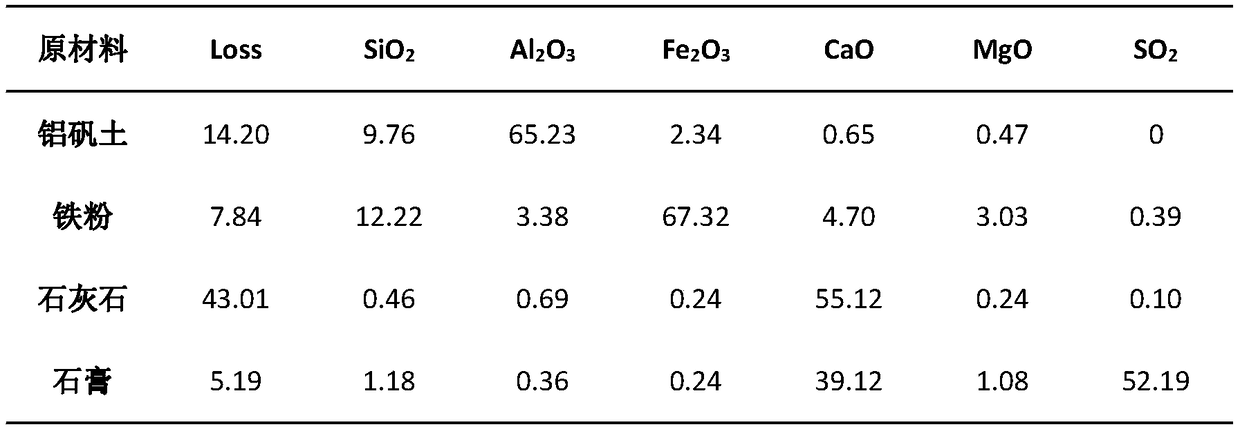

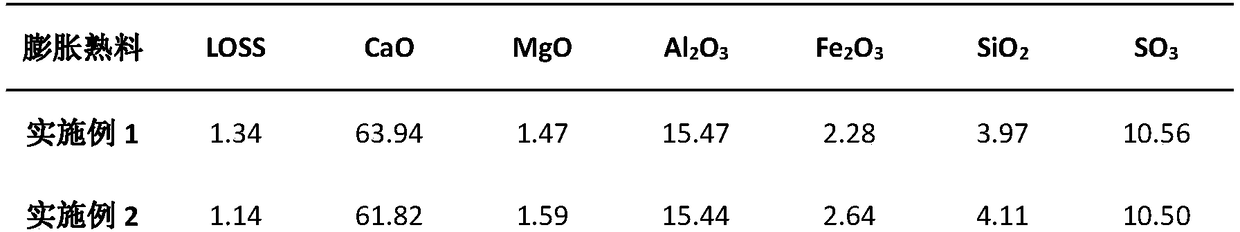

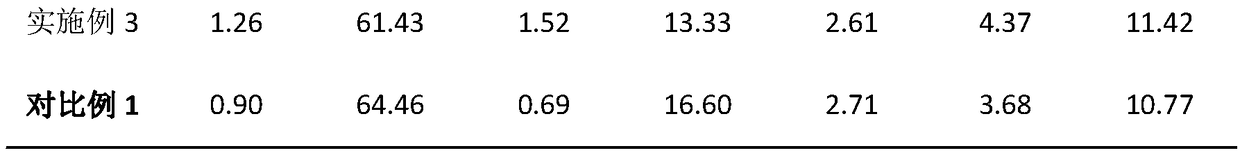

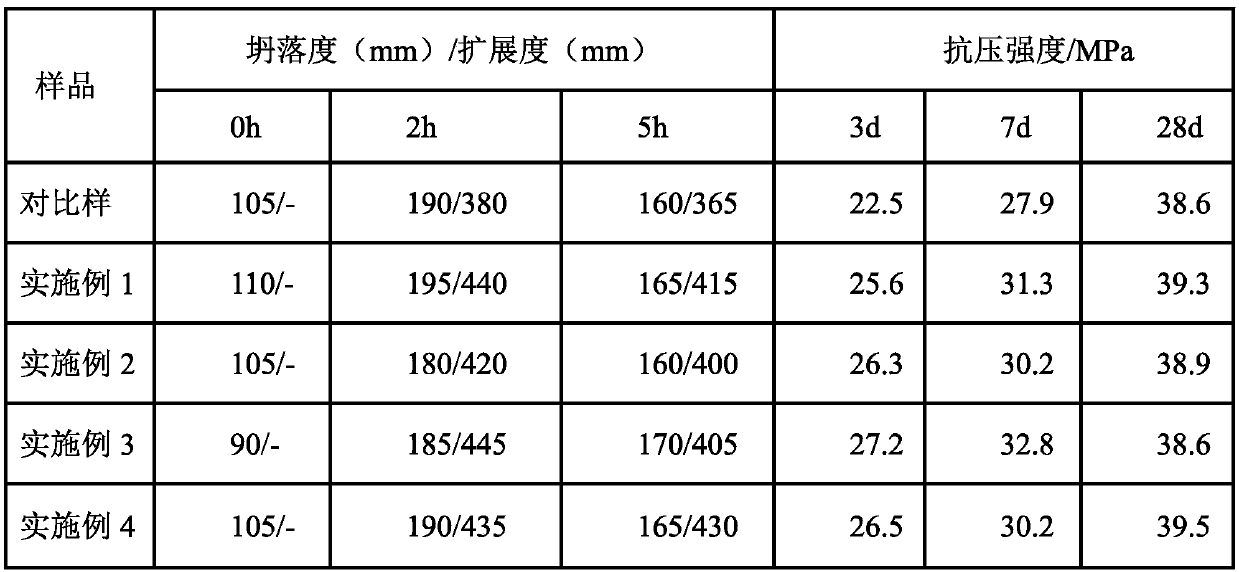

The invention discloses a hydration heat inhibition type concrete expanding agent and a preparation method thereof. The hydration heat inhibition type concrete expanding agent is prepared by compounding hydration heat inhibition type expanding clinker and gypsum, wherein the hydration heat inhibition type expanding clinker is prepared from the following raw materials in parts by weight: 50 to 70 parts of limestone, 5 to 15 parts of the gypsum, 2 to 5 parts of iron slag, 10 to 20 parts of bauxite and 0.1 to 3.0 parts of metal ions or metal oxide; the raw materials are fired at high temperatureby adopting an ion doping technology to prepare the hydration heat inhibition type concrete expanding agent. The preparation method provided by the invention is simple and feasible and the calcinationtemperature of expanding agent clinker is effectively reduced.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

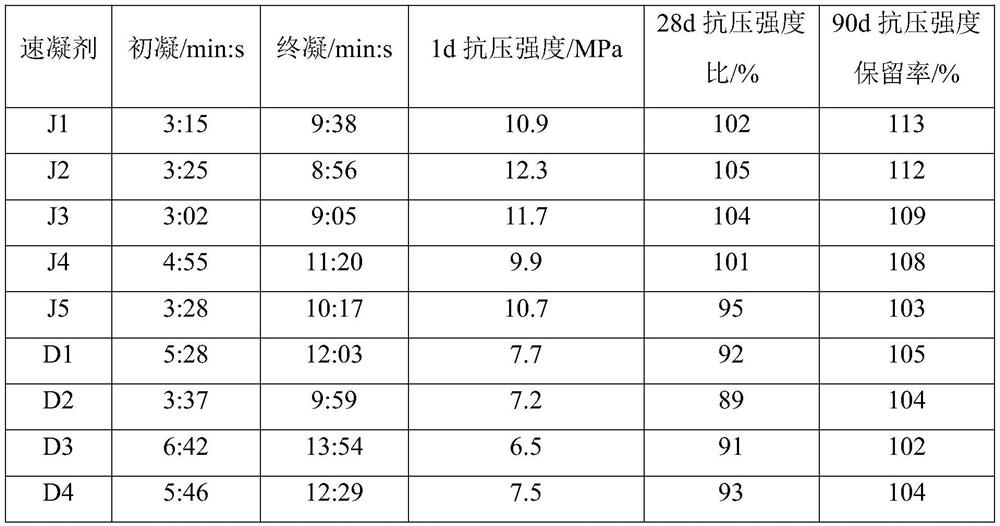

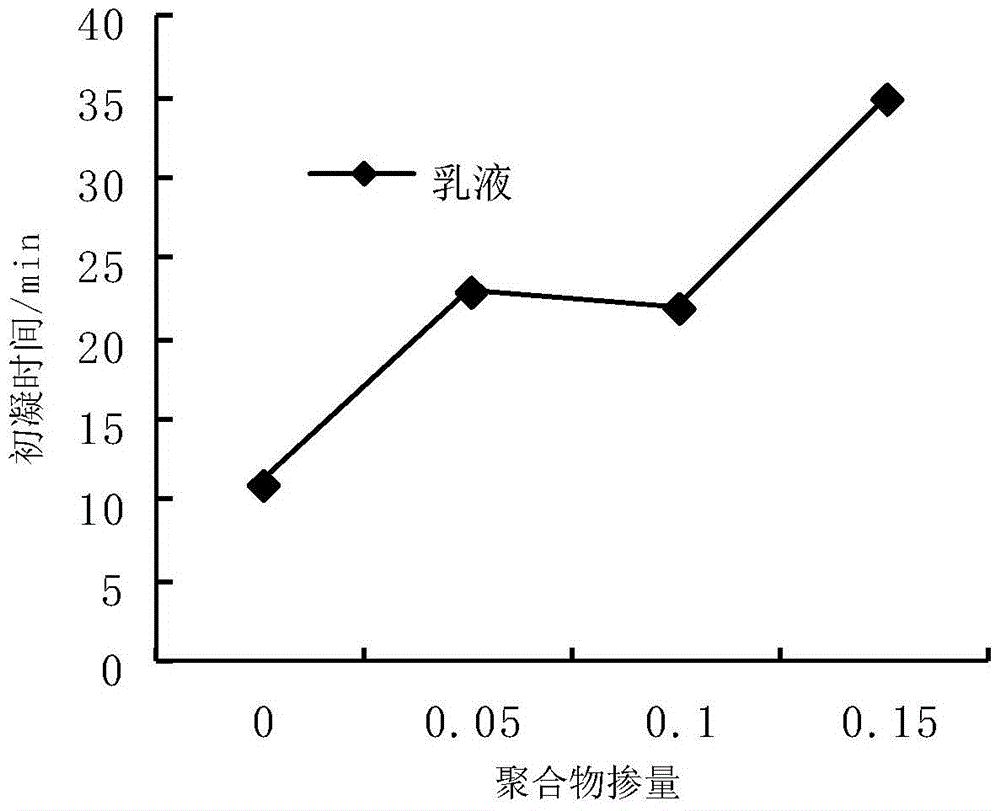

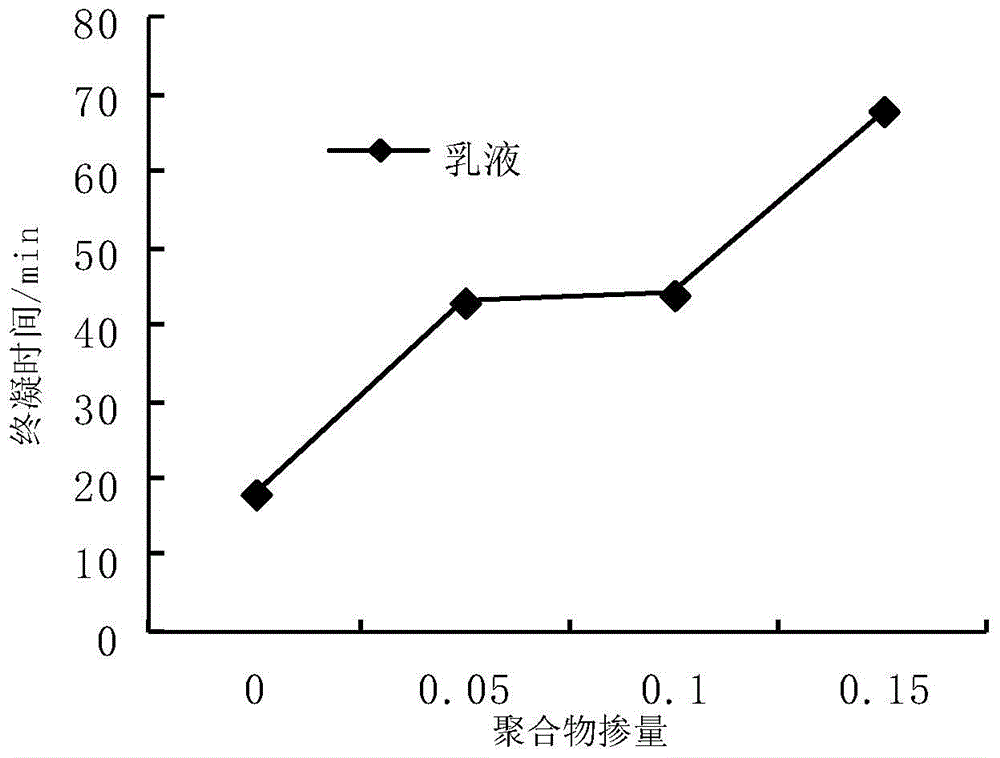

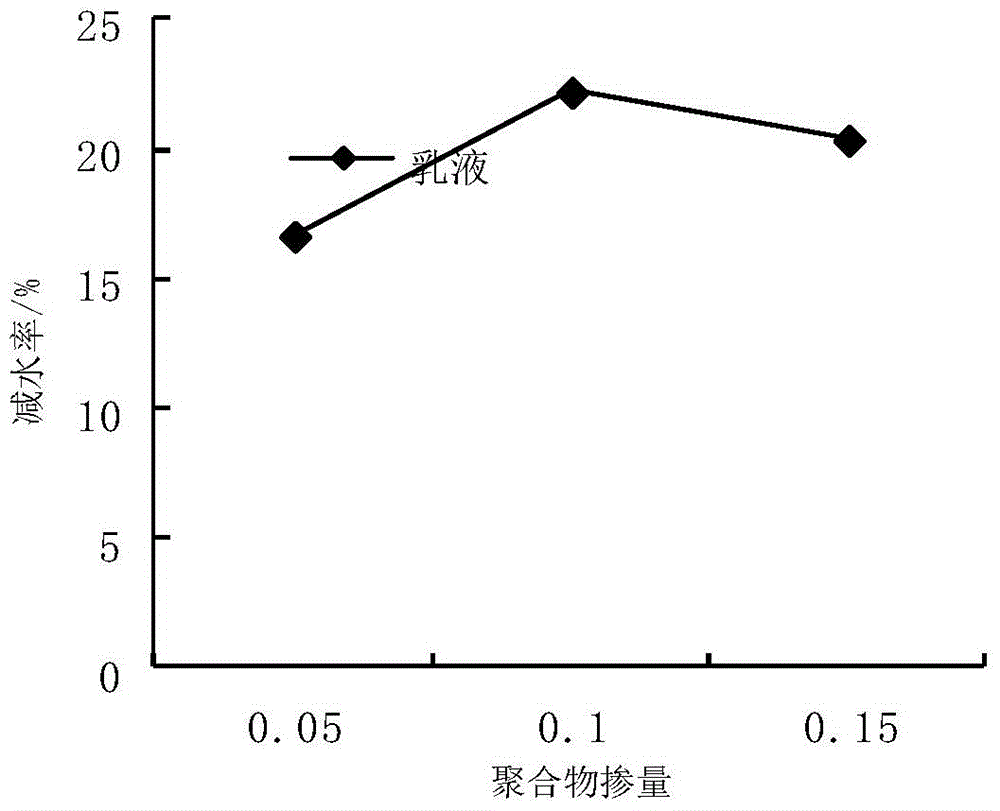

Retarder for sulphate aluminum cement and use method thereof

InactiveCN106746894AReduced hydration rateImprove the lubrication effectIsothiazolinonePolyethylene glycol

The invention discloses a retarder for sulphate aluminum cement and a use method thereof. The retarder is prepared from the following raw materials in parts by weight: 30-70 parts of polymer emulsion, 10-25 parts of metylchloro isothiazolinone, 2-10 parts of film-forming agent, 1-15 parts of water reducer and 5-15 parts of polyethylene glycol. The invention also discloses the use method for the retarder. The retarder disclosed by the invention can effectively reduce the coagulation speed of the sulphate aluminum cement; the initial setting time and the final setting time both can be prolonged for above 30min; the fluidity of the cement slurry can be obviously promoted; the fluidity of cement paste can be increased by above 15%. The retarder disclosed by the invention has no any adverse effect to the development of the cement strength, is low in cost, is high in performance stability and is easily stored and transported.

Owner:UNIV OF JINAN

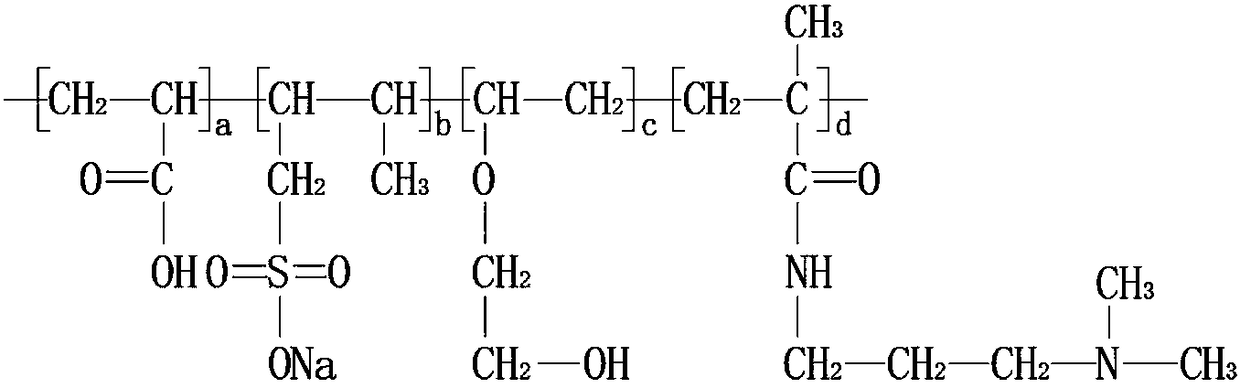

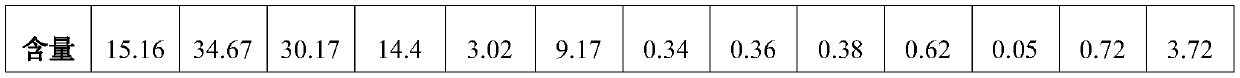

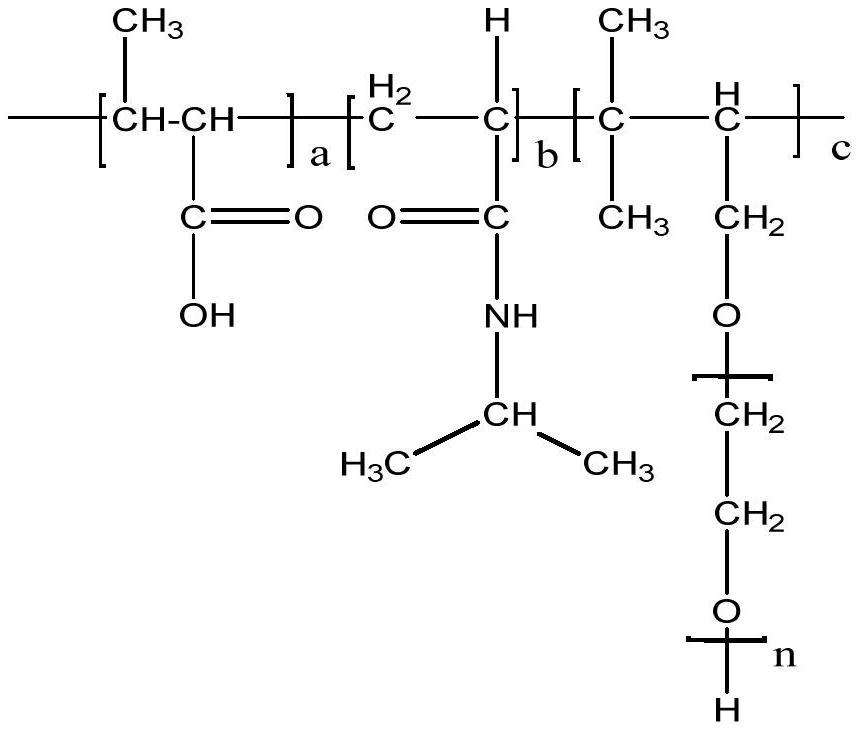

Preparation method of delayed coagulation type ether polycarboxylate water reducing agent

The invention discloses a preparation method of a delayed coagulation type ether polycarboxylate water reducing agent. The preparation method comprises the following steps: (1) preparing an esterification monomer; (2) performing a copolymerization reaction; and (3) performing a neutralization reaction. The preparation method uses a saccharide compound and crotonic acid to prepare the esterification monomer, and has the advantages of low costs and simple and convenient operation; the prepared saccharide esterification product participates in the next step of the copolymerization reaction, so that the main chain of the polycarboxylate water reducing agent has a polyhydroxy structure, the prepared polycarboxylate water reducing agent has a better delayed coagulation effect, the initial setting and final setting time of cement is effectively prolonged, and negative effects caused by using a retarder can be reduced; and the polyhydroxy structure of the saccharide compound enables the polycarboxylate water reducing agent to have better slump loss resistance, so that the pumping construction of concrete in summer is facilitated.

Owner:KZJ NEW MATERIALS GROUP CO LTD

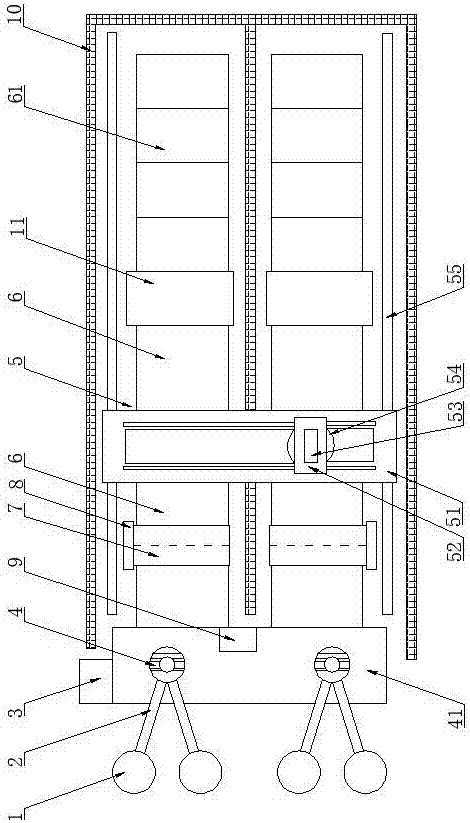

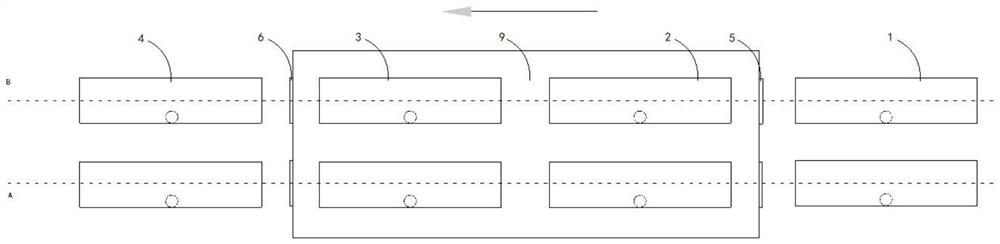

Foam concrete slab production line

PendingCN107379238AQuality improvementProlonged initial settingCeramic shaping plantsFeeding arrangmentsFoam concreteArchitectural engineering

The invention provides a foam concrete slab production line, and belongs to the technical field of concrete production equipment. The foam concrete slab production line comprises storage equipment, conveying equipment, foaming equipment, stirring equipment, slurry storing, transporting and pouring equipment, foam concrete slab shaping platforms, grid paving equipment and press flattening equipment, the storage equipment is connected with the conveying equipment through the stirring equipment, the foaming equipment is used for making foams and connected with the stirring equipment through pipelines, the slurry storing, transporting and pouring equipment is used for movably pouring foam concrete and is positioned above the foam concrete slab shaping platforms which are used for holding the foam concrete, the grid paving equipment is used for paving grids on the foam concrete, the grid paving equipment and the press flattening equipment are connected above the foam concrete slab shaping platforms, and foam concrete dies are arranged on the foam concrete slab shaping platforms. The foam concrete slab production line has the advantage that through arrangement of working processes and mutual matching of the equipment, continuous production of large-earthwork-volume foam concrete slabs is realized.

Owner:HEBEI SANSHAN BUILDING MATERIALS TECH

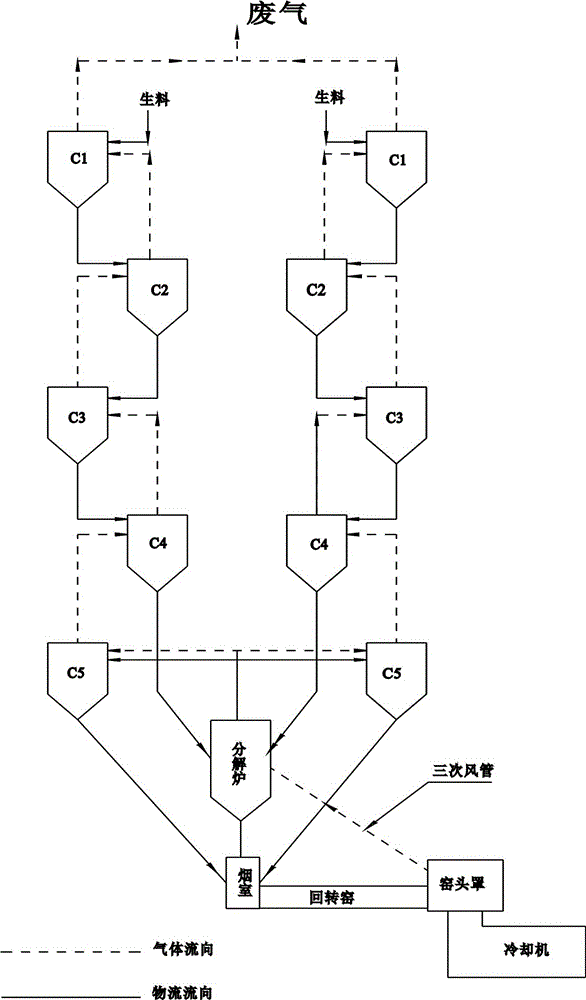

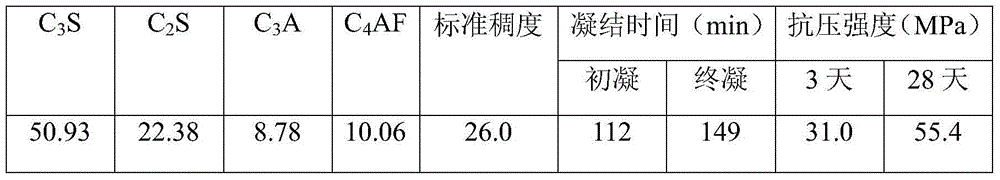

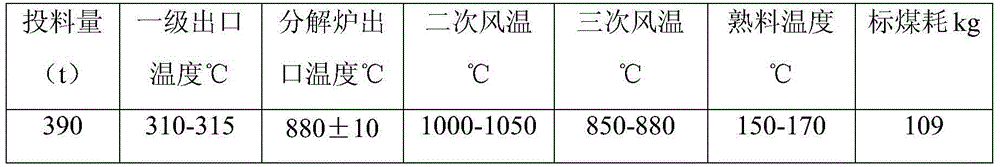

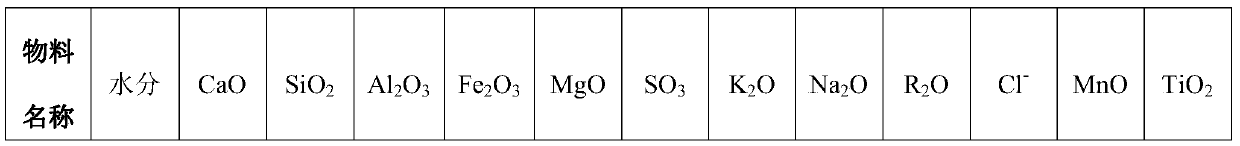

Cement clinker produced by use of copper-lead tailings and sulfuric acid residues and production method thereof

ActiveCN103601380AReduce coal consumptionIncrease productionCement productionChemical compositionCopper

The invention discloses cement clinker and a production method thereof. The method comprises the steps of preheating copper-lead tailings, sulfuric acid residues, limestone and sandstone by a step-by-step preheater, then decomposing by a decomposing furnace to obtain CaCO3, and firing into cement clinker, wherein the fired clinker comprises chemical components and mineral components, wherein the chemical components of the fired clinker include SiO2, Al2O3, Fe2O3, CaO, MgO, R2O and SO3, and the mineral components include tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminum (C3A) and tetracalcium aluminoferrite (C4AF). The method is simple, can remarkably reduce coal consumption, reduces the standard consistency of the clinker to 24.0%, increases the strength to 61-62MPa, and can be applied to large-scale industry and production.

Owner:GEZHOUBA DANGYANG CEMENT

Masonry cement for home decoration and production method thereof

InactiveCN110563355AImprove early strengthSpeed up the progress of the projectCement productionSocial benefitsBrick

The invention relates to the technical field of cement for home decoration, and specifically discloses masonry cement for home decoration. The masonry cement for home decoration is prepared from the following raw materials in percentage by mass: 60-64% of clinker, 5-6.5% of desulfurized gypsum, 28-30% of limestone and 3-4% of slag. A production method for the masonry cement comprises the followingsteps: rolling clinker, desulfurized gypsum, limestone, slag and a grinding aid by adopting a roller press so as to obtain powder A; selecting the powder A by adopting a V-shaped powder selecting machine to obtain fine powder B and coarse powder C; feeding the coarse powder C into a ball mill for ball milling so as to obtain powder D; repeating the step 2 and the step 3 for the powder D, whereinthe fine powder B obtained in the step 2 is a finished masonry cement product. The masonry cement provided by the invention has multiple use functions such as easiness in mixing, easiness in smearing,proper initial setting time, high early strength, no bleeding, no layering, no bottom grabbing, strong cohesiveness, good durability, no brick cracking and no sand returning, and produces obvious social benefits.

Owner:冀东水泥重庆合川有限责任公司

Preparation technology of high-efficiency set retarder

The invention discloses a manufacturing process of a high-efficiency retarder, which comprises the following steps: 1) weighing an organosilicon modified acrylic emulsion, a film-forming agent, a water reducing agent and polyethylene glycol in parts by weight, and mixing them uniformly; 2) placing them in water Add amantadine ethylamine, phosphorous acid, sodium glucoheptonate, stir and heat to 60-80 ℃, and add formaldehyde solution dropwise; 3) after dissolving white sugar, add citric acid, tartaric acid, borax, maltodextrin, stir and mix. 4) Mix the slurry prepared in steps 1), 2), and 3) together, stir, and mix to obtain a retarder. The retarder of the invention has good retardation effect, stable chemical properties when applied to cement slurry, easy adjustment of thickening time, can avoid premature coagulation of cement, reduce the loss rate of cement strength, and has good Regularity and operability, low cost and simple operation.

Owner:四川宏升石油技术开发有限责任公司

Special anti-sloughing liquid coagulant for foam concrete cast-in-place wall

The invention relates to the field of concrete auxiliary agents, in particular to a special anti-sloughing liquid coagulant for foam concrete cast-in-place wall. The special anti-sloughing liquid coagulant is prepared from the following components in parts by weight: 30-55 parts of polyaluminum sulfate, 5-10 parts of magnesium sulfate, 0.1-5 parts of tertiary amine, 1-5 parts of magnesium fluosilicate, 0.1-0.5 part of an amide modified polycarboxylate superplasticizer, 1-4 parts of mixed acid, 0.1-0.5 part of sodium bicarbonate, 0.1-0.5 part of hydroxypropyl methyl cellulose, 0.1-0.5 part of carboxymethyl starch ether, 1-3 parts of sodium tripolyphosphate and 400-500 parts of water. The early setting agent can shorten the initial setting time and the final setting time of the foam concrete, prevents a foam concrete wall from collapsing, avoids the bleeding phenomenon, and improves the mechanical property of the foam concrete to a certain extent.

Owner:SHANDONG JIAOTONG UNIV +1

Bare concrete and preparation method thereof

The invention discloses bare concrete. The bare concrete is characterized by being prepared from, by weight, 5-10 parts of surface modified nano-boron fiber, 5-10 parts of kaolin, 10-15 parts of illite powder, 20-30 parts of gravel, 5-10 parts of vermiculite sand, 20-30 parts of silver sand, 40-50 parts of Portland cement, 1-5 parts of a compound additive and 20-30 parts of water. The compound additive comprises, by weight, 20-25 parts of a phosphate borate copolymer, 2-5 parts of zinc citrate, 1-3 parts of pyrophyllite powder, 1-3 parts of wollastonite powder, 2-4 parts of porous magnesium silicate, 0.5-1 part of a defoaming agent, 0.8-1.5 parts of polyaminopropyl biguanide, 0.5-2 parts of hydroxypropyl cyclodextrin, 1-3 parts of an activator and 80-100 parts of water. The invention further discloses a preparation method of the bare concrete. The bare concrete is high in compressive strength, good in corrosion resistance, impermeability and crack resistance and excellent in comprehensive performance, and production and application are safe and environmentally friendly.

Owner:佛山市政通混凝土有限公司

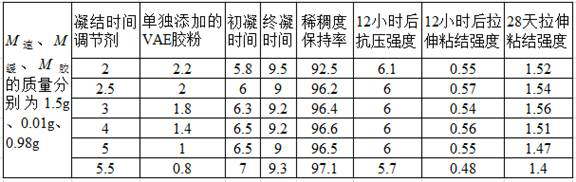

Setting time regulator, preparation method thereof and ceramic tile glue

The invention relates to the technical field of building materials, in particular to a setting time regulator, a preparation method thereof and a ceramic tile glue. The setting time regulator is a core-shell type material and comprises an inner core and a shell layer coating the inner core, wherein the shell layer is made of a composite material of a water-soluble organic gel material and a retarder; and the inner core is made of a setting accelerator, wherein the melting point of the setting accelerator is Taccelerator, the melting point of the retarder is Tslow, and the melting point of thewater-soluble organic gel material is Tgel, the Taccelerator being greater than the Tslow, and the Taccelerator being greater than the Tgel. The setting time regulator solves the problem that the material property is not matched with the robot construction process in the construction process of paving ceramic tiles by the building robot at present, and is suitable for the robot construction rhythm.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Retarding clinker and preparation method thereof

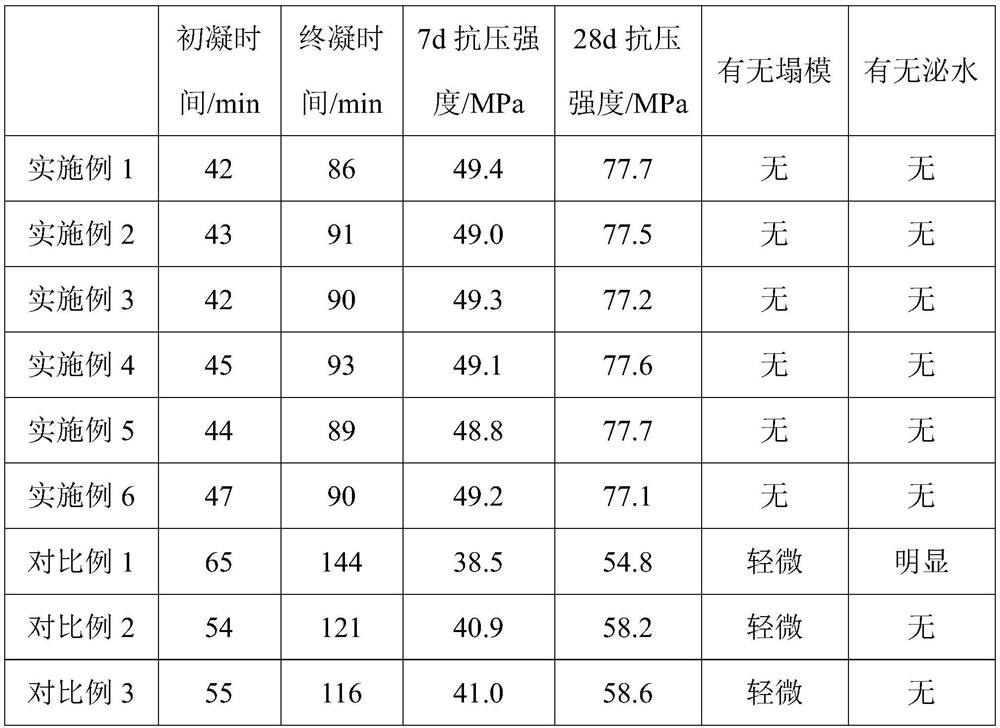

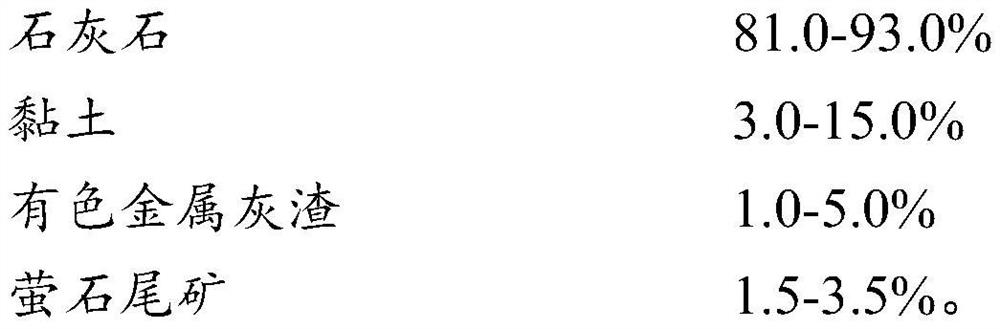

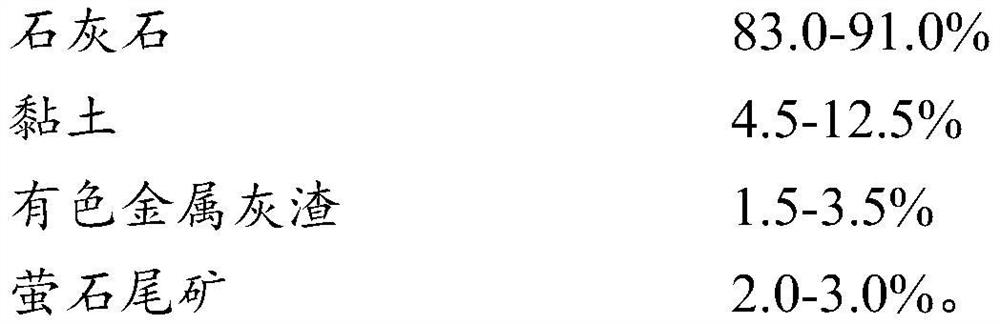

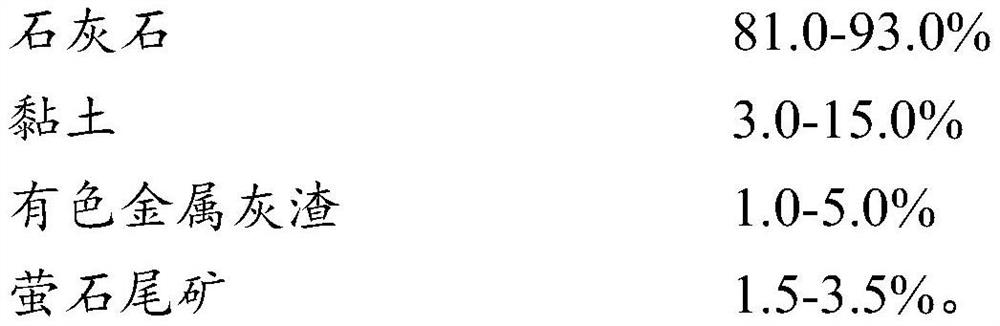

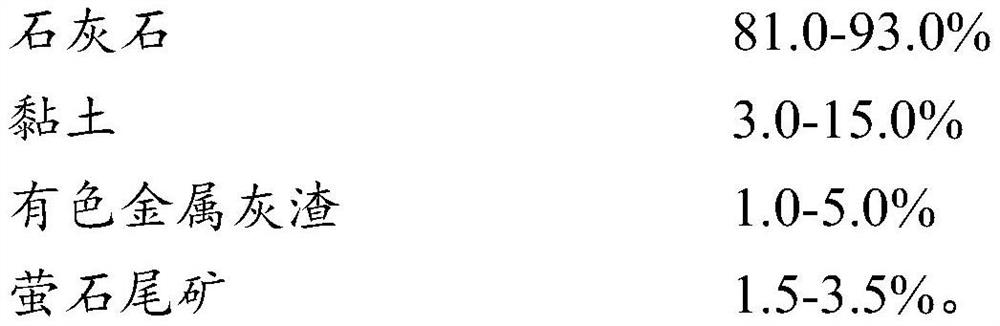

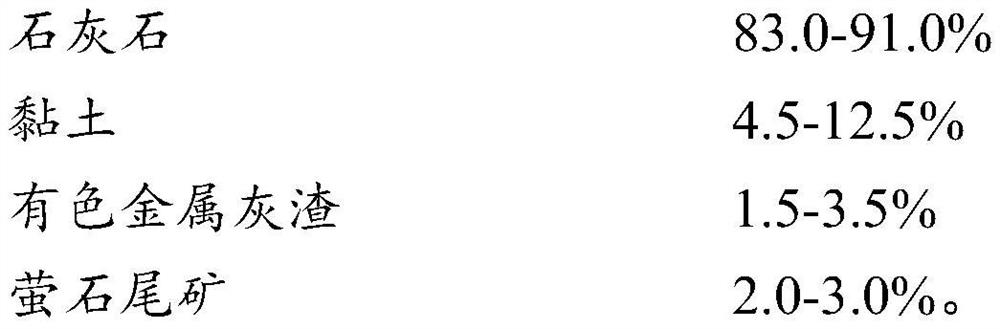

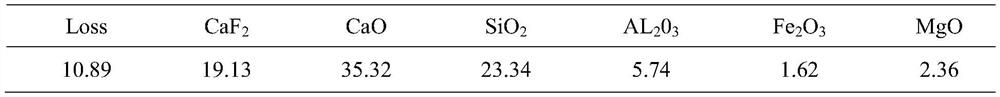

ActiveCN112341014AProlonged initial settingExtension of timeSolid fuelsCement productionClinker (waste)Nonferrous metal

The invention belongs to the field of cement, and particularly relates to a retarding clinker and a preparation method thereof. The retarding clinker comprises the following raw materials in percentage by mass: 81.0-93.0% of limestone, 3.0-15% of clay, 1.0-5.0% of non-ferrous metal ash residues, and 1.5-3.5% of fluorite tailings, wherein the content of calcium fluoride in the fluorite tailings is15-30%. By adding a certain amount of fluorite tailings, the initial setting time and the final setting time of the clinker are prolonged, and the production of the delayed coagulation clinker is realized, so the requirements of special engineering on the performance of retarding cement can be met; in addition, the mechanical property of the clinker is still maintained, so concrete quality can beensured while the requirements on cement retarding characteristics are met; and meanwhile, the fluorite tailings are effectively utilized, the utilization way of the fluorite tailings is broadened, stacking and external emission of waste production enterprises are reduced, and the demands of environmental protection are met.

Owner:兰溪南方水泥有限公司 +1

Cement slurry for concrete repair

The invention relates to cement slurry for concrete repair. The cement slurry for concrete repair comprises the following components in parts by mass: 30-60 parts of cement, 20-50 parts of a carboxyl material, 12-16 parts of coal ash, 5-10 parts of a butylbenzene emulsion, 0.5-5.5 parts of an early strength agent and 0.2-0.8 parts of a defoamer. The cement slurry for concrete repair provided by the invention has the advantages that according to the cement slurry for concrete repair provided by the invention, the carboxyl material is added into the formula, so that initial set of cement slurry can be accelerated, the water reducing rate of mortar can be improved, and the volume-weight of newly mixed mortar is reduced; the ratio of bending strength to compressive strength and the adhesive strength of the mortar are obviously improved, so that the quickly repaired concrete is better in durability.

Owner:如皋市磨头建设开发有限公司

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator. A preparation method for the alkali-free liquid accelerator comprises the following steps: dissolving 1-5 parts of iminodisuccinic acid or salt thereof in 100 parts of water, adding 15-30 parts of aluminum sulfate and 5-15 parts of pseudo-boehmite, conducting stirring for at least 30 minutes, adding 0.5-1 part of triisopropanolamine and 1-3 parts of a dispersion stabilizer after stirring, performing continuous stirring, dropwise adding 1-2 parts of latex, and after dropwise addition, adjusting the pH value of the whole system to 6-8. The alkali-free liquid accelerator is simple in preparation method, high in initial setting speed and final setting speed and high in later strength.

Owner:蓝盾(云南)工程技术有限公司

Modified cement slurry for concrete repair and preparation method thereof

The invention discloses a modified cement mortar for concrete repair and a preparation method thereof. The preparation method comprises the following steps: a) weighing and mixing predetermined amounts of cement, aggregate and fly ash; b) adding predetermined amounts of a butylbenzene emulsion, an antifoaming agent and an early strength agent into tap water and mixing the obtained solution with the mixture prepared in the step a); and c) controlling the fluidity of mortar to be in a range of 140 + / - 5 mm, separately measuring flow-table fluidity and unit weight of the newly-mixed mortar and carrying out casting molding for repairing when the determined flow-table fluidity and unit weight of the newly-mixed mortar are substantially identical to to-be-repaired concrete. According to the modified cement mortar for concrete repair and the preparation method thereof, initial set of the cement mortar can be accelerated, the water-reducing rate of the mortar can be increased, the unit weight of the newly-mixed mortar can be decreased, the ratio of bending-compressive strength of the mortar can be obviously enhanced, and rapidly repaired concrete has better durability.

Owner:SHANGHAI LIYANG ROAD REINFORCEMENT TECH

A kind of preparation method of retarding type ester polycarboxylate water reducer

The invention discloses a preparation method of a retarding type ester polycarboxylate water reducer, which comprises the following steps: (1) preparation of esterified monomers; (2) copolymerization reaction; (3) neutralization reaction. The preparation method of the present invention utilizes sugar compounds and crotonic acid to carry out esterification to prepare esterification monomers, which has the advantages of low cost and easy operation, and the prepared sugar esterification products participate in the next step of copolymerization reaction, making polycarboxylic acid The main chain of the superplasticizer has a polyhydroxyl structure, so that the prepared polycarboxylate superplasticizer has a good retarding effect, effectively prolonging the initial setting and final setting time of cement, and reducing the use of retarders. negative impact. Moreover, the polyhydroxy structure of sugar compounds makes the polycarboxylate superplasticizer have better slump retention performance, which is beneficial to the summer pumping construction of concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD

A kind of fair-faced concrete and preparation method thereof

The invention discloses a fair-faced concrete, which is characterized in that it is made of the following raw materials in parts by weight: 5-10 parts of surface-modified nano-boron fibers, 5-10 parts of kaolin, 10-15 parts of illite powder, and 20 parts of gravel ‑30 parts, 5‑10 parts of vermiculite sand, 20‑30 parts of fine sand, 40‑50 parts of Portland cement, 1‑5 parts of composite additives, 20‑30 parts of water. The composite additive includes the following components by weight: 20-25 parts of phosphate-based boric acid-based copolymer, 2-5 parts of zinc citrate, 1-3 parts of pyrophyllite powder, 1-3 parts of wollastonite powder, porous silicon Magnesium acid 2-4 parts, defoamer 0.5-1 part, polyaminopropyl biguanide 0.8-1.5 parts, hydroxypropyl cyclodextrin 0.5-2 parts, activator 1-3 parts, water 80-100 parts. The invention also discloses a preparation method of the fair-faced concrete. The fair-faced concrete disclosed by the invention has high compressive strength, good corrosion resistance, impermeability and crack resistance, excellent comprehensive performance, and safe and environment-friendly production and use.

Owner:佛山市政通混凝土有限公司

A kind of preparation method of retarding type ether polycarboxylate water reducer

The invention discloses a preparation method of a retarded ether type polycarboxylate water reducer, which comprises the following steps: (1) preparation of esterification monomer; (2) copolymerization reaction; (3) neutralization reaction. The preparation method of the present invention utilizes the esterification of saccharide compounds and crotonic acid to prepare esterified monomers, which has the advantages of low cost and simple operation, and the obtained saccharide esterification products participate in the next step of copolymerization reaction, so that polycarboxylic acid is The main chain of the superplasticizer has a polyhydroxy structure, so that the prepared polycarboxylate superplasticizer has a good retarding effect, effectively prolonging the initial setting and final setting time of cement, and reducing the use of retarders. negative impact. Moreover, the polyhydroxy structure of sugar compounds makes the polycarboxylate water reducer have better slump retention performance, which is beneficial to the summer pumping construction of concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD

A retarder suitable for sulphoaluminate cement

ActiveCN105000819BSlow down the rate of condensationProlonged initial settingFertilizer mixturesSulfonateGrowth plant

The invention discloses retarder applicable to sulphate aluminum cement. The retarder is composed of, by weight, 7-60 parts of carbamide, 3-11 parts of sodium lignin sulfonate, 2-7 parts of dinaphthyl methane disulfonic acid sodium, 2-5 parts of water reducing agent and 30-70 parts of vermiculite. By means of the retarder, the coagulation speed of the sulphate aluminum cement can be effectively reduced, the flowability of sulphate aluminum cement slurry can be remarkably improved, and the water demand in the sulphate aluminum cement mixing process can be reduced. The carbamide is added into the retarder, the coagulation time of the sulphate aluminum cement can be prolonged, nitrogen nutrient elements required by the plant growth can be further released slowly after the cement slurry is hardened, and the nitrogen nutrient elements are supplied to plants in porous plant-growing concrete for meeting the plant growth requirements.

Owner:UNIV OF JINAN

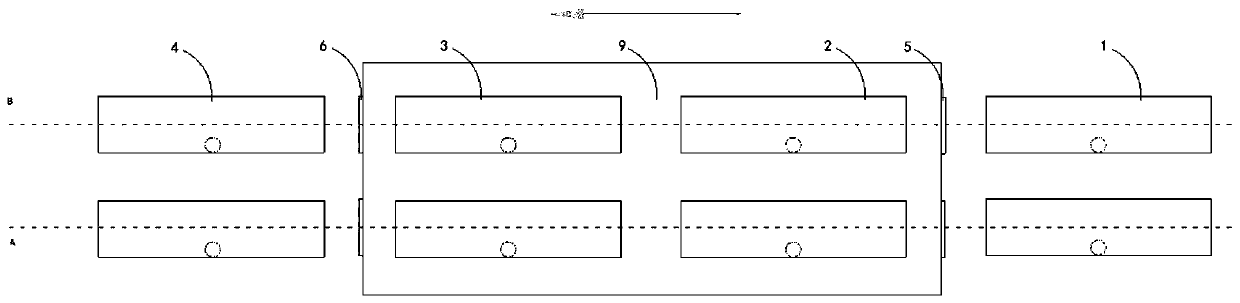

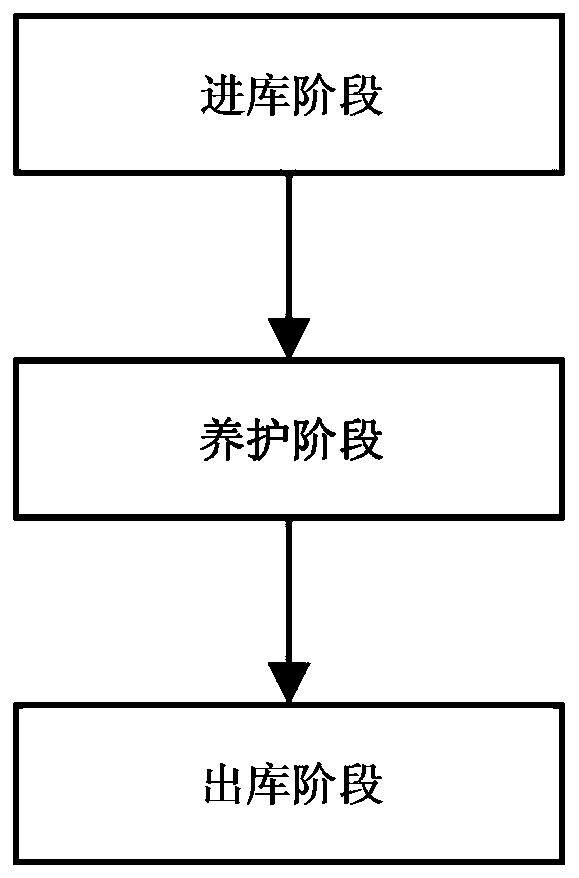

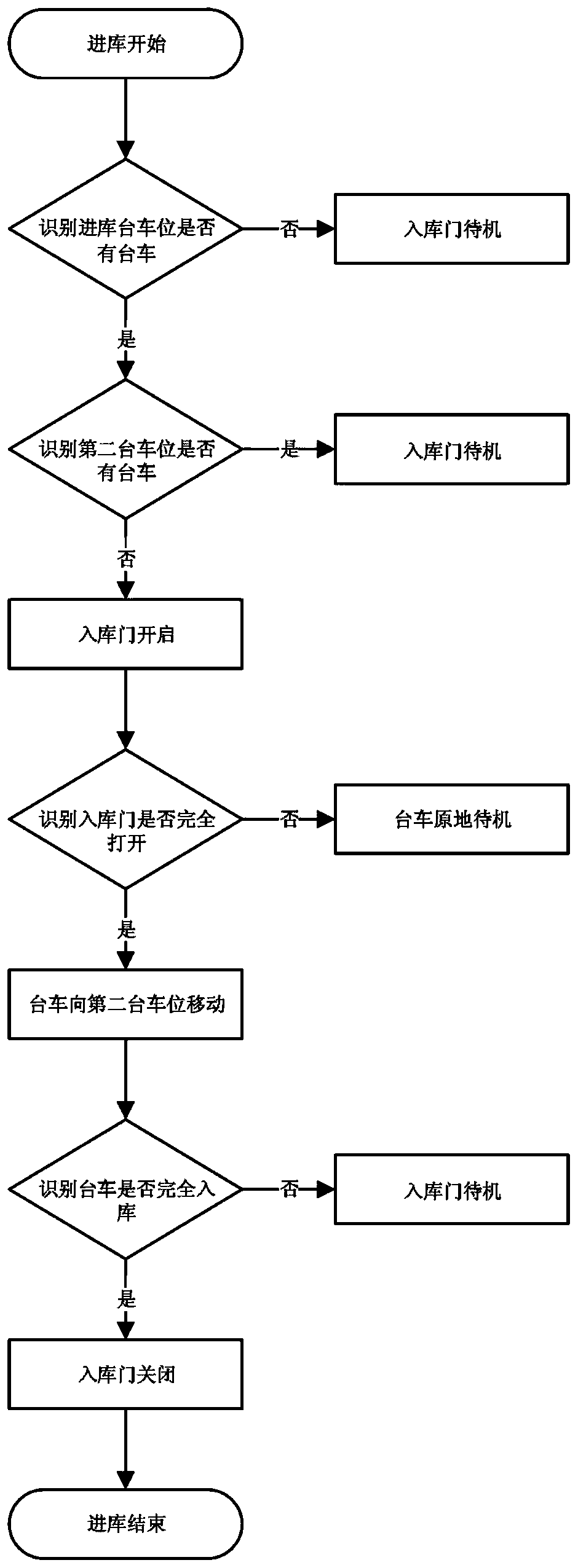

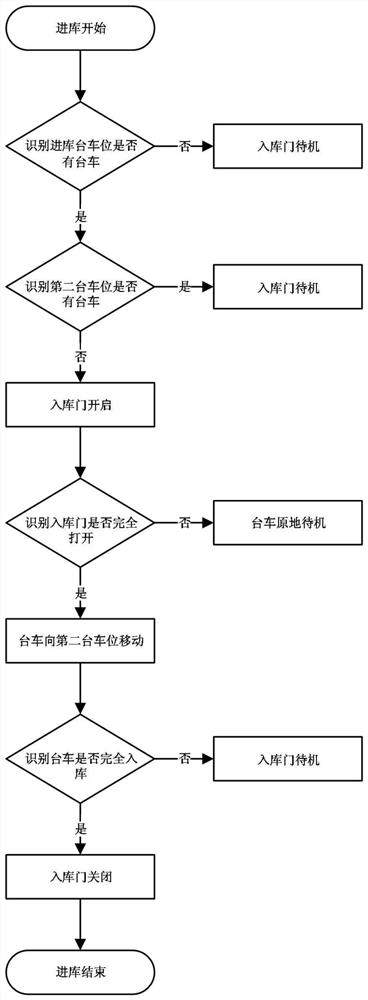

Automatic heating and opening-closing method for pre-curing kiln

ActiveCN110653930AProlonged initial settingIncrease profitCeramic shaping apparatusThermodynamicsProcess engineering

The invention discloses an automatic heating and opening-closing method for a pre-curing kiln, and relates to the technical field of precuring kilns. The automatic heating and opening-closing method comprises a feeding stage for a concrete-loaded trolley into a pre-curing kiln, a maintaining stage for the concrete-loaded trolley maintaining in the pre-curing kiln and a warehouse-out stage for loading the concrete-loaded trolley out of the pre-curing kiln. According to the automatic heating and opening-closing method, the problem that the initial setting time of the concrete in winter is lengthen can be solved.

Owner:中煤远大淮北建筑产业化有限公司 +1

A kind of retarded clinker and preparation method thereof

ActiveCN112341014BProlonged initial settingExtension of timeSolid fuelsCement productionClinker (waste)Nonferrous metal

The invention belongs to the field of cement, and particularly relates to a retarded clinker and a preparation method thereof. The raw material of the slow-setting clinker of the present invention is composed of the following components in mass fractions: limestone, 81.0-93.0%; clay, 3.0-15.0%; non-ferrous metal ash, 1.0-5.0%; fluorite tailings, 1.5‑3.5%. Wherein, the content of calcium fluoride in the fluorite tailings is 15-30%. By adding a certain amount of fluorite tailings, the invention prolongs the initial setting and final setting time of the clinker, and realizes the production of the retarded clinker, thereby meeting the performance requirements of the retarded cement for special projects; The performance is still maintained, so it can ensure the quality of concrete while meeting the requirements for the retarding characteristics of cement; at the same time, the effective use of fluorite tailings broadens the utilization of fluorite tailings, and reduces the stacking and external discharge of waste-producing enterprises. Meet the needs of green environmental protection.

Owner:兰溪南方水泥有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com