Masonry cement for home decoration and production method thereof

A technology for masonry cement and home decoration, applied to the field of home improvement cement, can solve the problem that slag cement cannot meet the needs of home decoration, and achieve the effects of reducing heat, improving project progress, and reducing radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

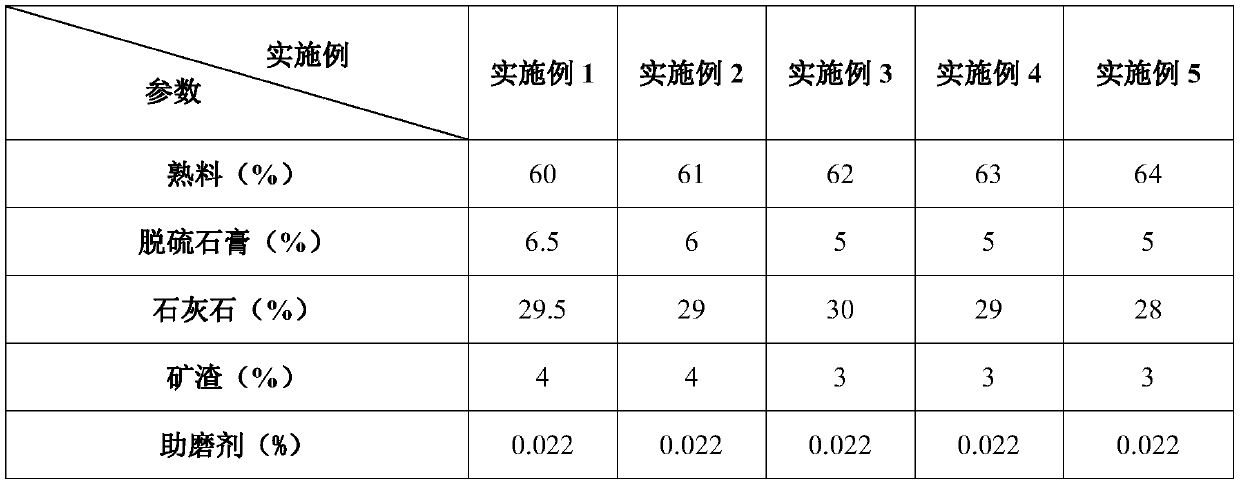

preparation example Construction

[0033] The clinker preparation process is as follows: Limestone is crushed by the mine and homogenized together with siliceous materials, aluminum materials, and iron materials in proportion to the raw meal mill and ground into raw meal powder, and the homogenized raw meal powder is passed through successively Preheater, calciner, rotary kiln and coal injection calcined clinker.

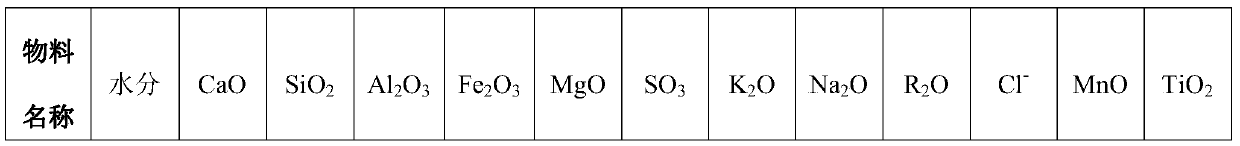

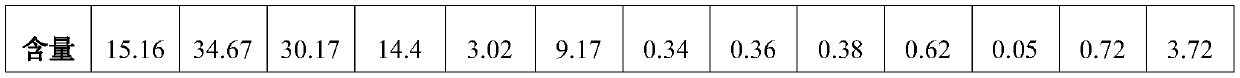

[0034] The main components of the slag in this application are shown in Table 2 below.

[0035] Table 2 is the main component and content (mass percentage %) of slag

[0036]

[0037]

[0038] The main components of the grinding aid are alcohol amine compounds. The grinding aid used in this application is the model: JY-GA-3FK provided by Tangshan Jidong Cement Admixture Co., Ltd. Chongqing Branch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com