Alkali-free liquid accelerator and preparation method thereof

A quick-setting agent and liquid technology, applied in the field of concrete additives, can solve the problems of reducing the strength of cement stones, and achieve the effects of enhancing strength, accelerating initial and final setting speeds, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

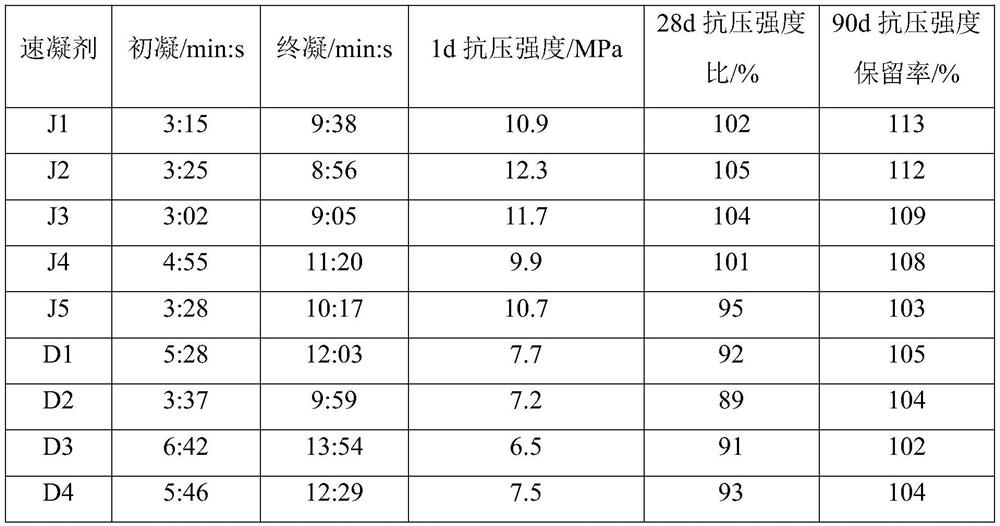

Examples

Embodiment 1

[0021] Dissolve 2 parts of iminodisuccinic acid in 100 parts of water, add 18 parts of anhydrous aluminum sulfate and 10 parts of pseudoboehmite, stir for 30 minutes, after the stirring is completed, add 0.6 parts of triisopropanolamine, 2 parts of carboxymethyl Base cellulose, and 1.8 parts of natural rubber latex was added dropwise to the solution, and the stirring was continued during the whole dropping process. After the stirring was completed, the pH was adjusted to 7 to obtain the alkali-free liquid quick-setting agent J1.

Embodiment 2

[0023] Take 2 parts of iminodisuccinic acid dissolved in 100 parts of water, add 25 parts of anhydrous aluminum sulfate, 9 parts of pseudoboehmite, stir for 30 minutes, after the stirring is completed, add 0.6 parts of triisopropanolamine, 2 parts of carboxymethyl Base cellulose, and 1.8 parts of natural rubber latex was added dropwise to the solution, and the stirring was continued during the whole dropping process. After the stirring was completed, the pH was adjusted to 7 to obtain the alkali-free liquid quick-setting agent J2.

Embodiment 3

[0025] Dissolve 3 parts of sodium iminodisuccinate in 100 parts of water, add 48 parts of aluminum sulfate octadecahydrate and 9 parts of pseudoboehmite, stir for 30 minutes, after the stirring is completed, add 0.6 parts of triisopropanolamine, 2 parts Carboxymethyl cellulose, and 2 parts of cis-butadiene latex are added dropwise to the solution, and the stirring is continued during the whole dropping process. After the stirring is completed, the pH is adjusted to 7 to obtain the alkali-free liquid quick-setting agent J3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com