Hydration heat inhibition type concrete expanding agent and preparation method thereof

A hydration heat suppression and concrete technology, applied in the field of concrete, can solve the problems such as unfavorable suppression of concrete cracking, unfavorable hydration temperature rise, short expansion stability period, etc., prolonging the initial setting time and final setting time, and the preparation method is simple and easy. The effect of long stable period of line and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

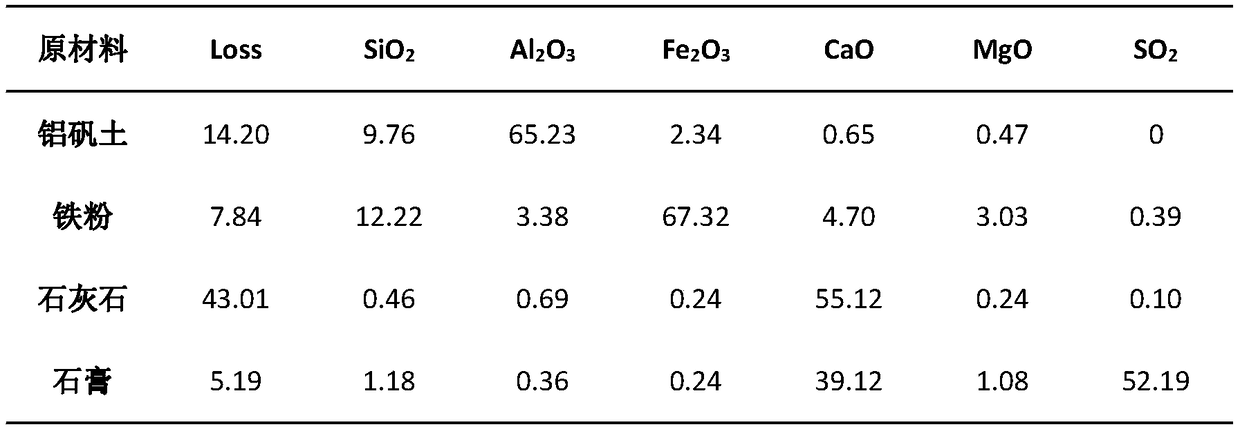

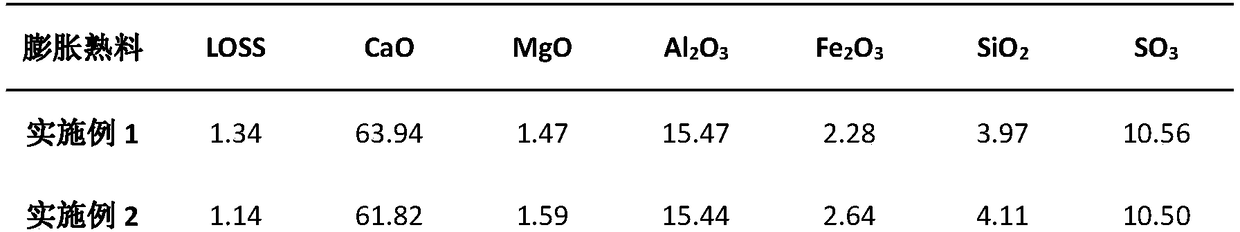

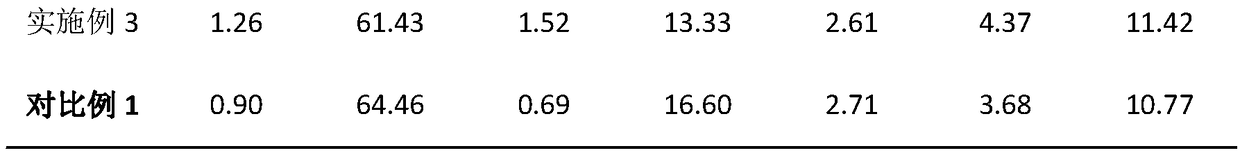

Embodiment 1

[0032] This embodiment provides a hydration heat-inhibited concrete expansion agent, which includes the following components by weight percentage: 70% by weight of hydration heat-inhibited swelling clinker and 30% by weight of gypsum. The hydration heat-inhibited expansion clinker is composed of: The raw materials in parts by weight are prepared: 67 parts of limestone, 12 parts of gypsum, 3 parts of iron slag, 17 parts of bauxite, and 1 part of copper oxide.

[0033] The preparation method of the hydration heat inhibited concrete expansion agent is:

[0034] (1) Mix the raw materials for preparing the hydration heat inhibited expanded clinker, crush and grind, and pass through a 200-mesh sieve, with a sieve remaining ≤ 1.5%;

[0035] (2) The above mixture is calcined at a high temperature at 1250°C, kept for 30 minutes, and cooled naturally to obtain hydration heat inhibited expanded clinker;

[0036] (3) The hydration heat inhibited expansion clinker is mixed and ground with gypsum, ...

Embodiment 2

[0038] This embodiment provides a hydration heat inhibited concrete expansion agent. Compared with Example 1, the difference is that the hydration heat inhibited concrete expansion agent includes the following components by weight percentage, hydration 70% by weight of heat-inhibited expansion clinker and 30% by weight of gypsum. The hydration heat-inhibited expansion clinker is prepared from the following raw materials in parts by weight: 66.5 parts of limestone, 12 parts of gypsum, 3 parts of iron slag, bauxite 17 parts, 1.5 parts of barium chloride.

Embodiment 3

[0040] This embodiment provides a hydration heat inhibited concrete expansion agent. Compared with Example 1, the difference is that the hydration heat inhibited concrete expansion agent includes the following components by weight percentage, hydration 70% by weight of heat-inhibited expansion clinker and 30% by weight of gypsum. The hydration heat-inhibited expansion clinker is prepared from the following raw materials in terms of jelly: 66 parts of limestone, 12 parts of gypsum, 3 parts of iron slag, bauxite 16 parts, 3 parts of titanium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com