A heat of hydration inhibiting concrete expansion agent and its preparation method

A technology of hydration heat suppression and expansion agent, which is applied in the field of concrete, can solve the problems of unfavorable inhibition of concrete cracking, long expansion and stable period, and short expansion and stability period, so as to prolong the initial setting and final setting time and extend the expansion and stability period , the effect of good expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

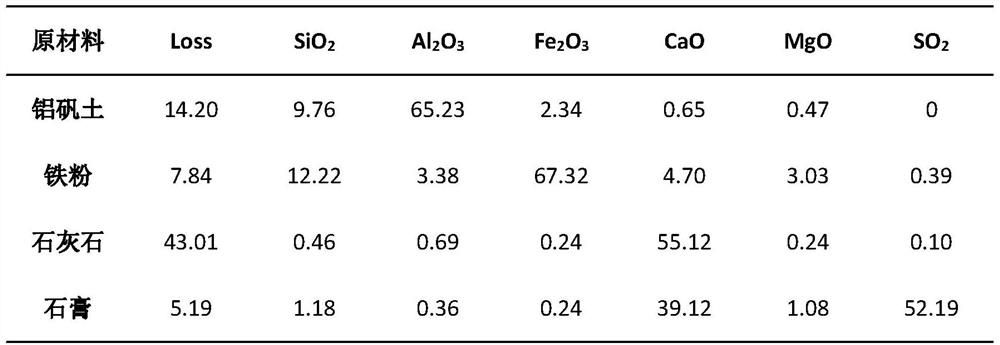

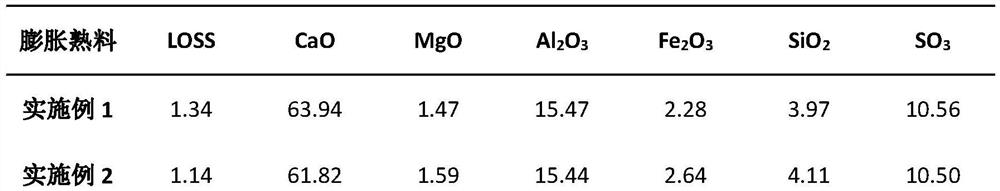

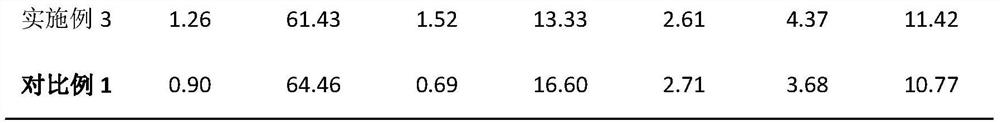

Embodiment 1

[0032] This embodiment provides a heat of hydration inhibiting concrete expansion agent, which includes the following components in weight percentage, heat of hydration inhibiting expansion clinker 70wt%, gypsum 30wt%, and the heat of hydration inhibiting expansion clinker consists of the following The raw materials prepared in parts by weight are: 67 parts of limestone, 12 parts of gypsum, 3 parts of iron slag, 17 parts of bauxite and 1 part of copper oxide.

[0033] The preparation method of described a heat of hydration inhibiting type concrete expansion agent is:

[0034] (1) Mix the raw materials for preparing the heat of hydration inhibiting expansion clinker, crush and grind, pass through a 200-mesh sieve, and the sieve residue is ≤1.5%;

[0035] (2) Calcining the above mixture at a high temperature of 1250° C., keeping it warm for 30 minutes, and cooling naturally to obtain a heat of hydration inhibited expansion clinker;

[0036] (3) Mix and grind the heat of hydrati...

Embodiment 2

[0038] This embodiment provides a heat of hydration inhibiting concrete expansion agent. Compared with Example 1, the difference is that the heat of hydration inhibiting concrete expansion agent includes the following components by weight percentage, hydration 70 wt% heat-inhibited expansion clinker, 30 wt% gypsum, the hydration heat-inhibited expansion clinker is prepared from the following raw materials in parts by weight: 66.5 parts of limestone, 12 parts of gypsum, 3 parts of iron slag, bauxite 17 parts, 1.5 parts of barium chloride.

Embodiment 3

[0040] This embodiment provides a heat of hydration inhibiting concrete expansion agent. Compared with Example 1, the difference is that the heat of hydration inhibiting concrete expansion agent includes the following components by weight percentage, hydration 70 wt% of heat-inhibited expansion clinker and 30 wt% of gypsum. The hydration heat-inhibited expansion clinker is prepared from the following raw materials: 66 parts of limestone, 12 parts of gypsum, 3 parts of iron slag, bauxite 16 parts, 3 parts of titanium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com