Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Play a preheating role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-steel bimetal casting improved technology

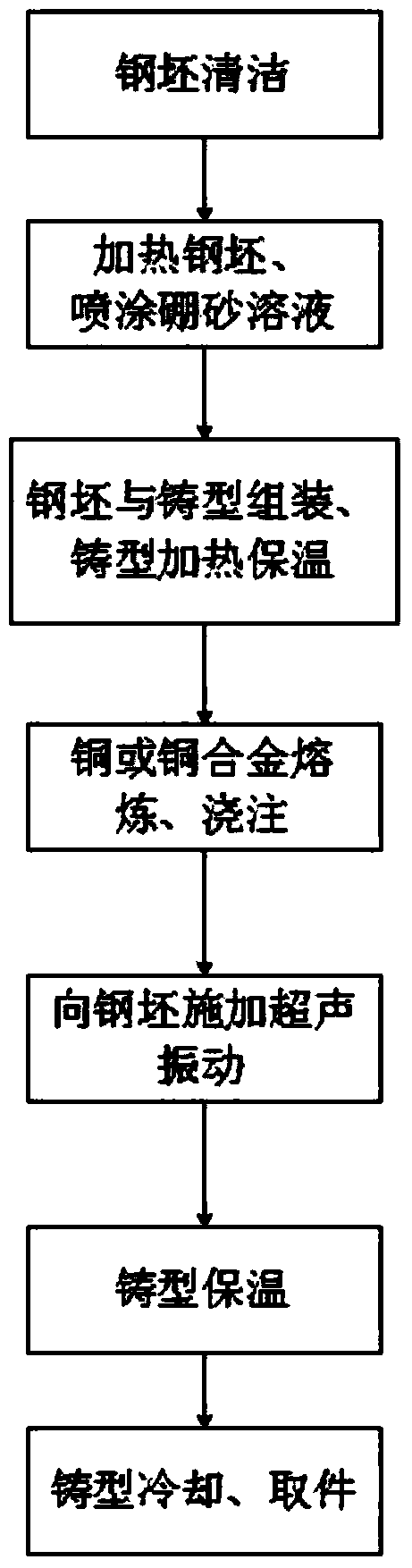

The invention provides a copper-steel bimetal casting improved technology. Copper or copper alloy in a certain thickness is directly cast on a steel base body through a static cast type casting method, and the main technical process comprises the steps of: cleaning a steel billet, heating the steel billet and spraying a borax solution on the heated steel billet, combining the cast, heating and keeping the heat, melting and pouring the copper or copper alloy, performing ultrasonic vibration on the steel billet, and keeping the high temperature of the cast. Through the copper-steel bimetal casting improved technology provided by the invention, the ultrasonic vibration and stirring step is added on the basis of the static embedding process technology, a copper or copper alloy layer in a certain thickness and without segregation can be obtained by casting on steel billets in various types and various sizes, and good metallurgical bonding can be realized between the copper or copper alloy layer of the obtained cast and the steel billet.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

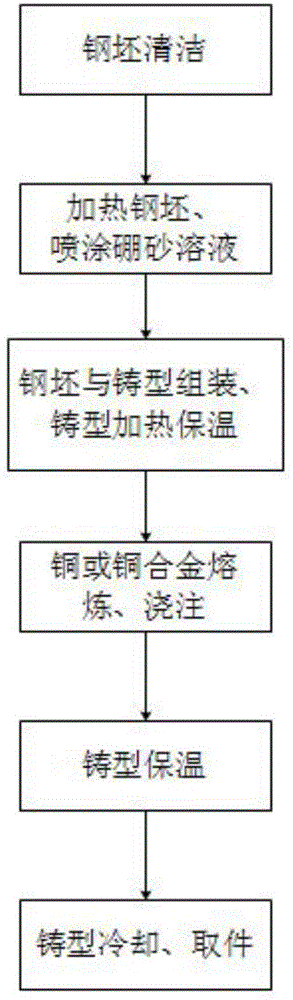

Copper and steel bimetallic casting application technology

The invention provides a copper and steel bimetallic casting application technology. Copper or copper alloy with certain thickness is directly cast on a steel base body by a static casting mold casting method. The technology mainly comprises the following steps of cleaning a steel billet, heating the steel billet, spraying a borax solution, combining a casting mold, heating and insulating heat, melting and casting the copper or the copper alloy, and insulating the heat of the casting mold at high temperature. The copper and steel bimetallic casting application technology has the advantages that a copper or copper alloy layer with certain thickness and without segregation can be cast on various shapes and various sizes of steel billets, and the good metallurgical combination between the copper or copper alloy layer of a casting and the steel billets is realized.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

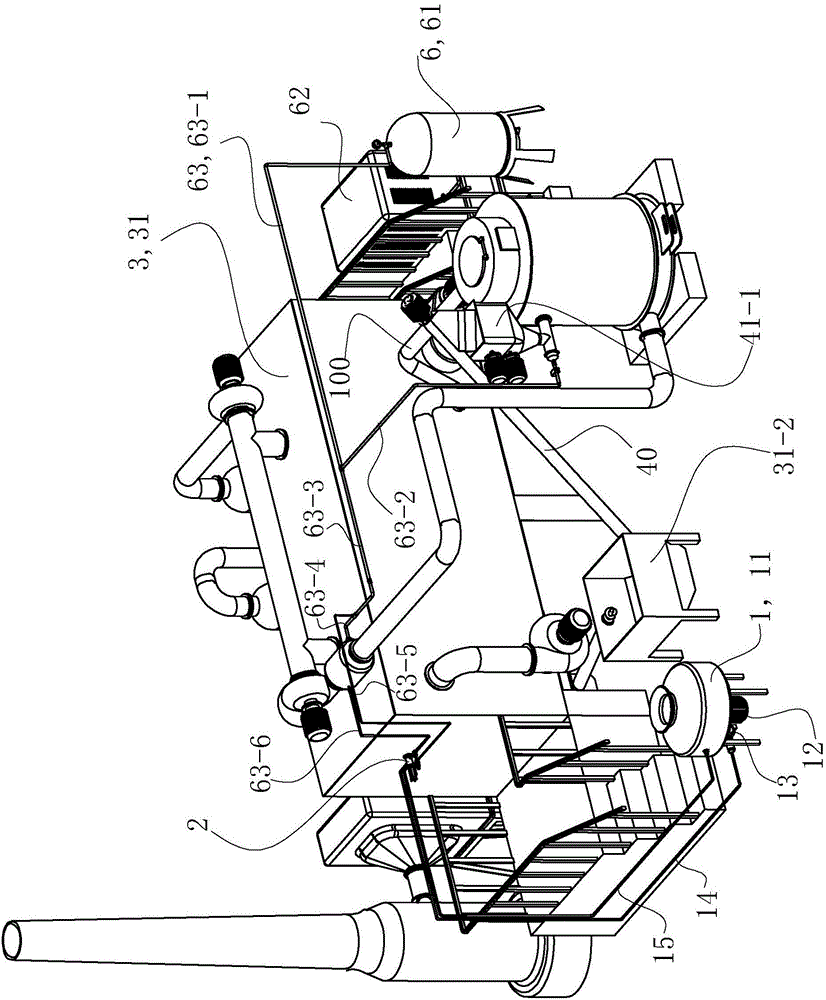

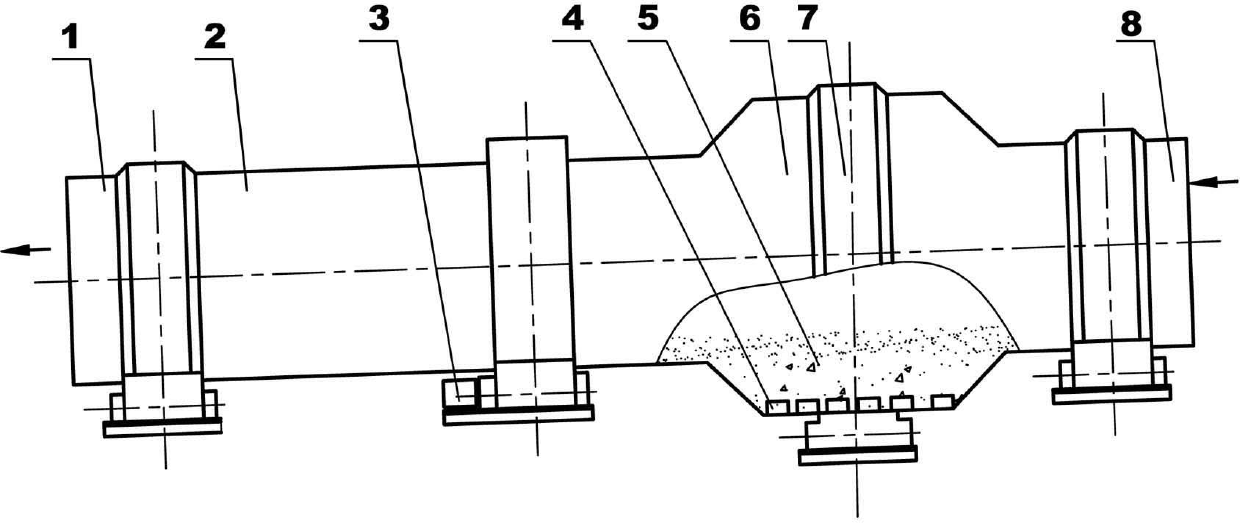

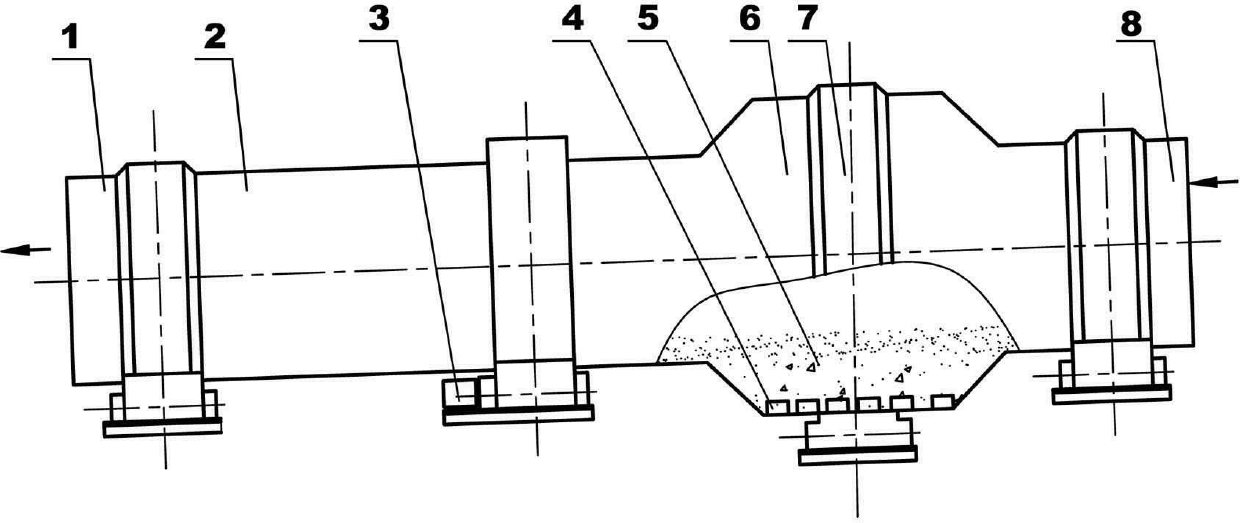

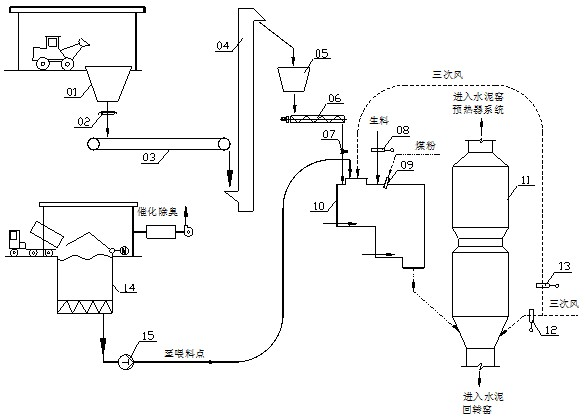

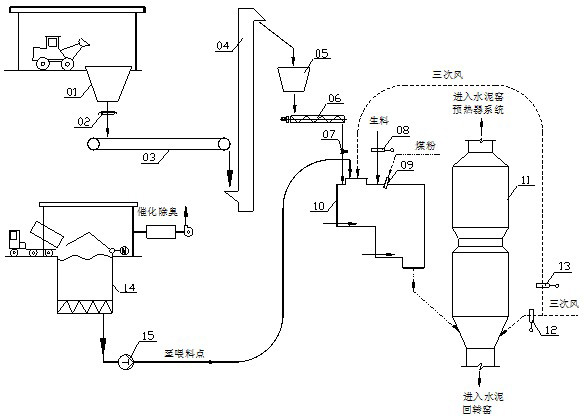

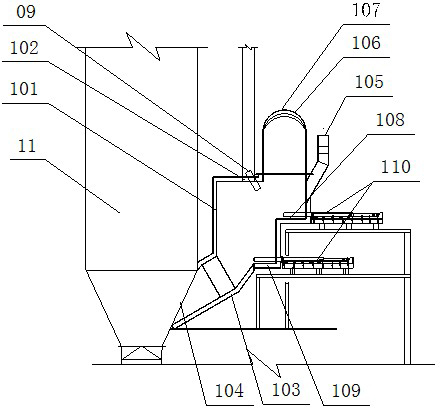

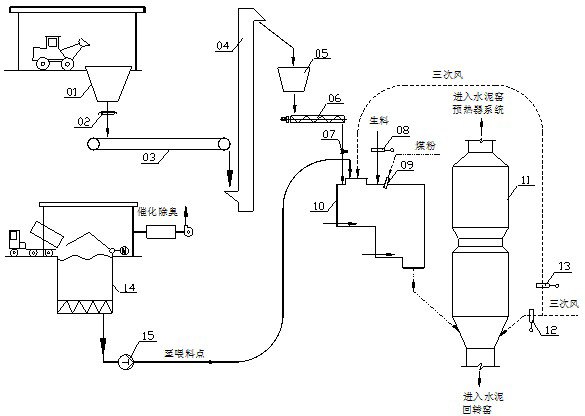

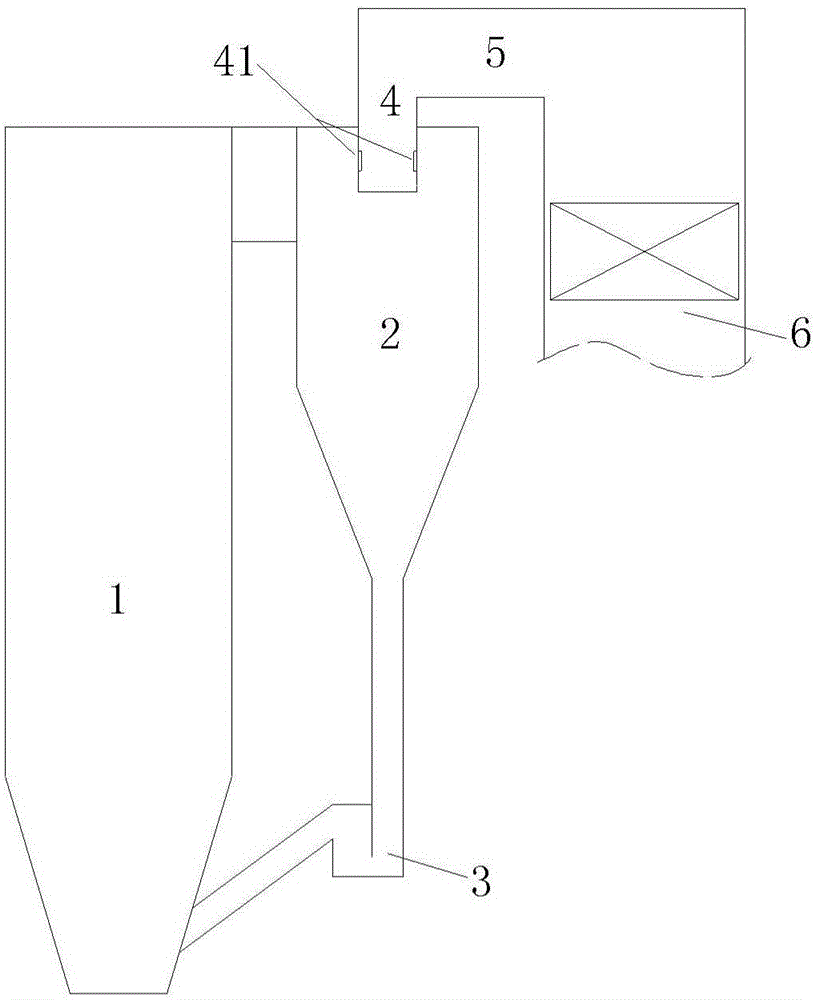

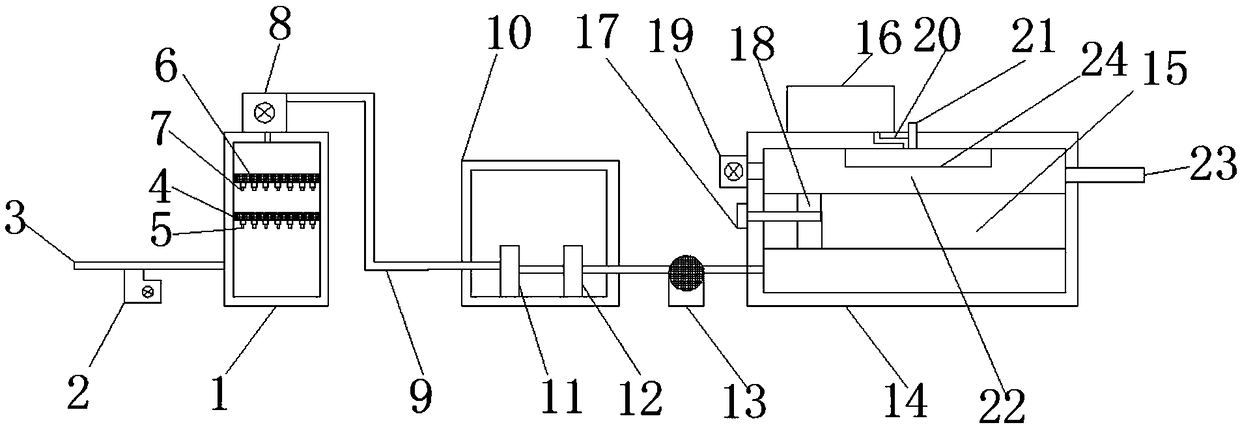

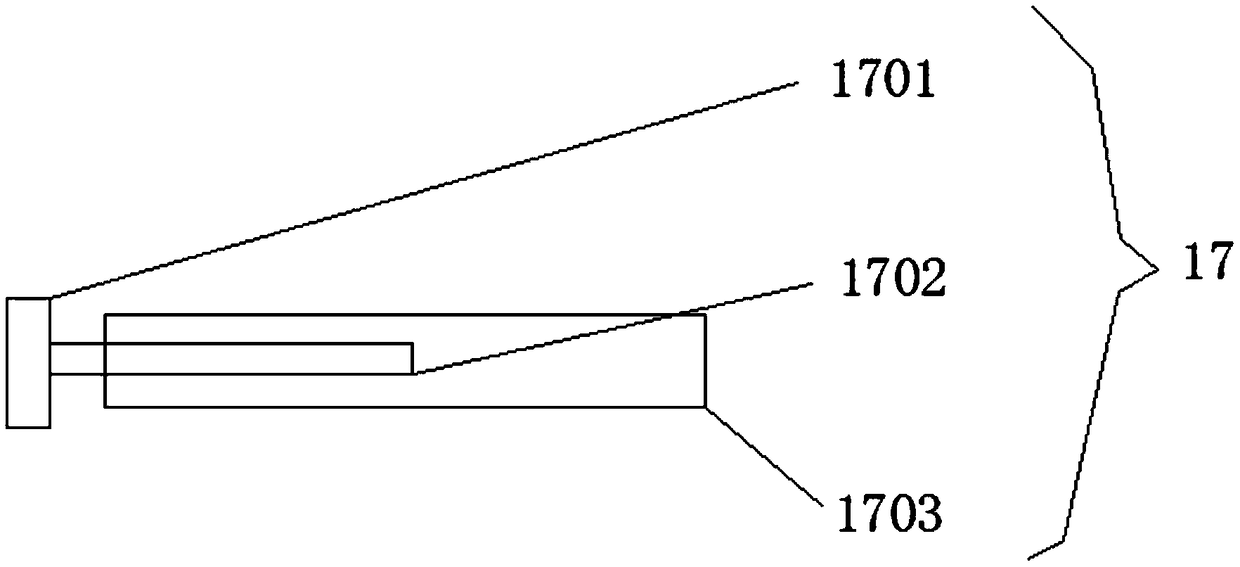

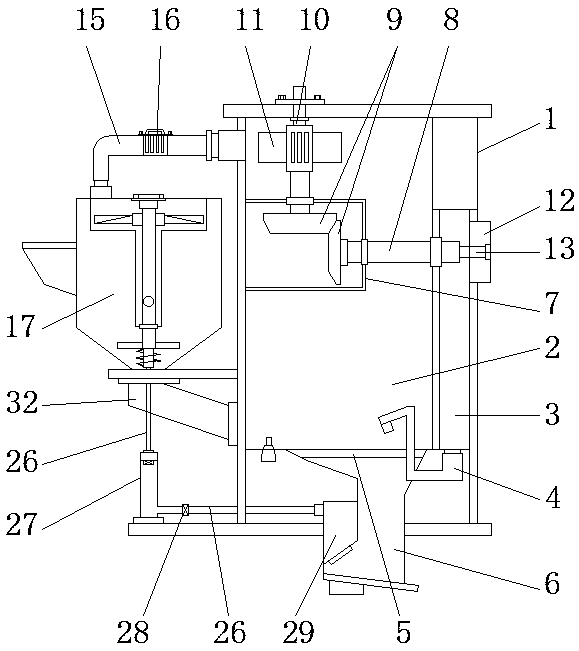

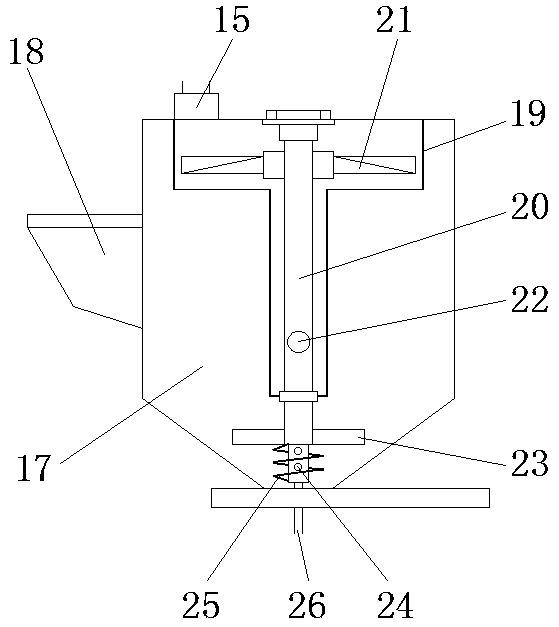

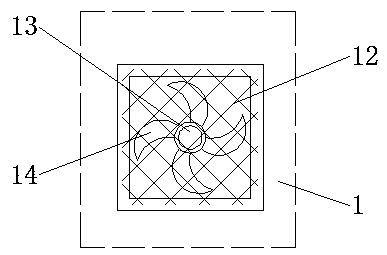

Sludge drying incineration system and method

ActiveCN104891769ABurn fullyPlay a preheating roleCombination devicesSludge treatment by de-watering/drying/thickeningHigh pressureSprayer

The invention discloses a sludge drying incineration system and method. The sludge drying incineration system comprises a wet sludge storage tank, a sludge high-pressure injection device, a drying box, an incinerator, a fume cleaning device and a gas feeder, wherein a sludge outlet end of a sludge feed pipeline of the wet sludge storage tank is communicated with a sludge inlet of the sludge high-pressure injection device; a sludge spraying port of a sprayer of the sludge high-pressure injection device is communicated with a sludge inlet of the drying box; a first fume outlet of the drying device is communicated with a gas inlet of the incinerator; a second fume outlet of the drying device is communicated with the fume cleaning device; and a fume outlet of the incinerator is communicated with the drying device. The sludge drying incineration system utilizes heat carried by high-temperature fume generated by sludge incineration to dry the wet sludge, and completely utilizes the heat generated by sludge incineration in the drying stage without any other energy.

Owner:常州振业机械设备有限公司

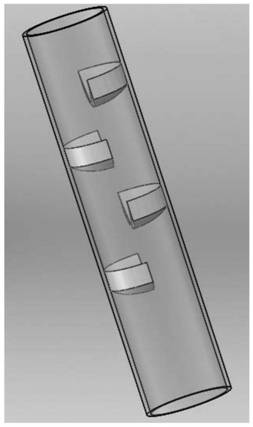

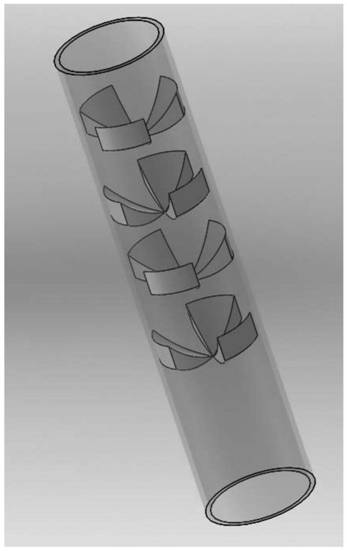

Lime rotary kiln

InactiveCN102564110ASimple structureSave energyRotary drum furnacesEngineeringMechanical engineering

The invention discloses a rotary kiln, in particular to a lime rotary kiln used in production of aluminum oxide or cement. The lime rotary kiln is structurally characterized in that a kiln head is connected with an inclined rotary kiln body, a transmission device driving the kiln body to rotate counterclockwise is arranged outside the rotary kiln body, a kiln tail is connected to the rear end of the rotary kiln body, a variable-diameter section is arranged at the kiln tail close to the rotary kiln body, and a raising plate is arranged on the inner wall of the variable-diameter section. The lime rotary kiln has the advantages that the lime rotary kiln is simple in structure, energy-saving, cost-saving and effective in preheating, and productivity is improved.

Owner:中铝国际技术发展有限公司

Laser welding method

InactiveCN104439587AImprove laser absorption rateHigh temperature toleranceSoldering apparatusLaser beam welding apparatusControl equipmentLaser

The invention provides a laser welding method. According to the method, a laser welding machine and a circuit board to be welded are provided, a plurality of bonding pads to be welded are arranged on the circuit board, the laser welding machine comprises a focusing head and a tin feeding head, the tin feeding head comprises a tin feeding end, the tin feeding end can feed a tin wire continuously, the tin feeding head is located between the focusing head and the bonding pads, before high-power light of the focusing head exits or while high-power light exits, a section of the tin wire is fed by the tin feeding head, and the tin wire, the focusing head and the bonding pads are located on the same straight line. According to the laser welding method, the welding speed is high, the welding precision is high, the requirement for control equipment is not high, the production cost is low, stability is improved greatly, and the laser welding method has high market value.

Owner:深圳云麟科技有限公司

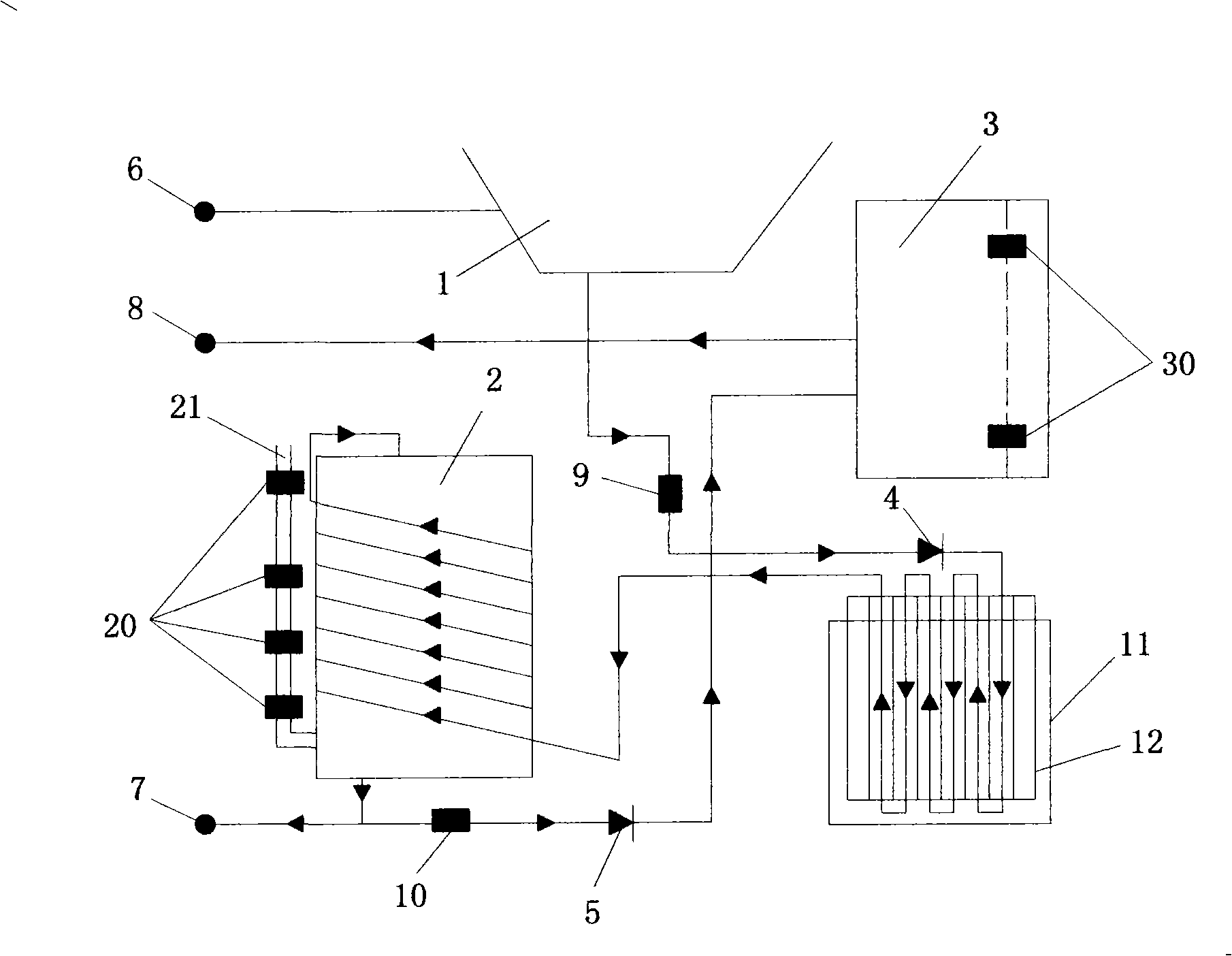

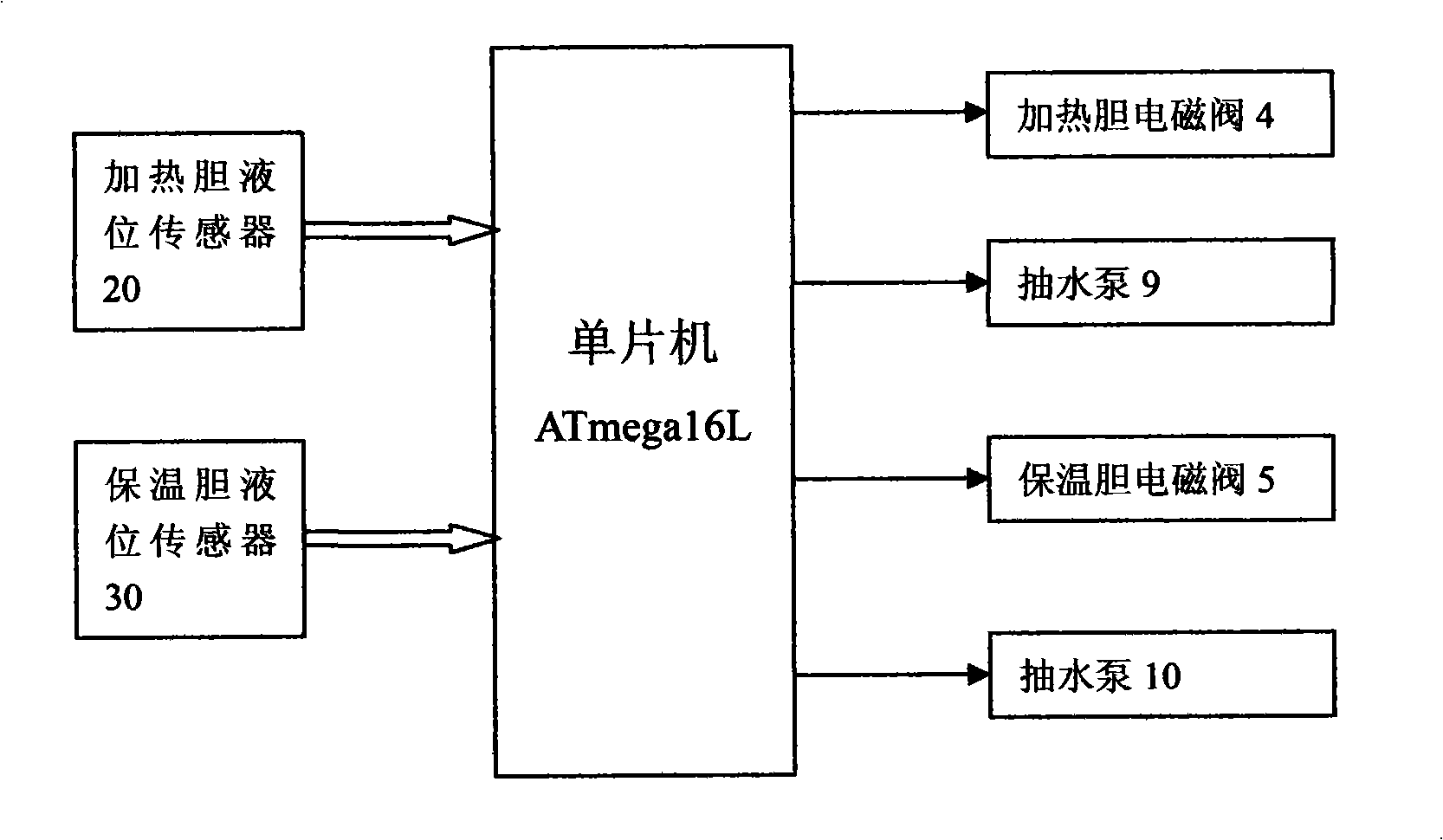

Intelligent healthy drinking machine

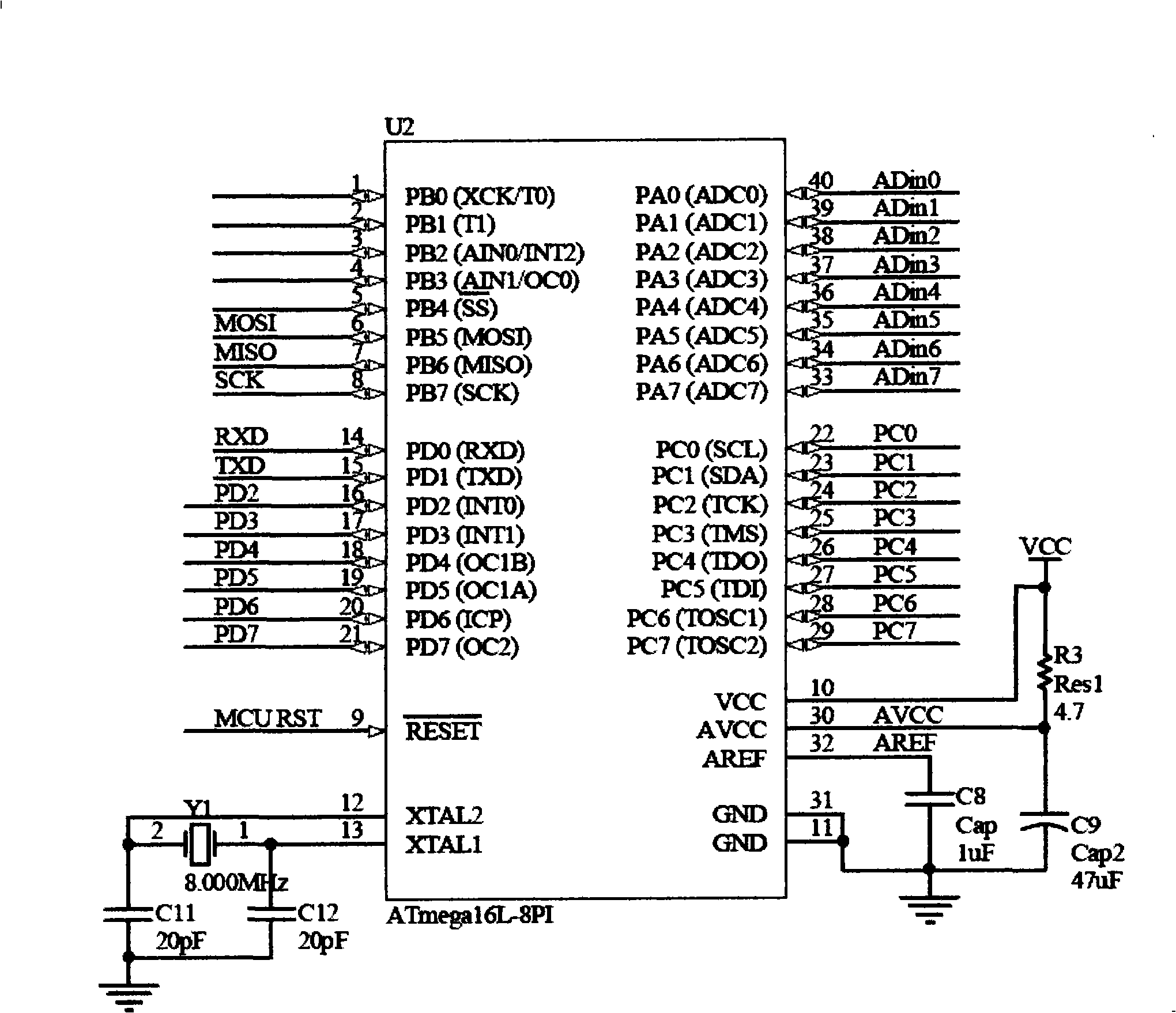

InactiveCN101268913ATo achieve the purpose of energy savingPlay a preheating roleBeverage vesselsMachines/enginesMicrocontrollerWater storage tank

The invention discloses an intelligent health Water dispenser which comprises a water storage tank, a heating flask, an insulation flask, a heating flask electromagnetic valve and an insulation flask electromagnetic valve, wherein, the water storage tank is connected with the heating flask electromagnetic valve by a water pipe, the heating flask electromagnetic valve is connected with the heating flask by the water pipe, the heating flask is connected with the insulation flask electromagnetic valve by the water pipe and the insulation flask electromagnetic valve is connected with the insulation flask by the water pipe; the heating flask is provided with a heating flask liquid-level sensor and the insulation flask is provided with an insulation flask liquid-level sensor; the heating flask liquid-level sensor, the insulation flask liquid-level sensor, the heating flask electromagnetic valve and the insulation flask electromagnetic valve are connected with a single chip integration circuit. The intelligent health water dispenser is added with the insulation flask with a part of water always set, thereby isolating heated water and unheated water and eliminating half boiling water and half cold water mixed together; the intelligent health water dispenser adopts the single chip integration circuit and prevents the water dispenser from heating again and again, thereby stopping water from boiling again and again and reaching the aim of energy conservation.

Owner:叶蓁 +1

Burning method for disposing wastes with various varieties and various phase states

ActiveCN102635866ASimple but very effective disposalReduce the impactCement productionIncinerator apparatusWaste processingSludge

The invention discloses a burning method for disposing wastes with various varieties and various phase states and belongs to the field of waste processing methods. The burning method comprises the following steps: passing wastes to be burnt through a burning device from top to bottom in the burning device, meanwhile, igniting the wastes to be burnt by high-temperature wind which passes through the burning device from top to bottom, and carrying a burnt product by high-temperature wind to leave the burning device; and burning the wastes which enters into the burning device and stay at the different height positions of the burning device, and after respectively controllably burning for an appointed time at the appointed height position, leaving the burning device. The burning method disclosed by the invention is a burning method which can be used for simultaneously disposing at least three wastes (industrial waste slag, waste liquor, municipal solid waste and sewage plant sludge) with various varieties and various phase states, has the advantages of reasonable flow structure and strong adaptability and can finish integrated disposal.

Owner:成都建筑材料工业设计研究院有限公司

Printing process capable of reducing ink consumption

ActiveCN108674047AEvenly distributedQuality improvementOther printing apparatusPrinting after-treatmentEngineeringCentrifugal force

The present invention relates to the technical field of printing, and discloses a printing process capable of reducing ink consumption. The printing process comprises the following steps of: (1) selecting; (2) preheating; (3) ink applying; (4) printing; and (5) drying. According to the printing process, an inner cavity is arranged in an ink applying roller to store ink, an outer layer and an innerlayer are in communication with each other through a through hole, and a centrifugal force is generated by rotation of the ink applying roller, so that ink is made to automatically flow from the inner cavity to an ink applying brush to apply the ink on an imprinting roller, thereby achieving uniform ink application without requiring an ink fountain in the prior art. Therefore, ink consumption isreduced, and investment cost is thus lowered. In addition, since ink is stored in the inner cavity, volatilization of the ink is greatly reduced and printing environment is improved.

Owner:DINGSHENG CORP

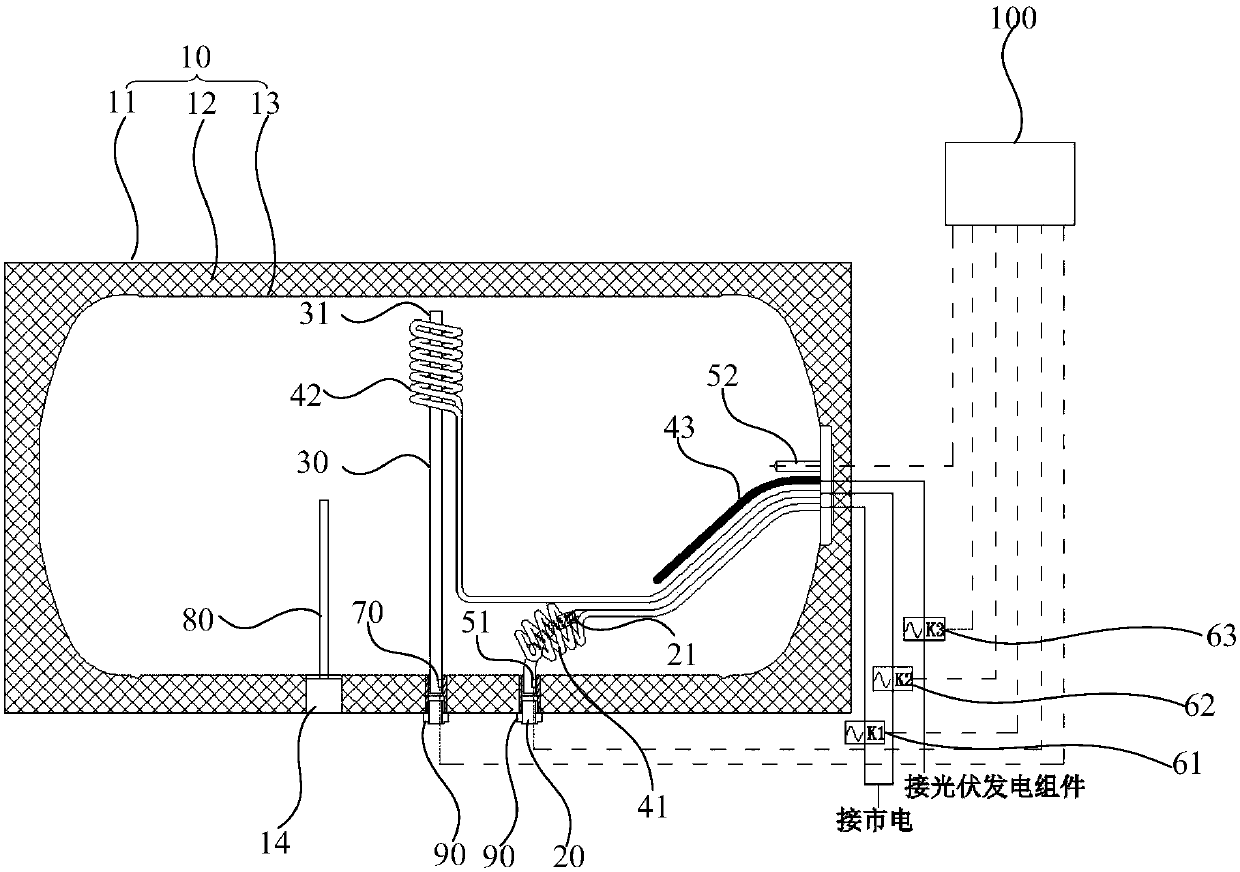

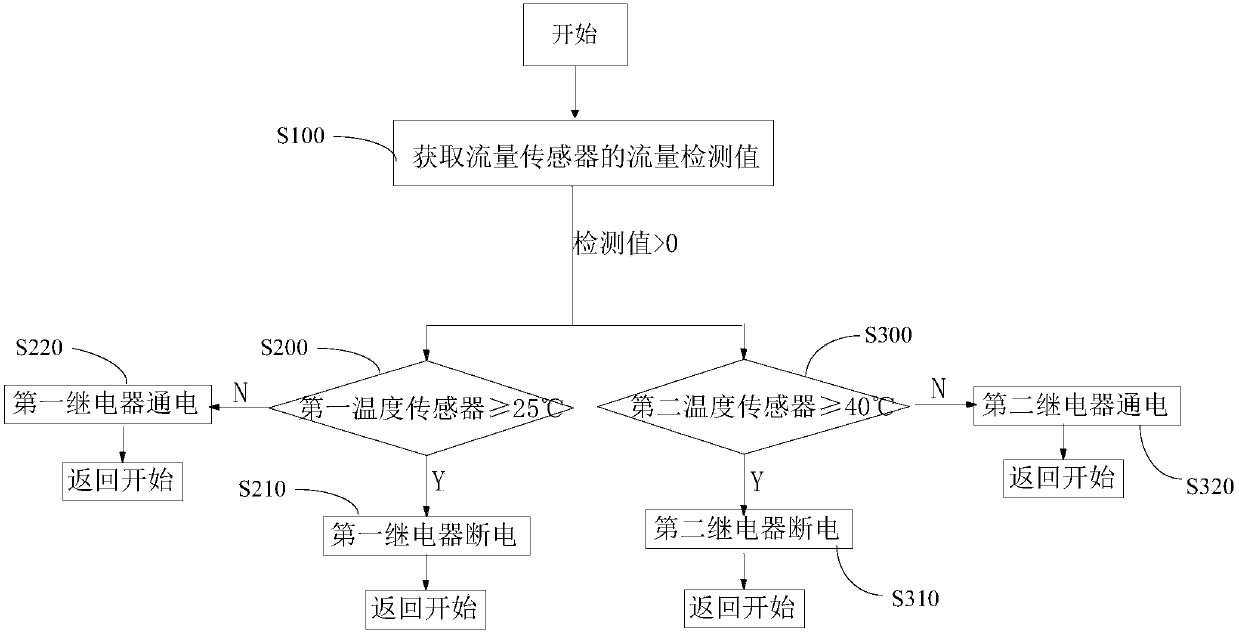

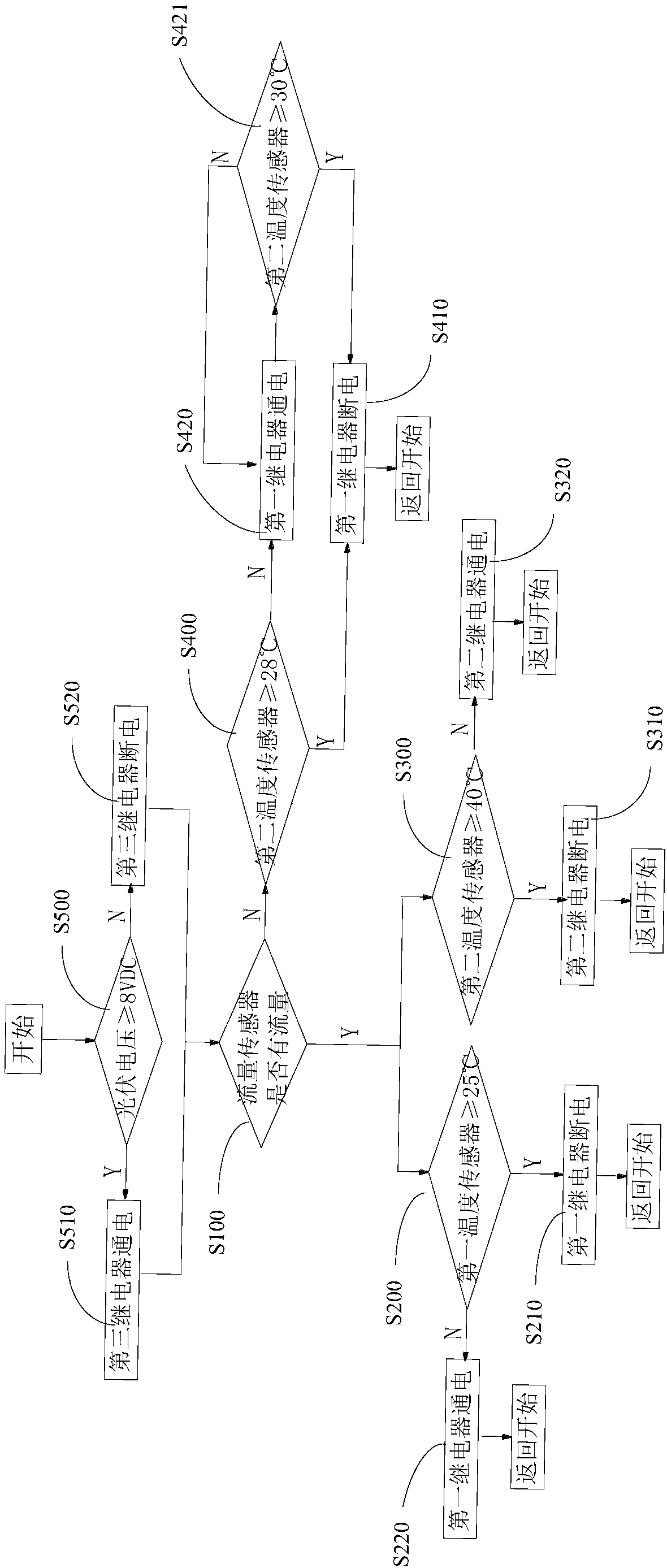

Water heater and control method thereof

The invention discloses a water heater and a control method thereof. The water heater comprises a water tank, a water inlet pipe, a water outlet pipe, a flow sensor, a first temperature sensor, a second temperature sensor, a first electric heating pipe, a second electric heating pipe and a controller, wherein the water inlet pipe is provided with a water inlet located in the water tank, and the water outlet pipe is provided with a water outlet located in the water tank and used for discharging hot water in the water tank; the first temperature sensor is used for detecting the water temperatureat the water inlet, and the first electric heating pipe is arranged at the water inlet; the second temperature sensor is used for detecting the water temperature in the water tank, and the second electric heating pipe is arranged at the water outlet; the flow sensor is arranged on the water outlet pipe; and the first temperature sensor, the second temperature sensor, the first electric heating pipe, the second electric heating pipe and the flow sensor are all electrically connected with the controller. According to the water heater and the control method thereof, low-temperature cold water atthe water inlet can be rapidly heated, hot water can also be discharged rapidly under the condition that the temperature of tap water is low in winter, and an instant heat cleaning function is achieved.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

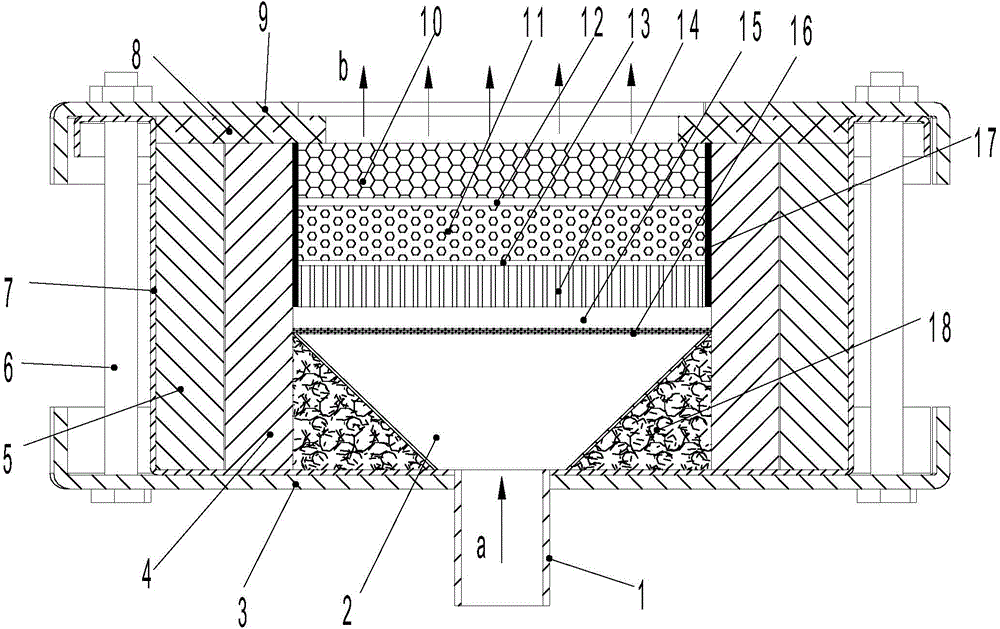

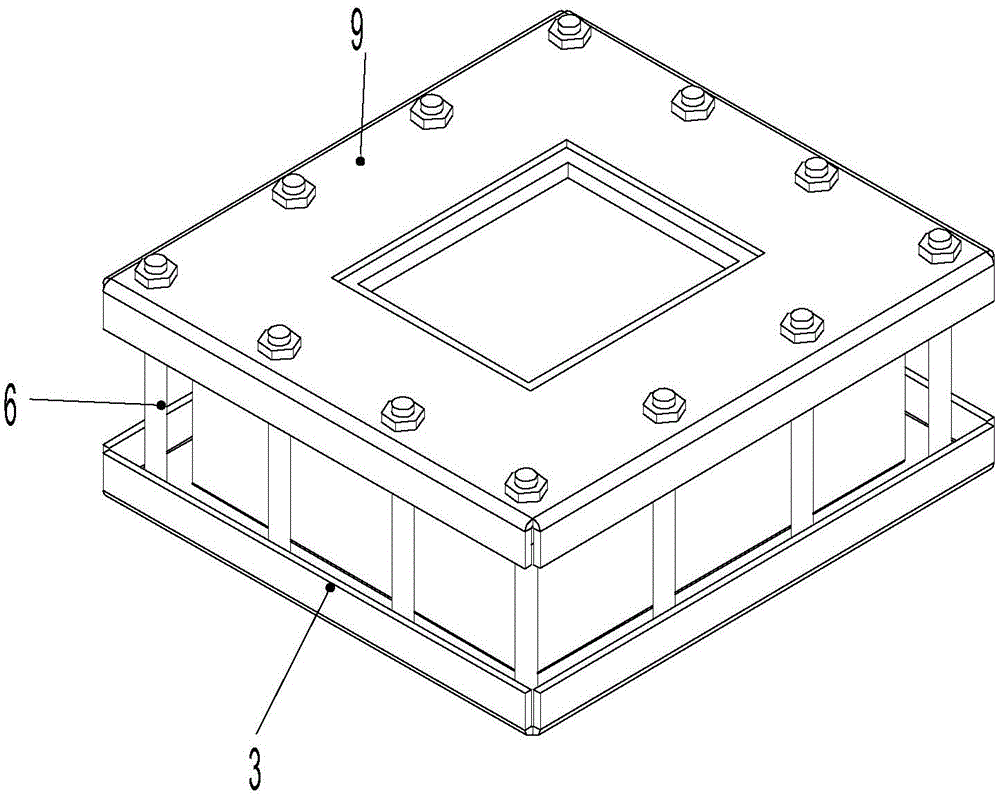

Fuel-gas-catalyzing flameless near-infrared direct heating porous medium combustor

InactiveCN104930513AImprove heating efficiencyPlay a preheating roleGaseous fuel burnerBrickPorous medium

The invention provides a fuel-gas-catalyzing flameless near-infrared direct heating porous medium combustor, and relates to a combustor. The combustor comprises a combustor body, a heat preservation layer and a fireproof brick layer. A premixed gas diffusion chamber, a perforated plate, a premixed gas pressure equalizing chamber, a flame retardant shield plate and a foam ceramic plate are sequentially arranged in the fireproof brick layer from bottom to top. The bottom of the premixed gas diffusion chamber is communicated with a premixed gas supply pipe. Heat preservation cotton is arranged between the periphery of the premixed gas diffusion chamber and the fireproof brick layer. The flame retardant shield plate is bonded to the foam ceramic plate through a bonding plate A. The upper end face and the lower end face of the combustor body are provided with an upper pressing plate and a lower pressing plate respectively. The upper pressing plate and the lower pressing plate are pressed and connected together through fastening pieces. By means of the fuel-gas-catalyzing flameless near-infrared direct heating porous medium combustor, smoke and flame are not generated in combustion, heating efficiency is high, even heating is achieved, emission of NOX can be lowered, the surface temperature is stable in combustion, radiation intensity is high, tempering can be prevented, and the combustor has the advantages of being convenient to mount, long in service life, wide in application range, capable of saving energy, environmentally friendly and the like and easy to apply and popularize.

Owner:周海波

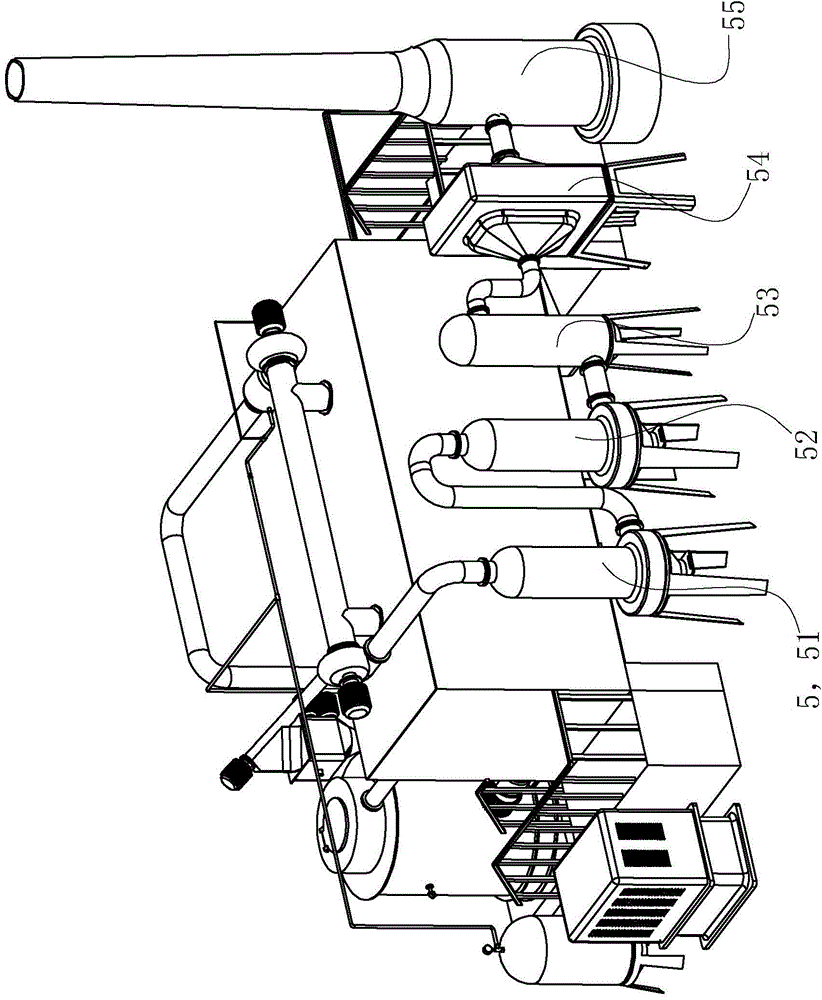

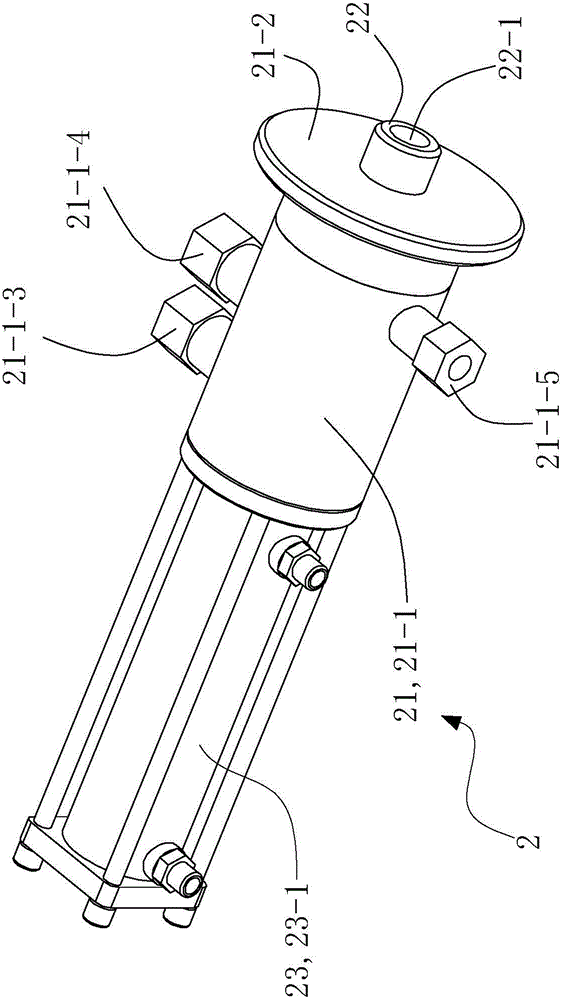

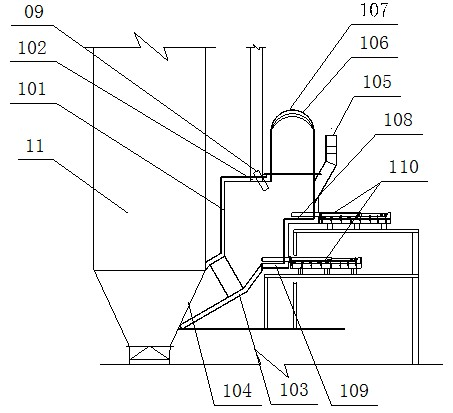

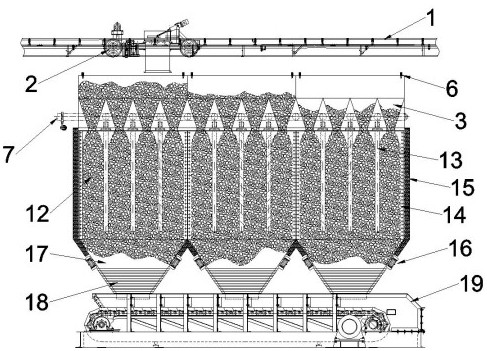

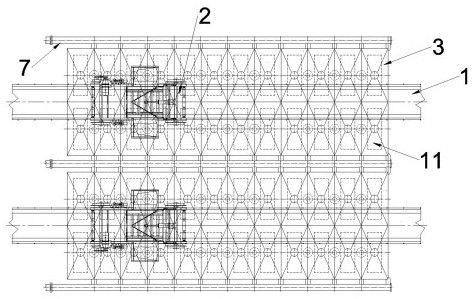

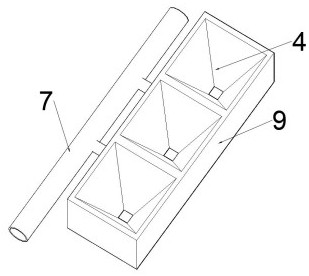

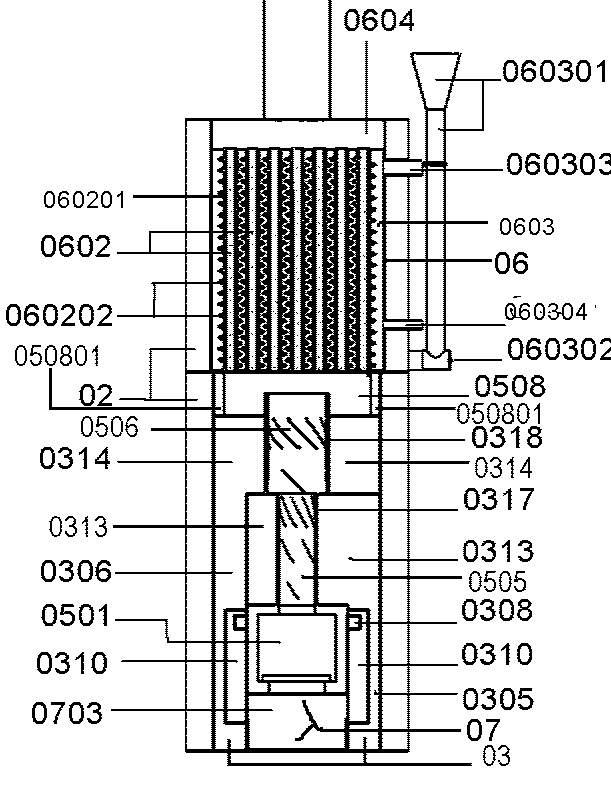

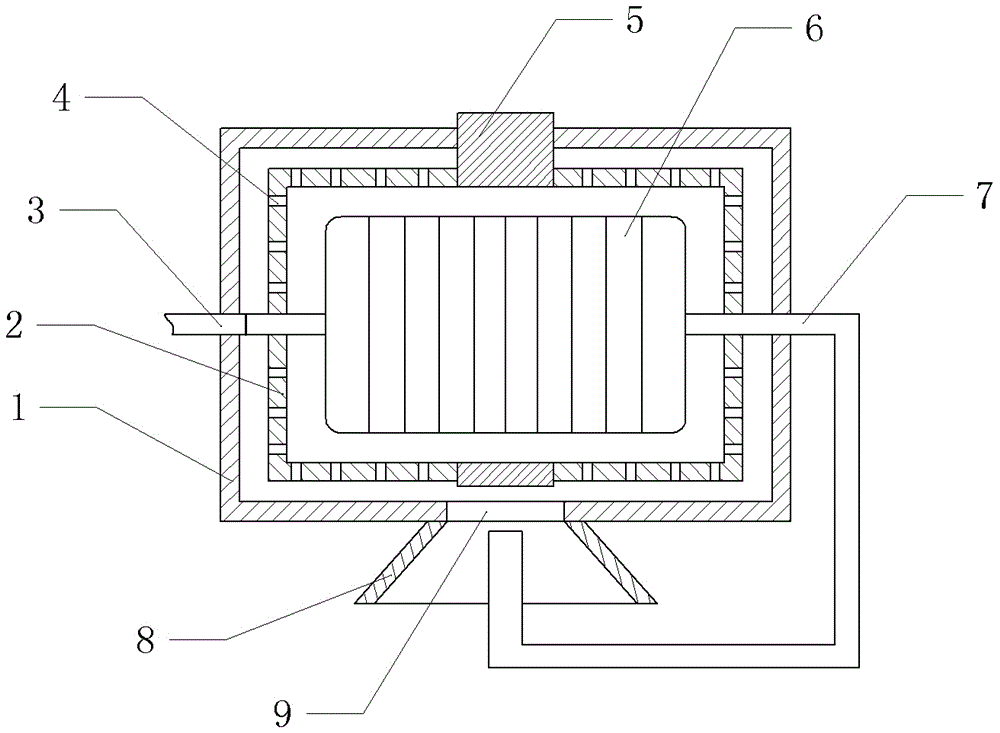

Incineration device for treating multi-variety and multi-phase wastes

ActiveCN102607044AEliminate secondary pollutionReduce the impactCement productionIncinerator apparatusIndustrial wasteProcess engineering

The invention discloses an incineration device for treating multi-variety and multi-phase wastes, belonging to the field of waste processing equipment. The incineration device comprises a furnace body of an incineration furnace; a feeding opening is arranged at the upper part of the furnace body and a discharging channel is arranged at the lower part of the furnace body; a discharging opening is arranged at the tail end; the feeding opening is provided with a high-temperature air opening and at least two stages of step-shaped material stoking platforms are arranged below the feeding opening in the furnace body; the discharging channel is arranged below the final stage of the material stoking platform; and each stage of the material stoking platform is provided with a material pushing device capable of pushing materials to drop into the next stage of the material stoking platform or the discharging channel. The invention provides the incineration device which can simultaneously treat three types or more types of the multi-variety and multi-phase wastes (industrial waste residue, waste liquid, municipal solid wastes and sludge of sewage plants), and has the advantages of reasonable flow and structure and strong adaptability, and can finish the integrated treatment.

Owner:成都建筑材料工业设计研究院有限公司

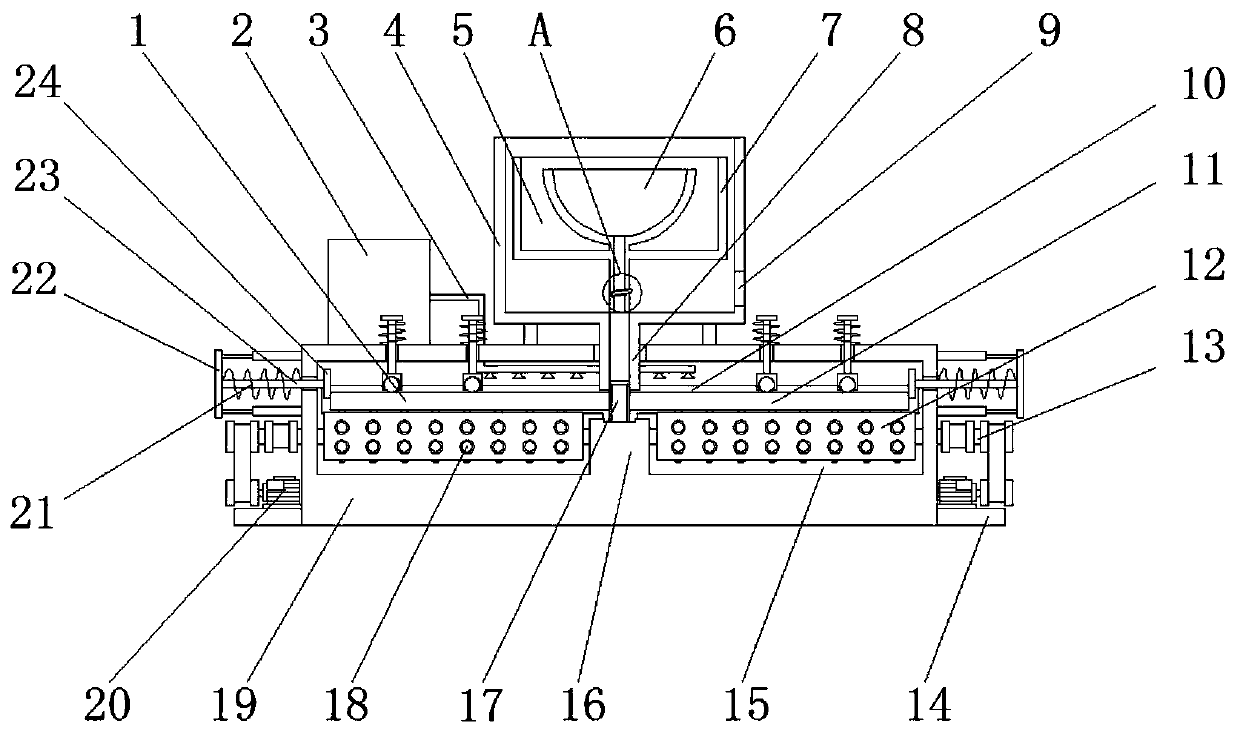

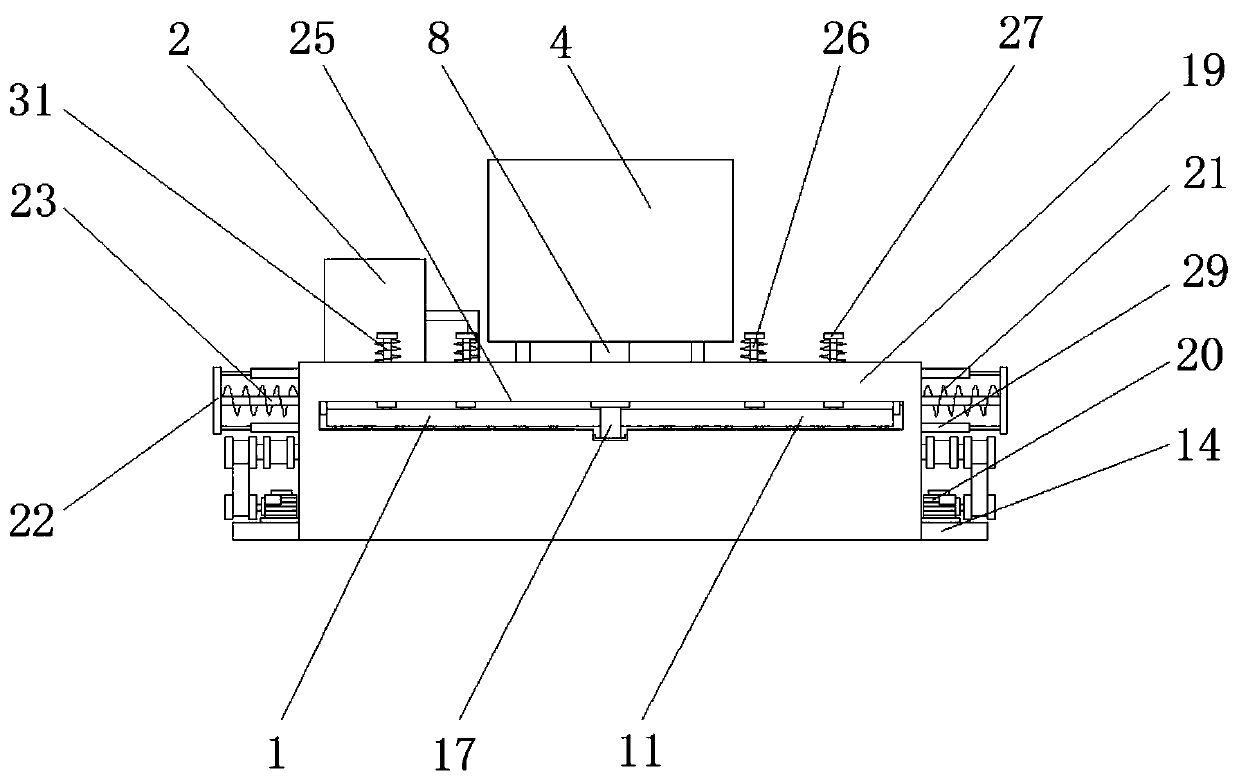

Steel-aluminum joint welding device

InactiveCN110253165AEasy to weldFor lateral movementWelding/cutting auxillary devicesAuxillary welding devicesAlloyEngineering

The invention discloses a steel-aluminum joint welding device. The steel-aluminum joint welding device comprises a protective base, a heating base, conveying rollers, mounting grooves and a shell. The shell is internally provided with the mounting grooves. A feed port is arranged on one side of the sell at the mounting grooves. According to the steel-aluminum joint welding device, a thin copper plate is arranged between a steel plate and an aluminum alloy plate; the aluminum alloy plate and the steel plate make contact with a material guide tube through the thin copper plate; on the one hand, the steel plate and the thin copper plate are isolated through limiting of the thin copper plate, and the situation that the steel plate and the aluminum alloy plate make contact with each other and have a reaction in the heating process and the welding quality is affected by brittle compounds generated from the reaction is avoided; and on the other hand, the thin copper plate achieves the heat conduction effect and conducts heat generated from a heating barrel to the welding ends of the aluminum alloy plate and the steel plate through a delivery tube, a material guide tube and the thin copper plate in sequence to achieve the preheating effect on the steel plate and the aluminum alloy plate. The influence of bubbles generated from uneven heating in the welding process on the welding quality is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Fuel-gas-catalyzed flameless near-infrared indirect heating porous medium burner

InactiveCN104964281AImprove heating efficiencyPlay a preheating roleGaseous fuel burnerPorous mediumMixed gas

The invention discloses a fuel-gas-catalyzed flameless near-infrared indirect heating porous medium burner, and relates to burners. The burner comprises a burner body, an inner refractory brick layer and an outer refractory brick layer; the outer refractory brick layer is internally provided with a gas inlet channel and a gas outlet channel, the inner refractory brick layer is internally provided with a pre-mixed gas diffusion chamber, a perforated plate, a pre-mixed gas voltage-sharing chamber, a flame-resistant protective screen plate and a foamed ceramic plate; the pre-mixed gas diffusion chamber is communicated with a pre-mixed gas supply pipe, and the outer refractory brick layer arranged on the foamed ceramic plate is provided with high-temperature-resistant infrared silica glass which blocks a burning opening; an upper compressing plate is arranged above the high-temperature-resistant infrared silica glass, a lower compressing plate is arranged on the lower end face of the burner body, and the upper compressing plate is connected with the lower compressing plate through a fastening piece. According to the fuel-gas-catalyzed flameless near-infrared indirect heating porous medium burner, during burning, smoke and flames are not generated, the heating efficiency is high, heating is even, the emission of NOX can be reduced, the burner can be used for an annealing technology where burner atmosphere needs to be ensured, and during the burning, the radiation intensity is high; the fuel-gas-catalyzed flameless near-infrared indirect heating porous medium burner has the advantages that the installation is convenient, the service life is long, the energy is saved, the environment is protected, and the application range is wide; the burner is easy to use and popularize.

Owner:周海波

Cotton fabric dyeing anti-wrinkle one-bath-process processing technique

InactiveCN105780549APlay non-ironingFunctionSucessive textile treatmentsWrinkle resistant fibresCooking & bakingHigh color

The invention relates to a cotton fabric dyeing anti-wrinkle one-bath-process processing technique and belongs to the technical field of treatment of fabric and the like. The processing technique includes: soaking fabric in a blended solution of dye, resin and auxiliaries; padding before baking, wherein in the blended solution, the dye is active dye, adding amount of the dye is 20-25 g / L, the resin is non-ironing resin, adding amount of the resin is 140-160 g / L, a softener is 15-30 g / L, a penetrant is 0.3-3 g / L, and padding allowance is 60-100%. The processing technique is applied to treatment of cotton fabric and has the advantages of short process, high color fastness and good anti-wrinkle performance.

Owner:SHAOXING UNIVERSITY

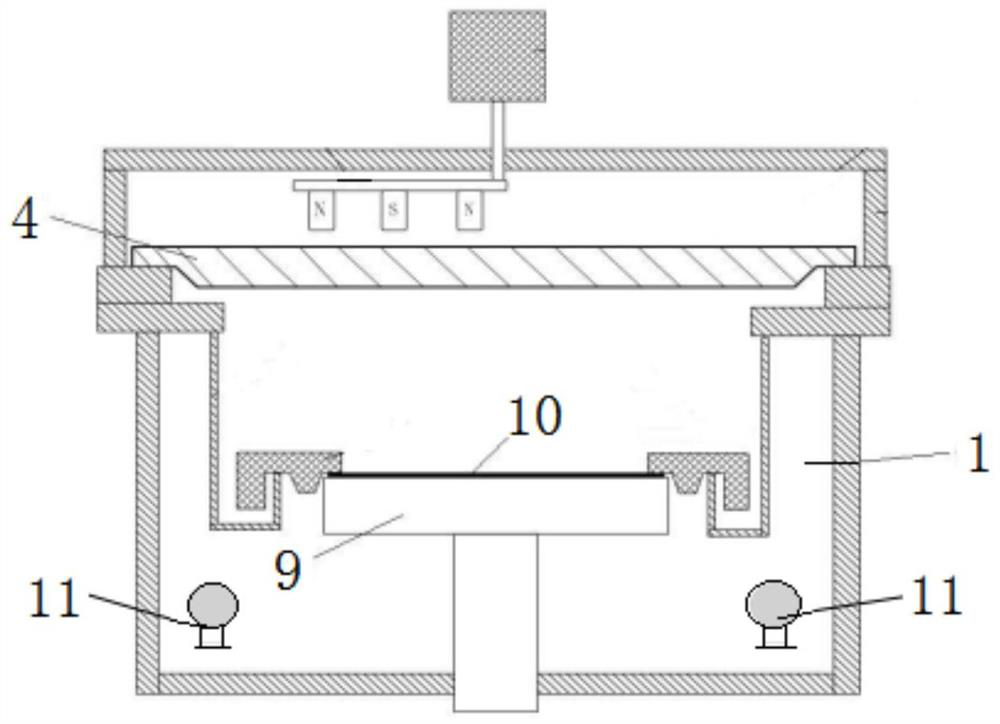

Brown fused alumina, supporting production equipment and production method thereof

The invention relates to the field of abrasive materials, particularly to brown fused alumina, supporting production equipment and a production method thereof. A purpose of the present invention is toprovide a low cost processing method for manufacturing high-strength brown fused alumina. The components of the formula comprise 0.01-6.1% of silica, 2.5-4% of titanium dioxide, and 90-97% of aluminapowder. The production equipment comprises a feeding device, wherein a material preparing device, a stirring device, a material falling device and a melting device are sequentially arranged along thefeeding device, the stirring device comprises a stirrer, a gas discharge pipe is arranged in the stirring blade in the stirrer, the outlet end of the gas discharge pipe is positioned above the stirring blade to form an aeration port, the inlet end of the gas discharge pipe is communicated to a gas source through a connecting pipe, and the stirrer is provided with an anti-dissipation baffle. According to the present invention, with the equipment and the method, the impurities in the finished product are less, the kinds of the raw materials are less, the materials are easy to prepare, almost noiron exists in the raw materials, the addition of coal or carbon coke during the processing can be avoided, the stability and the coloring performance of the product are increased, and the corrosionresistance and the oxidation resistance of the finished product are strong.

Owner:登封市阳光炉料有限公司

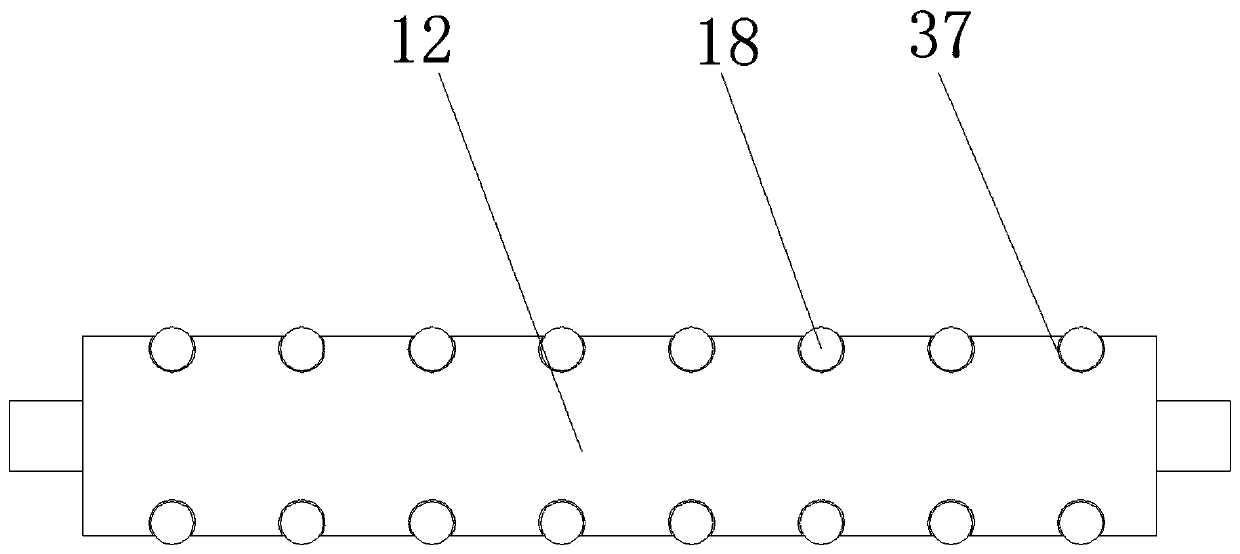

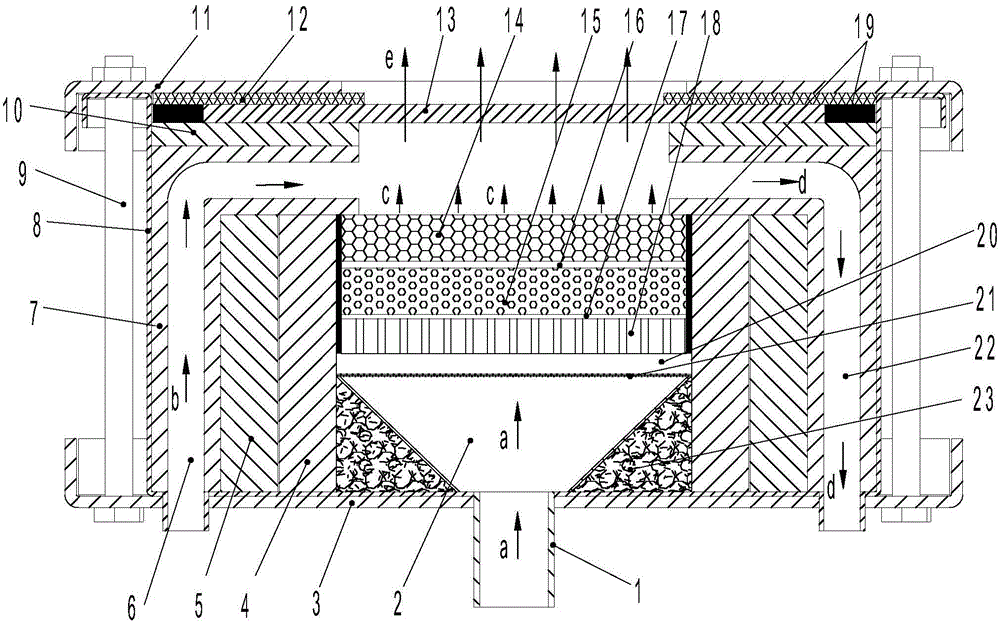

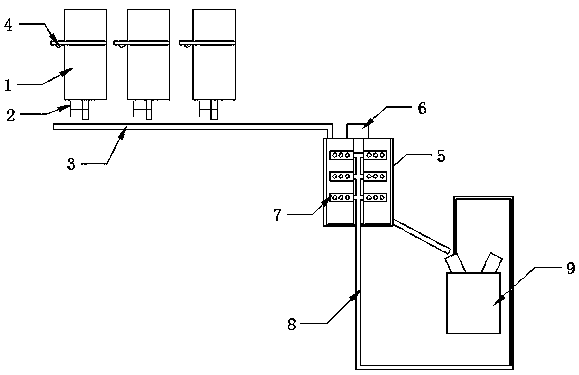

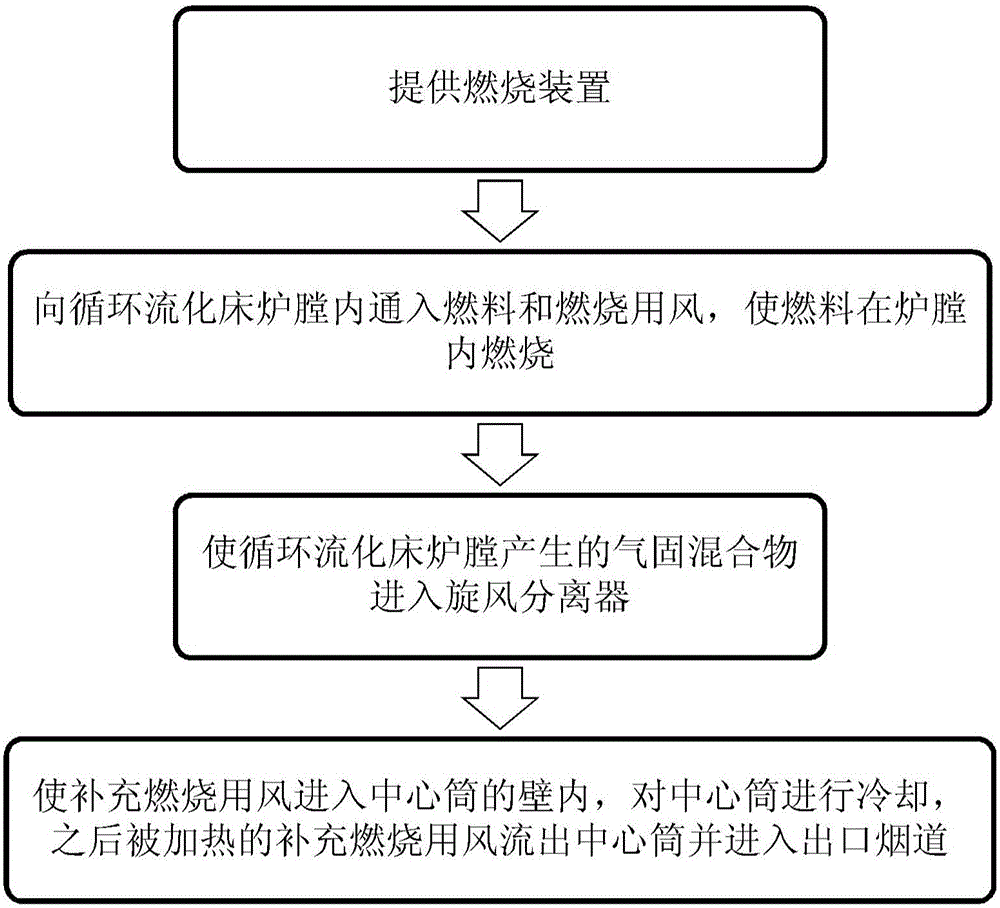

Supplemented-air-cooled central cylinder of cyclone separator

ActiveCN105135423ALower working temperatureReduce material requirementsFluidized bed combustionReversed direction vortexEngineeringCooling down

A central cylinder of a cyclone separator comprises an inner cylinder (72), an outer cylinder (71), an upper sealing plate (73), a lower sealing plate (74), at least one air inlet and at least one air outlet, wherein the inner cylinder and the outer cylinder form a jacket structure; the upper sealing plate (73) seals the space between the inner cylinder (72) and the outer cylinder (71) at the upper end of the jacket structure; the lower sealing plate (74) seals the space between the inner cylinder (72) and the outer cylinder (71) at the lower end of the jacket structure; the air inlets are formed in the outer cylinder (71); and the air outlets are formed in the inner cylinder (72). According to the central cylinder, the inner layer and the outer layer of the central cylinder form the jacket structure, and burning gas is supplemented to flow in the jacket structure, so that the central cylinder is effectively cooled down, the integral rigidity of the central cylinder is improved and deformation under the high-temperature condition is prevented.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

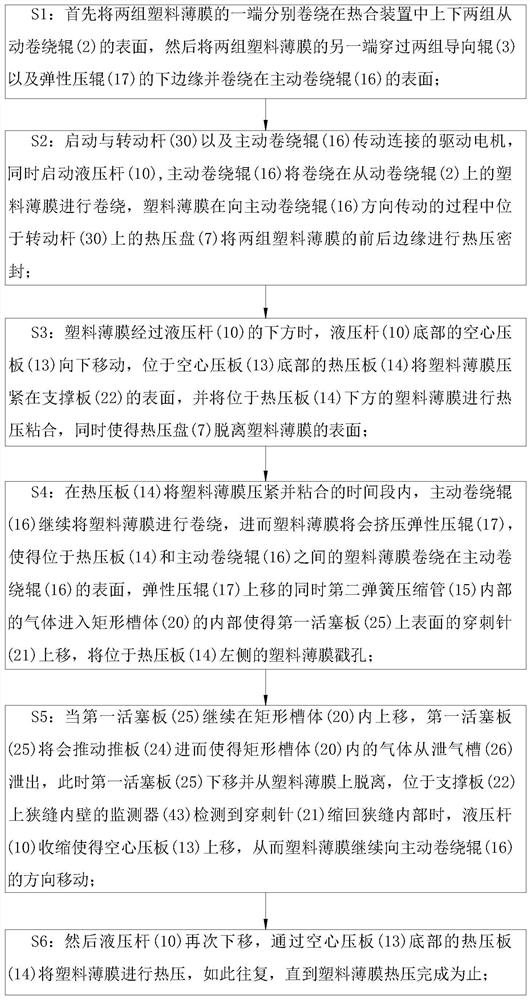

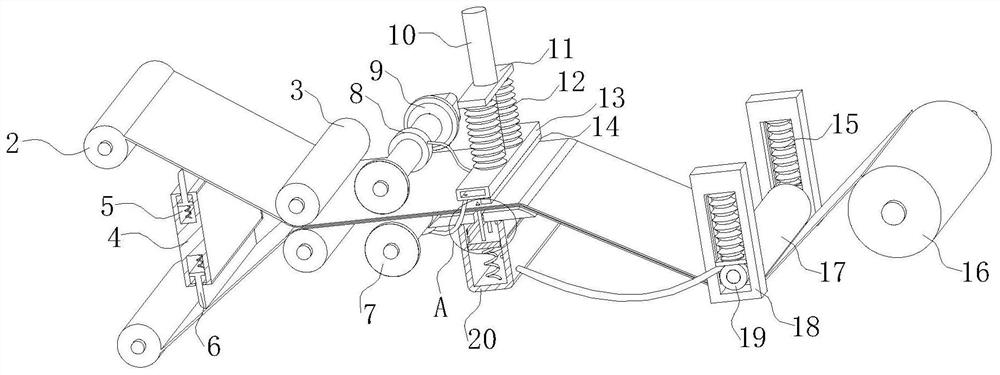

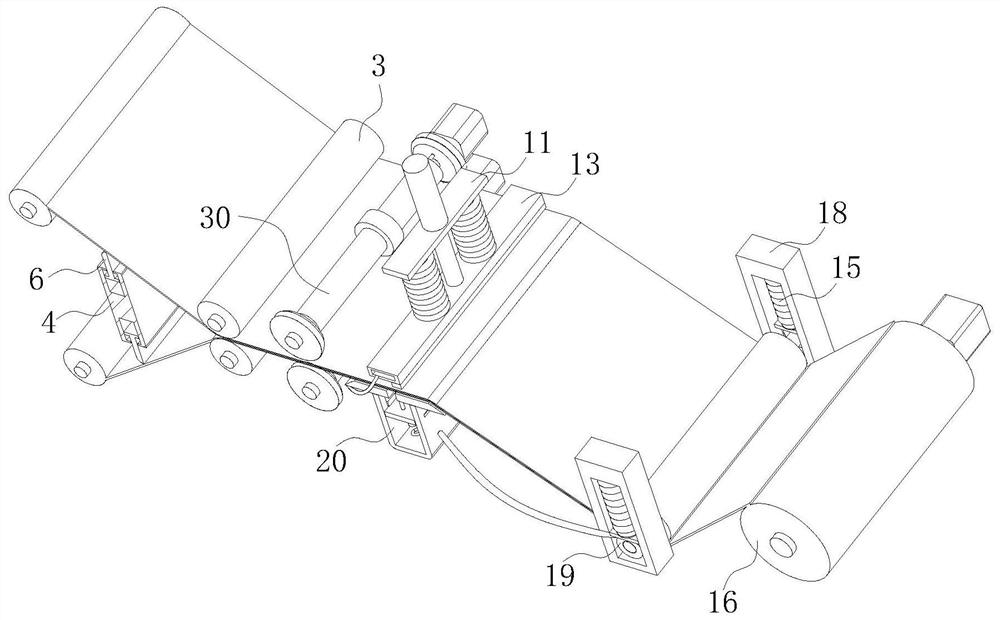

Improved plastic film heat-seal production process

InactiveCN112318880AExtension of timeAvoid accumulationCleaning using toolsElectric machineDrive motor

The invention belongs to the technical field of plastic film heat sealing processes, and particularly relates to an improved plastic film heat-seal production process. The process includes the steps of S1, firstly, respectively winding one ends of two groups of plastic films on the surfaces of an upper group of driven winding rollers and a lower group of the driven winding rollers in a heat sealing device; and then, the other ends of the two groups of the plastic films penetrate through the lower edges of the two groups of guide rollers and an elastic pressing roller and are wound on the surface of a driving winding roller. According to the improved plastic film heat-seal production process, the contact time of a hot pressing plate and the plastic films can be prolonged, and a driving motor in transmission connection with a rotating rod and a driving motor in transmission connection with the driving winding roller do not need to be stopped in the time period, so that the driving motoris prevented from being controlled to stop when a hollow pressing plate moves downwards each time, and therefore, control components and a system are saved; and the situation that the service life ofthe driving motor can be shortened by frequently switching on and off the driving motor, and the energy consumption can be increased is avoided.

Owner:王艳军

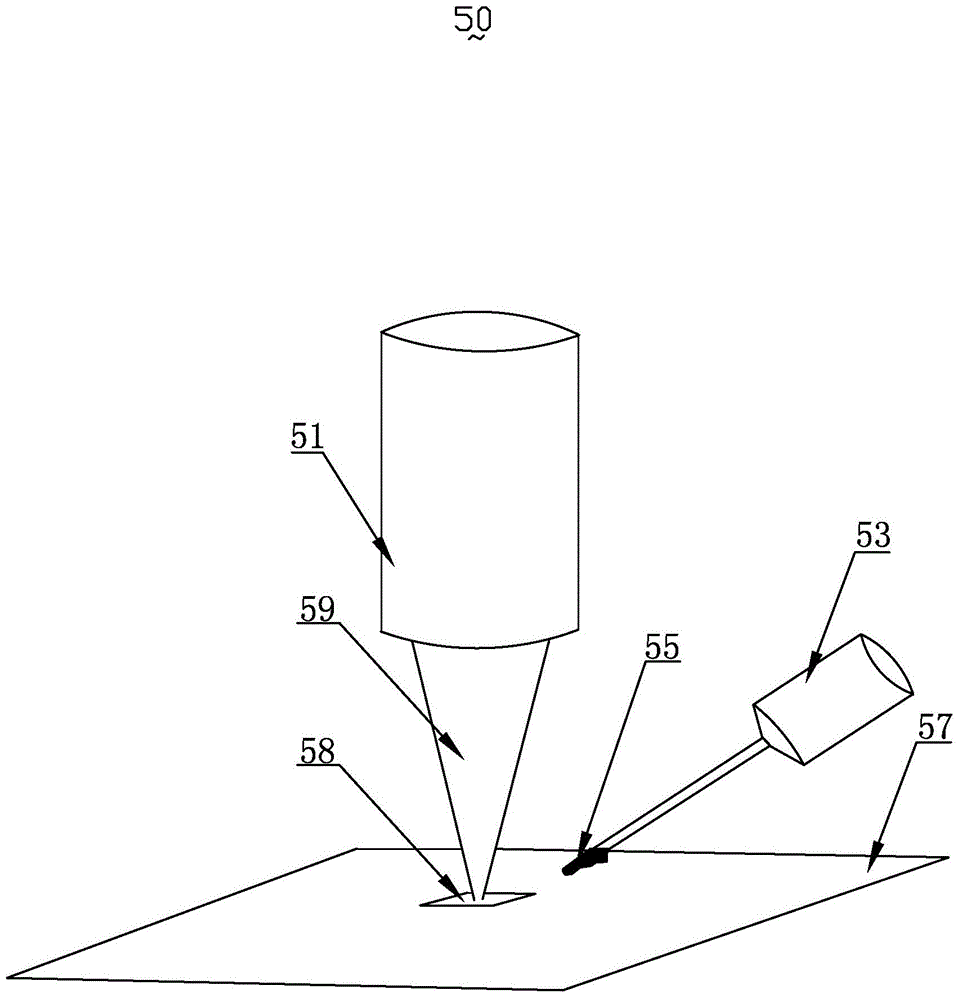

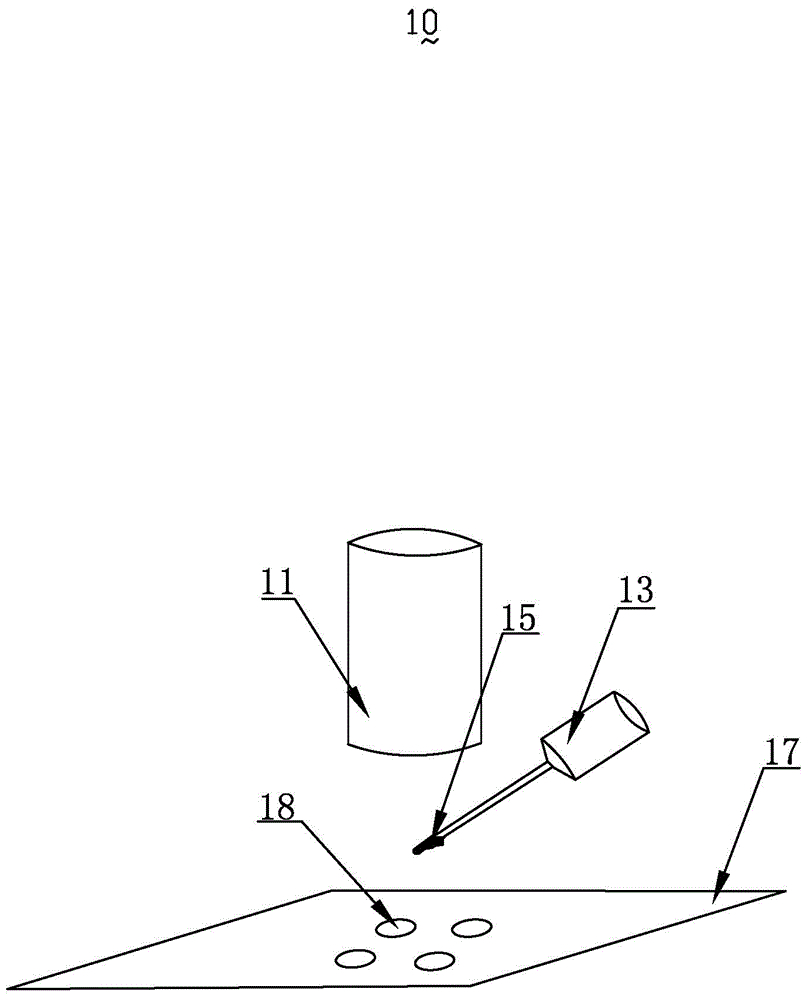

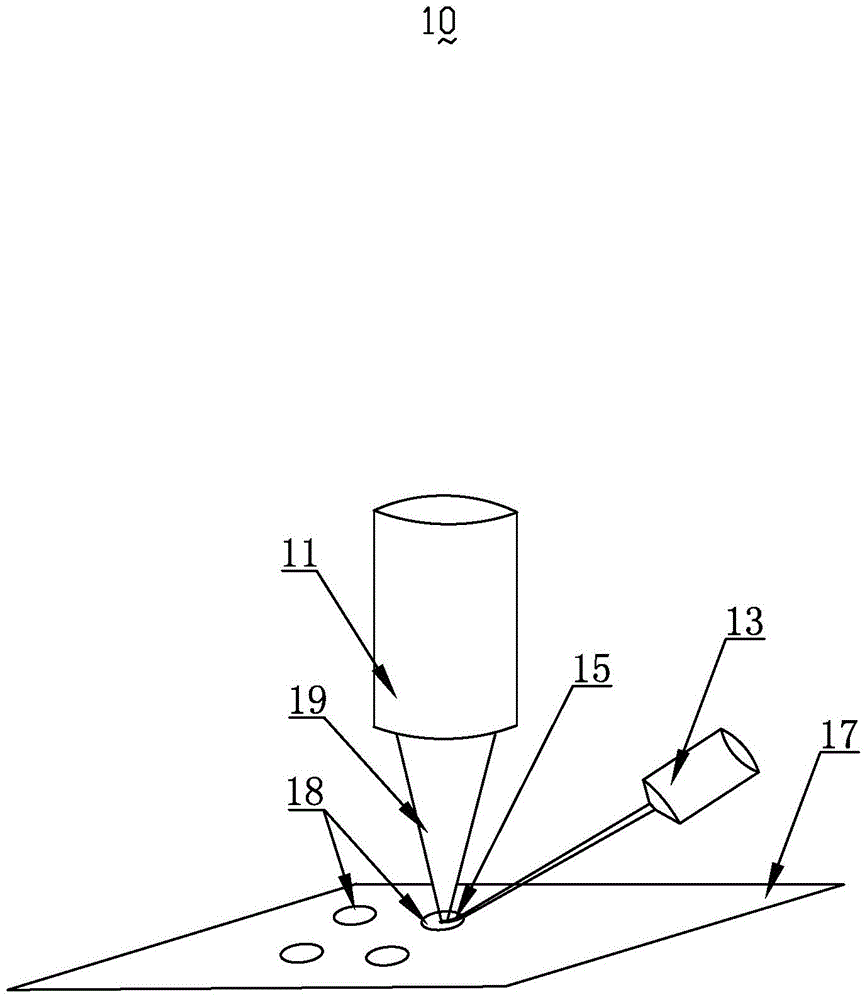

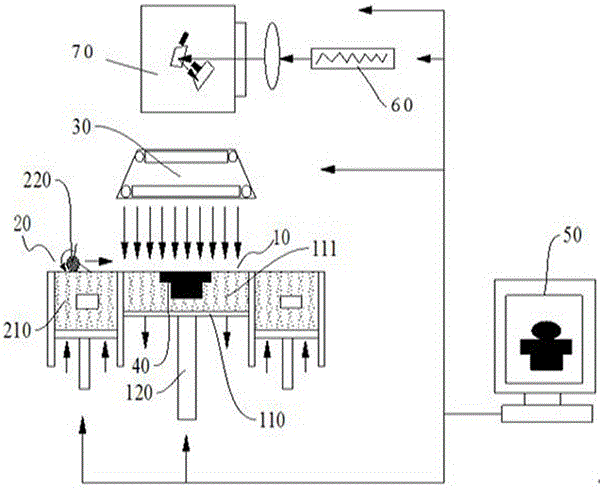

3D printing system for manufacturing human skeletons

InactiveCN105834425AImprove efficiencyLow efficiencyAdditive manufacturing apparatusCeramic shaping apparatusGalvanometerHuman skeleton

The invention provides a 3D printing system for manufacturing human skeletons. The 3D printing system comprises a laser device, a galvanometer connected to the laser device through an optical fiber, a heater for preheating, a worktable device with a forming area and a powder supply device used for supplying powder to the forming area, wherein the heater is arranged above the worktable device, and the powder supply device is arranged on one side of the worktable device. According to the 3D printing system for manufacturing the human skeletons, the SLM forming technology is adopted, and therefore the efficiency of manufacturing the human skeletons is improved, the steps are simplified, and the production cost is greatly lowered.

Owner:BEIJING UREAL 3D TECH CO LTD

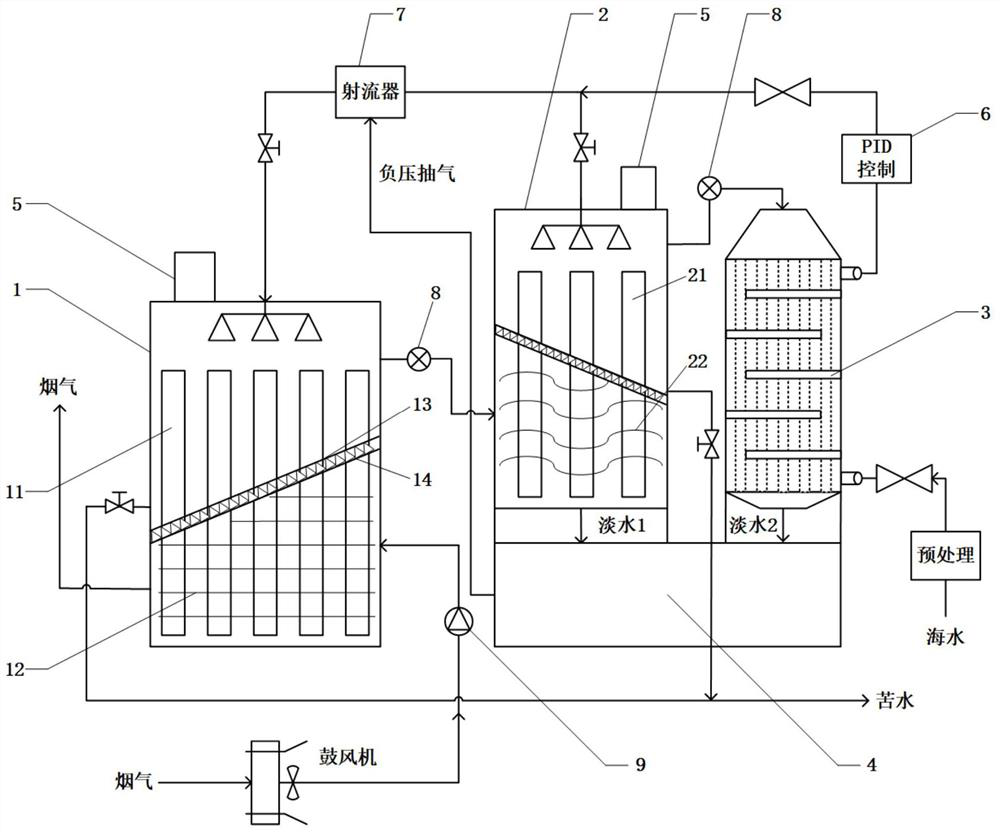

Flue gas temperature control music early warning heat pipe heat exchange device

ActiveCN114526621AAvoid Low Temperature CorrosionImprove utilization efficiencyGeneral water supply conservationSeawater treatmentData connectionTemperature control

The invention relates to a smoke temperature control music early warning heat pipe heat exchange device. A smoke exhaust pipe is provided with a temperature sensor, the temperature sensor is in data connection with a controller, the controller controls the input flow of smoke according to the smoke exhaust temperature, the smoke is conveyed to a cold end through an air blower, and when the detected smoke exhaust temperature is lower than a preset value, the air blower is turned on. If yes, the controller controls the power of the air blower to be increased, the smoke input amount is increased, the controller is connected with a music playing circuit, and the controller plays different sounds according to the detected smoke exhaust temperature. According to the heat exchange device capable of early warning the exhaust gas temperature in advance, intelligent detection is carried out according to the exhaust gas temperature, and meanwhile, intelligent different sound early warning is carried out, so that it is guaranteed that the exhaust gas temperature exceeds the critical value, and low-temperature corrosion is avoided.

Owner:SHANDONG UNIV

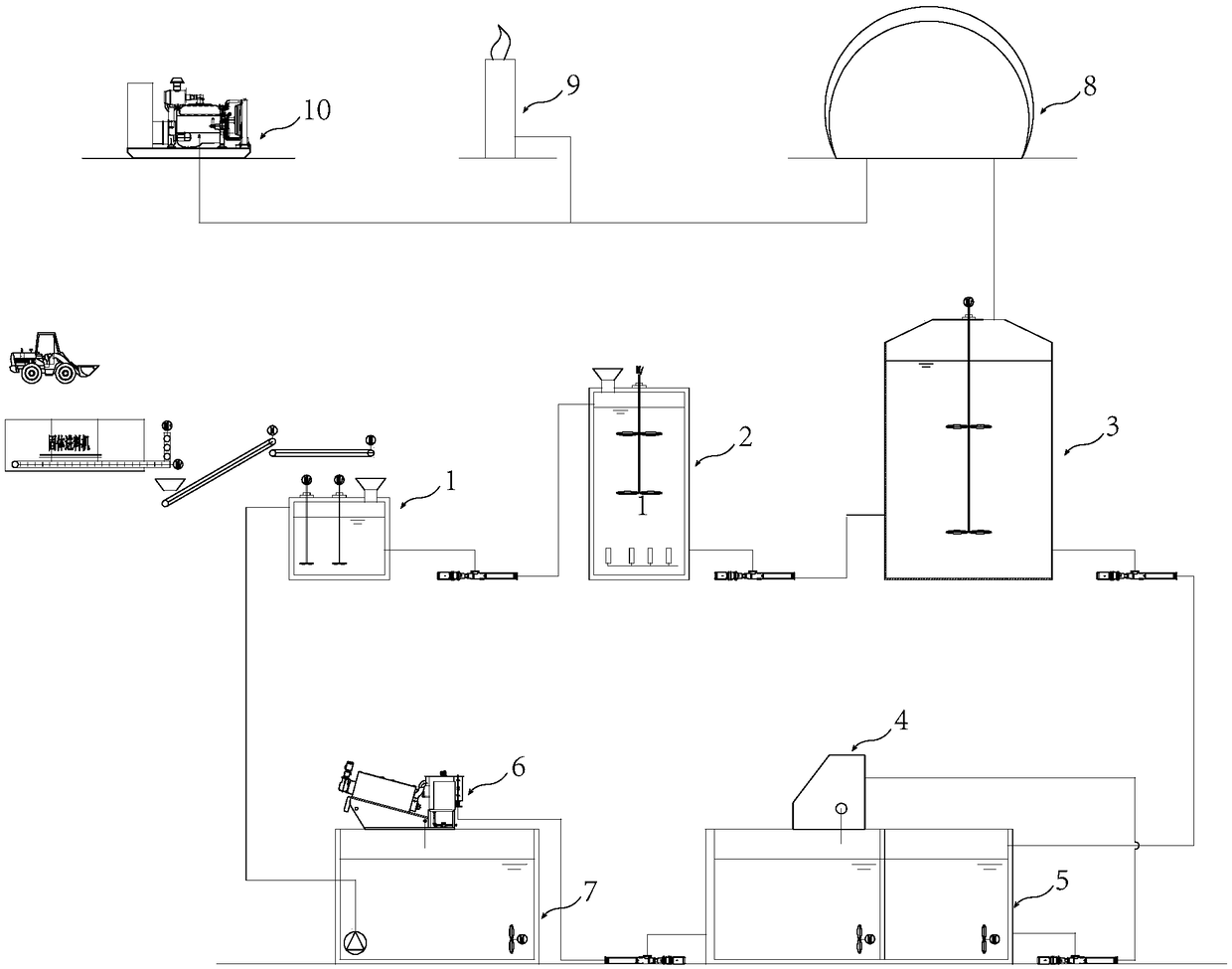

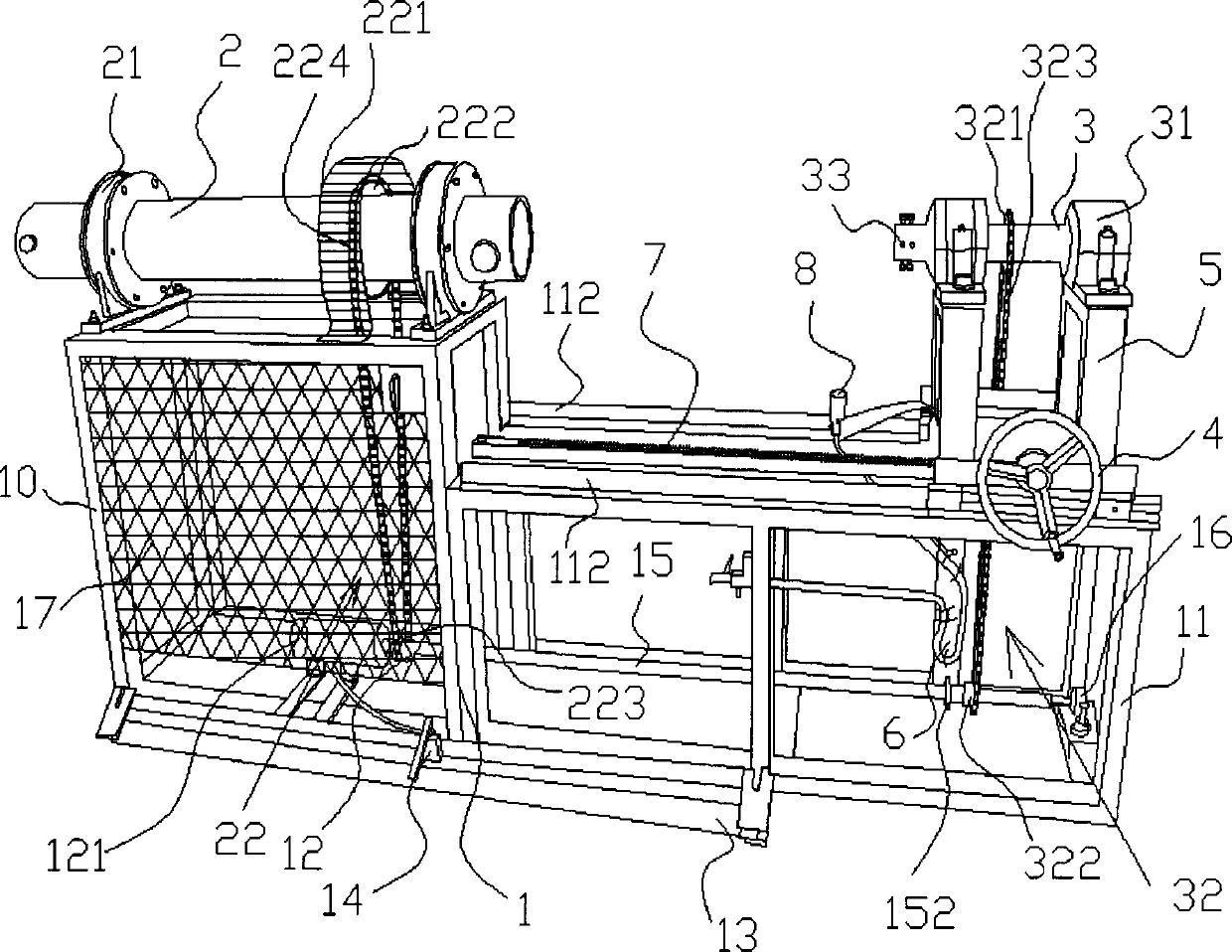

Technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials

InactiveCN108866110ASolve efficiency problemsSolve concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseOxygen

The invention belongs to the technical field of a biogas preparation method, and provides a technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials. The technology method comprises the following steps of material pulping, biological treatment, facultative hydrolyzing and acid production, anaerobic fermenting, solid and liquid separating, refluxing and the like. The technology method solves the problems of low pretreatment efficiency of the lignocellulose-rich materials, overhigh concentration of reflux biogas, and low biogas productionefficiency in the prior art.

Owner:河北京安瑞能环境科技有限公司

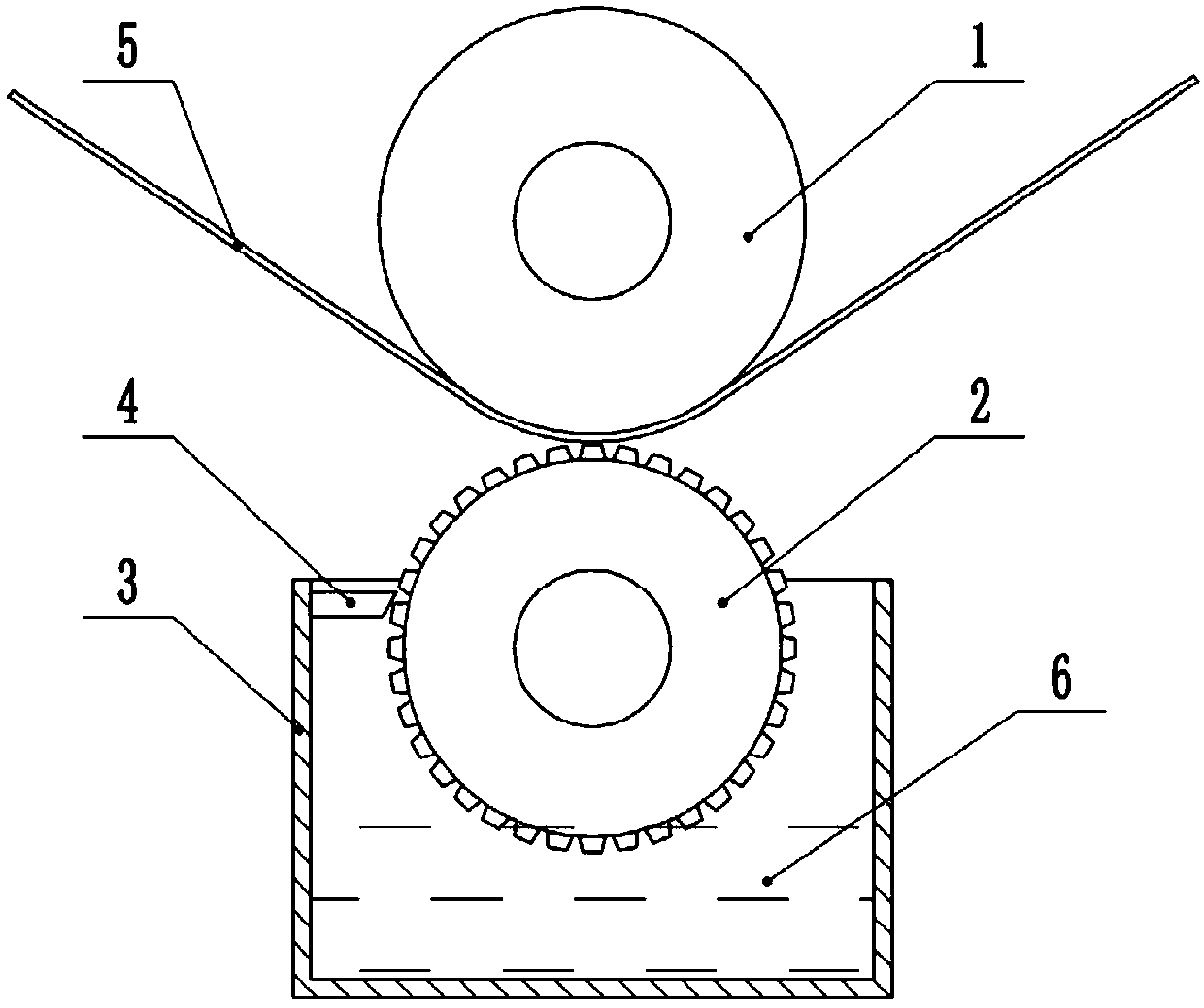

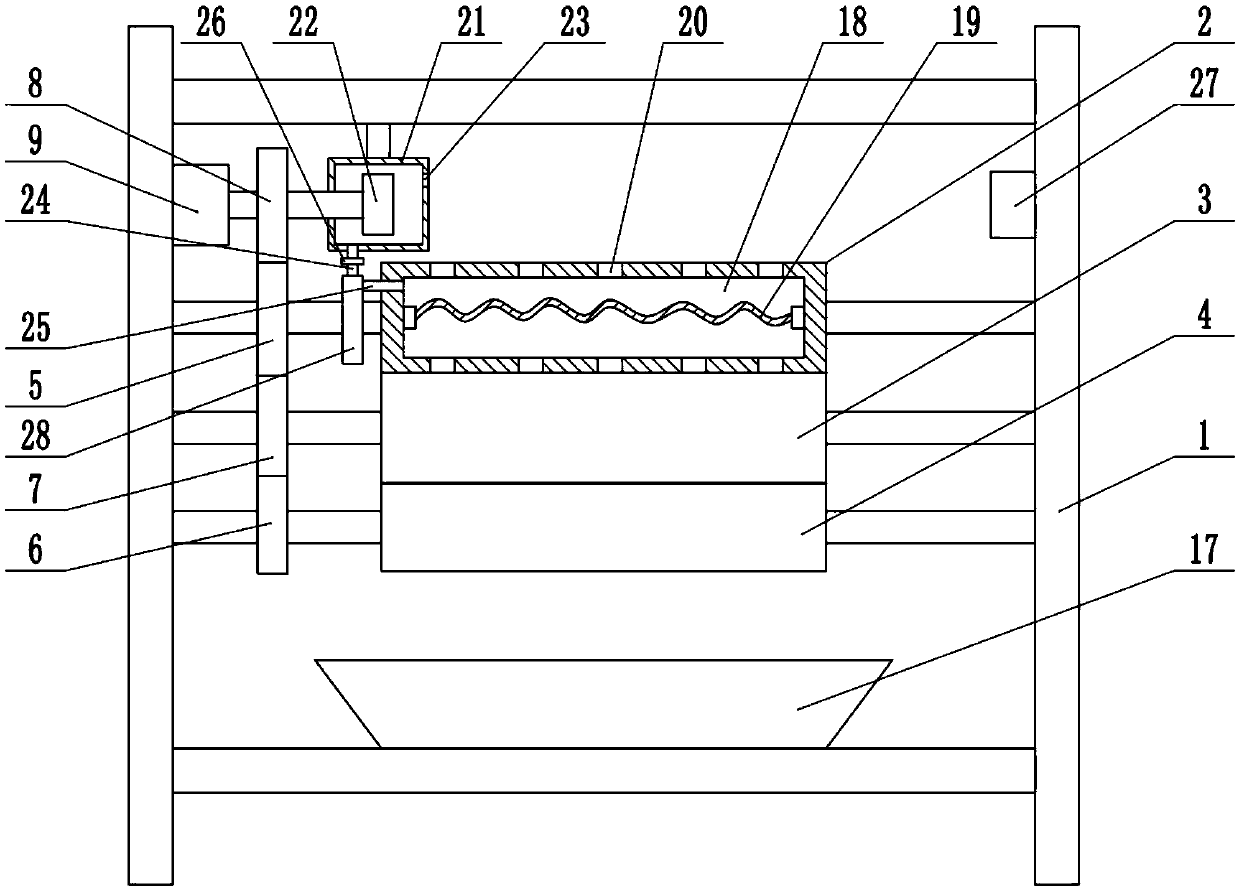

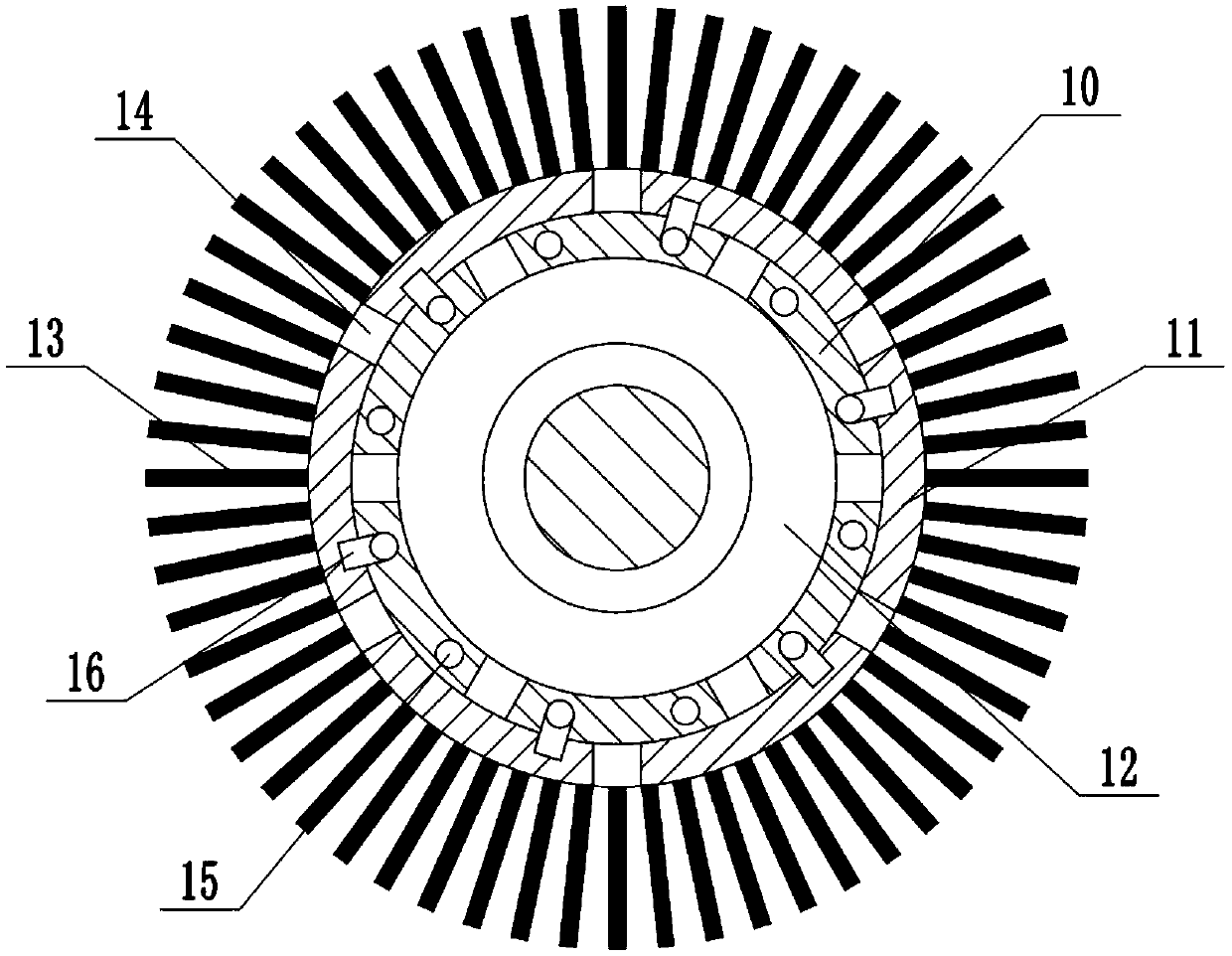

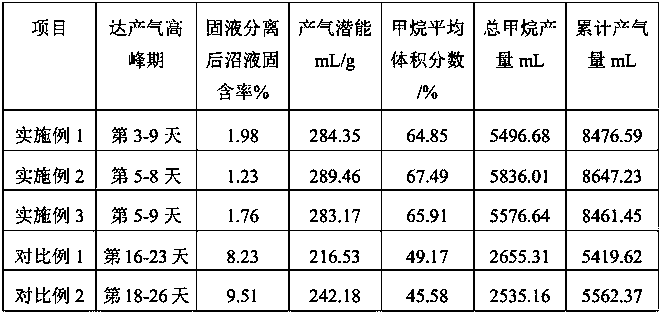

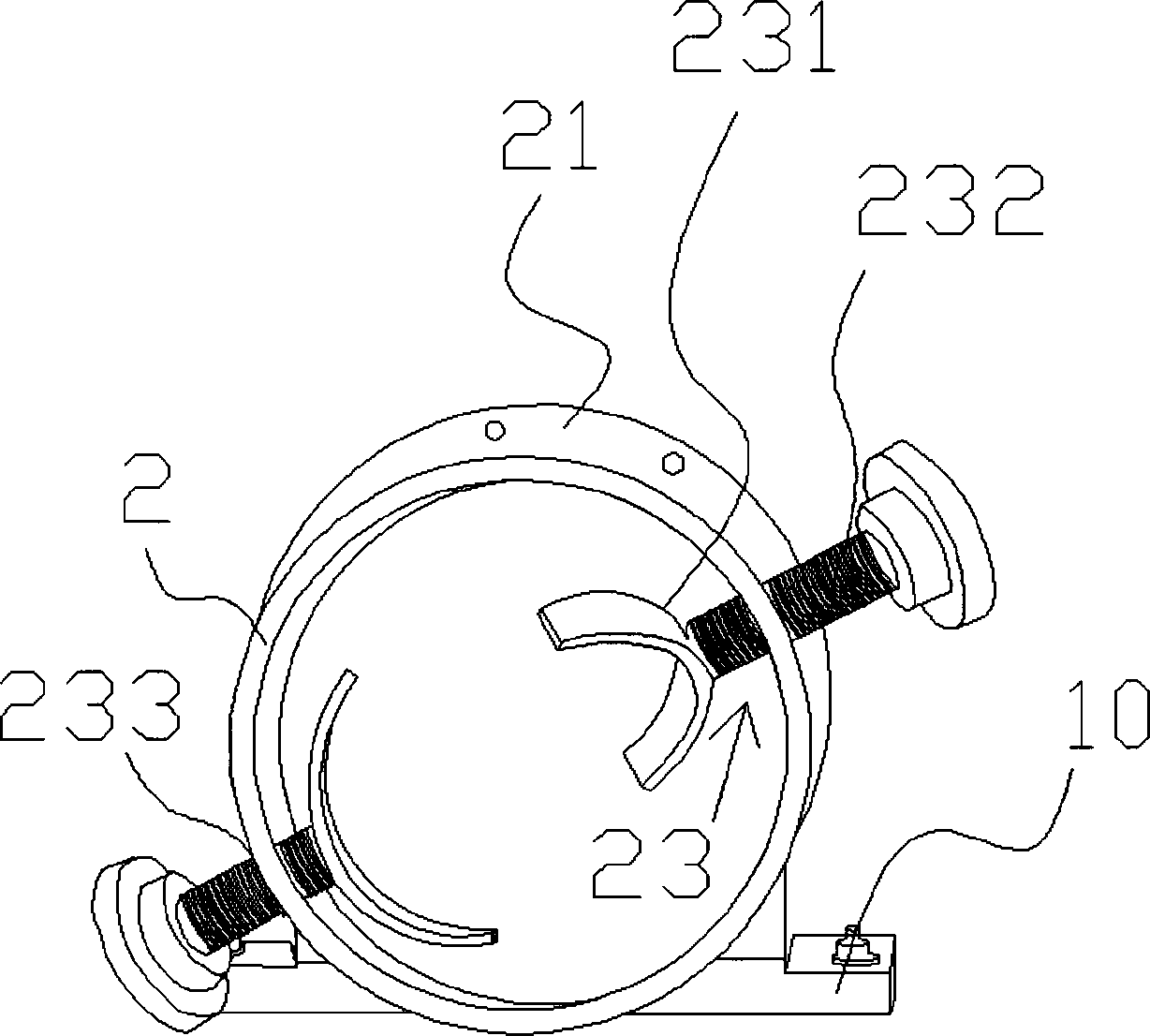

Machine tool for firing multicore laser tube completely made of glass

InactiveCN104211285APrevent explosion hazardPlay a preheating roleGlass reforming apparatusDetentMachine tool

The invention discloses a machine tool for firing a multicore laser tube completely made of glass. The machine tool comprises a first base part, a second base part, a first positioner, a second positioner, a motor and a roller shaft, wherein a fixture is mounted in the first positioner and is sleeved by a first driver and a first bearing sleeve; the second positioner is sleeved by a second driver and a second bearing sleeve; the roller shaft is mounted on the motor; the motor is in transmission connection with the first driver; and the second positioner is in transmission connection with a positioner on the roller shaft, and the first positioner and the second positioner are coaxially arranged. Based on the design, the first positioner is fixedly arranged on the machine tool, and a peripheral gas storing tube is fixed in the first positioner, so that the problem that the gas storing tube is difficult to manually operate because of having an overlarge diameter is solved; and meanwhile, the second positioner can be used for mounting an opening of the glass tube, so that the tube opening can be accurately fired on the end surface of the gas storing tube, and thus two difficult technical problems in the field of laser glass tube manufacturing at present are effectively solved.

Owner:徐桂扬

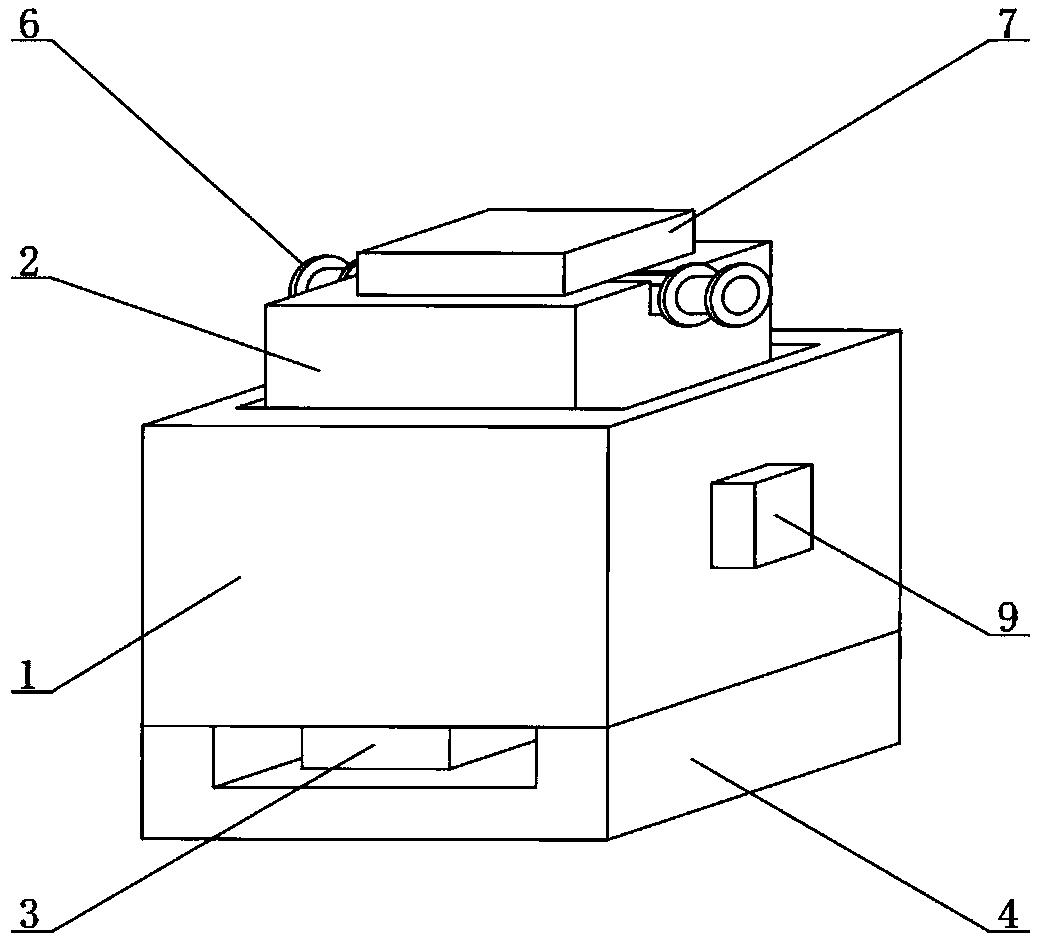

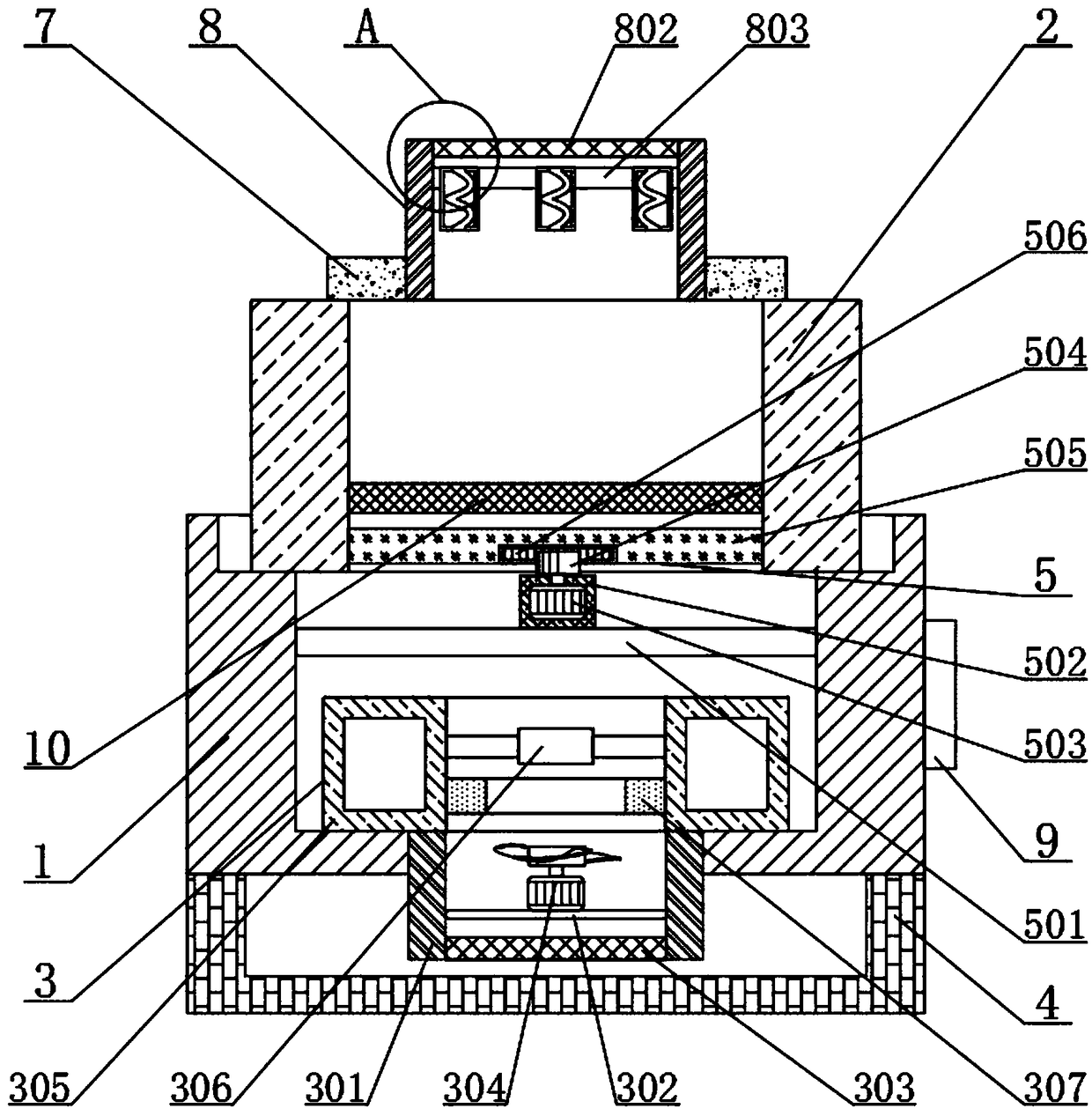

Drying device for honeysuckle production

InactiveCN109373718AAvoid wastingPlay a preheating roleDrying gas arrangementsDrying solid materialsEngineeringExcess heat

The invention relates to the technical field of honeysuckle production, in particular to a drying device for honeysuckle production. The drying device for honeysuckle production comprises a first boxbody, a drying device, a sliding device, a first anti-scalding device and a second anti-scalding device, wherein a second box body is slidably connected to the top end surface of the first box body; the drying device is arranged at the bottom end of the inner side of the first box body; a base is fixedly connected to the bottom end surface of the first box body; the sliding device is fixedly connected to the top end of the inner side of the first box body; and the sliding device is fixedly connected with the second box body, the inner side of the second box body is provided with a metal net fixedly connected with the second box body, and the first anti-scalding device is slidably connected to the top end of the inner side of the second box body. According to the drying device for honeysuckle production, due to the arrangement of a water tank, the characteristics of being large in specific heat capacity and absorbing heat of water and the water storage and heat conduction characteristics of the water tank, excess heat can be absorbed, a role of preheating is played for subsequent drying, and waste of heat energy and electric energy is avoided.

Owner:湖南龟寿堂健康产业发展有限公司

Burning treatment device of waste gas in semiconductor manufacturing process

The invention provides a burning treatment device of waste gas in the semiconductor manufacturing process and relates to the technical field of industrial environment-friendly equipment. The burning treatment device of the waste gas in the semiconductor manufacturing process comprises a dust removing box, wherein a gas inlet pipe is communicated with the left side of the dust removing box; a firstfan is arranged on the gas inlet pipe; a second fan is communicated with the top part of the dust removing box; a dryer is arranged on a first gas inlet pipe; a burning box is communicated with the right end of the first gas inlet pipe; a ceramic heat-transferring plate is fixedly connected with the interior of the burning box; a third fan is communicated with the left side of the burning box; aliquefied-gas box body is fixedly arranged at the top part of the burning box; a gas outlet pipe is communicated with the right side of the burning box. The burning treatment device of the waste gas in the semiconductor manufacturing process provided by the invention has the beneficial effects that by arrangement of the dust removing box, the gas can pass the device more smoothly; by arrangement of the device box, the acid-base neutralization is carried out on the primarily-filtered gas; by arrangement of the burning box, fully-burnt gas can enter the atmosphere through a gas outlet.

Owner:安徽京仪自动化装备技术有限公司

Combustion furnace for biomass burning

ActiveCN109404887AImprove combustion efficiencyAvoid safety accidentsMachines/enginesSolid fuel combustionCombustion chamberTurbine blade

The invention discloses a combustion furnace for biomass burning. The furnace comprises a furnace body, a feeding bin, a turbine blade and a gas storage cylinder. A combustion chamber is arranged in the furnace body, the right side of the combustion chamber is connected with a pressurizing bin, a gas discharge pipeline is arranged below the pressurizing bin, a cooling bin is connected below the combustion chamber, a transmission box is arranged in the combustion chamber, a conical gear is fixed to the left end of the fixed shaft, the furnace body is connected with the upper end of the feedingbin through a smoke pipeline mounted on the left side, the turbine blade is arranged at the upper end of the outer side of a hollow shaft, a stirring blade is arranged at the lower end of the hollow shaft, and the upper end of the gas storage cylinder is connected with the hollow shaft through a gas conveying pipe. According to the combustion furnace for biomass burning, smoke in the combustion chamber is used for driving paddle blades and the turbine blade to rotate, uniform discharging and oxygen supply are achieved, heat in the smoke can carry out combustion supporting on the fuel, and thesubsequent combustion efficiency is improved.

Owner:新昌县小将永进轴承厂

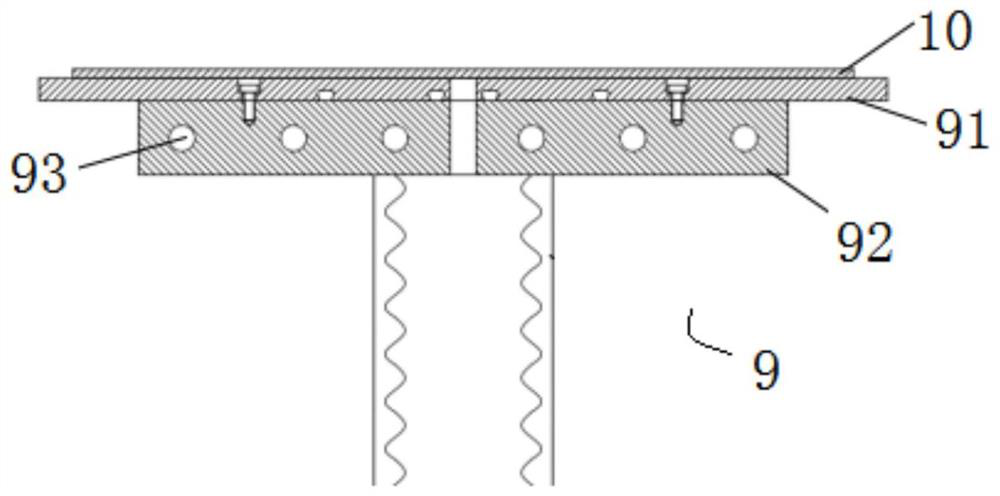

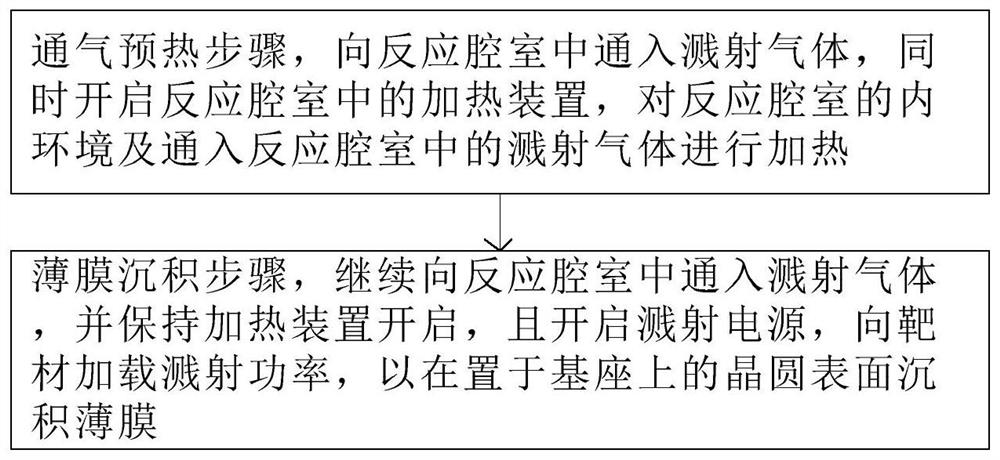

Thin film deposition method

PendingCN114369804APlay a preheating roleImprove thickness uniformityVacuum evaporation coatingSputtering coatingWaferPhysical chemistry

The invention provides a thin film deposition method which comprises the following steps: a ventilation preheating step: introducing sputtering gas into a reaction chamber, starting a heating device in the reaction chamber at the same time, and heating the internal environment of the reaction chamber and the sputtering gas introduced into the reaction chamber; a thin film deposition step: continuously introducing sputtering gas into the reaction chamber, keeping the heating device to be turned on, turning on a sputtering power supply, and loading sputtering power to the target material so as to deposit a thin film on the surface of the wafer arranged on the base; wherein the heating power output by the heating device in the ventilation preheating step is smaller than the heating power output in the thin film deposition step. According to the thin film deposition method provided by the invention, the problem of insufficient grain growth energy in the central area of the wafer can be solved, so that the thickness uniformity, the density and the density uniformity of the thin film can be improved, and the corrosion uniformity of the thin film can be further improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

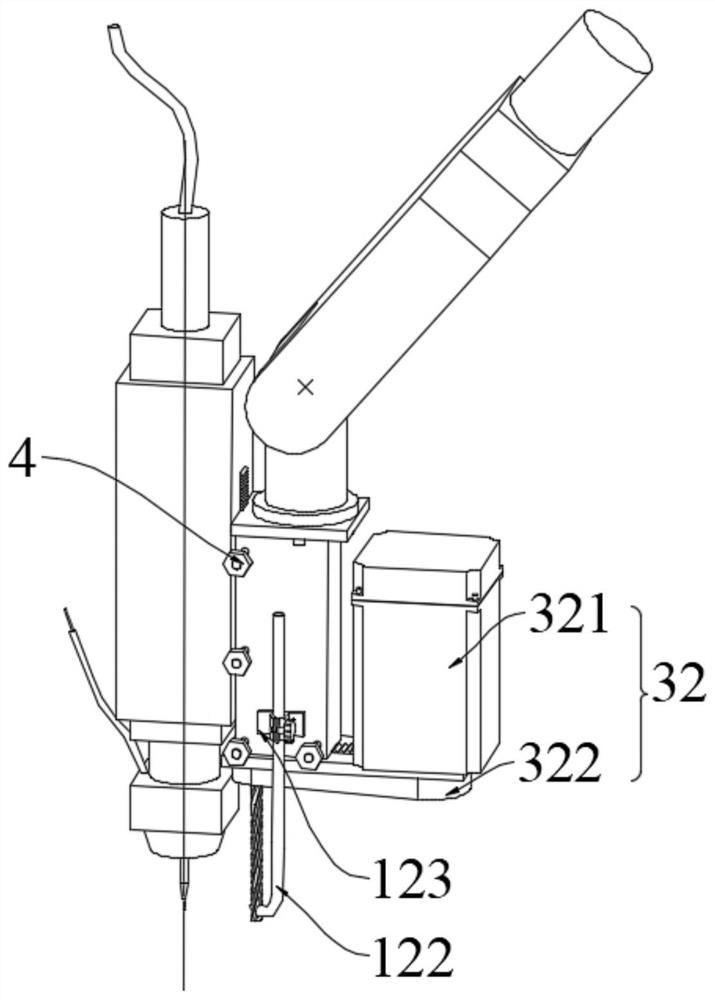

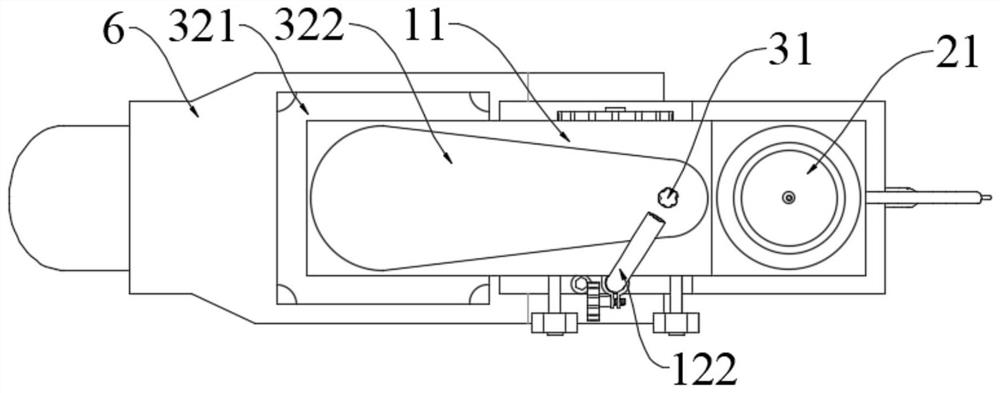

Laser-assisted additive and subtractive composite machining device and method

PendingCN113275737AImproved macro and micro formingQuality improvementOther manufacturing equipments/toolsLaser beam welding apparatusEngineeringLaser assisted

The invention provides a laser-assisted additive and subtractive composite machining device and method. The device comprises a frame body, a laser-assisted additive manufacturing assembly and a subtractive cutting assembly, wherein the laser-assisted additive manufacturing assembly comprises a laser head and a wire feeding nozzle, a first guide rail in the vertical direction is arranged on the side face of the laser head, and the wire feeding nozzle is arranged at the tail end of the laser head, and suitable for feeding a welding wire to a laser focus of an additive manufacturing laser source; the frame body comprises a support and a bracket, the bracket and the laser head are arranged in parallel; a first movement unit suitable for being matched with the first guide rail is arranged on the side face of the bracket; the first movement unit and the first guide rail are arranged in a sliding mode so as to adjust the laser head to move in the vertical direction relative to the bracket; the bracket is perpendicularly arranged on the support and connected with the support in a sliding mode, so as to adjust the distance between the support and the laser head; and the subtractive cutting assembly comprises a milling tool, and the milling tool is parallel to the laser head and arranged on the side, away from the bracket, of the support. The device is compact in structure, low in manufacturing cost and suitable for field operation.

Owner:广东中科德弗激光科技有限公司

Clean environment-friendly calcining furnace and method for indirectly treating dolomite

The invention provides a clean environment-friendly calcining furnace and method for indirectly treating dolomite. The calcining furnace comprises a gas trapping pipeline and a furnace body, wherein the furnace body comprises a blanking bin, a hearth and a discharging bin; a calcining area is formed in the hearth; the furnace body further comprises a heating device; a sealing plate for sealing a furnace opening of the hearth is arranged at the top of the hearth, and a communicating opening is formed in the sealing plate; a blanking port of the blanking bin communicates with the calcining area through the communicating opening; an exhaust cavity is formed between the outer wall of the blanking bin and the sealing plate through surrounding of a surrounding plate, and the exhaust cavity communicates with the calcining area through the communicating opening; and the gas trapping pipeline communicates with the exhaust cavity. According to the invention, the activity and purity of calcined dolomite can be improved, the impurity content of flue gas is reduced, high-purity CO2 gas is obtained, and the energy consumption required for calcining the dolomite can also be reduced.

Owner:CENT SOUTH UNIV

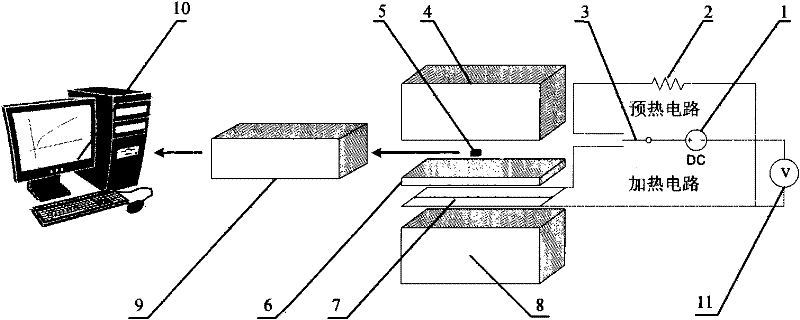

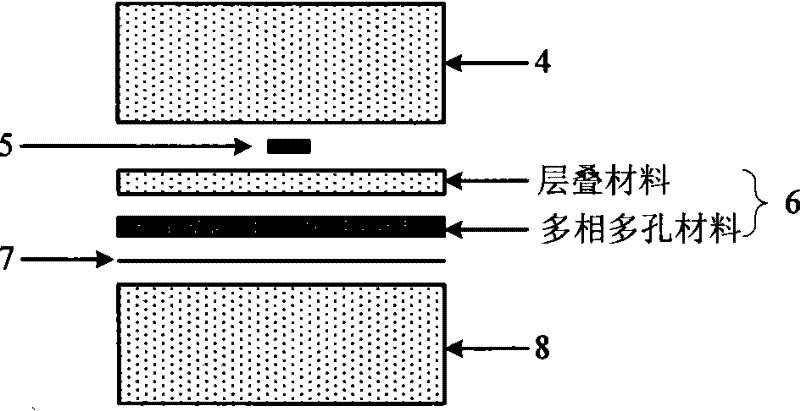

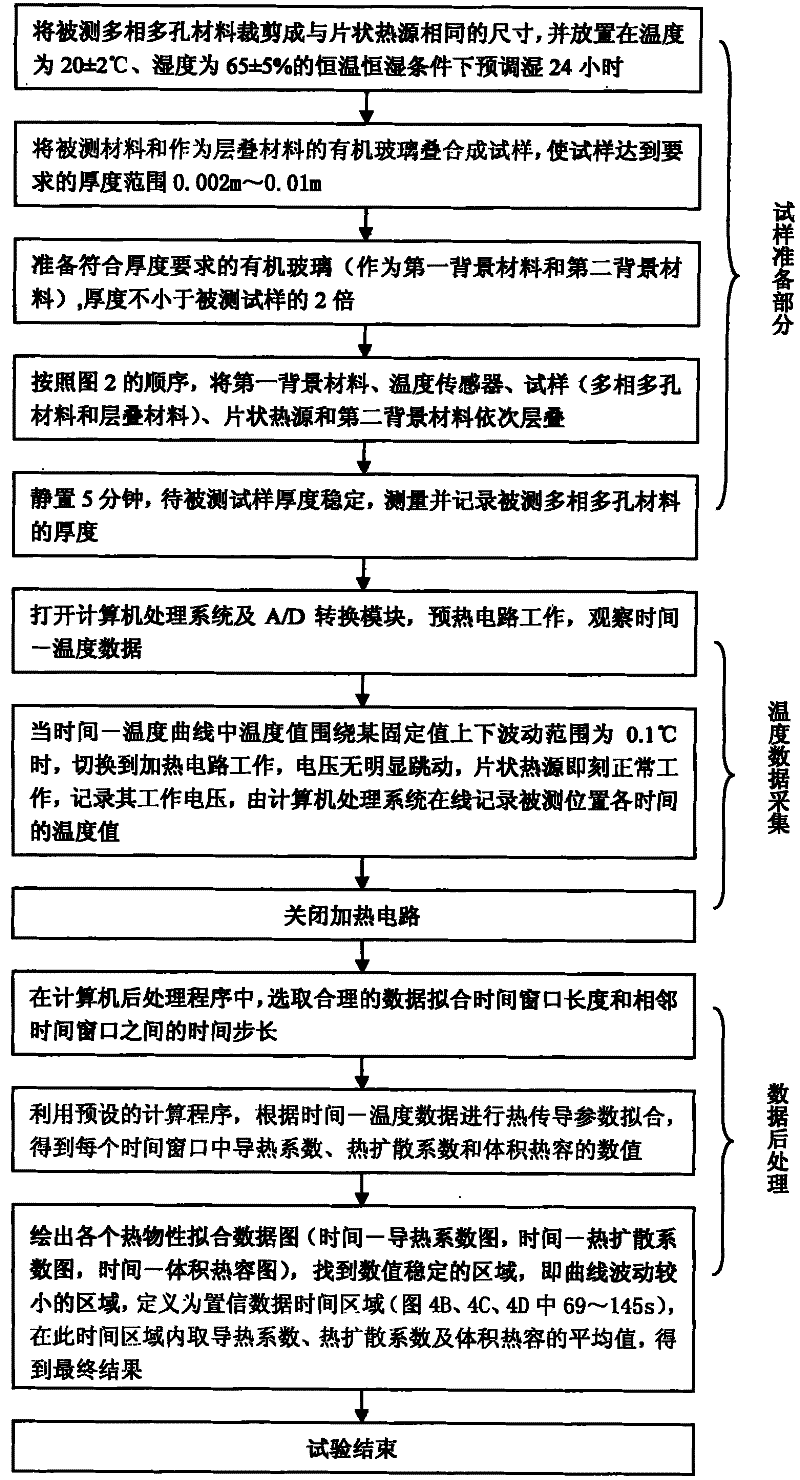

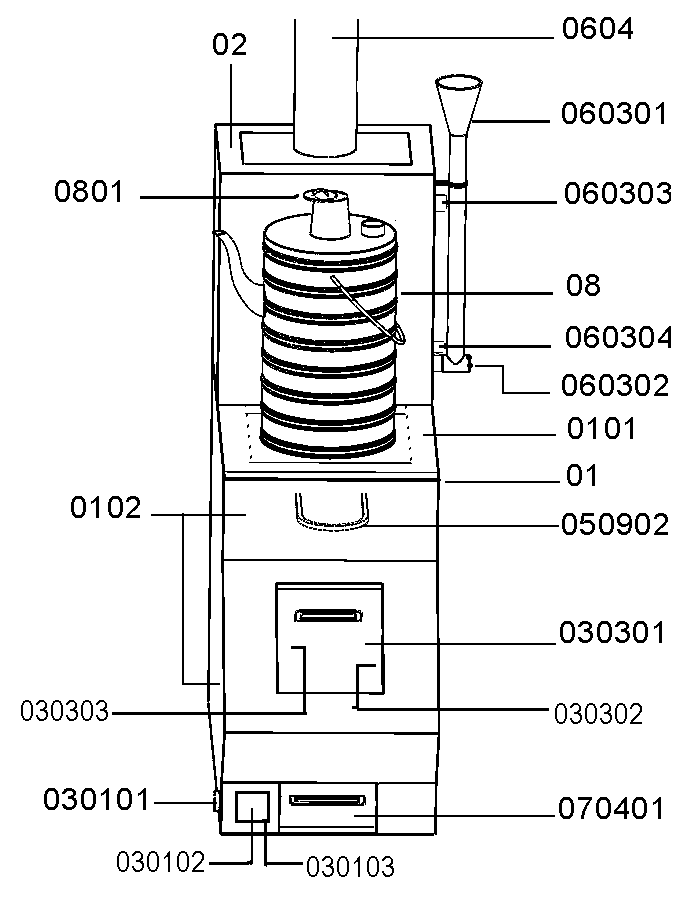

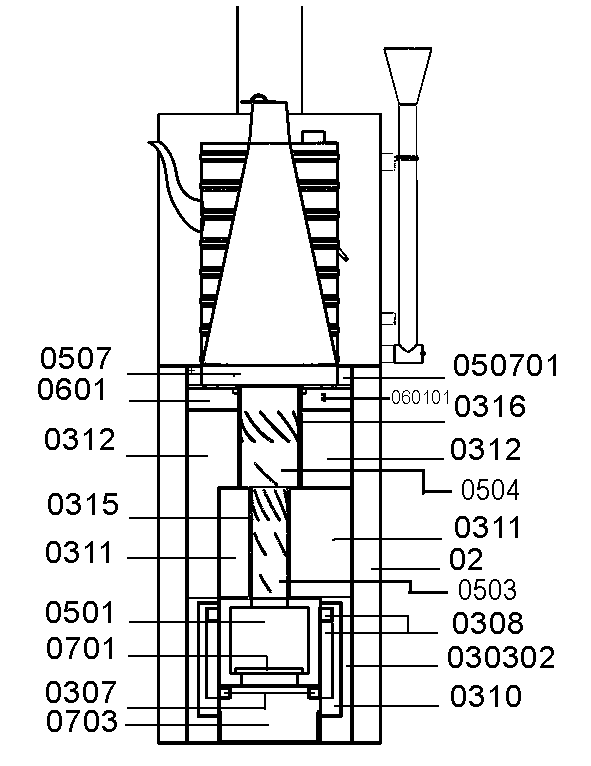

Unsteady-state measuring device and method of heat conduction performance of multi-phase porous material

InactiveCN101706463BSolve the problem of water evaporationThe effect of heat leakage is smallMaterial thermal conductivityMaterial heat developmentDiffusionThermal diffusion coefficient

The invention relates to an unsteady-state measuring device and a method of heat conduction performance of a multi-phase porous material. The device comprises a sample heating device, a data acquisition system and a computer processing system. The invention is characterized in that the sample heating device consists of four parts, namely a heating circuit, a preheating circuit, a sample and a background material, wherein the sample consists of a measured multi-phase porous material and a laminated material (organic glass), and the organic glass is selected as a first background material and asecond background material for measurement, thus forming the important advantage of the invention that various multi-phase porous materials from low volume density to high volume density can be measured. The testing method can be divided into three major parts, namely preparation of the sample and the background materials, temperature data acquisition and data post processing, and comprises six specific steps. The device can measure heat conduction coefficients, heat diffusion coefficients and volume heat capacity of the multi-phase porous sample, and is especially applicable to the multi-phase porous materials with low volume density. The device is simple and the testing speed is fast and can be finished only by minutes.

Owner:DONGHUA UNIV

Biomass cooking heating furnace

InactiveCN104791851AIncrease secondary air distributionFire fastDomestic stoves or rangesLighting and heating apparatusCombustion chamberCoal

The invention relates to a biomass cooking heating furnace. The biomass cooking heating furnace can be formed by one water heating unit and multiple cooking units to achieve multiple purposes. By adopting the double-mode design of natural air distribution and constraint air blasting, various firepower requirements can be met. By combining oxygenizing limiting and multi-stage oxygen supplying and combusting, according to the concentration of combustible gas, the amount of the oxygen supplying can be automatically optimized. According to step combining of oxygen supplying pipes with different shapes and apertures, the higher turbulence disturbance effect can be generated to prompt the sufficient degree of oxygen fuel gas mixing. Due to a fin type heat exchanger, the heat-exchange area is greatly increased. Due to special combining of a cooking combustor and a transverse exhaust gas channel, a hollow burning pot can be used inside, and efficient water boiling is carried out. Due to the wide adaptive capacity on the biomass fuel, the biomass cooking heating furnace can be used in the wide agricultural and pastoral area, can be matched with biomass forming fuel to replace a coal-based furnace which has the polluting emission, and can be popularized in cities and towns.

Owner:庄彦峰

Black tea de-enzyming device

PendingCN105961655APromote combustionPlay a preheating rolePre-extraction tea treatmentBiotechnologyMechanical engineering

The invention belongs to the technical field of black tea processing, and discloses a black tea de-enzyming device. The black tea de-enzyming device comprises a de-enzyming box, wherein a feeding opening is formed in a side wall of the upper side of the de-enzyming box; a first sealing cover is arranged at the position of the feeding opening; a hydrogen inlet tube is rotatably arranged on the side wall of the left side of the de-enzyming box; a hydrogen outlet tube is fixedly arranged on the side wall of the right side of the de-enzyming box; the side wall of the de-enzyming box has a double-layered structure; the double-layered structure comprises an inner-layer wall and an outer-layer wall; a group of ventilating holes are uniformly distributed in the inner-layer wall; apertures of the ventilating holes is 0.5-1 mm; an air sucking opening is formed in the lower side of the outer-layer wall; a stirring box plate is further arranged in the de-enzyming box, is fixedly connected with the hydrogen inlet tube, and is rotatably connected with the hydrogen outlet tube; a cavity in the stirring box plate communicates with the hydrogen inlet tube and the hydrogen outlet tube; and the hydrogen outlet tube extends to the air sucking opening. By the black tea de-enzyming device provided by the invention, the technical problems that at present, water is not sprinkled evenly during de-enzyming of the black tea, and the black tea is easily broken or hands of operators are easily scalded during de-enzyming are solved.

Owner:GUIZHOU QIANYUNFU ECOLOGICAL TEA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com