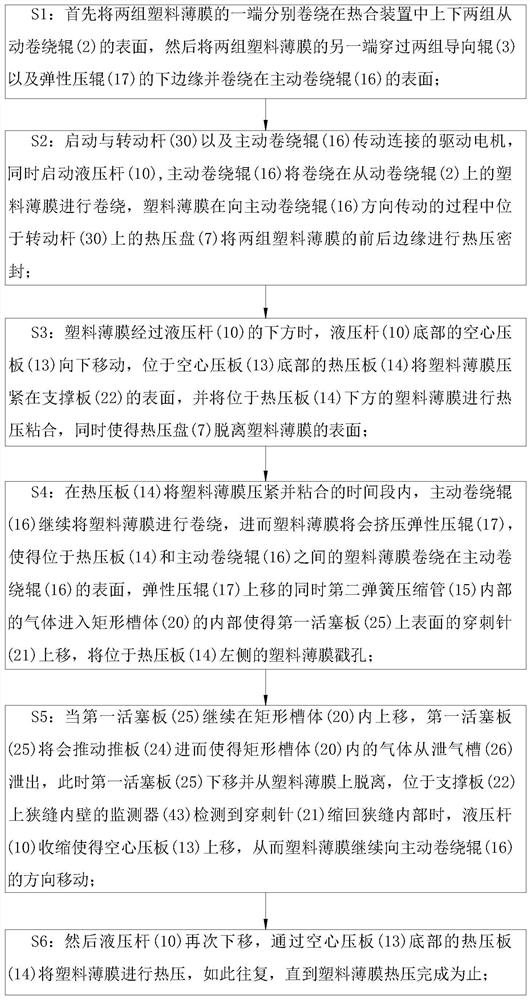

Improved plastic film heat-seal production process

A technology of plastic film and process, which is applied in the field of plastic film heat sealing production improvement process, can solve the problems of reducing the service life of the driving motor and increasing energy consumption of the driving motor, so as to save control components and systems, increase energy consumption, and prolong contact the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

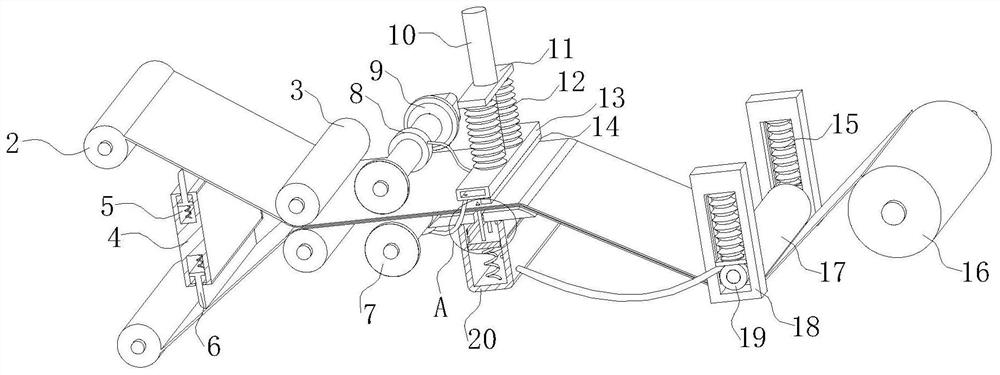

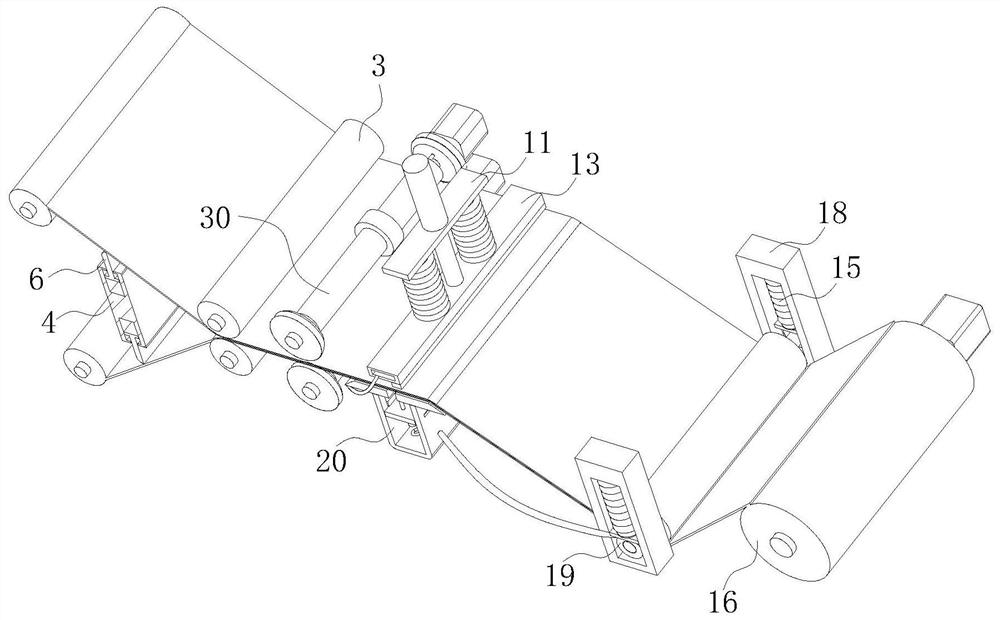

[0052]As an embodiment of the present invention, the punching mechanism includes a second spring compression tube 15, a rectangular groove body 20, a puncture needle 21 and a first piston plate 25; the top and bottom ends of the second spring compression tube 15 Are respectively fixedly connected to the top inner wall of the rectangular frame 18 and the upper surface of the movable plate 38; the rectangular groove body 20 is fixedly connected to the bottom of the support plate 22; the bottom of the rectangular groove body 20 is provided with a first piston plate 25 through a spring The upper surface of the first piston plate 25 is uniformly provided with puncture needles 21; the support plate 22 is provided with a slit at the position facing the puncture needle 21; the inner wall of the slit is provided with a monitor 43; the rectangular groove The bottom of the body 20 communicates with the bottom of the second spring compression tube 15 through a connecting pipe fitting; the recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com