Brown fused alumina, supporting production equipment and production method thereof

A production equipment and technology of brown steel, applied in the field of abrasives, can solve the problems of high cost in the smelting process, large environmental impact, poor quality of finished products, etc., and achieve the effects of fewer types of raw materials, lower production costs, and fewer impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A brown corundum, including 0.01% to 6.1% of silicon dioxide, 2.5% to 4% of titanium dioxide, and 90% to 97% of alumina powder. Specifically in this embodiment, 1.5% of silicon dioxide, 2.5% of titanium dioxide, and 96% of alumina powder are included.

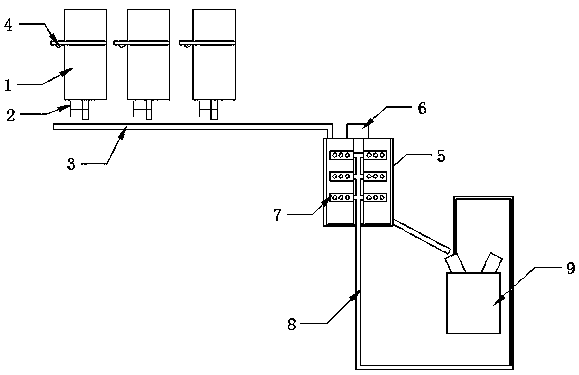

[0035] A kind of production equipment of processing above-mentioned brown corundum, see Figure 1 to Figure 2 , including a feeding device, along which a batching device, a stirring device, a blanking device and a smelting device are sequentially installed;

[0036] The feeding device includes a conveyor belt 3, and the surface of the conveyor belt 3 is provided with fish scale bearing plates 10, and the crimping direction between the fish scale bearing plates 10 is opposite to the displacement direction of the material to prevent gap storage.

[0037] The batching device includes at least three batching bins 1, the entrance of the batching bin 1 is equipped with a crushing mechanism, the outlet of the batching bin 1 is...

Embodiment 2

[0055] Example 2, 0.1% to 7% of chromium oxide is added to brown corundum, in this example, 3% of silicon dioxide, 3% of titanium dioxide, 3% of chromium oxide and 91% of aluminum oxide pink. The electricity required for the whole production process is 1600 degrees per ton, which is much lower than the previous electricity consumption of 4200 degrees per ton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com