Incineration device for treating multi-variety and multi-phase wastes

An incineration device and waste technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as adverse effects of cement production, difficulty in incineration temperature adjustment, single material performance, etc., to achieve suitable technical transformation and application promotion, reduce Fuel consumption, effect of increasing disposal scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

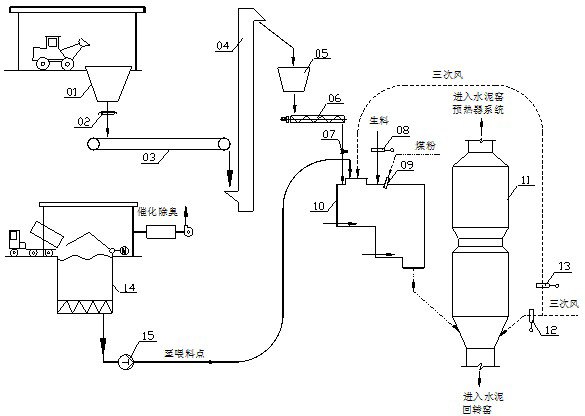

[0032] like figure 2 As shown, municipal solid waste is fed into the belt conveyor 03 through the discharge hopper 01 in the storage shed, and the flow is controlled by the discharge gate valve 02 in the middle. Then the waste is transported to the feeding hopper 05 through the elevator 04, and then unloaded from the feeding hopper 05 to the screw conveyor 06 and then fed into the incinerator 10, and the feeding pipe from the screw conveyor 06 to the incinerator adopts rotary feeding Device 07 carries out air lock.

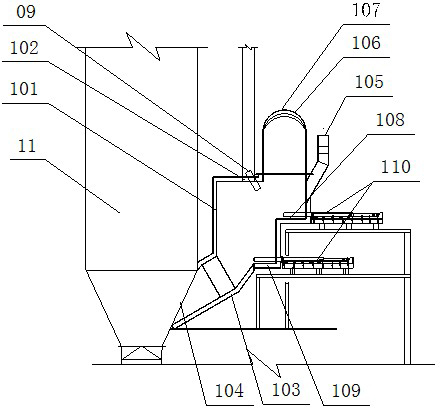

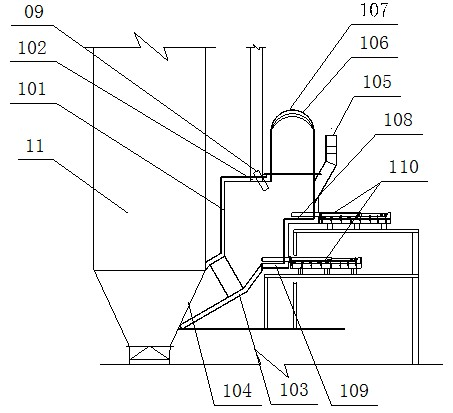

[0033] The sewage plant sludge, waste oil sludge, waste engine oil, waste lubricating oil, etc. are cached in the storage bin 14 to form a paste, and the waste is transported to the paste material port 106 of the incinerator 10 by the plunger pump 15 . The top of the incinerator is provided with a tertiary air (the temperature of the tertiary air is about 850-900°C) high-temperature tuyere 107, a raw meal port 102, and a burner 09. When the temperature in the in...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, and its difference is that the waste to be burnt is waste tires, and the time of staying in the incinerator is different. After ~15 minutes, if the degree of incineration reaches the requirements, then the waste is pushed into the second-stage stocker 109 by the pushing device 110 of the first-stage stocker 108, and is incinerated on the second-stage stocker 109 for 10~ Incineration was complete after 15 minutes.

Embodiment 3

[0039] This embodiment is basically the same as Embodiment 1, the difference is that the wastes burned are waste plastics, waste textiles, and waste paper, and the residence time in the incinerator is different. Incineration, after incineration for 1 to 2 minutes, if the degree of incineration reaches the requirements, the waste will be pushed into the second-level stacking platform 109 by the pushing device 110 of the first-level stacking platform 108, and then the waste will be pushed into the second-level stacking platform 109. After burning for 1 to 2 minutes, the burning is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com