Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Omit the welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

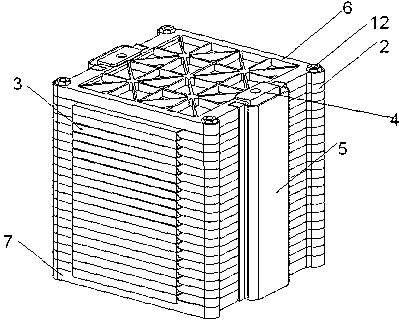

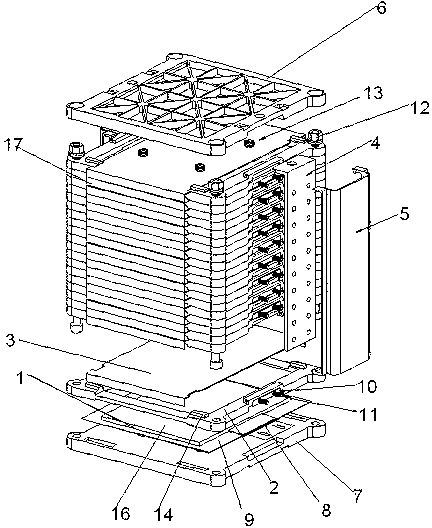

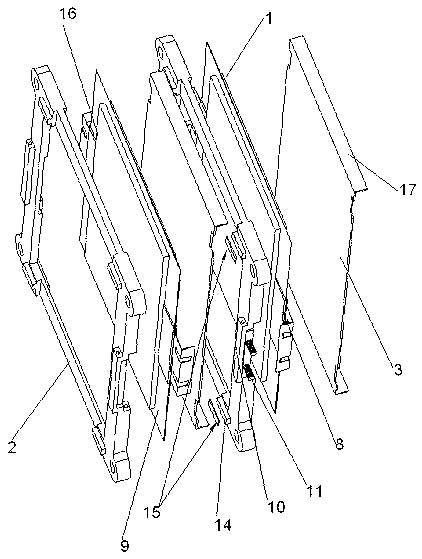

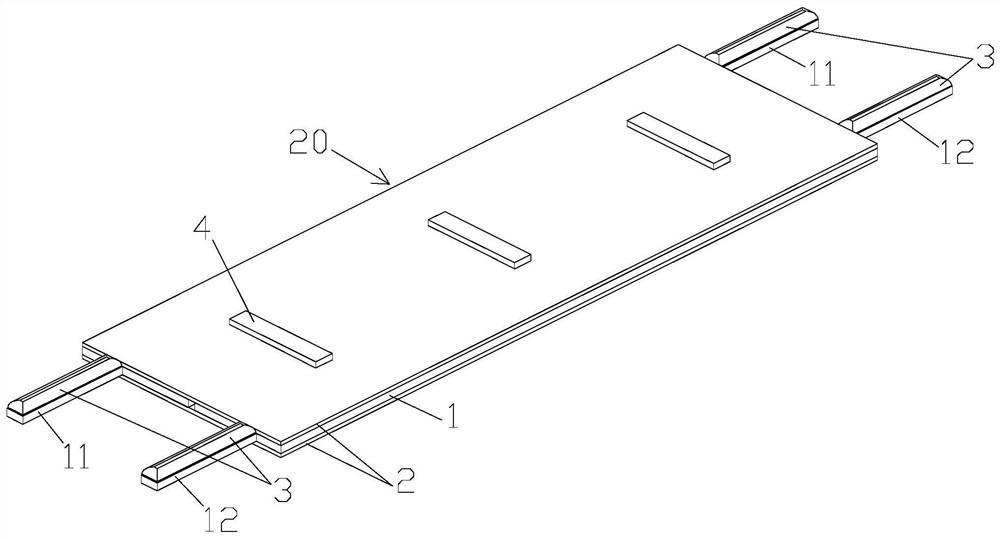

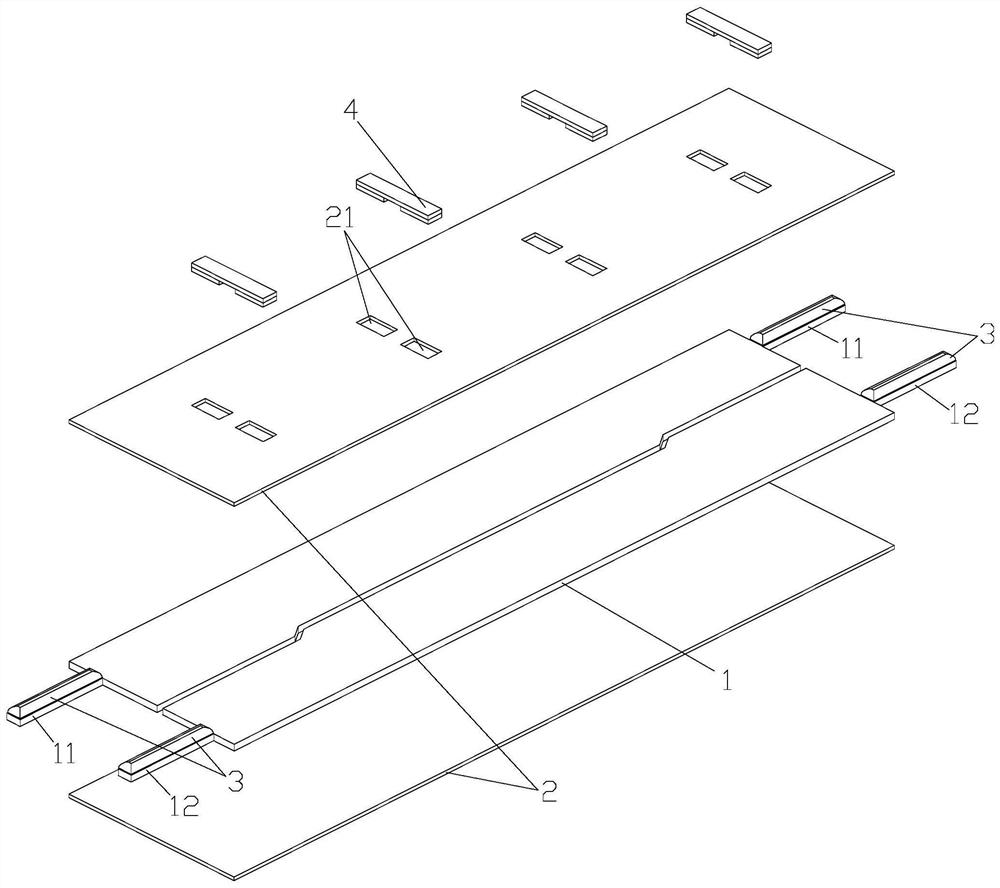

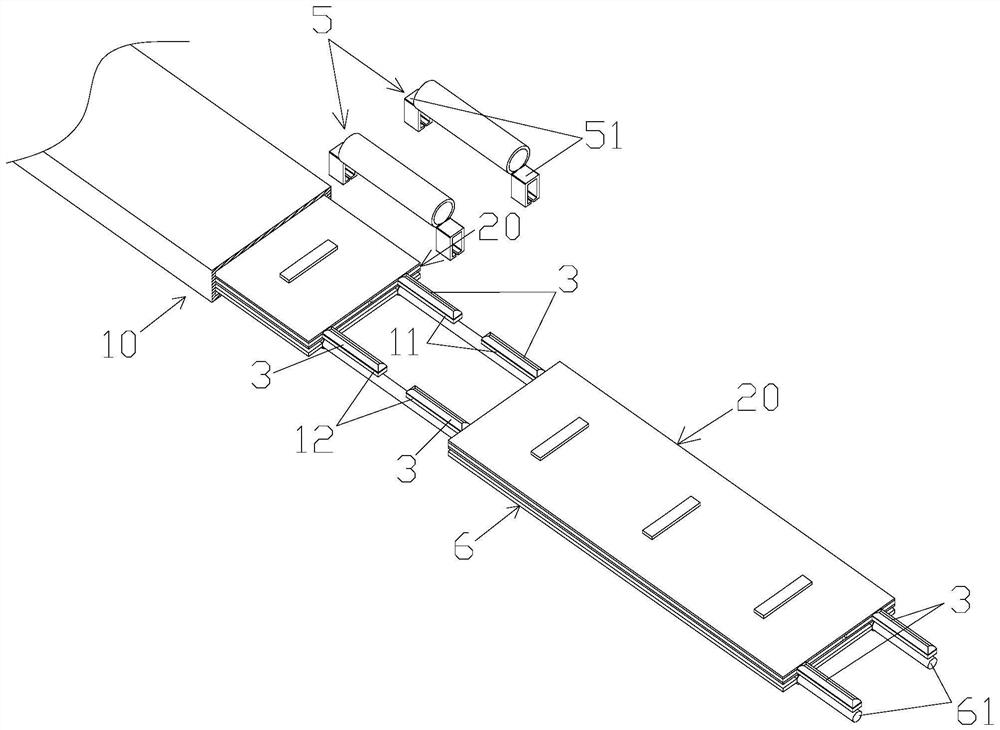

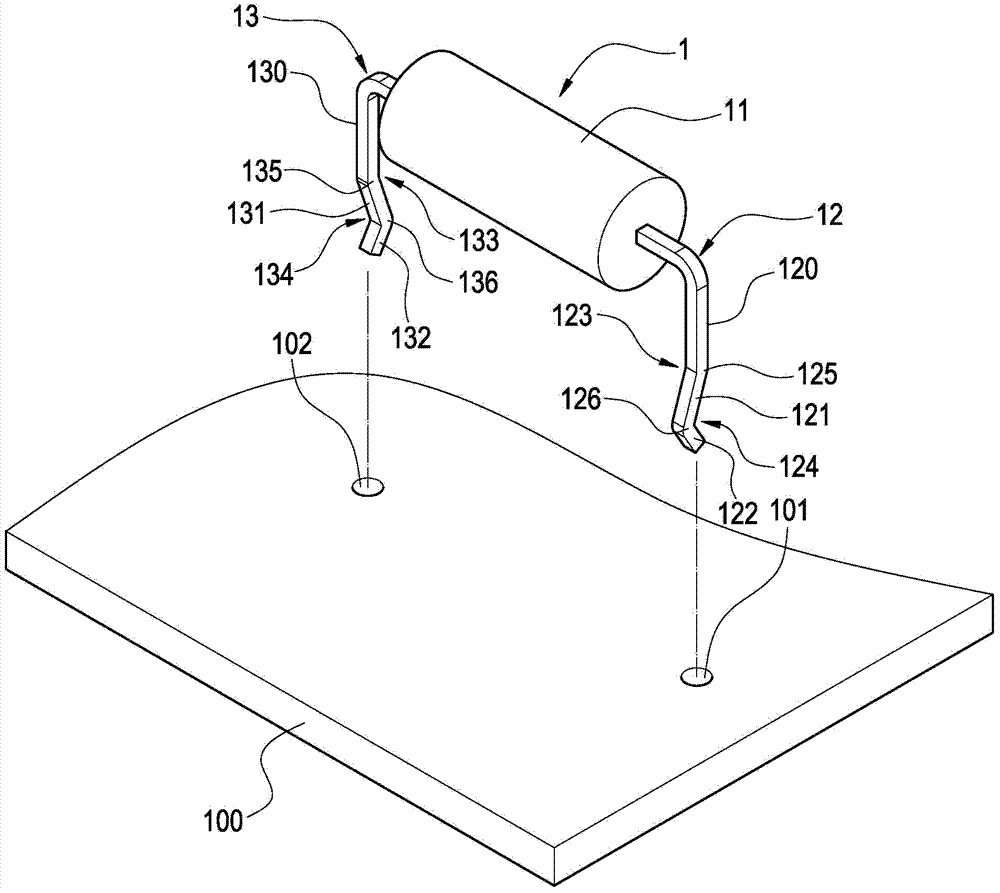

Lithium-ion flexible packaged battery pack structure

InactiveCN103346355AStructural advantagesEasy to replaceFinal product manufactureCell lids/coversElectrical batteryHeat sink

The invention discloses a lithium-ion flexible packaged battery pack structure which comprises individual lithium ion batteries, plastic clamping plates, heat radiating plates as well as current collection copper poles, current collection covers, an upper cover and a lower cover plate, wherein the current collection copper poles are arranged on the outer sides of two opposite side surfaces respectively; the current collection covers cover the current collection copper poles; the upper cover plate and the lower cover plate are arranged at the top end and the bottom end respectively, and a plurality of repetition units which are formed by the individual lithium ion batteries, the plastic clamping plates and the heat radiating plates are arranged between the upper cover plate and the lower cover plate; the side edges, corresponding to the current collection copper poles, of the individual lithium ion batteries are respectively provided with positive tabs and negative tabs, which are symmetric to each other; the plastic clamping plates and the individual lithium ion batteries are arranged at intervals sequentially, a galvanized copper block is arranged in each of two side surfaces of a frame of each plastic clamping plate, the inner sides of the galvanized copper blocks are connected with the tabs, the outer sides of the galvanized copper blocks are connected with the current collection copper poles through screws, and the heat radiating plates are respectively clamped between each individual lithium ion battery and each plastic clamping plate. The lithium-ion flexible packaged battery pack structure is high in energy density, strong in heat radiation capacity, high in safety, good in reliability and convenient to install and dismount.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

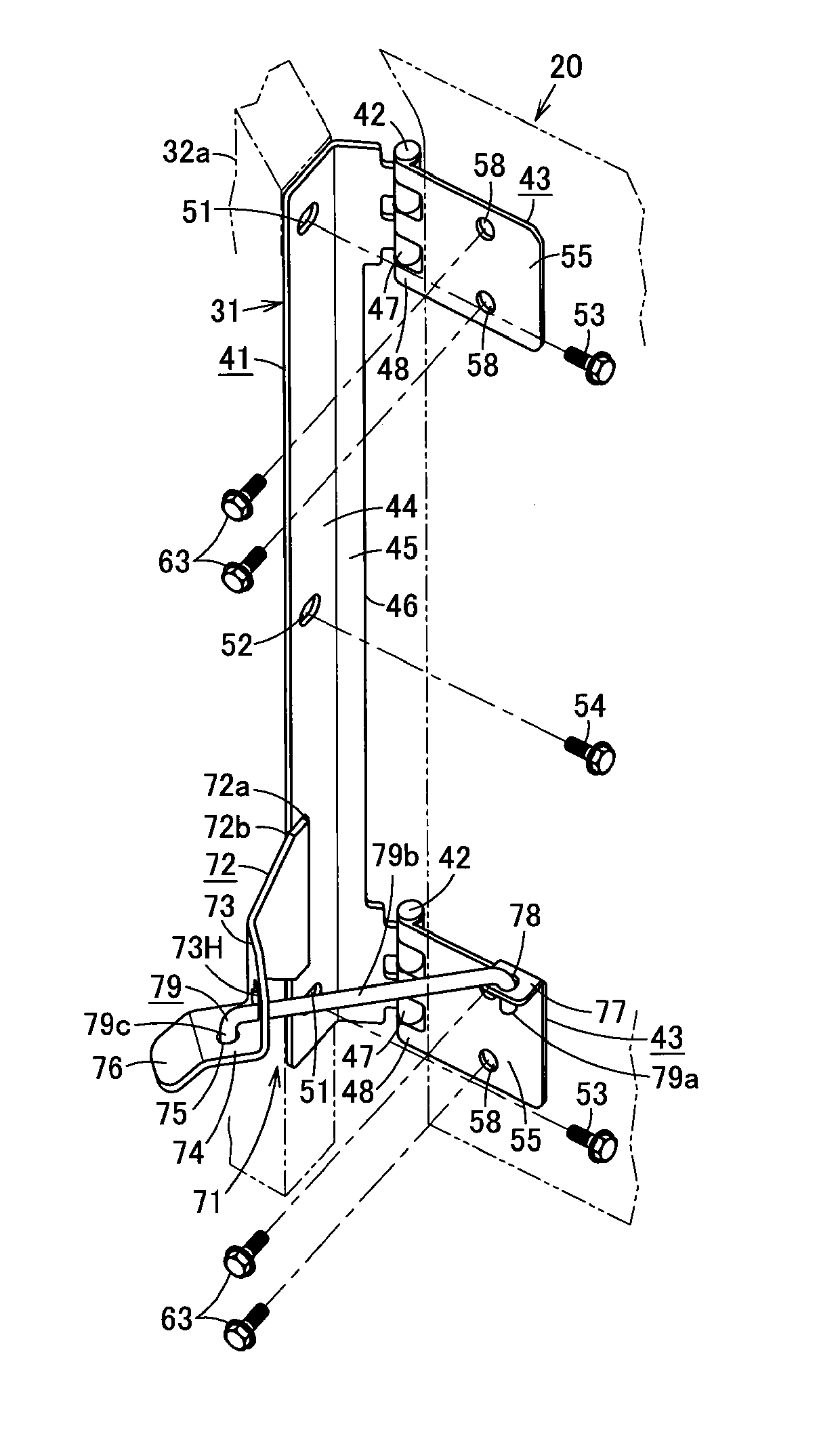

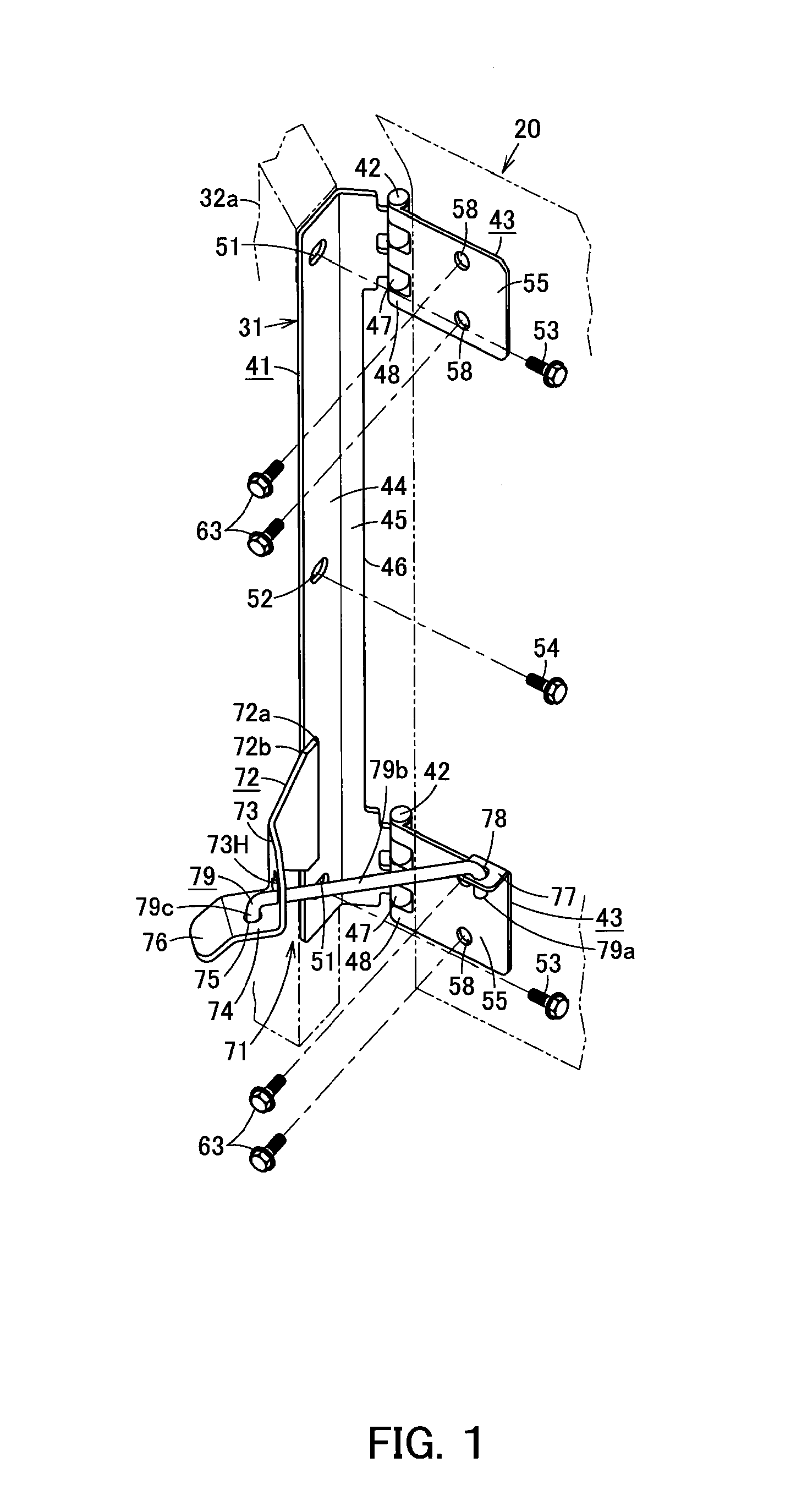

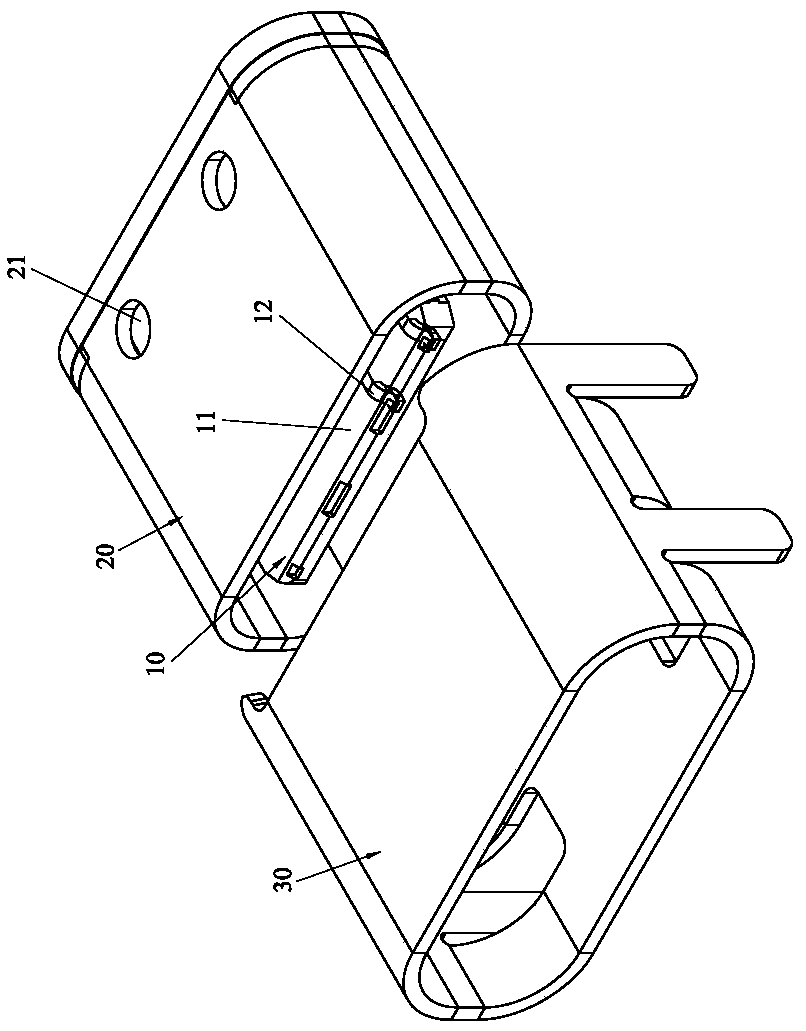

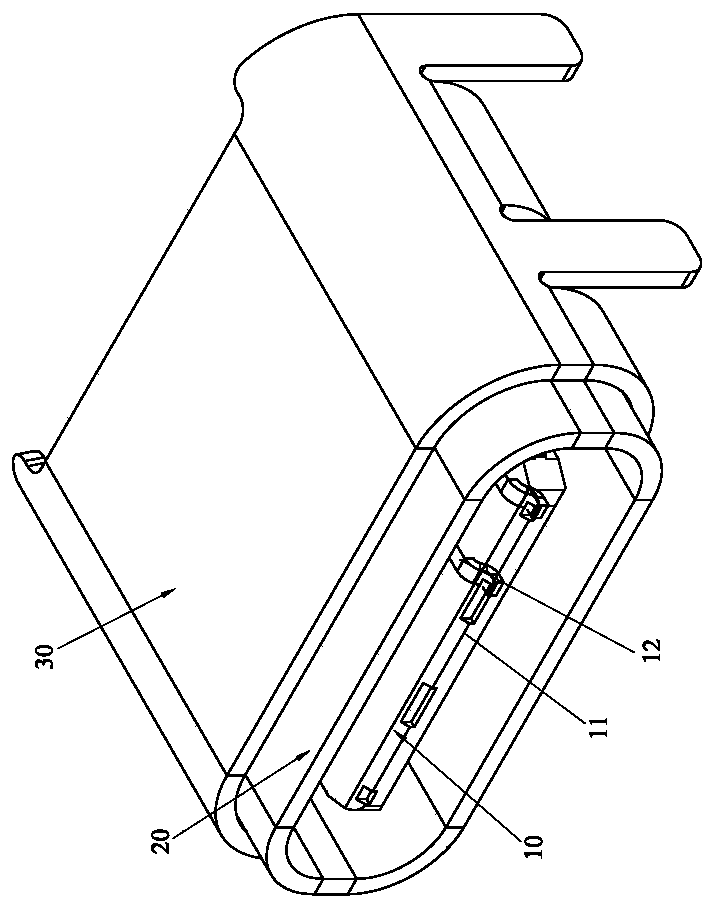

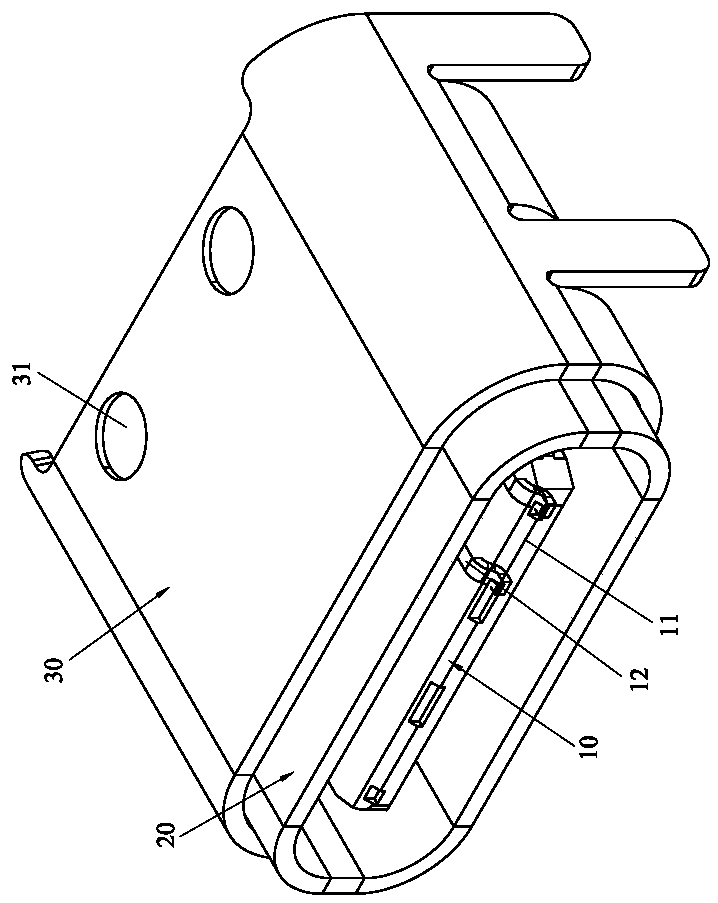

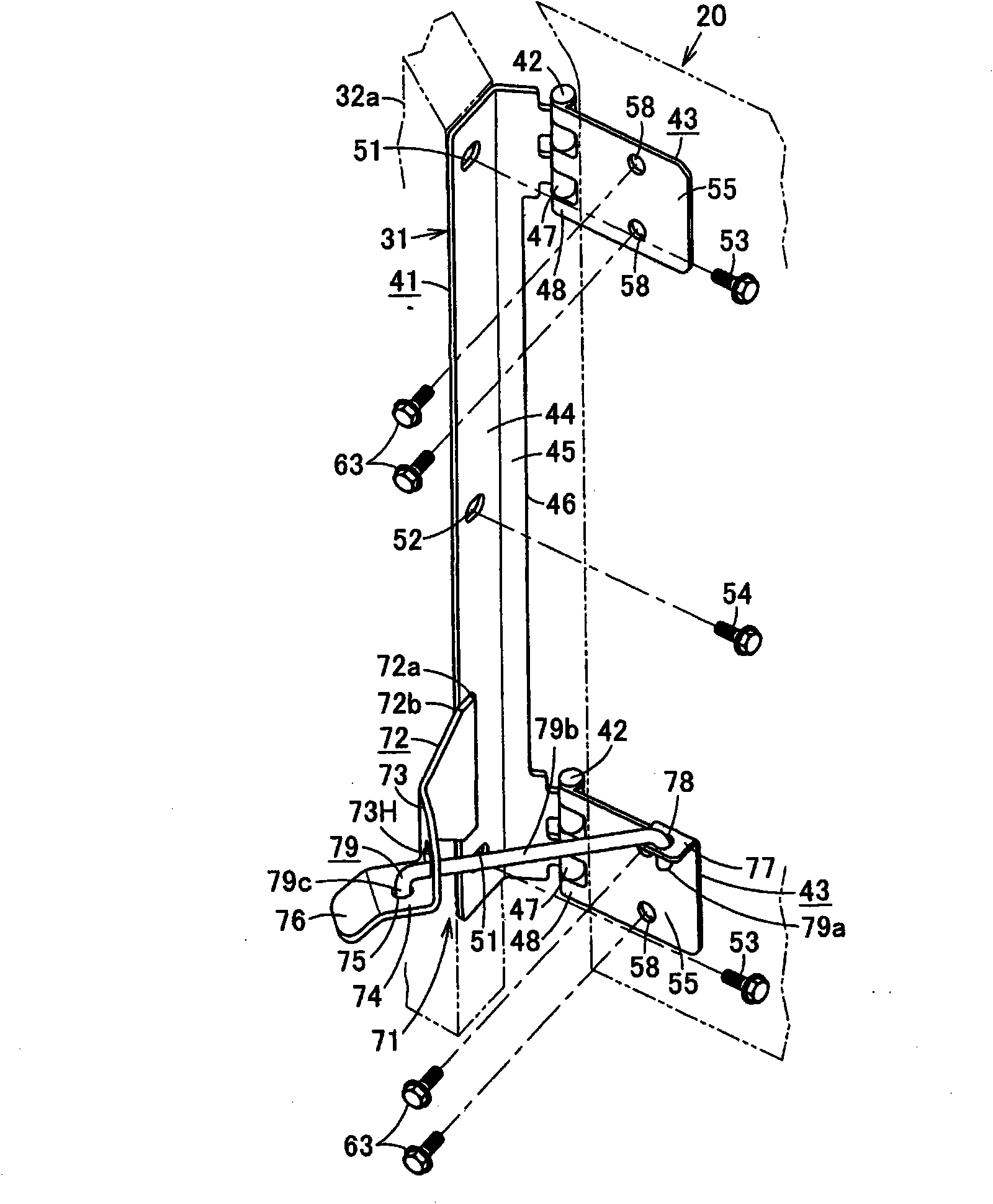

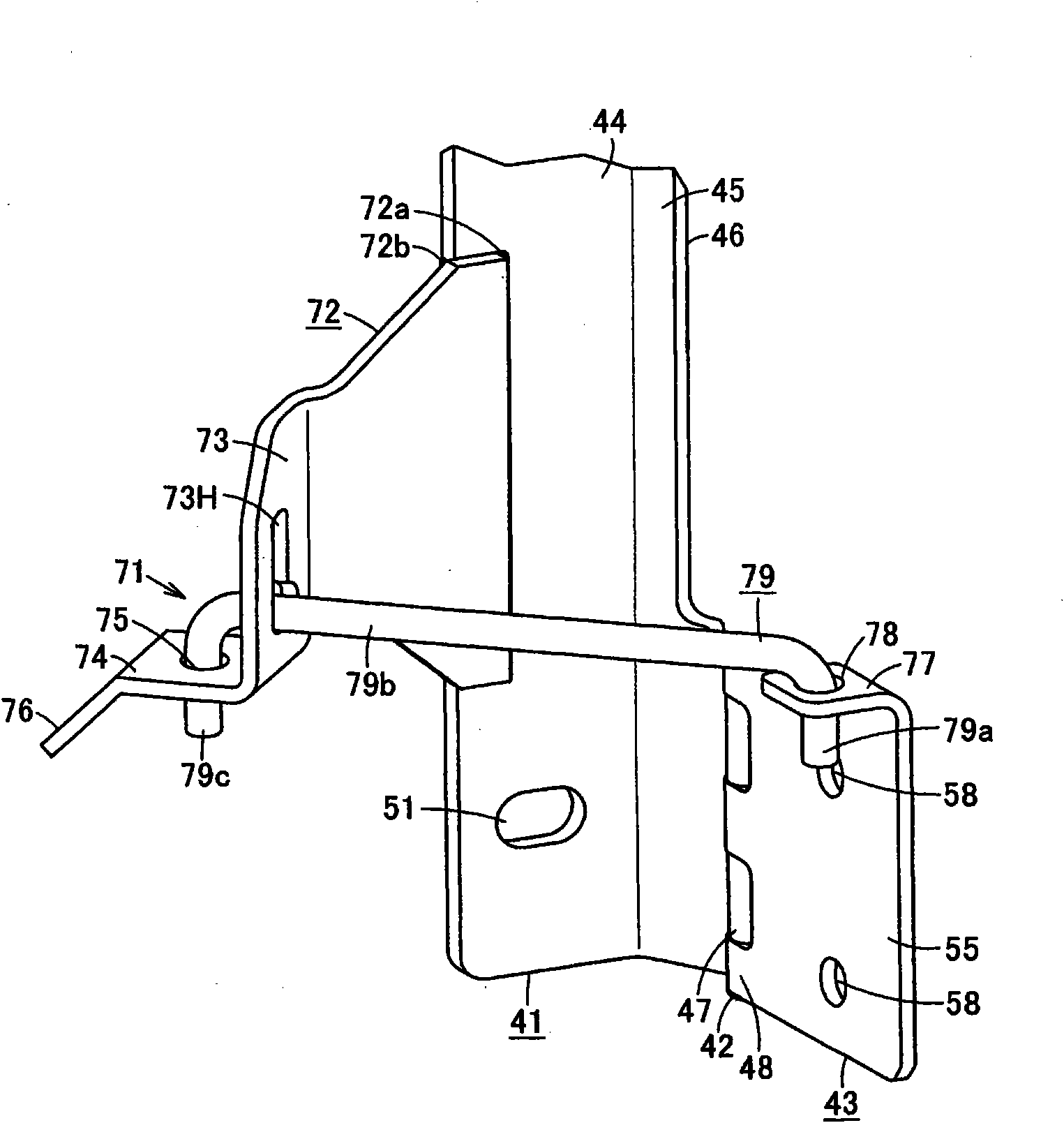

Hinge and door unit

InactiveUS20110126469A1Easily and finely stateImproving mounting workabilityWing accessoriesWing fastenersEngineeringMechanical engineering

Owner:CATEPILLAR SARL

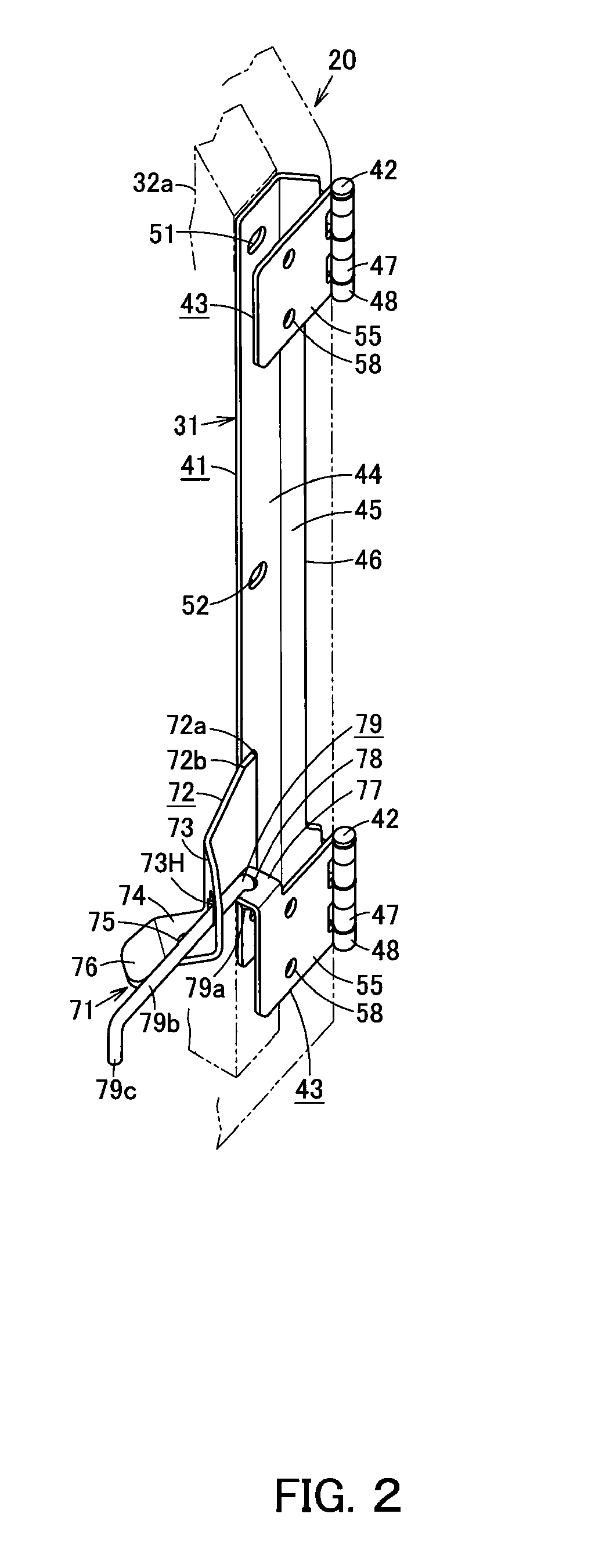

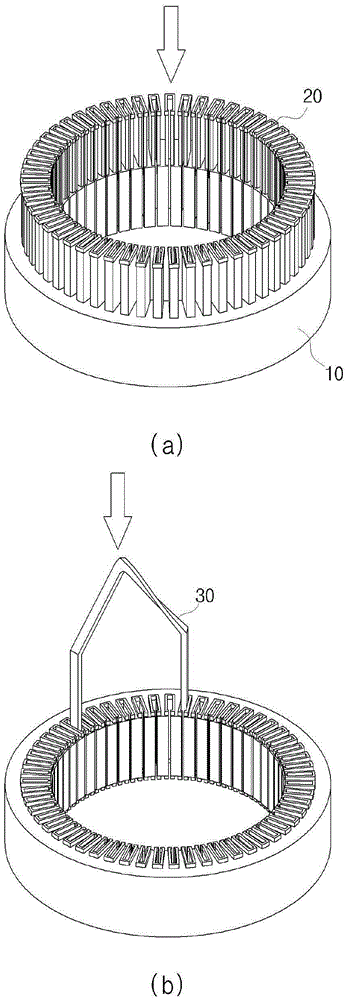

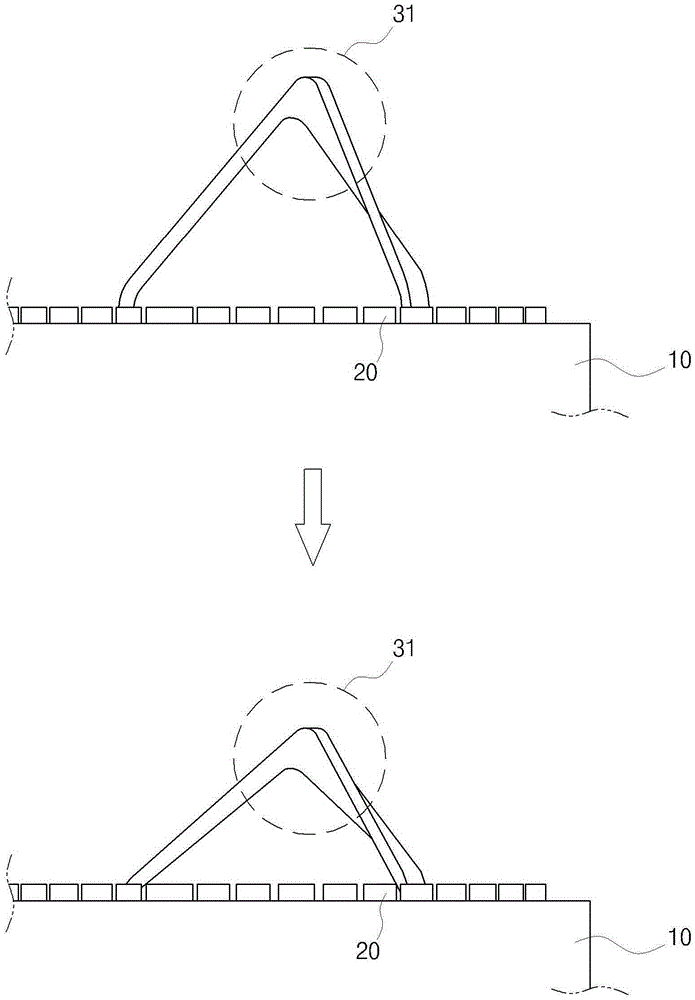

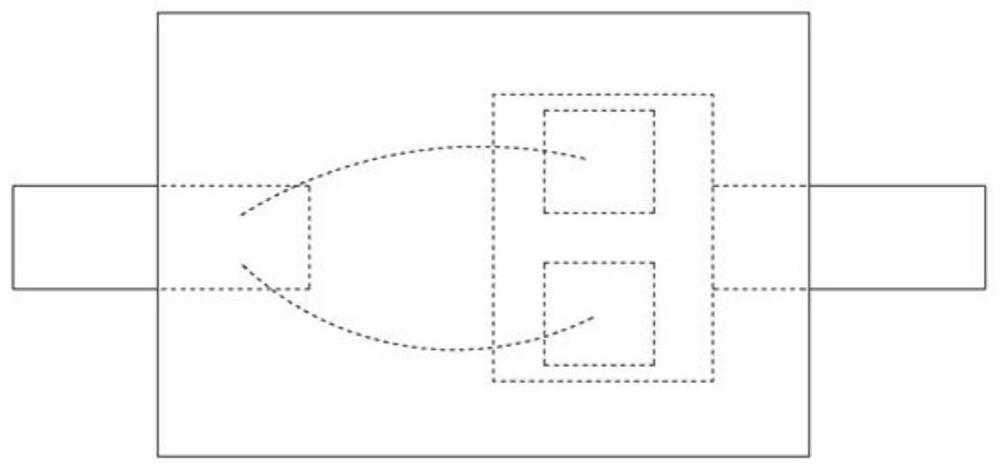

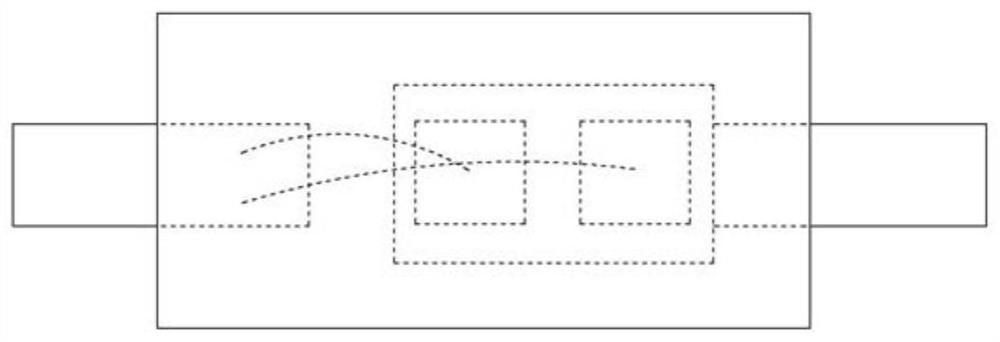

Apparatus of hairpin winding motor using stator plate and method of construction thereof

InactiveCN105576861AThe effect of preventing poor insulationAvoid deformationWindingsMagnetic circuit stationary partsConductor CoilElectrical and Electronics engineering

The invention relates to a vehicle motor suitable for a hair-pin winding. More specifically, the invention relates to a hair-pin winding motor device suitable for a stator plate, and a forming method of the device. According to the invention, the device comprises a stator core which comprises a plurality of narrow slots in the peripheral direction; a coil which is inserted into the narrow slots to be combined in insulating paper; and stator plates which are arranged on two surfaces of the stator core and support the coil during twisting.

Owner:HYUNDAI MOBIS CO LTD

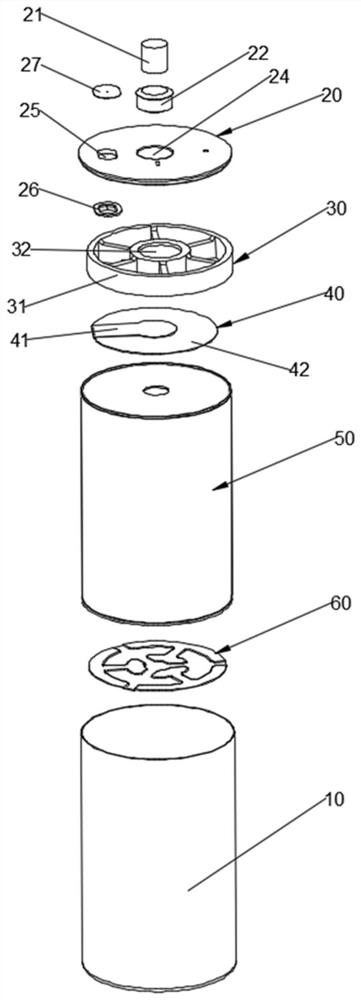

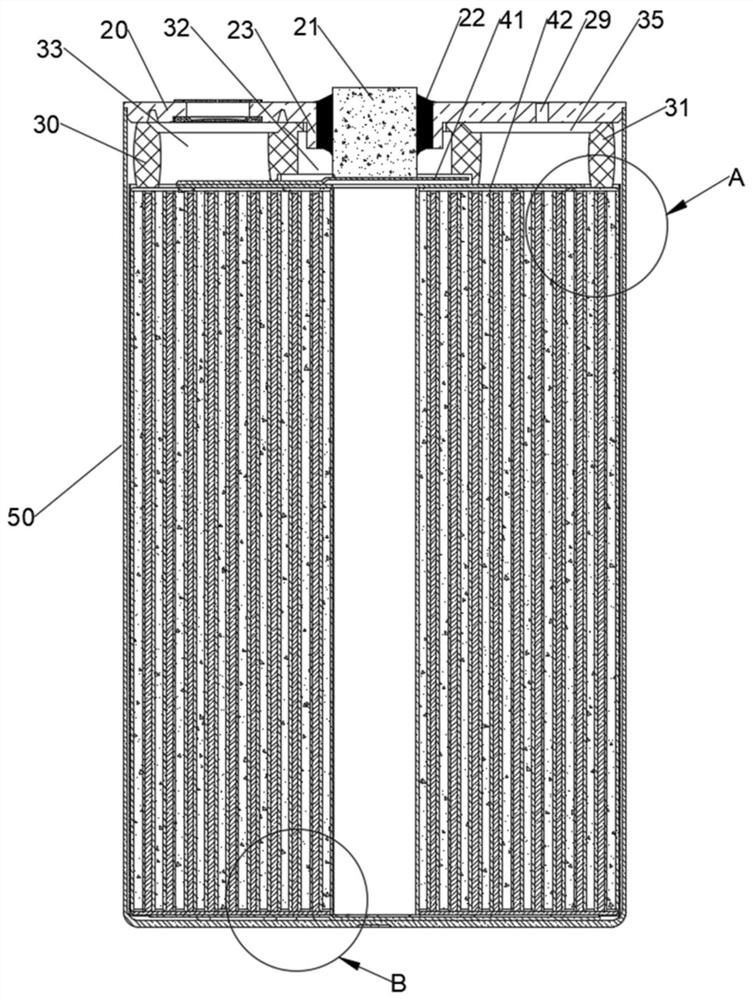

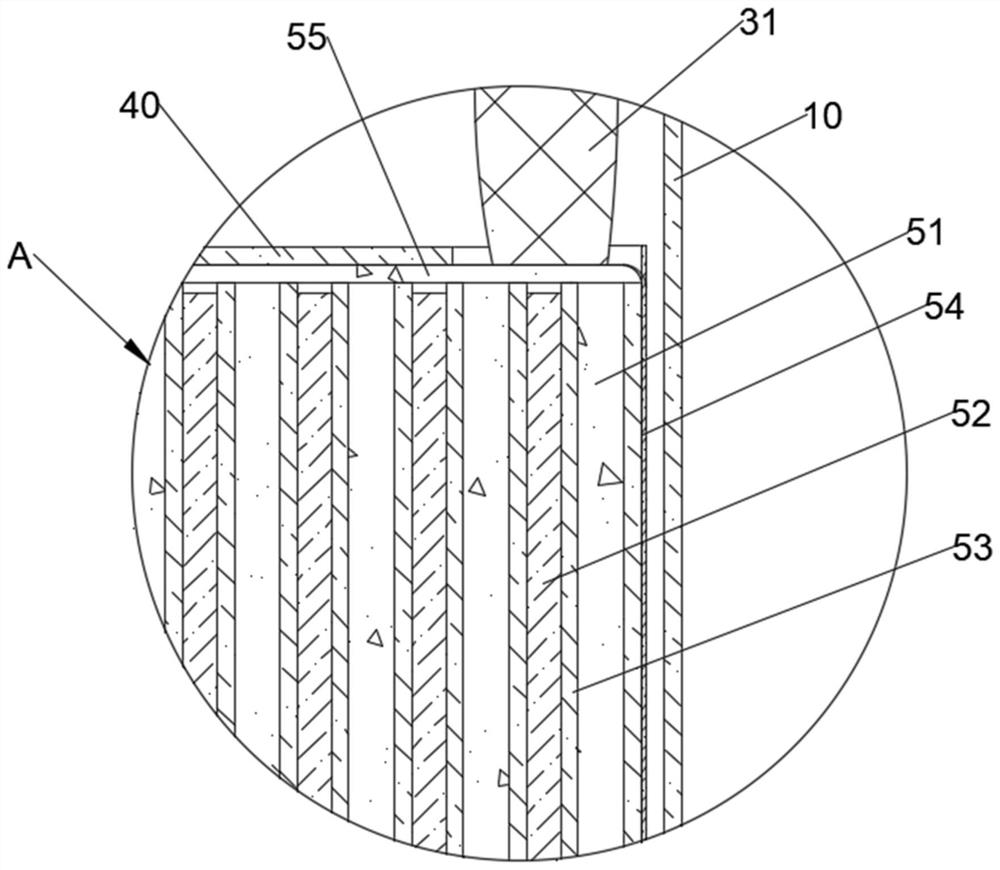

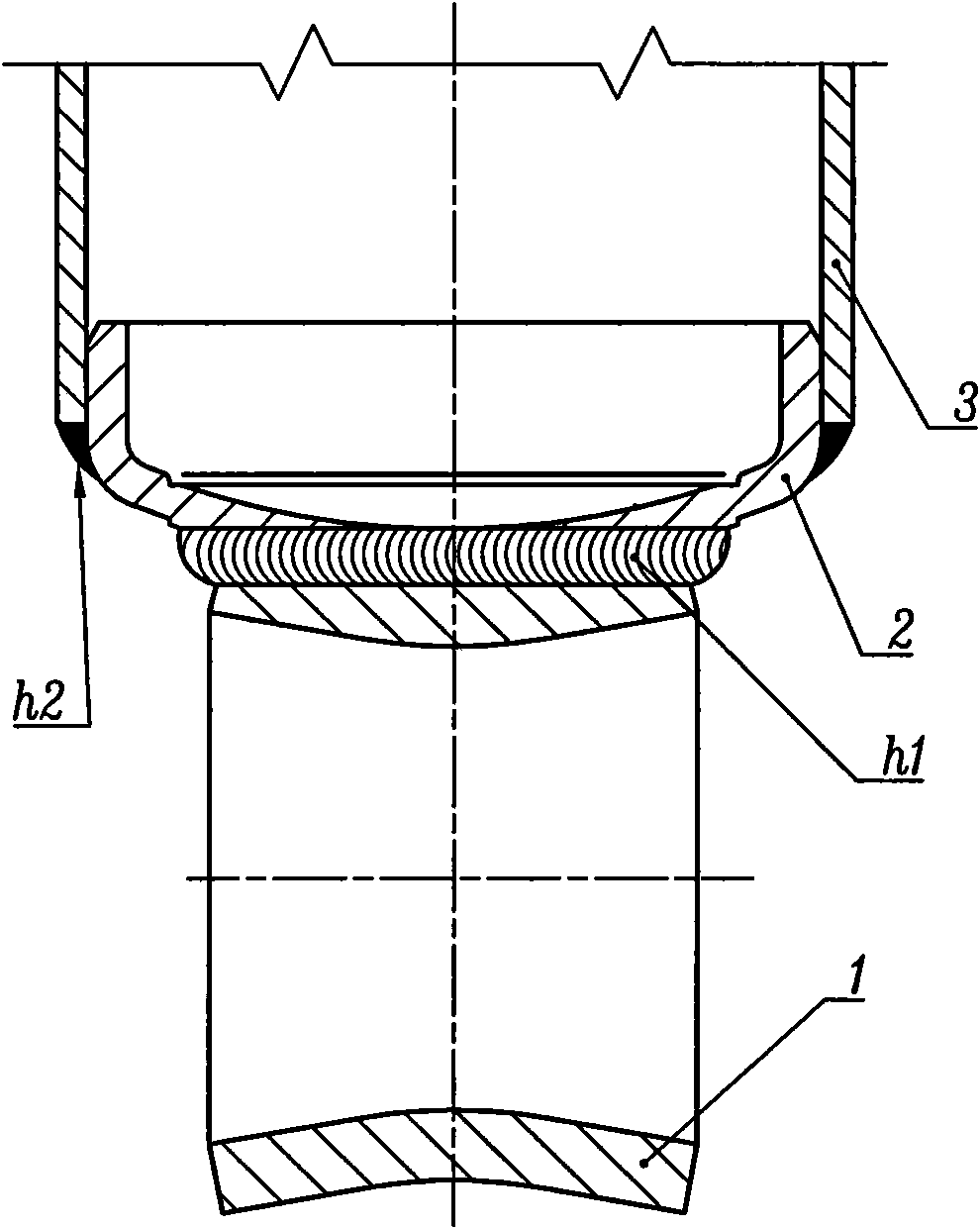

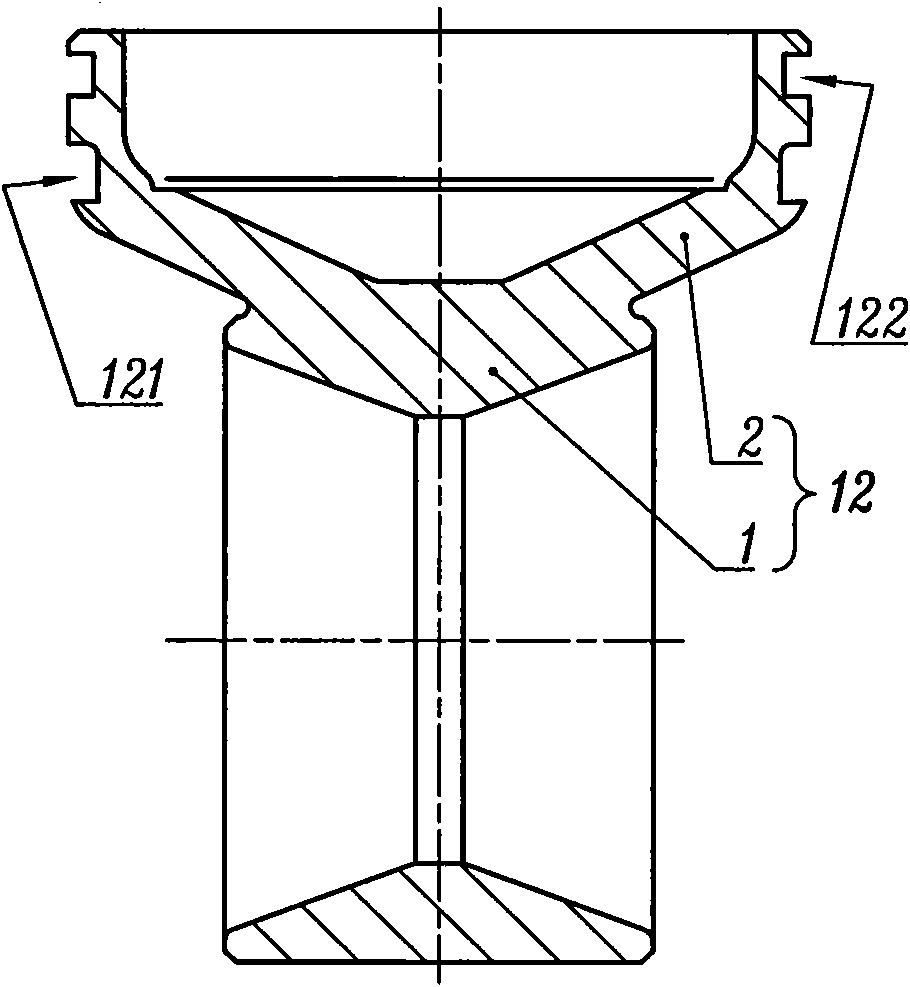

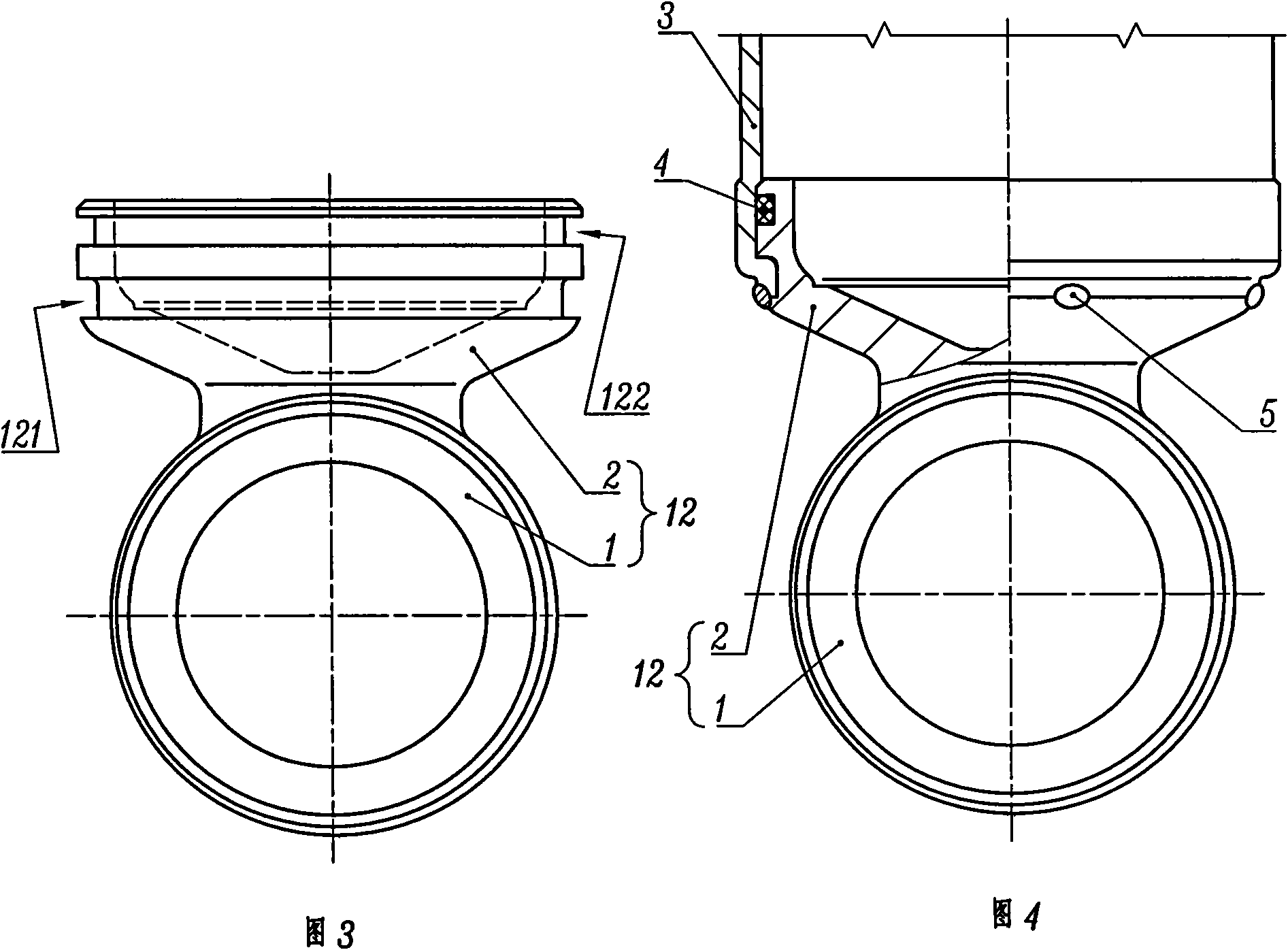

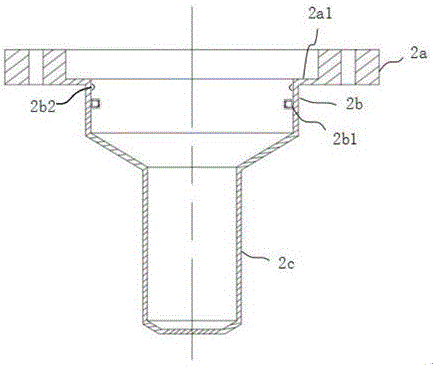

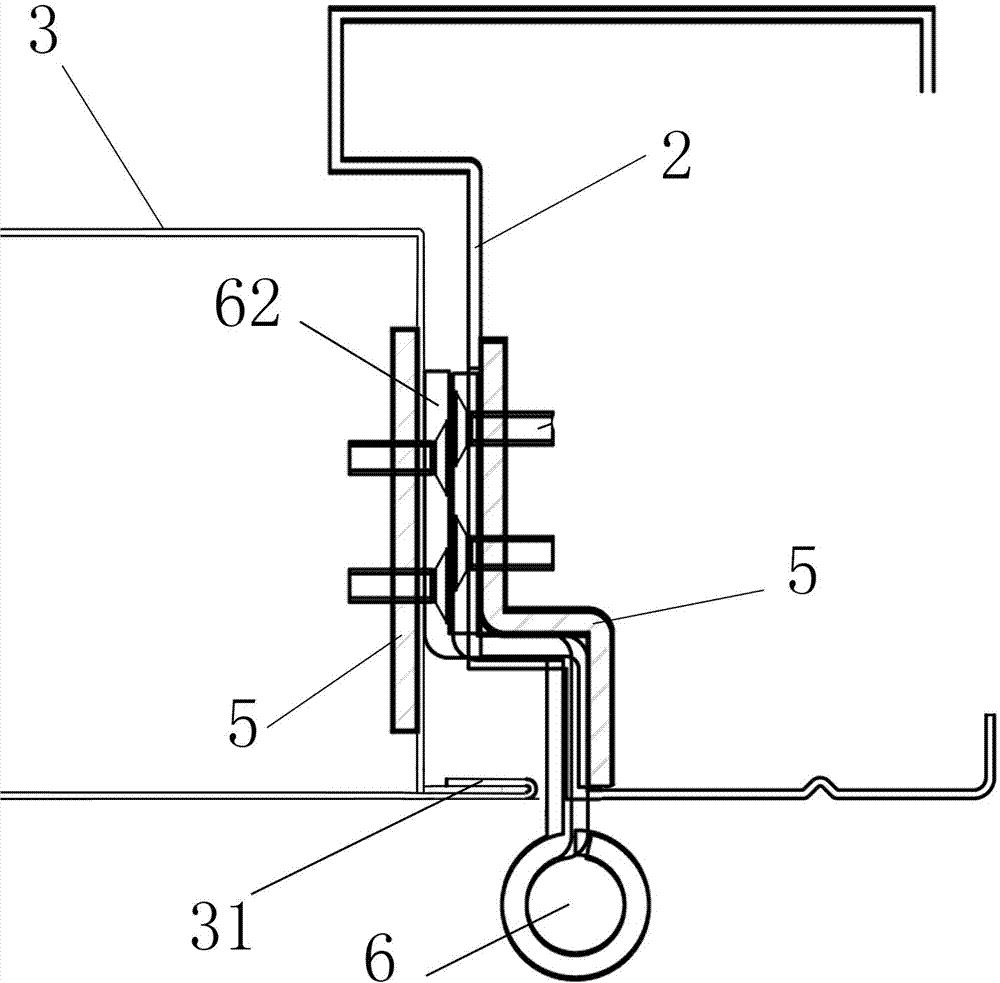

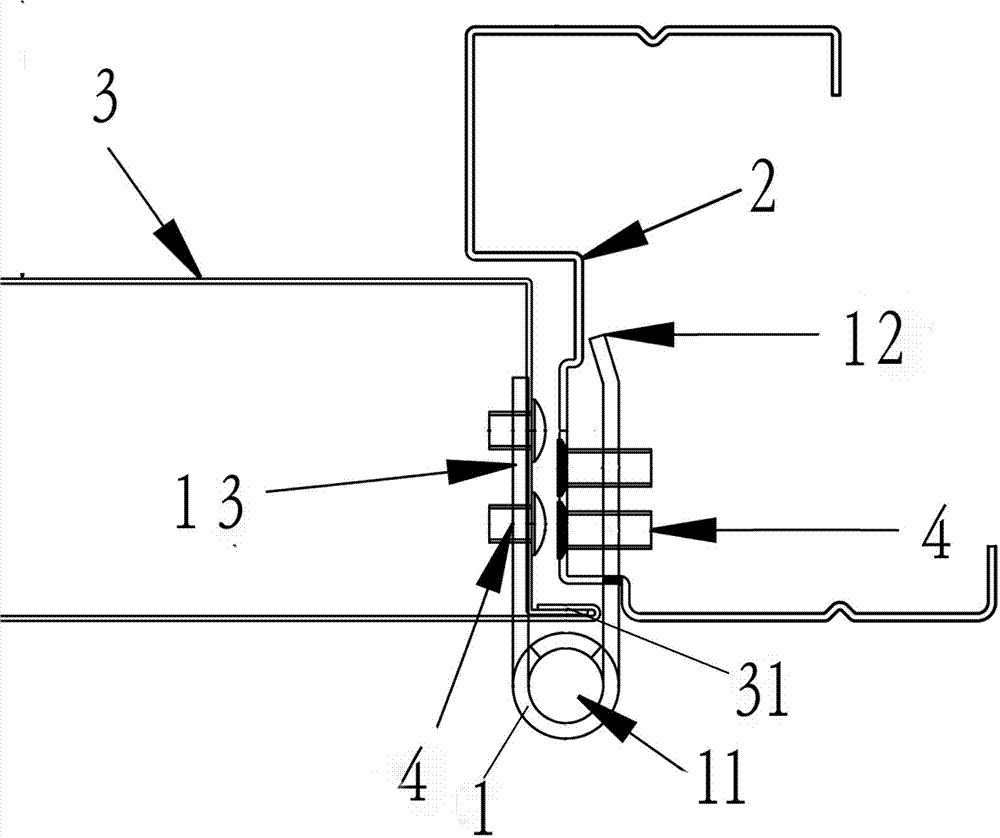

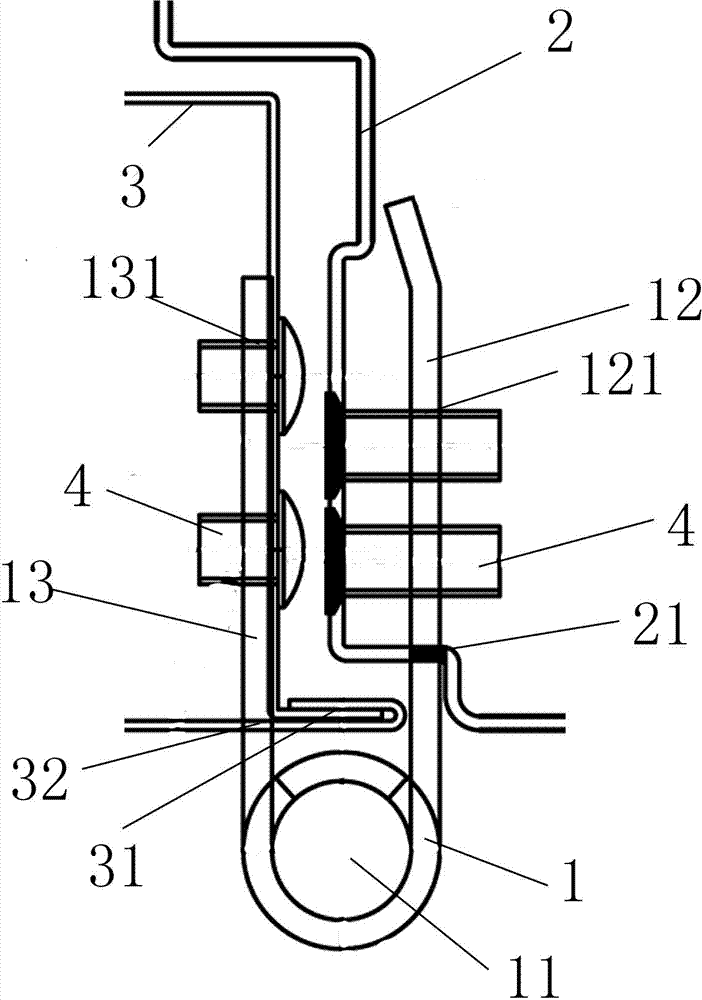

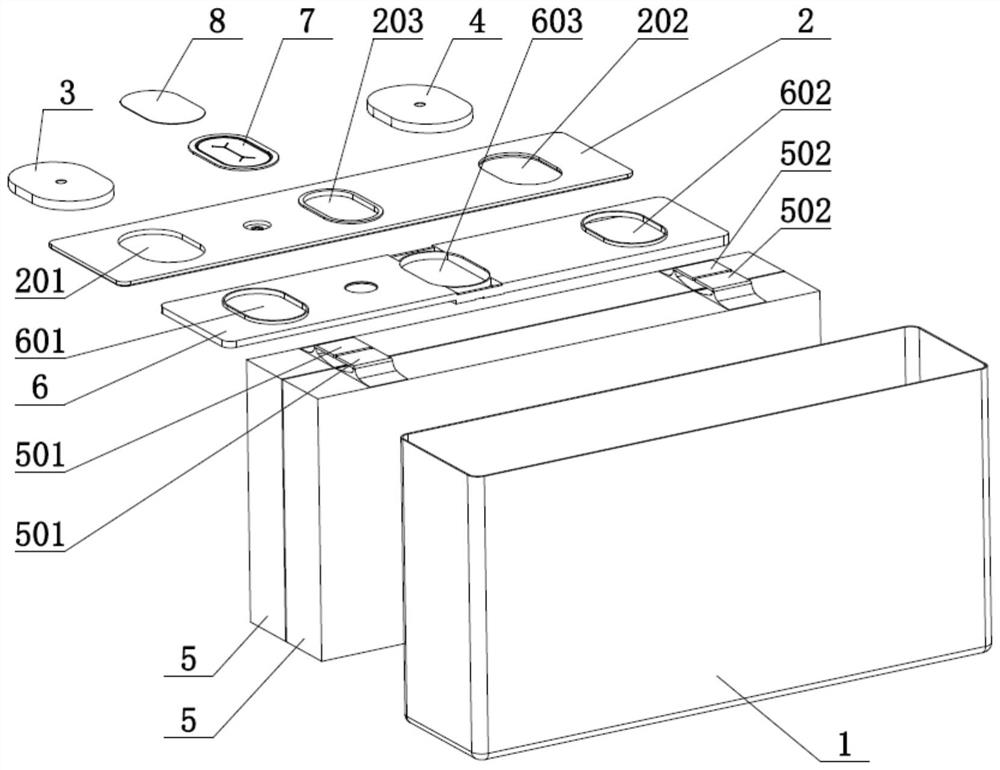

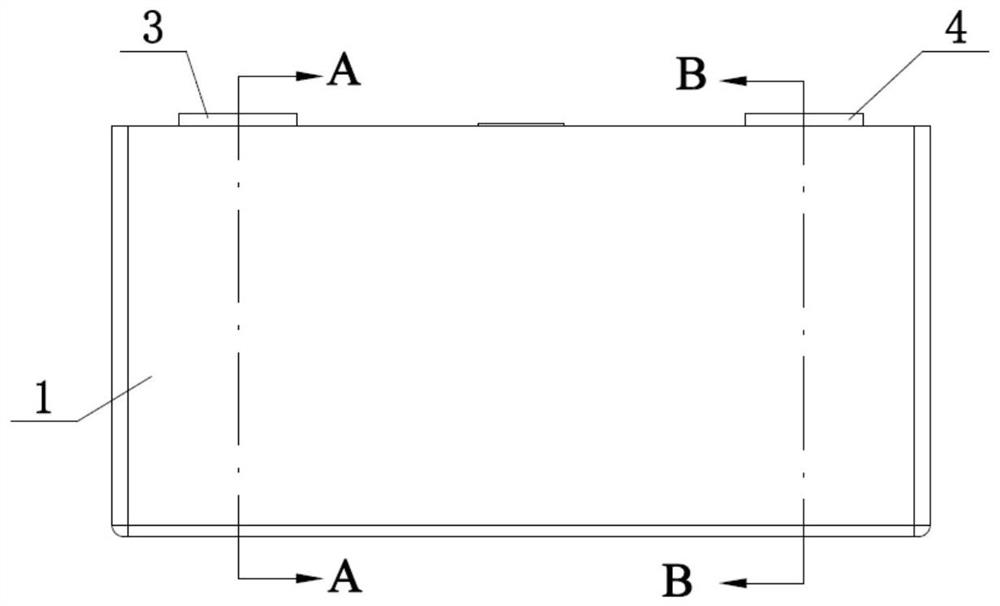

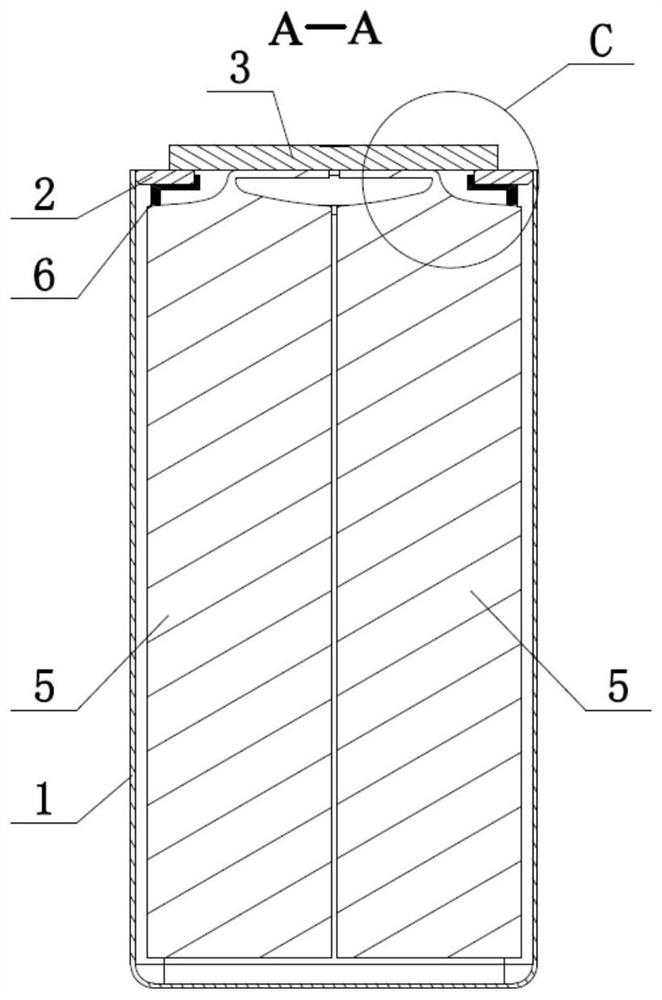

Single battery

PendingCN112510326AFull abutmentShorten the protruding lengthFinal product manufactureCylindrical casing cells/batteryPole pieceMechanical engineering

The invention discloses a single battery. The single battery comprises a shell and a cover plate, one of the two ends of the shell in the first direction is open, the other end of the shell is closed,and the cover plate covers the open end; the single battery further comprises an elastic support piece, a first current collecting plate, a battery cell and a second current collecting plate which are sequentially arranged in the shell along a first direction; the elastic support piece is configured to be in a compressed state so as to compress the first current collecting plate, the battery celland the second current collecting plate between the elastic support piece and the closed end of the shell; a first tab and a second tab are respectively arranged at two ends of the battery cell alongthe first direction, are respectively led out from pole piece foils of the battery cell, and are flattened into a flat shape; and the first current collecting plate is propped against the flat firsttab, and the second current collecting plate is propped against the flat second tab. According to the single battery disclosed by the invention, a welding process required by the traditional connection of the tab and the pole is omitted, the material of the pole piece foil is saved, and the production process and the equipment investment are simplified.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

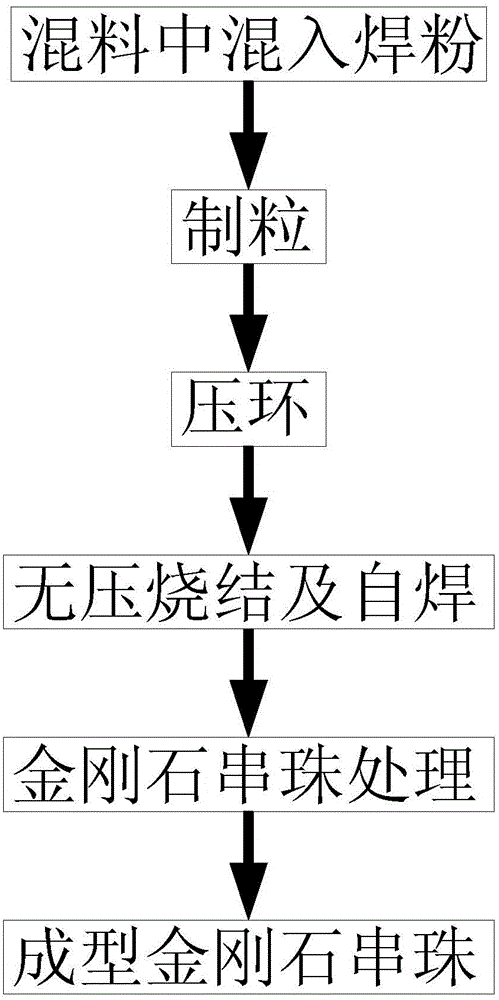

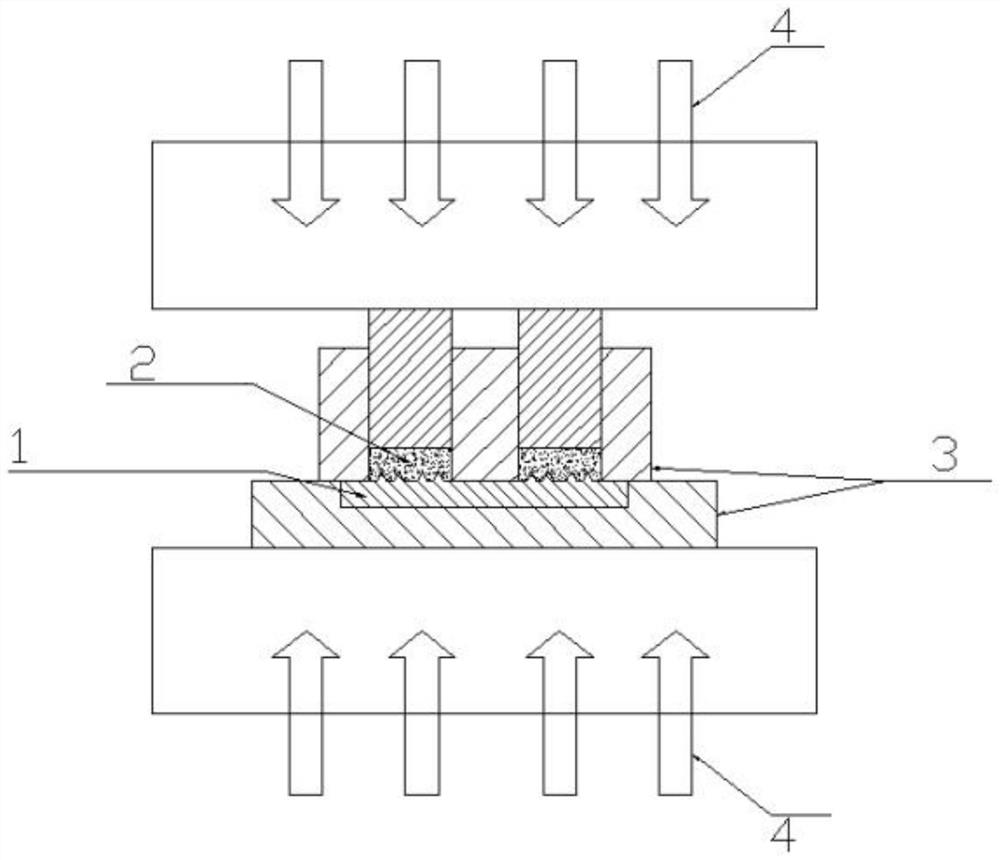

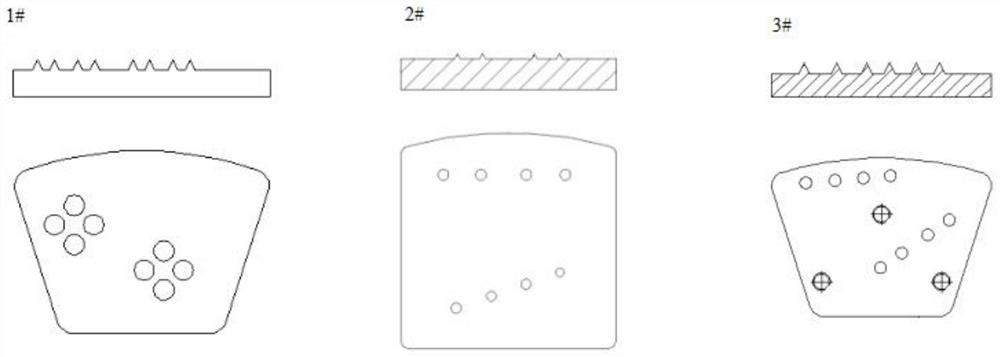

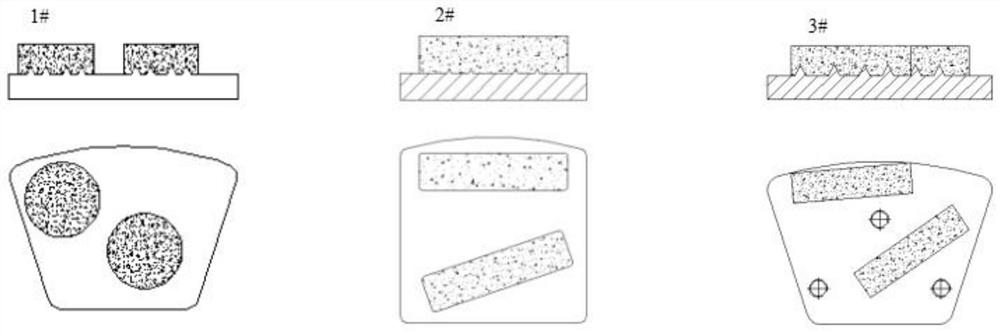

Pressure-free sintering preparation method of diamond string bead

InactiveCN105695830AGuaranteed bonding effectOmit the welding processTurbinesOther manufacturing equipments/toolsMixed materialsMelt temperature

The invention discloses a pressure-free sintering preparation method of a diamond string bead. The method comprises the following steps: a, adding welding powder with melting temperature similar to sintering temperature of a diamond string bead matrix to form a mixed material with the welding powder; b, pelletizing the mixed material to obtain pelletizing powder; c, carrying out ring pressing treatment on the pelletizing powder to obtain a pressed ring; d, carrying out pressure-free sintering treatment on the pressed ring and melting the welding powder while sintering to form a self-welded and integrated diamond string bead; and e, carrying out surface treatment on the diamond string bead to obtain a formed diamond string bead. Through the method, the integration of sintering and self-welding is implemented; the welding process in the conventional pressure-free sintering preparation process of the string bead is eliminated; the adhesion effect between the string bead matrix and a substrate is ensured; the production efficiency of the method is greatly improved; the production cost is reduced; the condition for further popularizing the pressure-free sintering preparation method of the string bead is created.

Owner:CHANGSHA BAICHUAN SUPERHARD MATERIAL TOOLS

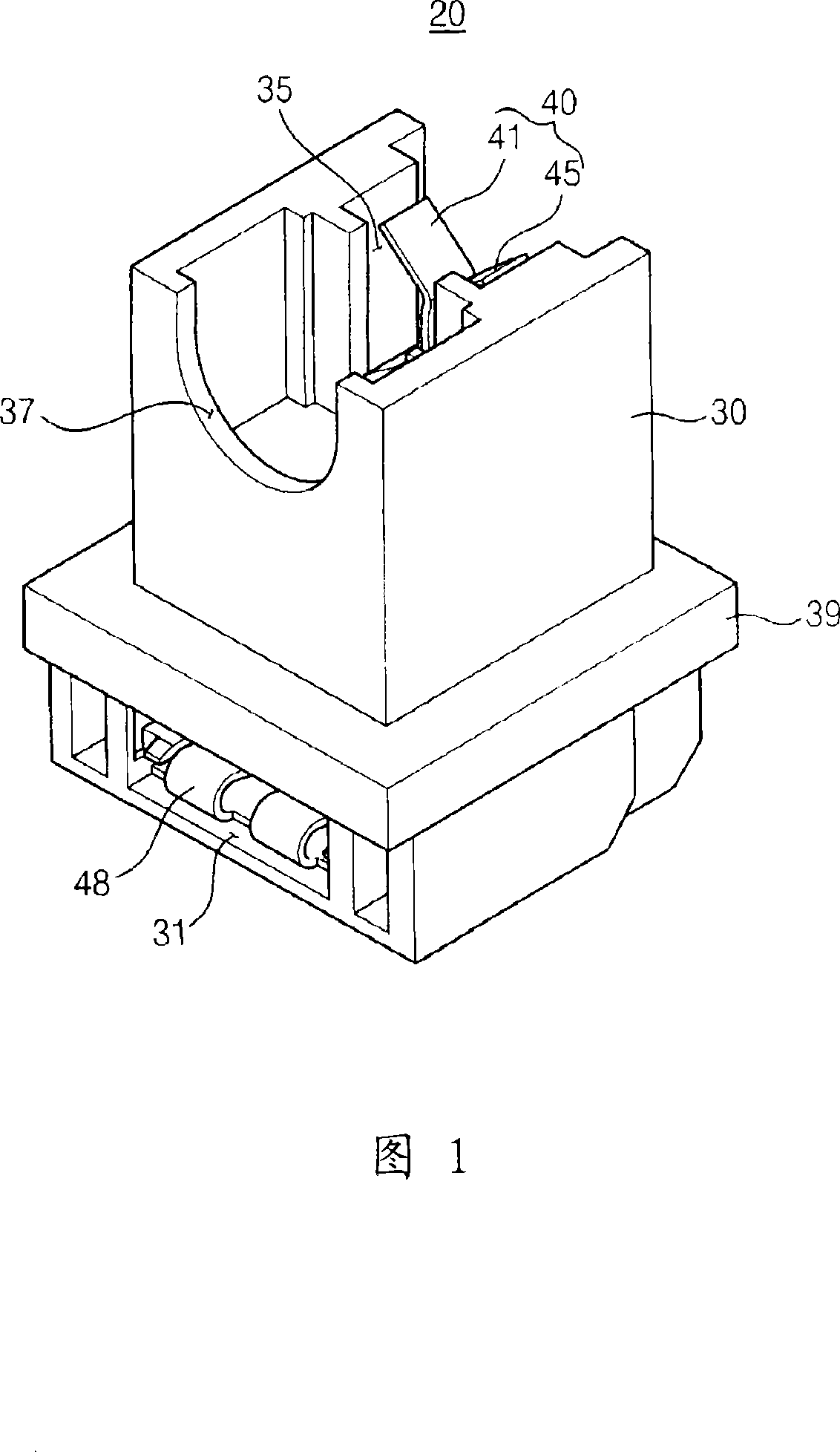

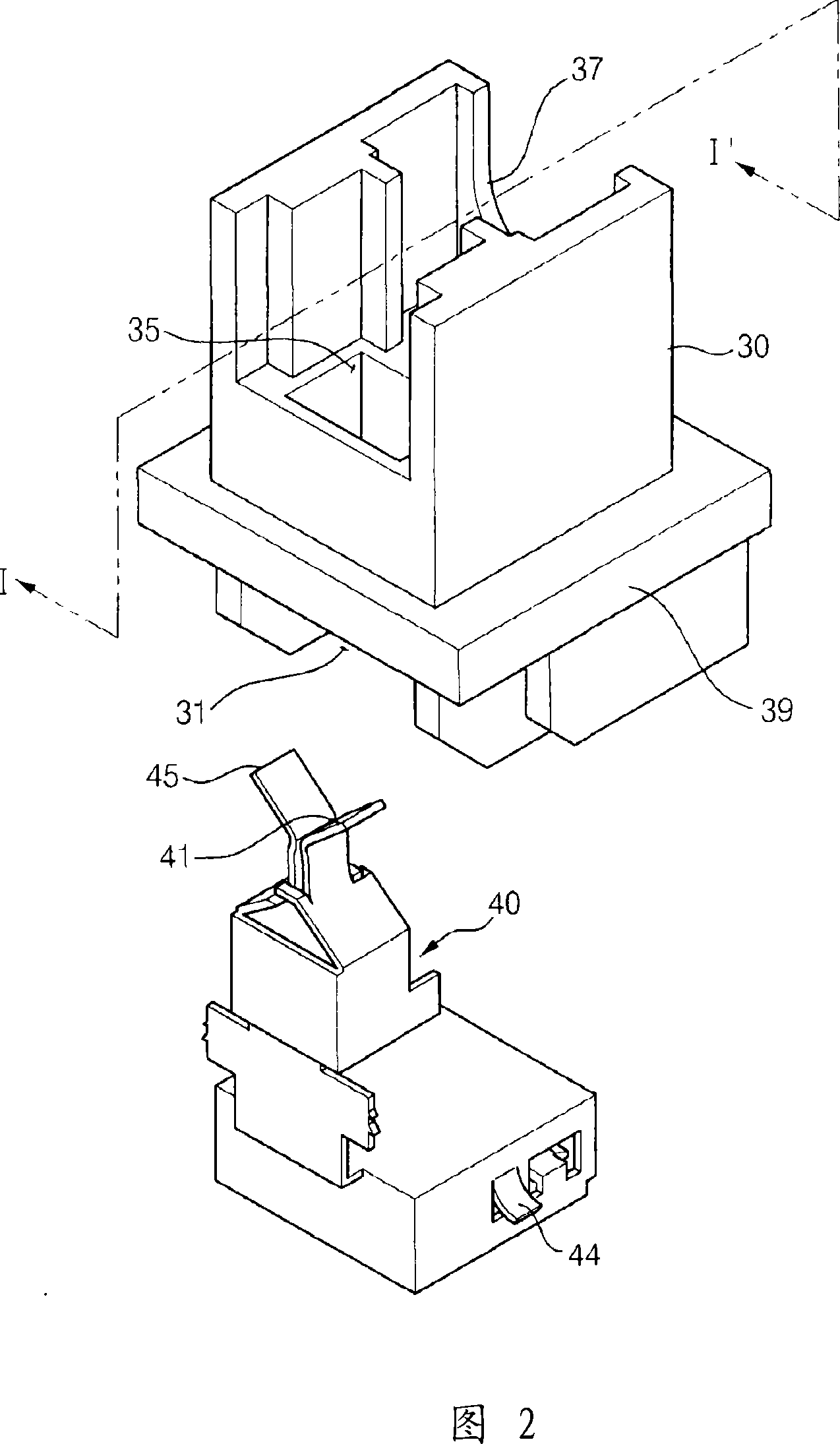

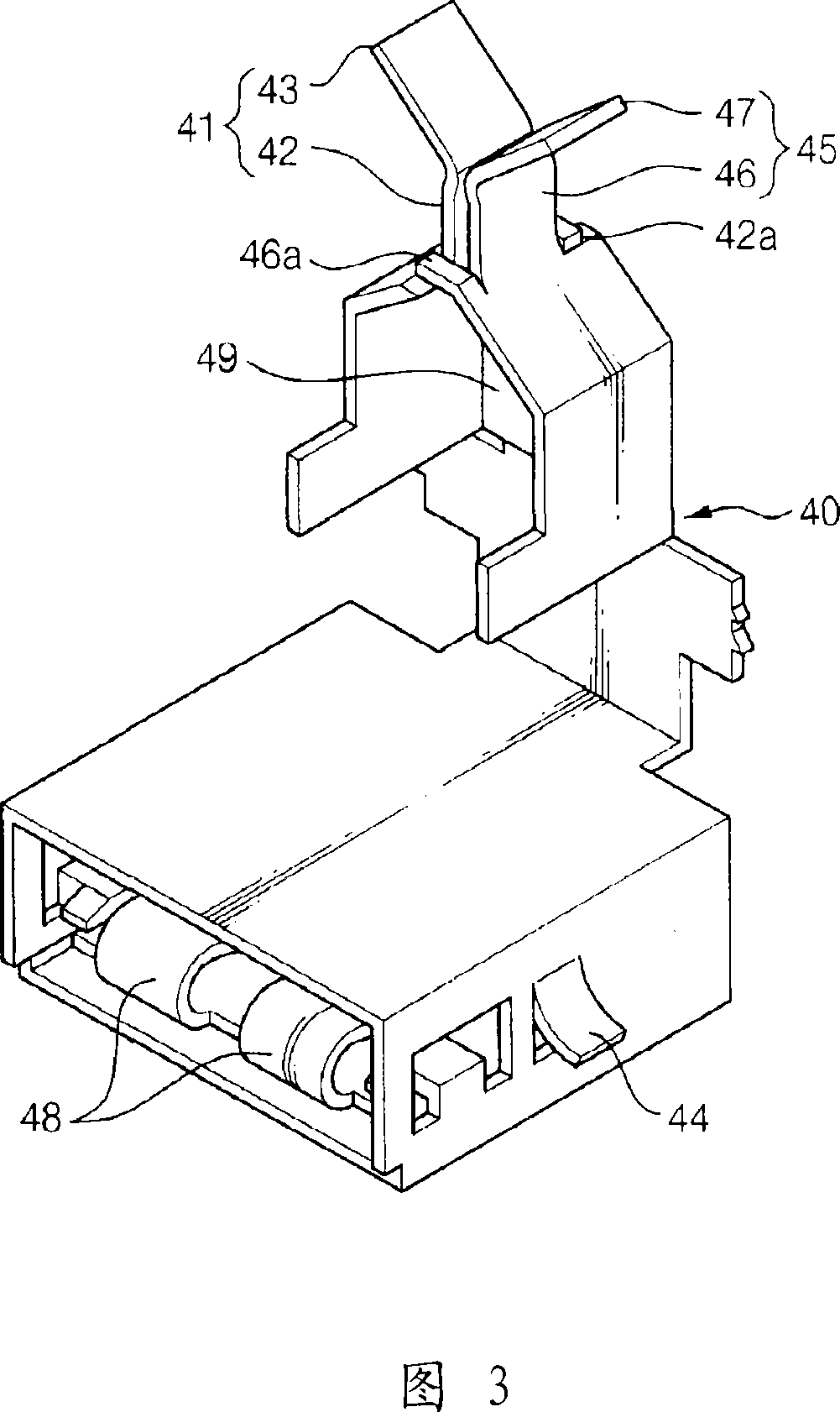

Lamp socket, back light assembly and display device having the same, method of assembling lamp module

InactiveCN101178167AReduce the number of stepsReduce in quantityCoupling device connectionsLighting support devicesDisplay deviceMechanical engineering

Owner:SAMSUNG DISPLAY CO LTD

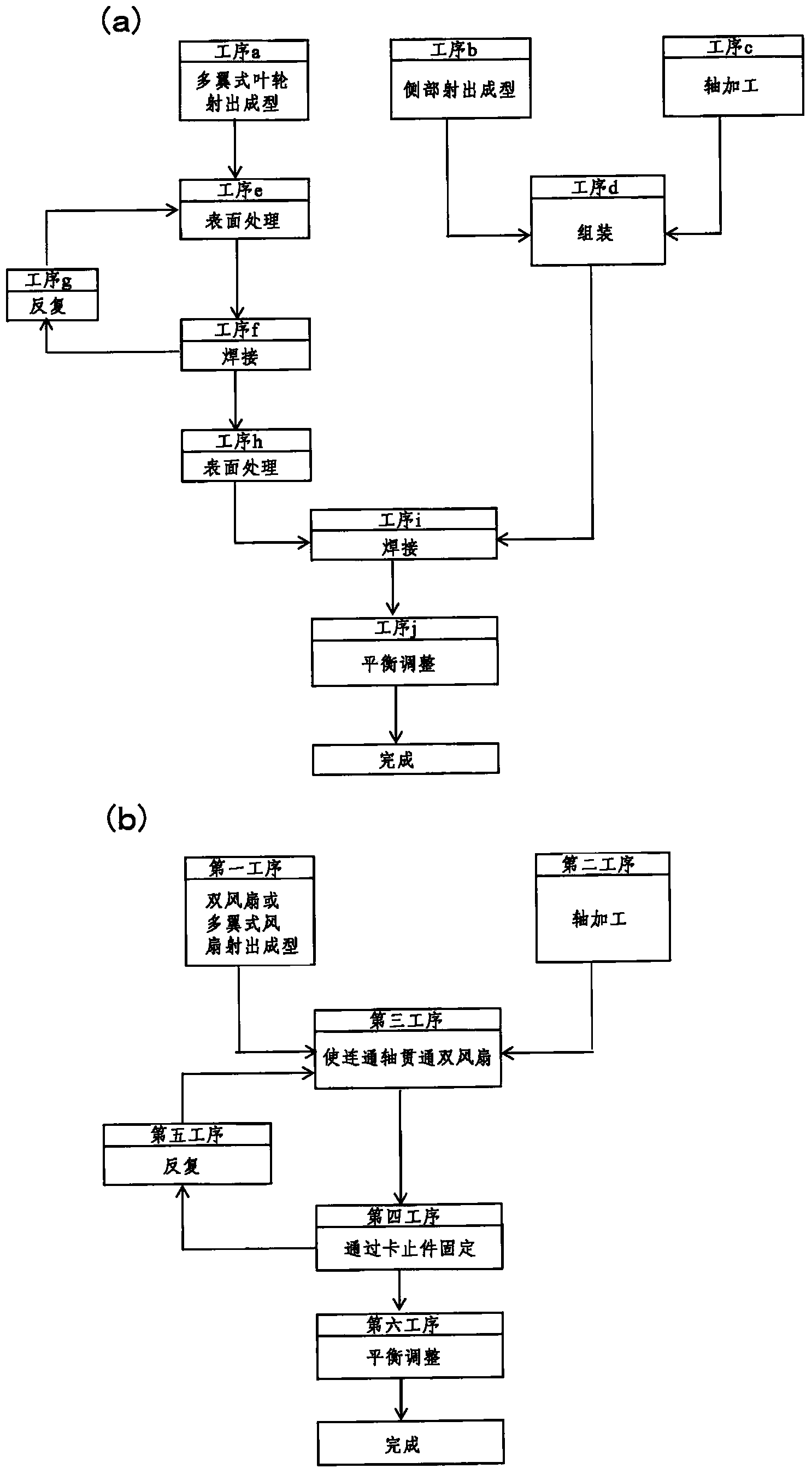

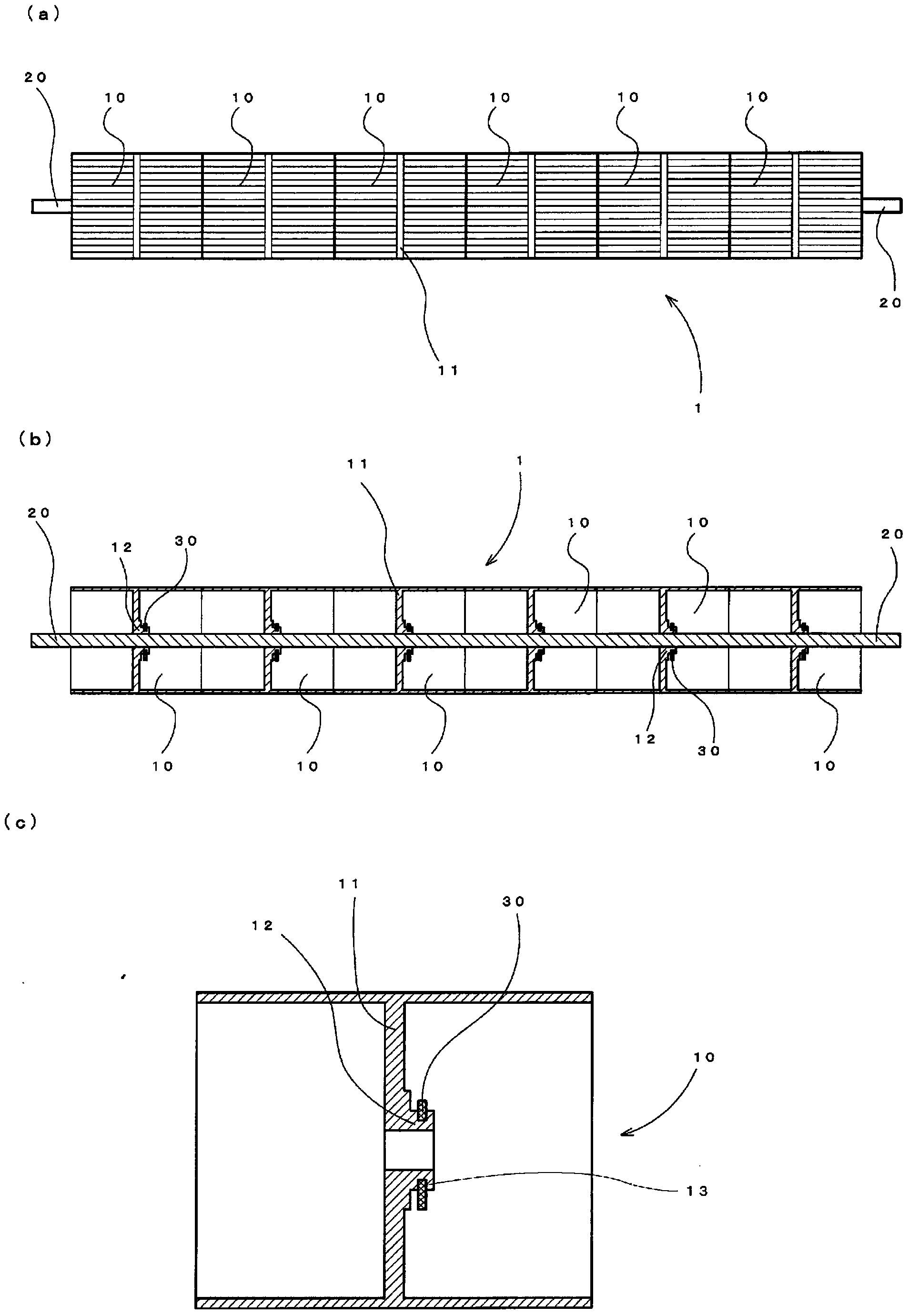

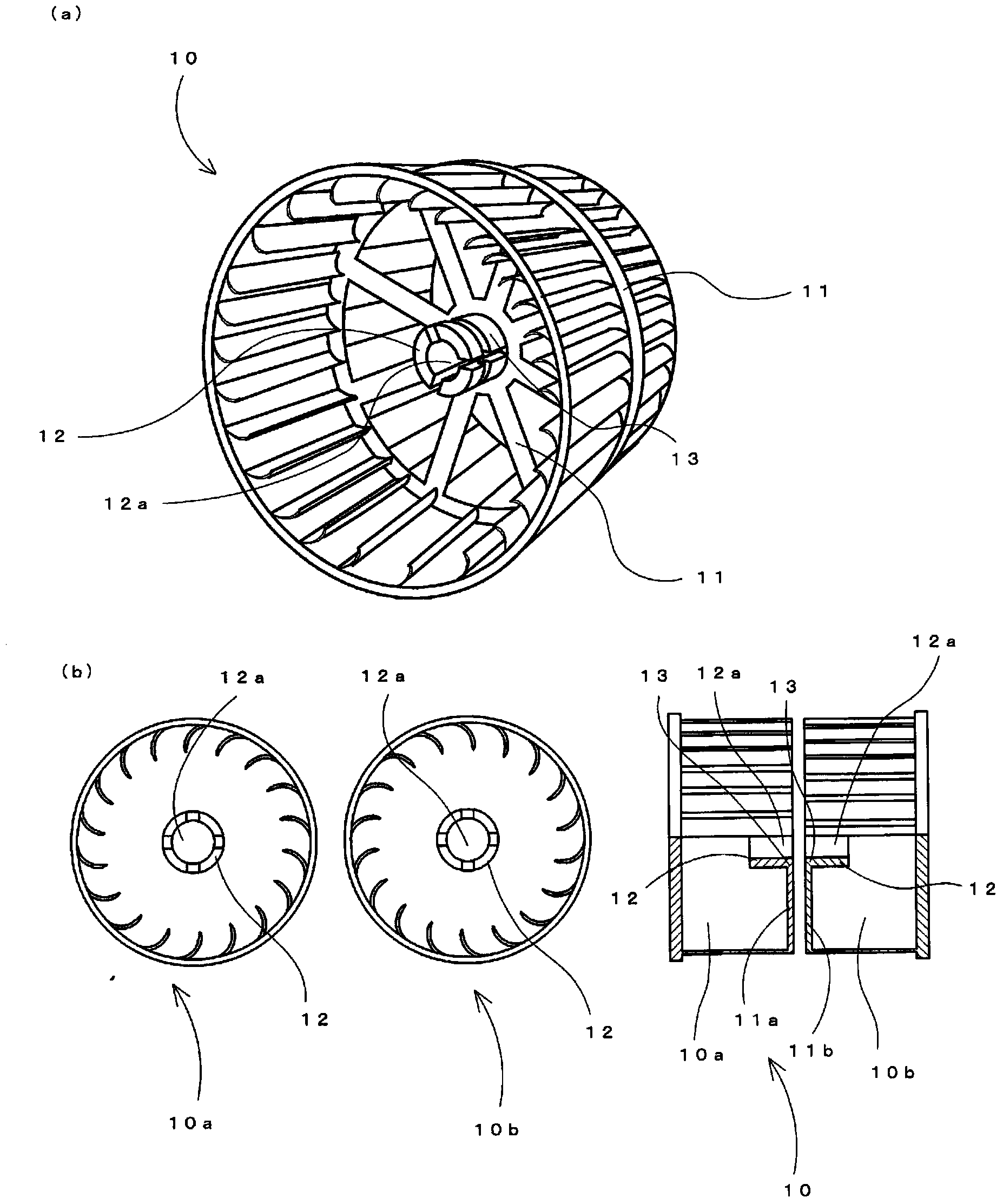

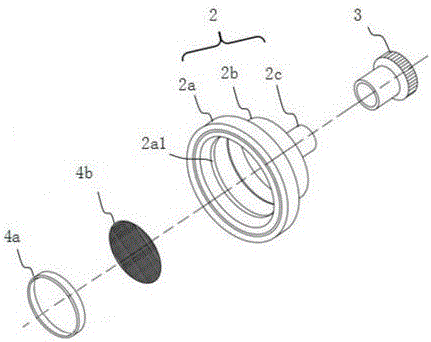

Shaft-type cross-flow fan and method for manufacturing same

InactiveCN103582764AHigh dimensional accuracyHigh quality such as dimensional accuracyPump componentsRadial flow pumpsUltrasonic weldingEngineering

[Problem] To provide a cross-flow fan having excellent ease of balance adjustment, low cost, high precision, high rigidity, and a high degree of silence without the need for an ultrasonic welding step, and to provide a method for manufacturing the cross-flow fan. [Solution] This method comprises: a first step of injection-molding a plurality of double fans made of resin and configured according to a cross-flow scheme, having a bearing portion and a fixed portion in a central wall; a second step of fabricating a connecting shaft corresponding to the desired fan length; a third step of inserting the connecting shaft fabricated in the second step into the bearing portion of the double fans molded in the first step; a fourth step of fixing the connecting shaft and the fixing portion using an engaging fixture; a fifth step of repeating the third and fourth steps to obtain the desired fan length; and a sixth step of adjusting balance as needed.

Owner:FANTEC

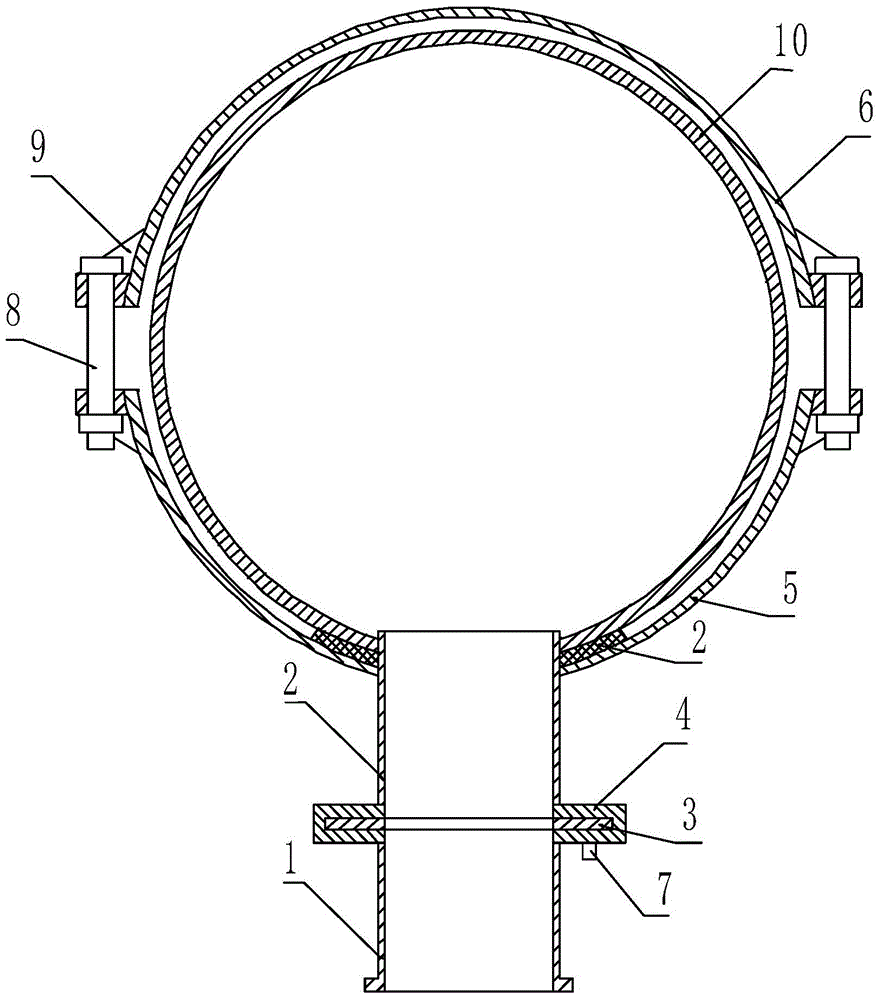

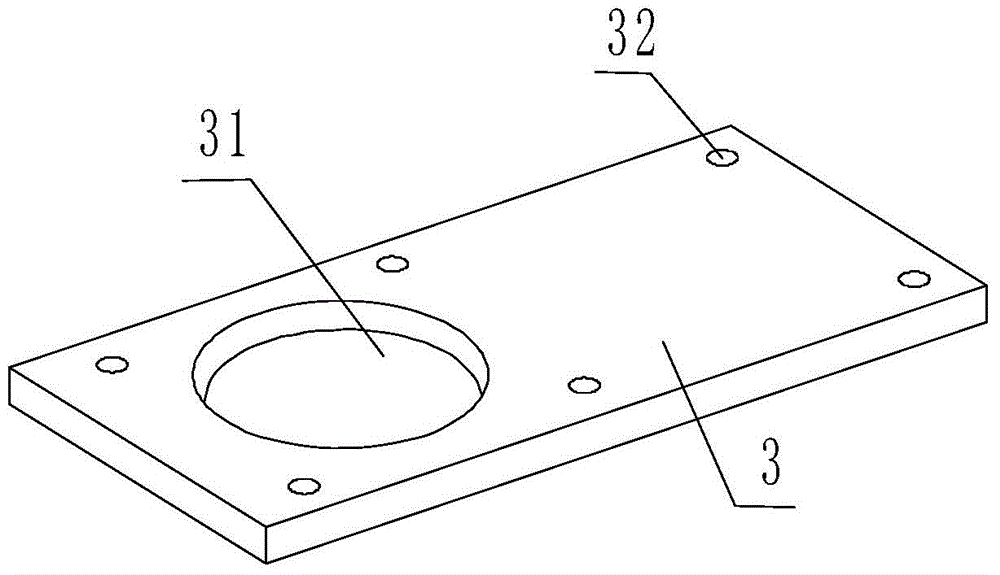

Steel pipe concrete jacking inserting plate type control device and method for connecting steel pipe concrete jacking inserting plate type control device to steel pipe column

InactiveCN104153464AReduce use costEasy to makeBuilding constructionsArchitectural engineeringSteel columns

The invention provides a steel pipe concrete jacking inserting plate type control device and a method for connecting the steel pipe concrete jacking inserting plate type control device to a steel pipe column. The steel pipe concrete jacking inserting plate type control device comprises a pumping pipe, a feeding pipe, an inserting plate, an inserting plate box, a front hoop and a rear hoop, wherein one end of the feeding pipe penetrates through and is welded to the front hoop, the other end of the feeding pipe is welded to the inserting plate box, the side, opposite to the feeding pipe, of the inserting plate box is welded to the pumping pipe, and the inserting plate is fixed into the inserting plate box through an inserting pin; the rear hoop is connected with the front hoop through a connector, a cavity is formed in the inserting plate box, the pumping pipe and the feeding pipe are both communicated with the cavity and are welded to the two sides of the inserting plate box coaxially, and the inserting plate inserted in the cavity controls on or off of concrete flow between the pumping pipe and the feeding pipe. When the steel pipe concrete jacking inserting plate type control device is connected to the steel pipe column, whether the wall thickness of each pipe meets the requirements or not is checked, then cleaning work is carried out, and installation is carried out finally. The steel pipe concrete jacking inserting plate type control device is low in manufacturing cost, can effectively connect a steel pipe to a concrete pump pipe together and can control concrete poured into the steel column to flow out. Meanwhile, the connecting method is simple, is feasible and enables detachment to be convenient.

Owner:MCC TIANGONG GROUP

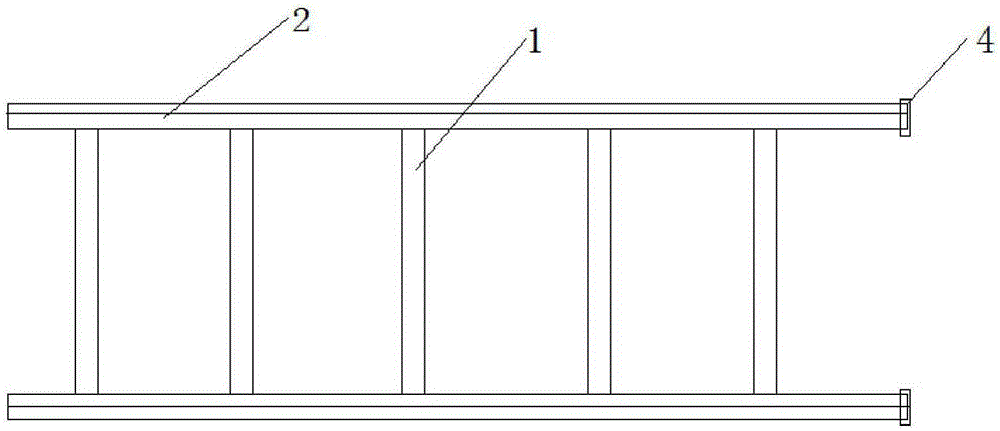

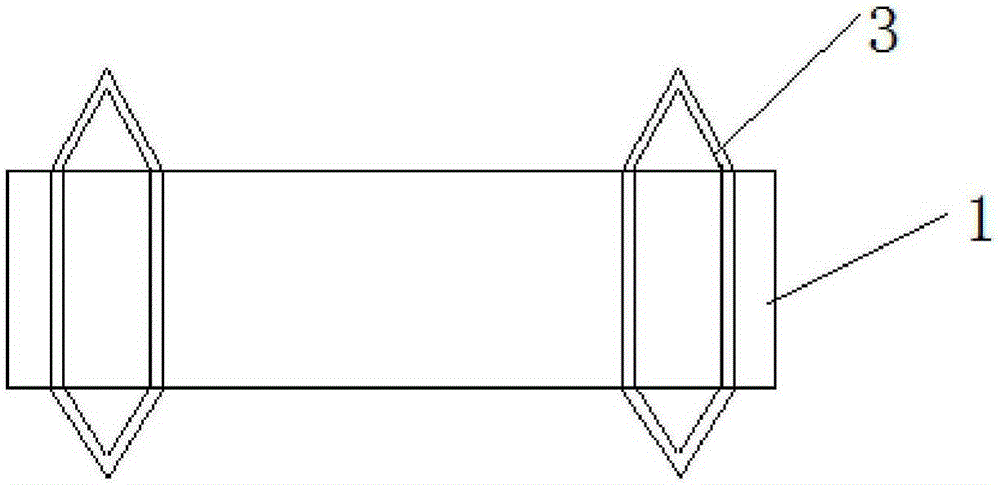

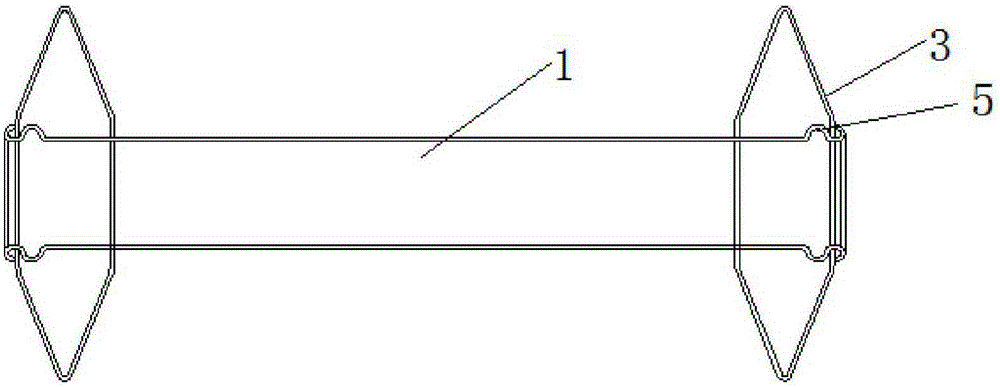

Rhombic cable ladder applied to wind power generation system

InactiveCN105244825APlay a protective effectAvoid wear and tearElectrical apparatusWind power systemWind power generation

The invention discloses a rhombic cable ladder applied to a wind power generation system. The rhombic cable ladder applied to the wind power generation system comprises a round tube and rhombic tubes, wherein the round tube penetrate through the two rhombic tubes, mounting holes are formed in opposite positions of the two rhombic tubes, and the rhombic tubes are not provided with indents. The rhombic cable ladder applied to the wind power generation system is simple in structure, simple in procedure and high in manufacturing efficiency; the rhombic tubes can effectively prevent a protective layer on the surface of a cable from being worn, protect the cable well and effectively prevent cable leakage and short circuit caused by breakage of the protective layer, thus improving the operating safety of the whole wind power generation system; the invention further relates to a processing technique for the rhombic cable ladder applied to the wind power generation system, which realizes indent-free connection and installation by adopting the technologies of stamping, expansion and the like during processing, thus effectively ensuring the appearance and flatness of the product.

Owner:SUZHOU BAOHAN SHUNTIAN IND CO LTD

Waterproof connector and production method thereof

PendingCN109273907ALow costOmit the welding processContact member cases/bases manufactureContact member assembly/disassemblyEngineeringLaser

The invention discloses a waterproof connector and a production method thereof. The waterproof connector comprises a body, wherein a stretching shell is arranged on the body, blanking holes are stamped on the stretching shell, a stamping shell is stamped and formed on the stretching shell, and a riveting point is stamped and formed on the stamping shell, and the riveting point is riveted and fixedwith the blanking holes. As that blank hole are formed in the stretch shell, and press forming the riveting point at the same time of forming the stamped shell, The riveting point is embedded in theblanking hole and riveted together, so that the stamping shell and the stretching shell are stably fixed together. The product can complete the assembly of the stamping shell and the stretching shellin a set of stamping dies without using laser welding, thus not only saving the equipment cost, but also eliminating the welding process, which is conducive to the improvement of the production capacity and reducing the defects of the product.

Owner:湖南中科存储科技有限公司

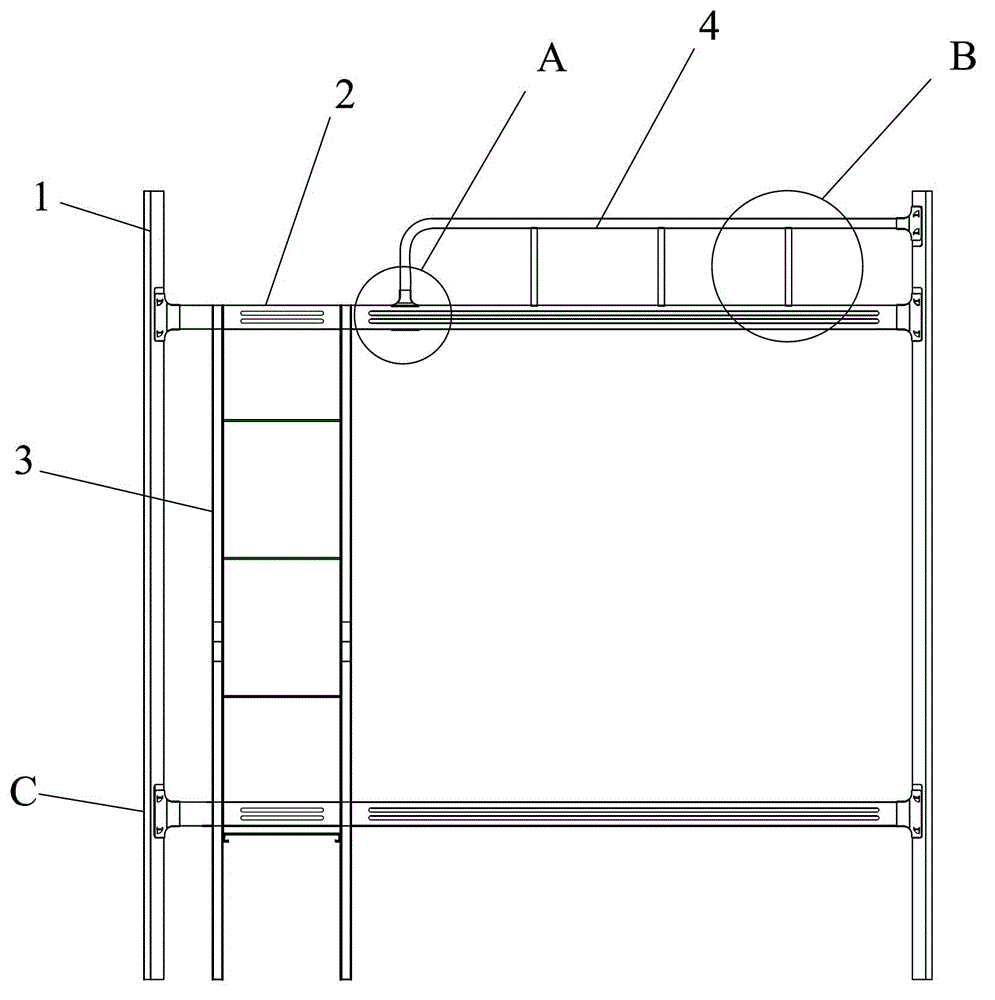

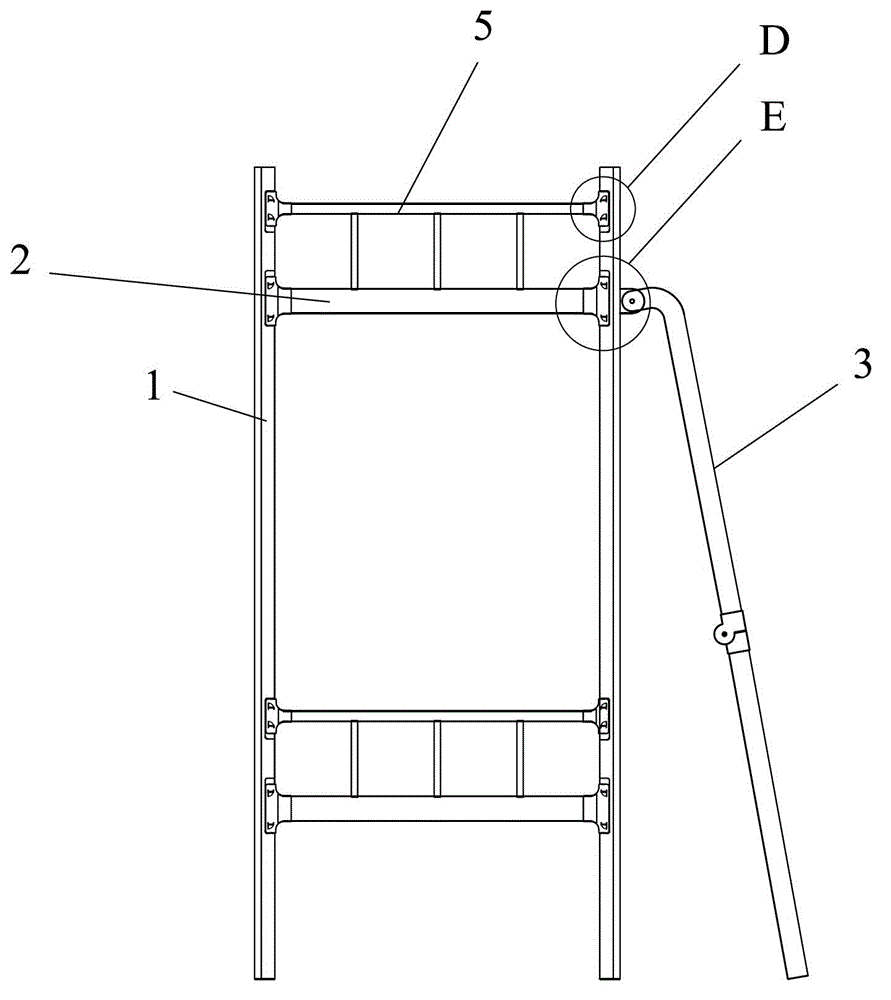

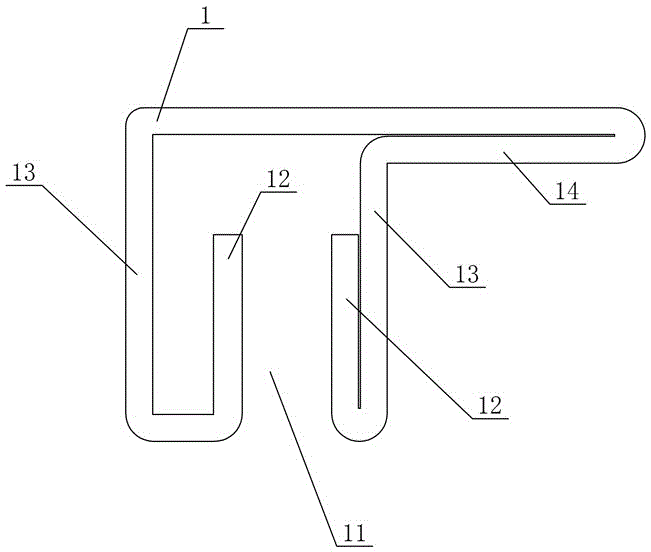

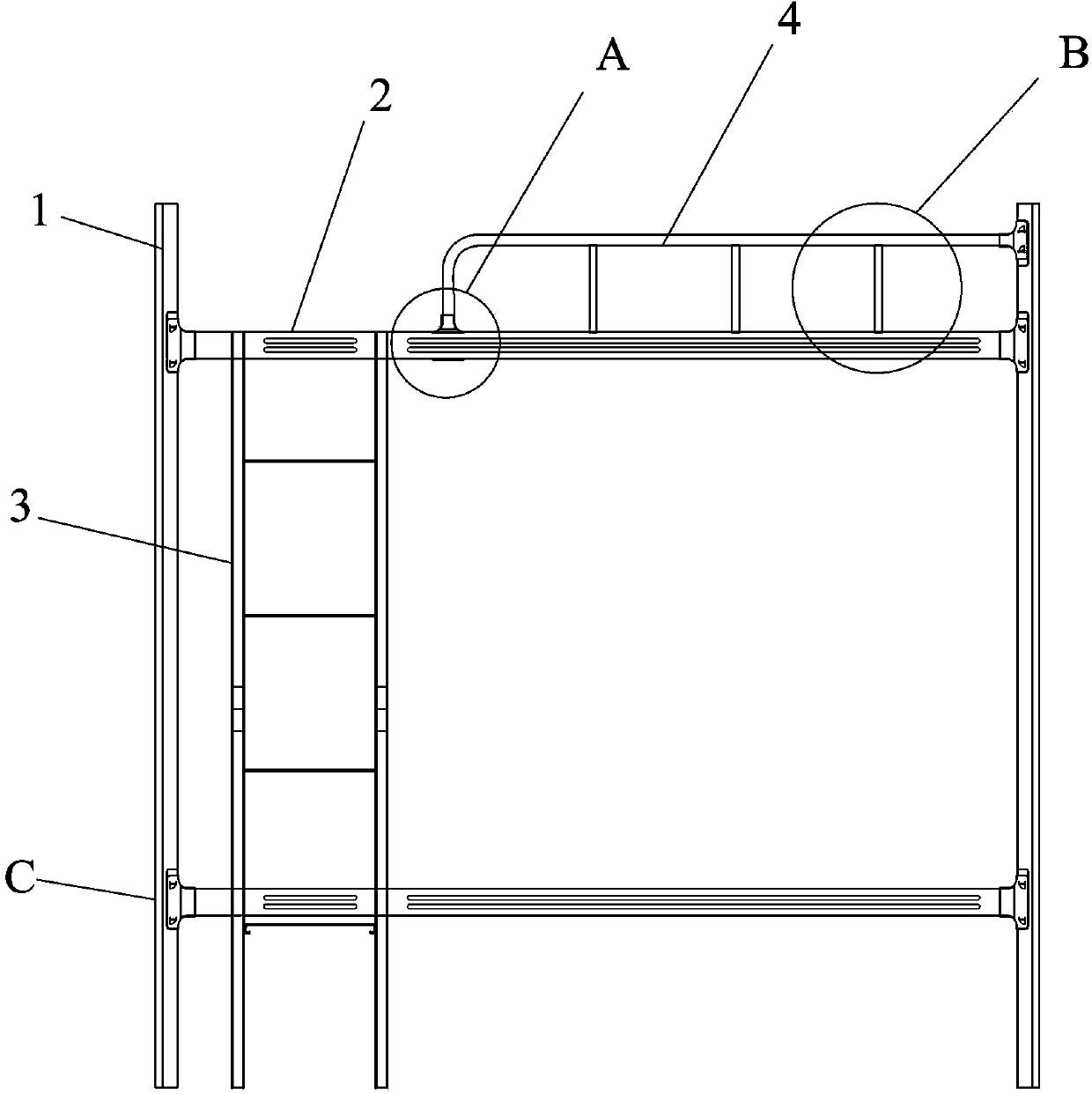

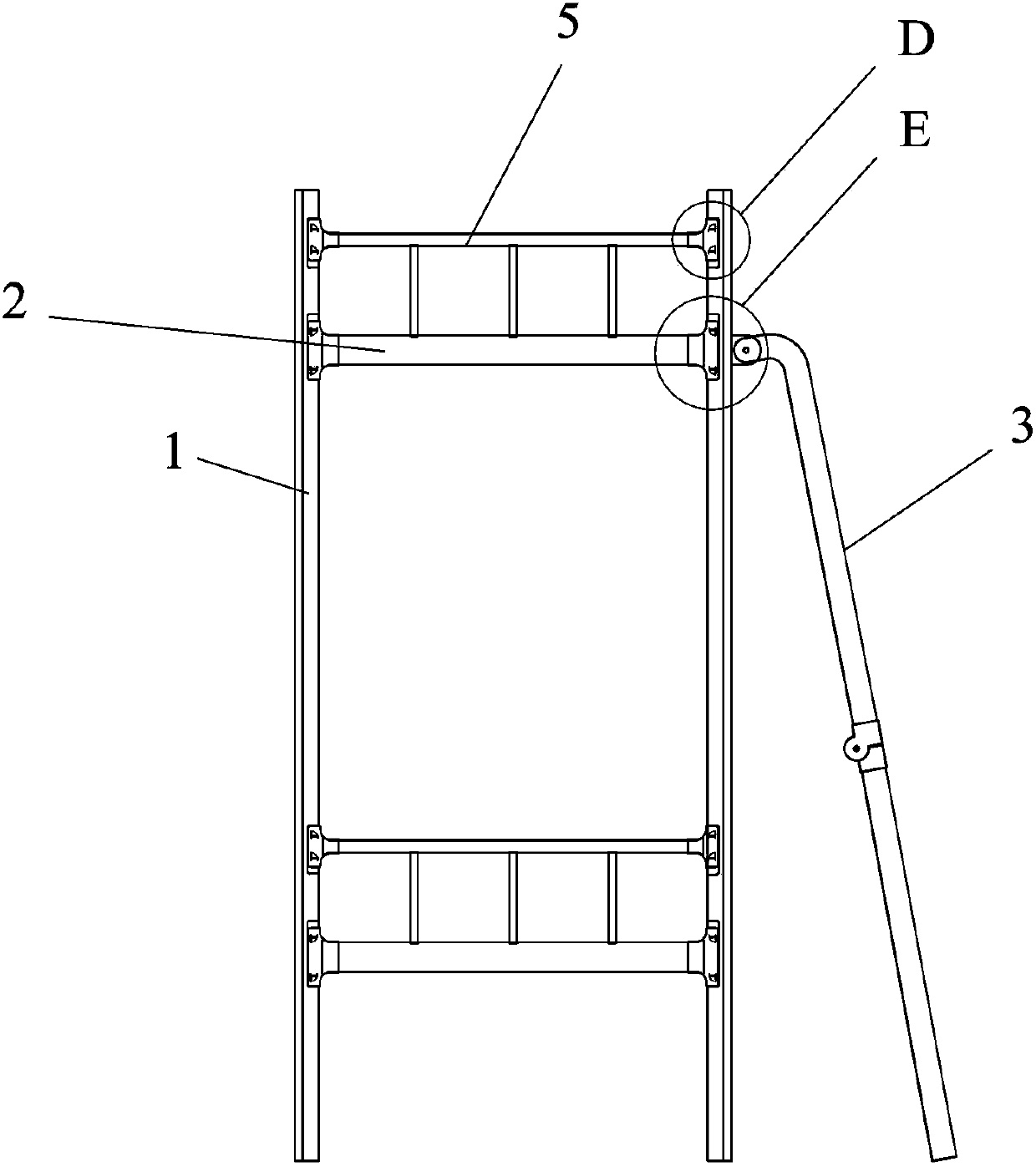

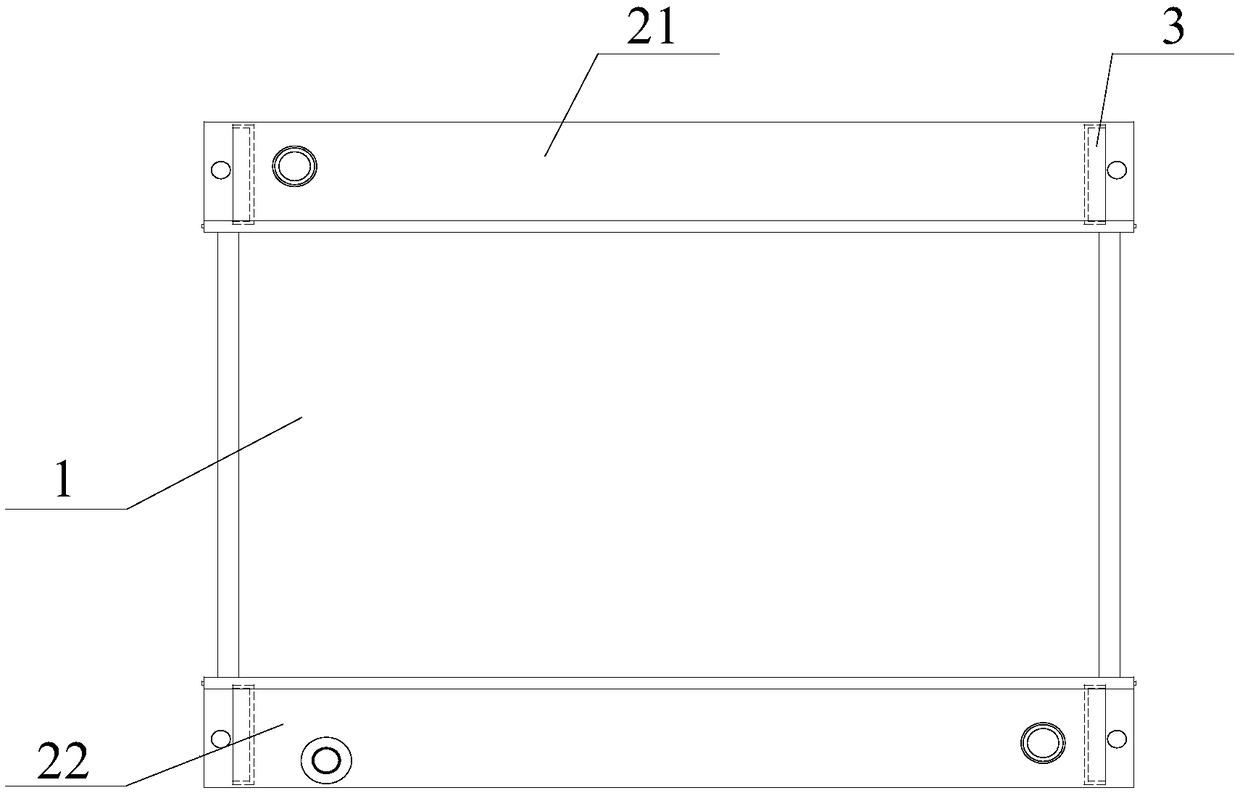

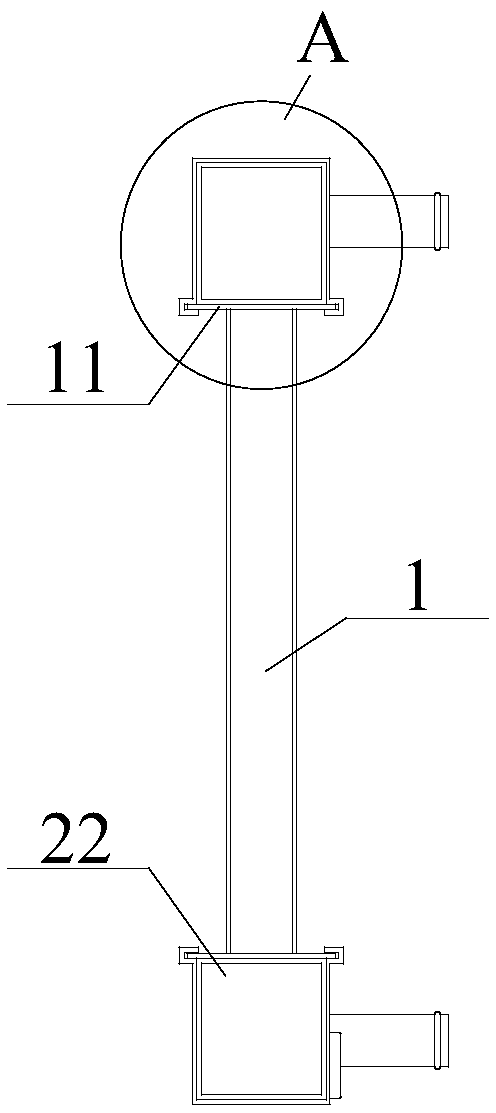

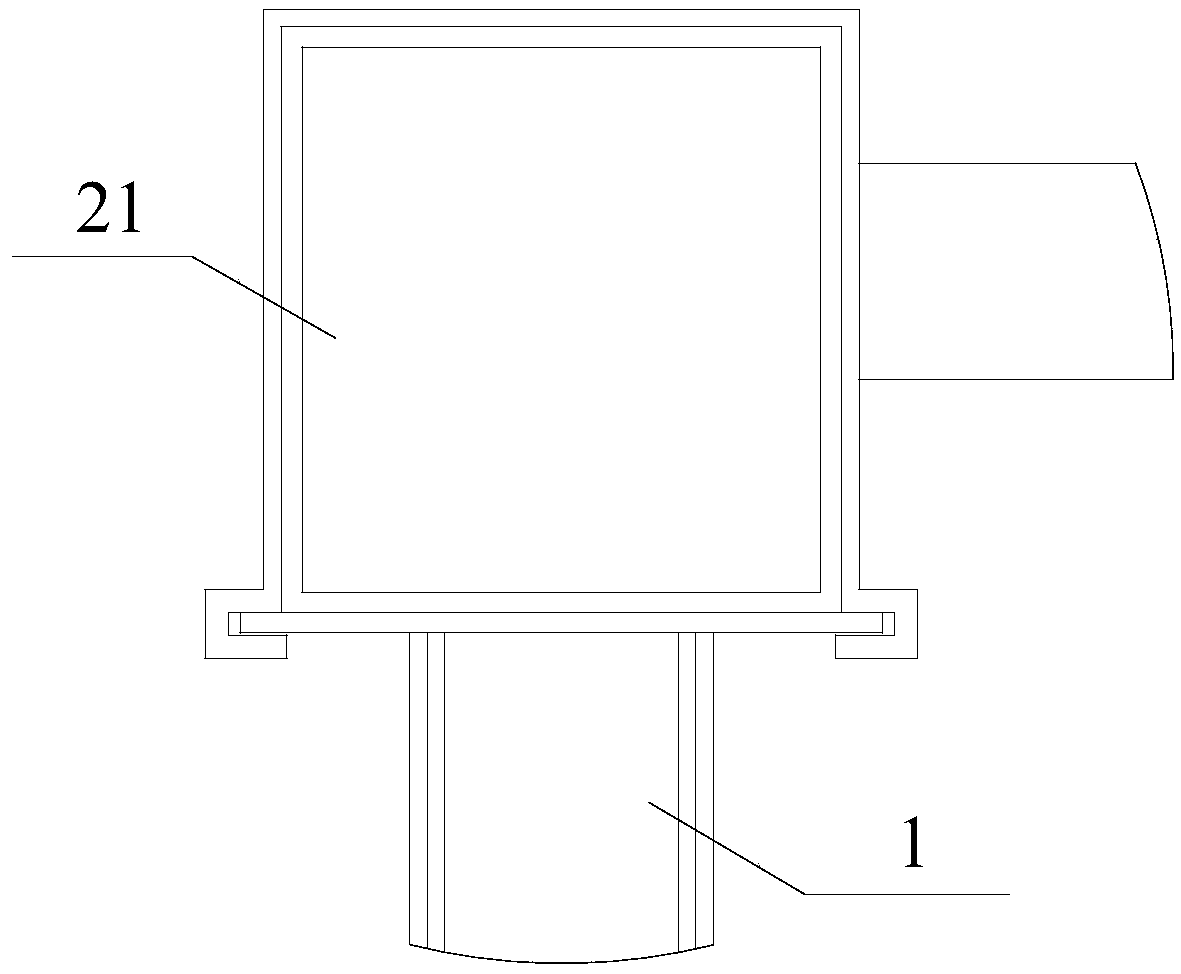

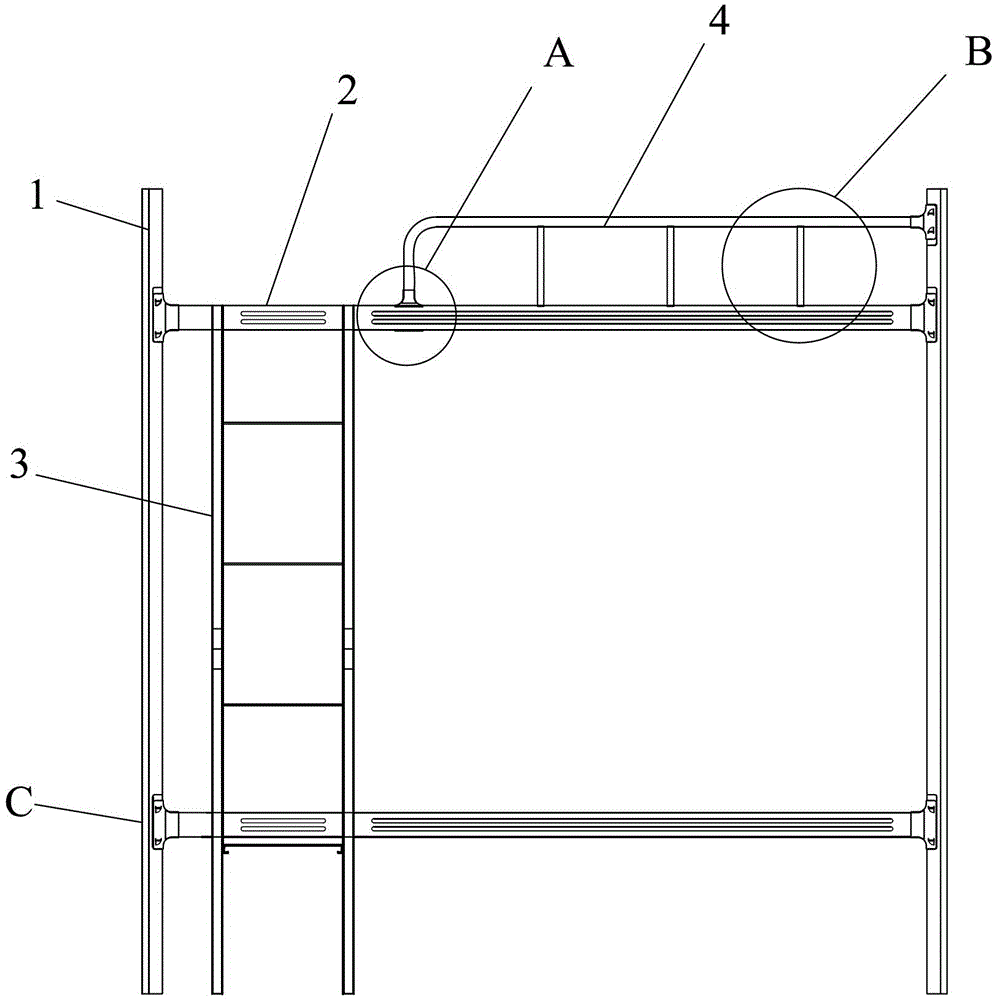

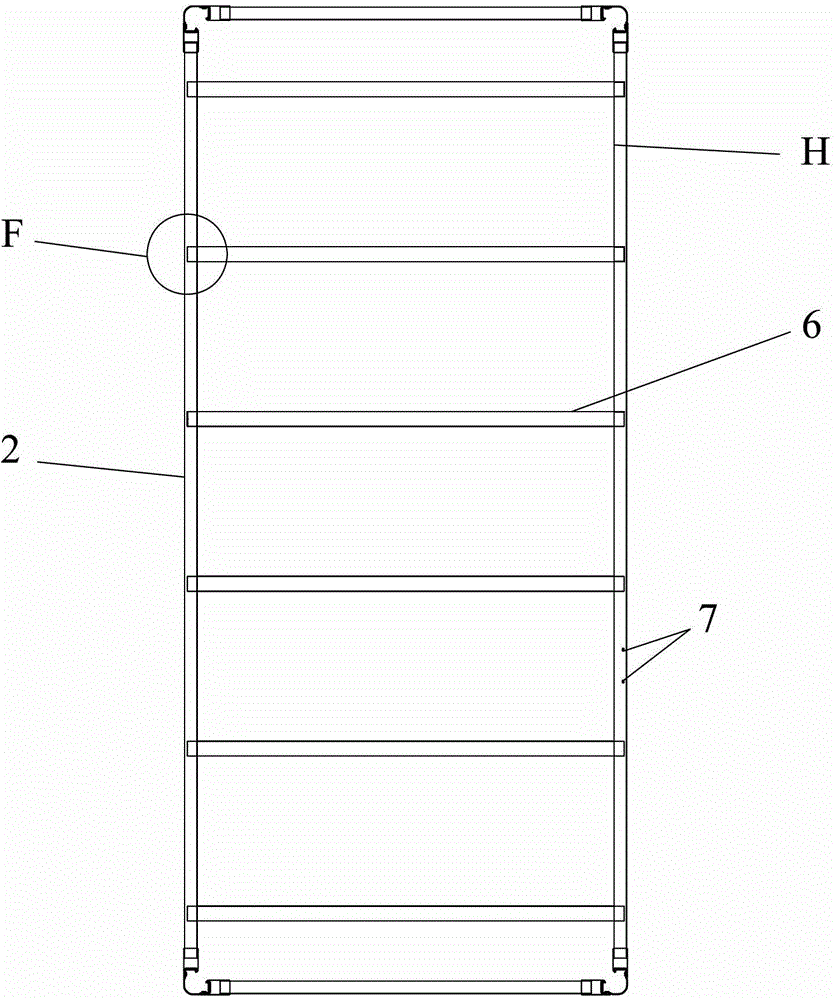

Double-decker bed based on plug-in type guardrail

The invention discloses a double-decker bed based on a plug-in type guardrail. The double-decker bed comprises a vertical post (1) as well as an upper and a lower layer bed surrounded by beams, wherein the upper layer bed is provided with a ladder stand (3); one outer side in the length direction of the upper layer bed is provided with an upper layer bed guardrail; the upper layer bed guardrail comprises a vertical rod (12) and an outer handrail (4); the outer handrail comprises a horizontal straight rod part and an arc-shaped connection rod part; the external end of the horizontal straight rod part is connected to the vertical post (1) by a connecting piece (8); and the arc-shaped connection rod part is connected to the lower beam (2) by an intermediate unit (11). The bed disclosed by the invention has the following characteristics of beauty, simplicity, fastness, endurance and environment friendliness. With the adoption of a stamping technique, the welding process is omitted, so that the production cost is reduced; and with the adoption of an insertion and combination part connection mode, the volume is reduced, and the bed is convenient to transport and mount.

Owner:徐华玉

Shielding box

InactiveCN102695410AOmit the welding processReduce manufacturing time and costMagnetic/electric field screeningEngineeringMechanical engineering

The invention discloses a shielding box. The shielding box comprises a bottom board and side boards, wherein two adjacent side boards are respectively marked as a side board A and a side board B, one side of the side board A, which is connected with the side board B, is provided with a bending part in an extension way, and the bending part is lapped on the outer side surface of the side board B. The shielding box provided by the invention has the advantages that the connection between the two adjacent side boards is realized through a lapping structure of the bending part, a welding technical process is omitted, and the manufacturing time and the manufacturing cost of the shielding box are reduced.

Owner:KUNSHAN WEIJIN HARDWARE PROD

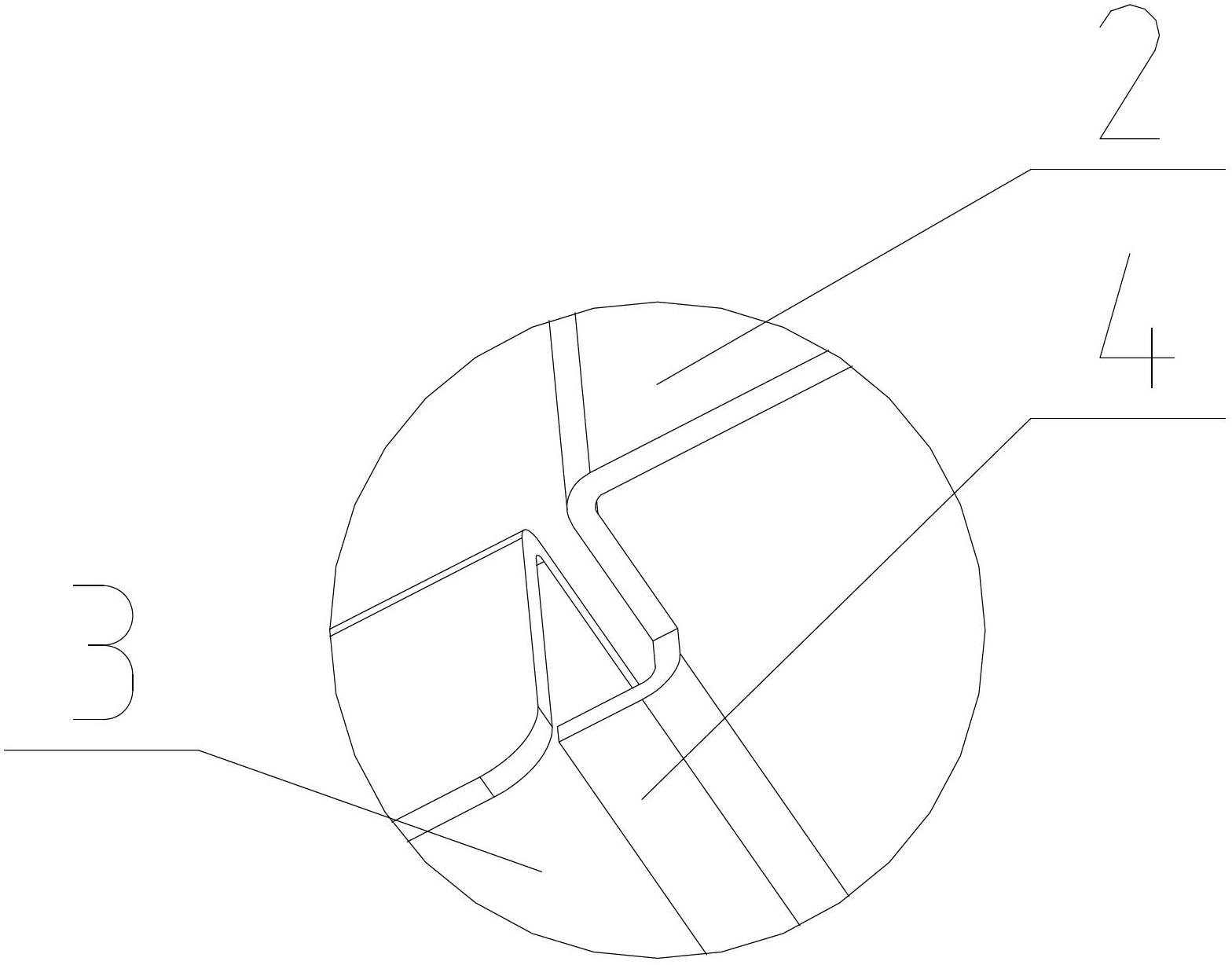

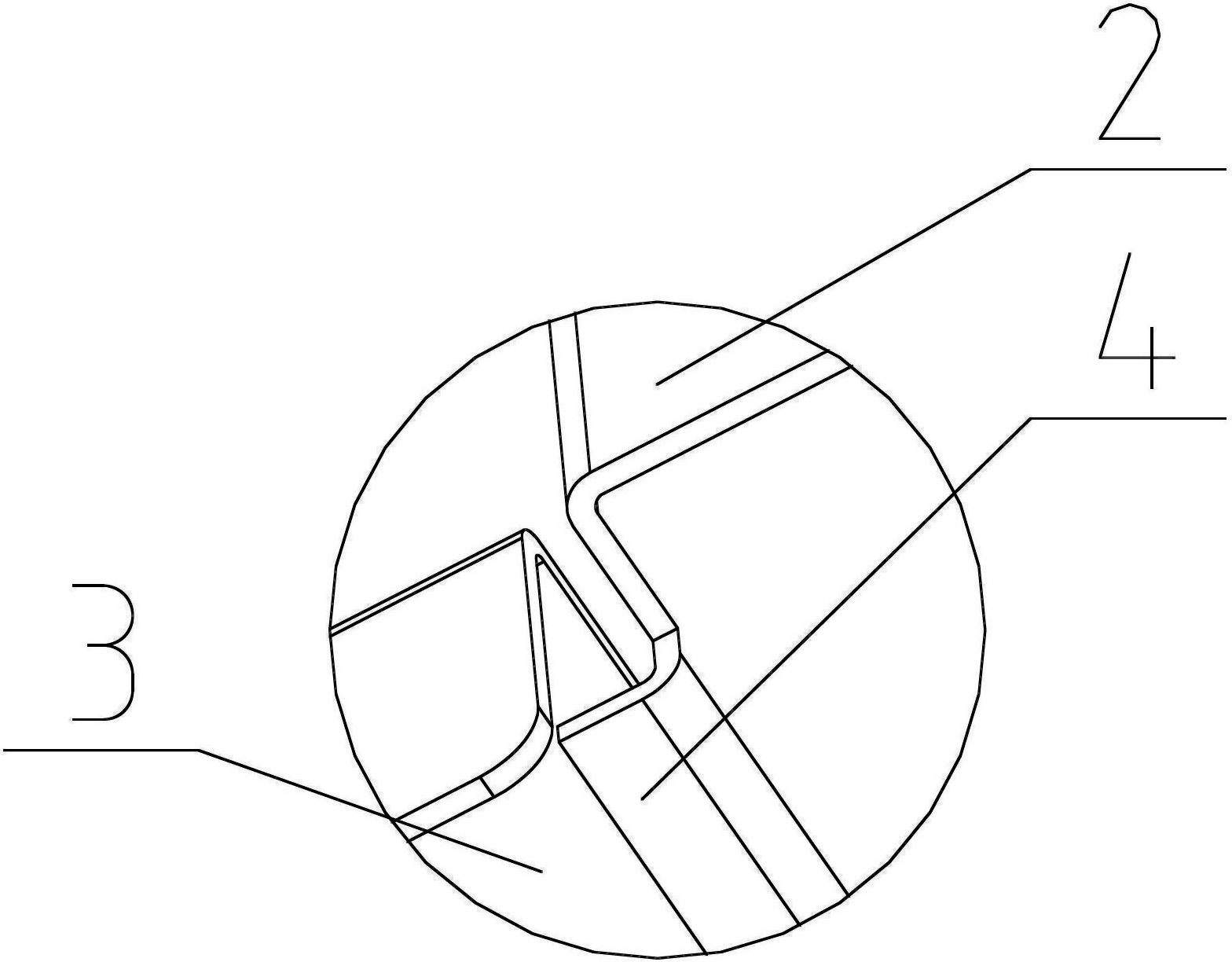

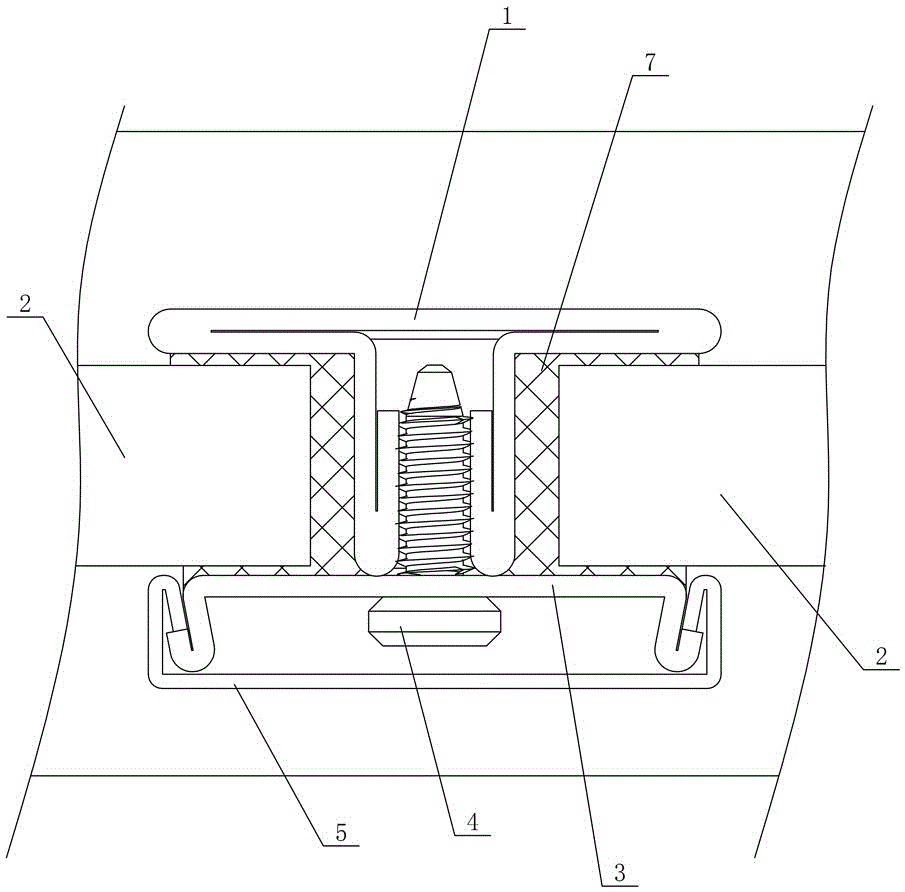

Open type profile door and window system

InactiveCN106437414AImprove aestheticsExcellent anti-rustWindow/door framesWing framesAgricultural engineeringWindow system

The invention discloses an open type profile door and window system which comprises a steel open frame, a plate and a compression bar, wherein the steel open frame surrounds the edge of the plate; the compression bar is in fastened connection with an opening of the steel open frame and drives the plate to be compressed on the steel open frame. The open type profile door and window system has the advantages of being easy to form, low in cost, energy-saving, environmental-friendly, attractive and presentable.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

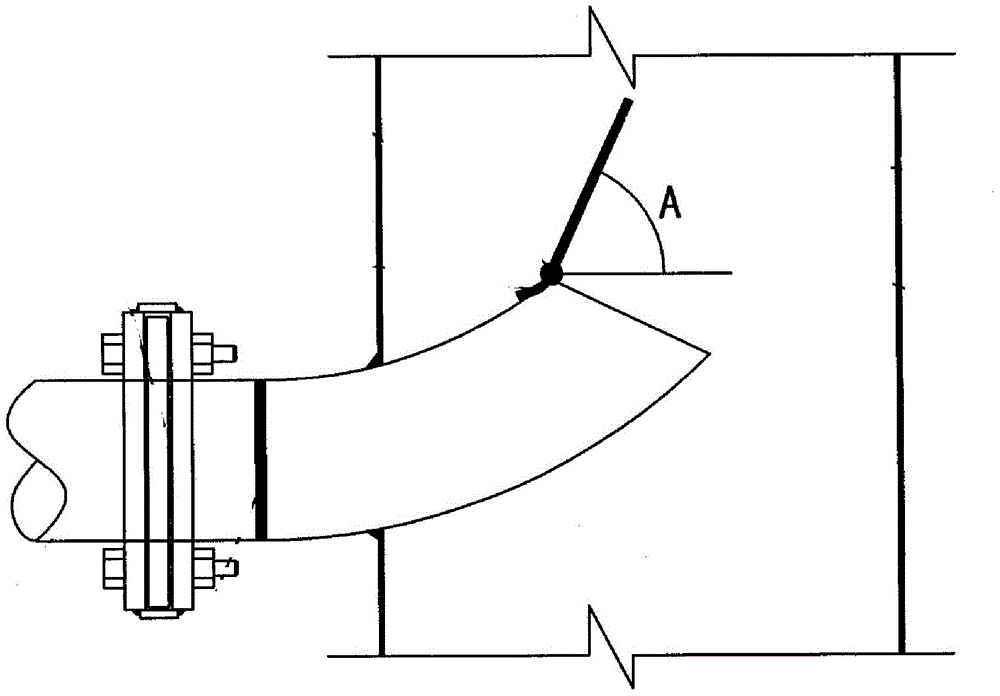

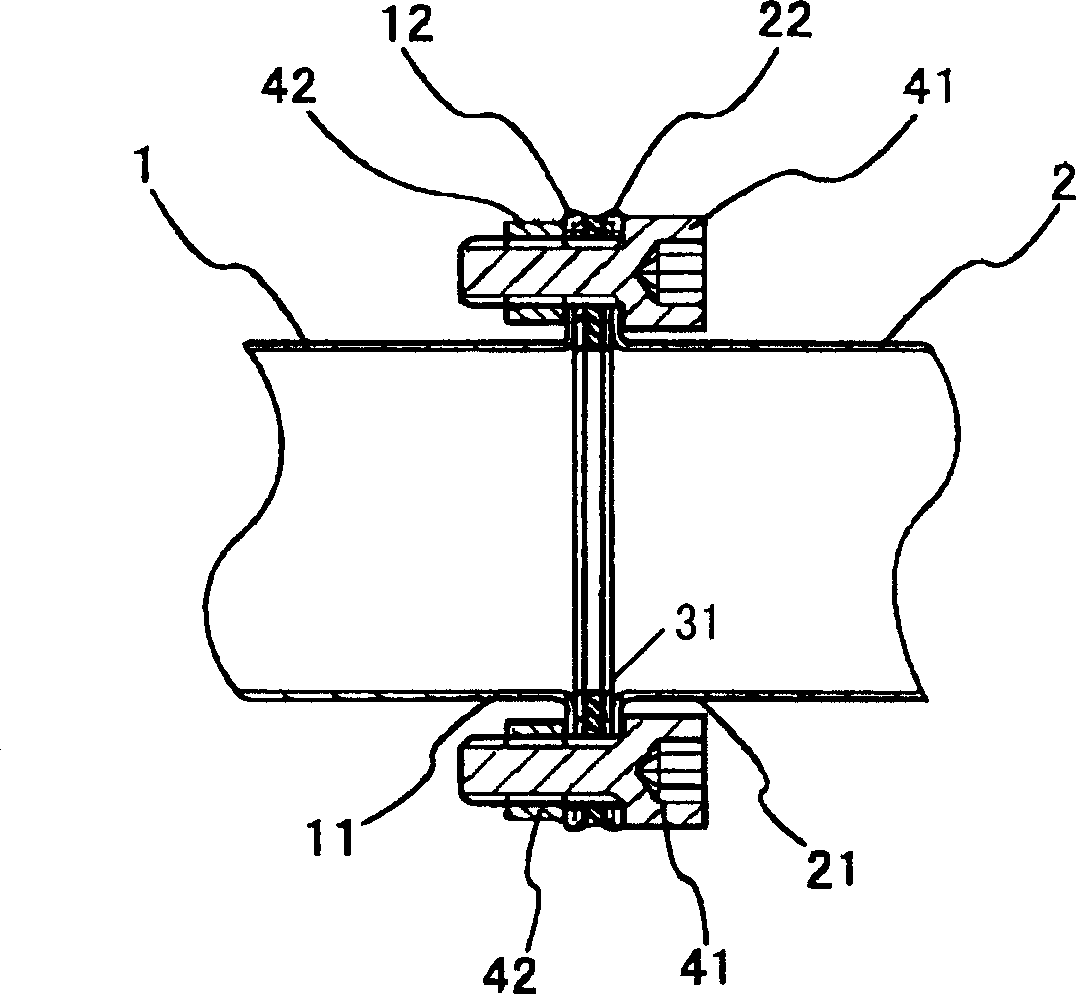

Construction of coupling exhaust pipes of vehicle

ActiveCN1811142AOmit the welding processNo hassle in the manufacturing processExhaust apparatusSilencing apparatusAerospace engineeringFlange

The present invention provides an opening edge of an upstream-side exhaust pipe and an opening edge of a downstream-side exhaust pipe opposed to the opening edge of the upstream-side exhaust pipe are bent radially outward and thereafter radially inward by molding to form a circumference of the upstream-side exhaust pipe and a circumference of the downstream-side exhaust pipe as a flange portion respectively. After both flange portions are butted to each other through a gasket disposed therebetween, they are mechanically coupled to each other with a bolt and a nut.

Owner:NAKAGAWA SANGYO

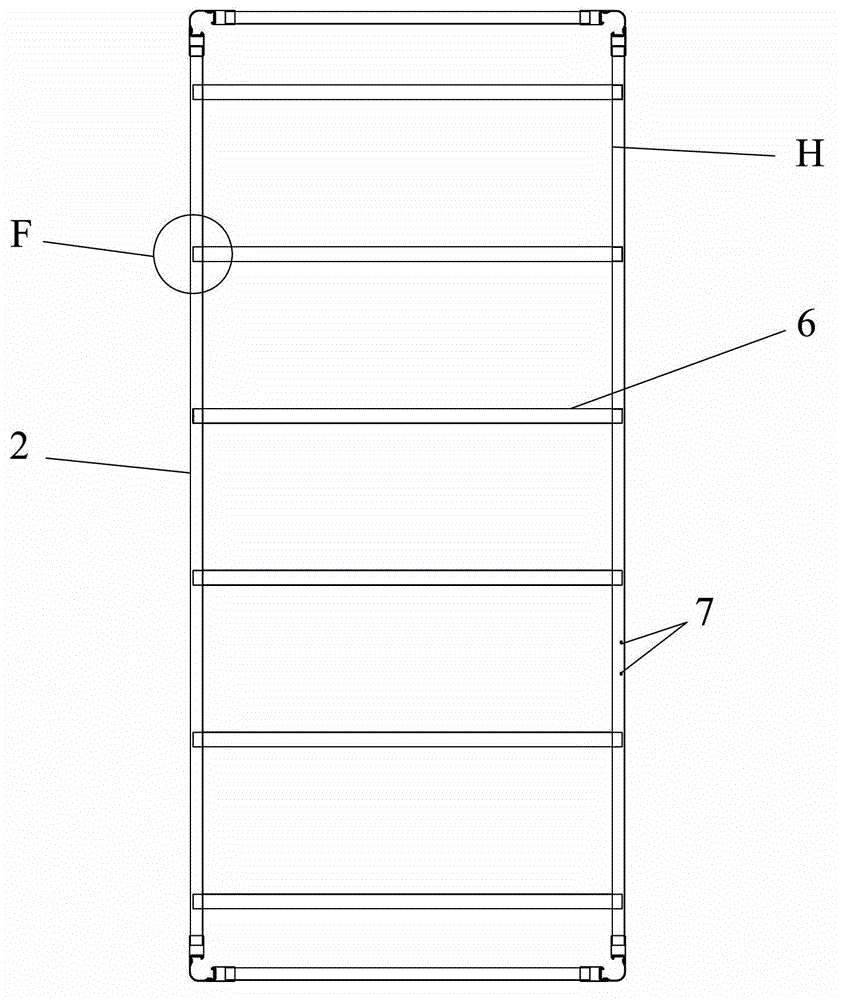

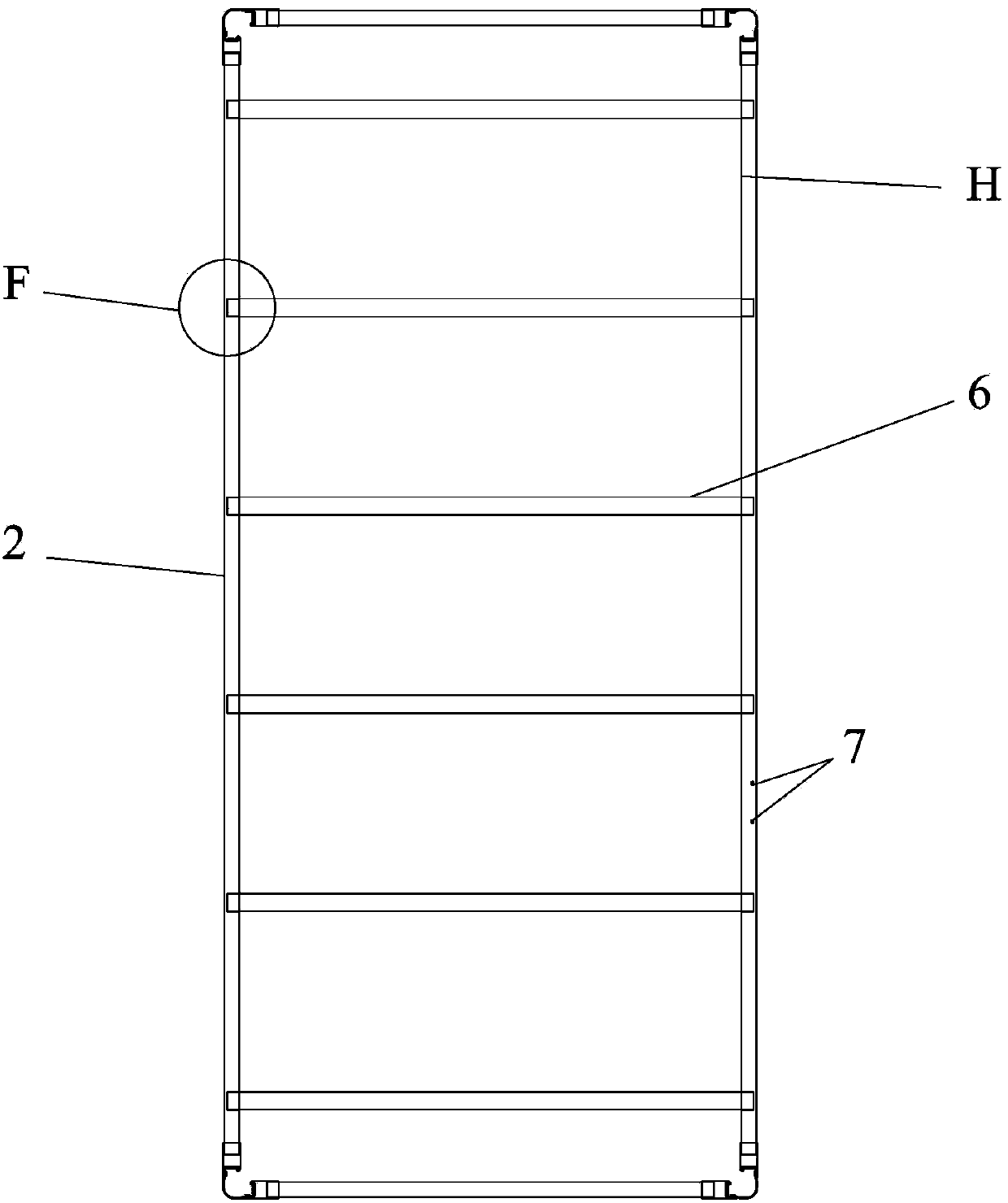

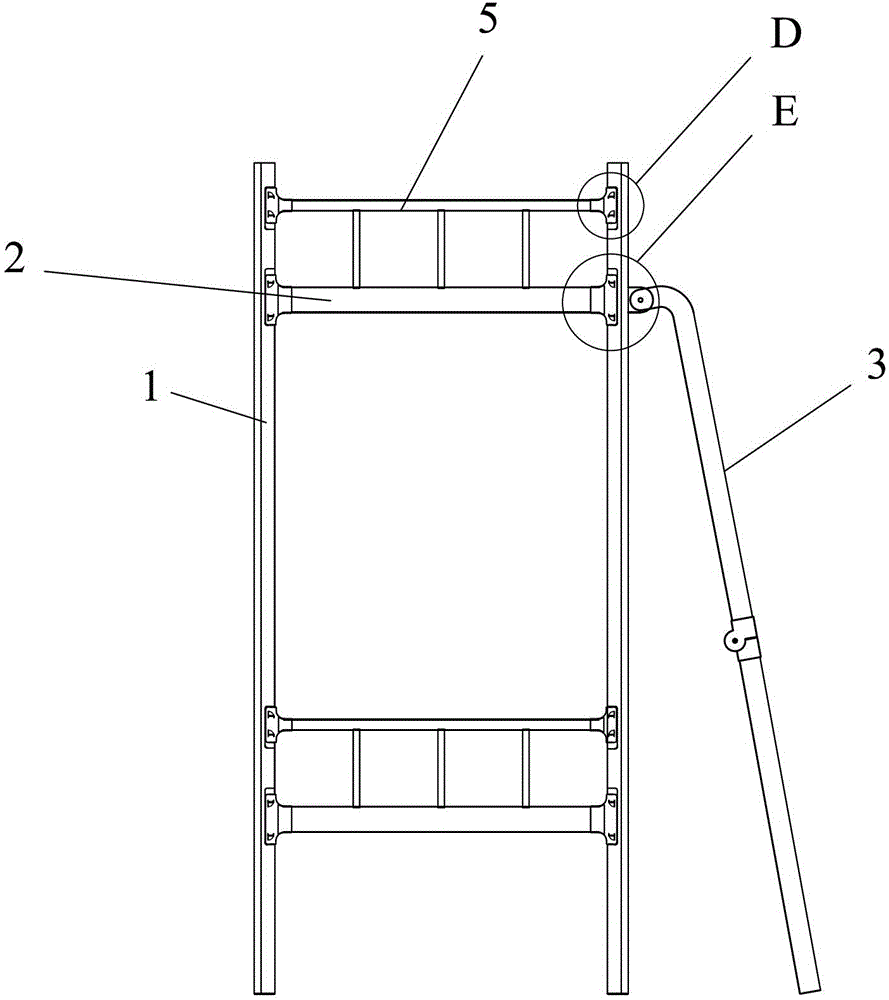

Plug structure for bed and plug structure-based bedding

InactiveCN102960978BAvoid collision damageGood lookingBedstandsFurniture joiningEngineeringStamping process

The invention discloses a plug structure for bedding. The plug structure comprises a column 1 and a cross bar connected with the column, and the column and the cross bar are connected through a connector 8 which comprises a cylinder 21 and a clamped hook body 22, wherein the clamped hook body comprises a hook-shaped part hooked at the column and a straight-edge part clamped at one side of the column; a cylinder port at the other side of the cylinder is formed with an internally retracted outer edge; and the cross bar is connected at the outer edge. The invention further provides basic forms of single-layer beds or bunk beds and apartment beds based on the above connecting structure. The bedding provided by the invention is beautiful, simple, firm, durable, green, and environmentally friendly. By using a stamping process, a welding process is omitted and production cost is reduced; and by using a component connecting form such as inserting and combining, size is reduced and transportation and installation are facilitated.

Owner:徐华玉

Hinge and door device

InactiveCN101861440AKeep it openKeep with keep openWing accessoriesWing fastenersEngineeringMechanical engineering

Owner:CATEPILLAR SARL

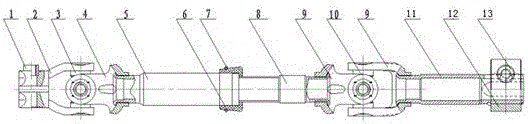

Automobile steering lower transmission shaft assembly without welding structures

InactiveCN106218706ASmooth rotationImprove securityMechanical steering gearsInterference fitDrive shaft

The invention provides an automobile steering lower transmission shaft assembly without welding structures. The automobile steering lower transmission shaft assembly comprises a telescopic transmission device, an upper universal joint and a lower universal joint, wherein the upper universal joint and the lower universal joint are arranged at two ends of the telescopic transmission device; the upper universal joint comprises two sleeve-loading universal joint forks and an upper universal joint cross shaft arranged between the two sleeve-loading universal joint forks; an upper locking nut is in interference fit with a locking sleeve; the locking sleeve is axially fixed on a connection sleeve; the connection sleeve is fixed on the sleeve-loading universal joint forks; the lower universal joint comprises a sleeve-unloading universal joint fork, a lower universal joint fork and a lower universal joint cross shaft arranged between the sleeve-unloading universal joint fork and the lower universal joint fork; a lower locking nut is in interference fit with the lower universal joint fork; the telescopic transmission device comprises a lower spline shaft; the lower spline shaft is fixed on the sleeve-loading universal joint forks, and is in sliding connection with a lower spline sleeve; a dustproof cover is fastened on the lower spline sleeve, and is fixed on the sleeve-unloading universal joint fork. The automobile steering lower transmission shaft assembly without the welding structures has the advantages that the welding process is eliminated, the problem of welding deformation of workpieces is solved, the overall structure is firm, the process is simple, the product quality is improved, and the production cost is reduced.

Owner:JIANGSU JINYE AUTO PARTS

Outer cylinder barrel of shock absorber

InactiveCN101975239AReduce labor costEliminate welding processSpringsShock absorbersHeavy dutySpot welding

The invention discloses an outer cylinder barrel of a shock absorber, which comprises a cylinder body, a shell cover in seal connection with the cylinder body, and a lifting lug fixedly connected to the lower part of the shell cover. In the outer cylinder barrel, the periphery of the shell cover is provided with a circle of seal ring groove below which a circle of catching groove is reserved; the cylinder body is in the seal connection with the shell cover in a way that the lower end part of the cylinder body is fastened in the catching groove after a seal ring is arranged in the seal ring groove; the fastening edge of the cylinder body is reinforced in a spot welding way; and the shell cover can be cast into a whole with the lifting lug on the lower part of the shell cover. The outer cylinder barrel has the advantages of relatively lower manufacture and detection cost and reduction in the cost of the product; and the shock absorber with the reinforced outer cylinder barrel is particularly applied to heavy-duty vehicles.

Owner:CHONGQING ENDURANCE ZHONG YI SHOCK ABSORBER LIABILITY

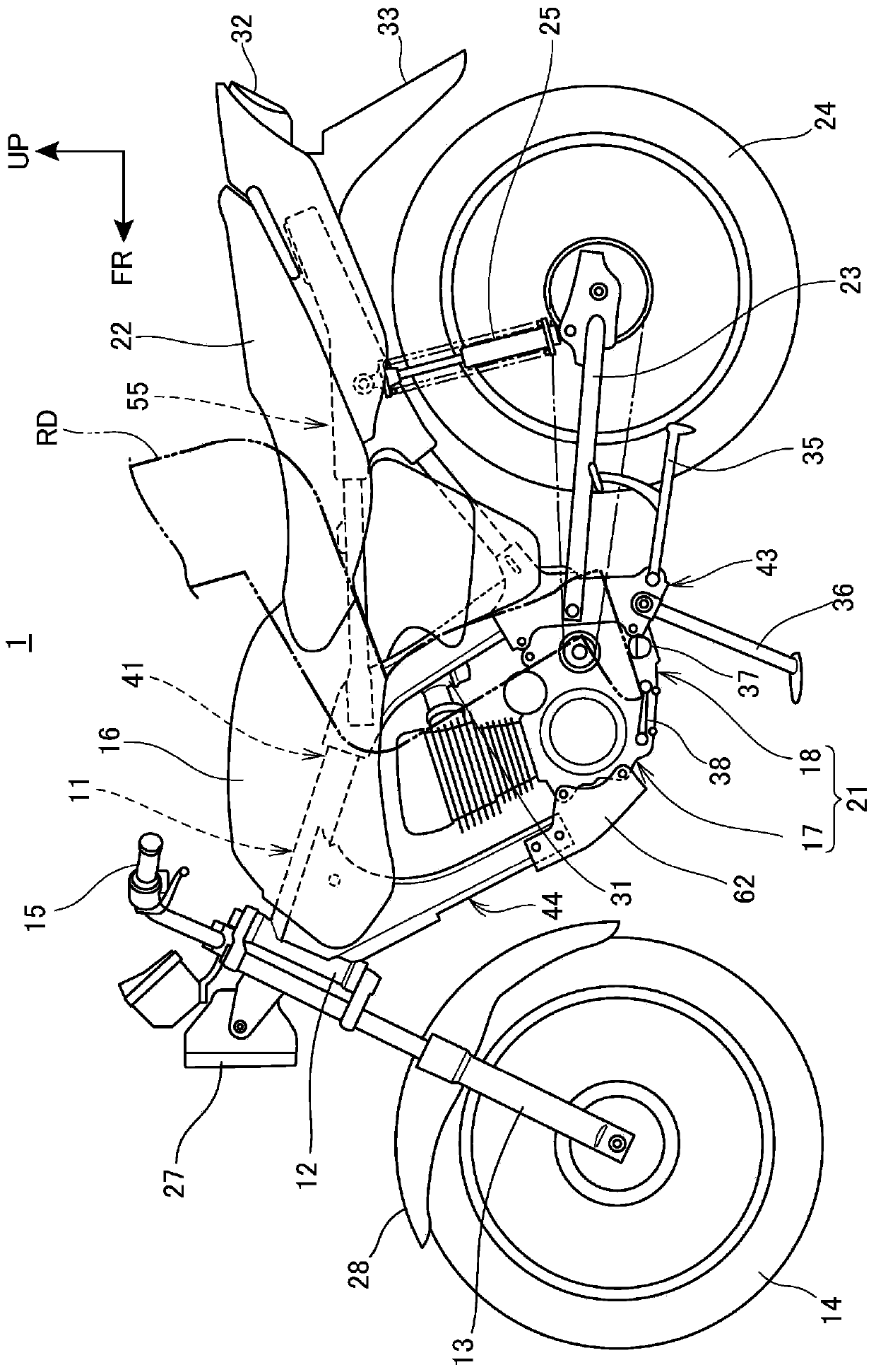

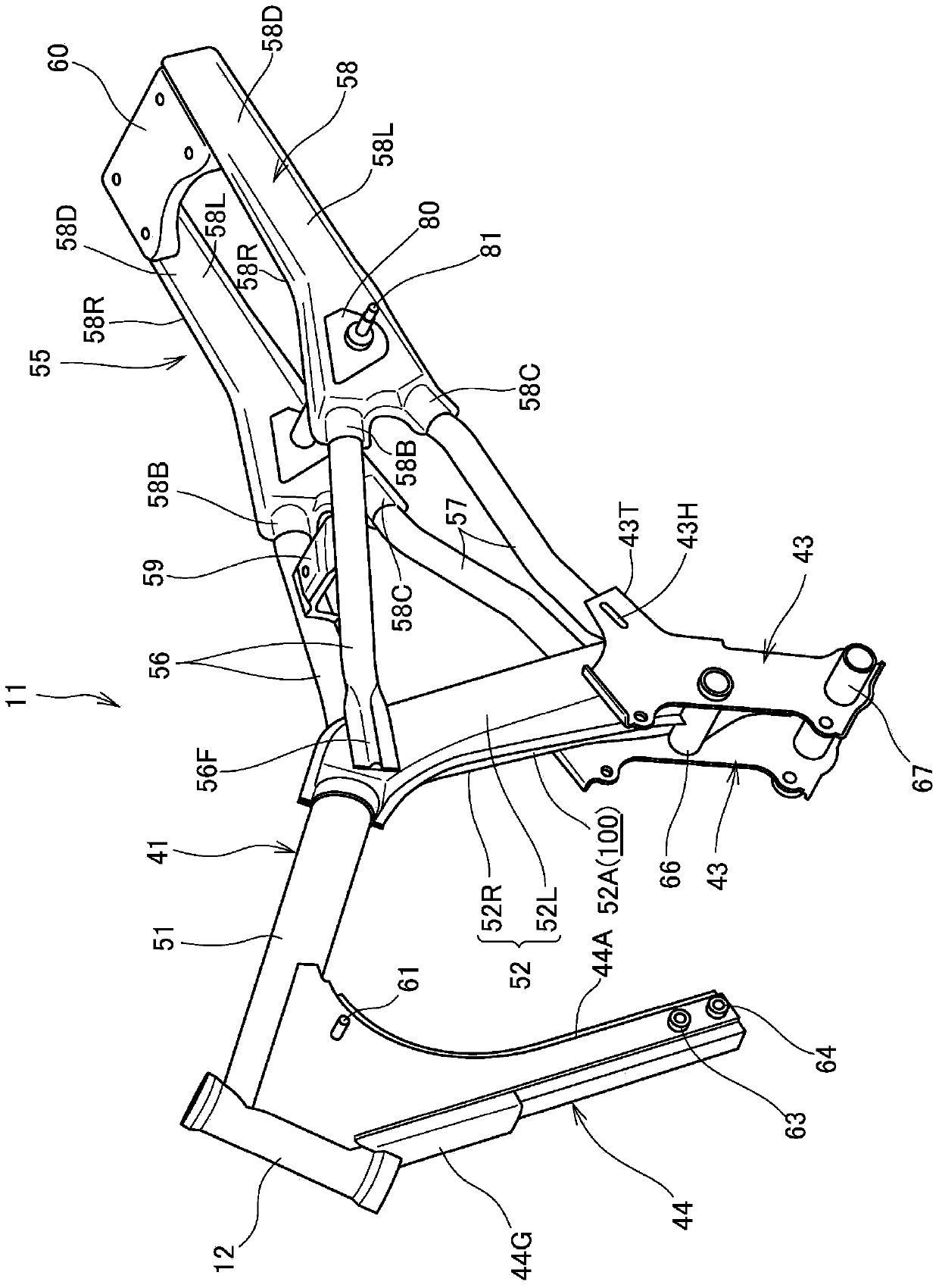

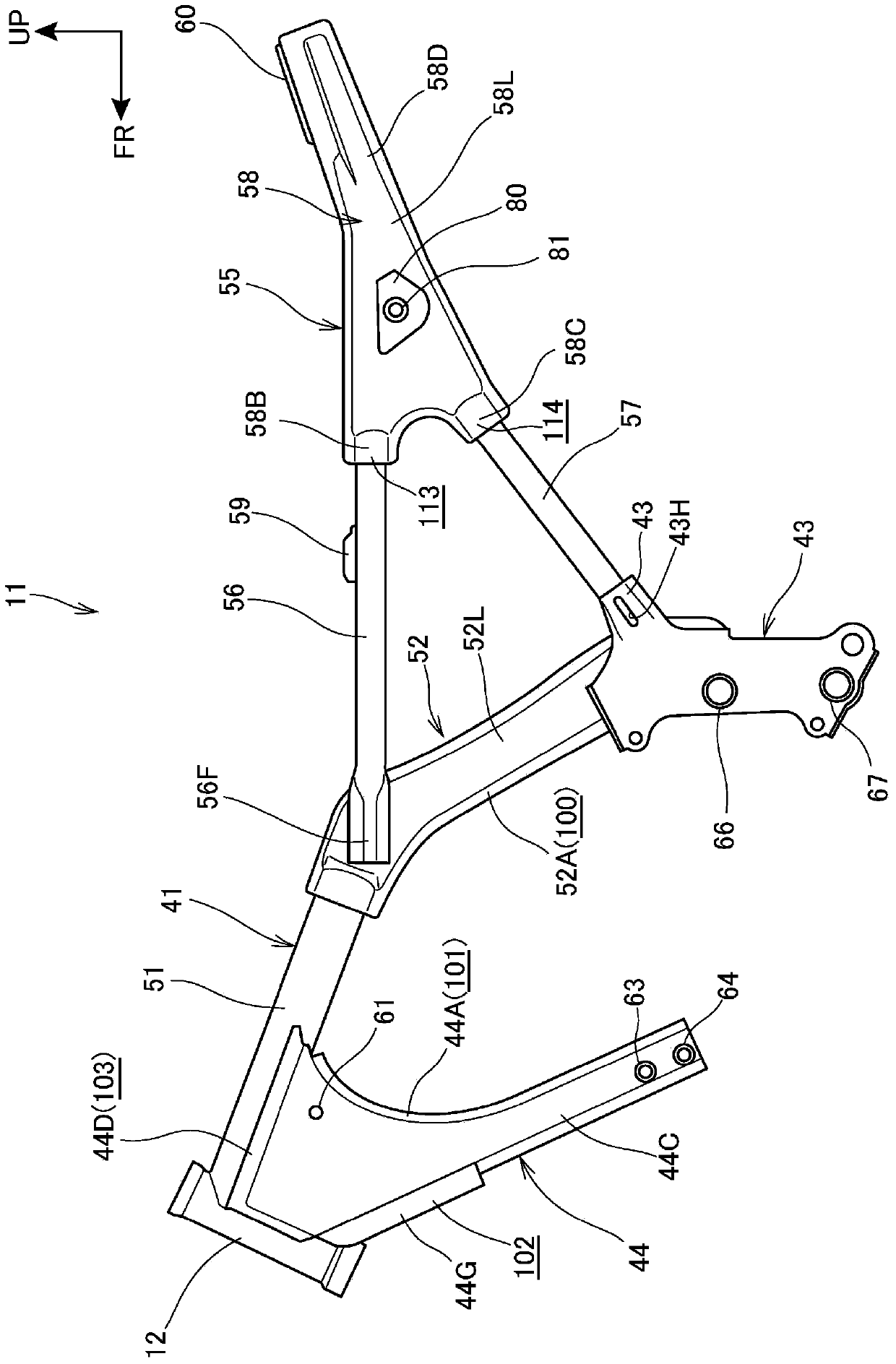

Body frame for saddle-riding vehicles

ActiveCN104943789BEasy to ensure section moment of inertiaCurb sticking outMotorcyclesCycle framesVehicle frameEngineering

Owner:HONDA MOTOR CO LTD

Hemodialysis machine cleaning stick

InactiveCN106620915AOmit the welding processEasy to operateDialysis systemsHemodialysisHaemodialysis machine

The invention discloses a hemodialysis machine cleaning stick, which comprises a cylindrical hollow tube body. The end of the tube body is welded in a first annular flange at one end of a stepped connection part, and the output port at the other end of the connection part is buckled with an end cap. The inner wall of the middle part of the connection part is provided with a second annular flange, and the inner wall of the connection part on the inner side of the second annular flange is provided with a plurality of flanges arranged in a circle, wherein a filter membrane press ring is clamped between the flanges and the second annular flange, and a filter membrane is arranged between the filter membrane press ring and the second annular flange. Compared with the existing technology, the hemodialysis machine cleaning stick has prominent advantages and benefits. According to the hemodialysis machine cleaning stick, the structure is more convenient for assembling, the welding process of the filter is eliminated, the cleaning effect can be improved by a spoiler, the risk of misoperation can be avoided by the whole hermetic package, automatic dilution and automatic formulating are adopted, cleaning and disinfection can be completed at one time, high efficiency is realized, the material is environmentally sound, the space volume is small and the operation of medical staff is more convenient.

Owner:TIANJIN SHITELEI BIOTECH

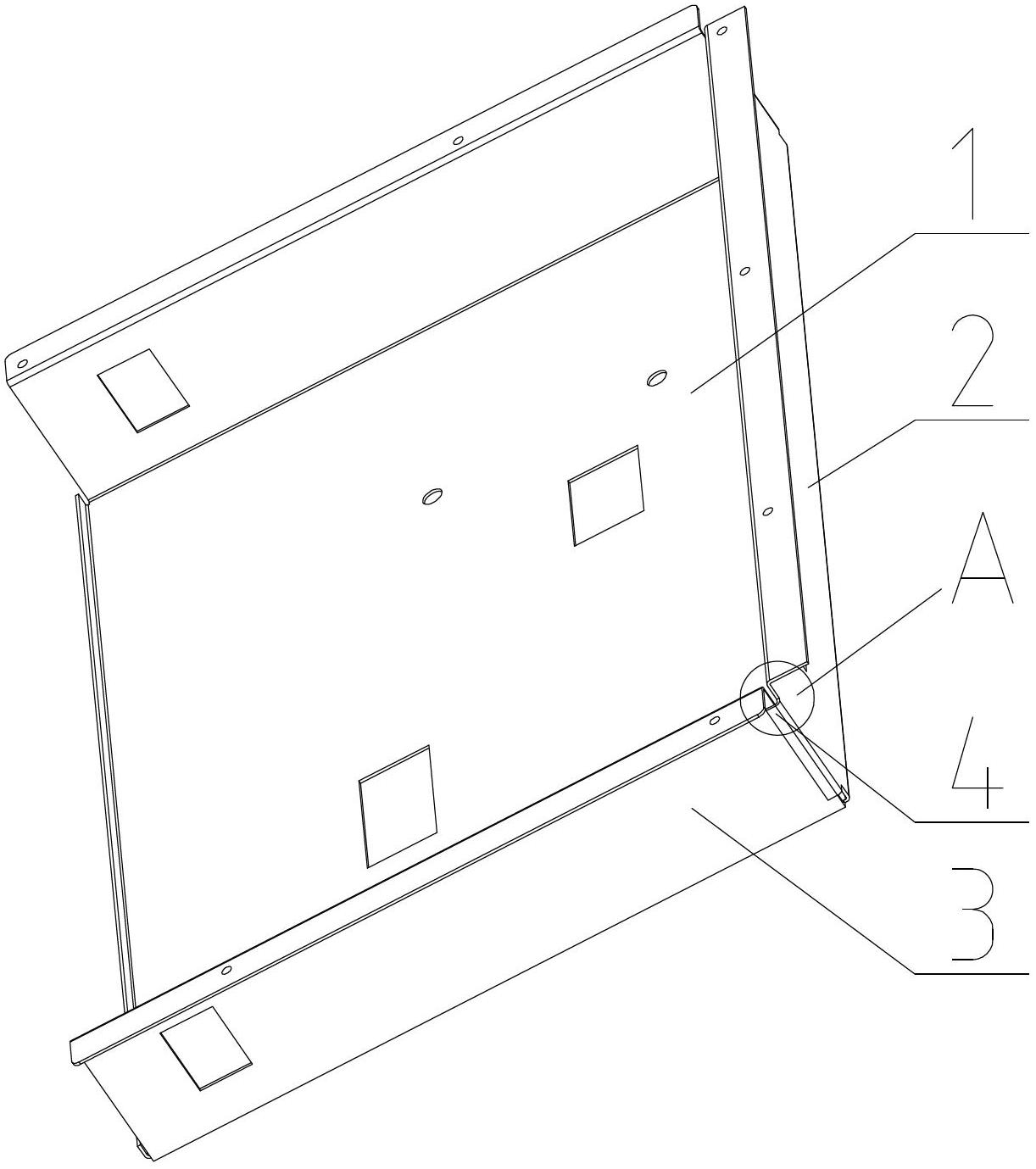

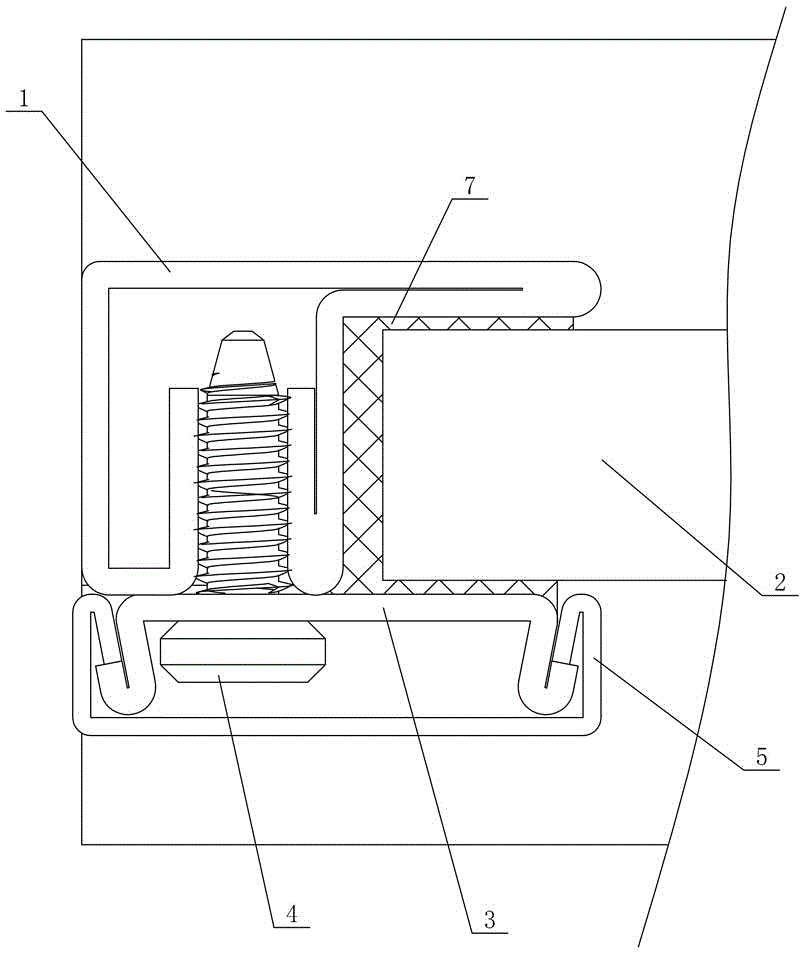

Hinge structure of steel security door

The invention discloses a hinge structure of a steel security door. The hinge structure comprises a door frame, a door leaf and a hinge. The hinged part of the door leaf with the door frame is provided with an anti-prizing projection, a protruding step surface is formed, and the door frame correspondingly forms a recess step surface. The hinge is provided with a pivot and two hinge pieces, the hinge pieces are fixed with the door frame and the door leaf respectively, the combined parts of the surfaces of the door frame and the door leaf with the hinge are provided with an elongated through hole respectively, the hinge pieces penetrate the elongated through holes respectively and extend into the door frame and the door leaf. The hinge pieces are substantially planar and provided with screw holes, and fastening bolts penetrate the surfaces of the door frame and the door leaf respectively and are connected with the hinge pieces in a threaded manner. The hinge pieces are provided with screw holes, and the hinge pieces are used as bases of the bolts. Thus, gaskets in the prior art and welding are omitted, and material quality and thickness of the hinge pieces are generally excellent than other parts, so that the hinge pieces as the bases of the bolts can guarantee firmness of mounting better.

Owner:浙江赛银将军门业有限公司

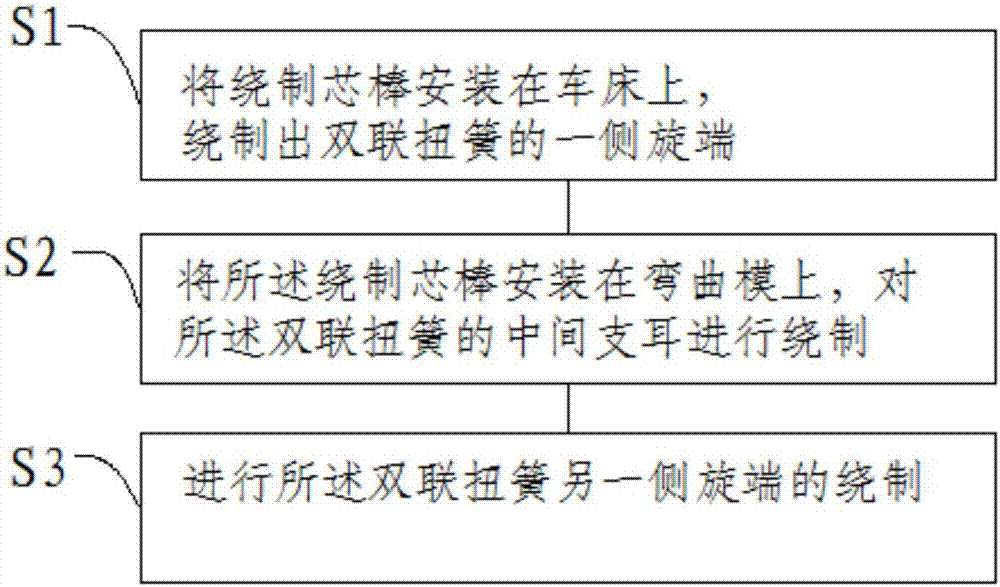

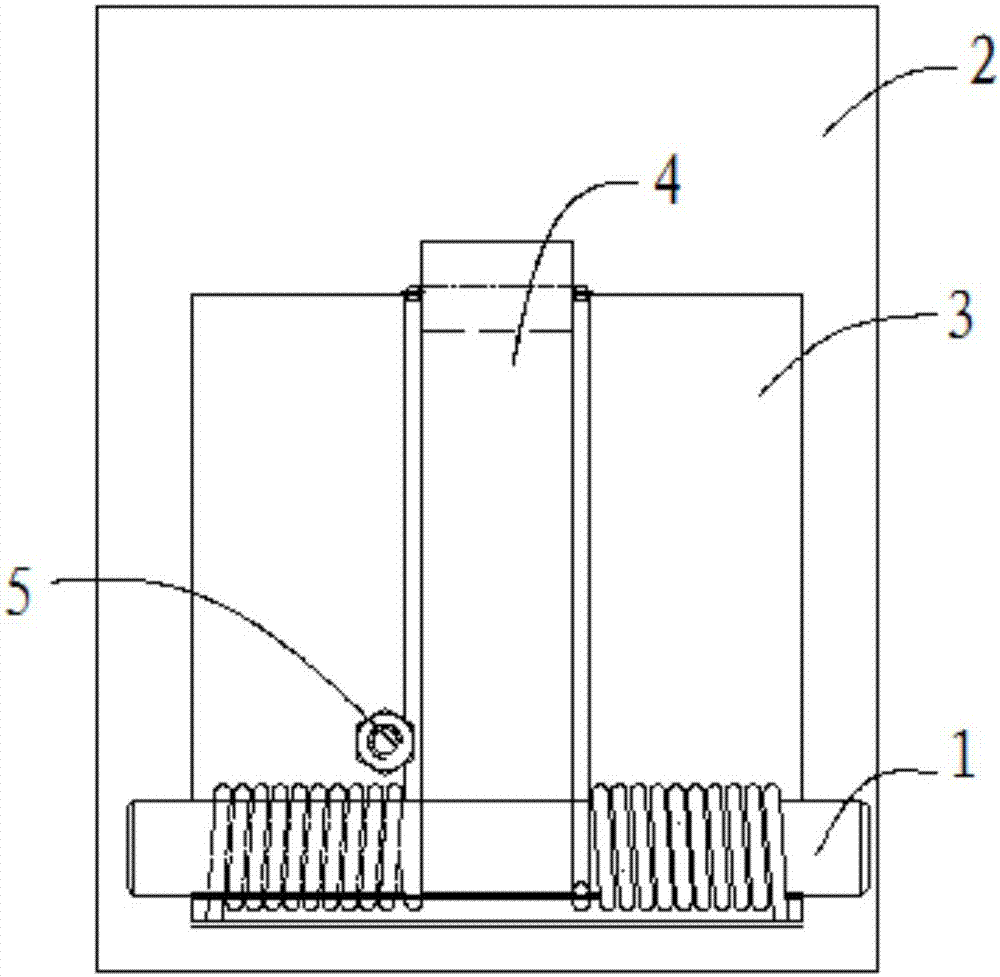

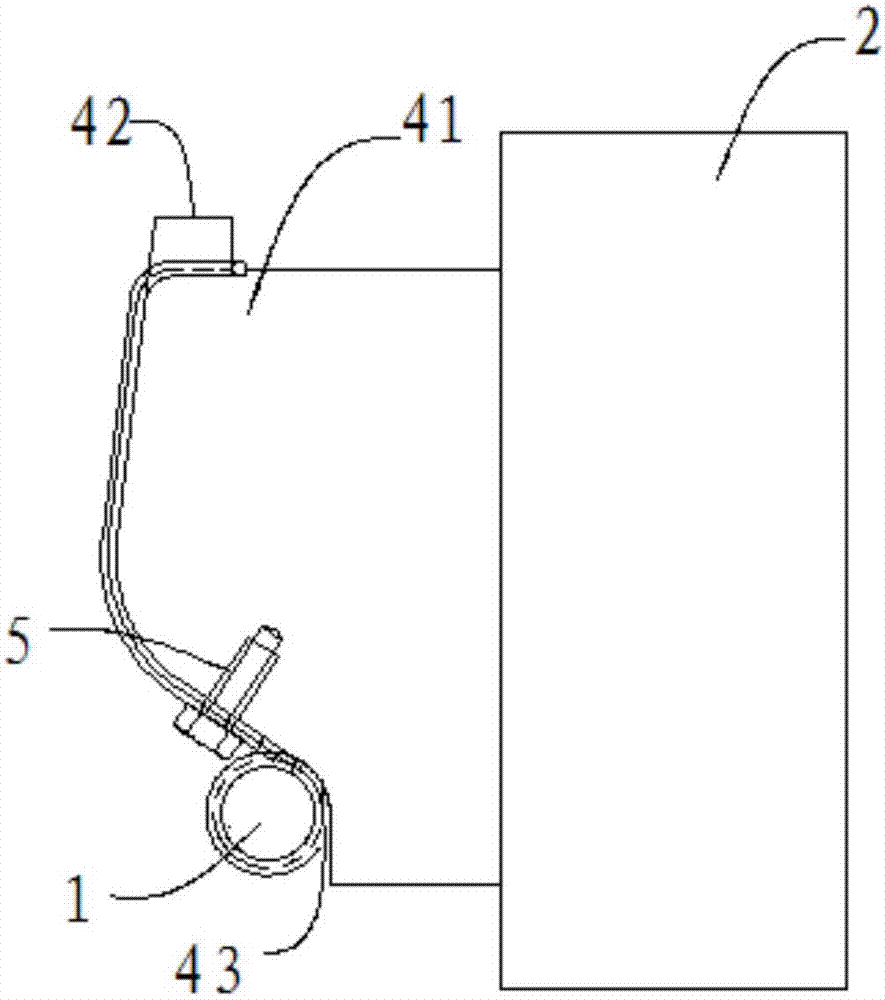

A kind of manufacturing method and mold of special double torsion spring

The invention discloses a manufacturing method and die for a special duplex torsional spring. The manufacturing method includes the following steps that S1, a winding core bar is mounted on a lathe, and the spiral end on one side of the duplex torsional spring is obtained through winding; S2, the winding core bar is mounted on a bending die, and copying winding is conducted on a middle support lug of the duplex torsional spring; and S3, the spiral end on the other side of the duplex torsional spring is obtained through winding. The duplex torsional spring is molded at a time, a welding procedure is omitted, the cost is reduced, and the service life of the duplex torsional spring is prolonged; and moreover, copying design is introduced to the design of the die, so that not only is production efficiency of the duplex torsional spring improved, but also machining precision of the duplex torsional spring is improved.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

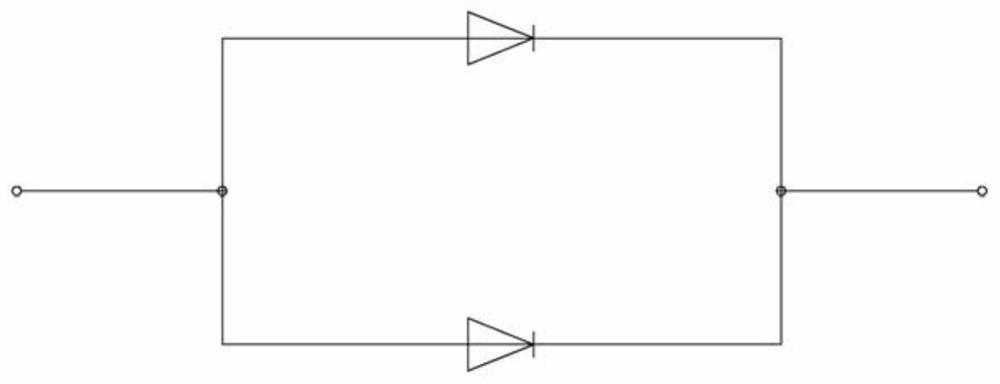

A high-power silicon carbide diode and its manufacturing method

ActiveCN113241339BSimple structureImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesCarbide siliconFilm-coated tablet

The invention provides a high-power silicon carbide diode and a manufacturing method thereof, comprising a first lead, a second lead, a first silicon carbide chip, a second silicon carbide chip, an insulating package, a first conductive plastic, a second Conductive plastic. The production method of the high-power silicon carbide diode of the present invention can be completed after bending, welding, plastic sealing, glue repair, and coating. The process is simple, the gold wire welding process is omitted, the processing efficiency is high, and the high-power carbonized Silicon diodes, the first silicon carbide chip and the second silicon carbide chip are arranged oppositely and welded on the first pin and the second pin respectively, which can reduce the volume of the insulating package after molding, and solve the problem of the large size of conventional silicon carbide diodes. The problem.

Owner:东莞市佳骏电子科技有限公司

A kind of diamond metal bond product and its integral molding manufacturing method and application

ActiveCN110948409BReduce consumptionOmit the welding processGrinding devicesCompression moldingMetallurgy

Owner:惠安宇信金刚石工具有限公司 +1

Integrated water tank for cooler

PendingCN109236454AShorten welding timeImprove work efficiencyMachines/enginesEngine cooling apparatusPipingWater tanks

Owner:安丘市汇航散热器有限公司

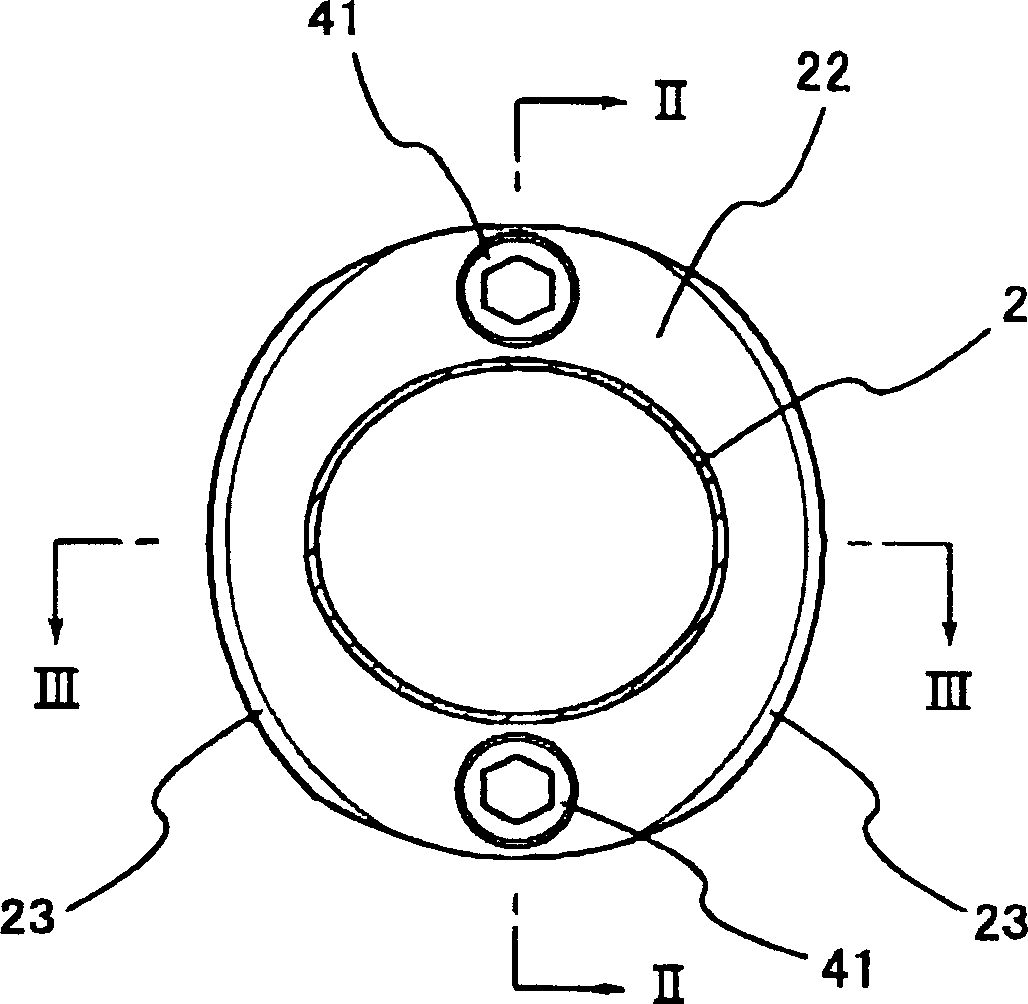

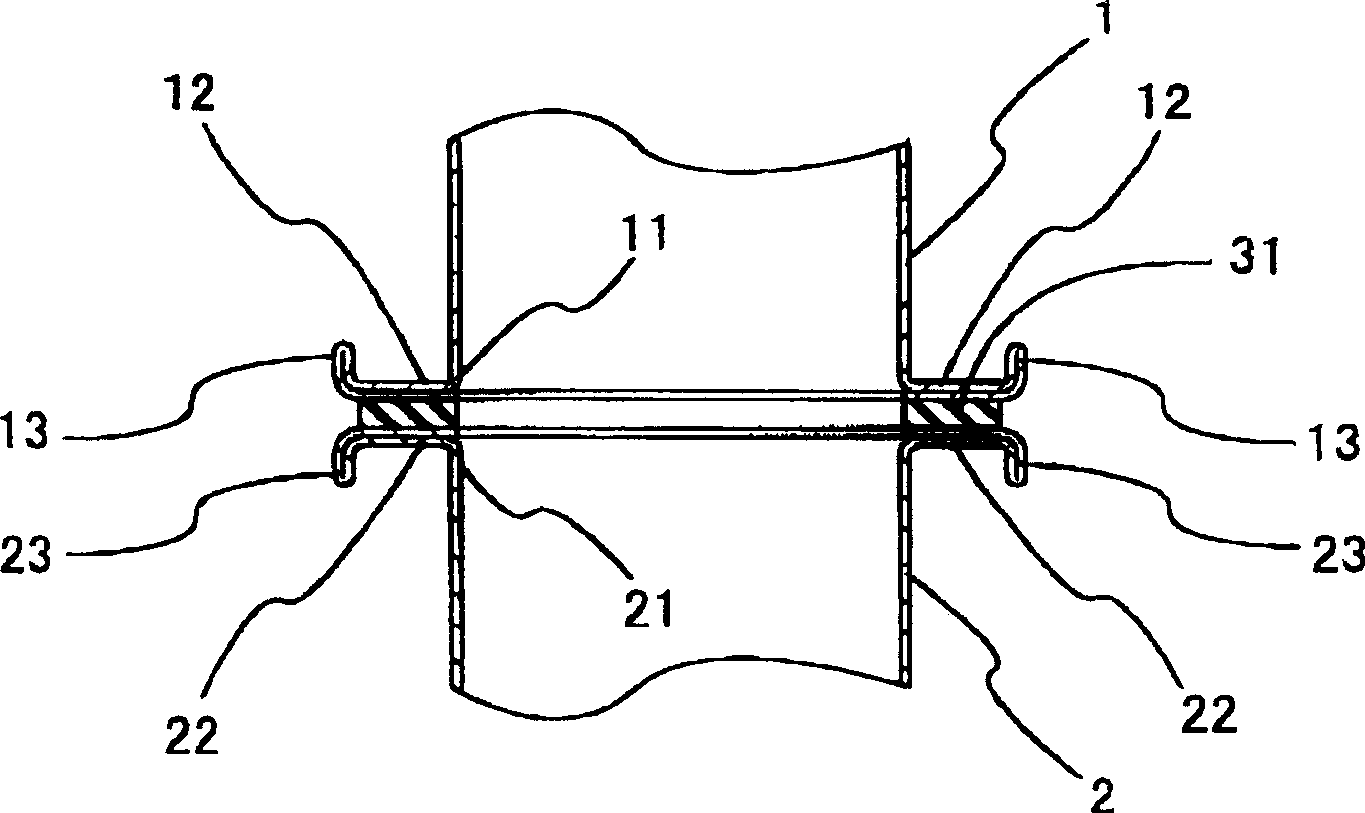

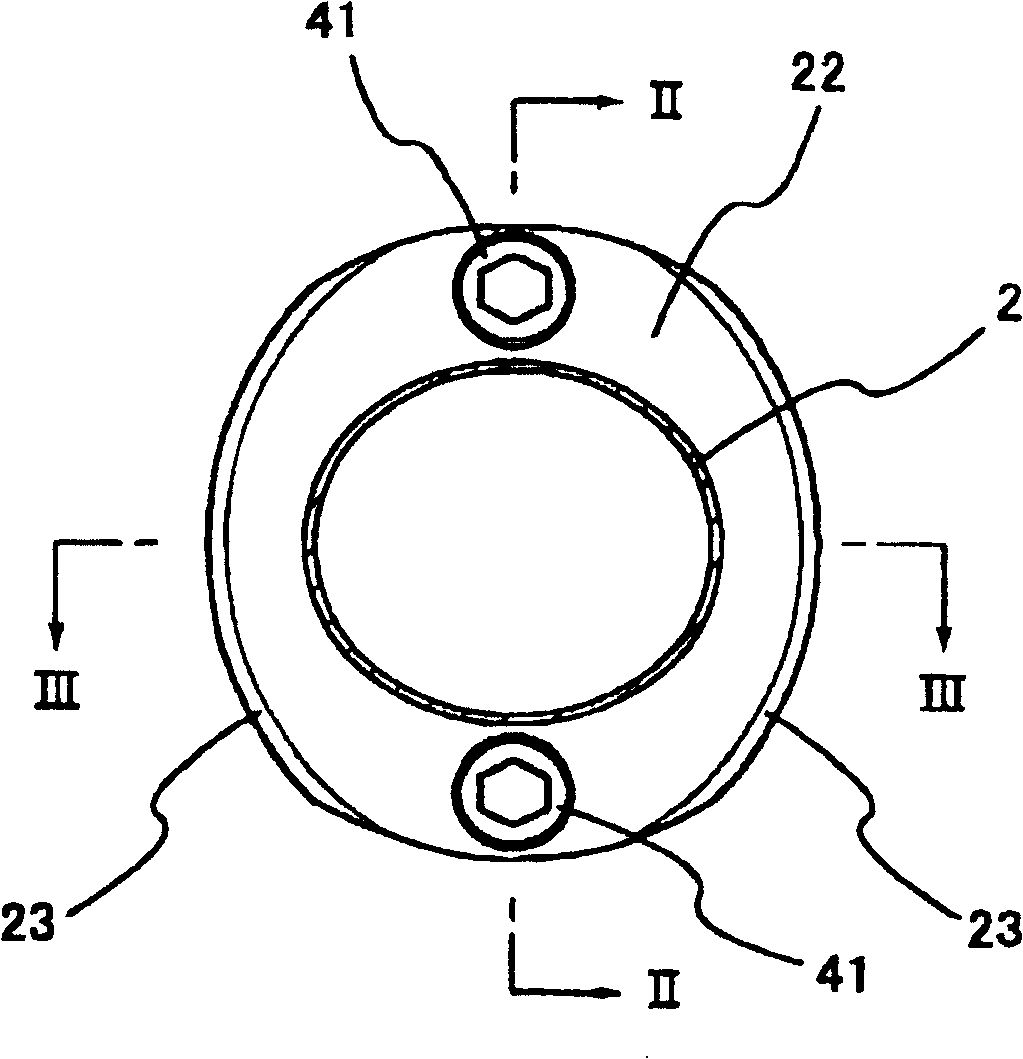

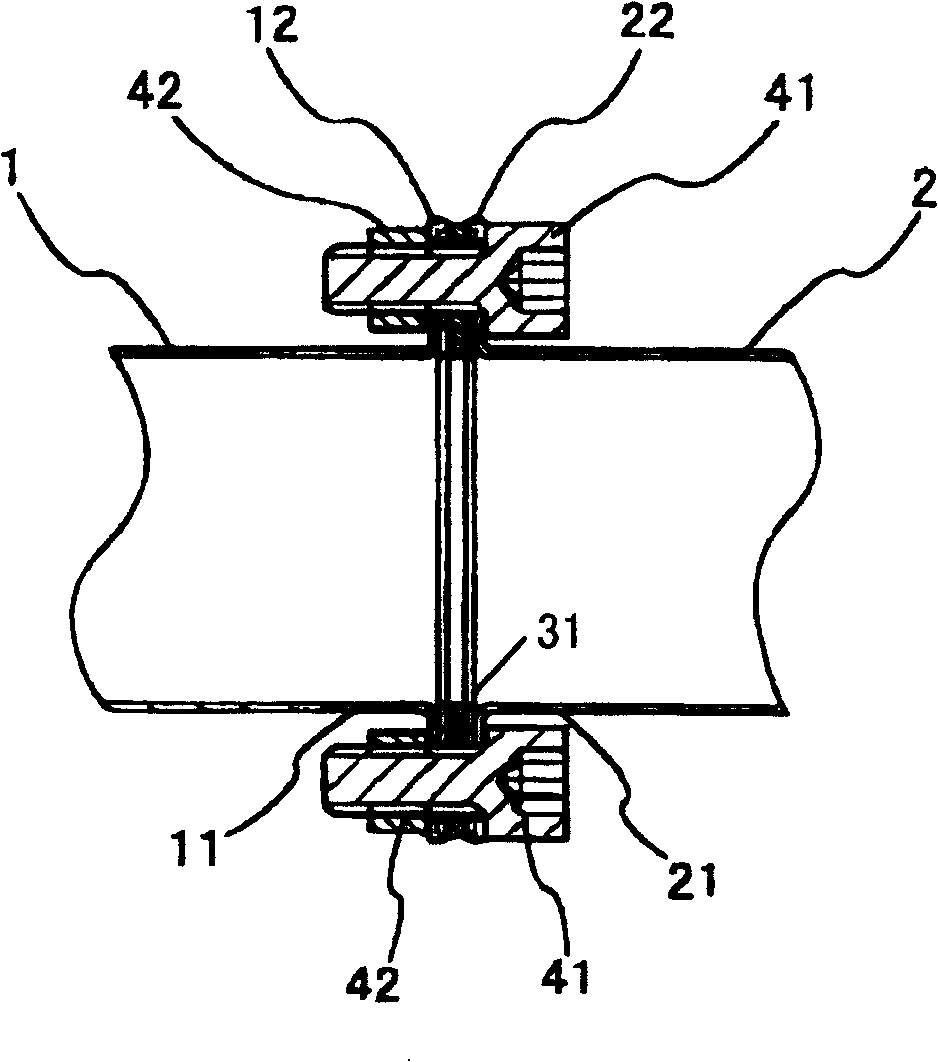

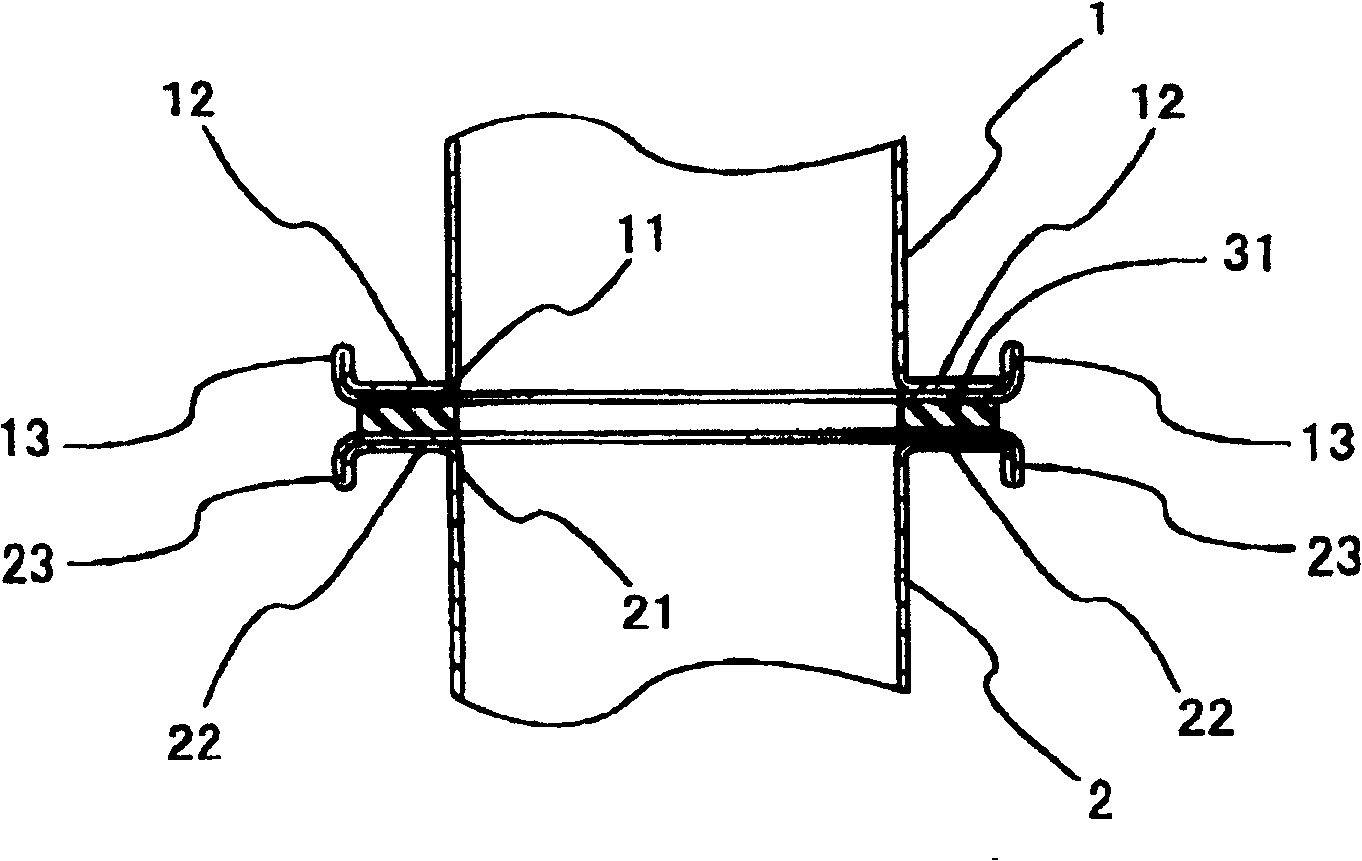

Construction of coupling exhaust pipes of vehicle

ActiveCN100447384CReduce in quantityWeight increaseFlanged jointsExhaust apparatusEngineeringExhaust pipe

The invention provides a connection structure of a vehicle exhaust pipe, in which the opening edges (11, 21) of the upstream exhaust pipe (1) and the downstream exhaust pipe (2) face each other along the radial direction by expanding and forming After being bent outward, it is folded inward along the radial direction to form a flange portion (12, 22). The two flange parts (12, 22) are butted through the gasket (31), and are mechanically resisted and combined with each other by bolts (41) and nuts (42).

Owner:NAKAGAWA SANGYO

LED flexible circuit board

PendingCN112839432ASimple structureAvoid damageLighting support devicesElectric circuit arrangementsElectrical conductorFlexible circuits

The invention discloses an LED flexible circuit board, which comprises a metal foil layer and a covering layer. The covering layer is provided with a window for welding an LED element, the metal foil layer forms an LED circuit, and a positive electrode pin and a negative electrode pin of the LED circuit extend out of the end part of the metal foil layer. Through the above scheme, as the positive electrode pins and the negative electrode pins extend out of the end parts of the LED flexible circuit boards, when the LED flexible circuit boards are used for assembling the flexible LED lamp strip, the positive electrode pins and the negative electrode pins can be respectively fixed on the corresponding wires of the wire array through the connecting conductors, and two adjacent LED flexible circuit boards can also be connected through the connecting conductors. The LED flexible circuit board is simple in structure, electric connection of the LED flexible circuit board, the connecting conductor and the wire array in the flexible LED lamp strip can be achieved without welding, the situation that the LED flexible circuit board is prone to being affected by high temperature and damaged due to the fact that high-temperature operation is needed in the welding process is avoided, the connecting mode is simple and convenient, and the production efficiency of assembling the flexible LED lamp strip can be improved.

Owner:ZHONGSHAN MLIGHT PHOTOELECTRIC

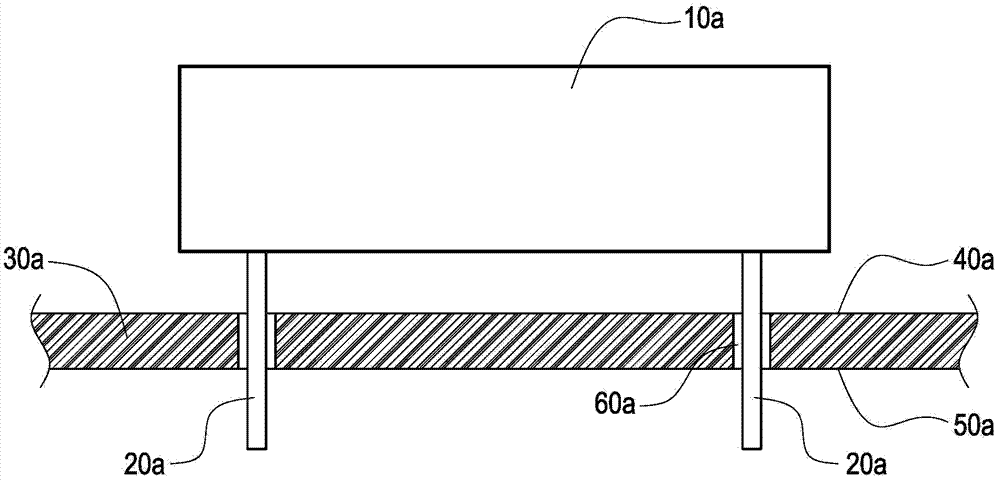

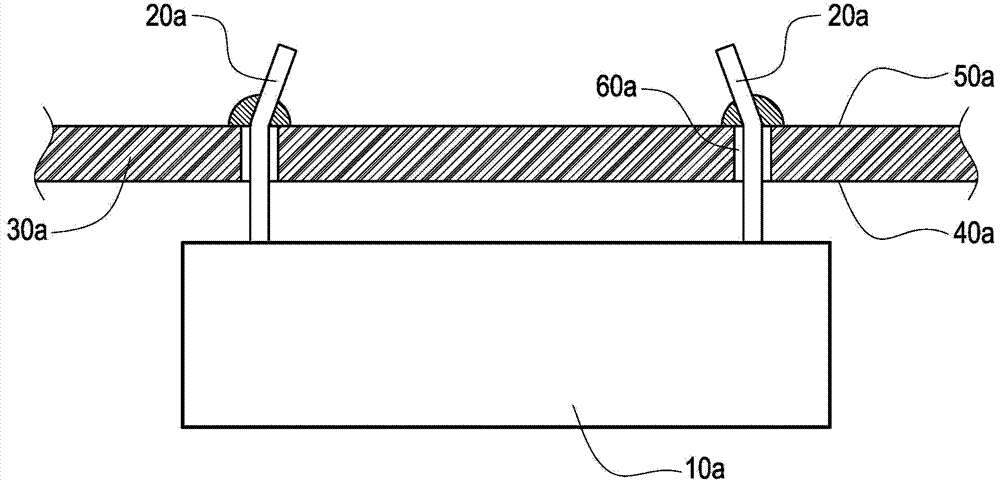

Element with pins and fixed to circuit board

InactiveCN102905466AGood assembly stability and convenienceAvoid damagePrinted circuit assemblingPrinted circuit non-printed electric components associationEngineeringElectrical and Electronics engineering

The invention discloses an element with pins and fixed to a circuit board. The circuit board is provided with a first through hole and a second through hole. The element with pins comprises a body, a first pin and a second pin, the first pin is connected to one side of the body and comprises a first section, a first bent section and a second bent section, and the first bent section is penetratingly clamped in the first through hole. The second pin is connected to the other side of the body and comprises a second section, a third bent section and a fourth bent section, and the third bent section is penetratingly clamped in the second through hole. Therefore, the body is prevented from falling, and fine assembly stability and convenience can be achieved.

Owner:DELTA ELECTRONICS INC

Double-decker bed based on plug-in type guardrail

The invention discloses a double-decker bed based on a plug-in type guardrail. The double-decker bed comprises a vertical post (1) as well as an upper and a lower layer bed surrounded by beams, wherein the upper layer bed is provided with a ladder stand (3); one outer side in the length direction of the upper layer bed is provided with an upper layer bed guardrail; the upper layer bed guardrail comprises a vertical rod (12) and an outer handrail (4); the outer handrail comprises a horizontal straight rod part and an arc-shaped connection rod part; the external end of the horizontal straight rod part is connected to the vertical post (1) by a connecting piece (8); and the arc-shaped connection rod part is connected to the lower beam (2) by an intermediate unit (11). The bed disclosed by the invention has the following characteristics of beauty, simplicity, fastness, endurance and environment friendliness. With the adoption of a stamping technique, the welding process is omitted, so that the production cost is reduced; and with the adoption of an insertion and combination part connection mode, the volume is reduced, and the bed is convenient to transport and mount.

Owner:徐华玉

Secondary battery, battery module, battery pack, and secondary battery manufacturing method

PendingCN114284611AImprove the safety of useImprove fill rateFinal product manufactureSecondary cells manufacturePower batteryCell fabrication

The invention discloses a secondary battery, a battery module, a battery pack and a manufacturing method of the secondary battery, and belongs to the technical field of power batteries. The secondary battery comprises a shell, a top cover plate, a terminal polar plate and a roll core, the shell is provided with a containing space, the top cover plate covers a top opening of the containing space, a tab through hole communicated with the containing space is formed in the top cover plate, the terminal polar plate is arranged on the side, away from the shell, of the top cover plate and covers the tab through hole, and the roll core is arranged on the side, away from the shell, of the terminal polar plate. The inner wall surface of the tab through hole and the bottom surface of the terminal polar plate form a tab accommodating cavity, the roll core is arranged in the accommodating space, and at least part of the roll core tab of the roll core penetrates through the tab through hole and is welded with the bottom surface of the terminal polar plate. According to the secondary battery, an electric connecting sheet is omitted, and the roll core tab is arranged in the tab accommodating cavity in the bent state, so that the welding frequency is reduced, the safety is improved, the tab filling rate is improved, the overcurrent capability is enhanced, the manufacturing cost is reduced, and the heat dissipation capability is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com