Pressure-free sintering preparation method of diamond string bead

A diamond beading and sintering temperature technology, applied in other manufacturing equipment/tools, mechanical equipment, engine components, etc., can solve the problems of restricting process development, low production efficiency, and high production cost, reducing production cost, improving production efficiency, The effect of eliminating the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

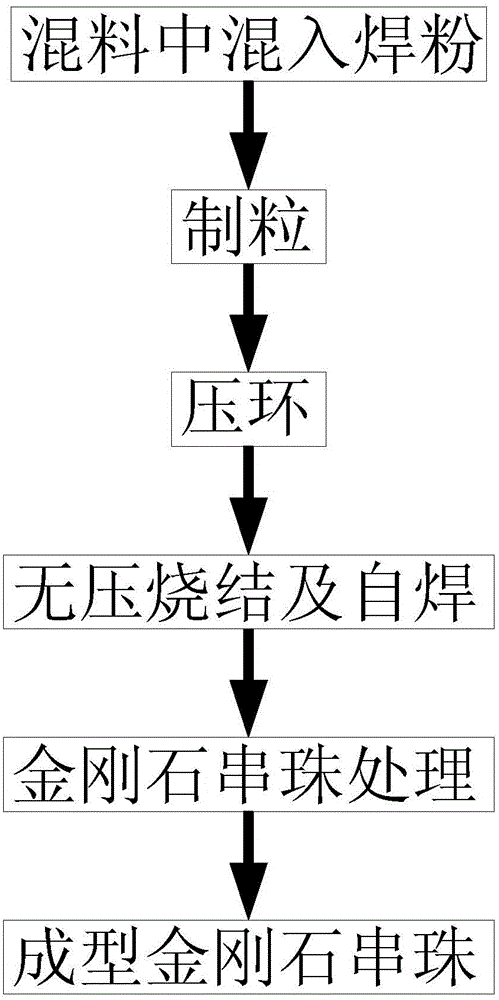

[0022] figure 1 It is a flow chart of the steps of the pressureless sintering preparation method of diamond beads in a preferred embodiment of the present invention. Such as figure 1 As shown, the pressureless sintering preparation method of the diamond beads of the present embodiment comprises the following steps: a, adding solder powder having a melting temperature close to the sintering temperature of the diamond bead matrix in the diamond bead formulation to form a mixture with solder powder; b. Granulate the mixed materials to obtain granulated powder; c. Press the granulated powder to ring to obtain compact; d. Sinter the compact without pressure, and the welding powder melts to form a self-welding integrated body during sintering Diamond beads; e, diamond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com