A high-power silicon carbide diode and its manufacturing method

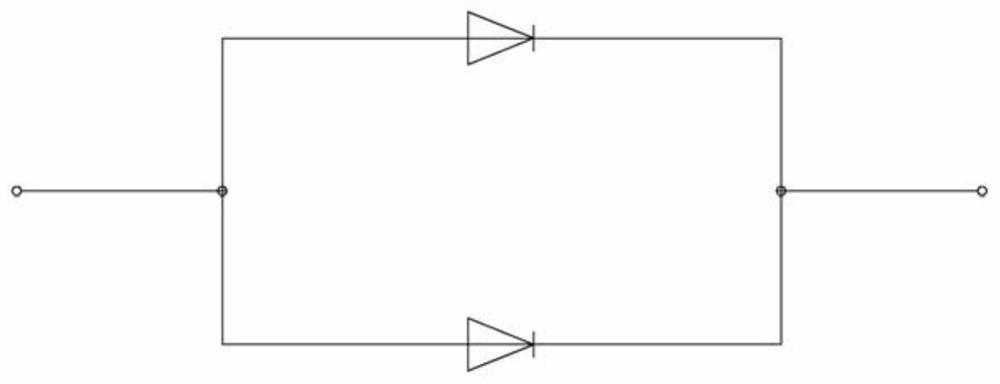

A technology of silicon carbide diodes and manufacturing methods, applied in the field of diodes, can solve the problems of unfavorable circuit board applications with multiple electronic components, easy winding of two gold wires, and large occupied area, so as to omit the welding process of gold wires and improve processing The effect of efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

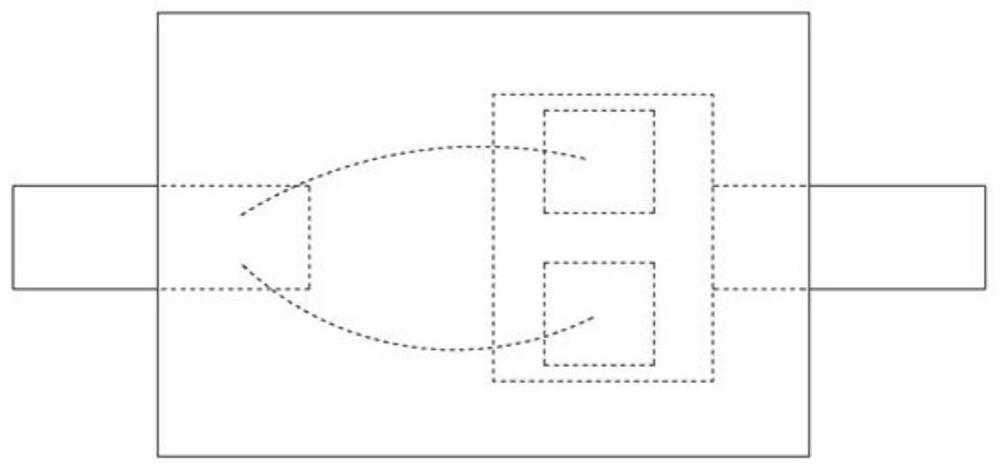

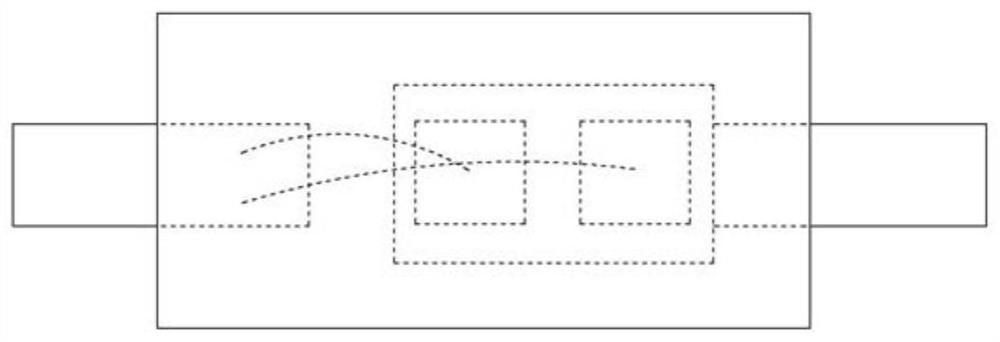

[0034] like Figure 4-5 shown:

[0035] A high-power silicon carbide diode, comprising a first lead 1, a second lead 2, a first silicon carbide chip 3, a second silicon carbide chip 4, an insulating package 5, a first conductive plastic 6, and a second conductive plastic 7;

[0036] The first lead 1 includes a first conductive portion 11, a first welding portion 12, a first bending portion 13, and a first mounting portion 14. The cathode of the first silicon carbide chip 3 is welded to the first welding portion 12, and the first conductive portion 12 is welded. The part 11 and the first welding part 12 have a 90° structure, and the first silicon carbide chip 3 and the first conductive part 11 are not in contact with each other;

[0037] The second lead 2 includes a second conductive portion 21 , a second welding portion 22 , a second bending portion 23 , and a second mounting portion 24 . The anode of the second silicon carbide chip 4 is welded to the second welding portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com