Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce labor/cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

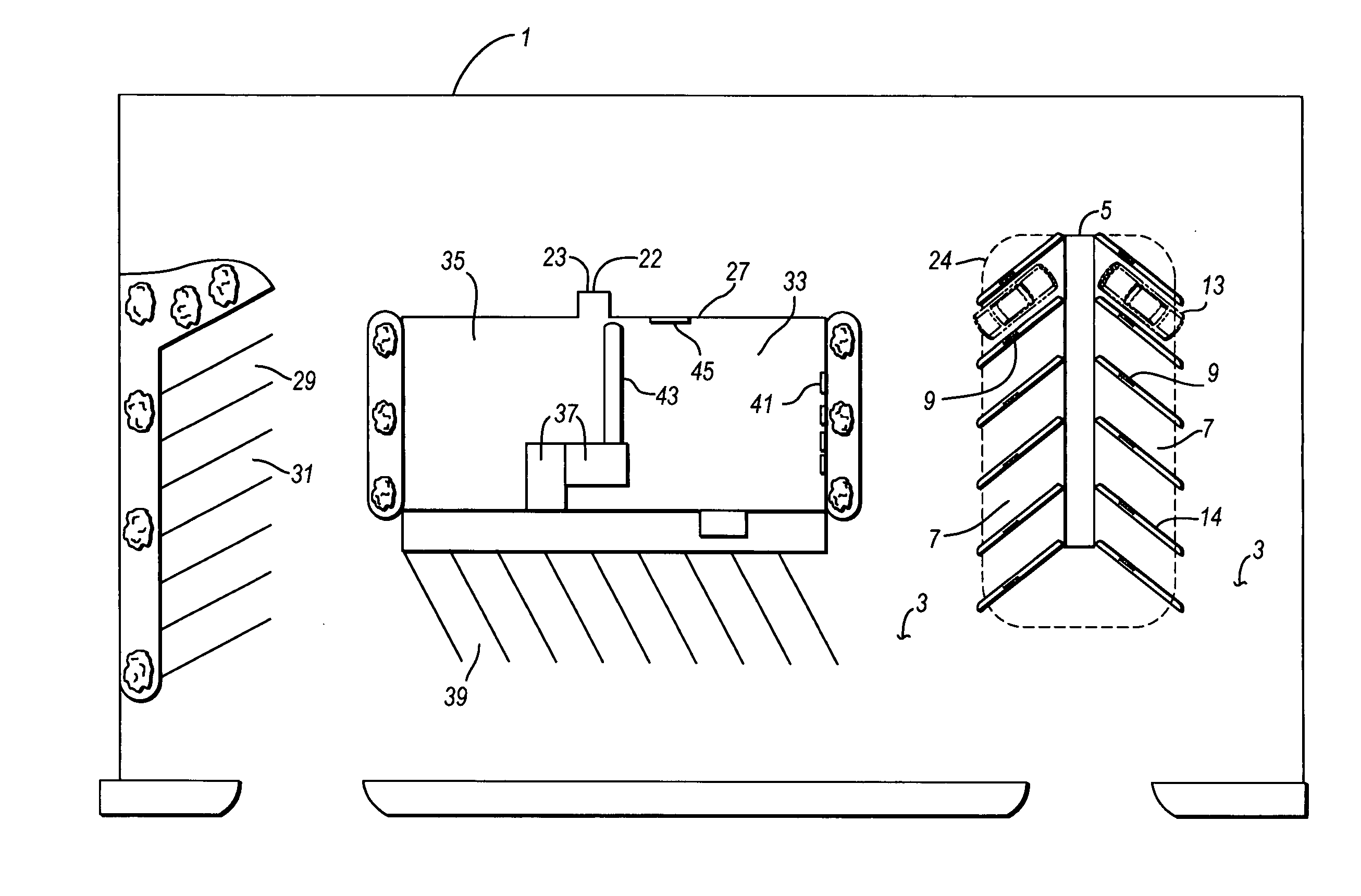

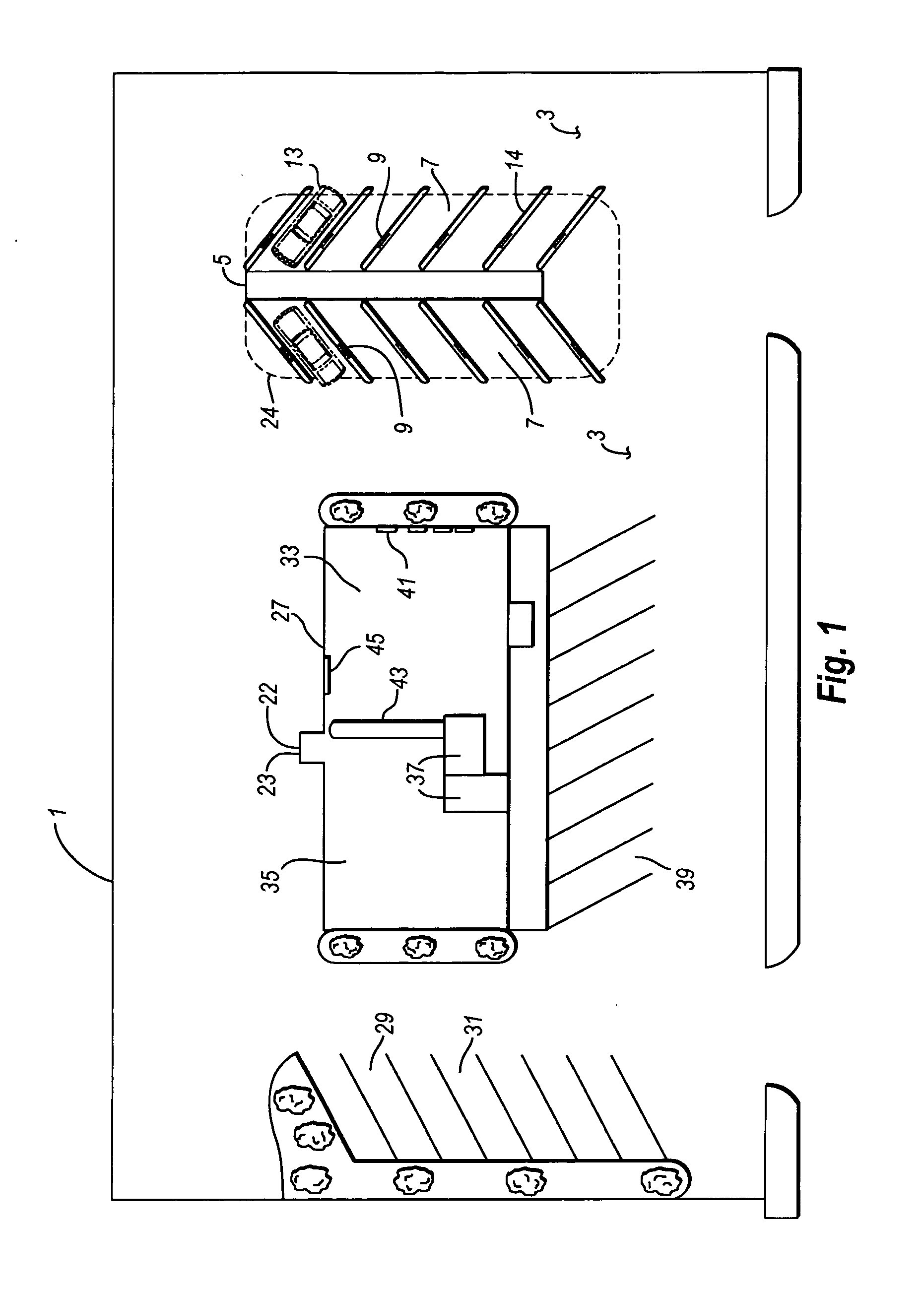

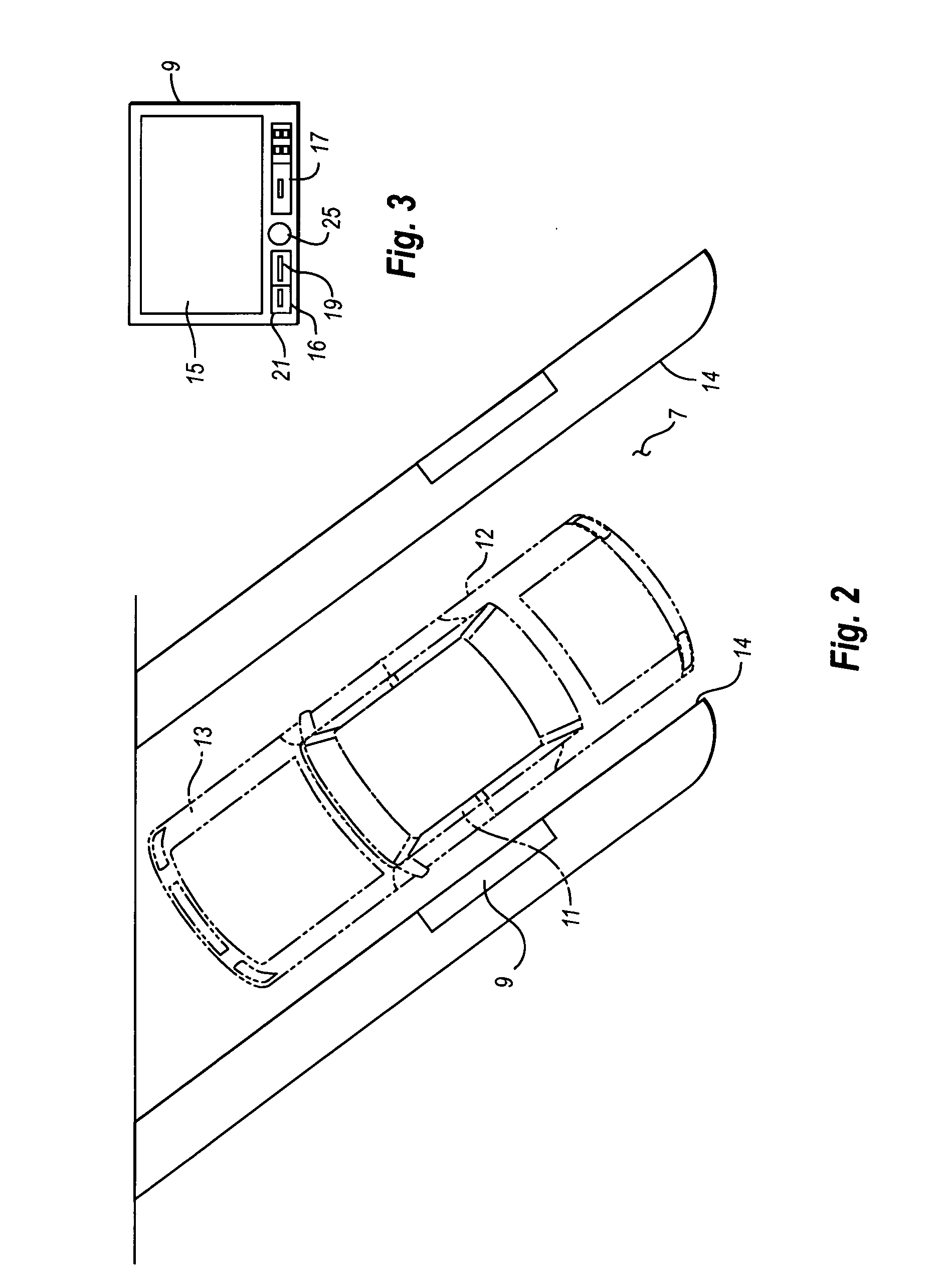

Enhanced fast food restaurant and method of operation

InactiveUS20060218039A1Reduce total transaction timeReduce labor costMarketingItem selectionDisplay device

A fast food restaurant and method of operating a fast food restaurant, the restaurant having an order and staging station for drive through customers. The order and staging station has a plurality of order stalls for customer vehicles, each order stall having an order panel with a menu display and a touch screen or voice or speech activator for self-service menu item selection and order placement. The order panel also has a payment acceptor and an order status reporter. The customer vehicle remains in the order stall until the customer is notified that the order is ready for pickup at a delivery station.

Owner:N P JOHNSON FAMILY PARTNERSHIP

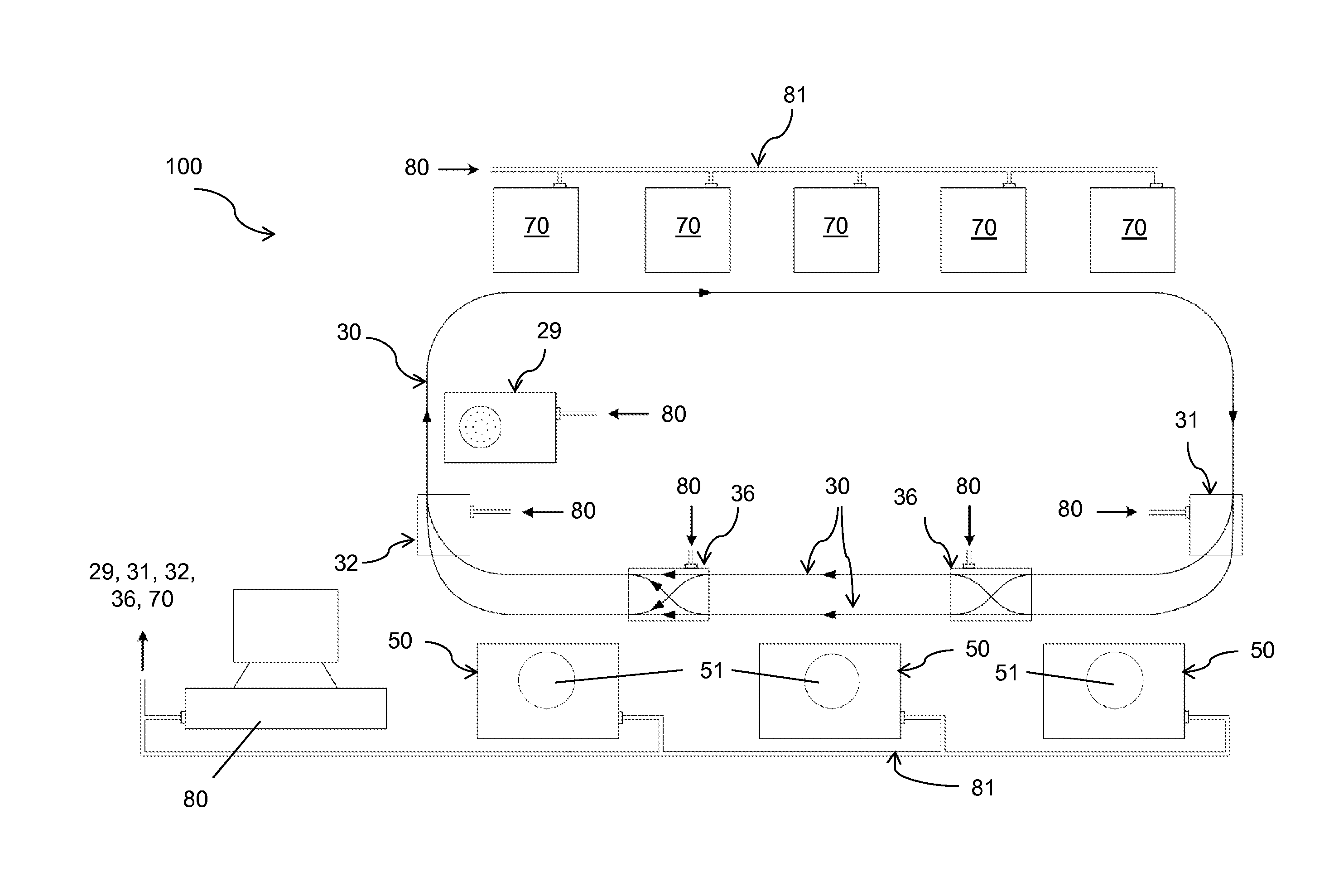

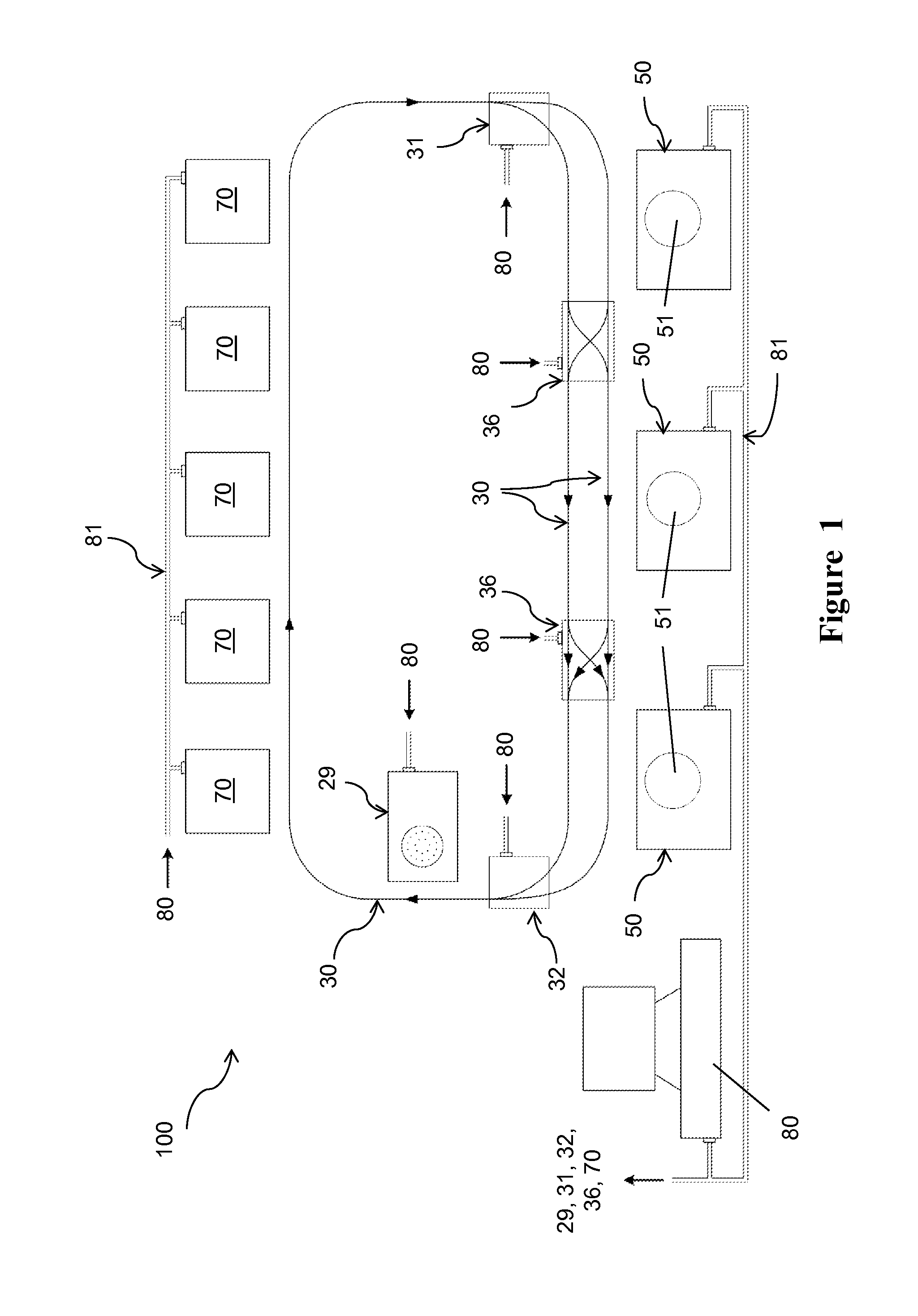

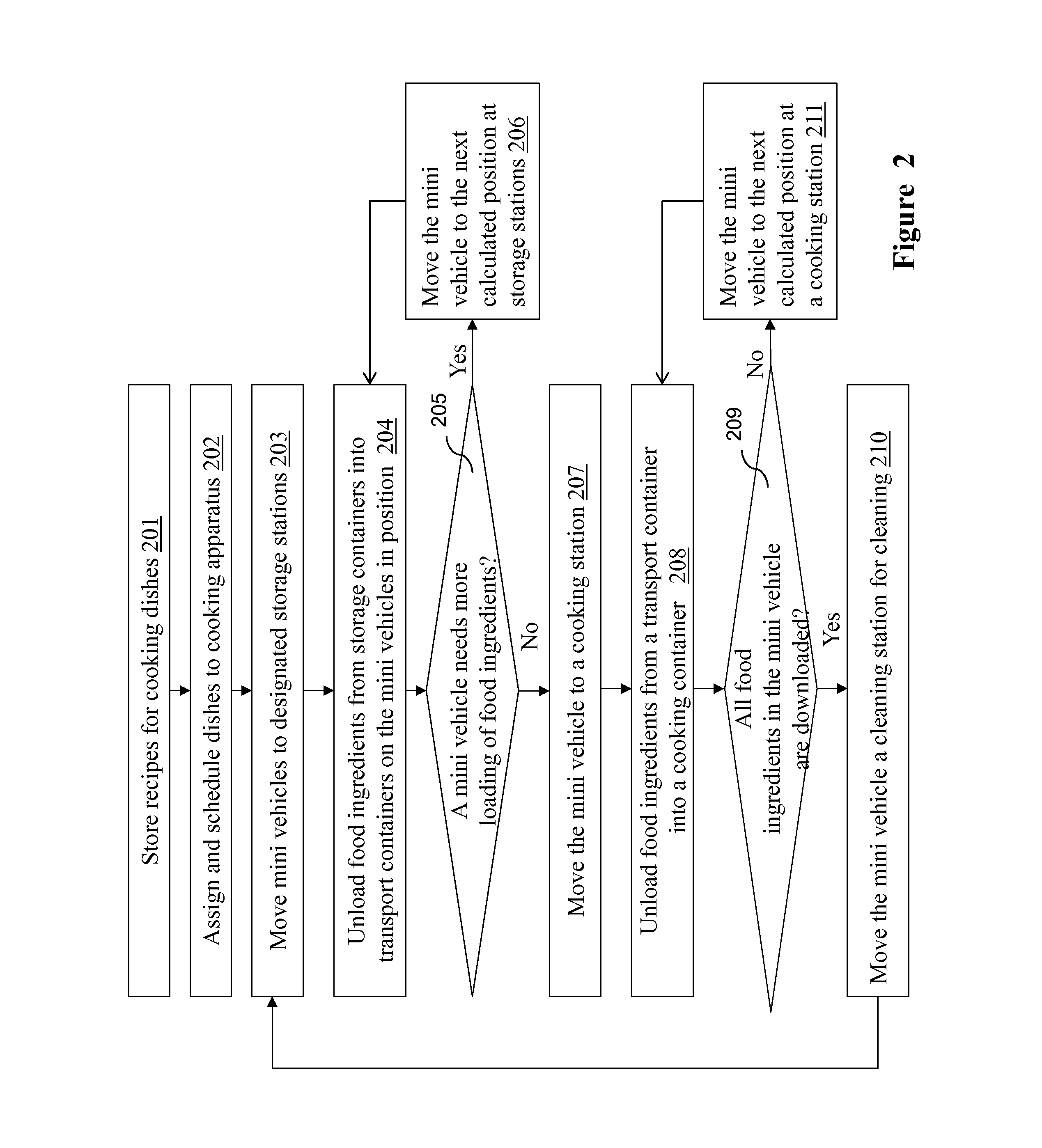

Scalable automated cooking system having small footprint and reduced labor cost

InactiveUS20140230660A1Reduced space requirementReduce labor costCooking vesselsFood preparationFood componentsSmall footprint

An automatic cooking system includes a computer system that stores recipes, cooking stations each comprising a cooking container that can cook food ingredients therein to produce a first cooked food, wherein the computer system can assign and schedule a plurality of dishes to be cooked at the cooking stations, storage containers configured to hold food ingredients, mini vehicles each carrying transport containers configured to hold the food ingredients, wherein the computer system can control at least some of movements of the mini vehicles in accordance to the recipes, a loading apparatus configured to load food ingredients from the storage stations to the transport containers on the mini vehicles, and an unloading apparatus that can transfer food ingredients from the transport containers on the mini vehicles to the cooking container at one of the cooking stations.

Owner:HE ZHENGXU

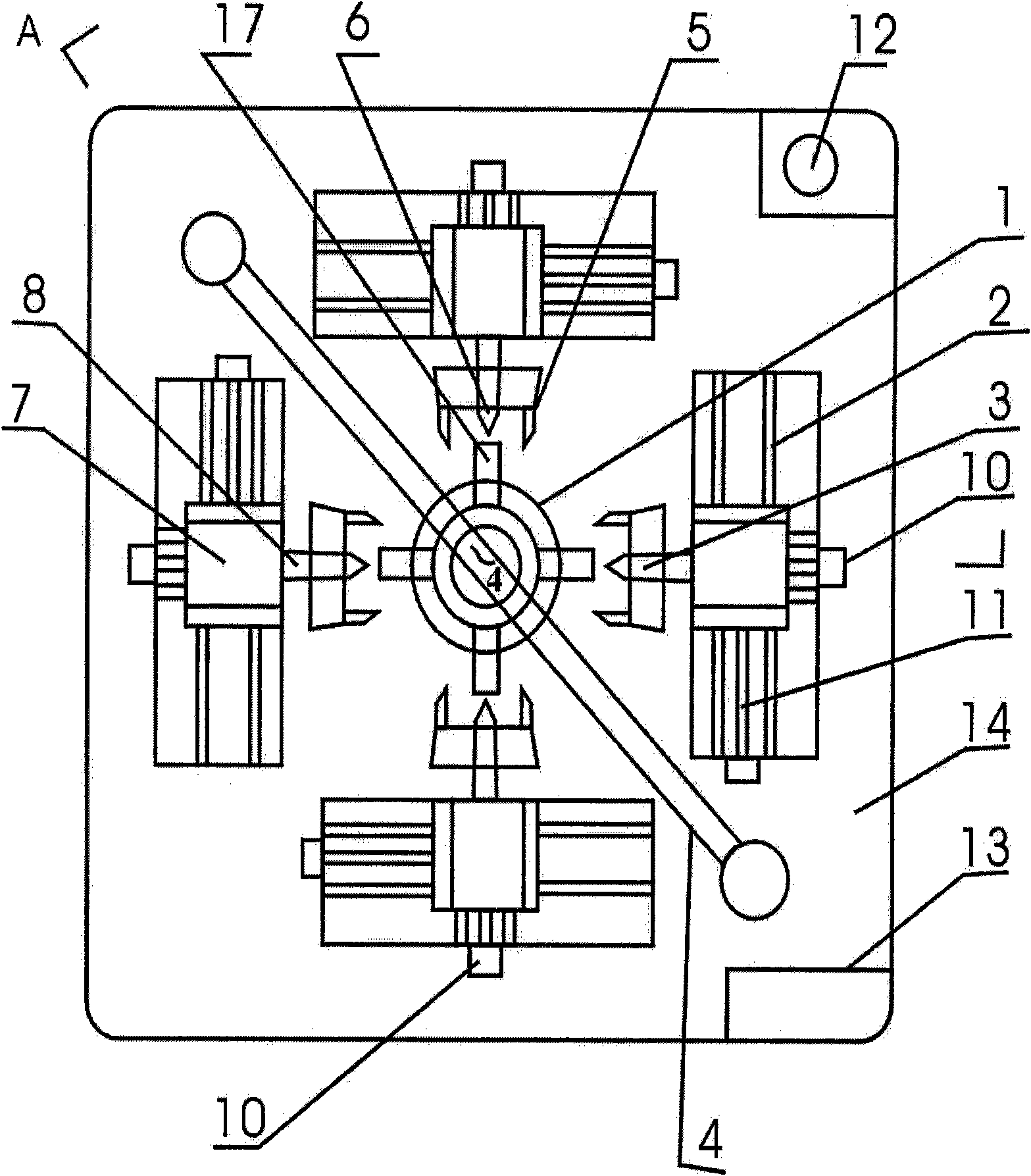

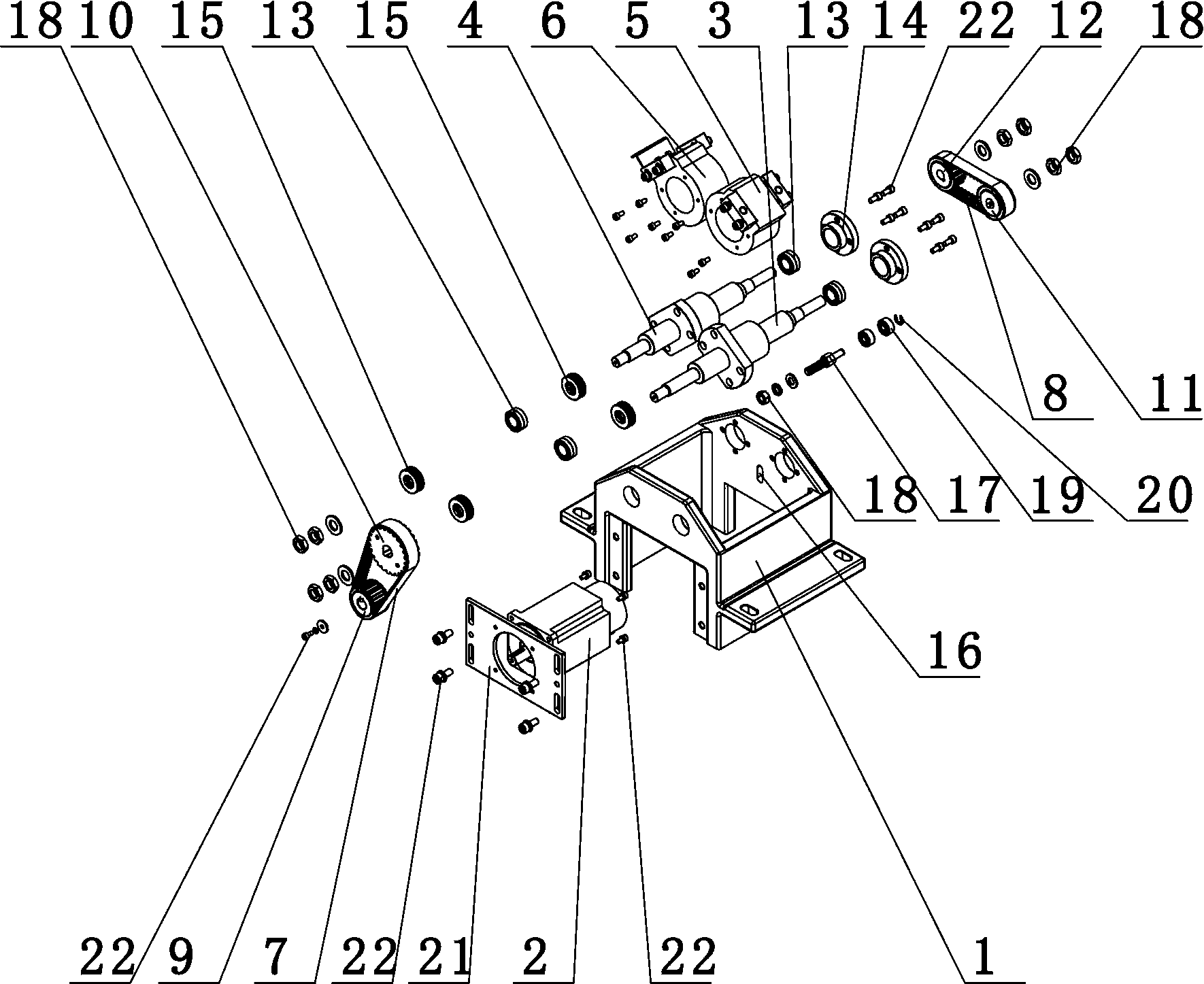

Technological method of clamping device of multi-position cross-shaft processing machine

InactiveCN101664886AReduce processing stepsReduce labor costPositioning apparatusMetal-working holdersProcessing accuracyEngineering

The invention relates to a technological method of a clamping device of a multi-position cross-shaft processing machine, by adopting the cross-shaft V-shaped slot positioning technology, milling and drilling tools are mounted on four rotating main shafts, the rotating main shafts are fixed on a workbench which can move left, right, frontward and backward, by utilizing the movement of the rotatingmain shafts, four end surfaces of the cross-shaft are firstly simultaneously milled, then the workbench is automatically returned onto a central line of the V-shaped slot, the four main shafts are simultaneously near to the cross-shaft, and four central holes are drilled on the cross-shaft at one time, thereby completing the processing of the end surfaces of the cross-shaft and the central holes on one working procedure at one time. The technological process comprises the following steps of: sawing-forging-milling-drilling-turning a shaft neck-thermal treatment-shot blasting-grinding the shaftneck-defect detection-inspection-packaging and warehousing, thereby not only reducing the processing working procedure of the cross-shaft, reducing the work time and the cost, reducing the labor intensity, improving the processing working efficiency by nearly 10 times, and saving the energy consumption by more than 60%, but also ensuring the concentricity and the vertical degree of the cross-shaft, realizing high processing precision and high qualified rate of the cross-shaft product.

Owner:谢振扬

Method for directly carrying out innocent treatment on electrolytic manganese residues in filter pressing plate frames

InactiveCN104690080ALow installation costReduce labor costSolid waste disposalMagnesiumPolyacrylamide

Provided is a method for directly carrying out innocent treatment on electrolytic manganese residues in filter pressing plate frames. The electrolytic manganese residues treated through the method are filter cakes obtained after filter pressing in the filter pressing plate frames of a plate-and-frame filter press, and sodium dihydrogen phosphate, calcium oxide, magnesium oxide and polyacrylamide are included in a treating agent. The method comprises the steps that 1, the electrolytic manganese residue filter cakes in all the filter pressing plate frames are washed through solutions obtained by mixing the sodium dihydrogen phosphate and water; 2, after the magnesium oxide, the calcium oxide and the polyacrylamide are dissolved in filter liquor collected in the step 1, the electrolytic manganese residue filter cakes are washed again; 3, filter liquor generated in the step 2 is collected, the plate-and-frame filter press is loosened to unload the filter cakes, and the electrolytic manganese residues generated after the innocent treatment are obtained. According to the method, soluble manganese in the electrolytic manganese residues is fixed, meanwhile, soluble ammonia nitrogen in the electrolytic manganese residues is fixed, and compared with the prior art, the advantages in the prior art are kept, the defects in the prior art are overcome, and the total cost of innocent treatment on the electrolytic manganese residues is lowered.

Owner:CHONGQING UNIV

Non-Vented Bladder System for Curing Composite Parts

ActiveUS20130327477A1Reduce needReduce labor costLaminationLamination apparatusAirbag deploymentInternal cavity

A composite part charge having an internal cavity is placed on a tool and covered by a vacuum bag for autoclave curing. A bladder is placed in the cavity to react autoclave pressure on the charge. The bladder is coupled with a flexible fluid reservoir located beneath the vacuum bag. The bladder is pressurized by autoclave pressure applied through the vacuum bag to the flexible fluid reservoir.

Owner:THE BOEING CO

System and Method for Finding and Locating Items

InactiveUS20170061175A1Reduce labor costIncrease efficiencyTransmissionLogisticsClient-sideSignal intensity

A system for finding and locating items, including an electronic tag adapted to be attached to the item, a tag reading device for reading the electronic tag, and a server. The server is adapted to communicate with the tag reading device via network connections. The tag reading device is adapted to search for and locate items within a predetermined range, and to determine the location information of the item according to the detected signal intensity sent by the electronic tag on the item. The location information is sent through the network connection to the server, and the server operates in the database and adds the location information on the original data format of the database. The present invention can effectively find items that are needed among a lot of items, and can determine the distance and position of the items according to parameters like signal strength. Such location information can be added to the inventory results and are added without affecting the original data format used by the client.

Owner:OSCL PACIFIC LTD

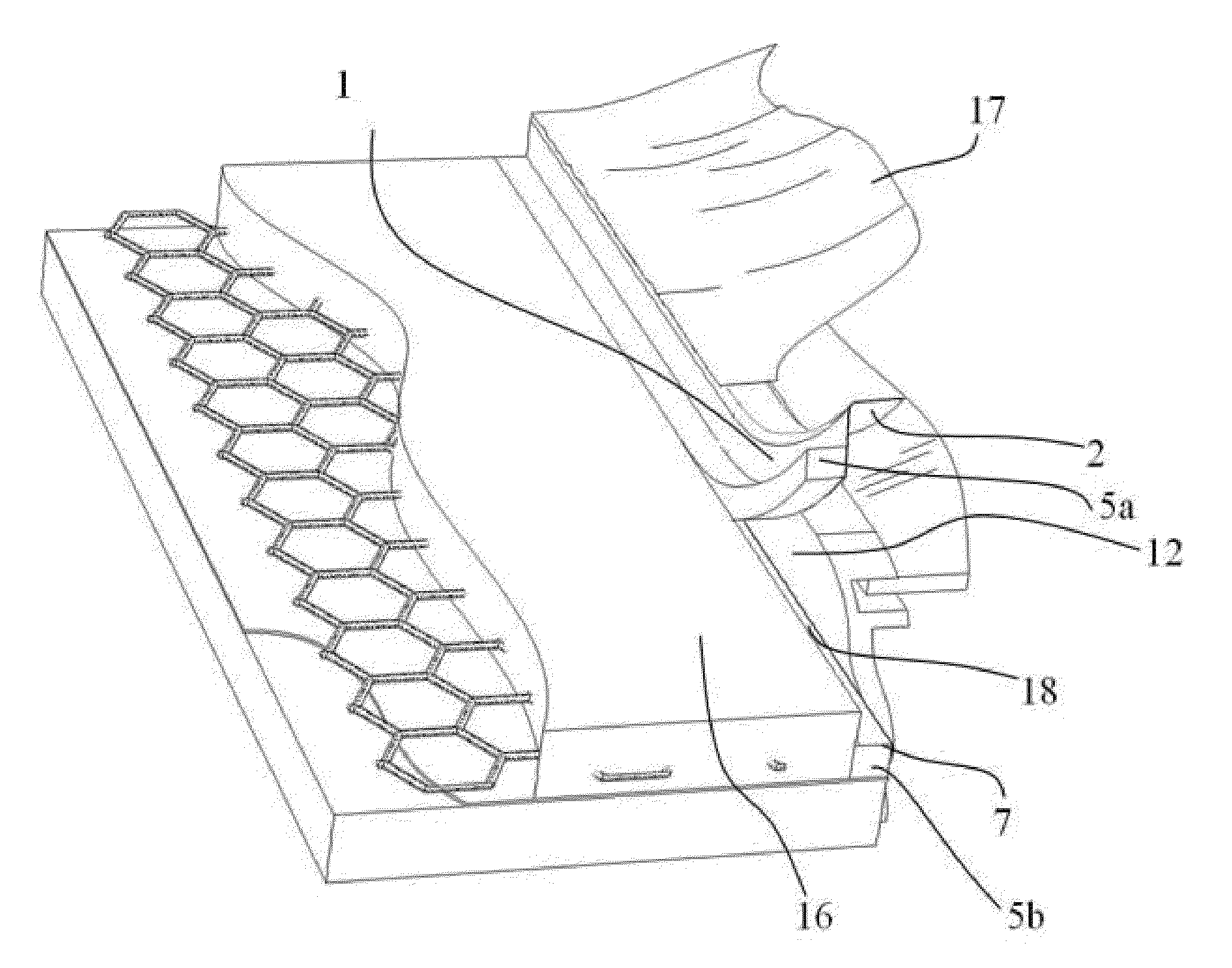

Paddy field leveller

InactiveCN103069941AImprove work efficiencyGuaranteed normal passageSoil-working equipmentsPaddy fieldPiston rod

The invention discloses a paddy field leveller. The paddy field leveller comprises a suspension bracket which is connected with a tractor; an oil cylinder and a large scraper are arranged on the suspension bracket; the large scraper is connected with the suspension bracket through a plurality of movable link shafts; a piston rod of the oil cylinder is connected with the large scraper; a folding oil cylinder, a supporting block and a small scraper are respectively arranged on two sides of the large scraper; a piston rod of the folding oil cylinder is connected with the small scraper through a connecting rod; the connecting rod is connected with the supporting block through a rotary shaft; and the small scraper is movably connected with the large scraper through the rotary shaft. The paddy field leveller can work with a wide range of eight metres and is high in working efficiency, foldable, high in safety and convenient to use. The paddy field leveller can run on a vehicle road, can scrape a paddy field, can level the field, and can be easily and flexibly operated. The payload of workers and production cost are reduced.

Owner:SHANGHAI YUEJIN MODERN AGRI

Non-axial actuable valve capable of retaining both high and low pressures

InactiveUS7677531B1Reduce labor costCount be minimizeOperating means/releasing devices for valvesAnimal watering devicesEngineeringHigh pressure

The present invention relates to improved fluid valves actuable by a non-axial movement of an actuation stem. The non-linear actuable valves embodied in the present invention maintain pressure containment through a novel approach over the prior-art. The exemplary embodiments teach improved non-linear actuable valves that reduce the chances for seal extrusion, particularly at elevated retaining pressure, while keeping the component count low, and are capable of functioning under both high and low pressure.

Owner:GENUINE INNOVATIONS

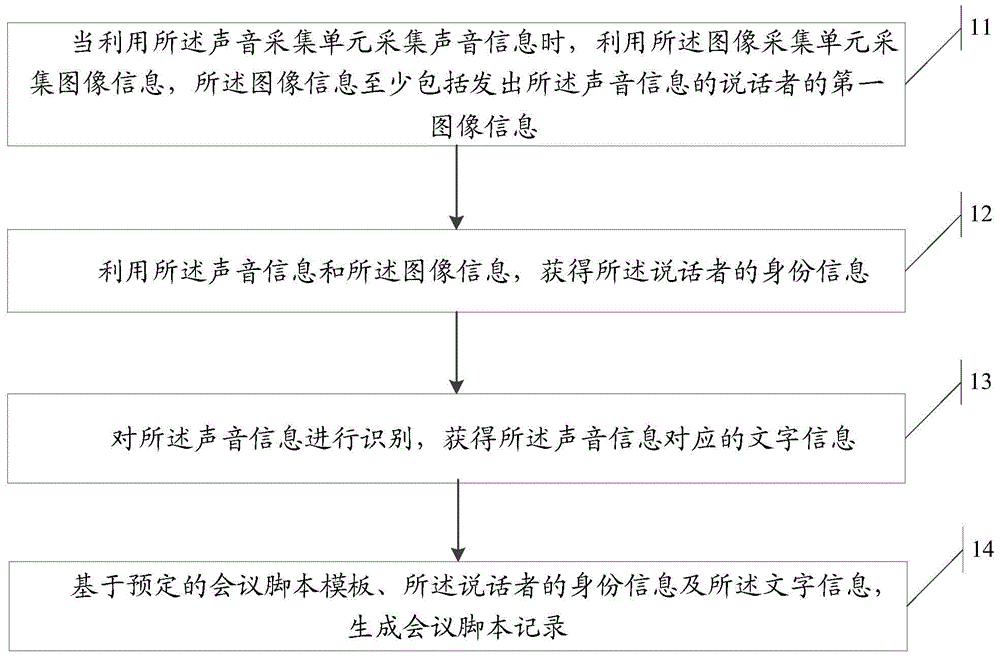

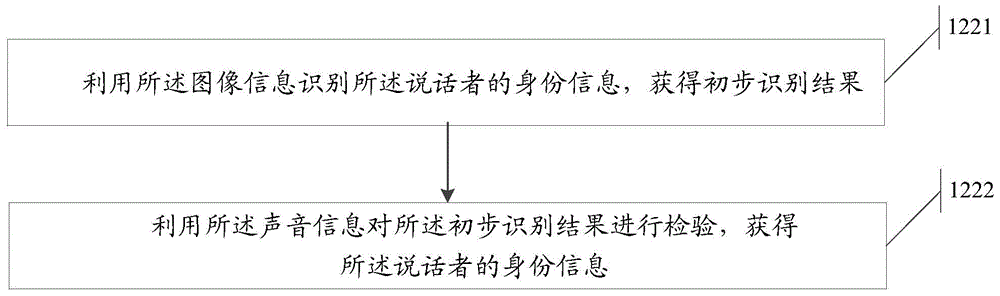

Information processing method and electronic device

InactiveCN106033339AReduce labor costImprove accuracySpeech recognitionSpecific program execution arrangementsImage acquisitionAcoustics

The invention provides an information processing method and an electronic device. The method is applied in an electronic device. The electronic device comprises an image acquisition unit and a sound acquisition unit. The method comprises: when the sound acquisition unit is used to acquire sound information, the image acquisition unit is used to acquire image information, the image information at least including first image information of a speaker who gives out the sound information; using the sound information and the image information to obtain identity information of the speaker; identifying the sound information, to obtain character information corresponding to the sound information; and based on a scheduled conference script template, the identity information of the speaker, and the character information, generating conference script record.

Owner:LENOVO (BEIJING) CO LTD

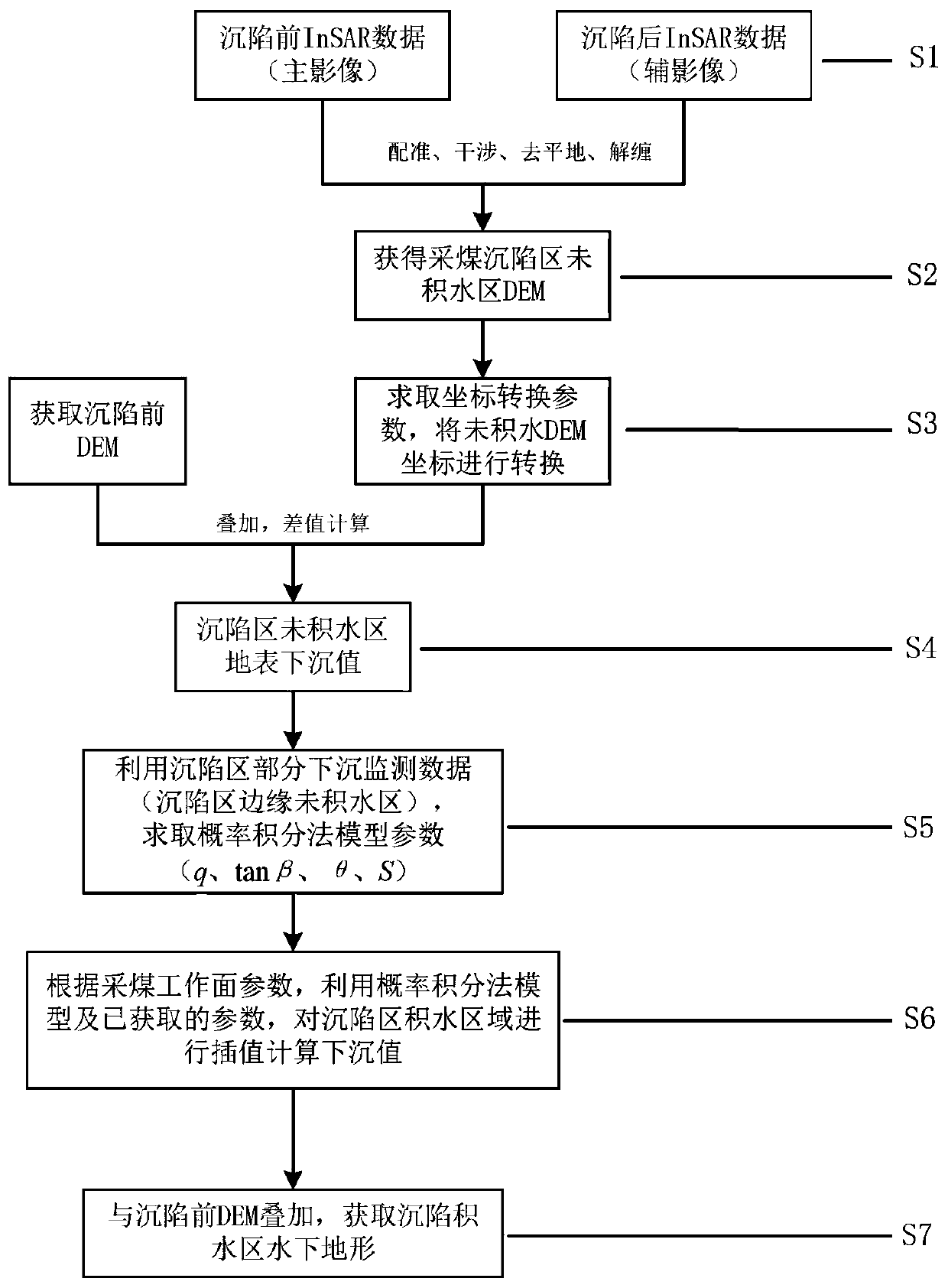

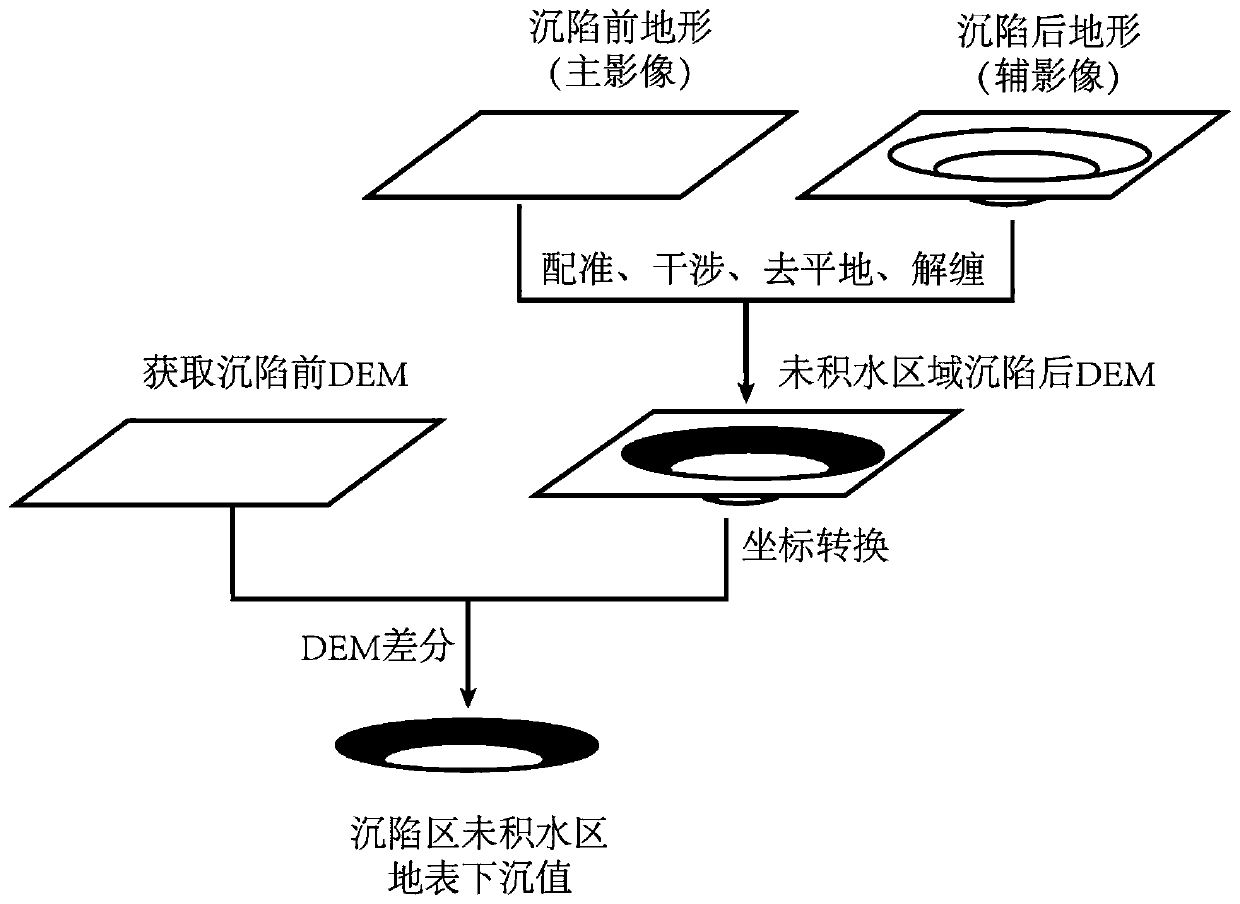

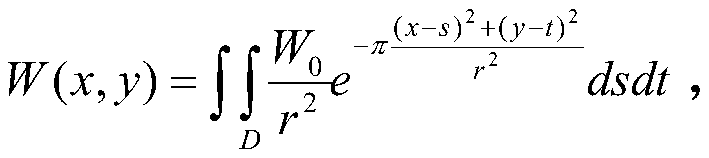

Underwater terrain inversion method for coal mining subsidence ponding area by utilizing InSAR monitoring data

The invention discloses an underwater terrain inversion method for coal mining subsidence ponding area by using InSAR monitoring data. The method comprises the steps: firstly obtaining SAR images before and after the subsidence of a research area and DEM data before the subsidence of the subsidence area, and obtaining surface subsidence information after subsidence through employing the D-InSAR technology; solving a probability integral method parameter of a working surface according to the surface subsidence information and parameters such as working surface angular point coordinates, miningthickness and inclination angle; and finally, inverting the dynamic change of the underwater topography of the subsidence area and the final form of the underwater topography after stopping mining byadopting a model based on a probability integral method. According to the method, the InSAR data acquisition cost is low; the surface subsidence data obtained by the D-InSAR technology is high in precision and large in data volume; the parameter inversion is based on semi-measured data, a parameter inversion result is suitable for the research area, the underwater topography of a ponding area in the mining process of a working face can be inversed, the establishment of an amphibious composite ecosystem of the subsidence area is guided, and an important reference is provided for land utilization planning, land reclamation, ecological restoration and the like of the land surface of the subsidence area.

Owner:ANHUI UNIVERSITY

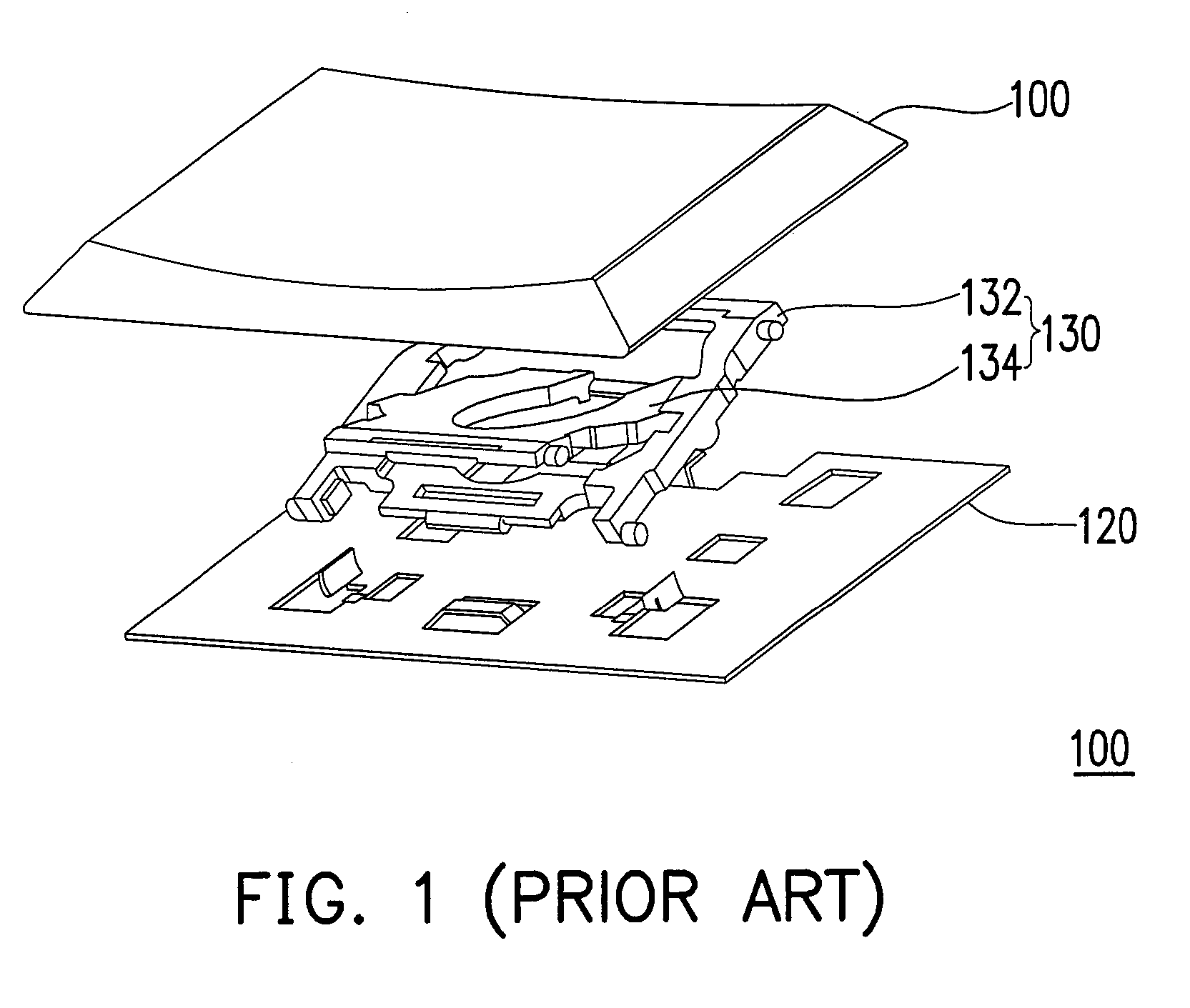

Keyboard structure and keyboard assembly method

InactiveUS20070102274A1Reduce labor costReduce labor costsContact mechanismsEngineeringMechanical engineering

Owner:JENSIN INTL TECH CORP

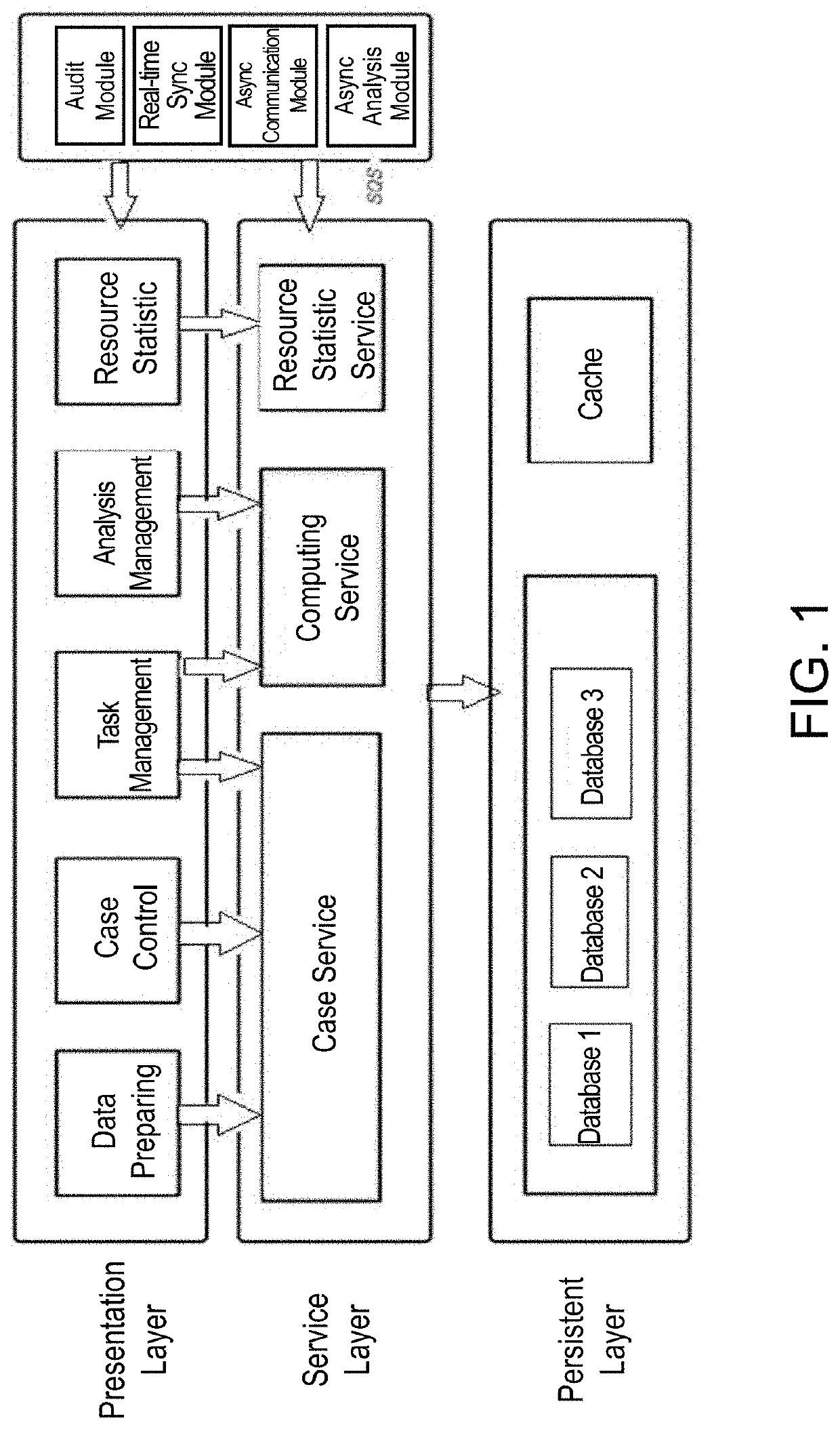

Scientific computing process management system

ActiveUS20190370264A1Reduce labor costImprove robustnessDatabase updatingDatabase management systemsResource utilizationData analysis

The invention belongs to the field of scientific computing, and particularly relates to a scientific computing process management system. The scientific computing process management system includes a basic data presentation layer, a case service module, computing service modules, a resource statistic service module, a persistent layer, an audit module, a real-time sync module, an async communication module and an async analysis module. According to the scientific computing process management system provided by the invention, a complex workflow is disassembled; on the macro level, the overall situation is grasped through planning performed on the whole work of scientific computing; on the micro level, management, monitoring and data analysis are performed with disassembled steps as independent management units; the robustness of a scientific computing process is improved, the operation is smoother, and the system complexity is reduced, so that the user experience is improved; and in addition, the control over a whole process is improved, the resource utilization rate is improved, and the labor cost is reduced.

Owner:SHENZHEN JINGTAI TECH CO LTD

Medical record file coding method, server, and computer readable storage medium

PendingCN109493931AImprove coding efficiencyRealize automatic extractionCode conversionNatural language data processingMedical recordProbability vector

The invention is suitable for the technical field of artificial intelligence, and provides a medical record file coding method, a server, and a computer readable storage medium. The method comprises the steps: obtaining medical record information of a patient from a to-be-coded medical record file, and performing word segmentation processing on the medical record information to obtain a pluralityof segmentation words; determining a first word vector of each segmentation word based on a preset reference word sequence; inputting the first word vector of the segmentation word into a preset coding model to obtain a first coding probability vector, a second coding probability vector and a third coding probability vector of the medical record file; determining the codes corresponding to the elements with the biggest values in the first coding probability vector, the second coding probability vector and the third coding probability vector as a first type code, a second type code and a thirdtype code of the medical record file, thereby reducing the labor cost and improving the coding efficiency of the medical record file.

Owner:PING AN TECH (SHENZHEN) CO LTD

Combination Expansion Joint Strip

ActiveUS20160097203A1Easily gripReduce labor costCovering/liningsJoints tightening/coveringScreedSurface finishing

Owner:BACKRTAPE INC

Sun tracking solar power system hardware and method of assembly

ActiveUS20150187975A1Reduce labor costSimplify and faster procedurePhotovoltaic supportsSolar heating energySun trackingAutomotive engineering

A solar energy collection system can include improved mounting hardware for reducing hardware costs and labor required for assembly. For example, mounting hardware can include surfaces for supporting part or all of the weight of a solar module as it is brought into contact with mounting hardware and then moved into a final engaged position. In some systems, a torque tube can include saddle mount assemblies that allow a solar module to be partially engaged and a registered with the saddle mount while being pivoted into a final locked engagement. Some systems can include arrangements sufficient to support the full weight of a solar module in a disengaged position, and as it is moved into a final engaged position. Some systems can include a configuration of apertures and interference or snap-fit features for providing tool-less connections, thereby simplifying the assembly process.

Owner:SUNPOWER CORPORATION

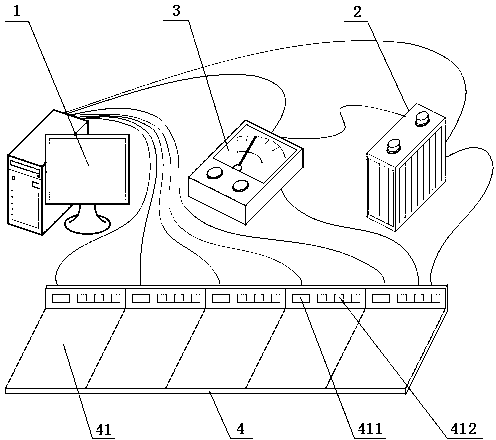

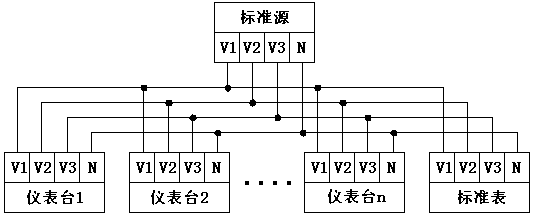

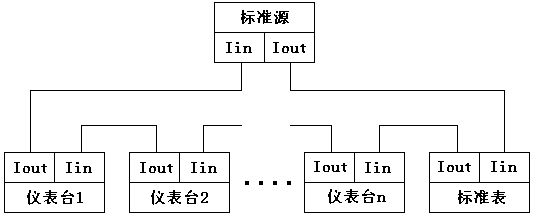

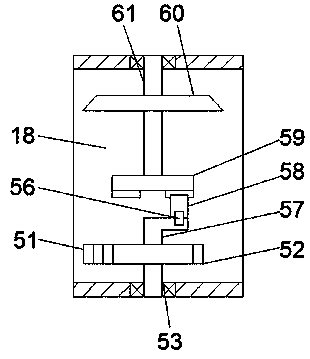

Multi-instrument correcting device and correcting method

InactiveCN103064050AIncrease productivityImprove product qualityElectrical measurementsStandard lineCorrection method

The invention discloses a multi-instrument correcting device and a correcting method. The correcting device comprises a host, a standard source, a standard scale and a test board. The test board comprises a plurality of instrument desks. Each instrument desk comprises a data connector and a test connector. The data connector is connected with the host through a data line. The test connector is connected with the standard source and the standard scale through a test line. The standard source and the standard scale are connected with the host through data lines. Because one standard source and one standard line simultaneously correspond to a plurality of instruments to be corrected, costs of hardware like the standard source and the standard scale are reduced; because the correcting process is controlled by a computer, and a parallel communication mode is adopted between the computer and the plurality of instruments to be corrected, response time is reduced, correcting time is greatly reduced and factory detection time of products is reduced.

Owner:NANJING TIANSU AUTOMATION CONTROL SYST

Spark plug

The invention discloses a spark plug. The spark plug comprises a test box and a storage mechanism arranged in the test box; a test cavity which is opened rightwards is formed in the test box; a cam cavity which is positioned at the right lower side of the test cavity is formed in the test box; a second rotating cavity which is located in the lower side of the cam cavity is formed in the test box;a classification cavity which is positioned in the right side of the cam cavity and is opened rightwards is formed in the test box; a motor is fixedly arranged on the top wall of the test cavity; thelower end of the motor is in power connection with a screw rod which is rotationally connected with the bottom wall of the test cavity; a fourth sliding groove is formed in the rear wall of the test cavity; a feeding block which is in threaded fit with the screw rod is arranged in the fourth sliding groove in a sliding mode; a detection motion box is fixedly arranged on the right end plane of thefeeding block; a first rotation cavity is formed in the detection motion box; and a lever cavity which is positioned in the lower side of the first rotation cavity is formed in the detection motion box.

Owner:何昊充

Binary Hydraulic Manifold System

ActiveUS20110303312A1Reduce labor costEasily changeWatering devicesPipeline systemsEngineeringFluid control

A hydraulic fluid manifold system for a spreader, the spreader including at least one bin for holding dry bulk material for distribution to at least one conveyor associated with the bin for receiving the dry bulk material from the at least one bin and transporting the dry bulk material to at least one spinner associated with the spreader. The hydraulic fluid manifold system includes a single, unitary manifold including a variable speed fluid control circuit for setting a speed for the at least one conveyor and a variable speed fluid control circuit for the at least one spinner of a spreader system for setting a speed for the at least one spinner, the variable speed control circuit for the at least one conveyor including an on / off device for the at least one conveyor that allows when fluid flow through the variable speed conveyor circuit to the at least one conveyor is turned on that the at least one conveyor can automatically operate at a speed set for the at least one conveyor prior to fluid flow to the at least one conveyor having been turned off. Further, the spreader can include at least two conveyors, and the variable speed control circuit for the at least two conveyors can further include flow of hydraulic fluid through the variable speed conveyor circuit to be changed between in-parallel flow to a first and a second of the conveyors simultaneously and in-series flow where flow of fluid is sent to a first one of the conveyors and then sent from the first one of the conveyors to a second one of the two conveyors.

Owner:SALFORD BBI

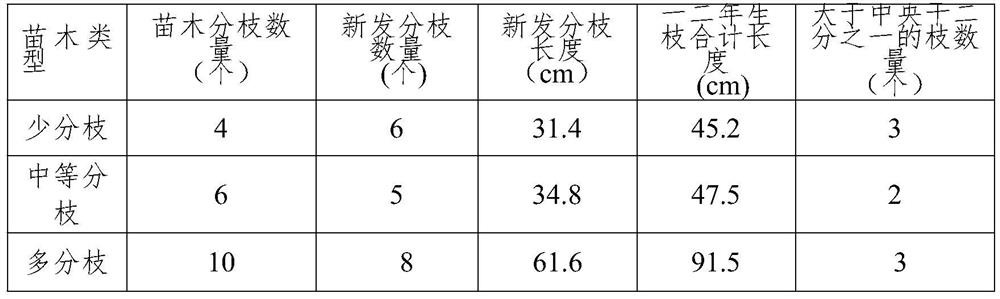

Apple tree spindle-shaped pruning method without manual branch pulling

InactiveCN112868453AReduce labor costPromote formationCultivating equipmentsHorticulture methodsPruningGrowth regulator

The invention discloses an apple tree spindle-shaped pruning method without manual branch pulling. The method comprises the following steps: selecting multi-branch big seedlings with horizontal branches to build a garden, spraying a growth regulator, promoting growth stop and flower bud formation, after the seedlings are planted, carrying out spraying and mixing to promote the upper portion of a tree body to grow horizontal branches, cutting back all the branches after planting, carrying out rootstock ridging in late autumn, removing vertical branches through pruning in winter, and pressing the branches by fruits to form horizontal branches. As the dwarf apples bear fruits early, the branches bear fruits as early as possible from the next year, and the branches are pressed to be below the level under the gravity action of the fruits. Manual branch pulling is not needed any more, and other technologies are completely the same as a spindle-shaped fruit cultivation method; and labor is greatly saved.

Owner:淳化天地生态农业科技有限公司

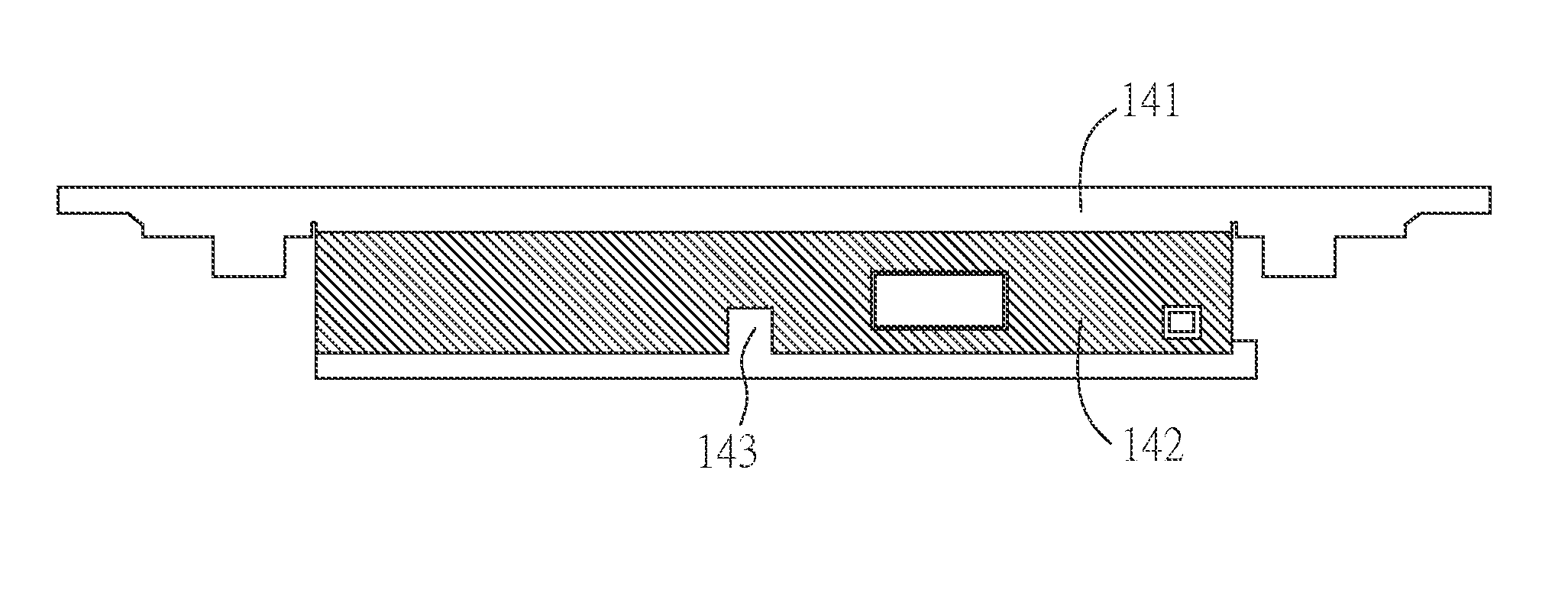

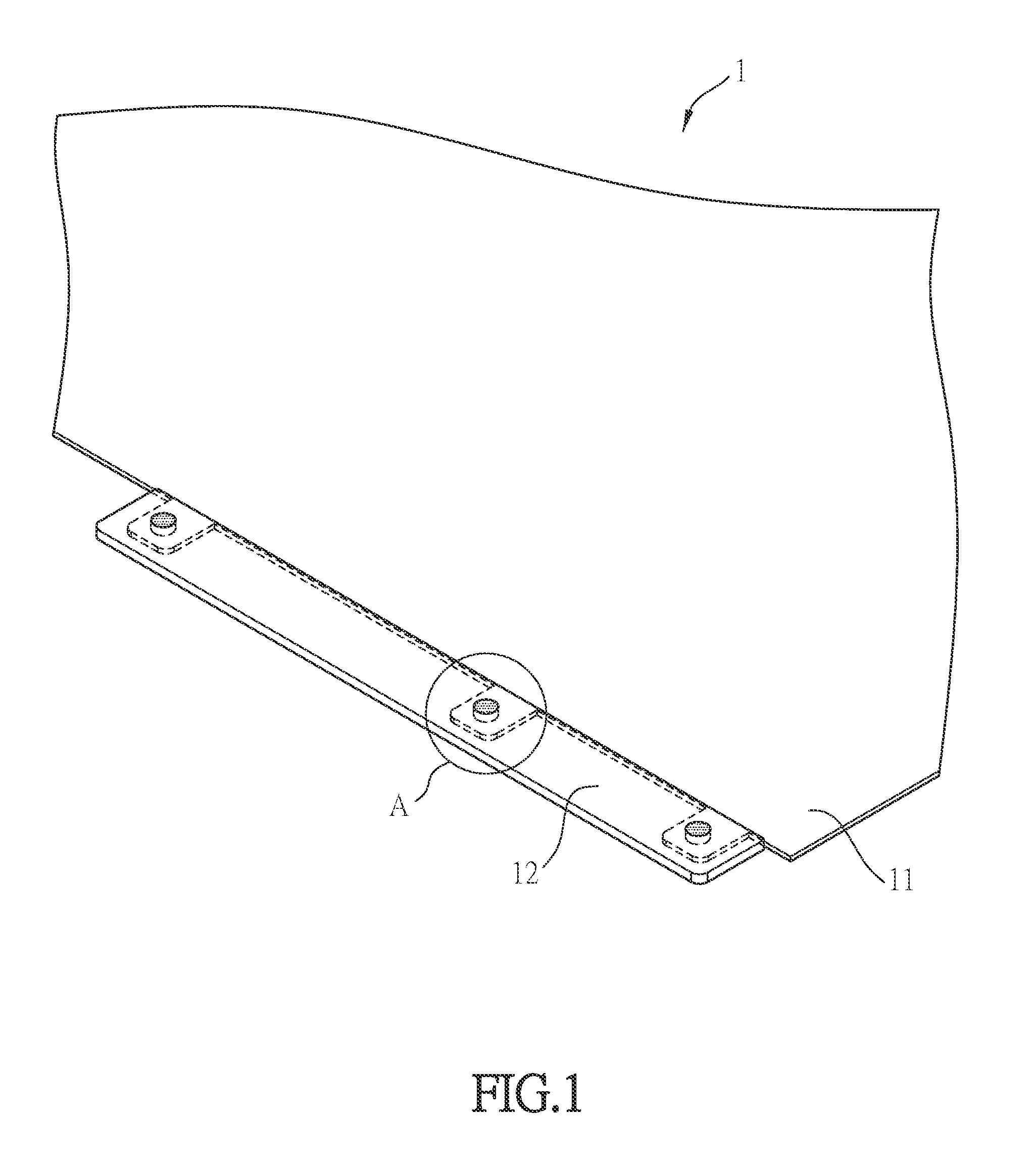

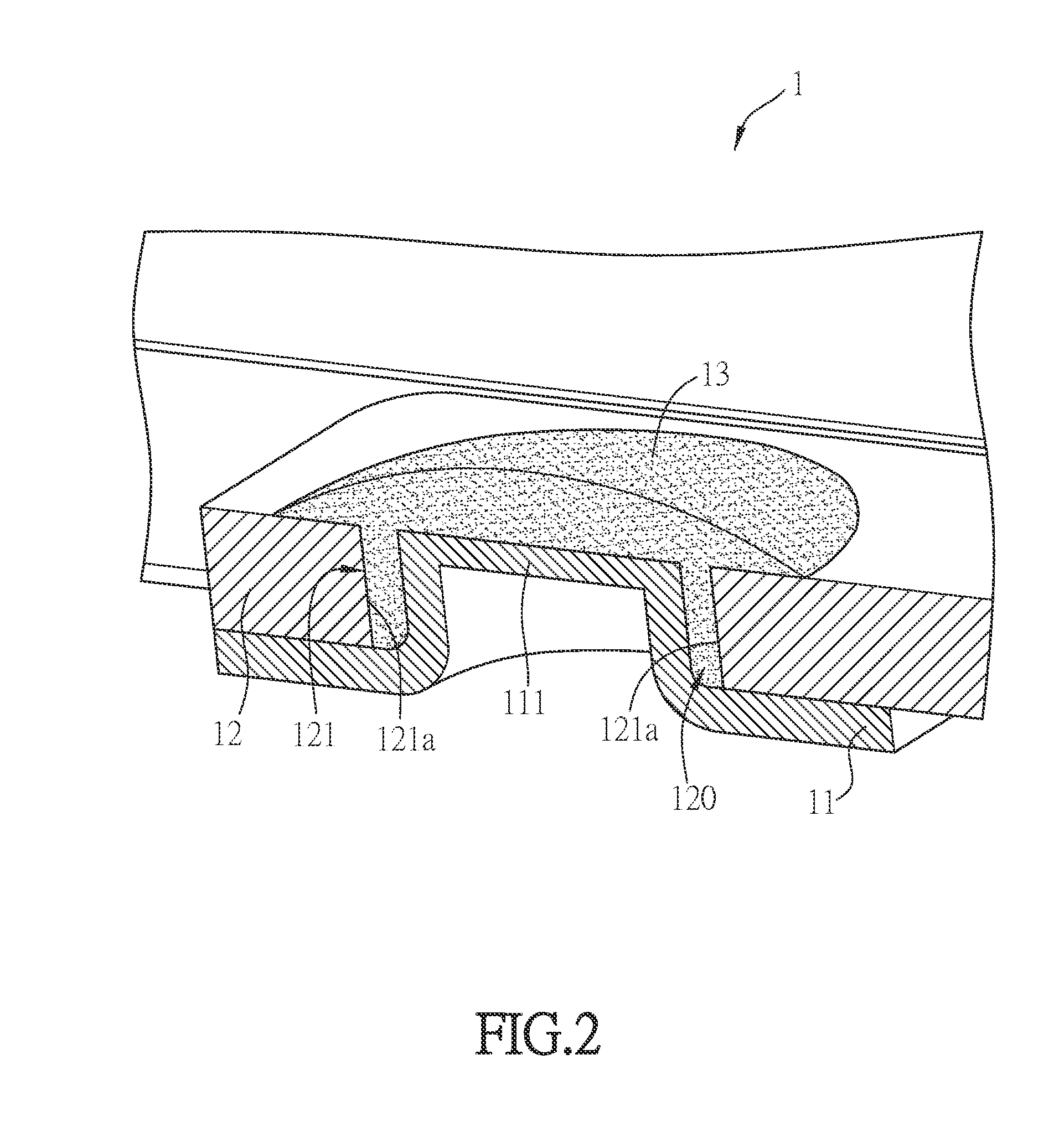

Electronic apparatus

InactiveUS20150245504A1Assembly efficiency be enhanceReduce labor costCasings with connectors and PCBMagnetic/electric field screeningManufacturing efficiencyAdhesive

An electronic apparatus includes a metallic housing, a circuit board and an adhesive. The metallic housing includes a first engaging structure. The circuit board includes a second engaging structure, which is coupled to the first engaging structure. The adhesive is disposed between the first and second engaging structures to connect the metallic housing and the circuit board. The manufacturing efficiency of the electronic apparatus can be enhanced by the adhesive connecting the metallic housing and the circuit board.

Owner:INNOLUX CORP

Reversing image camera assembly for vehicle

PendingCN108569221ALower assembly costsReduce labor costTelevision system detailsColor television detailsCavity wallEngineering

The invention relates to a reversing image camera assembly for a vehicle. The assembly is mounted on a rear cover or a rear bumper of the vehicle to provide a real-time image of the rear of the vehicle, the reversing image camera assembly is characterized by including a camera (1), a bracket (2) and a cover plate (3), and the camera (1) is arranged towards the rear of the vehicle; the bracket (2)is provided with a cavity (22) for receiving the camera (1), and a hole (23) for the camera (1) to shoot an image is formed in a cavity wall facing the rear of the vehicle; the cover plate (3) is detachably and rotatably connected to the bracket (2), and cavity (22) is covered by the cover plate (3) to precisely position the camera (1). The assembly can greatly optimize the assembly efficiency ofthe reversing image camera on the rear cover or the rear bumper of the vehicle, effectively save the working time and cost, and be beneficial for the wiring harness arrangement and waterproof performance of the reversing image camera.

Owner:PEZHO SITROEN AUTOMOBILS SA

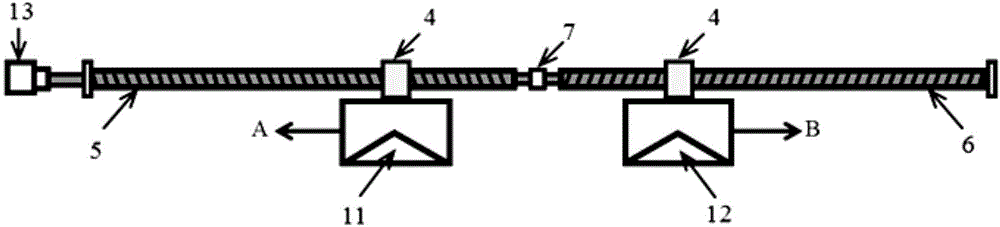

Automatic quick measuring system for common midpoint ground penetrating radar data

ActiveCN104635275AHigh degree of automationReduce labor costDetection using electromagnetic wavesMeasurement deviceData lines

The invention discloses an automatic quick measuring system for common midpoint ground penetrating radar data and relates to ground penetrating radar. The automatic quick measuring system is provided with an automatic measuring device for the common midpoint ground penetrating radar data, a computer and a radar host, wherein the measuring device is provided with driving nuts, a left screw rod, a right screw rod, a pipe coupling, a ground penetrating radar transmitting antenna, a ground penetrating radar receiving antenna and a stepper motor; the stepper motor is arranged at one end of the left screw rod; the left screw rod and the right screw rod are connected by the pipe coupling; the transmitting antenna and the receiving antenna are fixed on the left screw rod and the right screw rod through the driving nuts; the computer is connected with the stepper motor and the radar host through data cables; the stepper motor and the radar motor are used for respectively and synchronously controlling position moving and radar data acquisition of the transmitting antenna and the receiving antenna; the stepper motor is used for controlling the positions of the transmitting antenna and the receiving antenna and enabling the transmitting antenna and the receiving antenna to move toward opposite directions at equal distance by driving the left and right screw rods; the radar host is used for controlling the transmitting antenna to radiate high-frequency electromagnetic waves toward underground media; reflection echo from an underground target is recorded by the receiving antenna.

Owner:XIAMEN UNIV +2

Packaging bag for fresh noodles

The invention discloses a packaging bag for fresh noodles. The packaging bag comprises a packaging bag body, and is characterized by being composed of a packaging bag handle, a packaging bag upper seal, the packaging bag body, a breakpoint line, a bottom water storage area, water outlet holes, a pre-scribed vacuum edge-sealing line and a bottom handle; the packaging bag upper seal is formed on the upper part of the packaging bag body, and the packaging bag handle is arranged on the packaging bag upper seal; the bottom water storage area is formed on the lower part of the packaging bag body, a plurality of water outlet holes are formed in the bottom water storage area, the bottom water storage area is connected with the packaging bag body by the breakpoint line, and the pre-scribed vacuum edge-sealing line is formed above the breakpoint line; and the bottom handle is arranged at the lower left corner of the packaging bag body. The packaging bag disclosed by the invention is capable of combining steaming and sterilization processed needed for producing wet noodles together, simplifying a production process for the noodles, saving the cost, and protecting the unique eating taste and flavour of the noodles; in addition, the packaging bag is capable of effectively preventing secondary pollution in production, so as to prolong the expiration date of the noodles.

Owner:凌烈根

Method and apparatus for removing conductive film

The present disclosure discloses a method and an apparatus for removing a conductive film. The method includes: providing a display panel with the conductive film to be removed; treating the conductive film to be removed on the display panel by using a laser; and cleaning the display panel after the treating by using the laser.

Owner:HKC CORP LTD +1

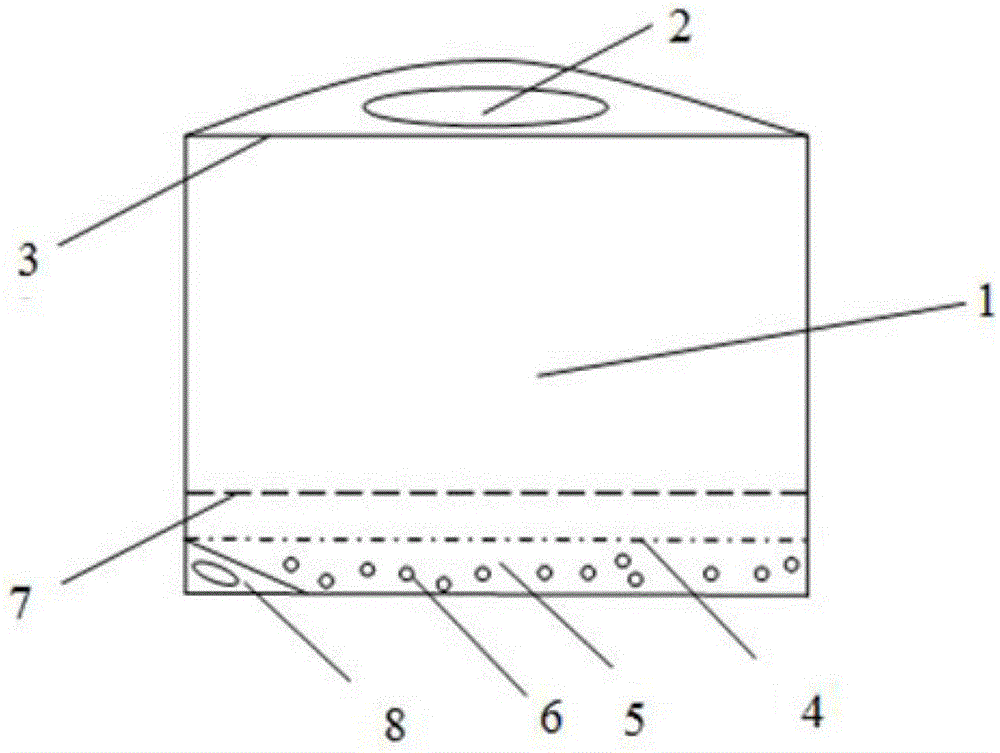

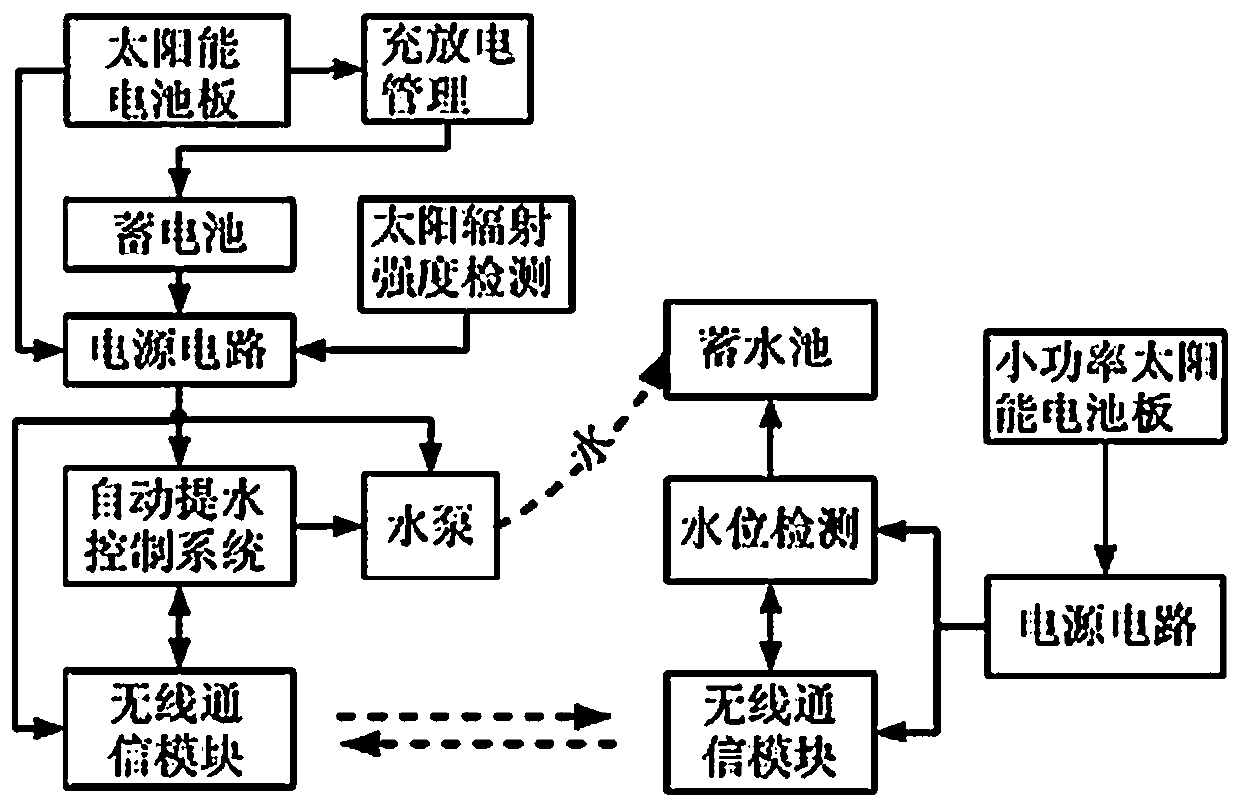

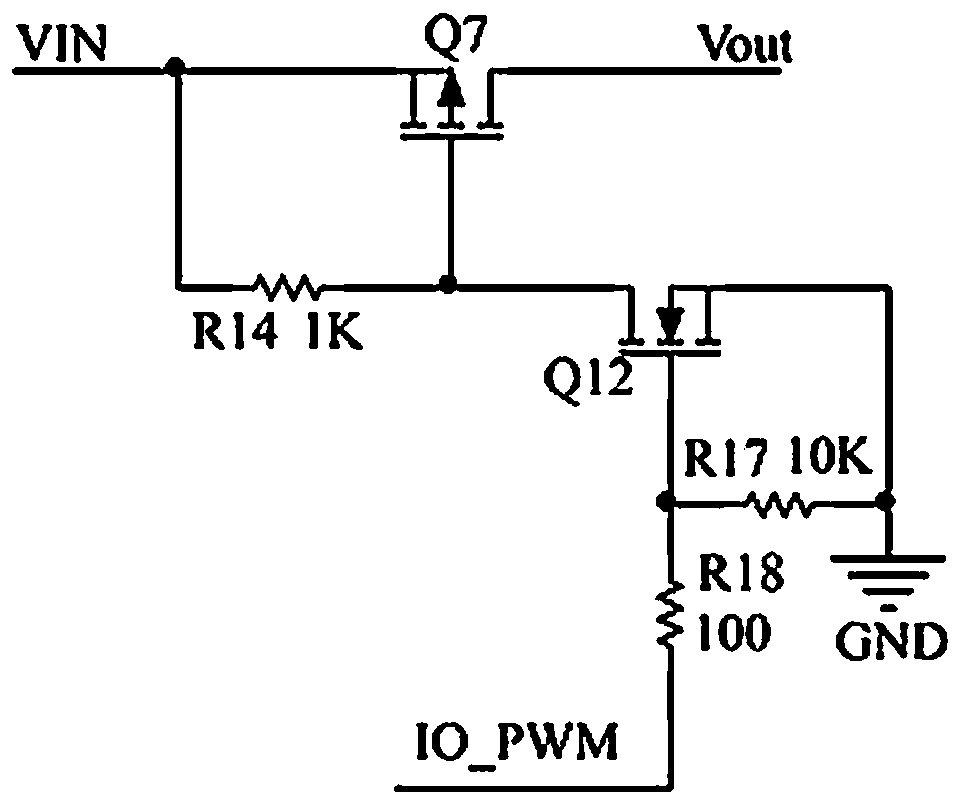

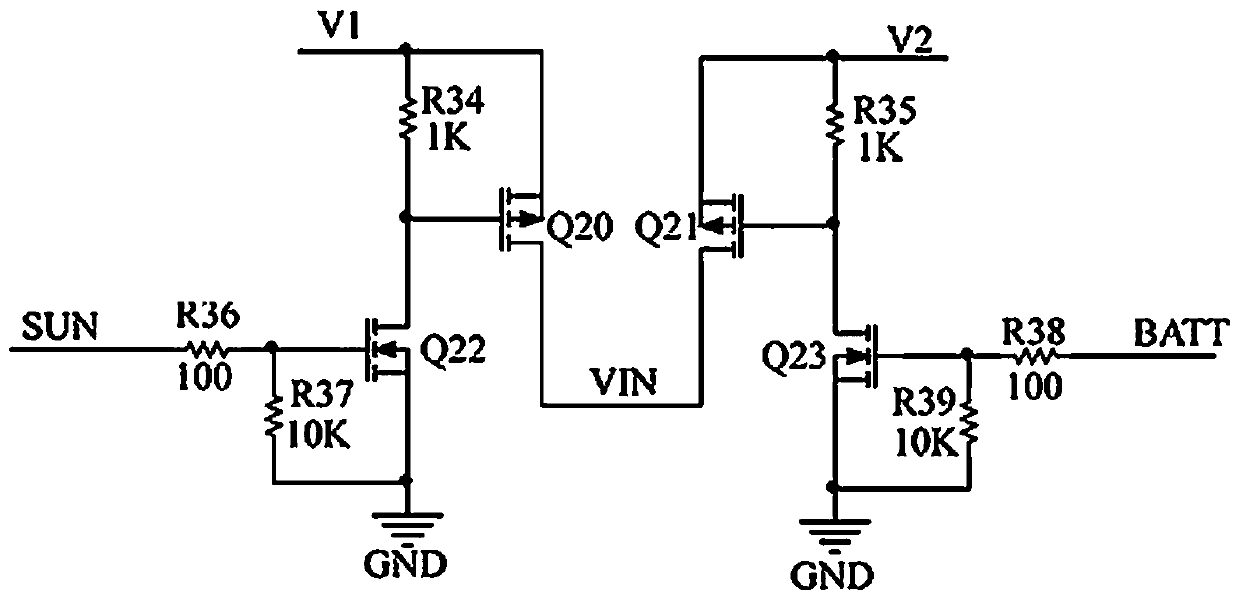

Solar-based constant-pressure water supply automatic control device for micro irrigation system

InactiveCN107581033AHigh degree of automationReduce labor costWatering devicesRenewable energy machinesAutomatic controlPower circuits

The invention discloses a solar-based constant-pressure water supply automatic control device for a micro irrigation system. The device comprises a solar cell panel, charging and discharging management unit, a storage battery, a solar radiation intensity detection unit, a power supply circuit, an automatic water lifting control system, a water pump, a wireless communication module, a water storagepond, a water level detection unit and a small-power solar cell panel. A liquid level sensor YZ-YO-LAG1 is used to online detect the water level of the water storage pond which is built at a high position, and DP-60 is controlled according to the water level information to lift water into the water storage pond, and enable the water level of the water storage pond to be kept at a certain fixed height in the drip irrigation process to realize constant-pressure water supply. The water level detection information of the water storage pond and the start and stop of the DP-60 are transmitted and controlled wirelessly by the wireless communication module CC1100.

Owner:郭洪

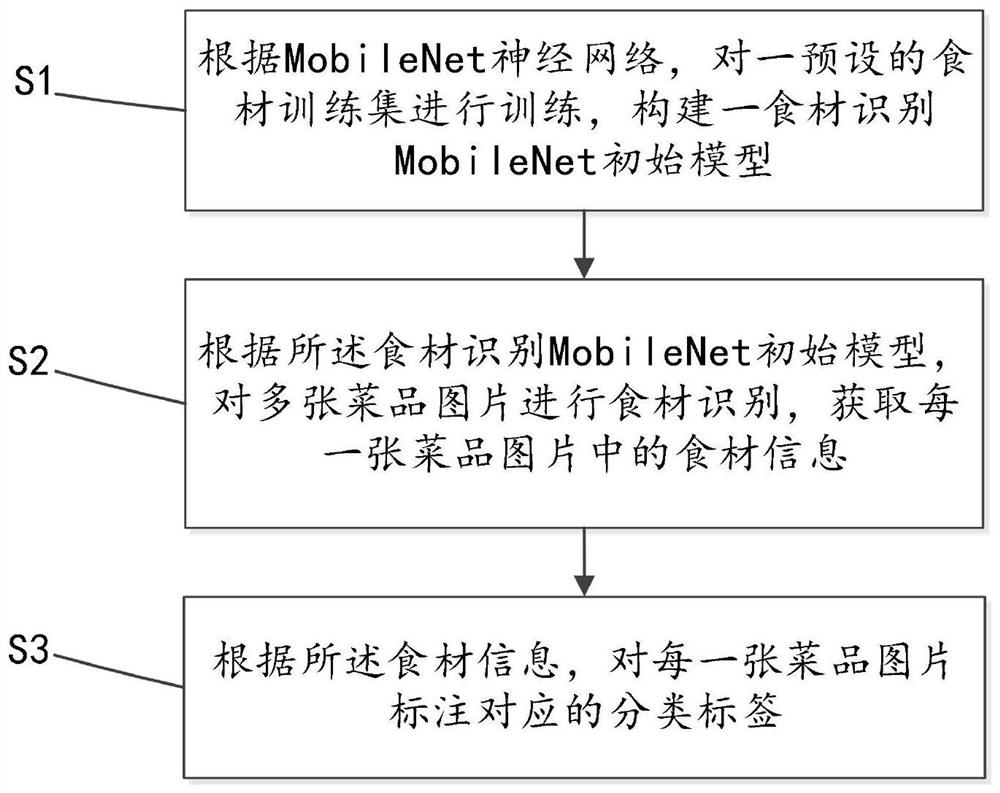

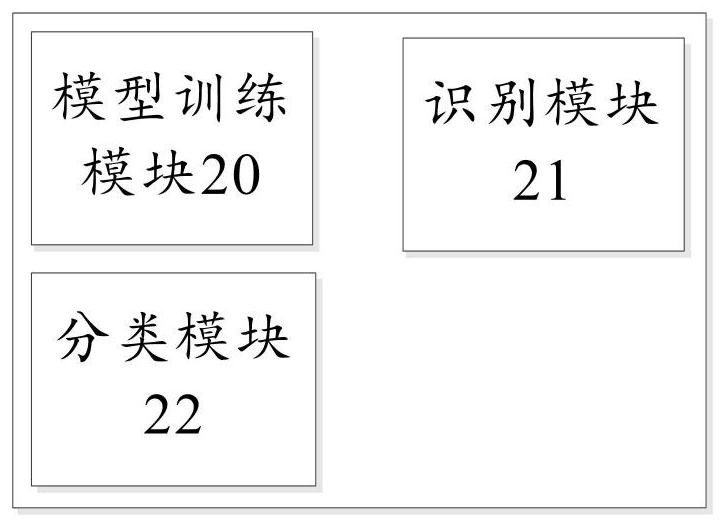

Data set labeling method and system

PendingCN111652255AReduce data volumeReduce labor costWeb data indexingCharacter and pattern recognitionEngineeringData mining

The invention discloses a data set labeling method, which comprises the following steps of: training a preset food material training set according to a MobileNet neural network, and constructing a food material recognition MobileNet initial model; according to the food material identification MobileNet initial model, carrying out food material identification on a plurality of dish pictures, and obtaining food material information in each dish picture; and according to the food material information, marking a classification label corresponding to each dish picture. The data set marking efficiency and accuracy are improved, and the workload of manual marking is greatly reduced.

Owner:上海铼锶信息技术有限公司

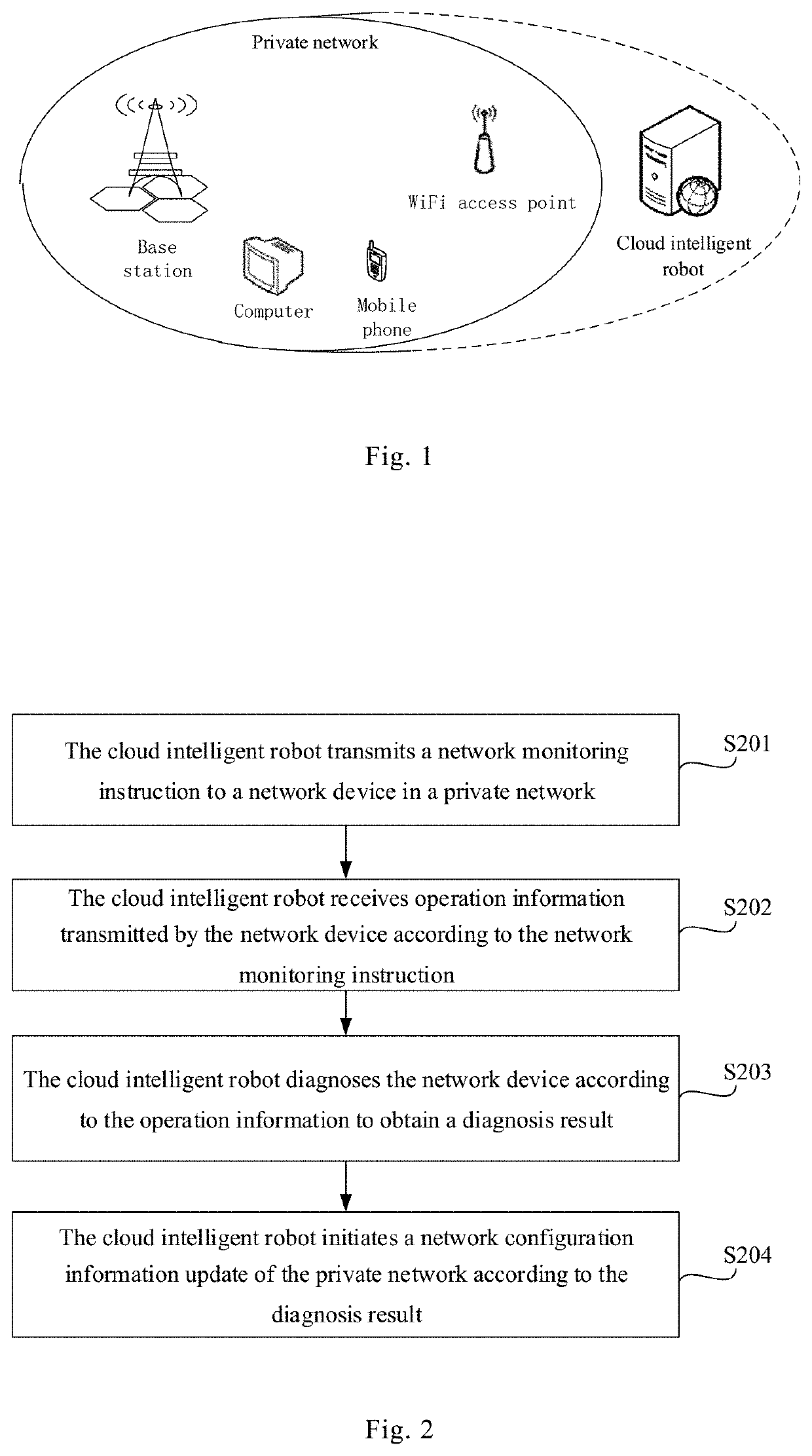

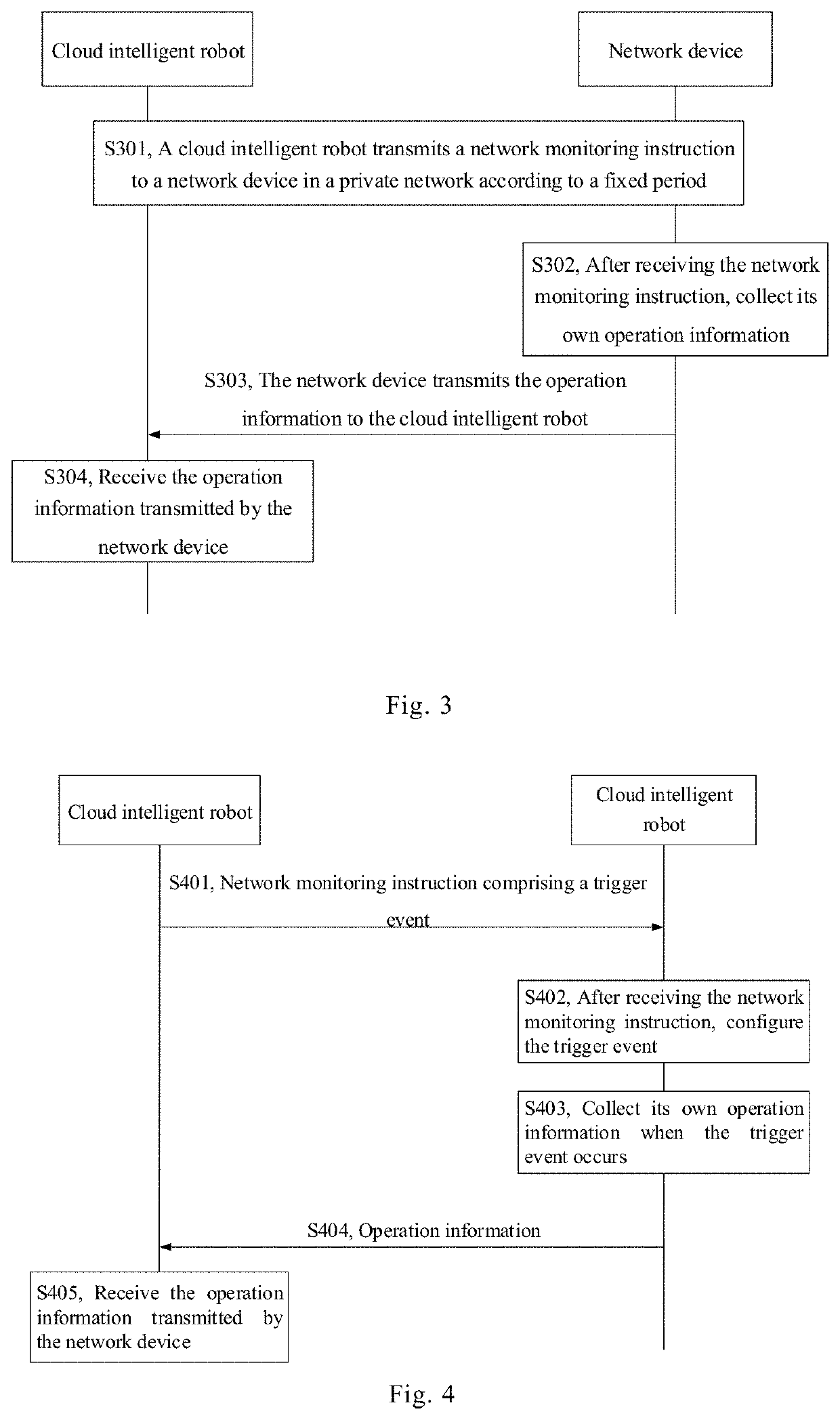

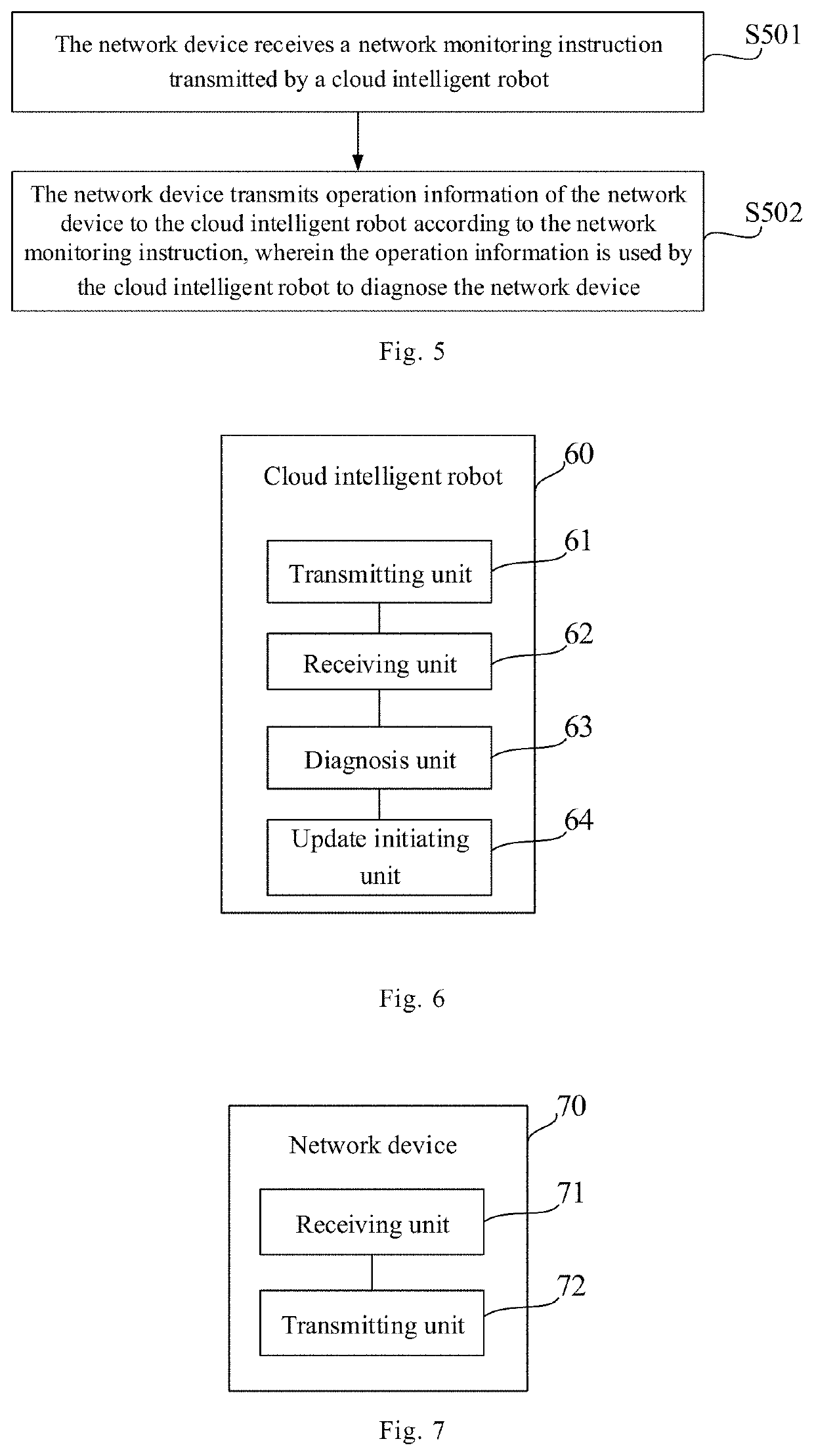

Network diagnosis method, cloud intelligent robot, network device and private network

ActiveUS20210099369A1Reduce labor costAvoid riskData switching networksWireless communicationEngineeringReal-time computing

A network diagnosis method, a cloud intelligent robot, a network device and a private network, relate to the technical field of communications, and are used for solving the technical problems of having low diagnosis efficiency and leakage risk for a private network in the prior art. The method comprises: an cloud intelligent robot transmitting a network monitoring instruction to a network device in a private network; receiving operation information transmitted by the network device according to the network monitoring instruction; diagnosing the network device according to the operation information to obtain a diagnosis result; and initiating a network configuration information update of the private network according to the diagnosis result.

Owner:CLOUDMINDS SHANGHAI ROBOTICS CO LTD

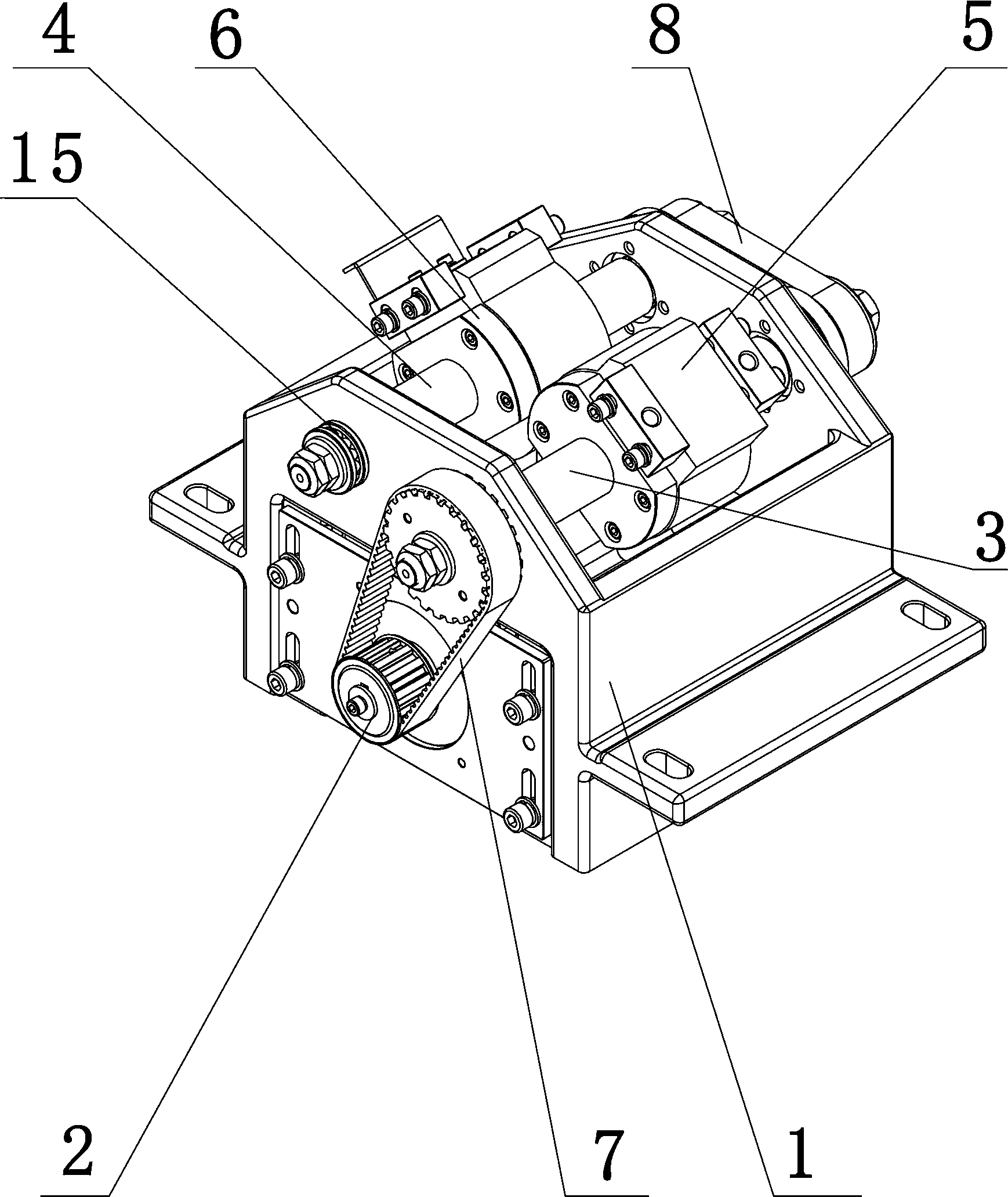

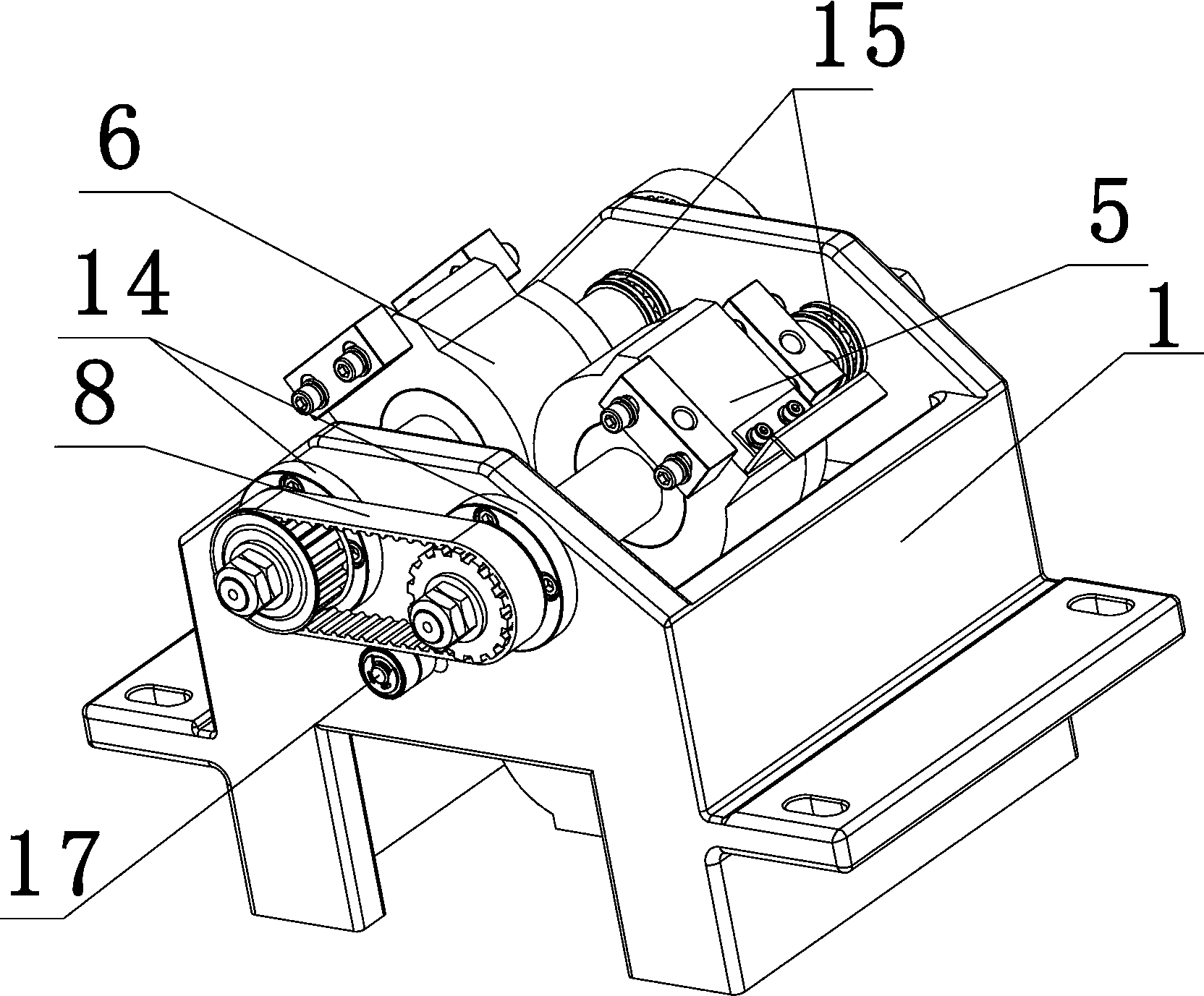

Duplex table transmission gear

The invention relates to the technical field of computerized flat knitting machines, in particular to a duplex table transmission gear. The duplex table transmission gear comprises a shaking table base and a servo motor, wherein the servo motor is fixed on the shaking table base, the shaking table base is provided with a first ball screw and a second ball screw which are parallel to each other in an erecting mode, the first ball screw is movably connected with a first hanging seat, the second ball screw is movably connected with a second hanging seat, one end of the first ball screw is connected with the servo motor through a first synchronous belt, and the other end of the first ball screw is connected with the second ball screw through a second synchronous belt. The duplex table transmission gear is simple in structure, high in knitting efficiency and capable of saving labor cost.

Owner:FLYING TIGER TEXTILE MACHINERY

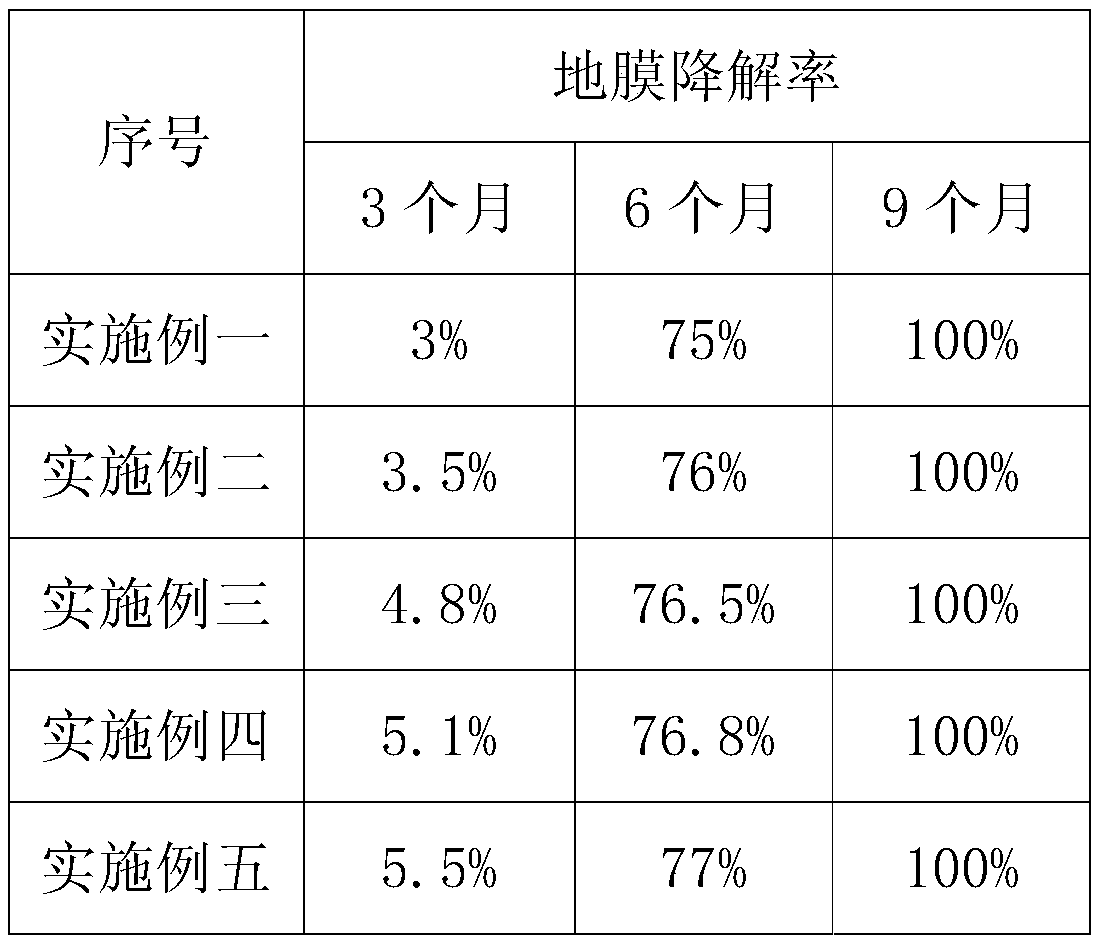

Fully-degradable agricultural biological intelligent mulching film and preparation method therefor

InactiveCN111108989AReduce labor costIncrease farmland moistureAgriculture tools and machinesOrganic fertilisersSodium carboxymethylcelluloseAgricultural science

The invention discloses a fully-degradable agricultural biological intelligent mulching film and a preparation method therefor. The fully-degradable agricultural biological intelligent mulching film comprises 0.5-1.5 parts of modified starch, 0.6-1 parts of polyvinyl alcohol, 0.4-0.8 parts of emulsifier, 0.3-0.7 parts of carboxymethyl cellulose, 0.2-0.4 parts of PH regulator, 0.2-0.4 parts of natural latex and 95.2-97.8 parts of distilled water in a weight ratio. The prepared fully-degradable agricultural biological intelligent mulching film can replace agricultural plastic mulching films usedin agricultural production at present, and the intelligent mulching film can be fully degraded within nine months after being sprayed onto farmland surfaces, does not need to be recycled, has no residue and is pollution-free.

Owner:深圳市常治互联网技术开发有限公司

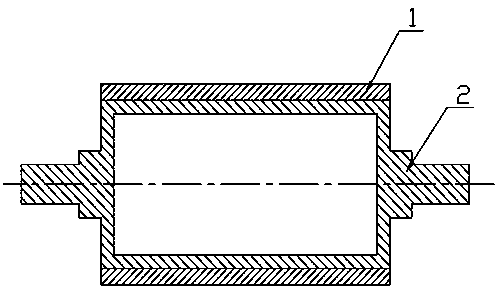

Antibacterial rubber roll

The invention discloses an antibacterial rubber roll which comprises a rubber roll surface and a roller core, wherein the rubber roll surface is adhered on the surface of the roll core, the roll surface is made of rubber, and the rubber comprises the following components in parts by mass: 100 parts of fluororubber, 23-33 parts of thermal cracking carbon black, 0.5-2 parts of lead stearate, 1-3 parts of accelerant NA-22, 4-7 parts of magnesium oxide, 2-4 parts of vulcanizing agent S-3, 0.9-1.2 parts of chlorhexidine acetate, 2-3 parts of resin acid copper salt and 0.5-1 part of organosilicone. By adopting the manner, the antibacterial rubber roll disclosed by the invention is capable of effectively killing bacteria generated on the rubber roll within a short time, thereby reducing the frequency of replacing a rubber roll on a machine, effectively saving the labor cost, and being capable of ensuring the safety of the machine.

Owner:SUZHOU CITY XIANGCHENG DISTRICT MINGDA COMPOSITE MATERIAL FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com