Construction of coupling exhaust pipes of vehicle

A connection structure and exhaust pipe technology, applied in the direction of flange connection, exhaust device, pipe/pipe joint/pipe fitting, etc., can solve the problems of increased weight and cost, large number of parts, troublesome welding process, etc., to achieve Avoidance of weight, ease of manufacture, effect of reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] (First Embodiment)

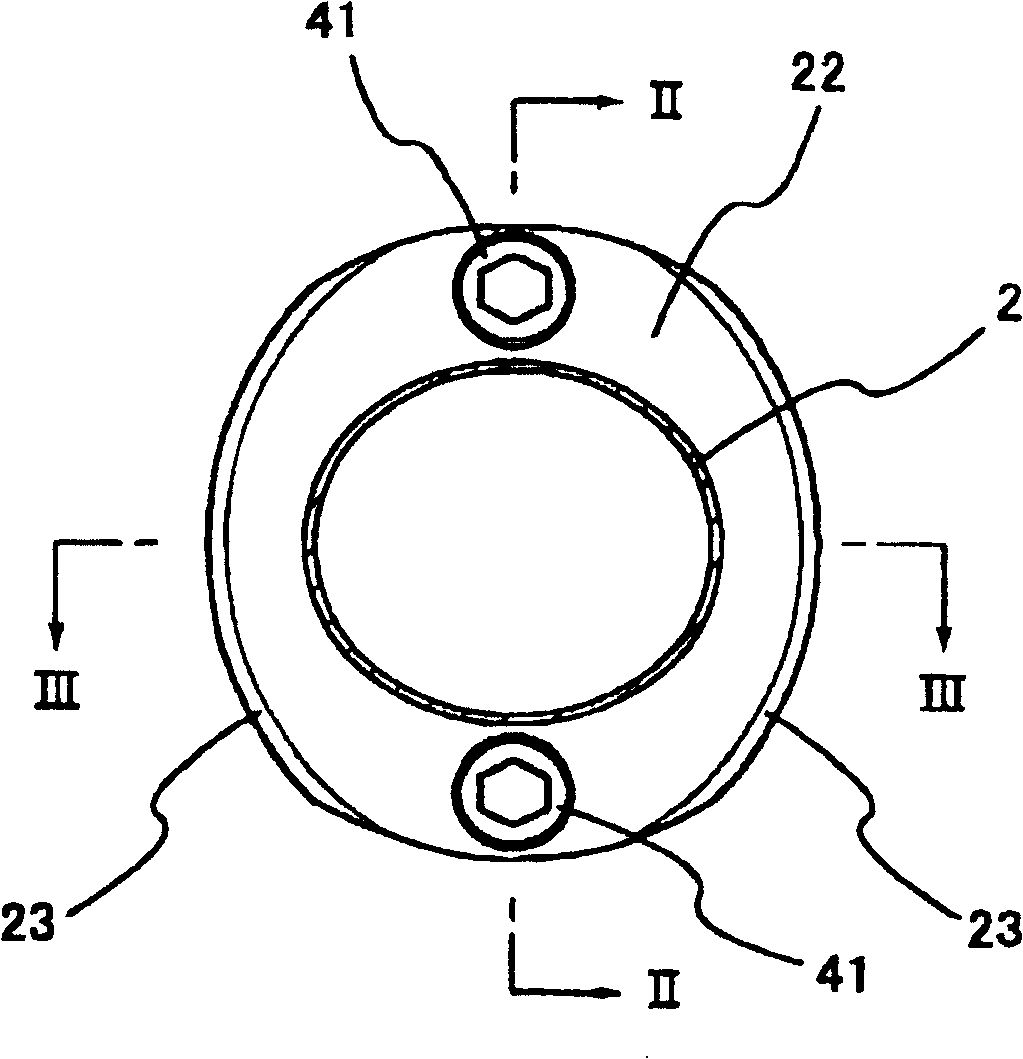

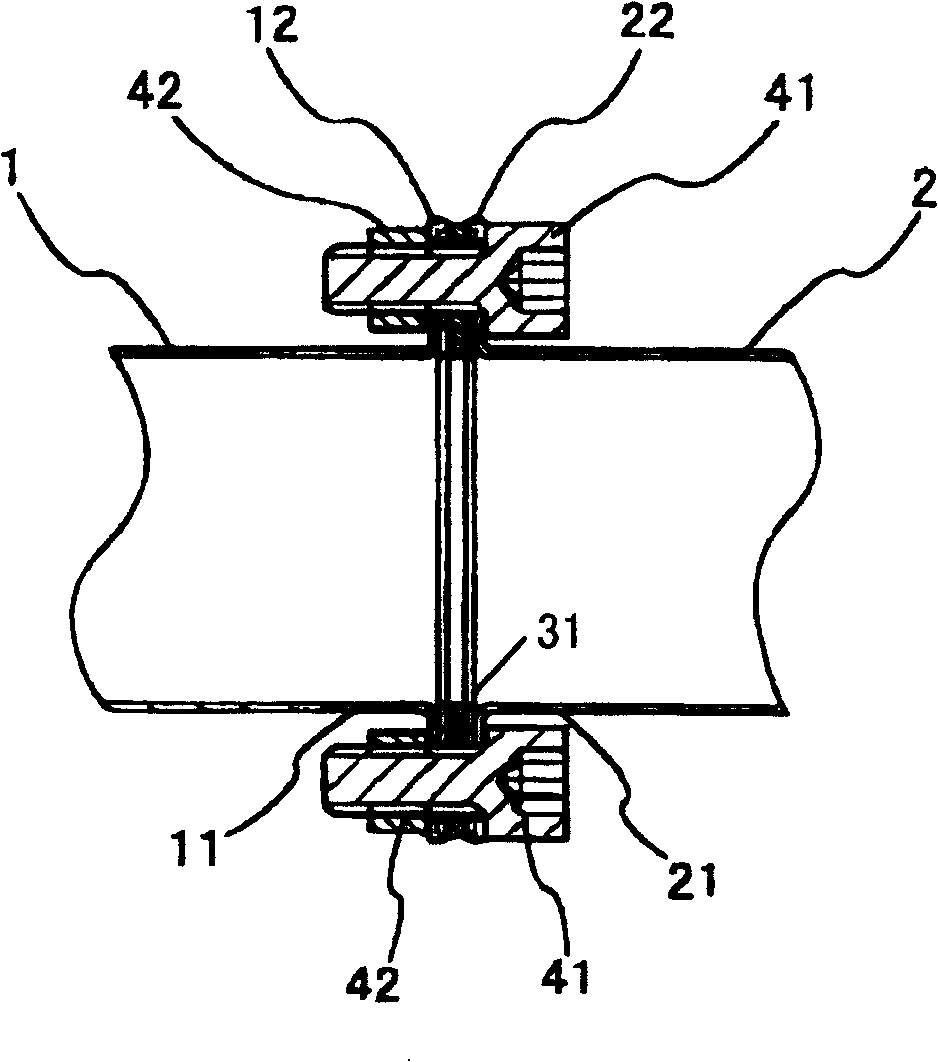

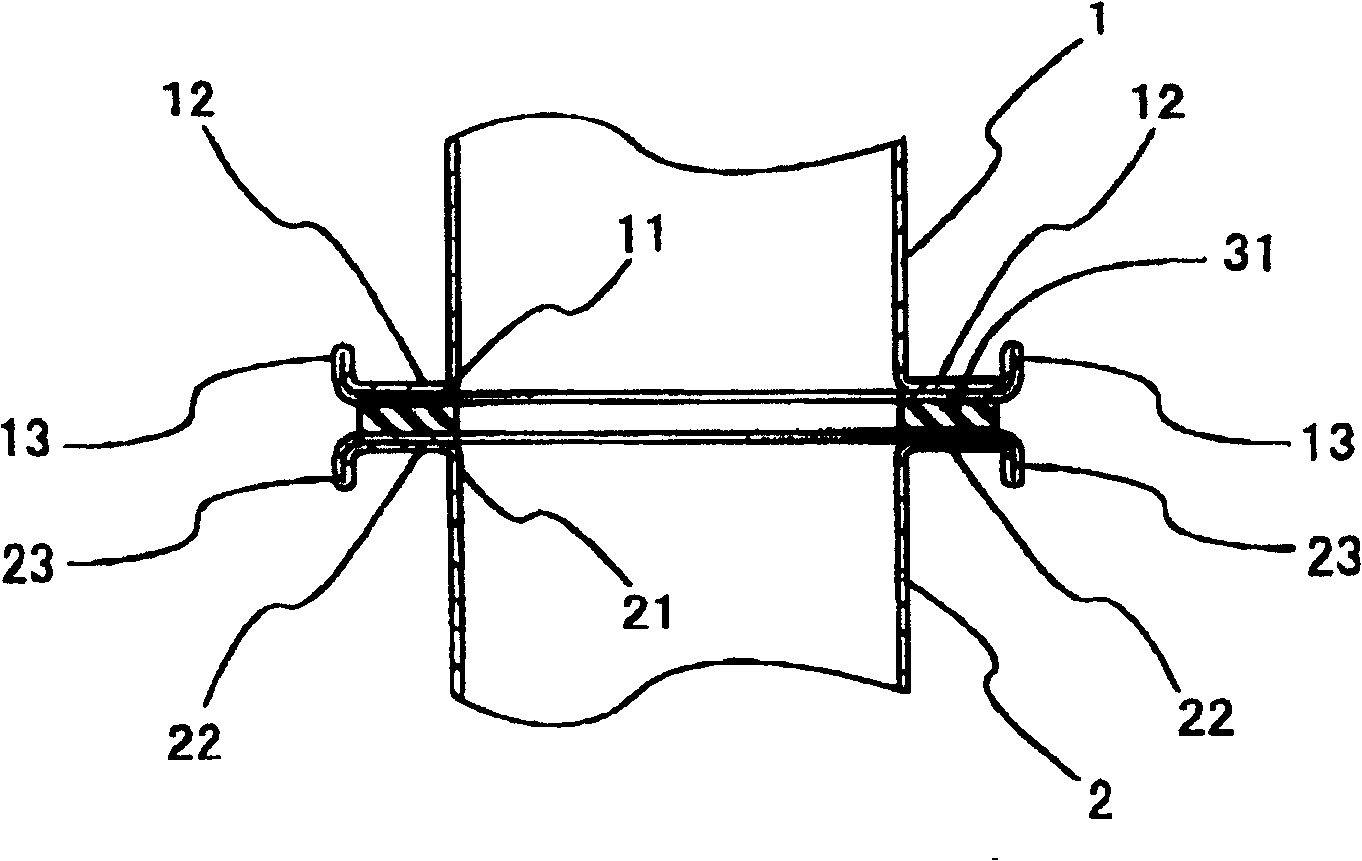

[0027] Figure 1 ~ Figure 3 An example of the connection structure of the present invention is shown. figure 1 Is a cross-sectional view of the connected vehicle exhaust pipe, figure 2 , image 3 Respectively along figure 1 The vertical cross-sectional view of the II-II line and the III-III line. in figure 2 , image 3 Among them, the upstream side exhaust pipe 1 and the downstream side exhaust pipe 2 are located such that the opening edges 11 and 21 face each other. The wall thickness of each exhaust pipe 1, 2 is, for example, 1.2 to 1.5 mm, and its opening edges 11, 21 are expanded and formed to bend outward in the radial direction, and then fold inward in the radial direction to form a convex of a predetermined width around the opening. Rim 12,22. The flanges 12 and 22 are provided with a gasket 31 between them, butt against each other, and are symmetrical in the radial direction ( figure 1 ) Combine with bolt 41 and nut 42. The two exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com