Shaft-type cross-flow fan and method for manufacturing same

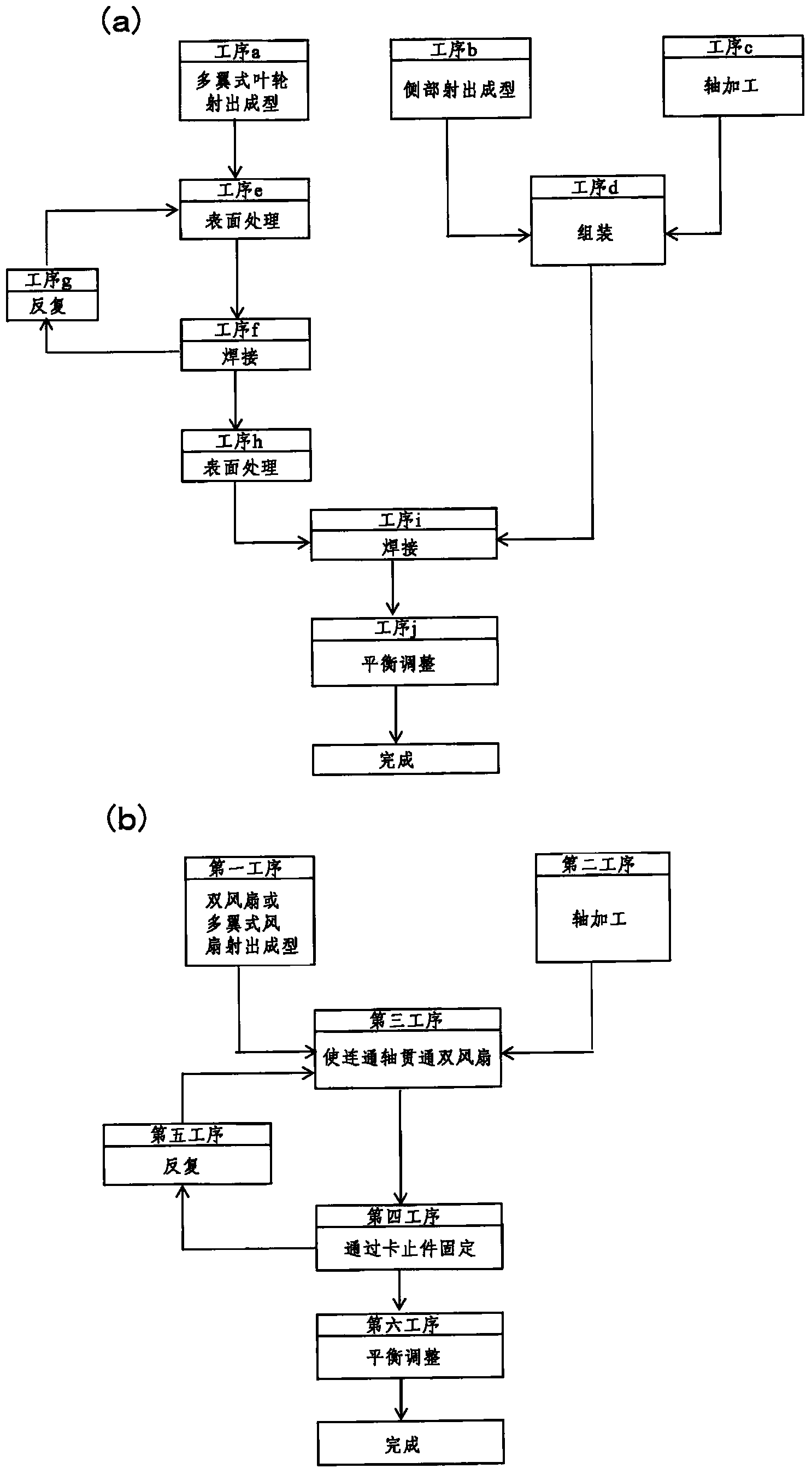

A cross-flow fan and manufacturing method technology, applied in the direction of non-variable pumps, non-volume pumps, radial flow pumps, etc., can solve problems such as residual weight balance and pressure difference, and achieve easy balance adjustment and shortening Manufacturing time, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

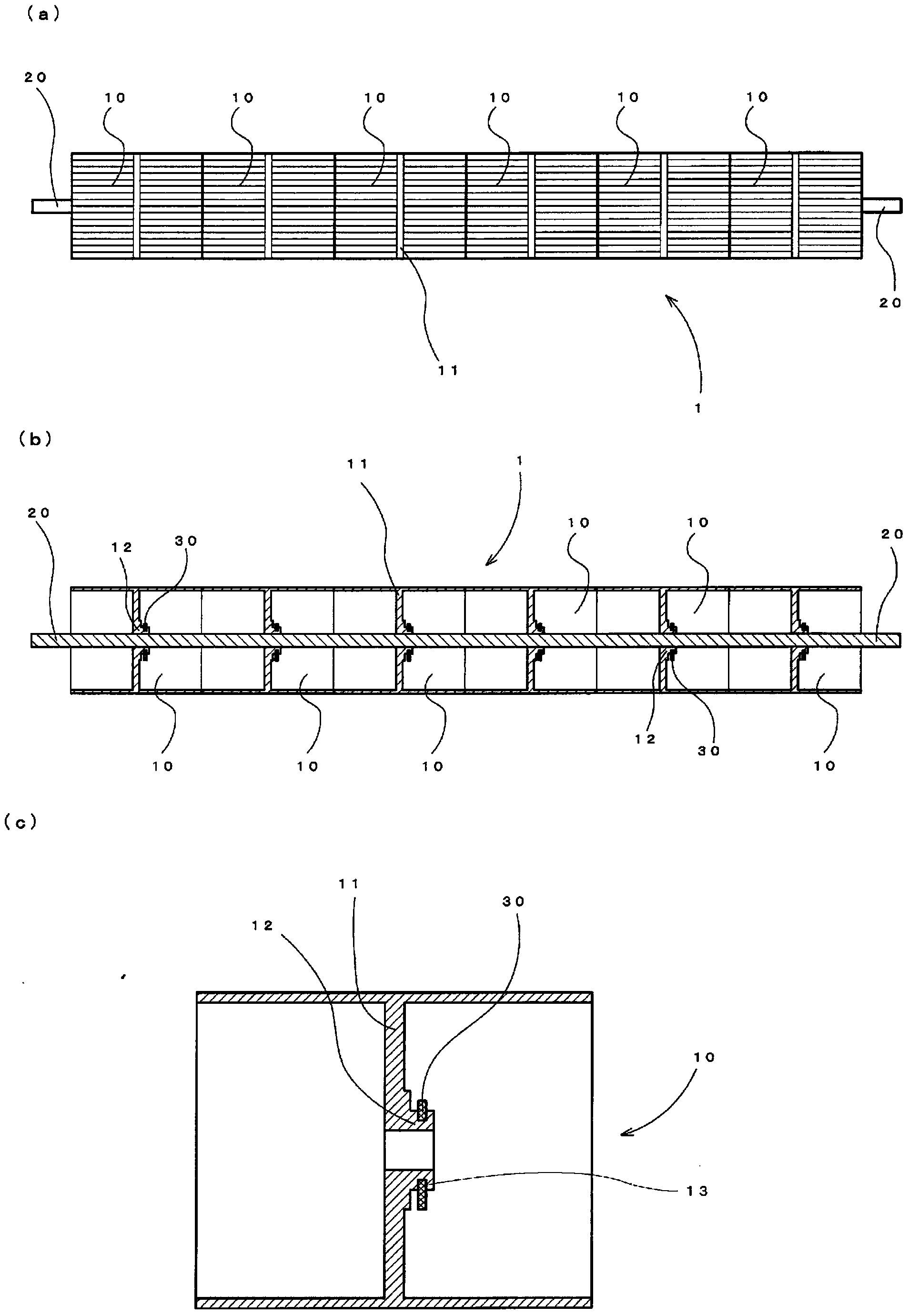

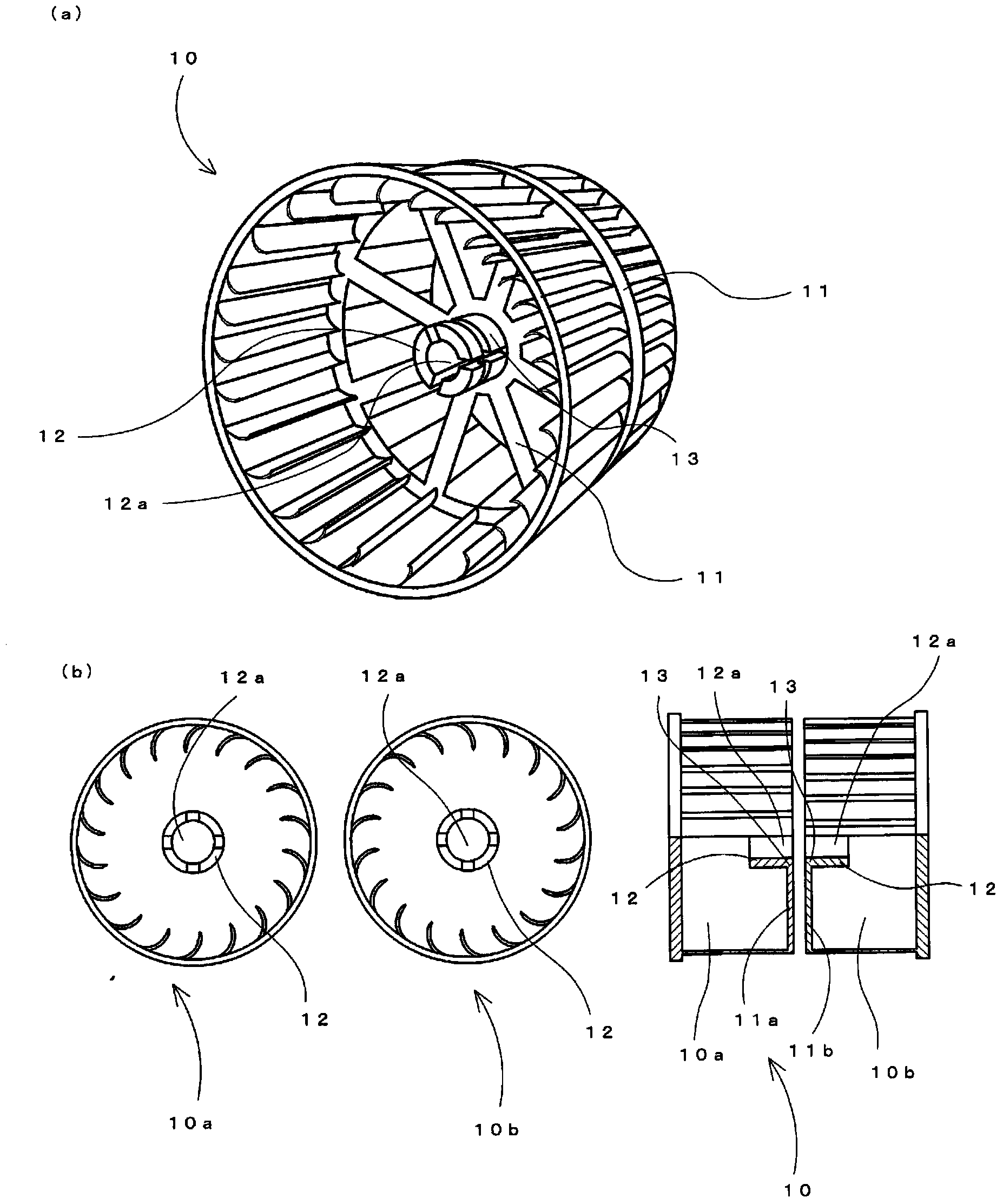

[0052] The biggest feature of the shaft type cross-flow fan 1 and its manufacturing method of the present invention is that a resin-made cross-flow double fan having a center wall 11, a bearing portion 12, and a fixing portion 13 is passed through a continuous shaft 20 that communicates with each other. 10 way to assemble, omitting the welding process. Embodiments are described below with reference to the drawings.

[0053] In addition, the double fan 10 described in the specification, claims and abstract of the present invention is a cross-flow fan obtained through the first process of the manufacturing method of claim 1 of the present invention (that is, the double fan 10 is formed on the center wall 11 A multi-blade impeller made of resin having a bearing portion 12 and a fixing portion 13, the double fan 10 is formed in a substantially cylindrical body, and on the cylindrical body, from the peripheral edge portions of the two faces of the central wall 11 toward both ends, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com