Shielding box

A shielding box, an integrated technology, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of increasing the manufacturing time and cost of the shielding box, and achieve the effect of omitting the welding process and reducing the manufacturing time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

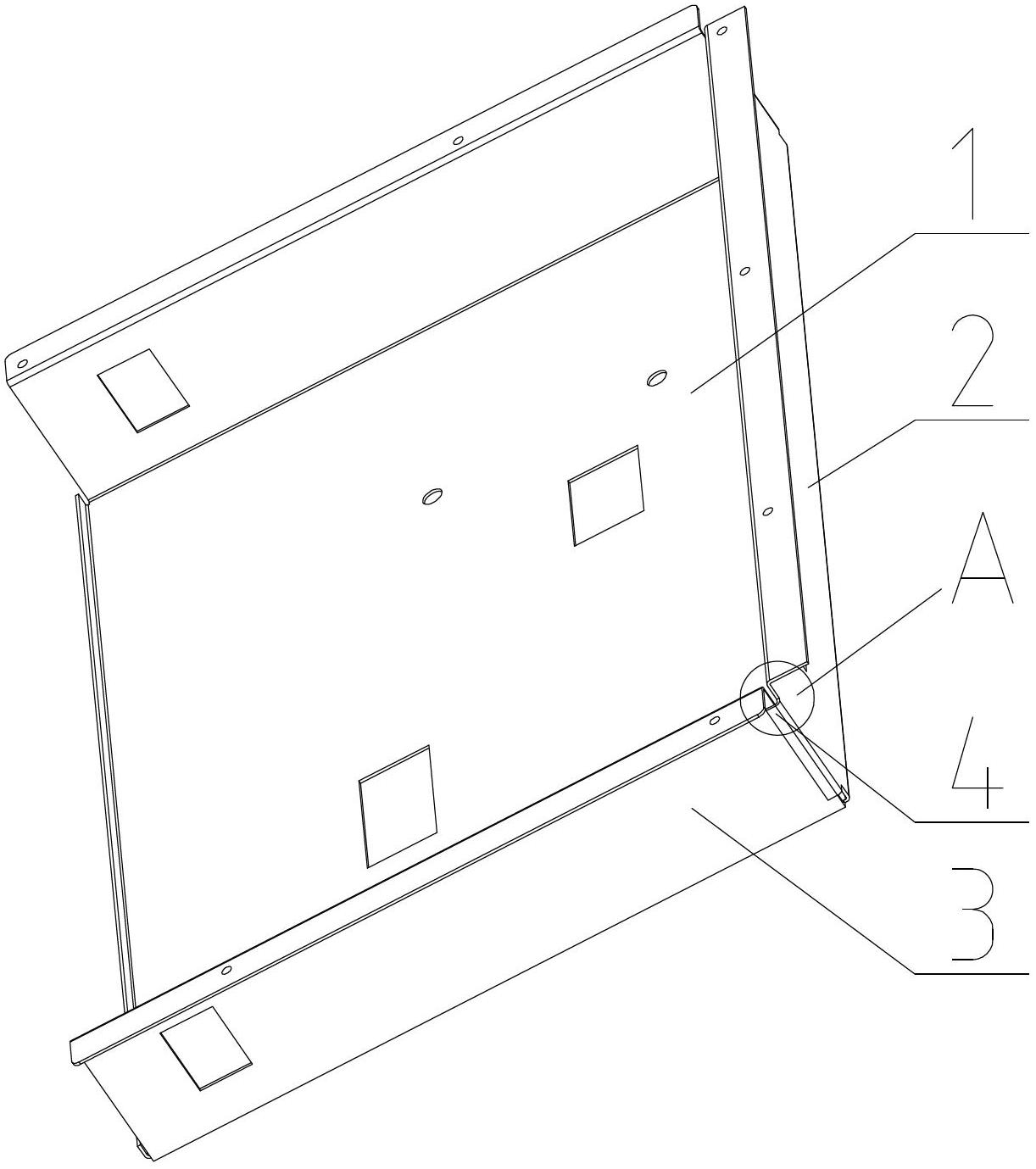

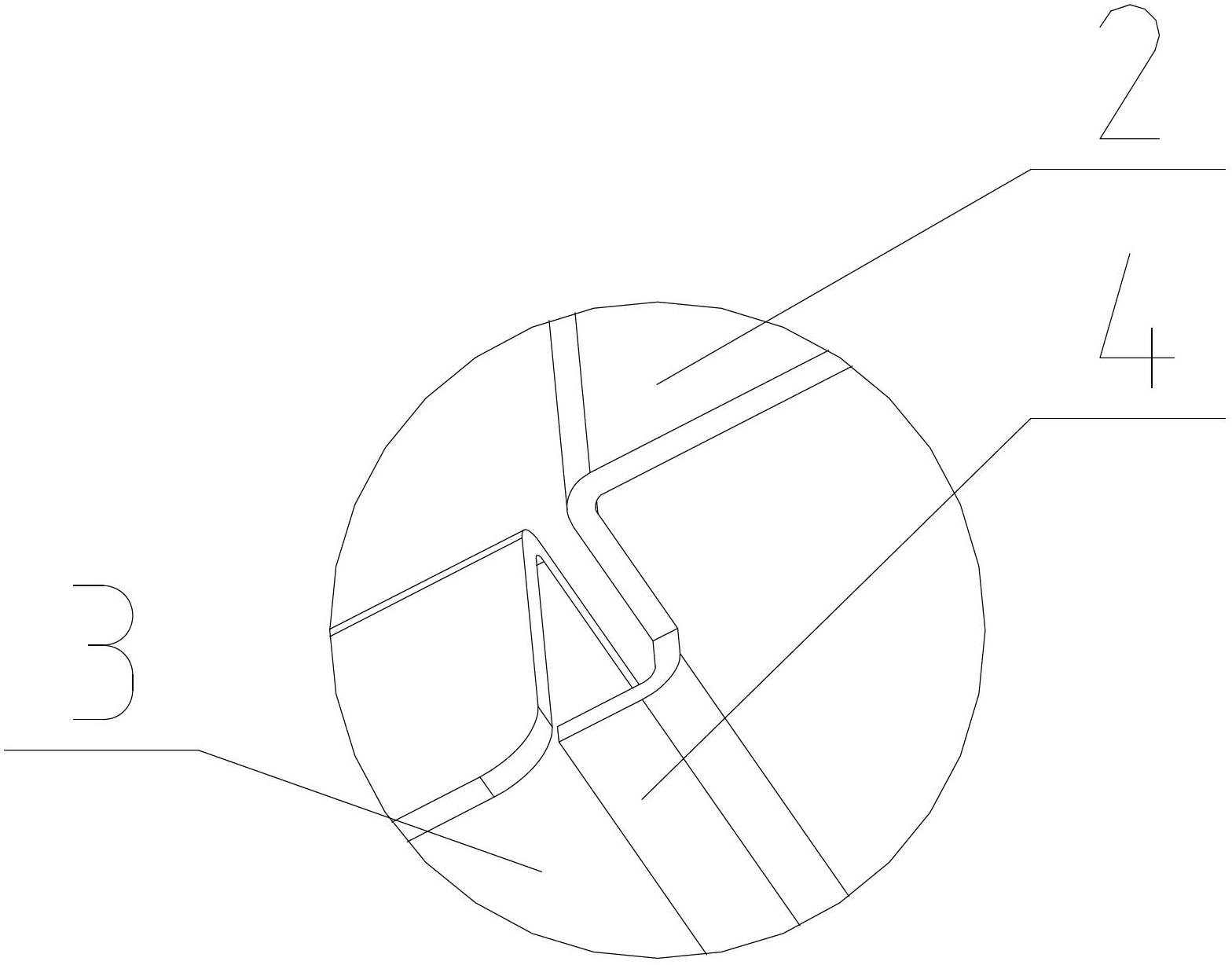

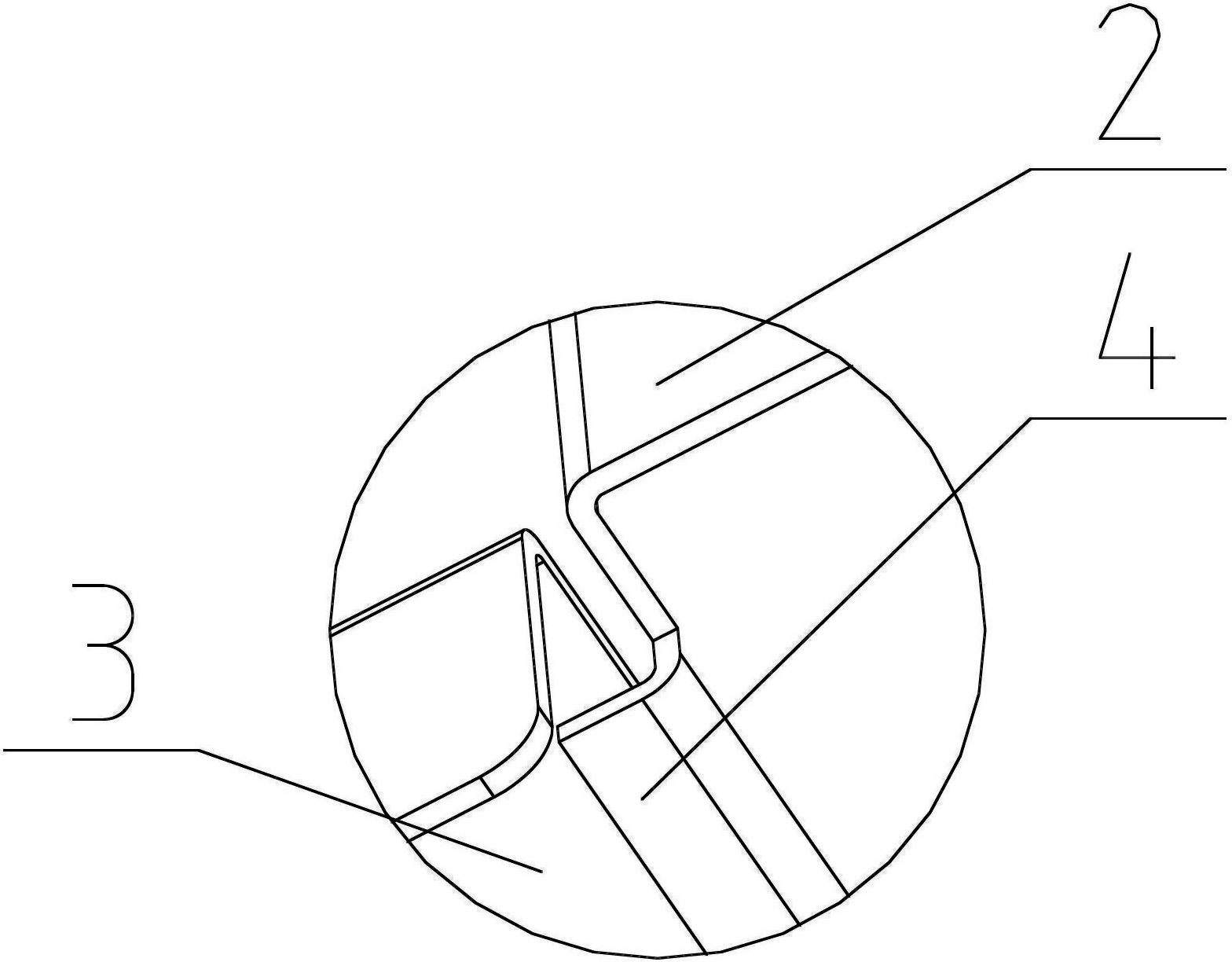

[0014] Such as figure 1 , figure 2 Shown is a shielding box with an integrated structure, including a bottom plate 1 and a side plate, and the two adjacent side plates are respectively marked as A side plate 2 and B side plate 3, and the A side plate 2 is in contact with the B side plate 3 There is a bent part 4 extending on one side of the side, and the bent part 4 is overlapped on the outer surface of the B side plate 3; the overlapping width of the bent part 4 and the B side plate 3 is greater than 5mm, and the bent The angle between the part 4 and the A side plate 2 is less than or equal to the angle between the B side plate 3 and the A side plate 2 .

[0015] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com