Body frame for saddle-riding vehicles

A car body frame and vehicle technology, applied to bicycle racks, motorcycles, motor vehicles, etc., can solve problems such as easy to increase size, difficulty in ensuring rigidity, and small moment of inertia of section, so as to ensure joint rigidity and omit welding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

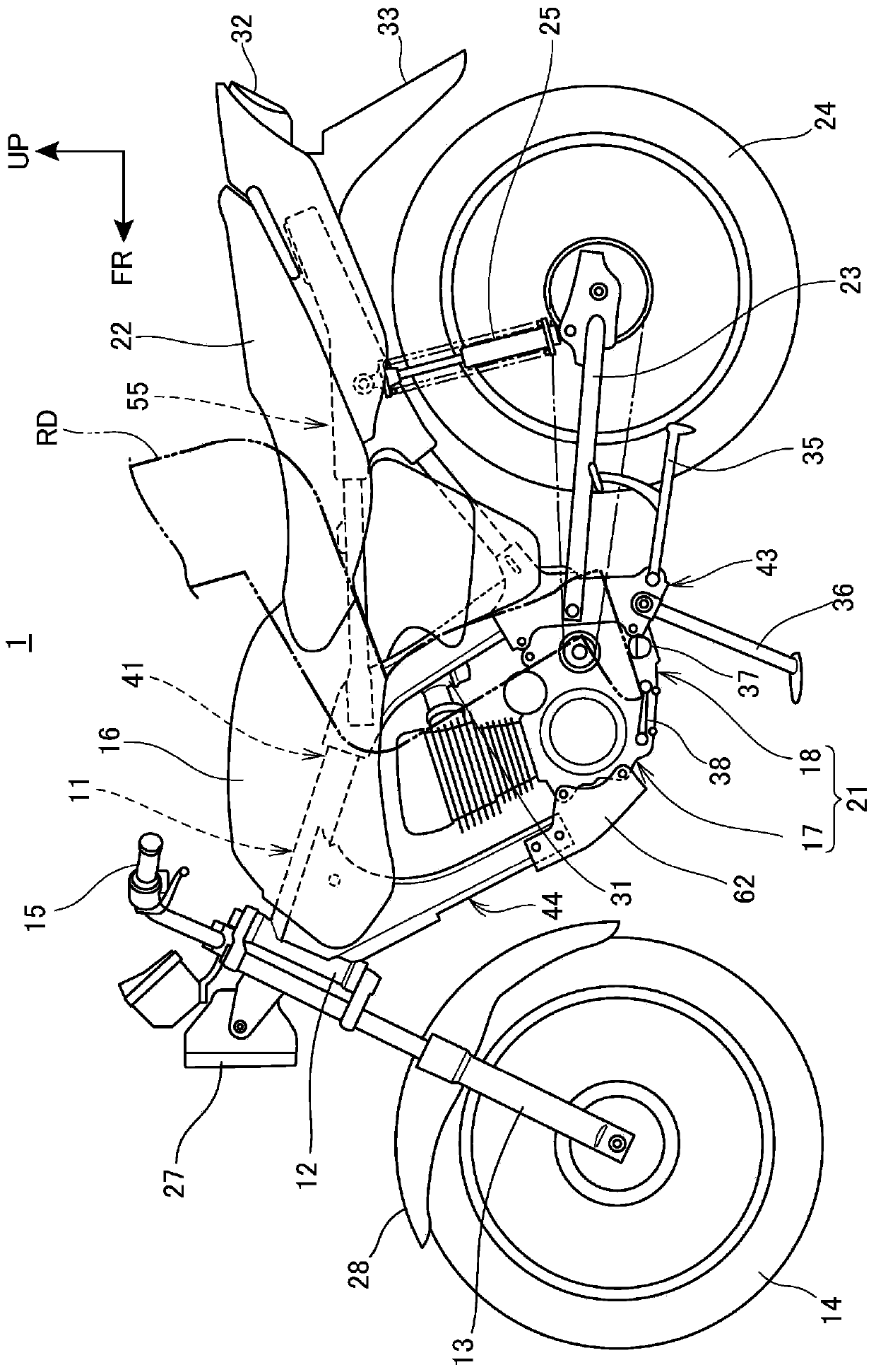

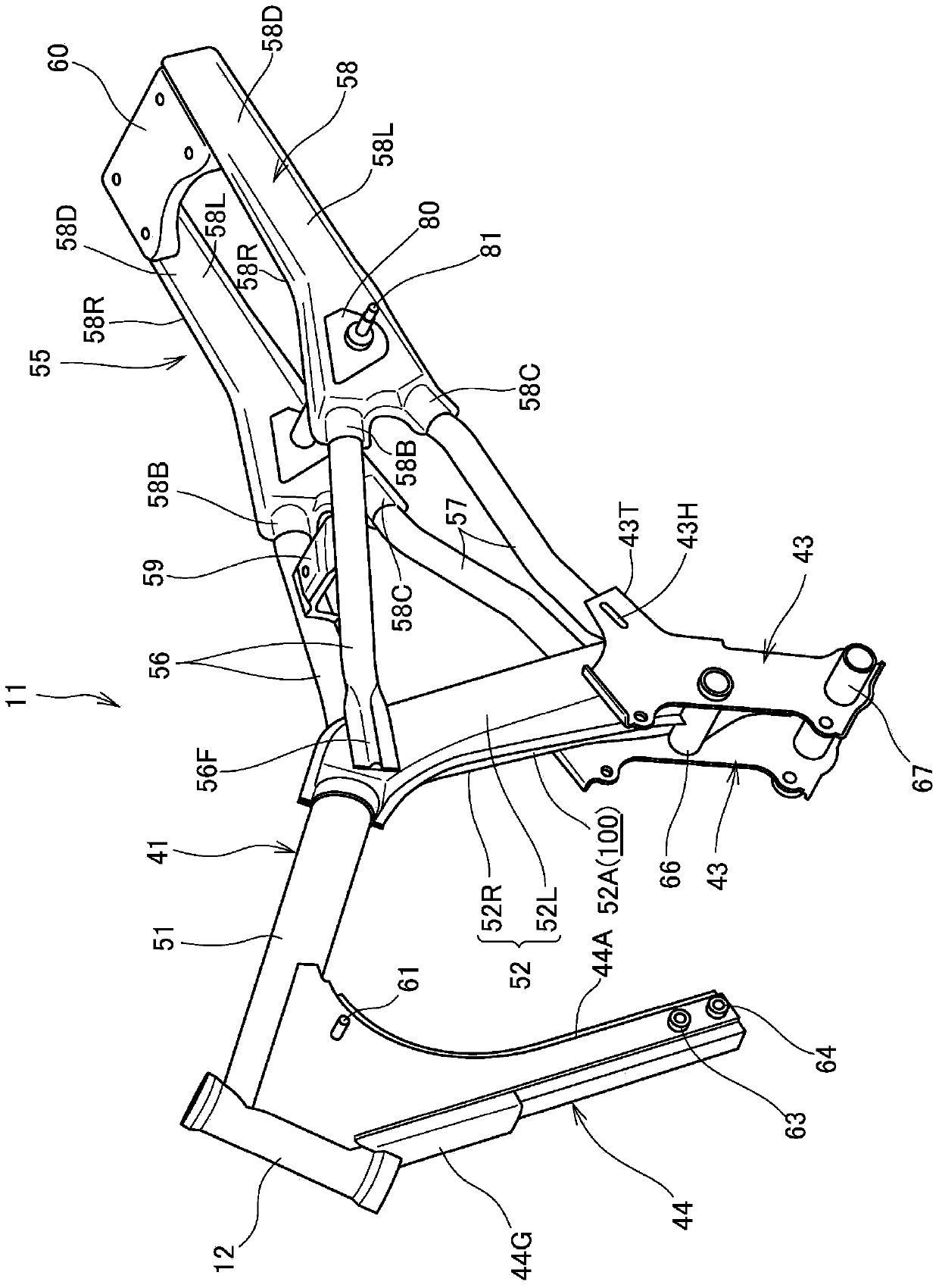

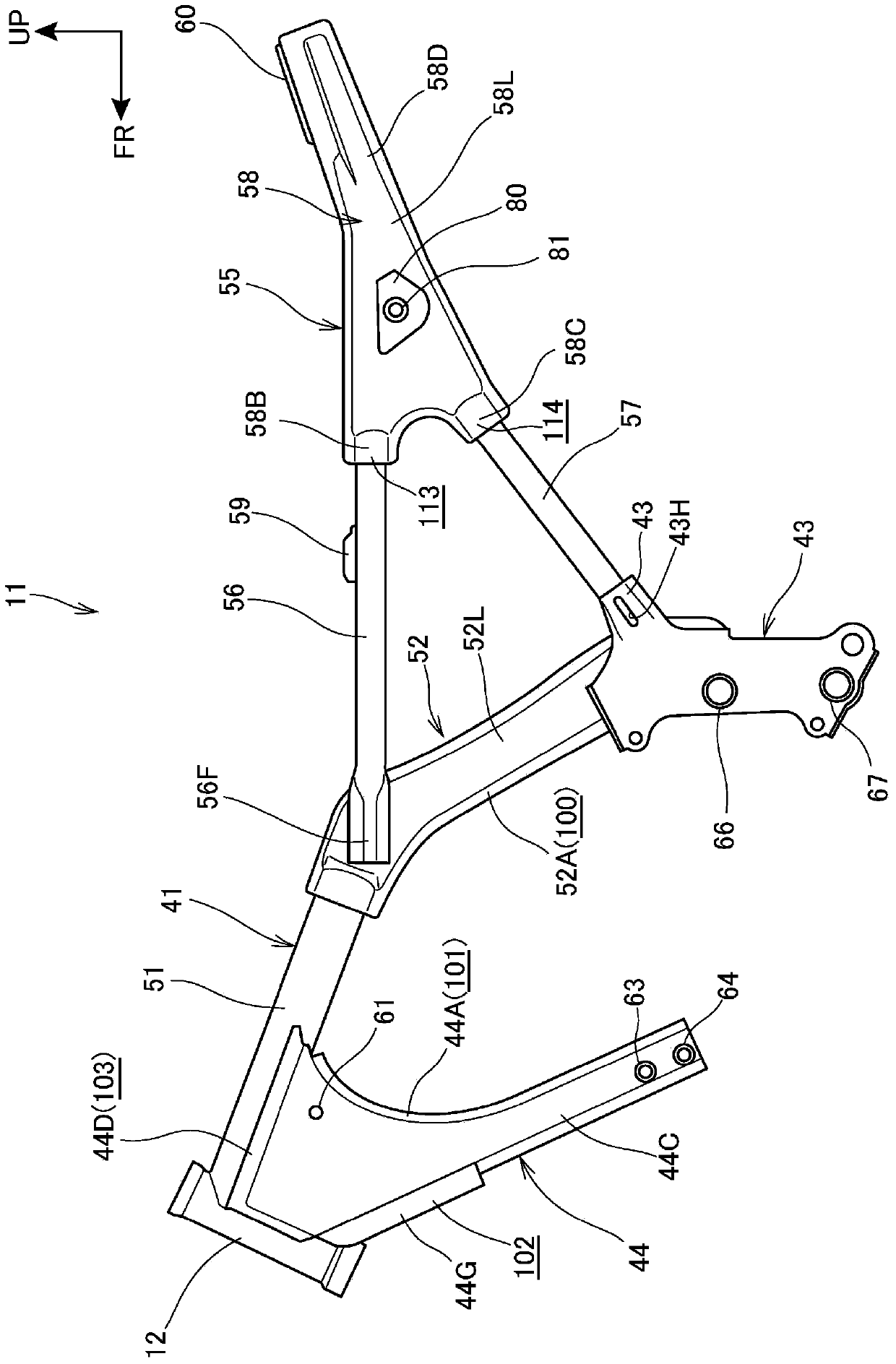

[0060] Next, a motorcycle according to an embodiment of the present invention will be described with reference to the drawings. In the description, descriptions of directions such as front, rear, left, right, and up and down are assumed to be the same as directions relative to the vehicle body unless otherwise specified. In addition, the symbol FR shown in each figure indicates the front of the vehicle body, the symbol UP indicates the upper side of the vehicle body, and the symbol LE indicates the left side of the vehicle body.

[0061]figure 1 It is a left side view of the motorcycle 1 according to the embodiment of the present invention.

[0062] The motorcycle 1 includes a body frame 11 , a front wheel 14 , a handle 15 , a fuel tank 16 , and a power unit 21 . A front end portion of the vehicle body frame 11 is provided with a front pipe 12, a front fork 13 constituting a steering system is pivotally supported on the front pipe 12, the above-mentioned front wheel 14 is piv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com