Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Not prone to hollowing" patented technology

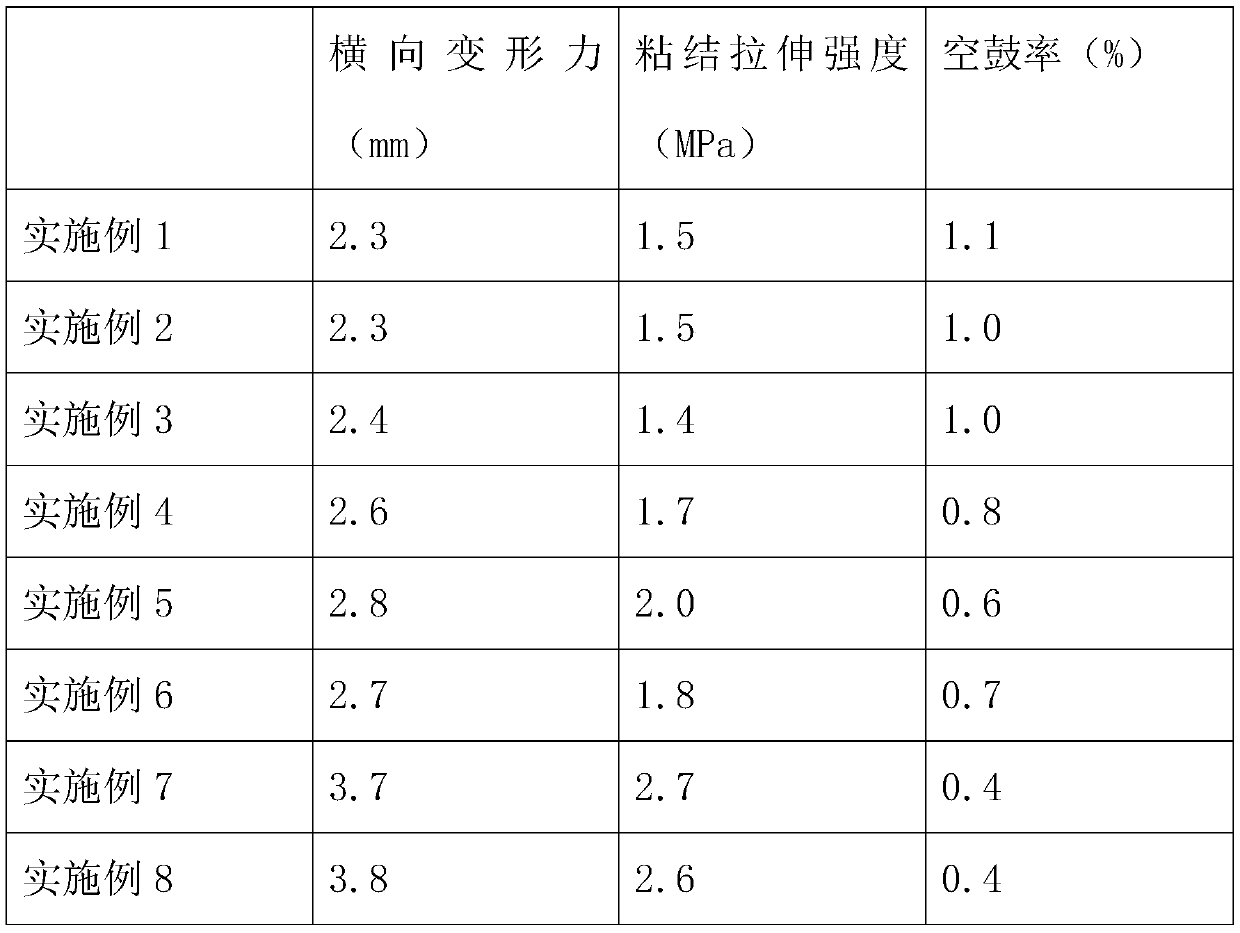

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

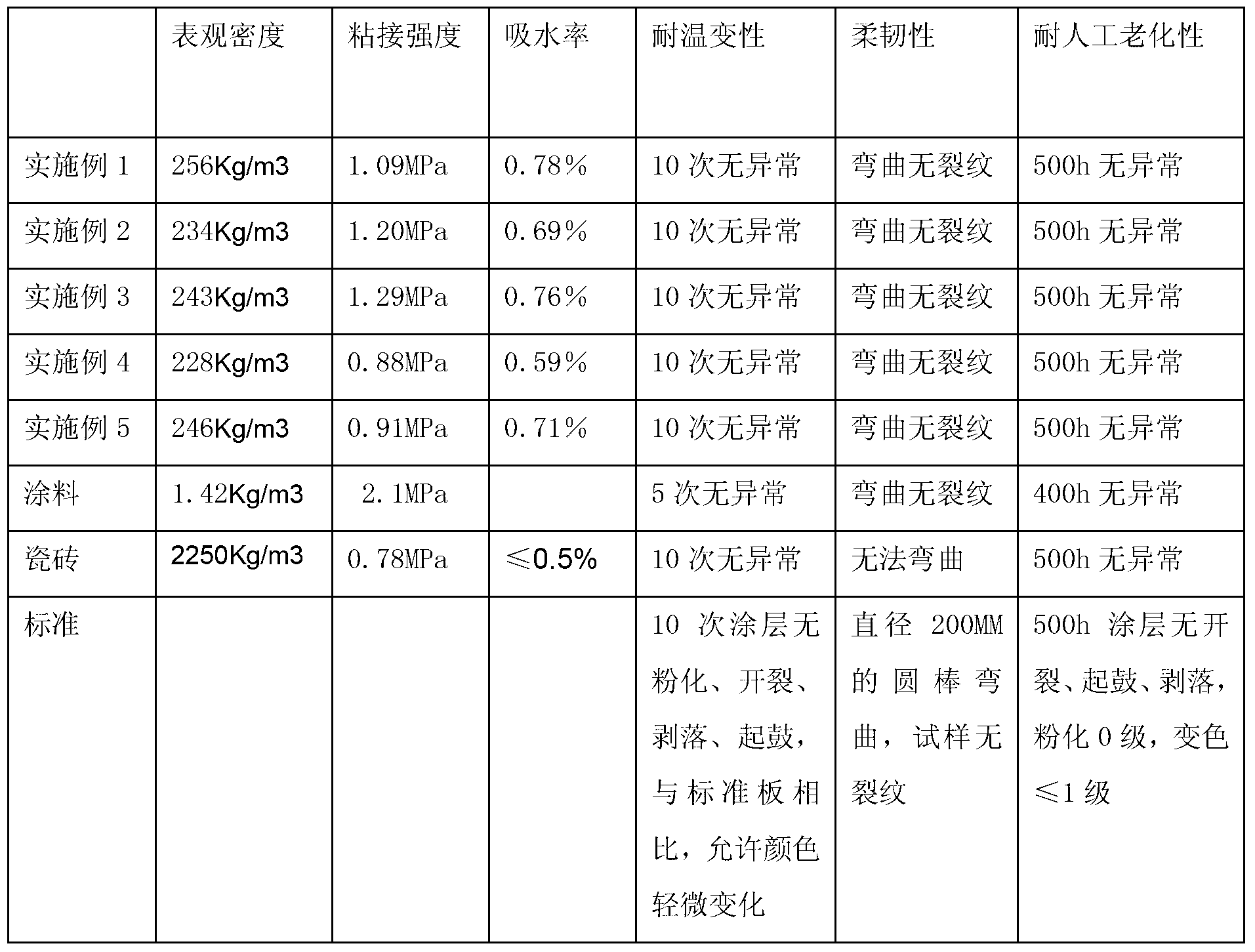

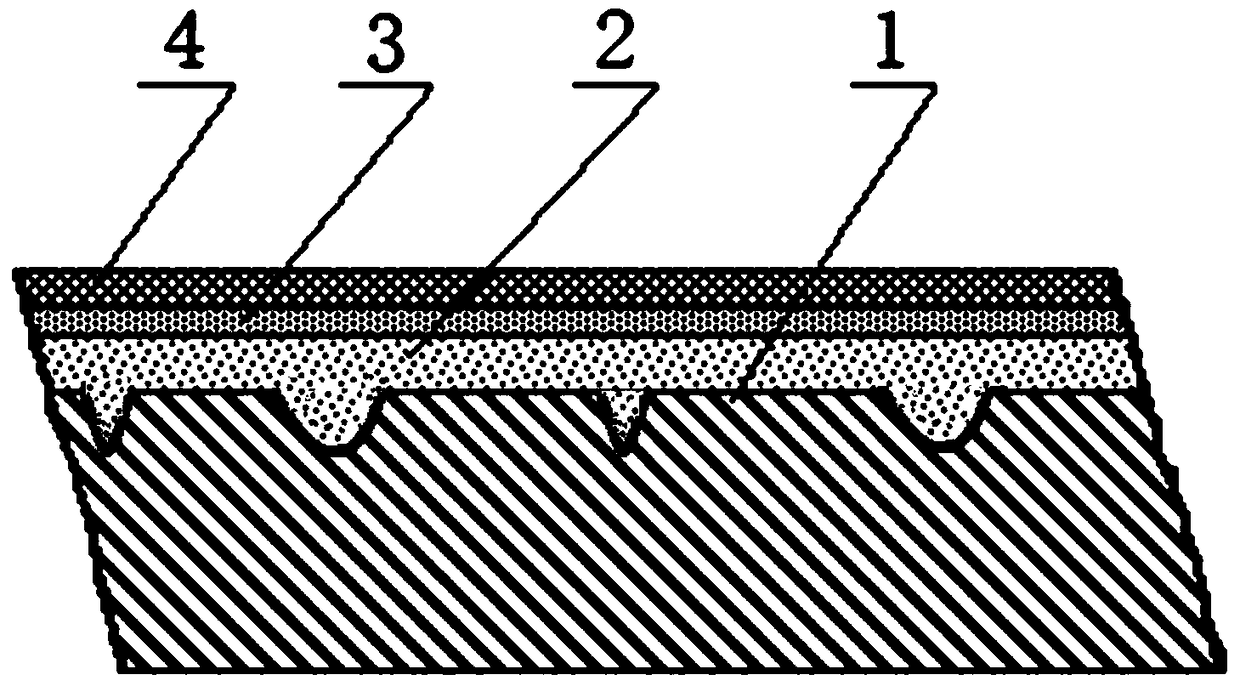

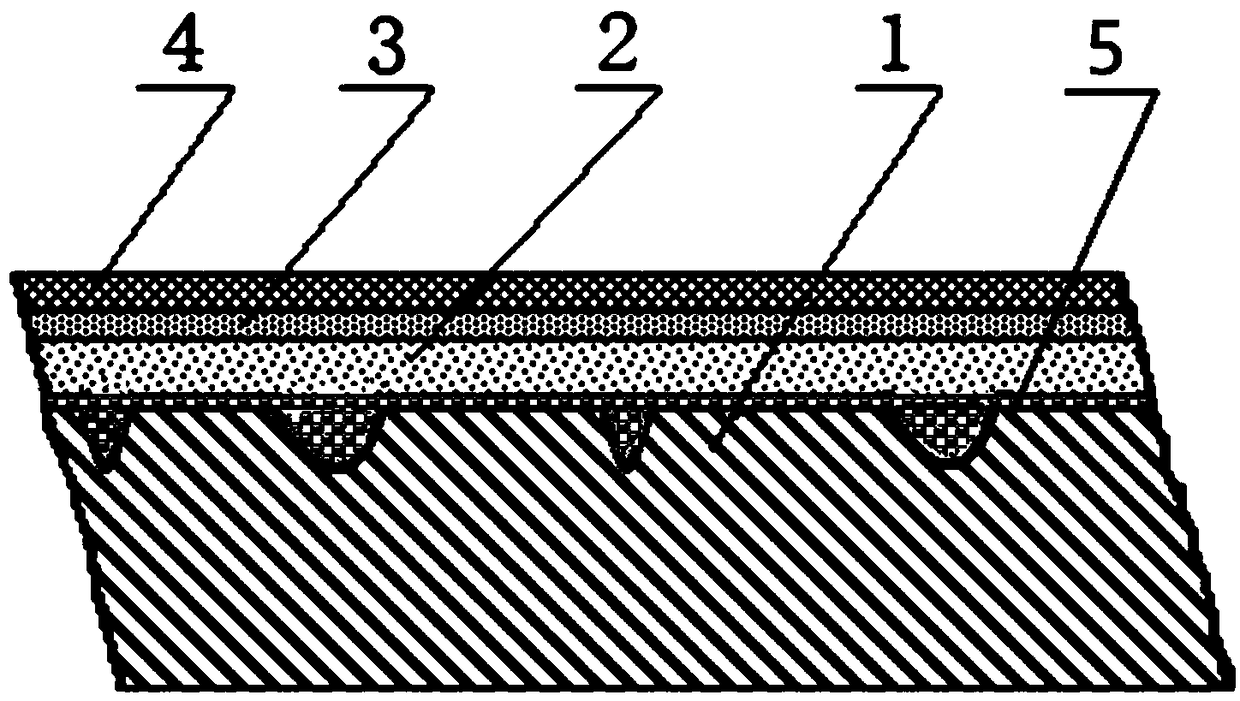

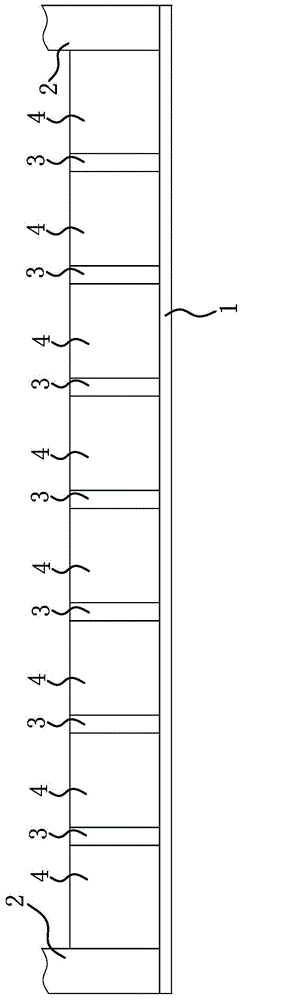

Inorganic composite flexible decorative coiled materials and producing method thereof

InactiveCN103266734ASolve empty drumSolve crackingCovering/liningsWater-setting substance layered productCelluloseGlass fiber

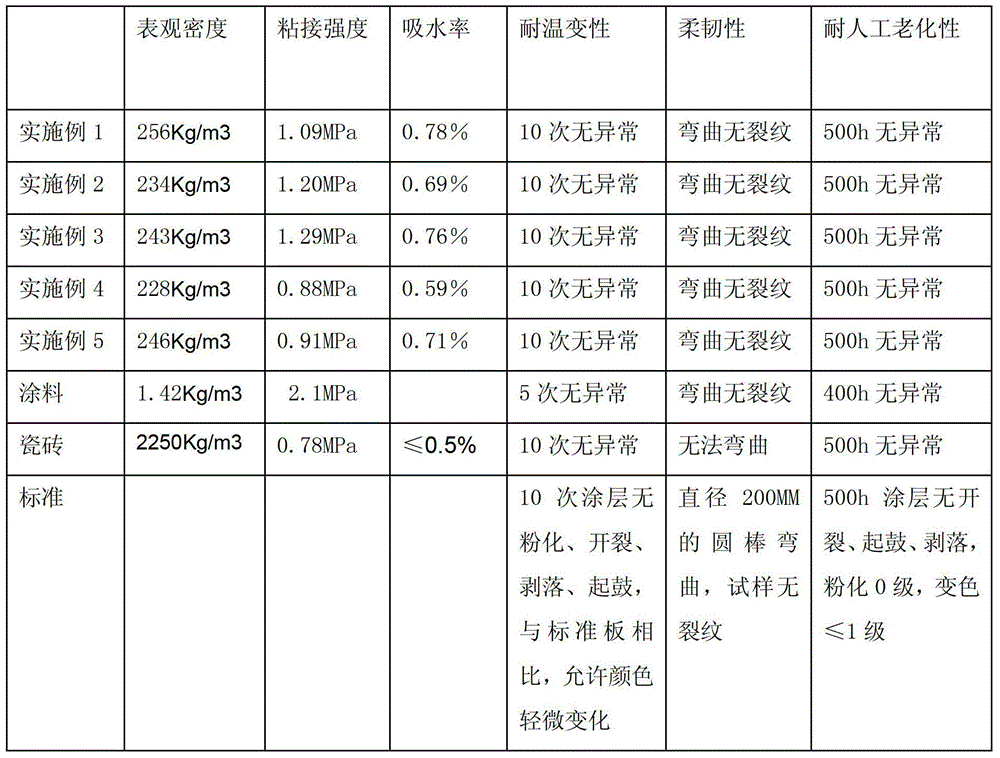

The invention belongs to the field of building, and discloses inorganic composite flexible decorative coiled materials. The thickness of the inorganic composite flexible decorative coiled materials is 2mm to 10mm, the inorganic composite flexible decorative coiled materials comprise an inorganic coiled material mortar layer, a decorative mortar layer is combined on the inorganic coiled material mortar layer, and reinforcing materials formed by alkali-resisting glass fiber gridding cloth or glass fiber roofing felts are arranged in the inorganic coiled material mortar layer or on the boundary of the inorganic coiled material mortar layer and the decorative mortar layer. The inorganic coiled material mortar layer is mainly formed by the following materials, by weight: 100 parts of portland cement with intensity no less than 42.5, 1.2 to 2.0 parts of cellulose, 350 to 450 parts of 50 to 100-mesh silica sand, 180 to 220 parts of coarse whiting, 1.8 to 2.2 parts of water reducing agent and 120 to 160 parts of 707 emulsion or cement-based elastic emulsion. The decorative mortar layer is mainly formed by the following materials, by weight: 150 parts of synthetic resin emulsion for maishi paint, 4 to 6 parts of coalescing agent, 8 to 12 parts of ethylene glycol, 1 to 2 parts of cellulose and 700 to 800 parts of natural color sand. The inorganic composite flexible decorative coiled materials are good in toughness, small in thickness, light in weight, good in application property, not prone to peeling off and good in weather fastness, and different decorative styles can be formed easily.

Owner:BEIJING SOLID BUILDING ENG

Carbon-based composite building wave absorption and heat preservation material and preparation method thereof

The invention discloses a carbon-based composite building wave absorption and heat preservation material and a preparation method thereof. According to the preparation method, carbon-based wave absorbing agent, common silicate cement, expanded and vitrified small balls, re-dispersible latex powder, hydroxypropyl methyl cellulose, wood fiber, polypropylene fiber, surfactant, foam stabilizer, waterreducing agent, coupling agent, water and the like are adopted; and the material is obtained by adopting the steps of stirring, pouring molding, curing and the like. The material has the advantages of good wave absorption performance and heat insulation performance, low apparent density, low cost, high fire resistance, durability and the like, and is easy to construct. The material can be used for pouring roofs and walls of buildings, so that aims of electromagnetic radiation protection and energy conservation of the buildings are fulfilled.

Owner:CHONGQING UNIV

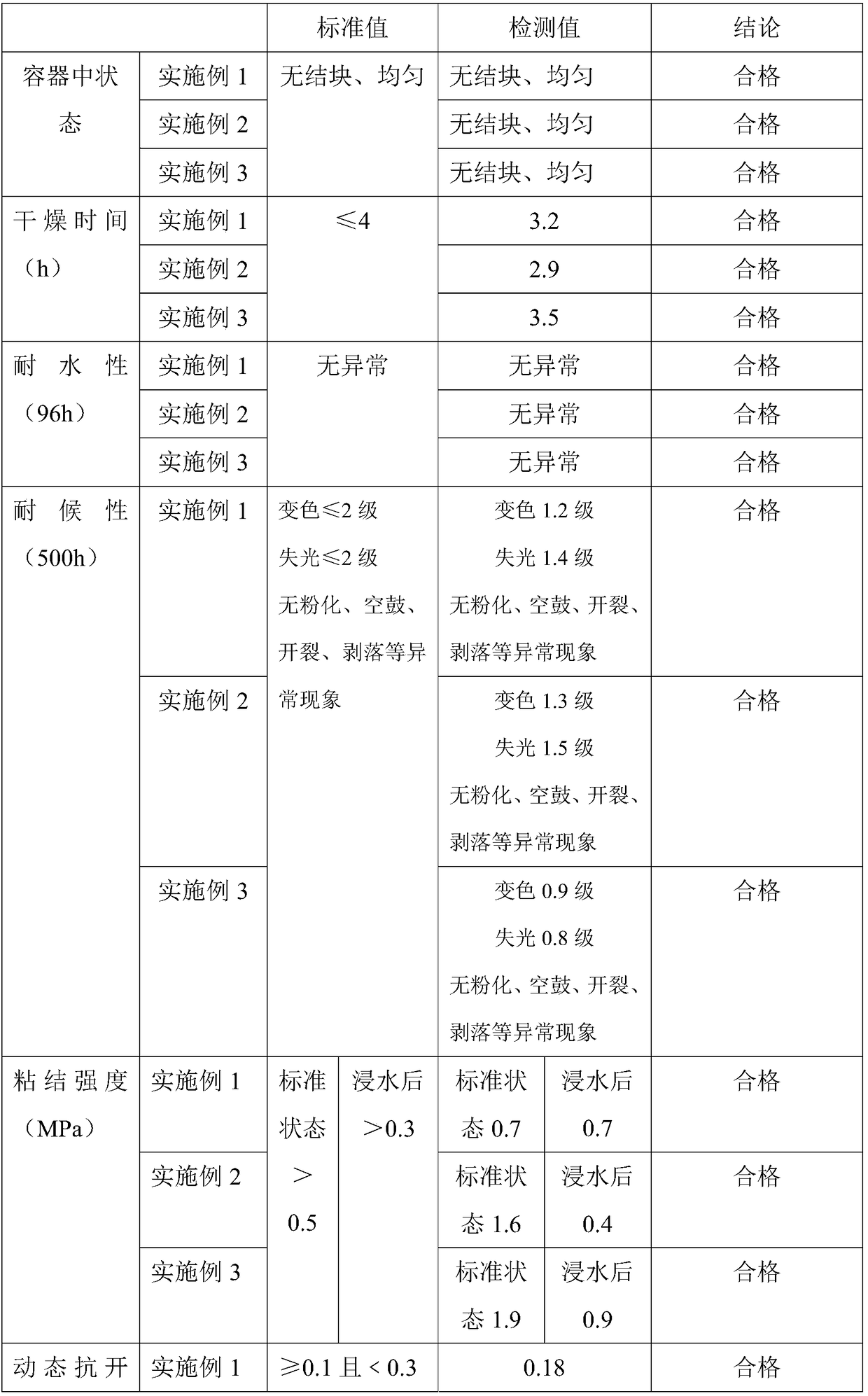

Plastic floor laying structure and construction method thereof

The invention discloses a plastic floor laying structure and a construction method thereof, and relates to the field of buildings. The plastic floor laying structure comprises a plastic floor laying structure body, and the plastic floor laying structure body is provided with a rough pitted surface layer, a self-leveling layer, a bonding layer and a plastic floor layer sequentially from bottom to top; and the rough pitted surface layer is formed by roughly polishing a surface layer of a ground structure. The construction method of the plastic floor laying structure comprises the following specific process that the surface layer of the original ground structure is polished into the rough pitted surface layer through matching of a cutting machine and an impact drill; the self-leveling layer is laid on the surface layer of the rough pitted surface layer; after being dried completely, the self-leveling layer is painted with the bonding layer; and the plastic floor layer is laid on the bonding layer. According to the plastic floor laying structure obtained through the construction method, original tiles do not need to be removed, construction is directly conducted on the basis of the original ground structure, manpower can be saved greatly, a large amount of construction waste is avoided, the construction cost is lowered, and the project construction period is shortened.

Owner:安徽智恒信科技股份有限公司

Sticking waterproof three-in-one mosaic adhesive filling joints

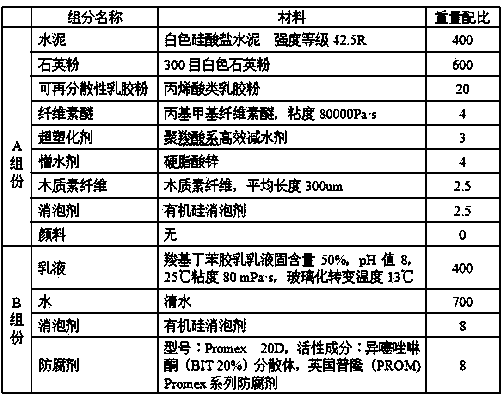

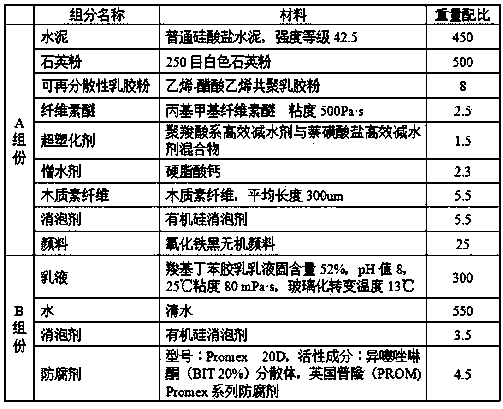

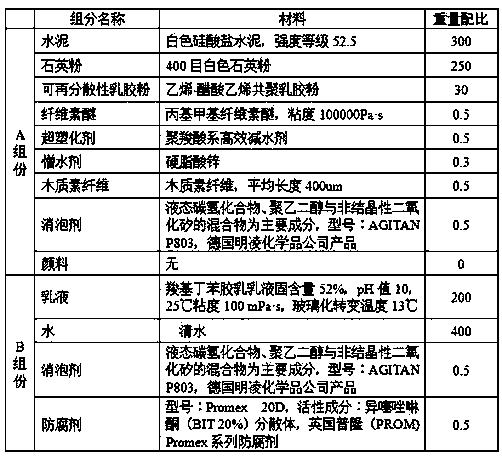

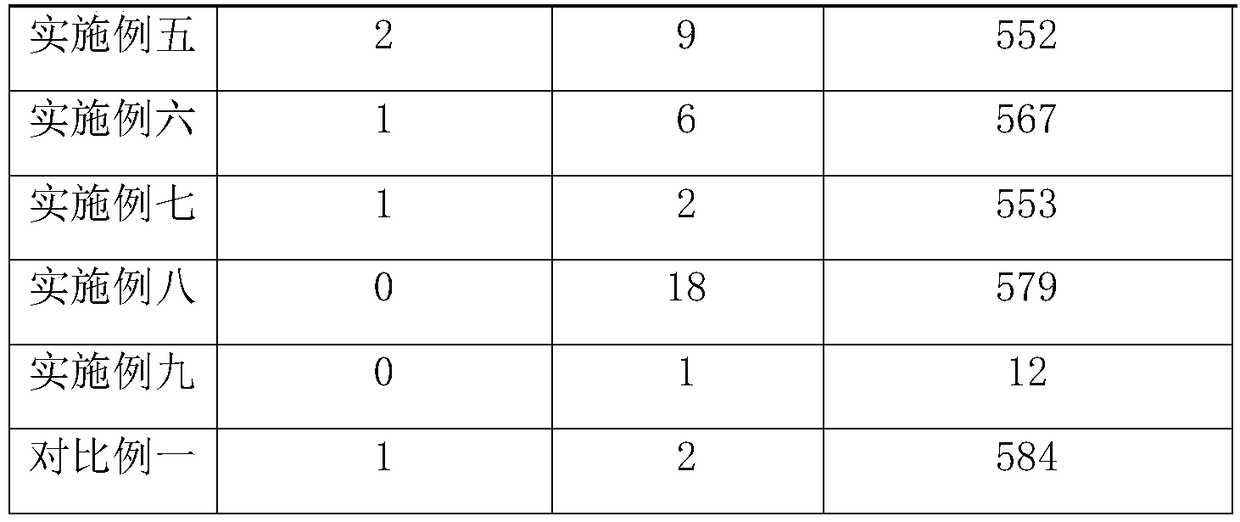

ActiveCN103482930AGood compatibilityImprove impermeabilitySolid waste managementCelluloseAdhesive cement

The invention relates to a sticking waterproof three-in-one mosaic adhesive filling joints. The sticking waterproof three-in-one mosaic adhesive filling the joints is a material of two components, wherein the component A comprises cement, quartz powder, emulsion powder with redispersibility, cellulose ether, super plasticizer, water repellent, lignin fiber, anti-foaming agents and pigments added according to needs, and the component B comprises emulsion, water, anti-foaming agents and preservatives. According to the adhesive, outer wall leakage due to the fact that a waterproof layer is not arranged or a waterproof material is poor can be reduced, the cohesive force of a bonding material and the compatibility of the bonding material and the waterproof layer are improved, the flexibility and the quality of the bonding material are improved, the phenomena of hollowing and falling of mosaics, water leaking and cracking of outer walls and the like are reduced, an airless sprayer can be adopted for carrying out fast spraying, the integrated construction of sticking, filling the joints and preventing water is achieved, the working processes are simplified, the construction period is shortened, and the construction difficulty is lowered.

Owner:PAREXDAVCO GUANGZHOU CO LTD

Paint painting construction method for wall decoration

ActiveCN108952100ANot prone to hollowingNot prone to qualityBuilding constructionsSurface layerStructural engineering

The invention discloses a paint painting construction method for wall decoration, and relates to the field of building decoration. According to the technical scheme points, the paint painting construction method comprise the following steps that Step 1, a finishing layer of an original wall surface is eradicated, and then an interface agent is painted on the wall surface; Step 2, a white glue stick is pasted on a crack of the wall surface, then a gridding cloth is laid on the whole wall surface, and then cement mortar is brushed until the wall surface is flat; Step 3, a layer of base putty isapplied first, surface layer putty is applied twice, and then polishing is performed; and Step 4, an anti-alkali primer is painted first, and then a latex topcoat is painted twice. After the originalfinishing layer is eradicated, the interface agent is applied to improve the physical and chemical properties of the original wall surface, the bonding capacity between the cement mortar and a wall body is enhanced, and a cement mortar leveling course is prevented from hollowing and peeling; and cracking treatment is simultaneously performed, and the original wall surface is repaired. After the original wall surface is subjected to the above treatment, the paint is painted, the quality is remarkably improved, and the wall surface is not prone to causing quality problems such as hollowing and cracking.

Owner:浙江云信装饰工程有限公司

Tile type roof waterproof heat-insulating binding mortar and preparation method thereof

The invention discloses tile type roof waterproof heat-insulating binding mortar. The tile type roof waterproof heat-insulating binding mortar consists of a powder material component and a liquid material component in the mass ratio of 1:0.8; the powder material component comprises the following components in parts by mass: 1 to 50 parts of cement, 20 to 80 parts of sand, 0.5 to 2 parts of dispersible latex powder, 0.5 to 5 parts of cellulose ether, 0.1 to 5 parts of a waterproof agent, 1 to 20 parts of glass fibres and 10 to 30 parts of glass micro-beads; the liquid material component is acrylate emulsion. The invention also discloses a preparation method of the mortar. The tile type roof waterproof heat-insulating binding mortar disclosed by the invention can be widely applied to construction of a characteristic town tile type roof and a common tile type roof, has water resistance, heat insulating property, toughness, crack resistance and durability that common cement mortar does nothave, and is convenient to construct.

Owner:厦门宏鹭升建筑新材料有限责任公司

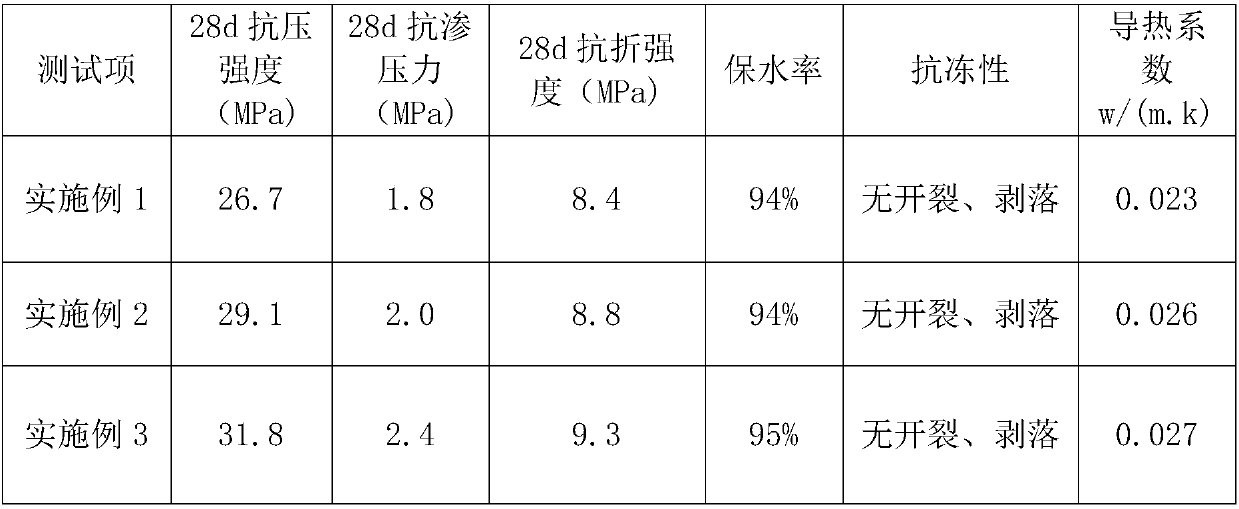

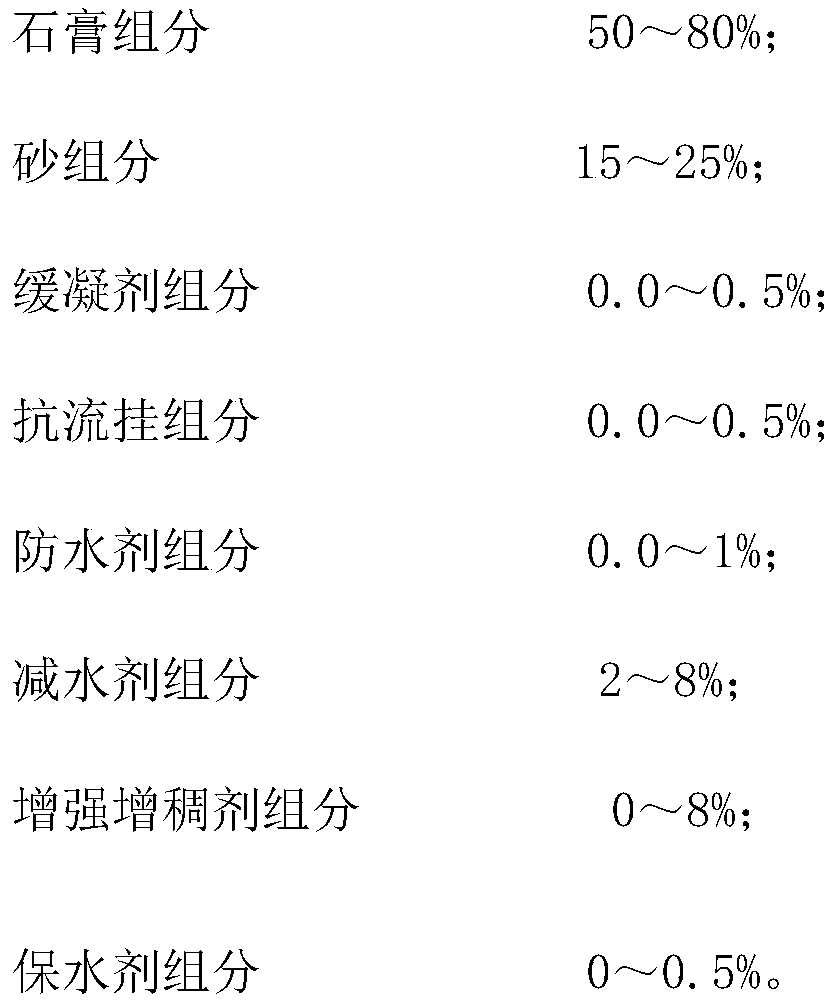

Gypsum-based ceramic tile adhesive and preparation method thereof

The invention discloses a gypsum-based ceramic tile adhesive and a preparation method thereof. The adhesive comprises a gypsum component, a sand component, a retarder component, an anti-sag component,a waterproof agent component, a water reducing agent component, a water retaining agent component and a reinforcing thickening agent component. The absolute dry tensile bonding strength of the adhesive can reach 1.0 MPa and can reach more than 0.56 MPa after 24 hours of immersion. The gypsum-based ceramic tile adhesive meeting the standard of common cement-based ceramic tile adhesives is preparedfrom low-strength gypsum powder as a binding material, an aggregate and an additive, so that the defects of the cement-based ceramic tile adhesives are effectively overcome; the industrial byproductgypsum is wider in application, and the gypsum-based ceramic tile adhesive follows the thought of national resource recycling economy, and expands the advantages of gypsum.

Owner:贵州蓝图磷石膏环保科技有限公司

Blocking method of outer wall hole and blocking filling hopper

The invention provides a blocking method of an outer wall hole and meanwhile further provides a blocking filling hopper of the outer wall hole. The inner wall of the hole is roughened and cleaned completely, then the filling hopper is arranged on the inner side of the outer wall hole, a blocking piece is arranged on the outer side of the outer wall hole and connected and fixed through a three-section type water stop split bolt, and then concrete is poured from the filling hopper. The method is simple, operation is convenient, the outer wall hole can be effectively blocked, and the permeabilityresistance is improved. In filling, self-weight of the concrete can be utilized, filling is facilitated, operation is convenient, the structure is simple, and hollowing and cracks are not prone to occurring.

Owner:福建建工集团有限责任公司 +1

Horizontal floor tile laying method for house construction

ActiveCN113530156AImprove insulation effectFully soakedBuilding constructionsComposite materialCeramic tiles

The invention relates to a horizontal ground tile laying method for house construction. The horizontal ground tile laying method specifically comprises the following steps: cleaning the ground, specifically, laying tiles in one area every day, removing foreign matters or dust on the ground when the tiles in one area are laid, and then spraying water mist on the ground for wetting; soaking ceramic tiles in water, specifically, soaking the ceramic tiles in water by using ceramic tile water soaking equipment while performing the step 1; laying a datum, specifically, firstly laying a row of ceramic tiles and a line of ceramic tiles, one ceramic tile at the end of the row of ceramic tiles and one ceramic tile at the end of the line of ceramic tiles are the same ceramic tile, reserving a gap between every two adjacent ceramic tiles, and knocking the ceramic tiles to be flat through a rubber hammer; laying the ceramic tiles, specifically, laying each ceramic tile in a flush mode corresponding to the adjacent ceramic tile; and conducting gap treatment, specifically, after cement on the ceramic surfaces of the ceramic tiles is dried and solidified, filling gaps between every two adjacent ceramic tiles with a gap beautifying agent. The effect that the possibility of the hollowing phenomenon after the ceramic tiles are laid can be reduced is achieved.

Owner:深圳市中弘建设工程有限公司

Method for paving new ground tiles on original cushion layer

The invention discloses a method for paving new ground tiles on an original cushion layer. The method for paving the new ground tiles on the original cushion layer is characterized by comprising removing old ground tiles, retaining the cushion layer under the old ground tiles, cleaning up foreign materials and sands on the cushion layer, and carrying out a leveling treatment; watering and moistening the cushion layer; immersing the new ground tiles in clear water until no bubbles are generated, and drying the new ground tiles; pouring a layer of cement glue to the surface of the cushion layer, paving the new ground tiles on the cement glue, and pressing the new ground tiles tightly and flatly. The method for paving the new ground tiles on the original cushion layer is advantaged in that the original cushion layer does not need to be removed, materials can be greatly saved, time is saved, and the method is environmentally-friendly, and problems of empty drums, bulges and looseness and the like are not liable to occur.

Owner:PUTIAN UNIV

High-strength water-resistant odorless putty powder and preparation process thereof

The invention discloses a high-strength water-resistant odorless putty powder and a preparation process thereof, and belongs to the technical field of building materials, wherein the high-strength water-resistant odorless putty powder comprises the following raw materials: modified heavy calcium carbonate, kaolin, ash calcium powder, white cement, modified talc powder, bentonite, a high water absorption resin, a natural resin, lignocellulose, polypropylene cellulose, redispersible latex powder, polyvinyl alcohol, sodium carboxymethyl cellulose, murraya paniculata powder, hedera nepalensis powder, bamboo charcoal fiber, pomelo peel powder, seaweed soil, a whitening agent, an auxiliary agent, an antifoaming agent, a preservative, and a retarder. According to the present invention, the high-strength water-resistant odorless putty powder is prepared through mixing, stirring, grinding and other steps, has strong water resistance, cannot produce hollowing and peeling after being wet, has characteristics of refreshing odor, formaldehyde absorbing, health benefiting and long service life, can be organically combined with various coating materials, and has broad application value and marketprospects.

Owner:王再青

Environment-friendly concrete

The invention relates to the technical field of concrete, in particular to environment-friendly concrete. The environment-friendly concrete comprises the following components: in parts by weight, 120-162 parts of cement, 80-100 parts of deionized water, 80-98 parts of crushed stone, 78-90 parts of river sand, 45-59 parts of fly ash, 25-55 parts of aramid fiber, 68-96 parts of an epoxy resin emulsion, 3-6 parts of chlorinated paraffin, 2-4 parts of rosin soap and 3-10 parts of calcium lignosulfonate, wherein the aramid fiber is modified aramid fiber. A preparation mehtod of the modified aramidfiber comprises the steps: (1) pre-treating aramid fiber, (2) performing waterproof treatment on the pretreated aramid fiber, and (3) baking the aramid fiber treated in the step (2) so as to obtain the modified aramid fiber. When the environment-friendly concrete is applied in areas with heavy rain, good waterproof performance can still be maintained for a long period of time.

Owner:东莞市建工集团有限公司

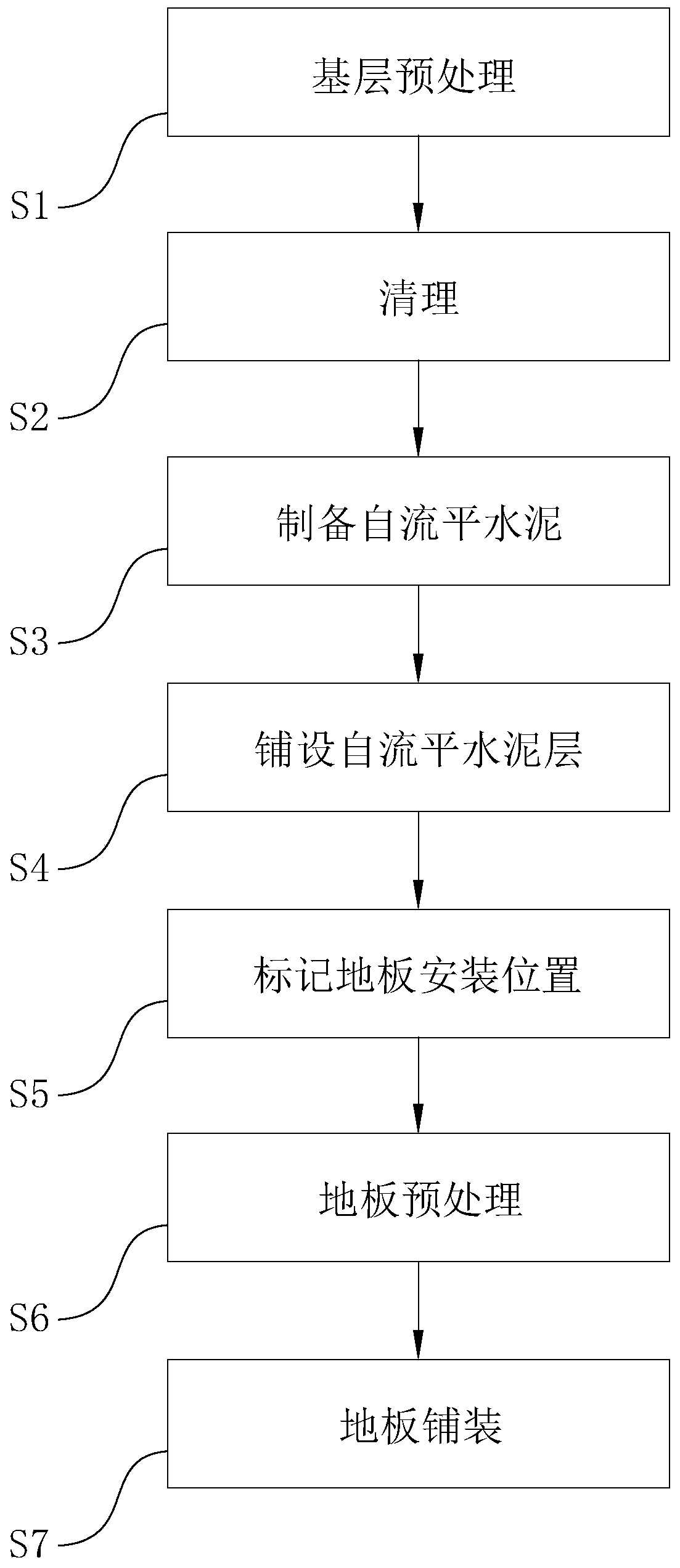

Floor paving method

The invention relates to the field of building decoration, and provides a floor paving method aiming at the problem that a floor is prone to bulging and warping. According to the technical scheme, thefloor paving method comprises the following steps of S1, preprocessing a base layer; S 2, cleaning; S3, preparing self-leveling cement; S4, laying a self-leveling cement layer; S5, marking a floor installation position; S6, preprocessing a floor; and S7, paving the floor, wherein the self-leveling cement comprises the following components of, by mass, 30-35 parts of silicate cement, 5-6 parts ofwater, 0.1-0.2 parts of a water reducing agent, 65-70 parts of sand, 35-40 parts of fly ash, 0.1-0.3 parts of a retarder, 1-3 parts of epoxy resin, 0.1-0.2 parts of 2-anilino pyridine, and 0.01-0.02 parts of periflanthene. The epoxy resin, the 2-anilino pyridine and the periflanthene are compounded for use, so that the flexibility of the self-leveling cement is improved, the bonding strength of the self-leveling cement is improved at the same time, and a floor is less prone to bulging and warping.

Owner:广东优鼎装饰设计工程有限公司

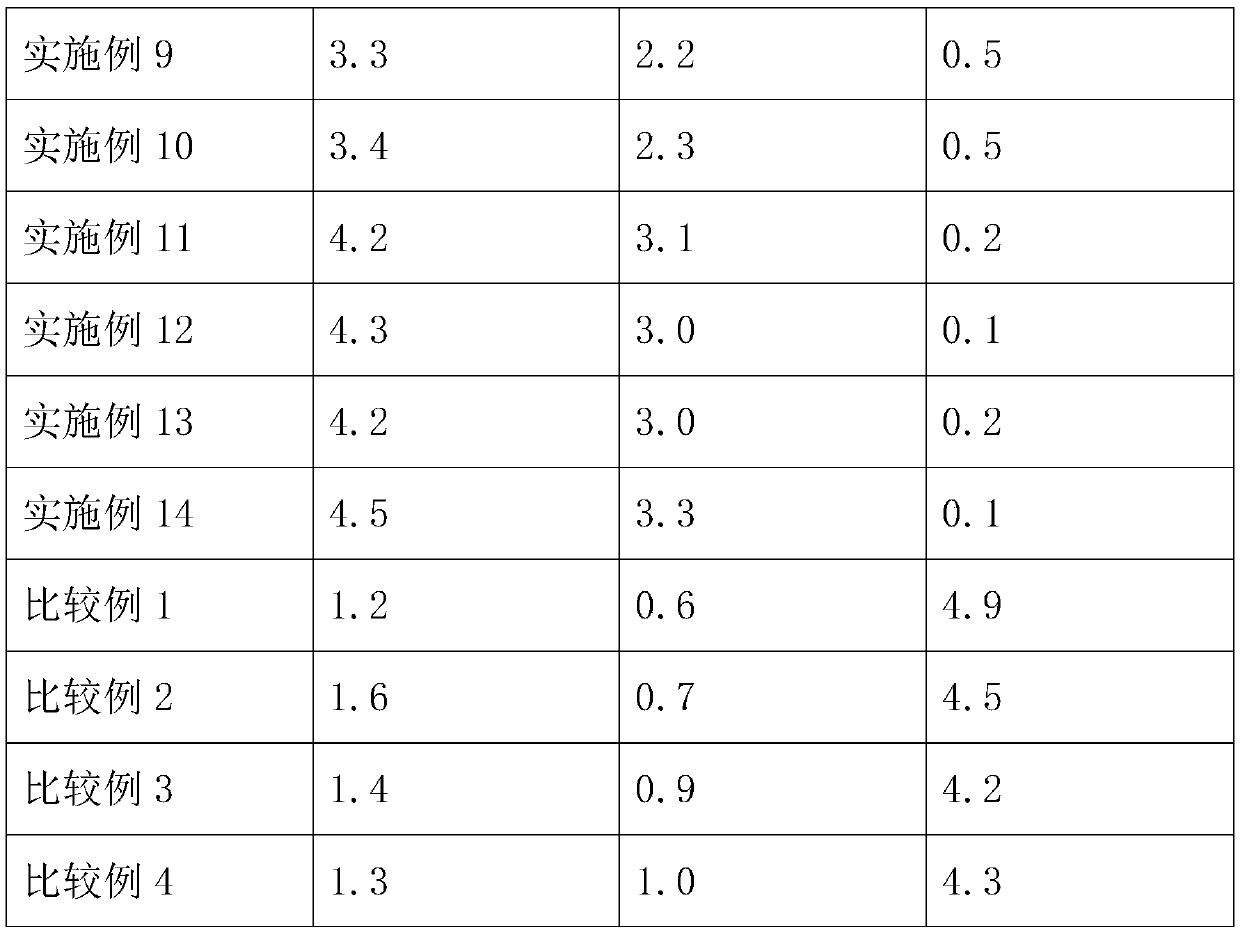

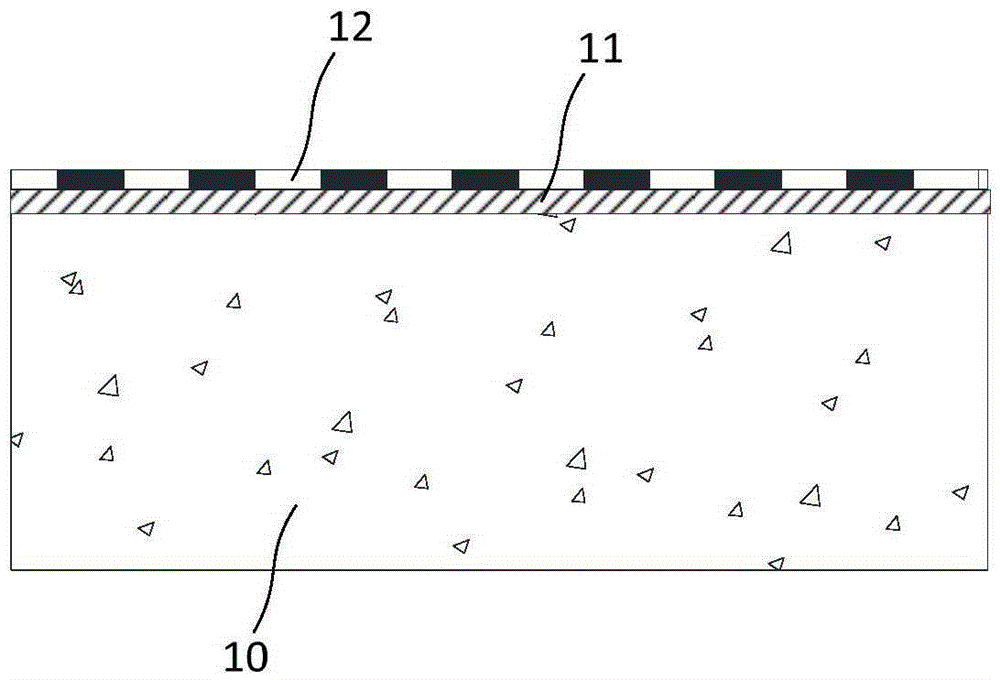

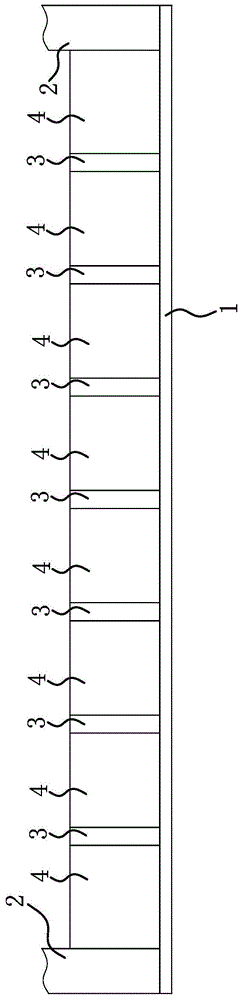

Roof waterproof structure and construction method thereof

InactiveCN105298032AHigh bonding strengthNot prone to hollowingBuild-up roofsBuilding material handlingStructural engineeringUltimate tensile strength

The invention discloses a roof waterproof structure and a construction method thereof. The construction method includes the following steps: 1), treating the surface of a roof concrete structure layer; 2), coating a concrete interface treating agent layer on the surface of the roof concrete structure layer; 3), pasting a waterproof roll on the surface of the concrete interface treating agent layer. A shot blasting process is used to treat the surface of the roof concrete structure layer, laitance and a dusting layer on the surface of the roof concrete structure layer can be stripped, and the surface of the roof concrete structure layer can be made coarse. The waterproof roll is less prone to hollowing after being pasted after the laitance and the dusting layer are stripped. The coarse surface of the roof concrete structure layer can increase bonding strength between the roof concrete structure layer and the concrete interface treating agent layer, so that bonding strength between the waterproof roll and the roof concrete structure layer is increased.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

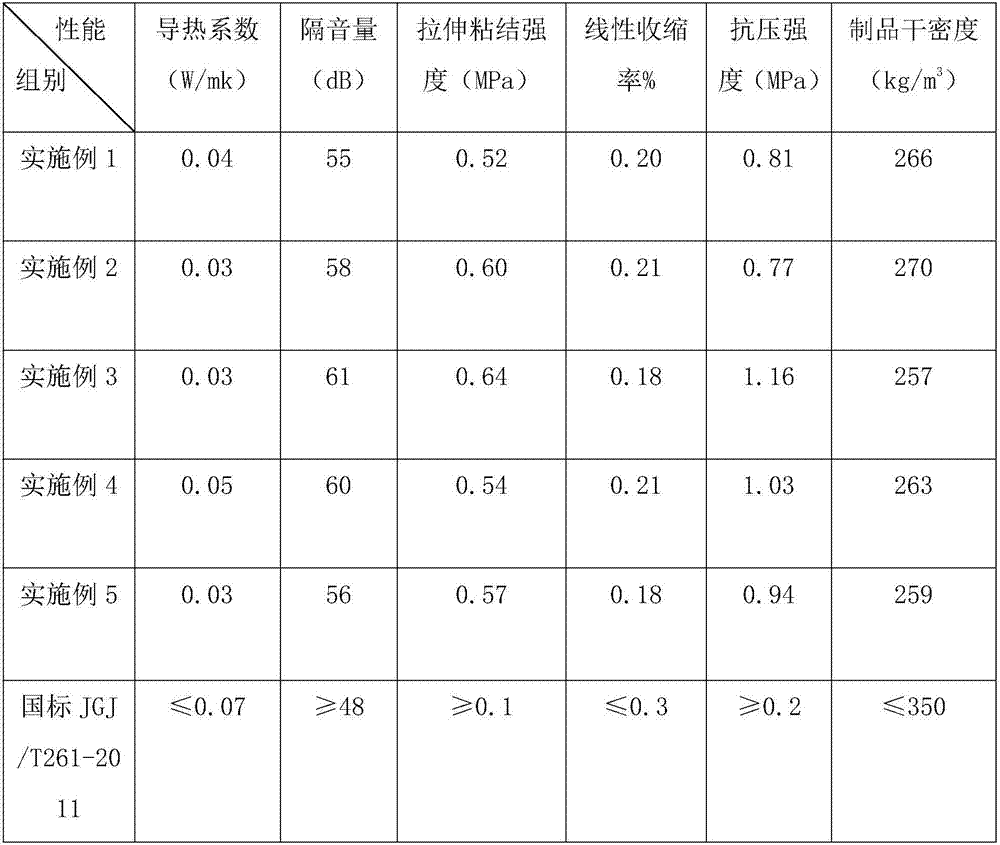

Vitrified microbead thermal insulation mortar and preparation method thereof

The invention discloses vitrified microbead thermal insulation mortar and a preparation method thereof. The thermal insulation mortar is prepared from the following raw materials: portland slag cement, lime paste, river sand, vitrified microbeads, sugar calcium, calcium carbonate, white latex, modified attapulgite clay powder, sodium lignin sulfonate, barium stearate, polyester fibers, hydroxypropyl methyl cellulose, polyvinyl alcohol, an organosilicon waterproofing agent and water. The preparation method comprises the following steps: firstly mixing the raw materials such as the vitrified microbeads and sugar calcium, and uniformly stirring, so that slurry A is obtained; then mixing the raw materials such as sodium lignin sulfonate, and uniformly stirring, so that slurry B is obtained; and finally conveying the portland slag cement, the lime paste and the river sand to a mortar stirring machine, and sequentially adding the slurry B and the slurry A, so that the vitrified microbead thermal insulation mortar finished product is obtained. The thermal insulation mortar disclosed by the invention has the advantages that tension and compression strengths and thermal insulation and sound insulation performances are further enhanced compared with the national standard and existing thermal insulation mortar, so that the problems of empty drums, cracks and drops are hardly caused when the mortar disclosed by the invention is applied to a wall body, and durability and practicability of the mortar are improved.

Owner:合肥天沃能源科技有限公司

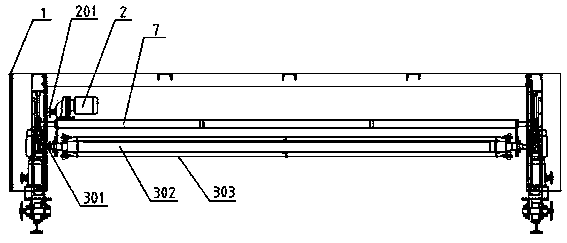

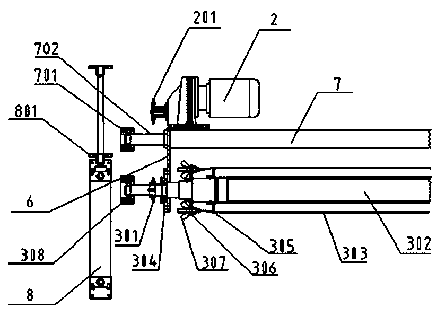

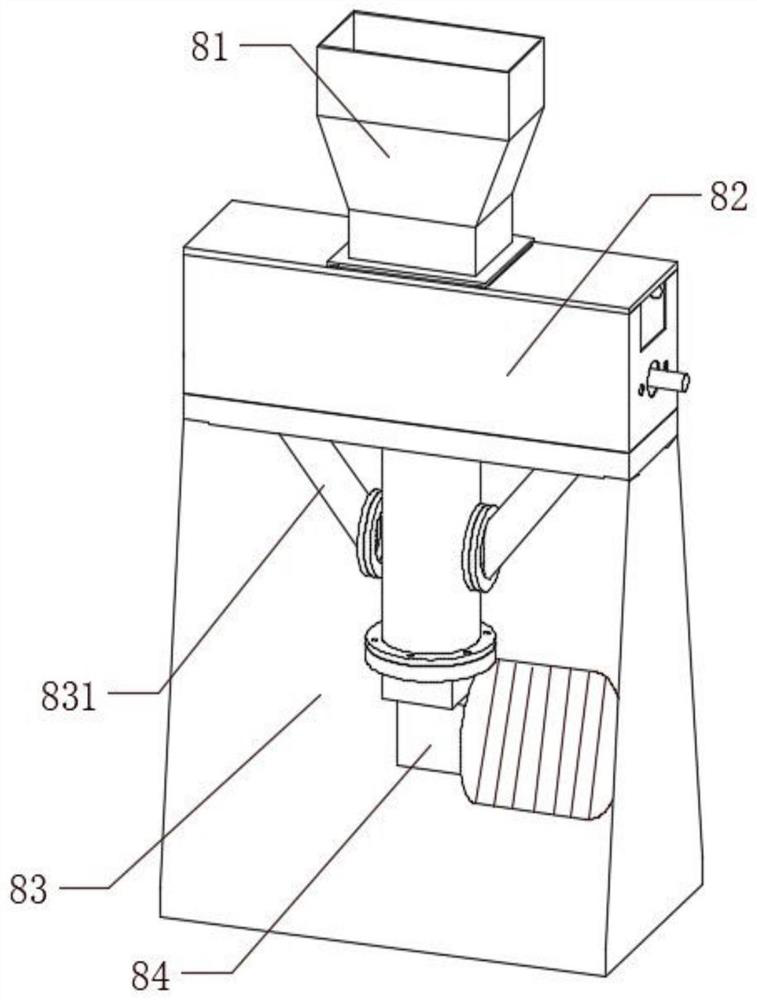

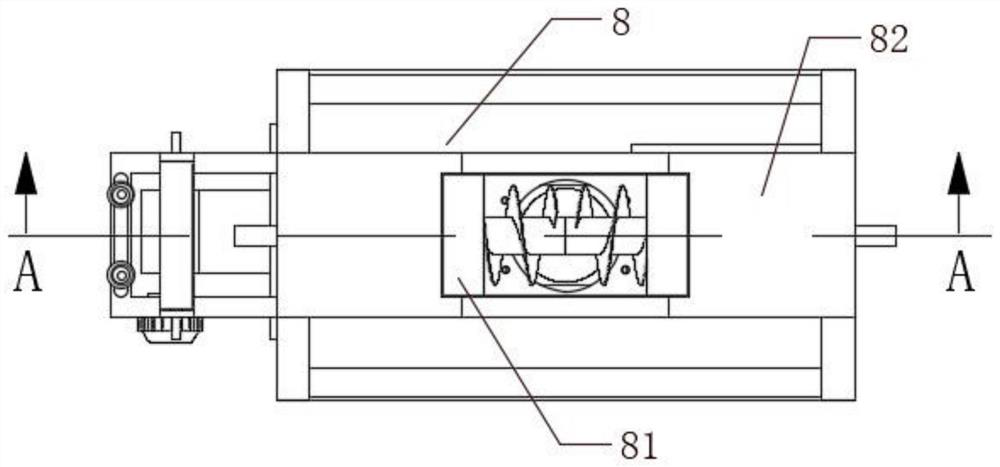

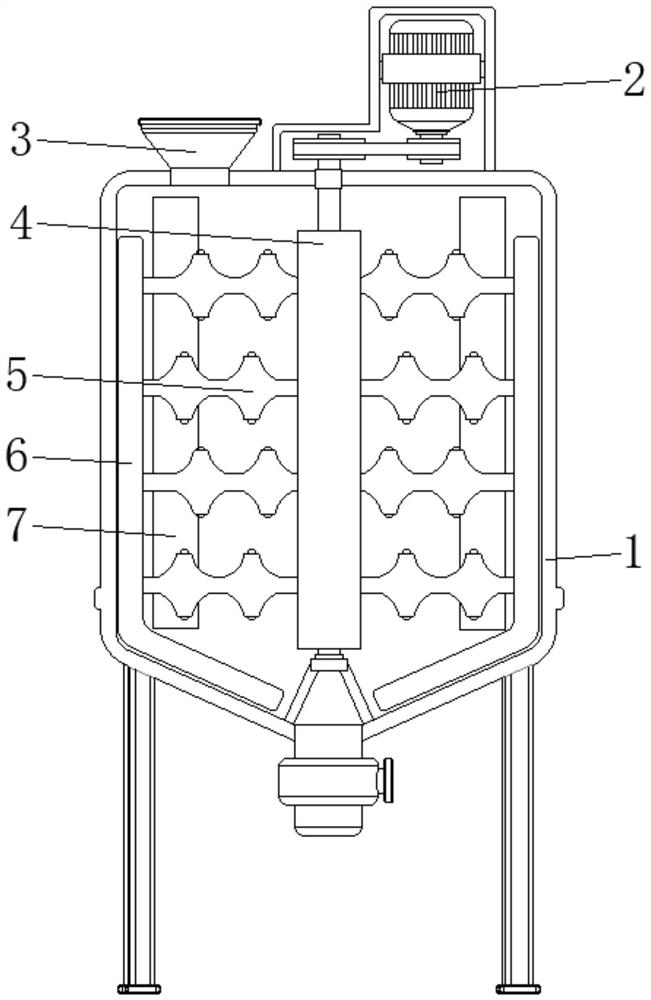

Defoaming machine

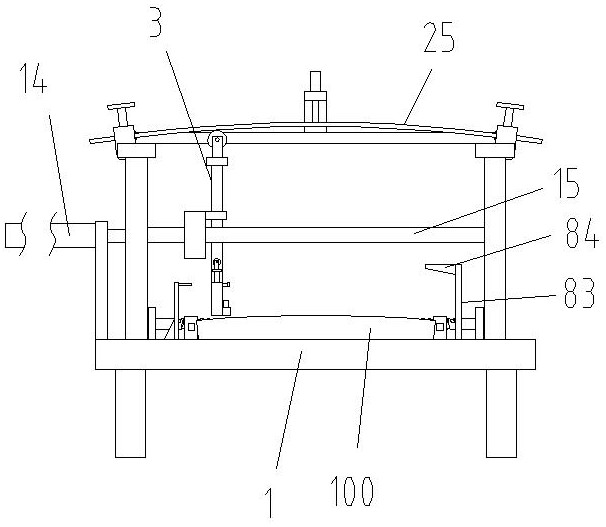

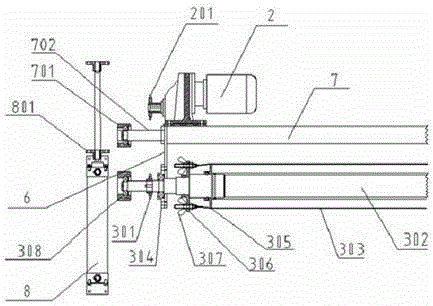

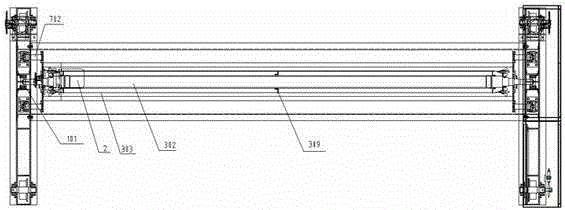

ActiveCN103434012AAvoid smearingImprove bearing strengthCeramic shaping apparatusElectric machineProcess engineering

The invention provides a defoaming machine. The defoaming machine comprises a frame, wherein the frame is horizontally provided with a supporting plate, the two ends of the supporting plate are fixedly connected with connection steel plates, and the lower parts of the connection steel plates are fixedly connected with bearings arranged on a main shaft; one end of the supporting plate is fixedly provided with a main shaft driving motor; the main shaft can rotate in the bearings, and the surface of the outer side of the main shaft is uniformly provided with defoaming components; the main shaft driving motor drives the main shaft to rotate. The defoaming machine disclosed by the invention directly removes air bubbles in surface foaming bodies of foam cement, so that the surface foaming bodies become a net slurry layer and can be subjected to composite connection with core materials so as to have very high strength; the waste caused by cutting off the surface foaming bodies in the prior art is avoided, and the surface foaming bodies after becoming the net slurry layer can be synchronously solidified with the below foam cement so that a hollowing situation is unlikely to generate; the processes of cutting off the surface foaming bodies, smearing cement slurry with fiberglass net and the like, are avoided, so that the technical process can be reduced, and the production efficiency is improved.

Owner:CUBIC DIGITAL TECH CO LTD

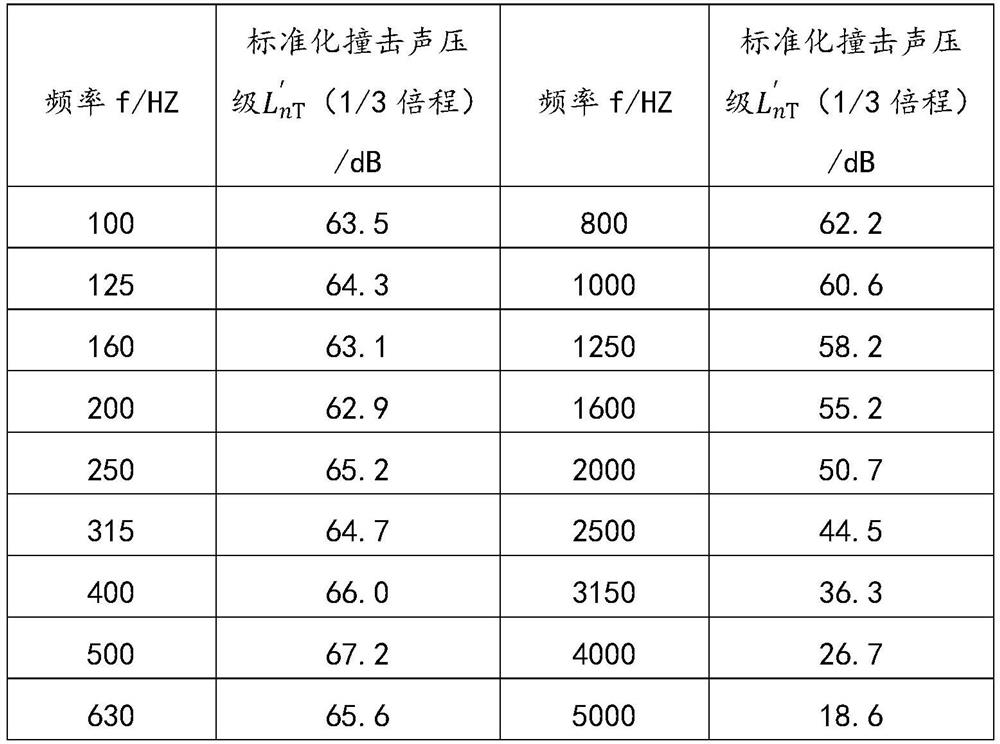

Sound insulation mortar, sound insulation floor slab, building and construction method of sound insulation floor slab

InactiveCN112575977AWorkability is goodImprove sound insulation performanceCovering/liningsSound proofingInsulation layerFloor slab

The invention relates to the field of buildings, and provides sound insulation mortar, a sound insulation floor slab, a building and a construction method of the sound insulation floor slab. The soundinsulation mortar is formed by mixing functional raw materials and water, wherein the functional raw materials comprise the following components in percentage by weight: 28-42% of cement, 30-50% of elastic sound insulation particles, 0-10% of sand, 6-25% of vermiculite, 2-15% of mica powder and 5-18% of a building adhesive. The vermiculite enables the sound insulation mortar to have better workability, and is beneficial to improving the sound insulation effect of the sound insulation mortar; the mica powder is beneficial to improving the consistency of the sound insulation mortar, so that thesound insulation mortar is not prone to hollowing and cracking; and therefore, the sound insulation mortar can be laid to form a thin sound insulation layer, the self-weight of the sound insulation floor slab can be reduced, the material consumption of the sound insulation mortar can be saved, the economic efficiency of the sound insulation floor slab can be improved, protection and maintenance are not needed after the sound insulation mortar is laid, and the construction process of the sound insulation floor slab can be simplified.

Owner:珠海市荣烁绿色建筑节能科技有限公司

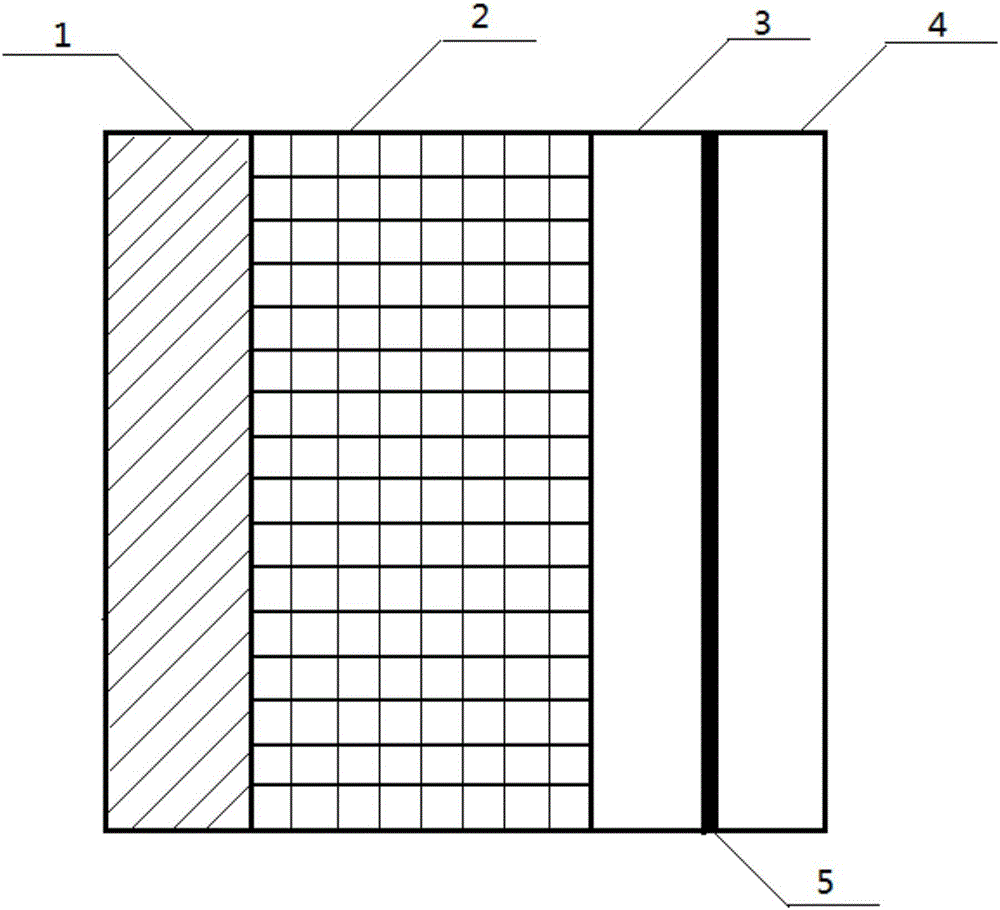

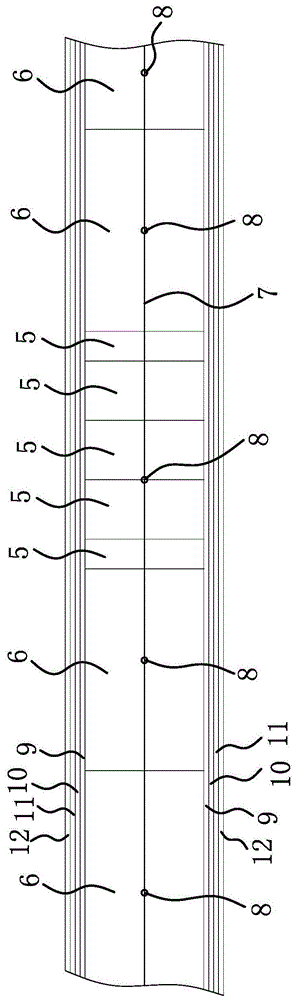

Novel energy-saving construction wall body and construction method thereof

InactiveCN106245805AExtended service lifeReduce energy consumptionWallsClimate change adaptationThermal insulationArchitectural engineering

The invention discloses a novel energy-saving construction wall body and a construction method thereof. The energy-saving wall body sequentially comprises a base layer, a heat insulating layer, a floated layer and a finish layer from the outside to the inside; the base layer is connected with the heat insulating layer through adhesion agents; a strengthening net cloth is installed between the floated layer and the finish layer; and thermal insulation materials of the insulating layer comprise crop stews, adhesion agents, water proof agents, corrosion proof agents and fire retardants. The invention further provides the construction method of the novel energy-saving construction wall body. The novel energy-saving construction wall body has the characteristics that hollowing and falling off are not prone to happening, and service life is long; the novel energy-saving construction wall body is suitable to be promoted and applied.

Owner:XINJIANG AGRI UNIV

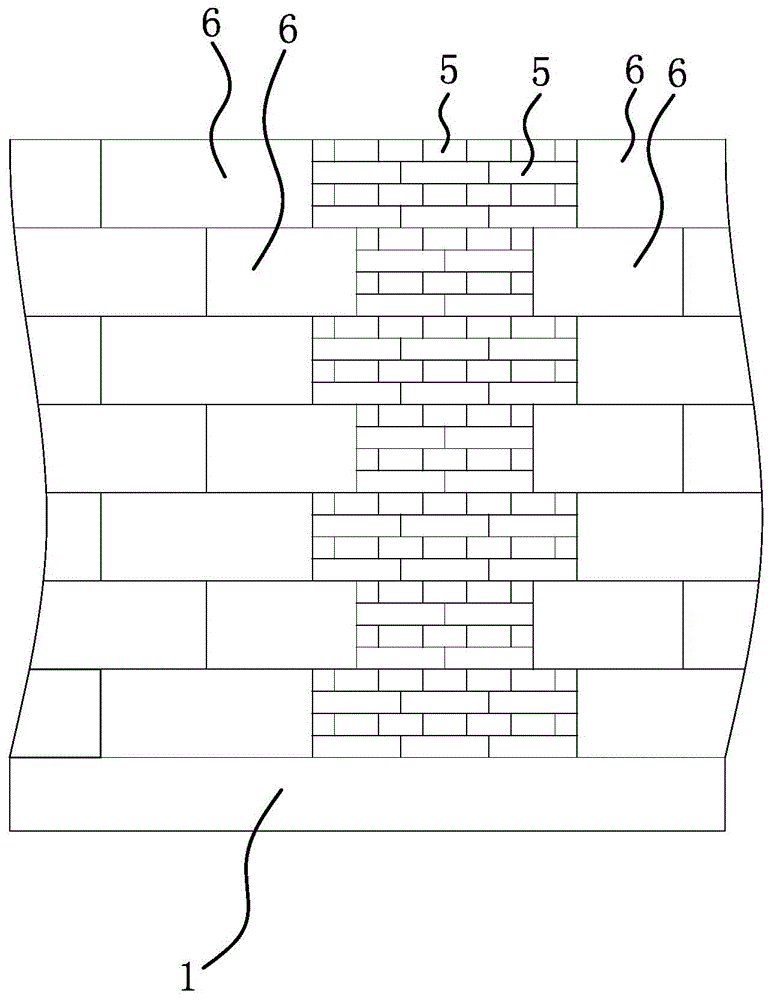

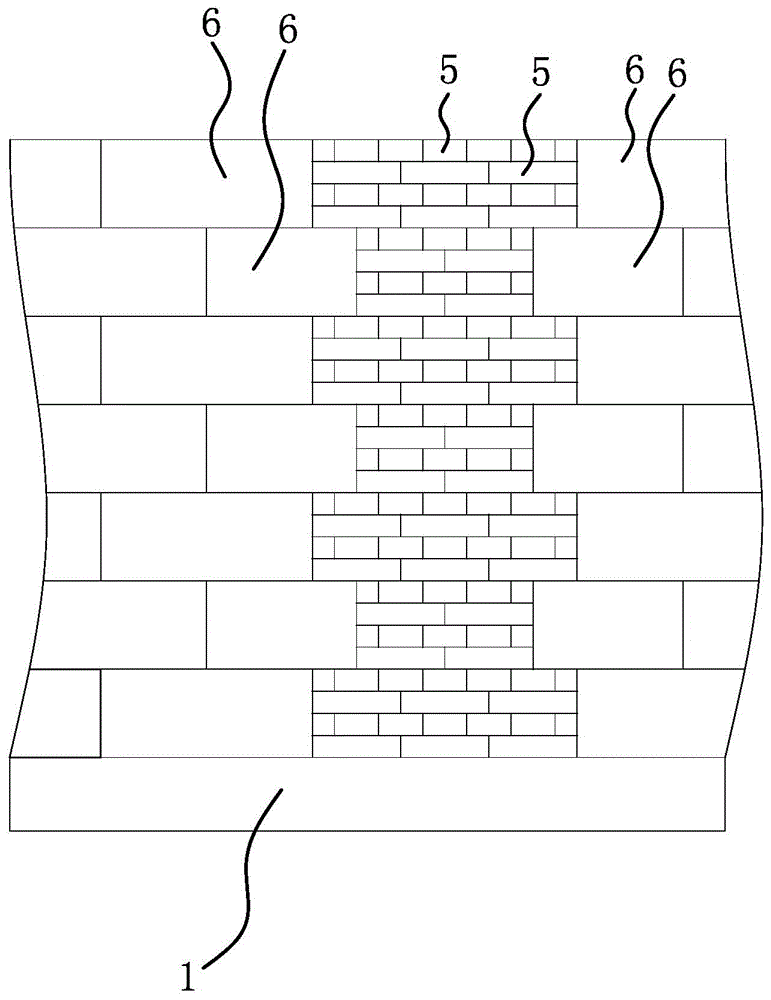

Partition Wall Construction Method

The invention provides a division wall and a division wall construction method, which belongs to the technical field of a building, and solves the problems that the existing division wall is easy to generate secondary damage and cannot conform to the safety requirement of the enterprise. The division wall comprises a wall body and a plastered surface, wherein the wall body is formed by alternately arranging red-brick solid wall and building blocks in an occluding manner; the thickness of the red-brick solid wall is identical to that of a building-block structured wall; the length of the red-brick solid wall is 0.4m to 0.75m, and the distance between every two adjacent red-brick solid walls is 3m to 4m; the top surface of each layer of aerated concrete building block in the building block structured wall is provided with a nylon thin rope, the nylon thin rope is provided with a steel nail in a fastening manner, and each section of red-brick solid wall and each section of building block structured wall are respectively provided with a steel nail in a hammering manner. According to the wall body, besides the curing and binding of cement mortar, the steel nails and nylon thin ropes are also adopted for connection, so that the division wall has advantages of being high in integrity, unlikely to fall and high in safety coefficient.

Owner:TAIZHOU BUILDING INSTALLATION ENG

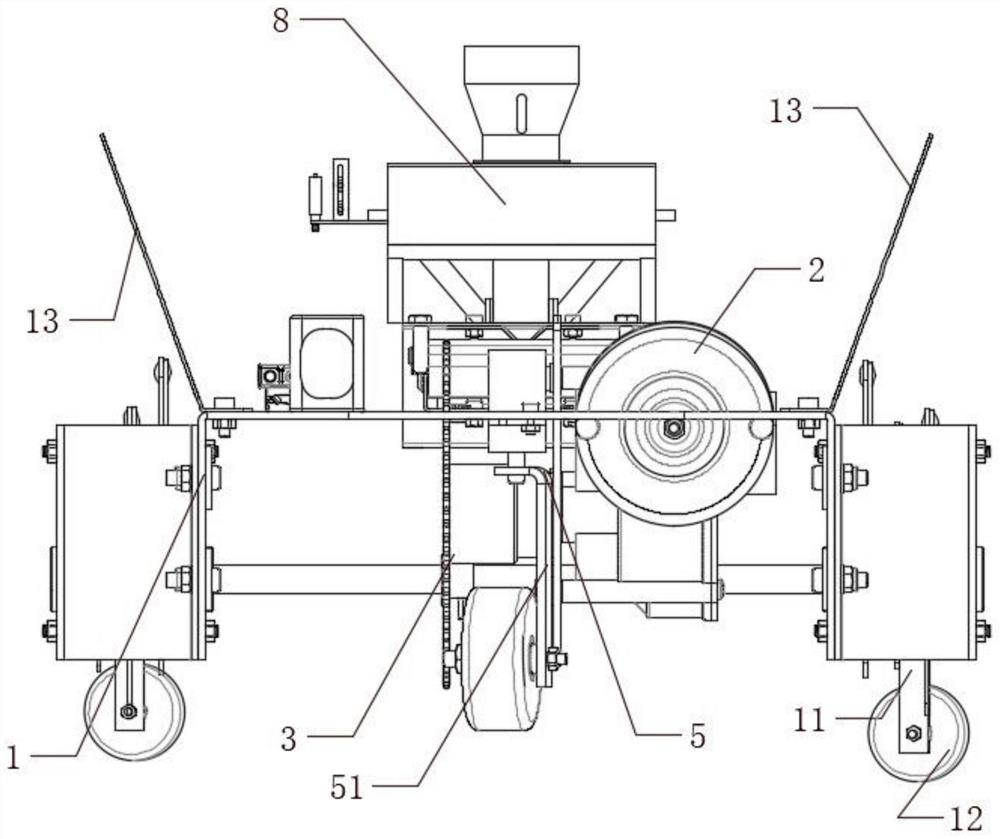

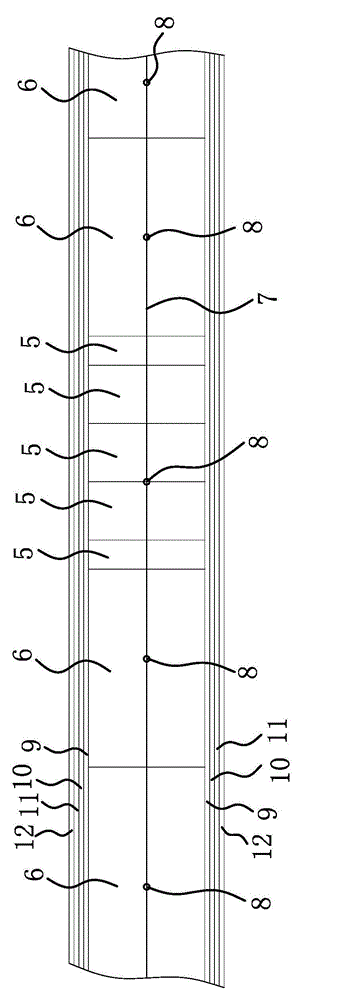

Indoor decorative stone laying equipment and process

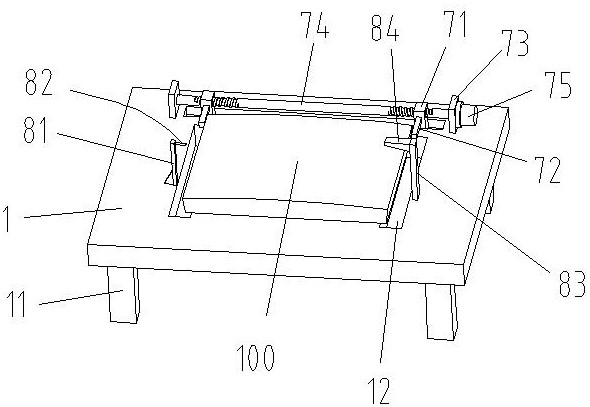

ActiveCN113565301AThe amount of mortar is consistentStable cutting processBuilding constructionsBrickStructural engineering

The invention belongs to the technical field of mechanical equipment, and particularly relates to indoor decorative stone laying equipment. The indoor decorative stone laying equipment comprises a traveling mechanism, a power mechanism and a cutting mechanism, wherein the power mechanism and the cutting mechanism are arranged on the lower end of the traveling mechanism and are connected with the traveling mechanism, a brick body sizing device is further arranged on the upper end of the traveling mechanism, the brick body sizing device comprises a guiding cover body, a material adding part and a mixing part from top to bottom, a first material pushing unit and a second material pushing unit are arranged in the material adding part, and the first material pushing unit and the second material pushing unit rotate to stir materials and push the materials towards the two sides. According to the indoor decorative stone laying equipment, the problems that after a ceramic tile is cut by an operator, mortar needs to be proportioned independently on the ground, the operator must run back and forth, the mortar cannot be taken and smeared on the back face of the ceramic tile at a fixed point, additionally, when too much materials are added, added materials are easy to accumulate or cake, and a machine is stuck in existing ceramic tile paving construction equipment are solved.

Owner:百合盛华建筑科技有限公司

Division wall and division wall construction method

The invention provides a division wall and a division wall construction method, which belongs to the technical field of a building, and solves the problems that the existing division wall is easy to generate secondary damage and cannot conform to the safety requirement of the enterprise. The division wall comprises a wall body and a plastered surface, wherein the wall body is formed by alternately arranging red-brick solid wall and building blocks in an occluding manner; the thickness of the red-brick solid wall is identical to that of a building-block structured wall; the length of the red-brick solid wall is 0.4m to 0.75m, and the distance between every two adjacent red-brick solid walls is 3m to 4m; the top surface of each layer of aerated concrete building block in the building block structured wall is provided with a nylon thin rope, the nylon thin rope is provided with a steel nail in a fastening manner, and each section of red-brick solid wall and each section of building block structured wall are respectively provided with a steel nail in a hammering manner. According to the wall body, besides the curing and binding of cement mortar, the steel nails and nylon thin ropes are also adopted for connection, so that the division wall has advantages of being high in integrity, unlikely to fall and high in safety coefficient.

Owner:TAIZHOU BUILDING INSTALLATION ENG

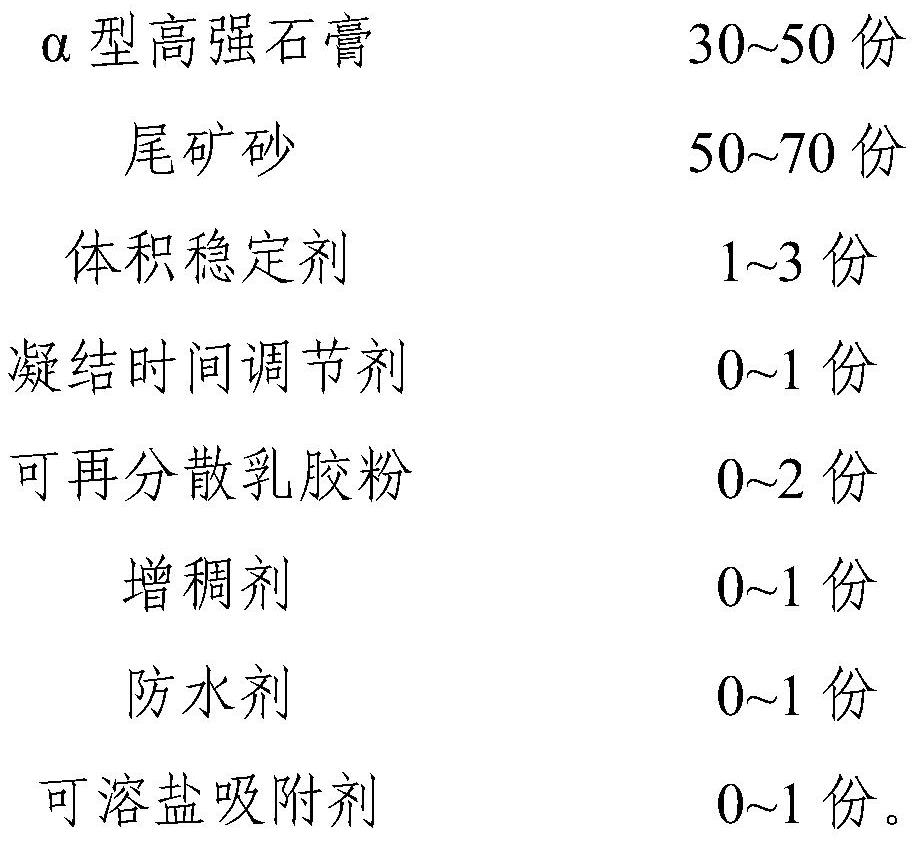

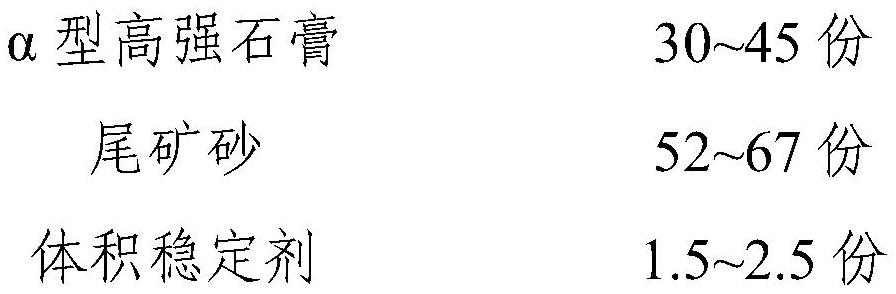

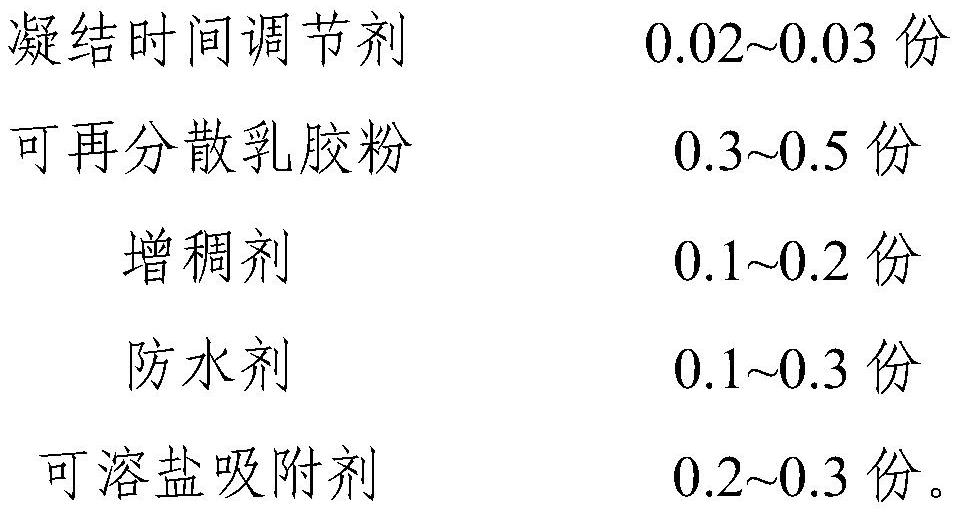

A special binder for glass-ceramics

The present invention relates to the field of building materials, in particular to a special binder for glass-ceramics; the special binder for glass-ceramics includes α-type high-strength gypsum, tailings sand, and a volume stabilizer; wherein, α-type high-strength gypsum is produced by an industrial vice The gypsum is prepared by dissolving and recrystallizing in a saturated water vapor medium; the volume stabilizer is a mixture of expansion reducing agent and shrinkage reducing agent; the expansion reducing agent is tartaric acid; the shrinkage reducing agent is type II anhydrous anhydrite ; The mass ratio of the α-type high-strength gypsum, the tailings sand and the volume stabilizer is 30-50:50-70:1-3. The pH value of the special binder for glass-ceramics of the present invention is neutral, has good compatibility with glass-ceramics, and is especially suitable for masonry and bonding of glass-ceramics; Compared with the adhesives in the prior art, the strength development speed of the adhesive is fast, the construction efficiency is high, the bonding strength is high, it is not easy to fall off, the dimensional stability is good, and hollowing is not easy to occur; and the cost is low.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

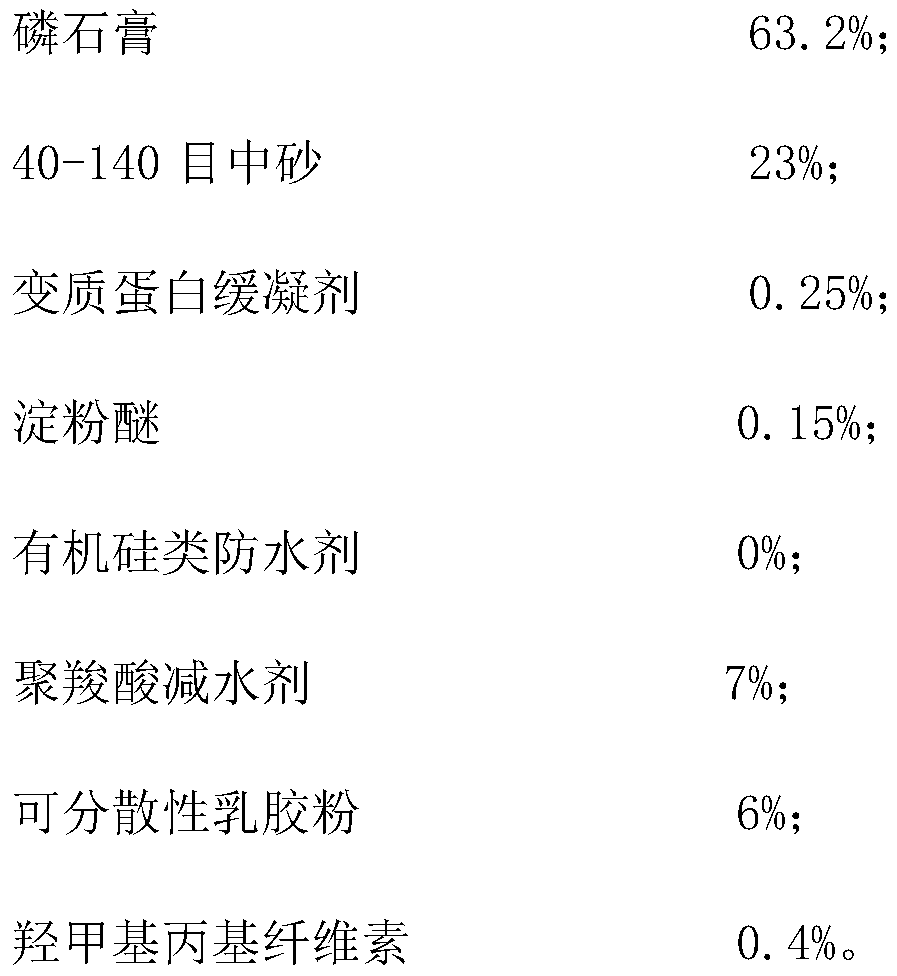

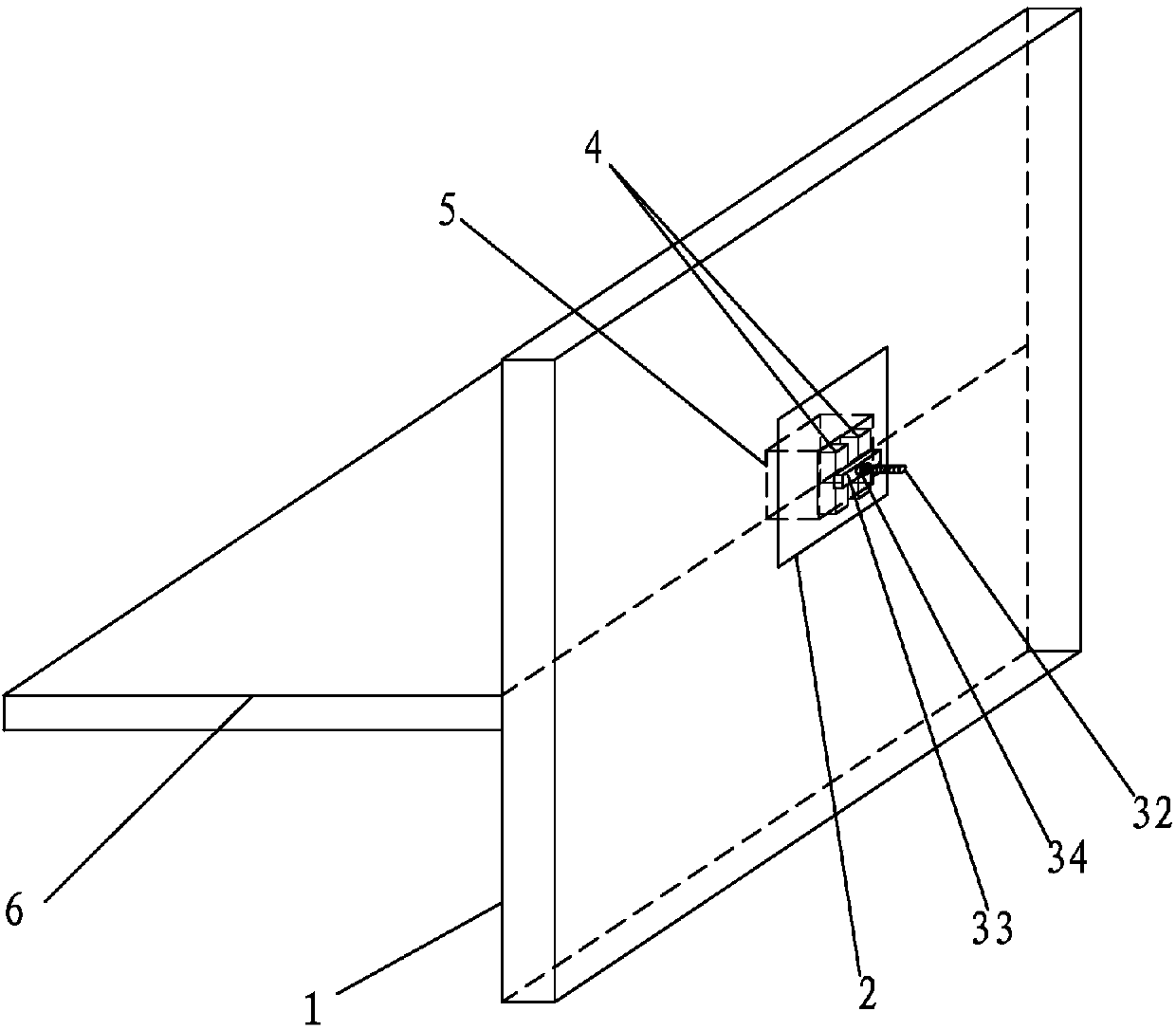

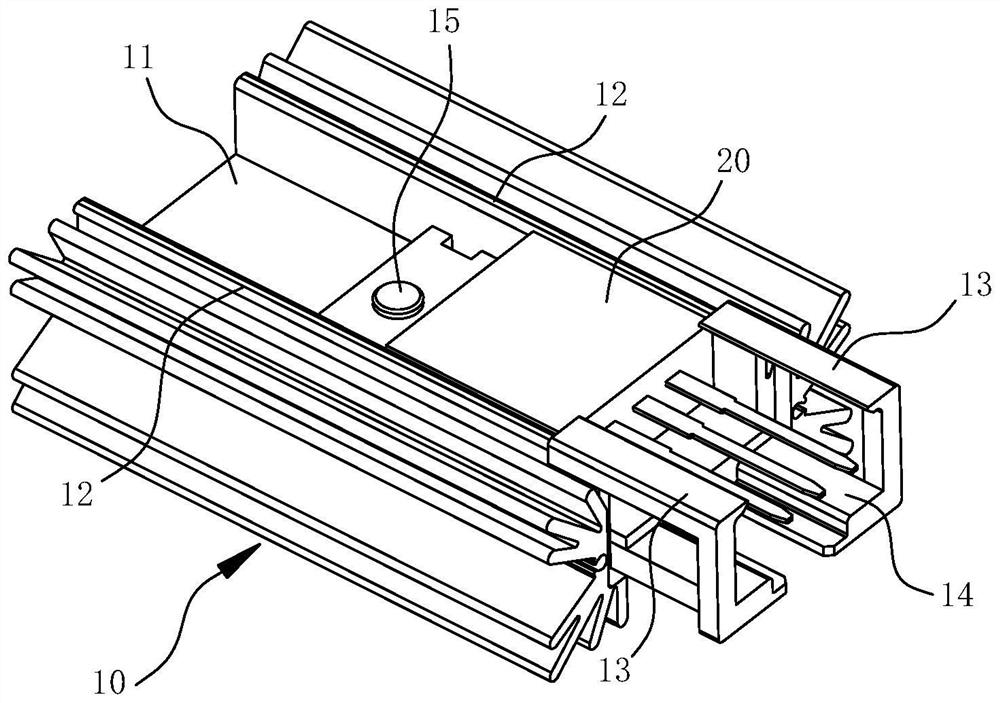

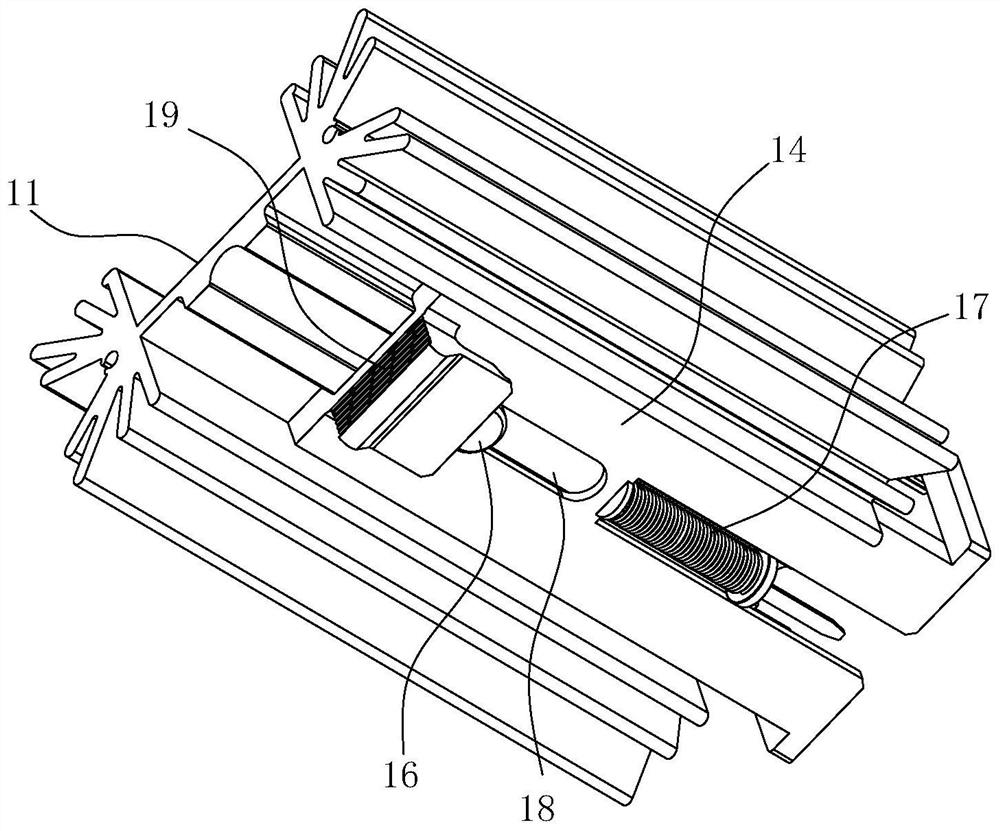

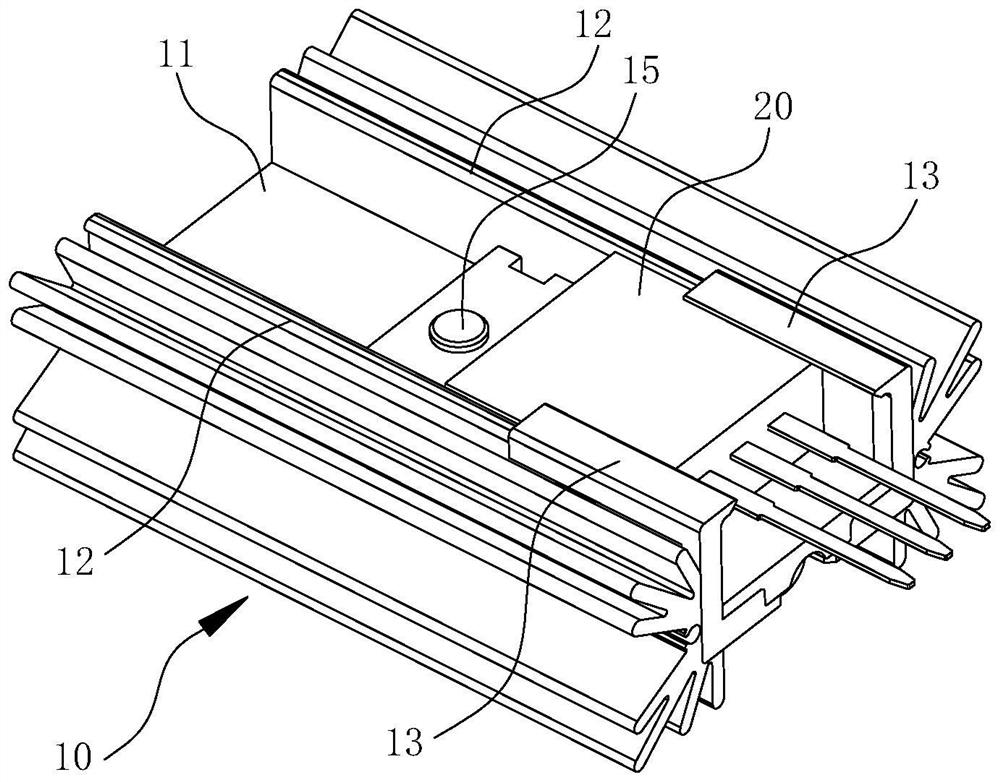

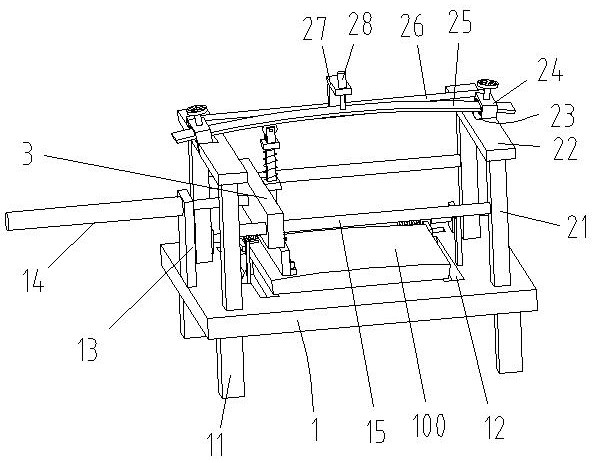

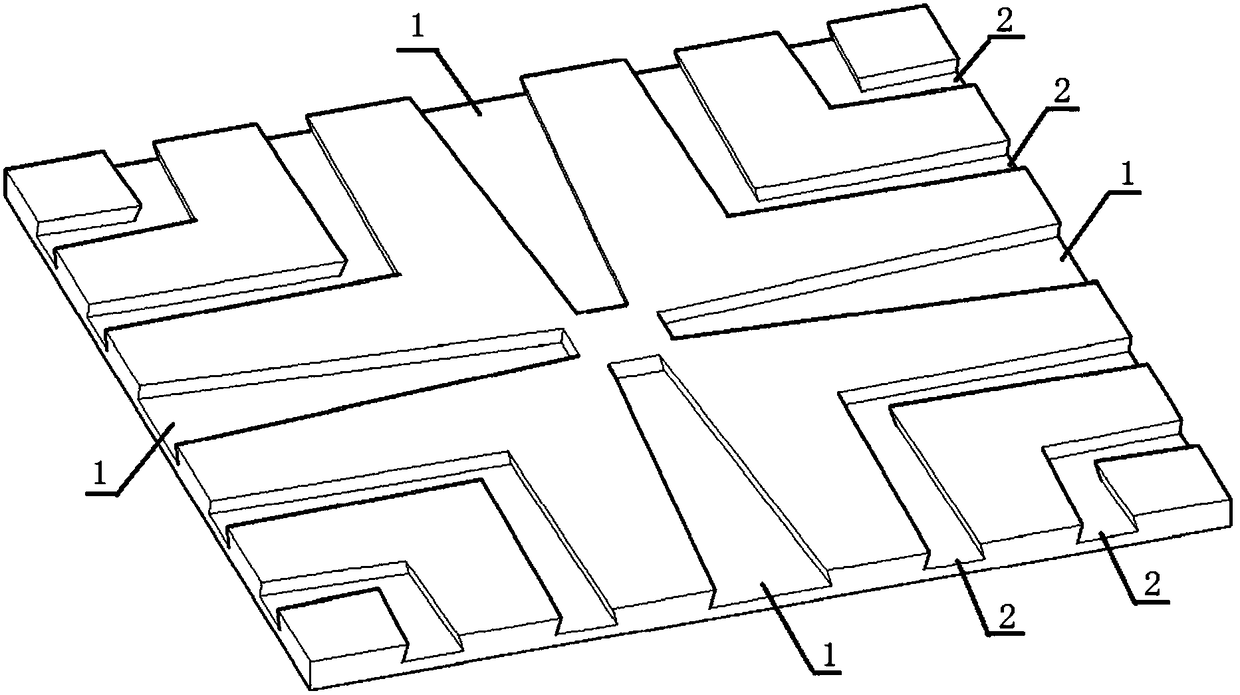

MOS tube assembly and assembling device thereof

ActiveCN114743939ANot prone to hollowingImprove assembly efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention belongs to the technical field of semiconductor processing, and particularly relates to an MOS tube assembly and an assembling device thereof.The MOS tube assembly comprises an MOS tube and a heat dissipation block, the heat dissipation block comprises a mounting plate, heat dissipation fins arranged in a radial shape are arranged on the two sides of the mounting plate, positioning columns protruding out of the plate face of the mounting plate are arranged on the mounting plate, and the positioning columns are arranged on the mounting plate. The MOS tube is provided with a positioning hole matched with the positioning column; and a clamping mechanism is arranged on the heat dissipation block. According to the invention, the positioning column is used for preliminarily positioning the MOS tube, then the clamping mechanism is used for integrally pressing the MOS tube on the heat dissipation block, the MOS tube is integrally restrained, and hollowing does not easily occur between the MOS tube and the heat dissipation block; in addition, linkage between the downward pressing action of the MOS tube and the clamping action of the clamping mechanism is achieved through the linkage mechanism, the clamping mechanism can be automatically triggered to act while the MOS tube is pressed on the heat dissipation block, no extra assembling tool needs to be used, and the assembling efficiency between the MOS tube and the heat dissipation block is improved.

Owner:上海晶岳电子有限公司

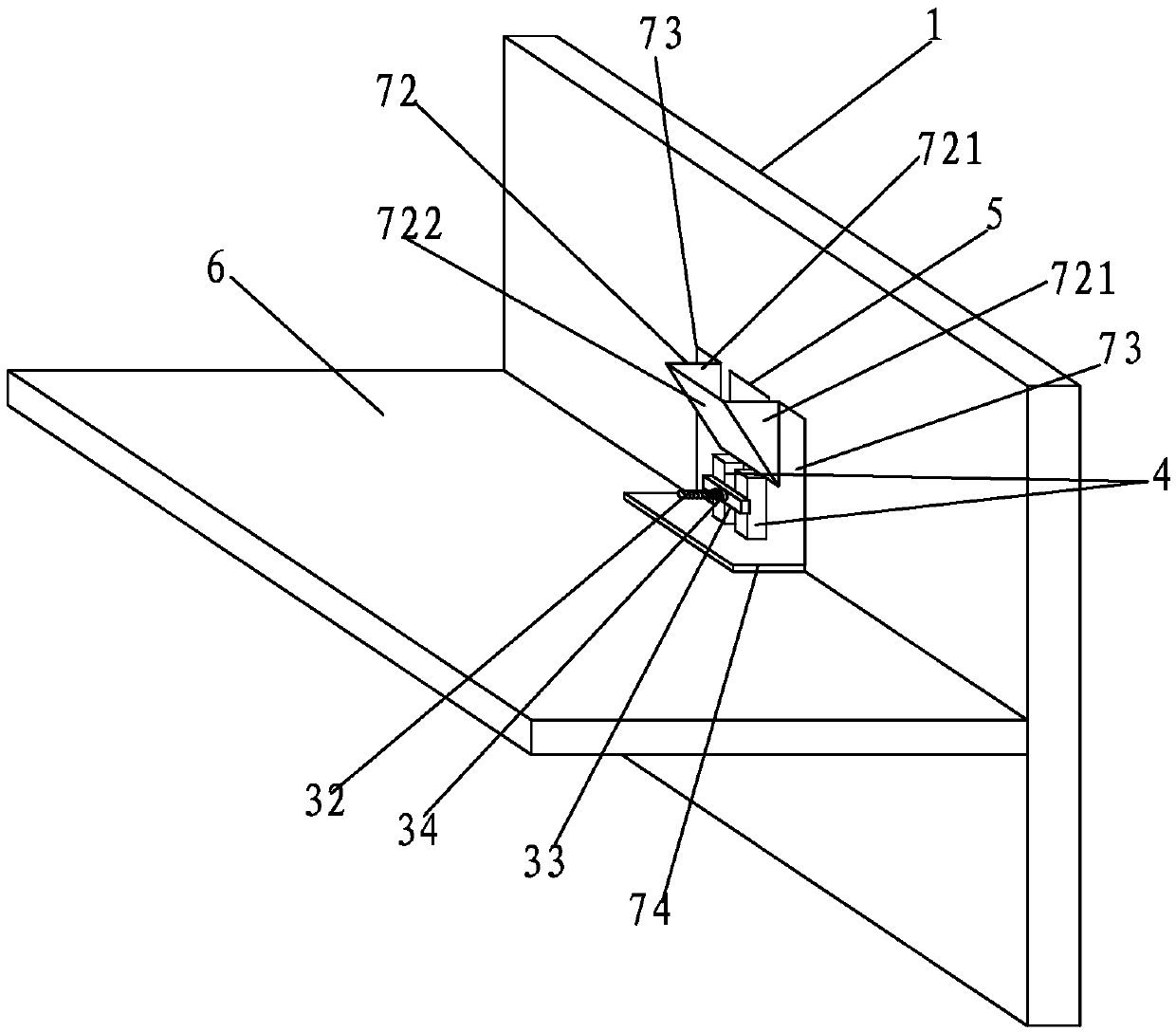

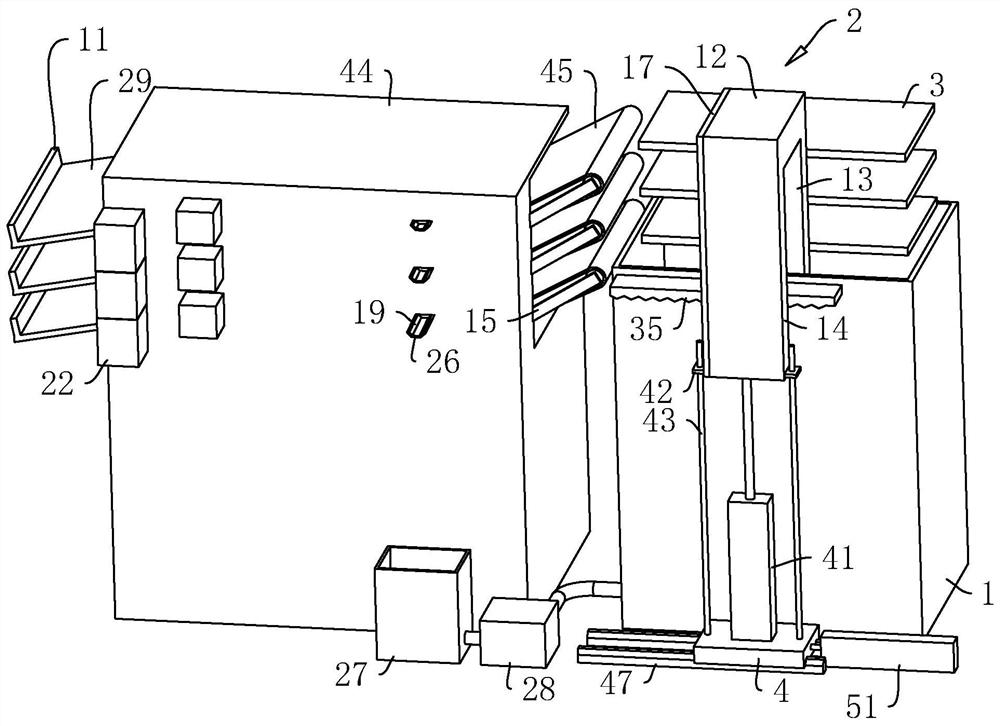

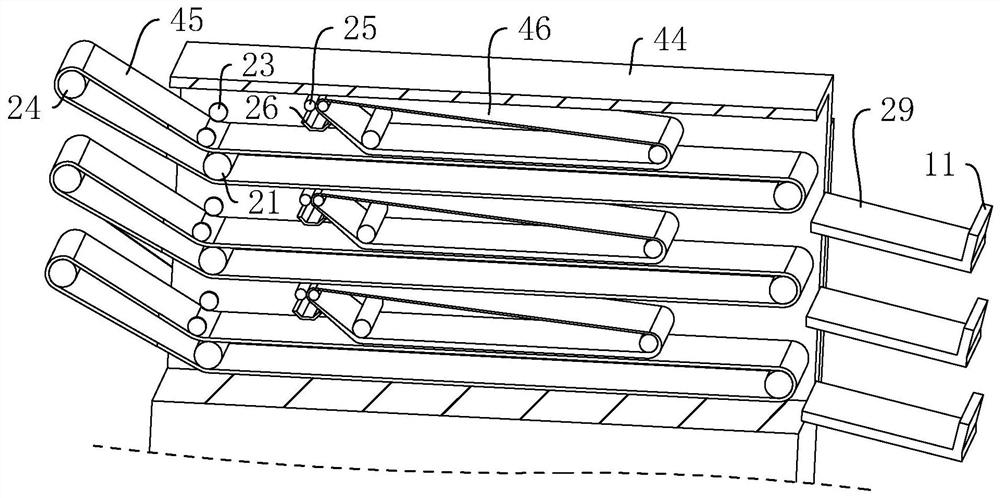

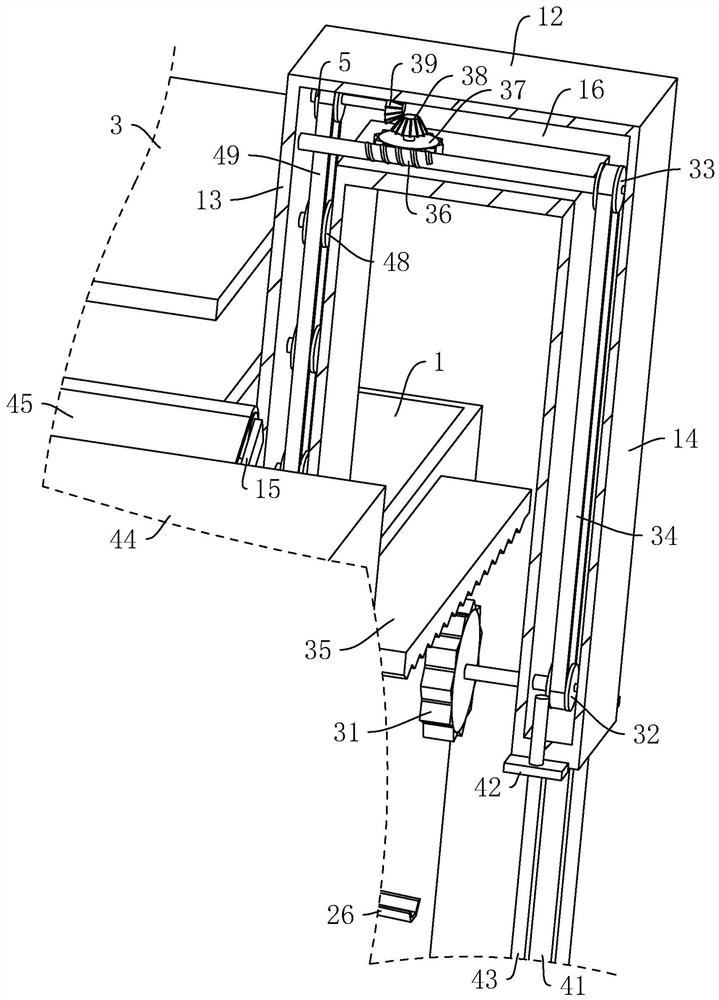

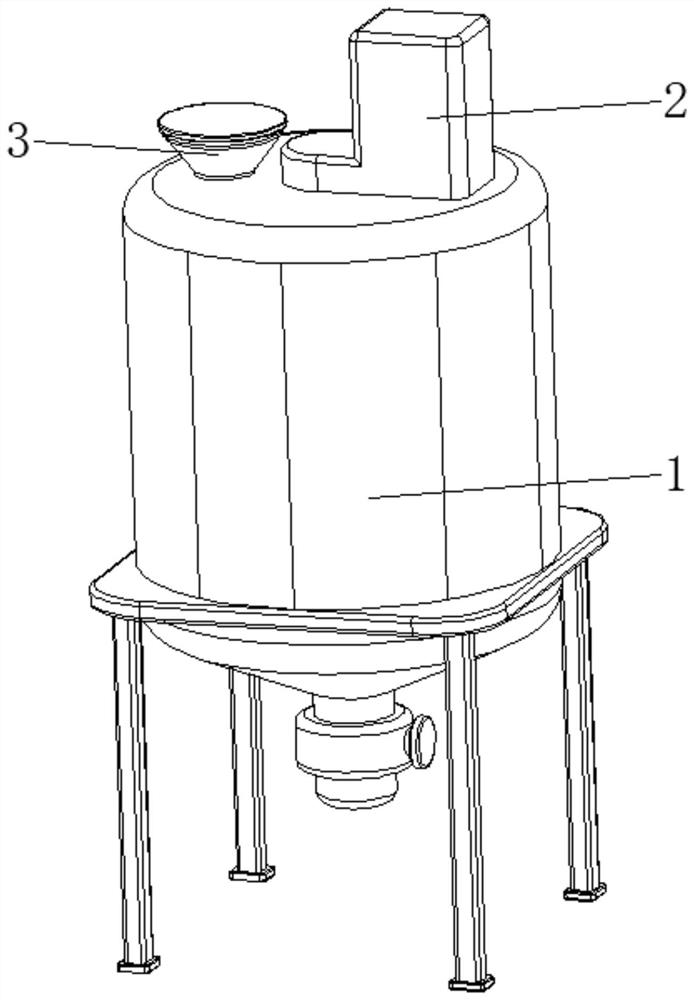

Mortar pasting system for building external wall insulation board

ActiveCN113235874ANot prone to hollowingNot prone to crackingBuilding material handlingHydraulic cylinderArchitectural engineering

The invention discloses a mortar pasting system for a building external wall insulation board. The mortar pasting system for the building external wall insulation board comprises a bottom plate, wherein a clamping device used for clamping the insulation board is arranged on the upper side of the bottom plate, one side of the upper part of the bottom plate is fixedly connected with a stand column, one side of the stand column is fixedly connected with a hydraulic cylinder, and the telescopic end of the hydraulic cylinder is fixedly connected with a mortar smearing device. The mortar pasting system for the building external wall insulation board has the advantages that e strip-shaped cement mortar on the surface of the insulation board can be uniform in thickness and equal in interval, the smearing area meets the construction standard, the insulation board is not prone to hollowing, cracking and falling off when attached to a wall, and the mortar smearing speed is high.

Owner:湖北三固建材科技有限公司

Wall painting agent

The invention discloses a wall painting agent. The wall painting agent comprises the following components according to the parts by mass: 40-55 parts of inorganic glue, 7-8 parts of a resin, 30-40 parts of aggregate, 4-8 parts of plant fibers, 0.1-0.5 parts of a modifier, 0.1-1 part of an anti-cracking agent, 0.2-0.5 parts of a water-retaining agent, 0.2-0.5 parts of a thickening agent, 15-20 parts of inorganic filler, and the balance of water. From the above, the wall painting agent is capable of effectively improving an adhesive force and bonding strength between a painting layer and a wallsurface, and enabling the wall and the painting layer to form as a whole without additionally pasting gridding cloth. A hollow is not easy to be generated between the painting layer and the wall, anddefects, such as cracking, do not appear on the painting layer.

Owner:钟翔

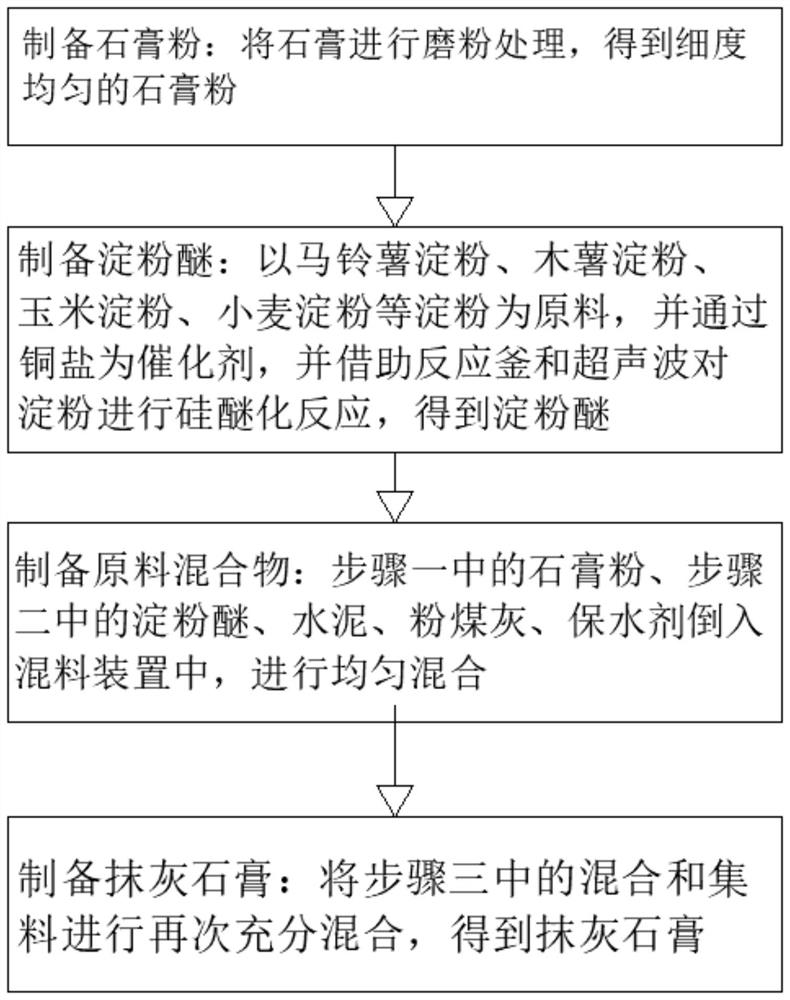

Lightweight plastering gypsum mortar and preparation method thereof

PendingCN113771222AGood thickening effectExtended service lifeCleaning using toolsCement mixing apparatusPtru catalystGypsum

The invention discloses lightweight plastering gypsum mortar and a preparation method thereof. The preparation method comprises the following steps of preparing gypsum powder: grinding gypsum to obtain gypsum powder with uniform fineness; preparing starch ether: carrying out a silicon etherification reaction on starch serving as a raw material with a copper salt as a catalyst by means of a reaction kettle and ultrasonic waves to obtain the starch ether; preparing a raw material mixture: pouring the gypsum powder, the starch ether, cement, fly ash and a water-retaining agent into a mixing device, and uniformly mixing; and preparing plastering gypsum: fully mixing the mixture obtained in the third step and aggregate again to obtain the plastering gypsum. According to the lightweight plastering gypsum mortar and the preparation method thereof, the effect of improving the comprehensive capacity is achieved, the thickening capacity is good, meanwhile the influence of humid weather is reduced, the quality problems of hollowing, cracking, surface dusting or falling are not prone to occurring, the service life of a building is prolonged, and the use performance is improved.

Owner:康琳

A kind of low elastic tile adhesive

The invention discloses a low-elasticity tile adhesive, belonging to the field of tile adhesives. The low-elasticity tile adhesive is prepared from the following components in parts by mass: 300-500 parts of Portland cement, 0-100 parts of calcium powder, 0-200 parts of 30-100-mesh quartz sand, 200-400 parts of 100-180-mesh quartz sand, 0-10 parts of an early strength agent, 1-3 parts of hydroxypropyl methyl cellulose, 1-5 parts of guar gum ether, 0-2 parts of starch ether, 4-10 parts of a magnesium aluminum silicate thixotropic thickener and 5-20 parts of redispersible latex powder. According to the low-elasticity tile adhesive, the mixing amount of hydroxypropyl methyl cellulose is reduced, and the guar gum ether, the starch ether and the magnesium aluminum silicate thixotropic thickener are added, so that the cohesion and elasticity of tile adhesive slurry are greatly reduced when the primary excellent water retention capacity of the tile adhesive is guaranteed, the contradiction between the low elasticity and high water retention capacity is solved, the construction and the rolling are easy, the adhesion is flat, the hollowing is unlikely to occur, and the adhesion quality of tiles is improved.

Owner:西卡(上海)管理有限公司

Defoaming machine

ActiveCN103434012BAvoid smearingImprove bearing strengthCeramic shaping apparatusGlass fiberElectric machinery

Owner:CUBIC DIGITAL TECH CO LTD

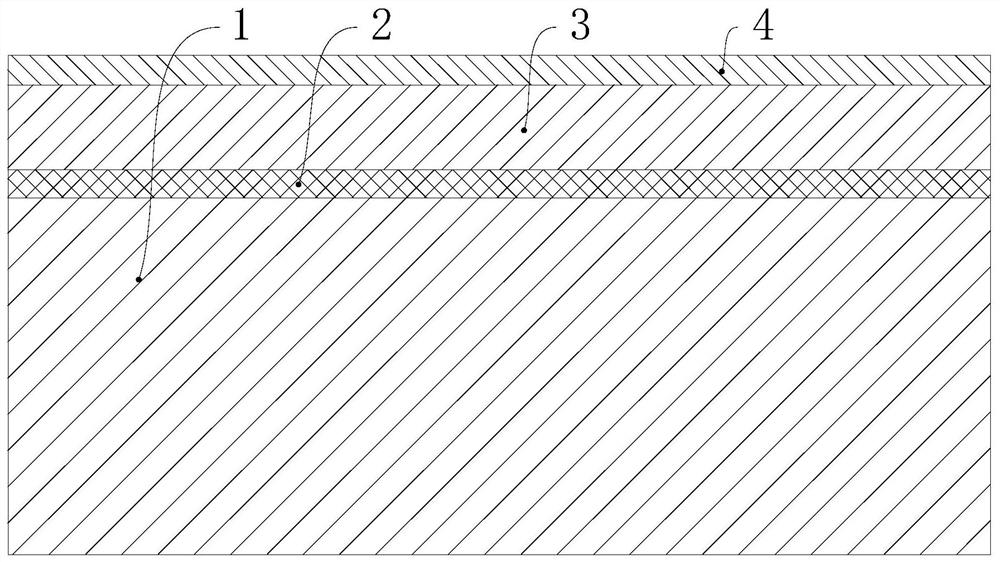

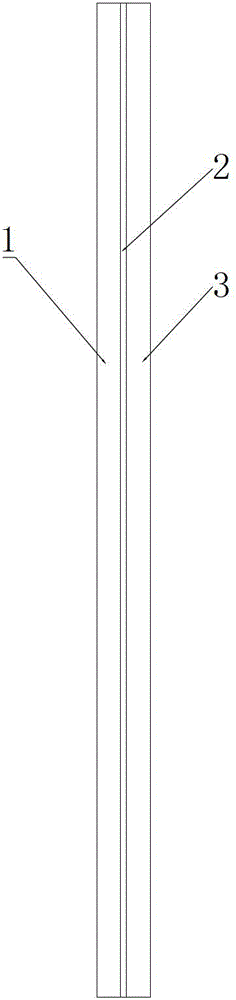

Inorganic composite flexible decorative coiled materials and producing method thereof

InactiveCN103266734BFlexibleNot prone to hollowingCovering/liningsWater-setting substance layered productCelluloseGlass fiber

The invention belongs to the field of building, and discloses inorganic composite flexible decorative coiled materials. The thickness of the inorganic composite flexible decorative coiled materials is 2mm to 10mm, the inorganic composite flexible decorative coiled materials comprise an inorganic coiled material mortar layer, a decorative mortar layer is combined on the inorganic coiled material mortar layer, and reinforcing materials formed by alkali-resisting glass fiber gridding cloth or glass fiber roofing felts are arranged in the inorganic coiled material mortar layer or on the boundary of the inorganic coiled material mortar layer and the decorative mortar layer. The inorganic coiled material mortar layer is mainly formed by the following materials, by weight: 100 parts of portland cement with intensity no less than 42.5, 1.2 to 2.0 parts of cellulose, 350 to 450 parts of 50 to 100-mesh silica sand, 180 to 220 parts of coarse whiting, 1.8 to 2.2 parts of water reducing agent and 120 to 160 parts of 707 emulsion or cement-based elastic emulsion. The decorative mortar layer is mainly formed by the following materials, by weight: 150 parts of synthetic resin emulsion for maishi paint, 4 to 6 parts of coalescing agent, 8 to 12 parts of ethylene glycol, 1 to 2 parts of cellulose and 700 to 800 parts of natural color sand. The inorganic composite flexible decorative coiled materials are good in toughness, small in thickness, light in weight, good in application property, not prone to peeling off and good in weather fastness, and different decorative styles can be formed easily.

Owner:BEIJING SOLID BUILDING ENG

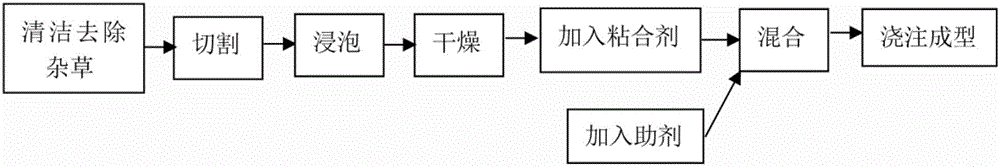

Tile not likely to hollow

InactiveCN108468415AIncrease contact areaNot easy to break awayCovering/liningsAdhesivesIsosceles trapezoidAdhesive

The invention relates to a tile not likely to hollow. Grooves running through the four sides of the tile are formed in the four directions of the tile along the center line of the tile respectively, wherein the grooves are in isosceles trapezoid shapes, the sides, located on the edges of the tile, of the grooves are the bottoms of isosceles trapezoids, the cross sections of the grooves are also inisosceles trapezoid shapes, and the bottoms of the isosceles trapezoids are located on the bottom walls of the grooves. Since the grooves and side grooves are filled with adhesives, the contact areabetween the adhesives and the tile is increased. In addition, since the adhesives in the grooves and the side grooves and the block adhesives on the bottom wall of the tile form a whole part, the phenomenon of hollowing is less likely to occur, and the tile is less likely to be detached from the adhesives.

Owner:广州元坤新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com