Defoaming machine

A defoaming machine and defoaming technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problems of poor quality, waste, and hollowing of foamed cement, saving installation space, improving production efficiency, and reducing process costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

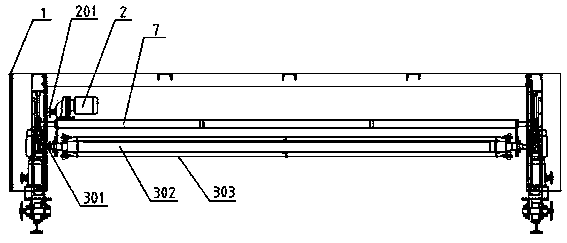

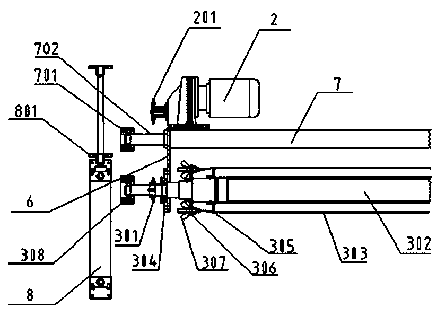

[0055] like Figure 1-2 As shown, the defoaming machine of this embodiment includes a frame 1, on which a support plate 7 is horizontally fixed, on which a drive motor 2 is installed, and two ends of the support plate 7 are respectively fixed with The connecting steel plate 6 is equipped with a main shaft 302, and the outer surface of the main shaft 302 is evenly arranged with defoaming parts along the circumferential direction; the defoaming machine of this embodiment also includes a transmission assembly, which is connected to the drive motor 2 and the main shaft 302, It is used to transmit the driving force of the driving motor 2 to the main shaft 302 to drive the main shaft 302 to rotate. The above-mentioned support plate 7, drive motor 2, connecting steel plate 6 and transmission assembly together constitute the defoaming assembly of the defoaming machine. When the driving motor 2 is working, the main shaft 302 rotates under the action of the transmission assembly, which...

Embodiment 2

[0077] This embodiment is a modification on the basis of Embodiment 1, and its difference from Embodiment 1 is that the limiting track is a highly undulating limiting track, and when the limiting wheel 901 walks on the limiting track, Its height is constantly changing, so that the height of the main shaft 302 and the steel wire 303 on the main shaft 302 relative to the body to be defoamed is constantly changing, so that this kind of defoaming machine can be used to have a non-horizontal upper surface to prepare the upper part with a specific thickness. Foamed cement for air-bubble cleaning layer.

[0078] Specifically, set limit rails with target height undulations on both sides of the object to be defoamed, adjust the horizontal upper surface of the object to be defoamed to match the highest track position, and adjust the defoamer to the position to be defoamed by the lifting device Above the body, adjust the relative height relationship between the limit wheel 901, the limit...

Embodiment 3

[0080] like Figure 12 As shown, this embodiment is a deformation on the basis of embodiment 1 or embodiment 2, the difference is that the above-mentioned defoaming member does not use steel wire, but by setting angle steel 309 on the defoaming main shaft, and connecting nylon on the angle steel 309 The ribbon 310 and the defoaming spindle 302 drive the nylon ribbon 310 to rotate, and then perform defoaming treatment on the defoaming layer of the defoaming body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com