Floor paving method

A technology for flooring and paving, applied in construction, adhesives, building structures, etc., can solve the problems that the surface of cement mortar is difficult to level, the cement mortar is easy to be uneven, and the floor is prone to warping, etc., and it is not easy to hollow and rise. warping, lower maintenance costs, and improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

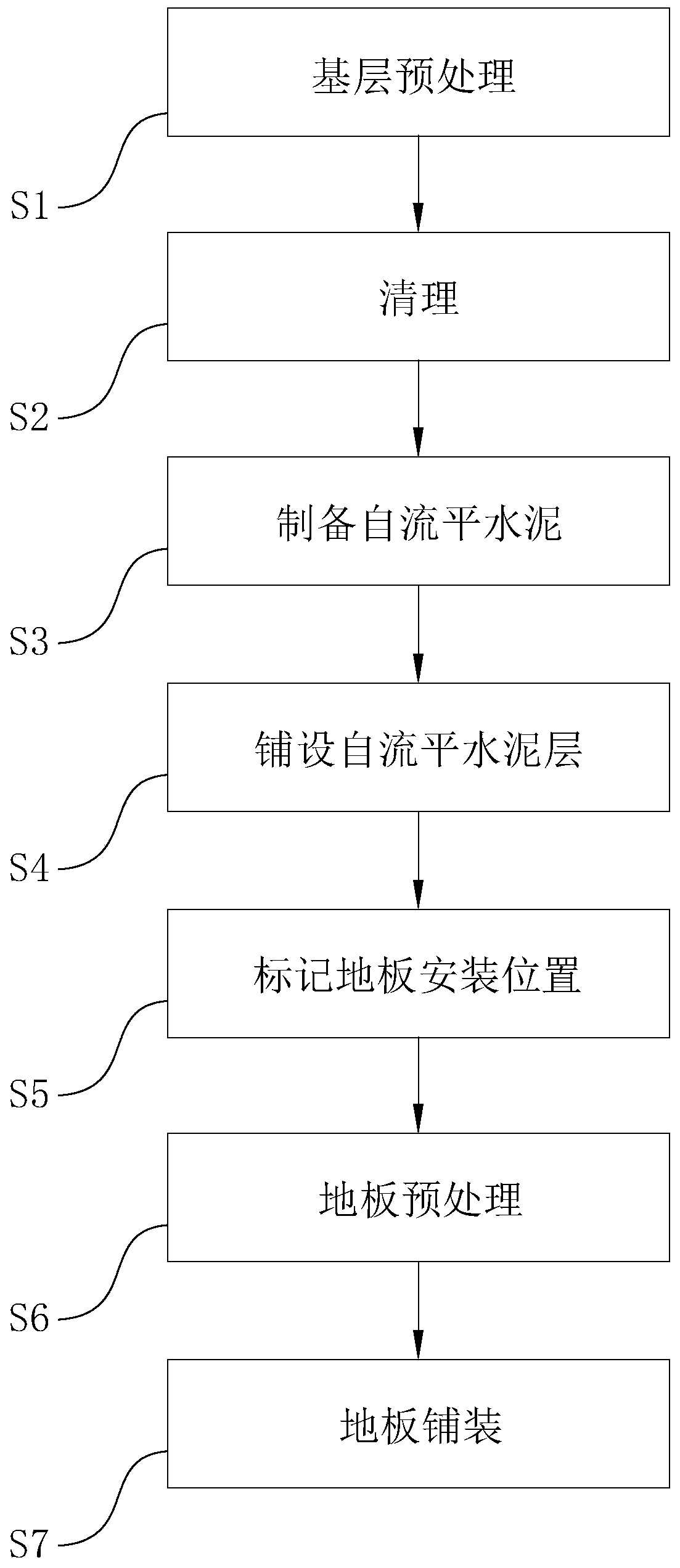

[0075] A method for laying a floor, comprising the steps of:

[0076] S1. Grass-roots pretreatment, details are as follows:

[0077] Grinding machine is used to grind the base layer of the ground to remove impurities, floating dust and sand particles of the base layer of the ground, and to smooth the partially protruding part of the base layer of the ground.

[0078] S2, clean up, specifically as follows:

[0079] Clean up the dust, impurities, etc. on the surface of the ground base, and use a vacuum cleaner to clean it.

[0080] S3, prepare self-leveling cement, specifically as follows:

[0081] In a 200L stirring tank, stir at a speed of 250r / min under normal temperature conditions, add water 3kg, sand 65kg, fly ash 37.5kg while stirring, after stirring evenly, add Portland cement 35kg, 3kg of water, 0.2kg of water reducer, 0.3kg of retarder, 1kg of epoxy resin, 0.2kg of 2-anilinopyridine, and 0.02kg of bisindeno, and stir evenly to form self-leveling cement.

[0082] S4...

Embodiment 2

[0091] The difference with embodiment 1 is:

[0092] S3, prepare self-leveling cement, specifically as follows:

[0093] In a 200L stirring tank, stir at a speed of 250r / min at room temperature, add 2.5kg of water, 70kg of sand, and 35kg of fly ash while stirring, and then add 32.5kg of Portland cement while stirring , water 2.5kg, water reducing agent 0.1kg, retarder 0.1kg, epoxy resin 3kg, 2-anilinylpyridine 0.1kg, bisindeno 0.01kg, stir evenly to form self-leveling cement.

Embodiment 3

[0095] The difference with embodiment 1 is:

[0096] S3, prepare self-leveling cement, specifically as follows:

[0097] In a 200L stirring tank, stir at a speed of 250r / min at room temperature, add 2.75kg of water, 67.5kg of sand, and 40kg of fly ash while stirring, and then add 30kg of Portland cement while stirring , 2.75kg of water, 0.15kg of water reducer, 0.2kg of retarder, 2kg of epoxy resin, 0.15kg of 2-anilinylpyridine, and 0.02kg of bisindena, and stir evenly to form self-leveling cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com