Lightweight plastering gypsum mortar and preparation method thereof

A technology for plastering gypsum and mortar, applied in the field of lightweight plastering gypsum mortar and its preparation, which can solve the problems of reduced performance, dusting, cracked surface, etc., and achieve the goal of increasing the stirring direction, improving the stirring efficiency, and improving the use performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

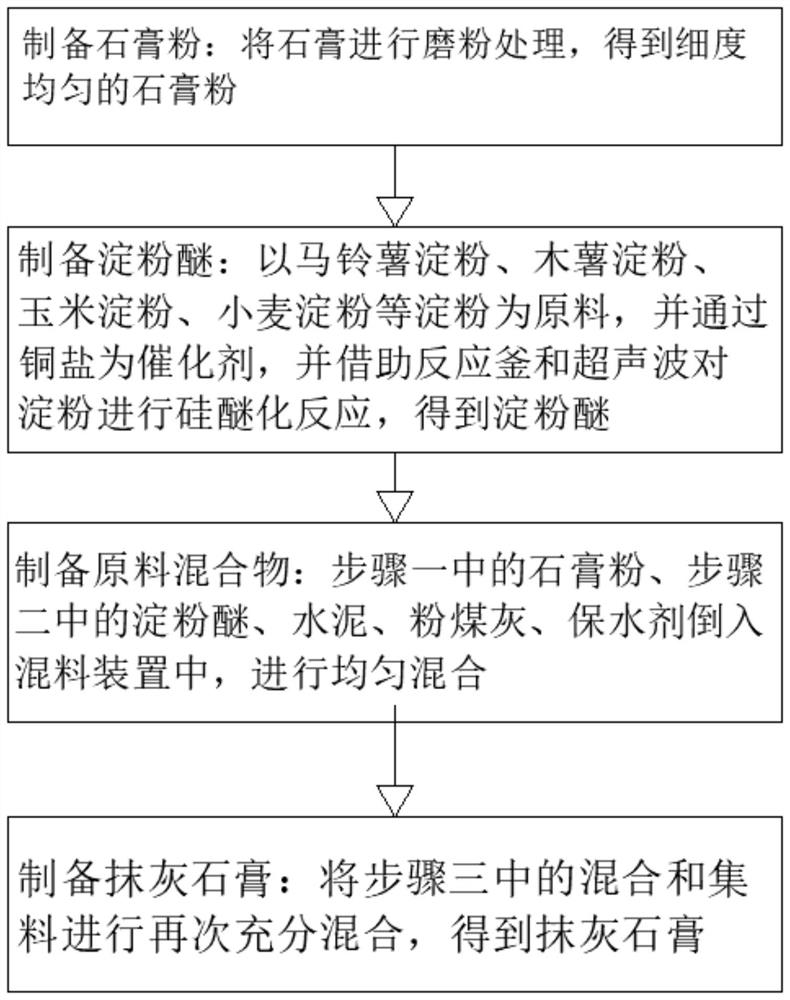

[0035] See Figure 1-7 The present invention provides a technical solution: a method of preparing a light plaster plaster mortar, composed of the following steps:

[0036] Step 1, preparation plaster powder: Treatment of gypsum to get a metallic plaster powder with uniform fineness;

[0037] Step 2, a starch ether: is prepared by potato starch, cassava starch, corn starch, wheat starch, etc., and passes through the copper salt as a catalyst, and the starch ether is obtained by means of a reaction kettle and ultrasonic waves to obtain a starch ether;

[0038] Step three, prepare a raw material mixture: step one in the plaster powder, step two of the starch ether, cement, fly ash, water storage agent in the mixing device, and mix;

[0039] Step 4, prepare plasterite: completely mix the mixing and collectivity in step three, get plaster plaster, make the gypsum mortar thickens, while reducing the influence of moisture weather, it is not easy to have empty drums, cracking, The surface ...

Embodiment example 2

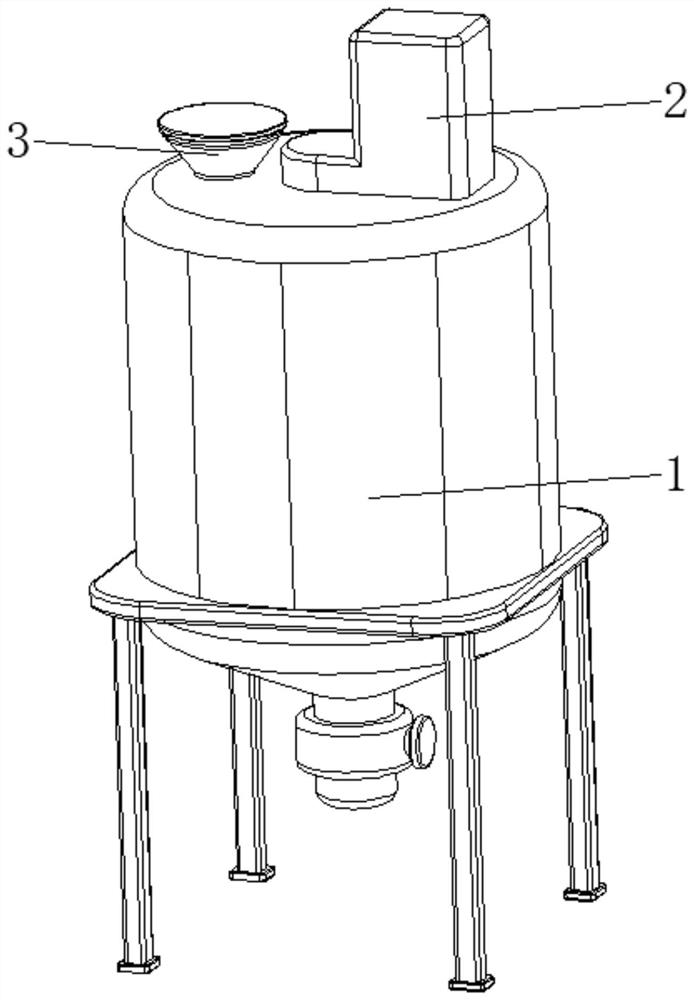

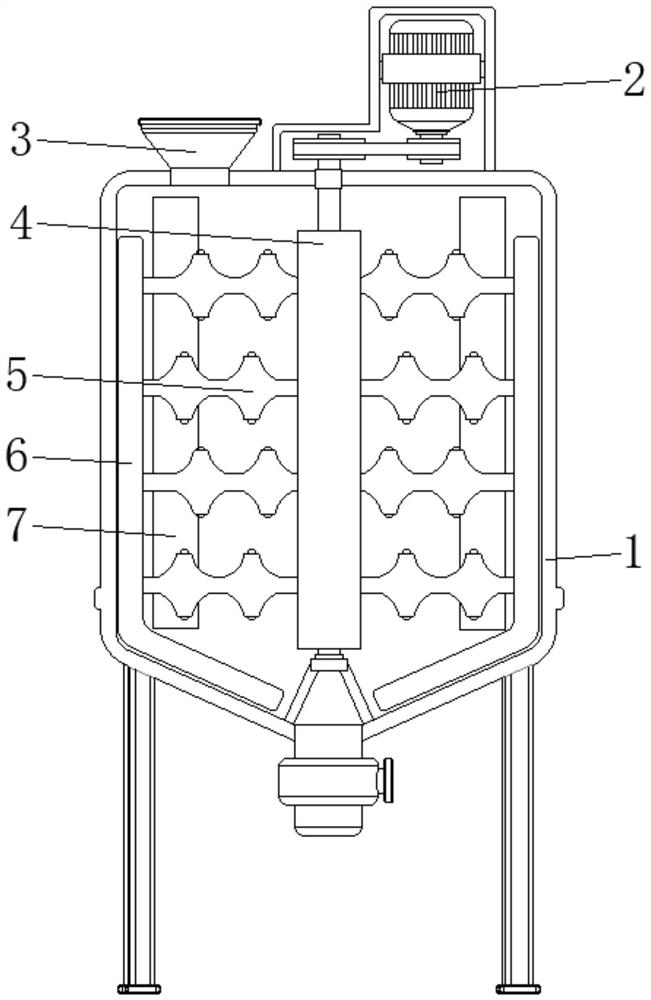

[0041]The mixing device includes a body 1, and the top portion of the body 1 is provided with a power mechanism 2, the top of the body 1 is provided with the position of the body 3, the top of the body 1, the top and bottom of the body 1, corresponding to the bottom. The central position is rotated and connected to the top end of the rotating roller 4 through the inner wall of the rotating roller 4, and the power mechanism 2 is fitted, and the surface of the rotating roller 4 is fixedly connected to the stirring device 5, the stirring device 5 away from the rotary roller 4 At one end and the position close to the inner wall of the body 1, the inner wall of the body 1 is provided with a projection device 7, and the rotation of itself is utilized, and the material can be quickly uniformly stirred by increasing the agitation direction, and the structure is mutually Connecting and combined with magnetic force, self-cleaning equipment, is not prone to material sticky, helping to clean ...

Embodiment example 3

[0043] The stirring device 5 is provided with stirring teeth 51, the ball head slider 52, the reset spring 53, the push rod 54, the arc bulk block 55, and one end of the agitating teeth 51 is fixed to the surface of the rotary roller 4, the ball head slide 52 slides the connection Inside and in the surface position, the reset spring 53 is fixed between the end of the ball head slider 52 and the inside of the agitation teeth 51, and the push rod 54 slides to be attached to the inside of the agitating teeth 51, the arc surface bump 55 is disposed. When the surface of the stirring teeth 51 is fixed, the stirring teeth 5 and the wiper wall device 6 are rotated, and when the material is stirred, the inner wall of the body 1 is adhered to the inner wall of the body 1 in time. The viscous powder is scraped to reduce the viscosity, and the push rod 54 and the curved block are passed through the push rod 54 and the curved block by the push of the scraping device 6 by the pressing of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com