A kind of low elastic tile adhesive

A technology of tile adhesive and elasticity, applied in the field of tile adhesive, can solve the problems of poor construction and kneading, low elasticity tile adhesive, not easy to stick and smooth, etc., to improve the quality of paste, reduce cohesion and elasticity, and not easy to empty. drum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] It is prepared from the following components in parts by mass: 370 parts of Portland cement, 50 parts of calcium powder, 100 parts of 30-100 mesh quartz sand, 456.8 parts of 100-180 mesh quartz sand, 5 parts of early strength agent, hydroxyl 2 parts of propyl methyl cellulose ether, 2 parts of guar gum ether, 0.2 parts of starch ether, 4 parts of magnesium aluminum silicate thixotropic thickener, 10 parts of redispersible latex powder. Among them, hydroxypropyl methyl cellulose ether, guar gum ether, starch ether and magnesium aluminum silicate thixotropic thickener are mixed and prepared to form the elasticity regulator.

[0047] Portland cement is gray Portland cement, and the strength grade of Portland cement is 42.5. The specification of calcium powder is 200 mesh. The early strengthening agent adopts calcium formate. The redispersible latex powder adopts ethylene-vinyl acetate copolymer.

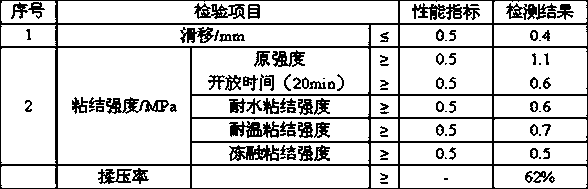

[0048] The mixed powder of Example 1 is mixed with clear water according ...

Embodiment 2

[0052] It is prepared from the following components in parts by mass: 350 parts of Portland cement, 70 parts of calcium powder, 100 parts of 30-100 mesh quartz sand, 456.8 parts of 100-180 mesh quartz sand, 5 parts of early strength agent, hydroxyl 2 parts of propyl methyl cellulose ether, 2 parts of guar gum ether, 0.2 parts of starch ether, 4 parts of magnesium aluminum silicate thixotropic thickener, 10 parts of redispersible latex powder. Among them, hydroxypropyl methyl cellulose ether, guar gum ether, starch ether and magnesium aluminum silicate thixotropic thickener are mixed and prepared to form the elasticity regulator.

[0053]Portland cement is gray Portland cement, and the strength grade of Portland cement is 42.5. The specification of calcium powder is 200 mesh. The early strengthening agent adopts calcium formate. The redispersible latex powder adopts ethylene-vinyl acetate copolymer.

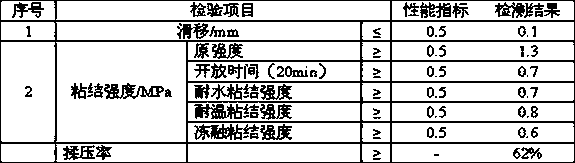

[0054] The mixed powder of Example 2 is mixed with clear water according t...

Embodiment 3

[0058] It is prepared from the following components in parts by mass: 300 parts of Portland cement, 50 parts of calcium powder, 150 parts of 30-100 mesh quartz sand, 456.8 parts of 100-180 mesh quartz sand, 5 parts of early strength agent, hydroxyl 2 parts of propyl methyl cellulose ether, 2 parts of guar gum ether, 0.2 parts of starch ether, 4 parts of magnesium aluminum silicate thixotropic thickener, 10 parts of redispersible latex powder. Among them, hydroxypropyl methyl cellulose ether, guar gum ether, starch ether and magnesium aluminum silicate thixotropic thickener are mixed and prepared to form the elasticity regulator.

[0059] Portland cement is gray Portland cement, and the strength grade of Portland cement is 42.5. The specification of calcium powder is 200 mesh. The early strengthening agent adopts calcium formate. The redispersible latex powder adopts ethylene-vinyl acetate copolymer.

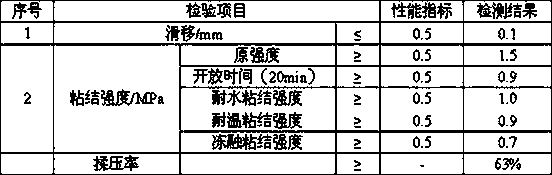

[0060] The mixed powder of Example 3 is mixed with clear water according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com