Strain gauge pasting tool and pasting method

A technology of strain gages and tools, which is applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of inability to paste, limited access to the patch, and difficulty in pasting the strain gauge, so as to achieve convenient and efficient work and good paste quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

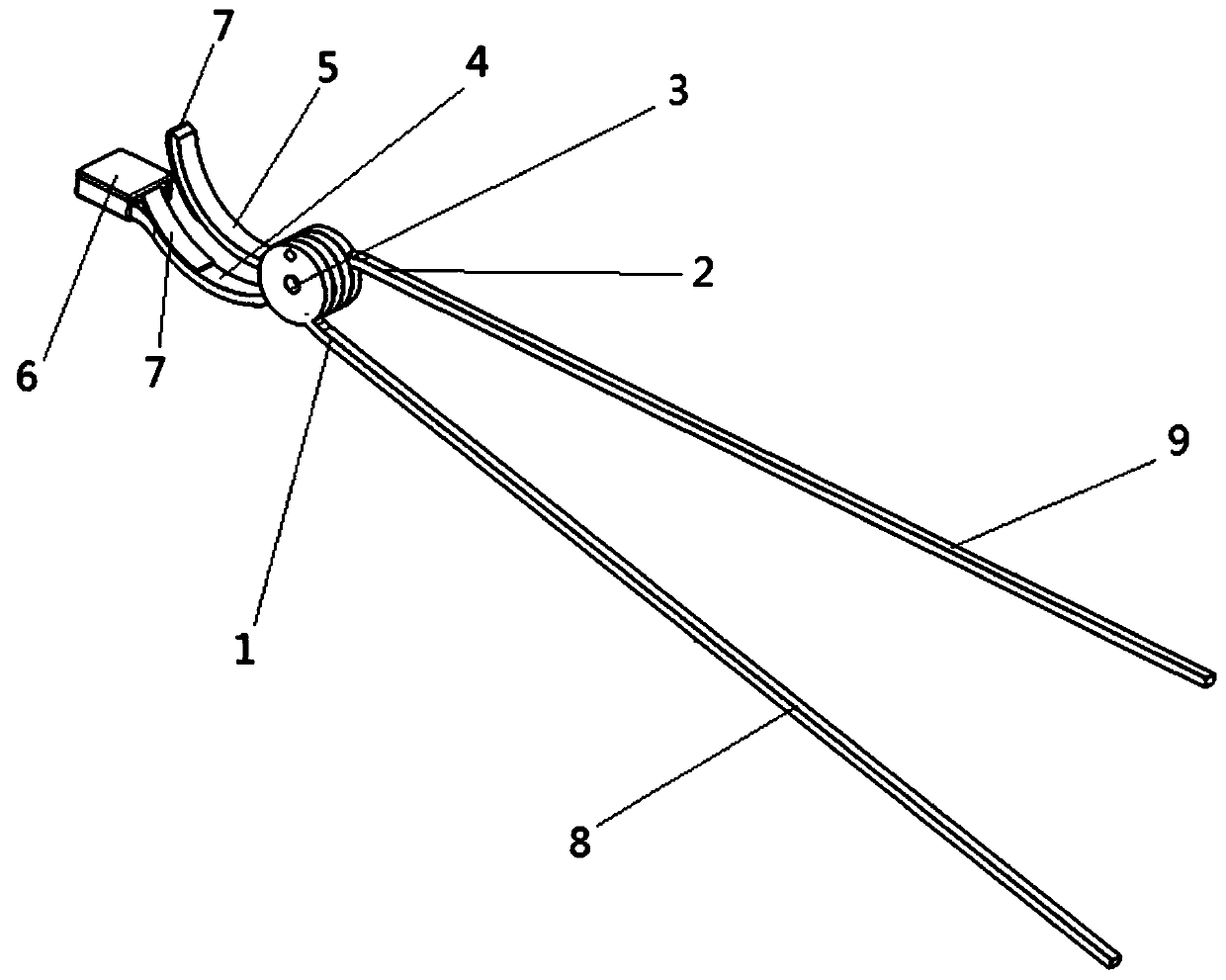

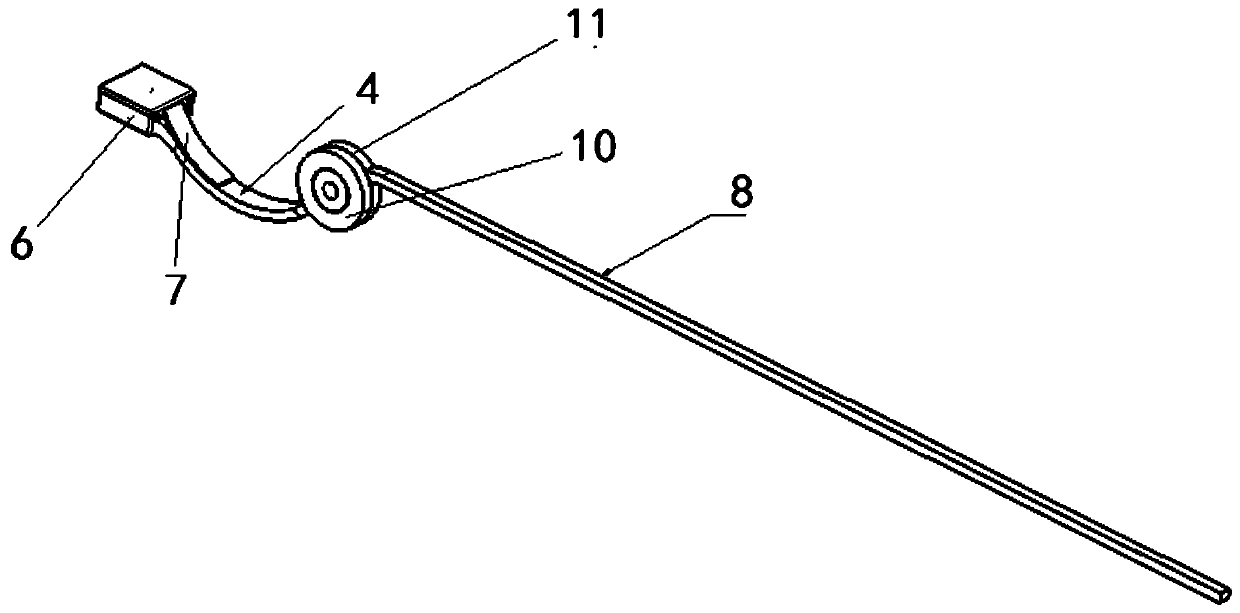

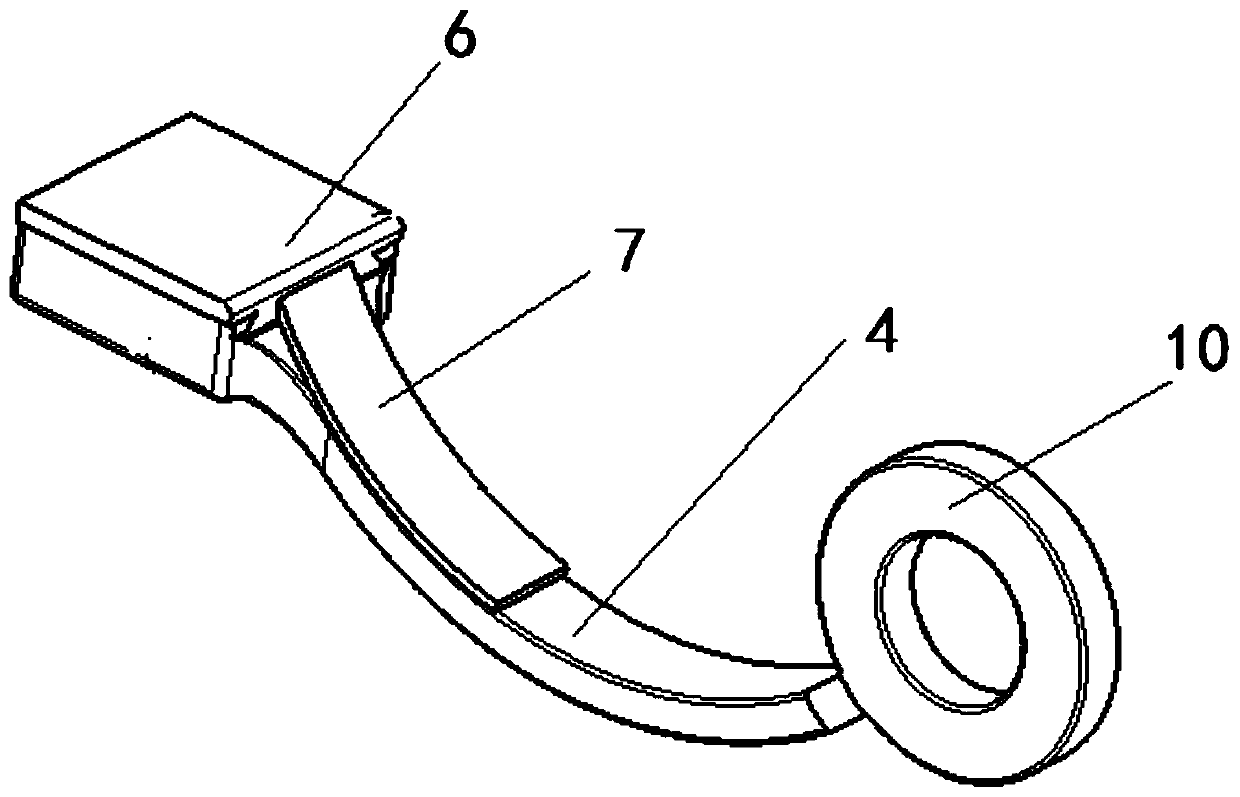

[0020] Referring to the accompanying drawings, the strain gauge sticking tool of the present application includes a first handle 1 and a second handle 2, and the proximal ends of the first handle 1 and the second handle 2 are hinged by a pin shaft 3, and the first handle 1 The front end is the first clamping handle 4, the front end of the second handle 2 is the second clamping handle 5, the first clamping handle 4 cooperates with the second clamping handle 5, and the front end of the first clamping handle 4 has a Pasting station 6 corresponding to the strain gauge.

[0021] In order to prevent the adhesive from sticking to the sticking table 6 when the strain gauge is pasted, a plastic non-stick layer is inlaid on the upper surface of the sticking table. Plastic non-stick patch.

[0022] The first clamping handle 4 and the second clamping handle 5 are an arc-shaped structure that is sunken relative to the pasting table 6. Such a structure makes the pasting table 6 protrude re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com