Environment-friendly concrete

An environmentally friendly concrete and mixture technology, applied in the field of concrete, can solve the problems of reduced waterproof performance of concrete, lower waterproof performance, lower waterproof performance, etc., and achieve the effects of improving frost resistance, increasing strength and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

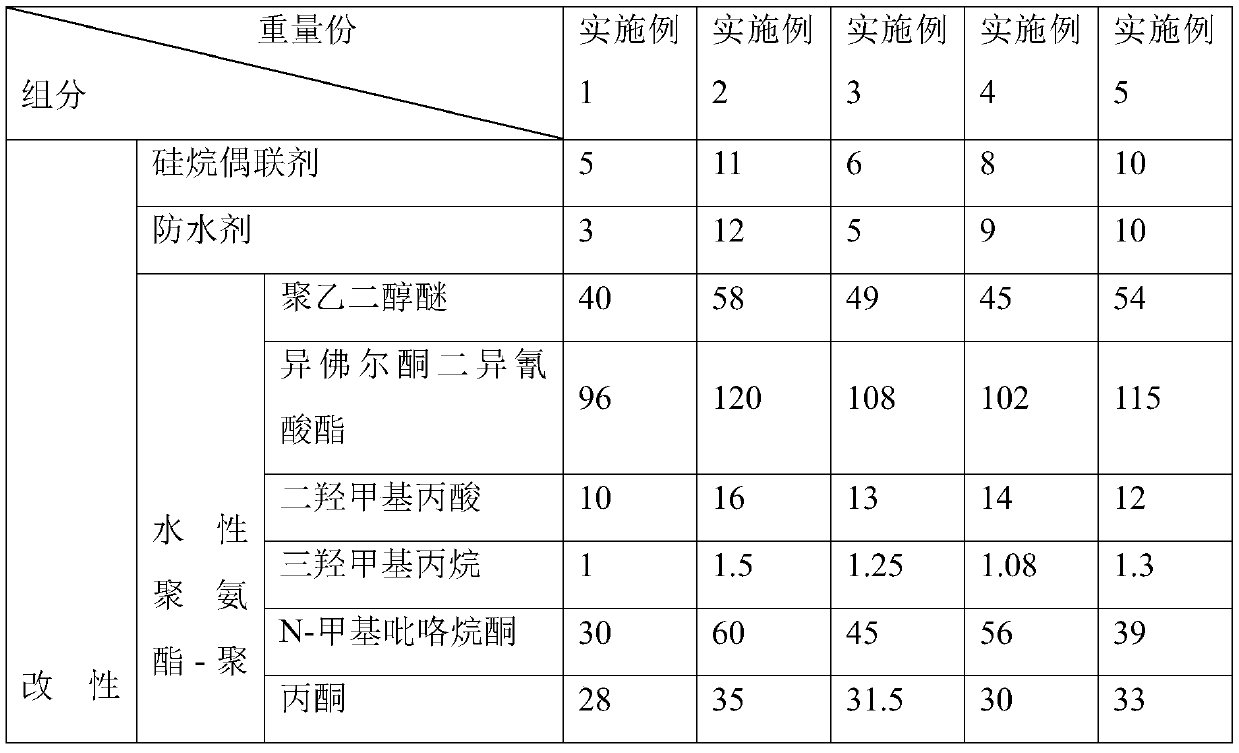

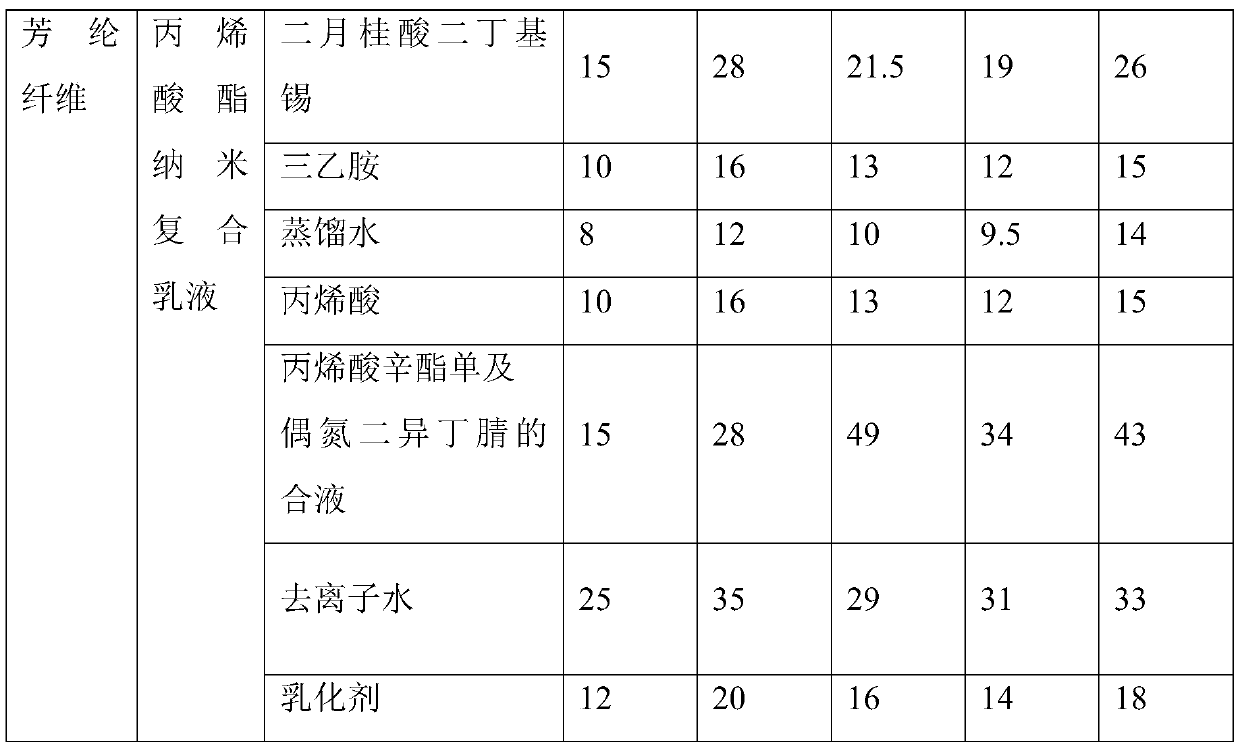

[0058] A kind of environment-friendly concrete, its component and corresponding parts by weight are as shown in Table 1, and obtain through following steps preparation:

[0059] In the first step, cement, river sand, and crushed stones in corresponding parts by weight are mixed, and mechanically stirred for 20 minutes to stir evenly to obtain the first mixture.

[0060] In the second step, the fly ash, rosin soap, calcium lignosulfonate and aramid fiber in corresponding parts by weight are fully mixed, and uniformly stirred for 15 minutes to prepare the second mixture.

[0061] In the third step, the first mixture and the second mixture were uniformly mixed and stirred for 25 minutes to obtain the third mixture, which was prepared by mixing and stirring the corresponding parts by weight of chlorinated paraffin, epoxy resin emulsion and deionized water of corresponding parts by weight The fourth mixture, adding the fourth mixture to the third mixture while stirring, stirring an...

Embodiment 2

[0084] A kind of environment-friendly concrete, the difference with embodiment 1 is:

[0085] Its components and corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0086] In the first step, cement, river sand, and crushed stones in corresponding parts by weight are mixed, and mechanically stirred for 25 minutes to stir evenly to obtain the first mixture.

[0087] In the second step, the fly ash, rosin soap, calcium lignosulfonate and aramid fiber in corresponding parts by weight are fully mixed, and uniformly stirred for 20 minutes to prepare the second mixture.

[0088] In the third step, the first mixture and the second mixture were uniformly mixed and stirred for 30 minutes to obtain the third mixture, and the corresponding parts by weight of the epoxy resin emulsion and the deionized water of the corresponding parts by weight were mixed and stirred to obtain the fourth mixture, The fourth mixture was added into the third mixt...

Embodiment 3

[0104] A kind of environment-friendly concrete, the difference with embodiment 1 is:

[0105] Its components and corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0106] In the first step, cement, river sand, and crushed stones in corresponding parts by weight are mixed, and mechanically stirred for 30 minutes to stir evenly to obtain the first mixture.

[0107] In the second step, the fly ash, rosin soap, calcium lignosulfonate and aramid fibers in corresponding parts by weight are fully mixed and uniformly stirred for 25 minutes to prepare the second mixture.

[0108] In the third step, the first mixture and the second mixture were mixed uniformly and stirred for 40 minutes to obtain the third mixture, and the corresponding parts by weight of the epoxy resin emulsion and the deionized water of the corresponding parts by weight were mixed and stirred to obtain the fourth mixture, The fourth mixture was added into the third mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com