Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Meet the grinding requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

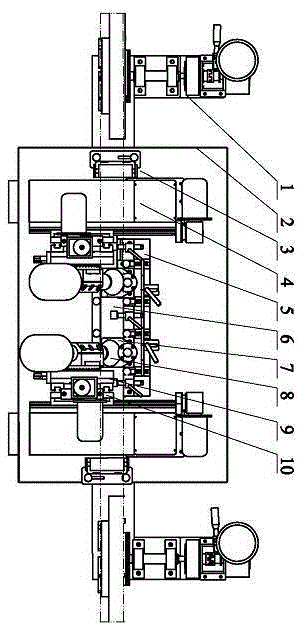

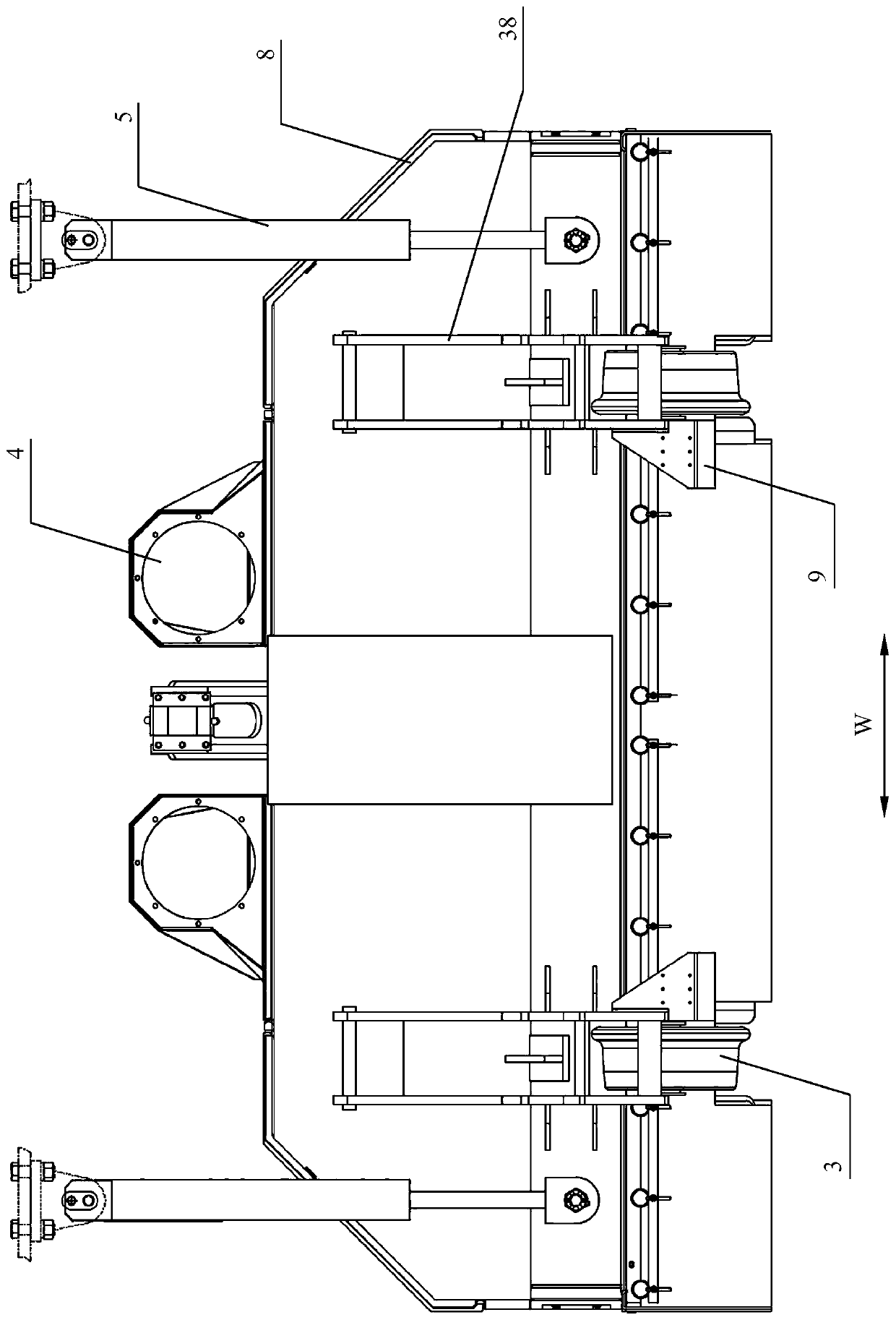

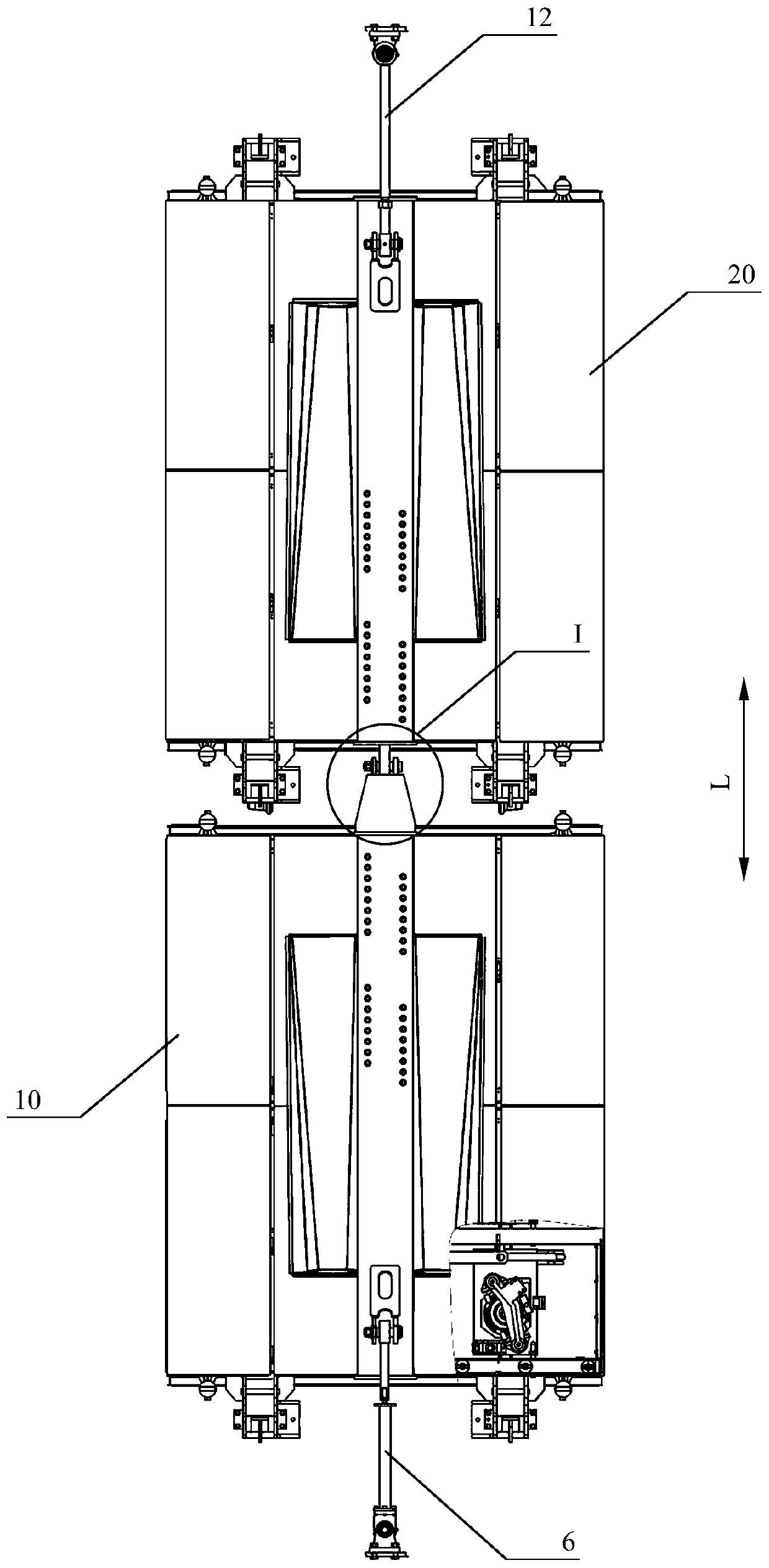

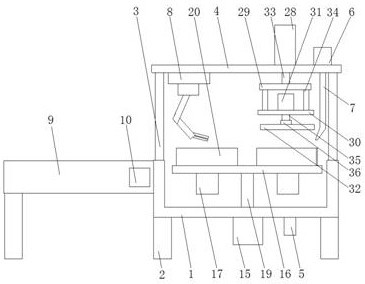

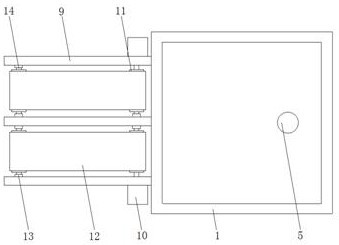

Large wind power blade multi-robot collaboration grinding system and method

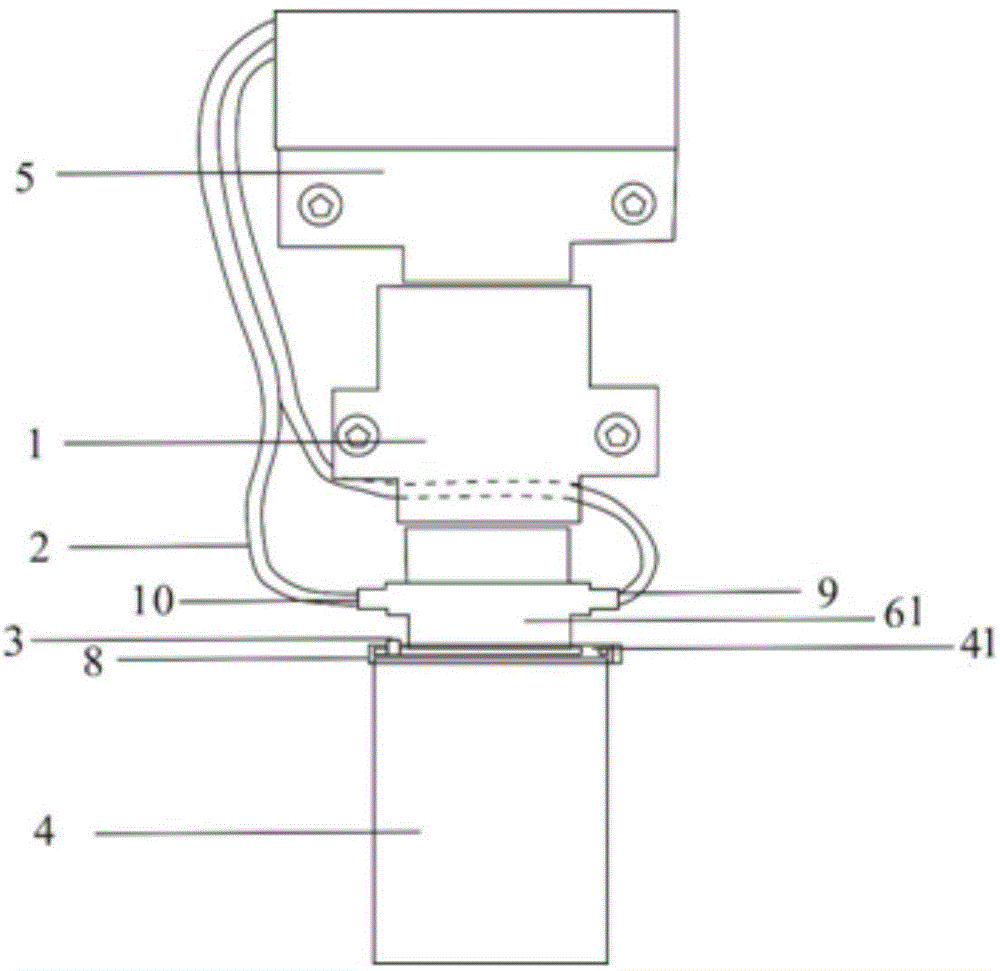

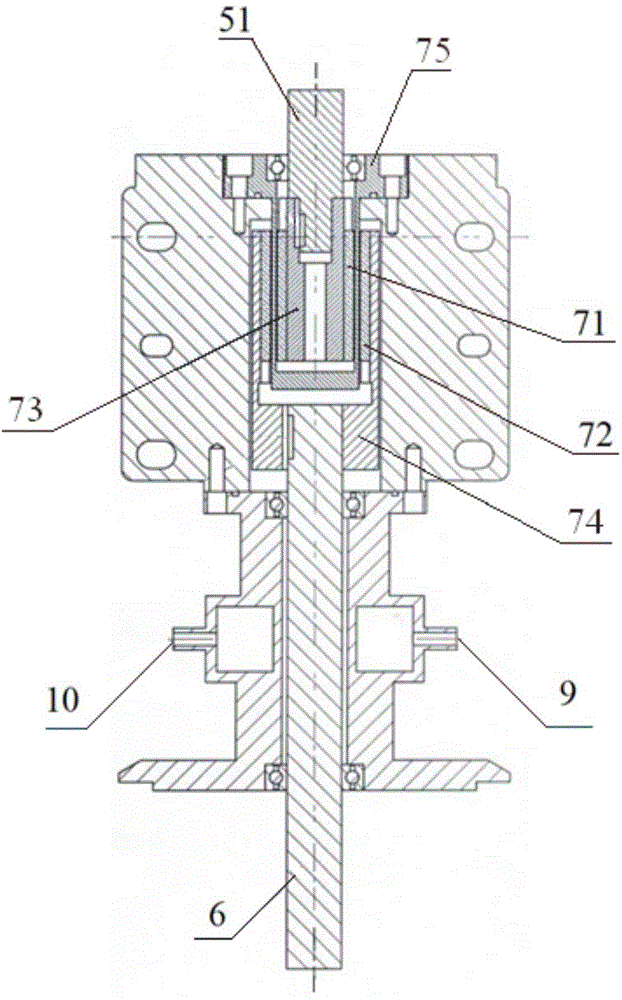

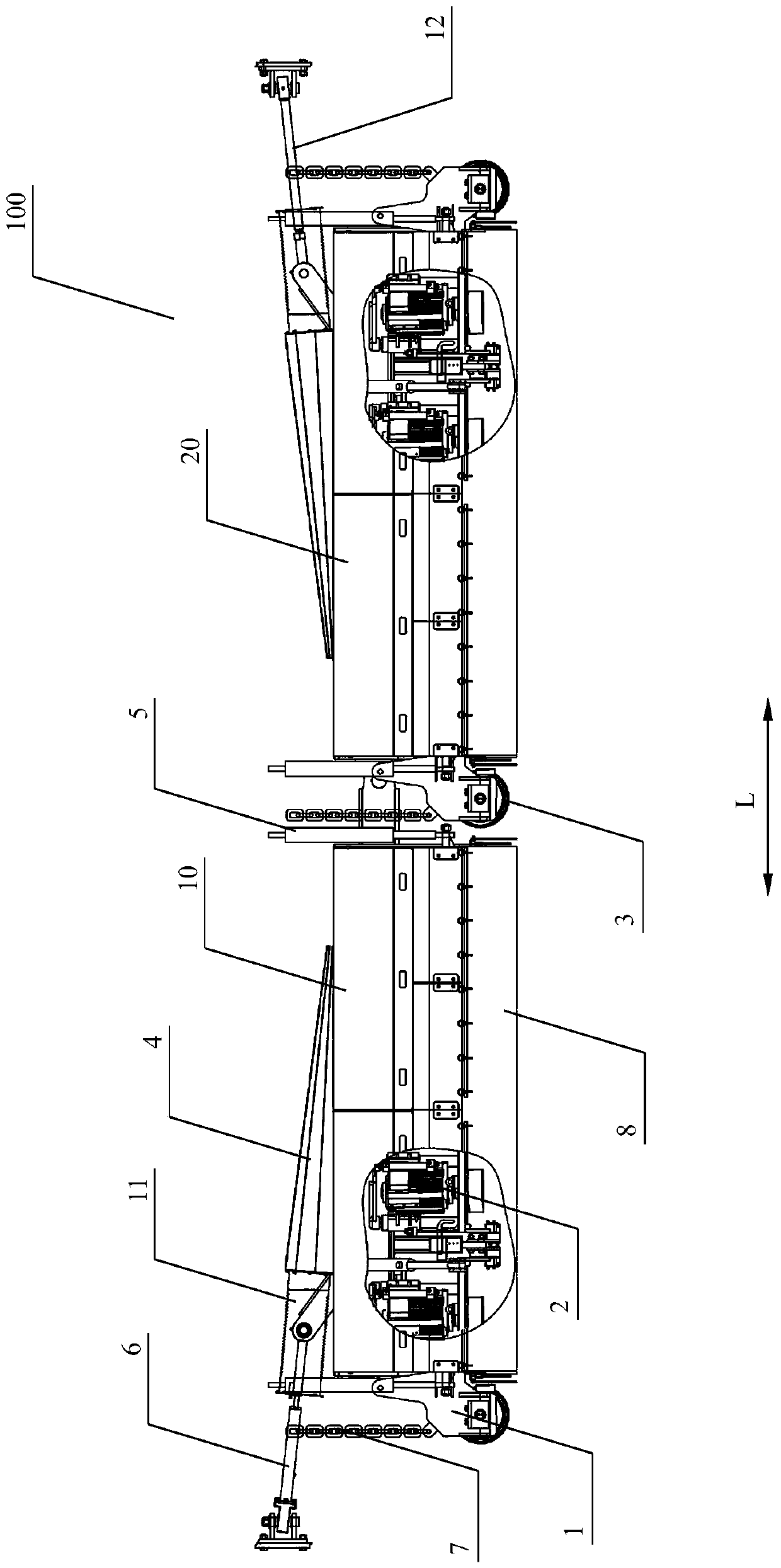

InactiveCN105538095AMeet the grinding requirementsReduce distortionGrinding feed controlAutomatic grinding controlElectricityEngineering

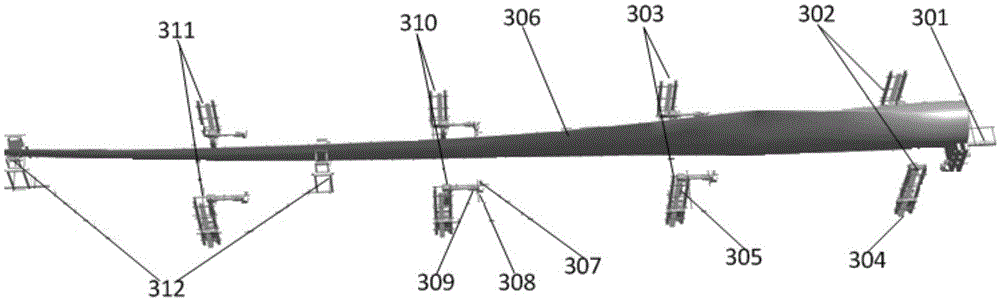

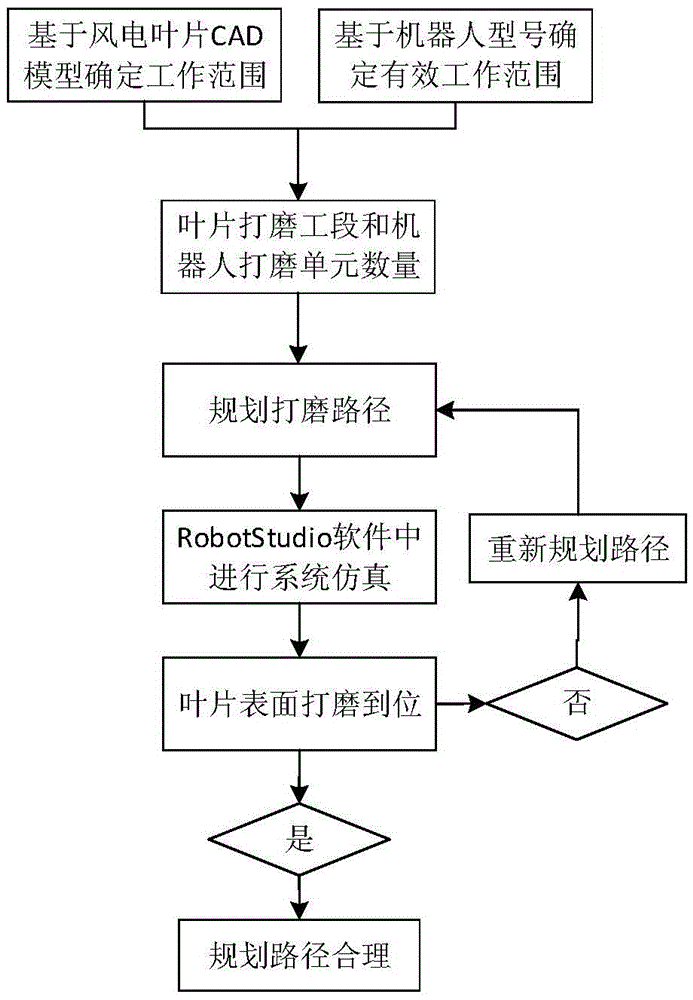

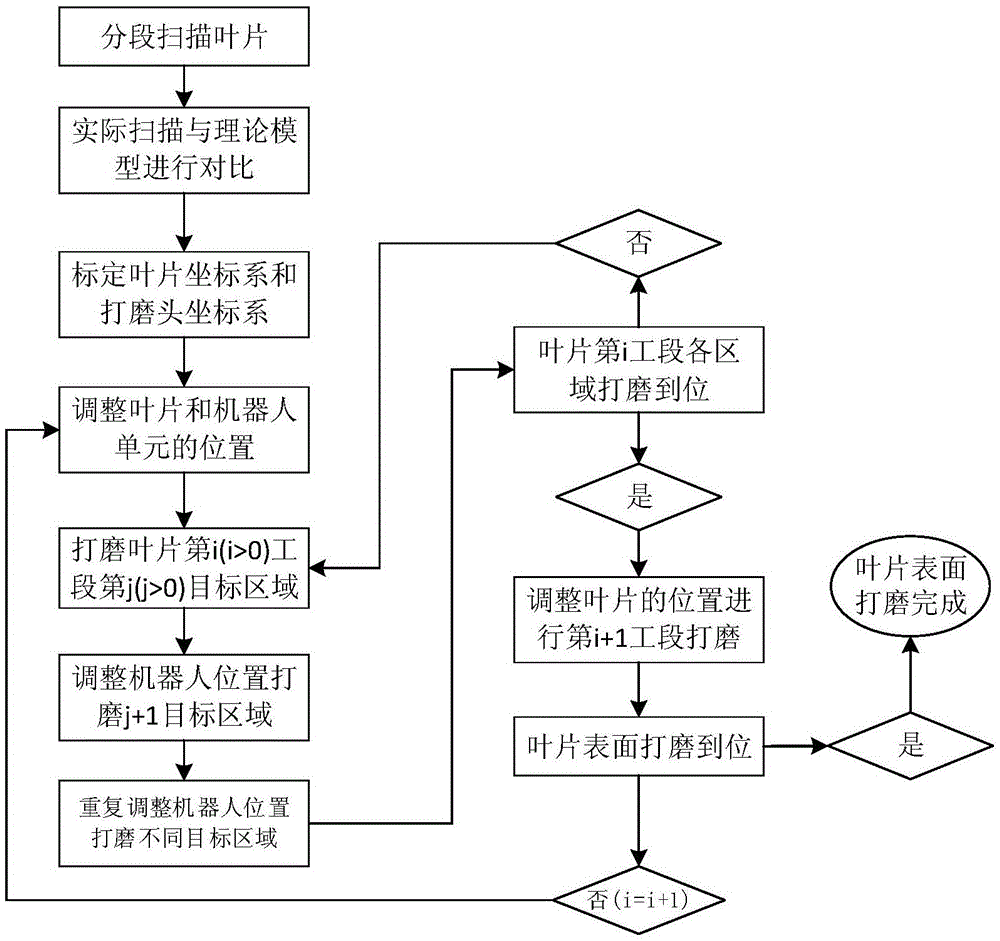

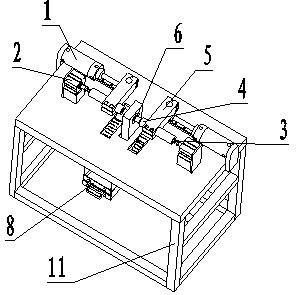

The invention discloses a large wind power blade multi-robot collaboration grinding system and a method. The grinding system comprises a workpiece horizontal guide rail, N robot grinding units, robot control cabinets and a system control cabinet. Each robot grinding unit comprises two robots and vertical guide rails, grinding heads, scanning detectors and force control devices corresponding to the two robots. According to the large wind power blade multi-robot collaboration grinding system, the collaborative movement of the workpiece horizontal guide rail, the vertical guide rails and the robots isrealized through a control command; the robots drive the grinding heads to grind a workpiece according to planned routes; the labor intensity of workers is greatly lowered; meanwhile, the two robots of each robot grinding unit collaboratively work, so that the corresponding grinding heads grind the surface of the blade and leave the surface of the blade simultaneously, and grinding pressure on two sides of the blade can be basically offset; the deformation of the blade is effectively reduced; and the surface quality and machining efficiency of the blade are improved. The large wind power blade multi-robot collaboration grinding system has the characteristics of high automation degree, safety, stability, high efficiency, high flexibility and transportability.

Owner:无锡中车时代智能装备研究院有限公司

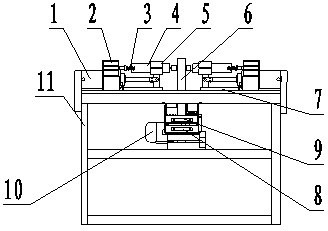

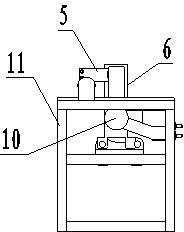

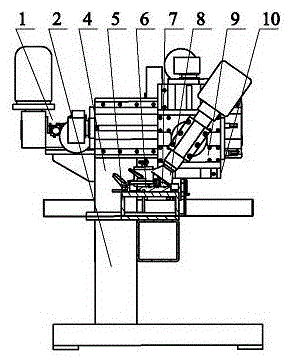

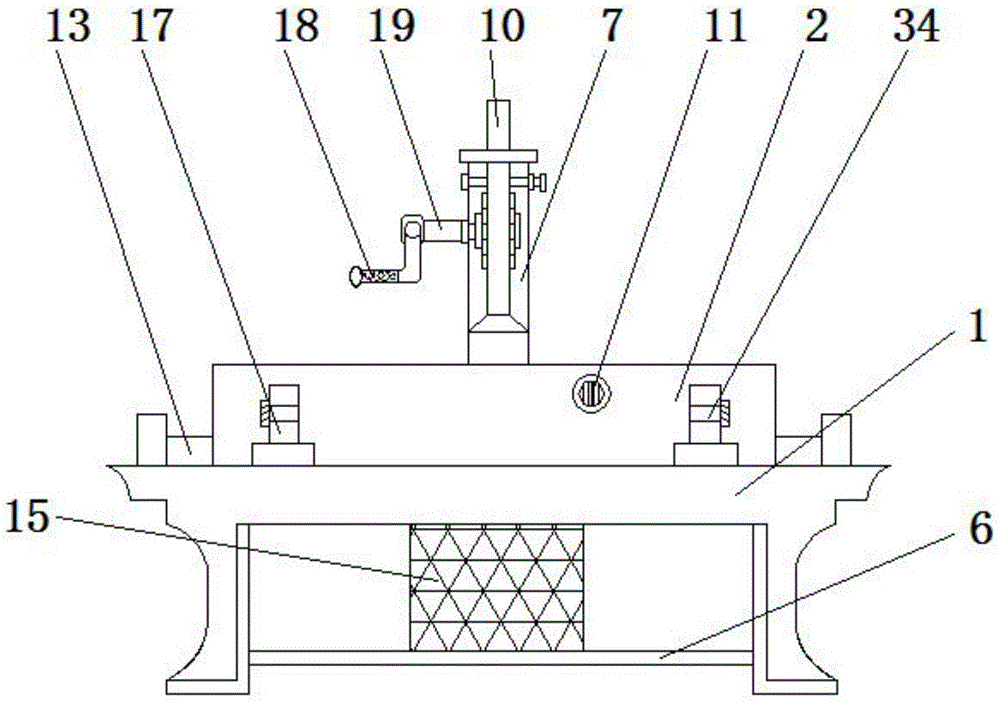

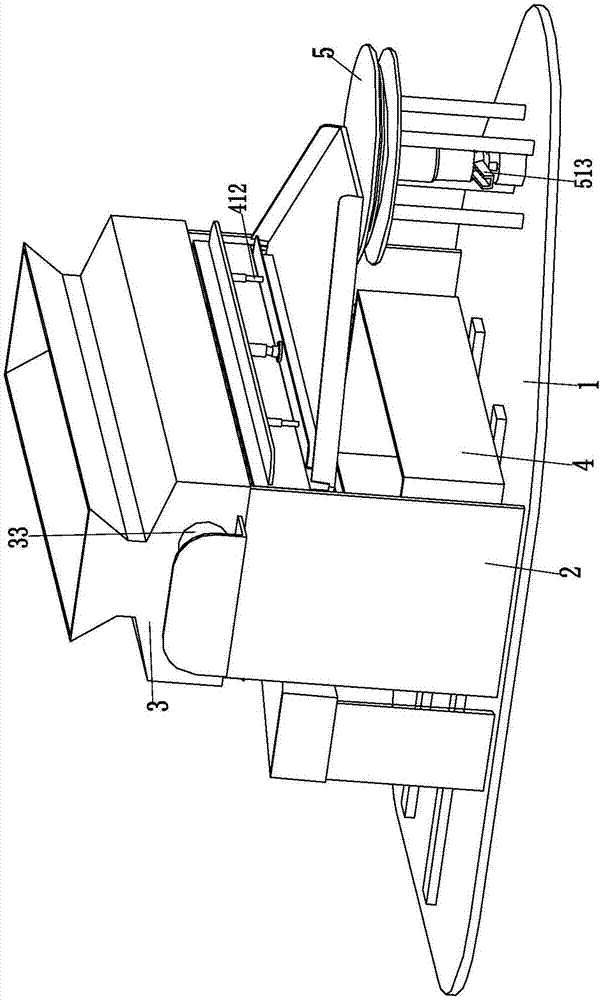

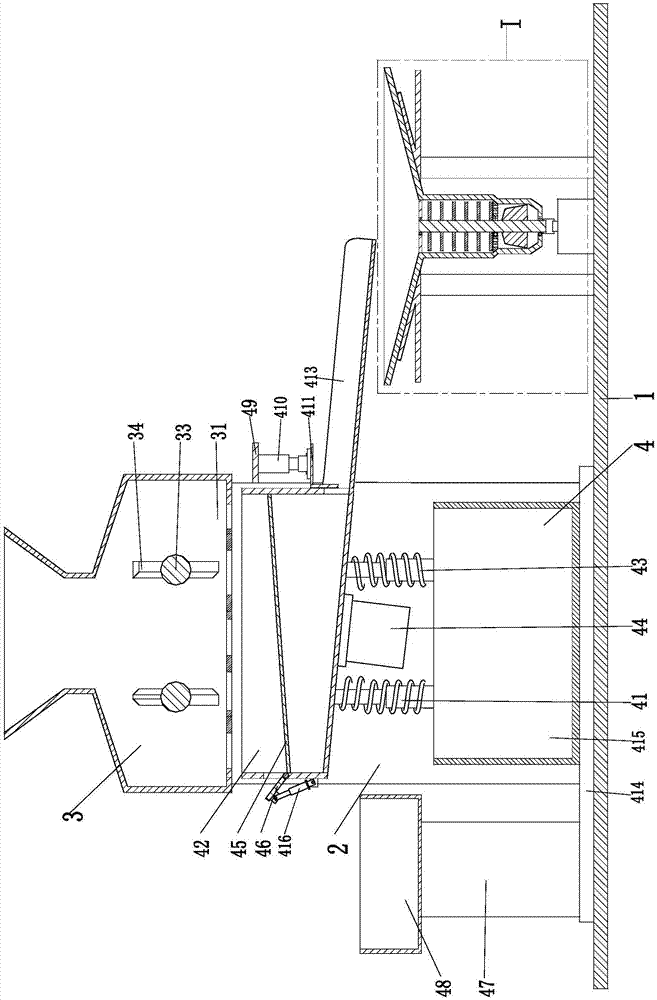

Table device for polishing electrode caps

InactiveCN102672577AMeet the grinding requirementsPrevent water leakageGrinding machinesGrinding/polishing safety devicesProduction lineEngineering

The invention relates to a table device for polishing electrode caps, which is used for solving the problems existing in the process of polishing the electrode caps of resistance welding tongs. The device comprises a motor and speed reduction mechanism, a polishing cutter, an electrode cap installing and pushing mechanism, a discharging mechanism, a worktable and an electric control system, wherein the motor and speed reduction mechanism is arranged below a table top of the worktable and connected with the polishing cutter; the polishing cutter is provided with two sets of blades for supporting the simultaneous polishing of left and right electrode caps, is positioned at the middle position of the table top of the worktable, and is arranged in an axial floating mode; and each of the electrode cap installing and pushing mechanism and the discharging mechanism comprises two eudipleural parts and is arranged on the table top of the worktable. The device has the characteristic of high automation degree, is convenient to operate and maintain, can ensure the polishing quality of the electrode caps, improves the polishing efficiency of the electrode caps, and is maintenance equipment necessary for a welding production line.

Owner:GREAT WALL MOTOR CO LTD

Process for producing super-soft sand cloth

The invention belongs to the field of coated abrasive tools, and relates to a process for producing super-soft sand cloth, comprising the steps of base cloth treatment, base glue application, sand planting, composite glue application and after treatment. The process for producing the super-soft sand cloth is characterized in that adhesives used for base cloth treatment comprises latex and resin, and comprises the following components in percentage by weight: 75-92 percent of latex, 5-20 percent of epoxide resin and 1-5 percent of thickening agent; and meanwhile, polyurethane is adopted for modifying main adhesives such as phenol-formaldehyde resin and the like, and the main adhesives comprises the following components in percentage by weight: 15-35 percent of polyurethane elastomer, 60-80 percent of phenol-formaldehyde resin, 2-5 percent of accelerator and 2-4 percent of curing agent. The sand cloth product produced by the process has good grinding and adhesion performances, remarkably improved plasticity and elasticity, and the characteristic of small bending radius, and can satisfy the grinding requirement of workpieces with complicated surfaces and slim slotted hole type special workpieces.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

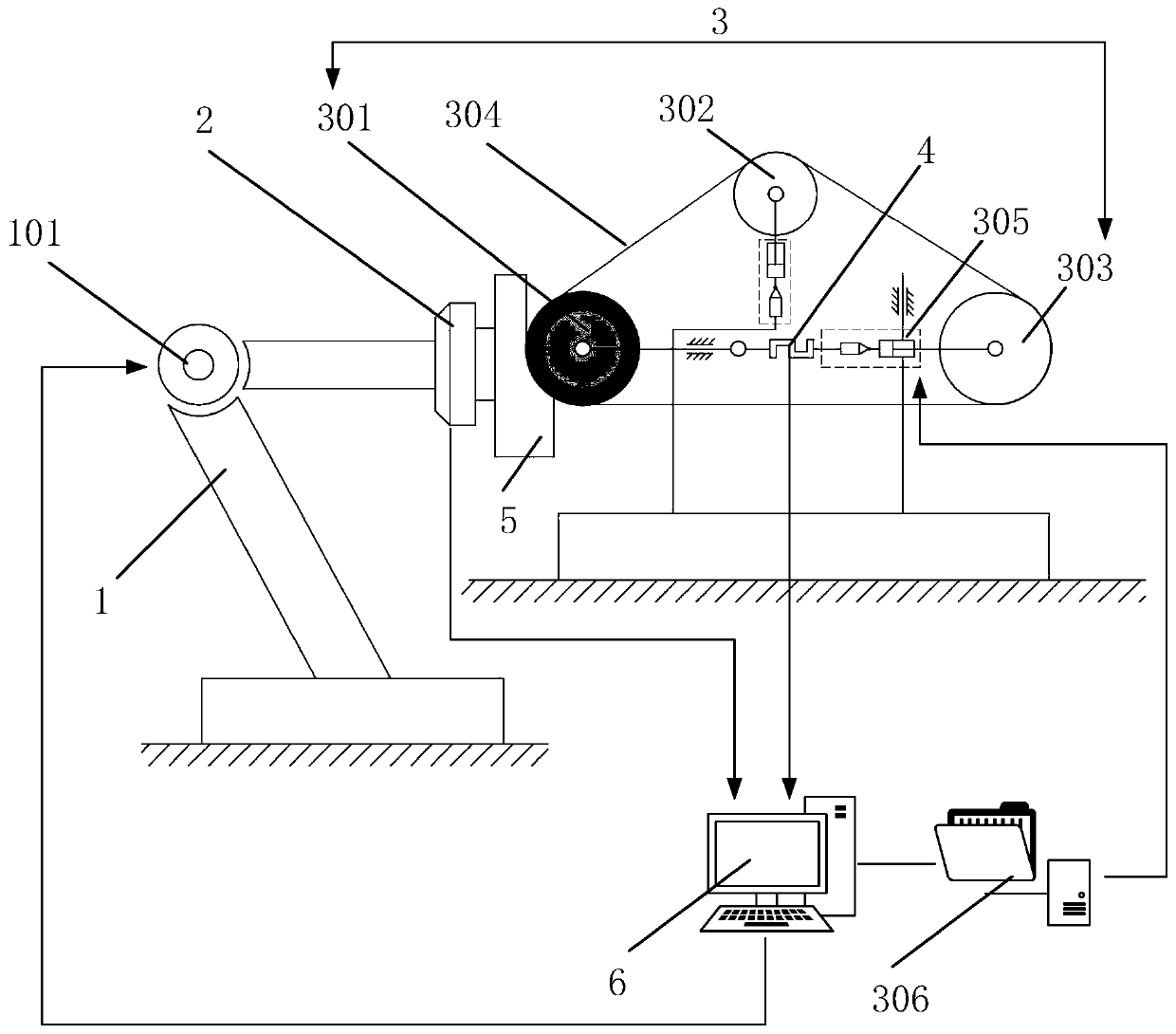

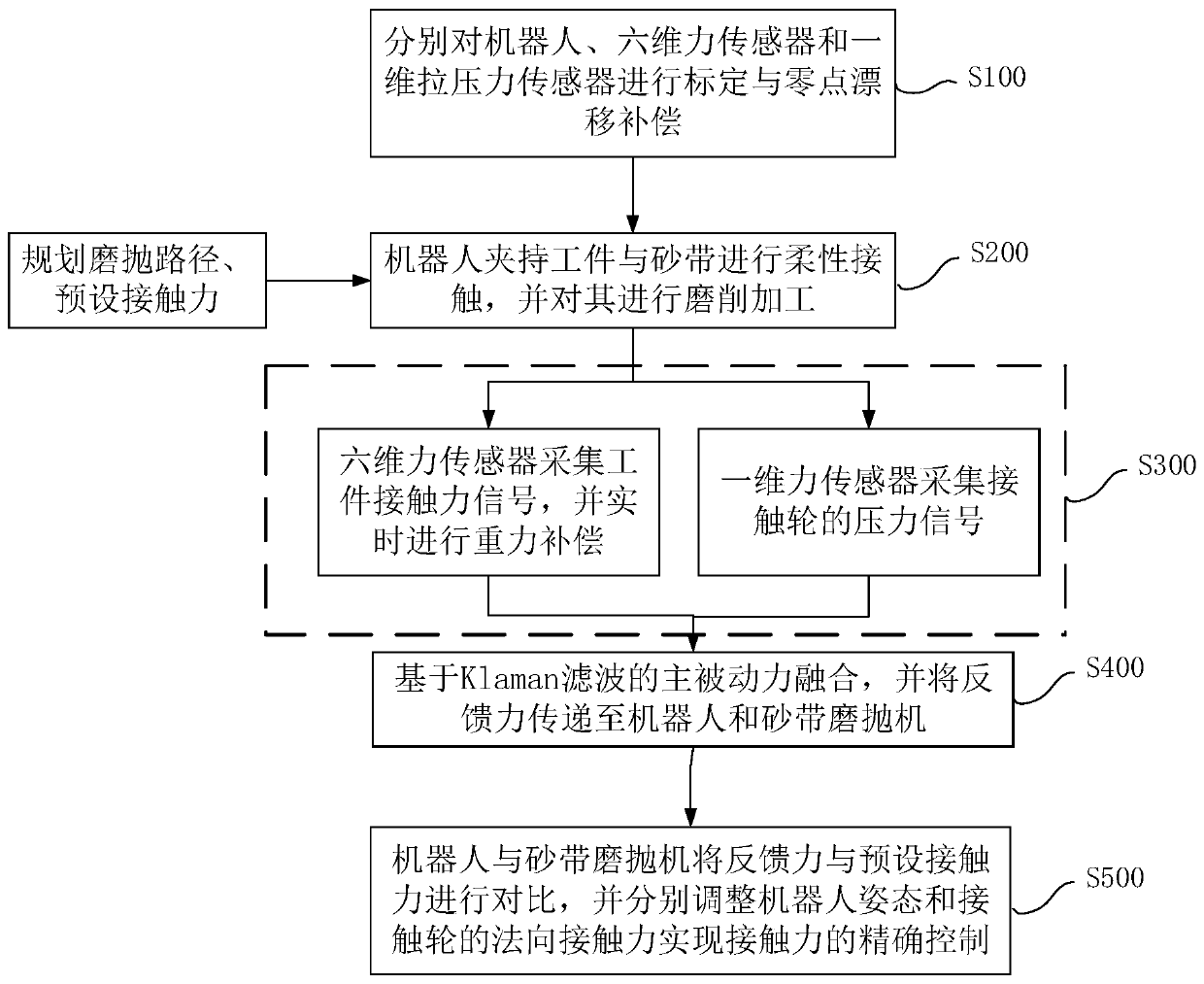

Robot abrasive belt grinding method and system combining active and passive force control

ActiveCN110561237AHigh control precisionGuaranteed Removal ConsistencyBelt grinding machinesGrinding feed controlMaterial removalControl engineering

The invention discloses a robot abrasive belt grinding method combining active and passive force control. The method comprises the steps of S100, calibrating a robot, an active force sensor and a passive force sensor; S200, enabling the robot to clamp a workpiece to make flexible contact with an abrasive belt, and grinding the workpiece; S300, enabling the active force sensor to collect a contactforce signal of a workpiece in real time, carrying out real-time gravity compensation to obtain an active contact force signal, and enabling a one-dimensional force sensor to real-time collect a passive force signal of a contact wheel; S400, on the basis of the Kalman filtering method, carrying out information fusing on the active contact force signal and the passive force signal to obtain a feedback force signal; and S500, enabling the robot and an abrasive belt grinding and polishing machine to compare the feedback force and the preset contact force. The invention further discloses a grinding system. According to the method, the control precision of the contact force in the grinding machining environment of the robot is effectively improved; and on the other hand, the over and under grinding phenomena generated in the grinding process can be optimized, and material removal consistency of a machining workpiece and good surface roughness can be ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

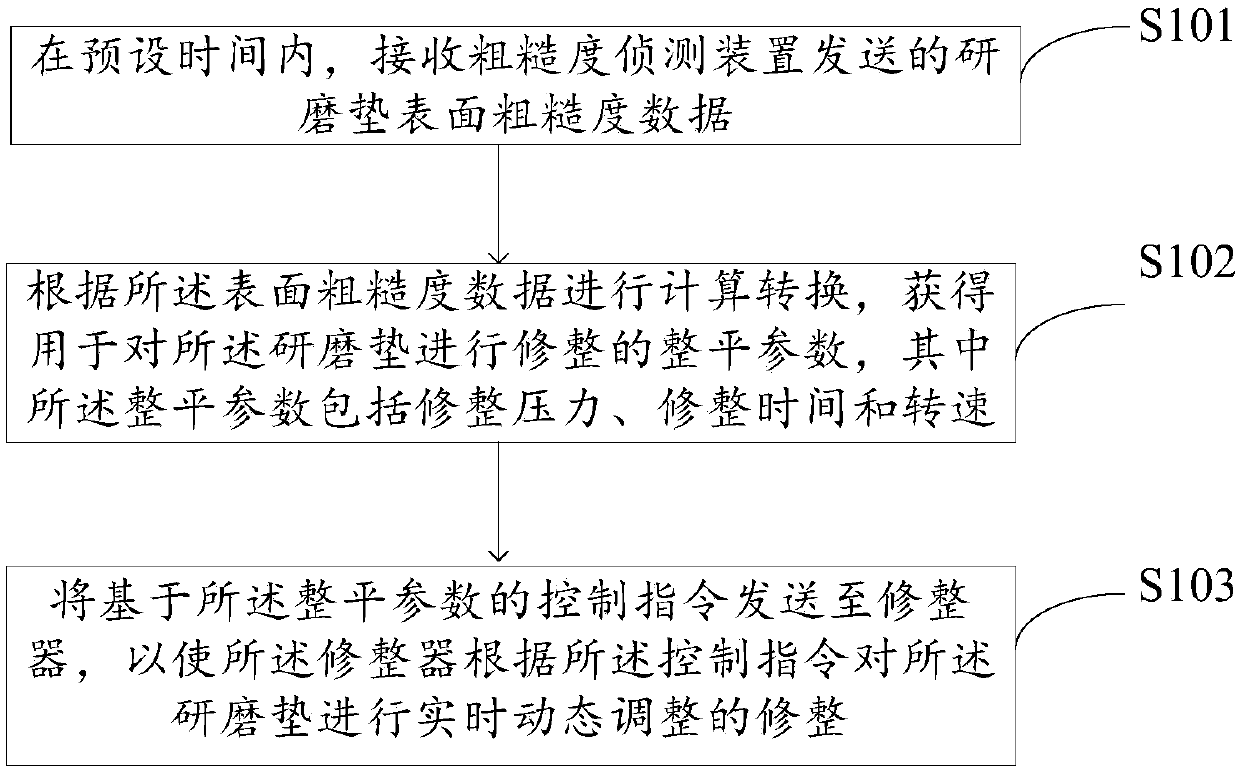

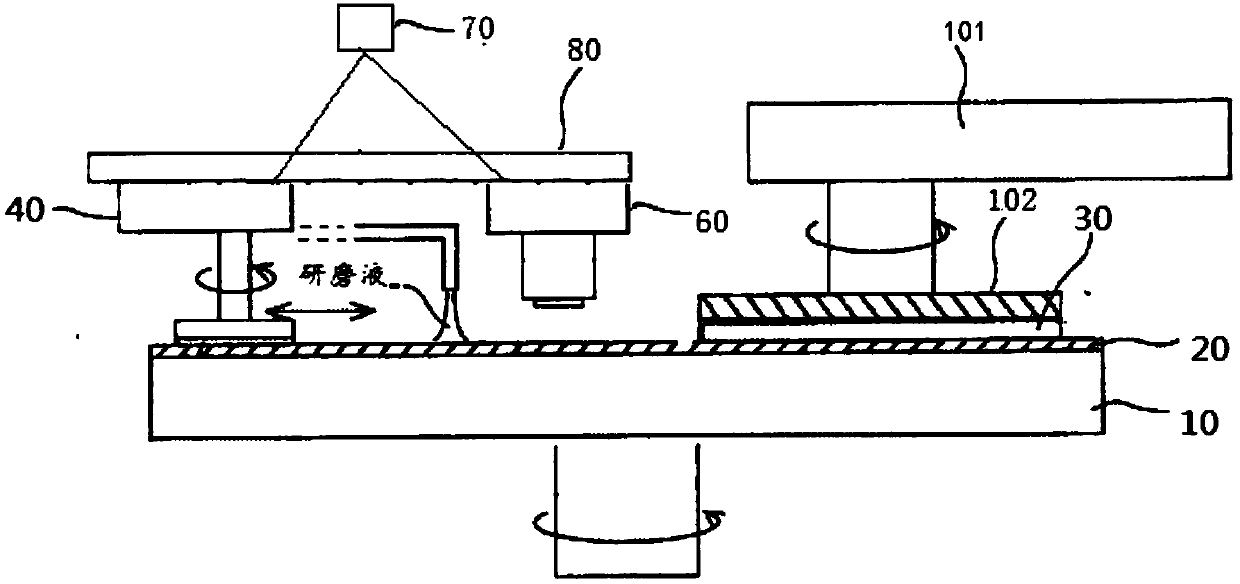

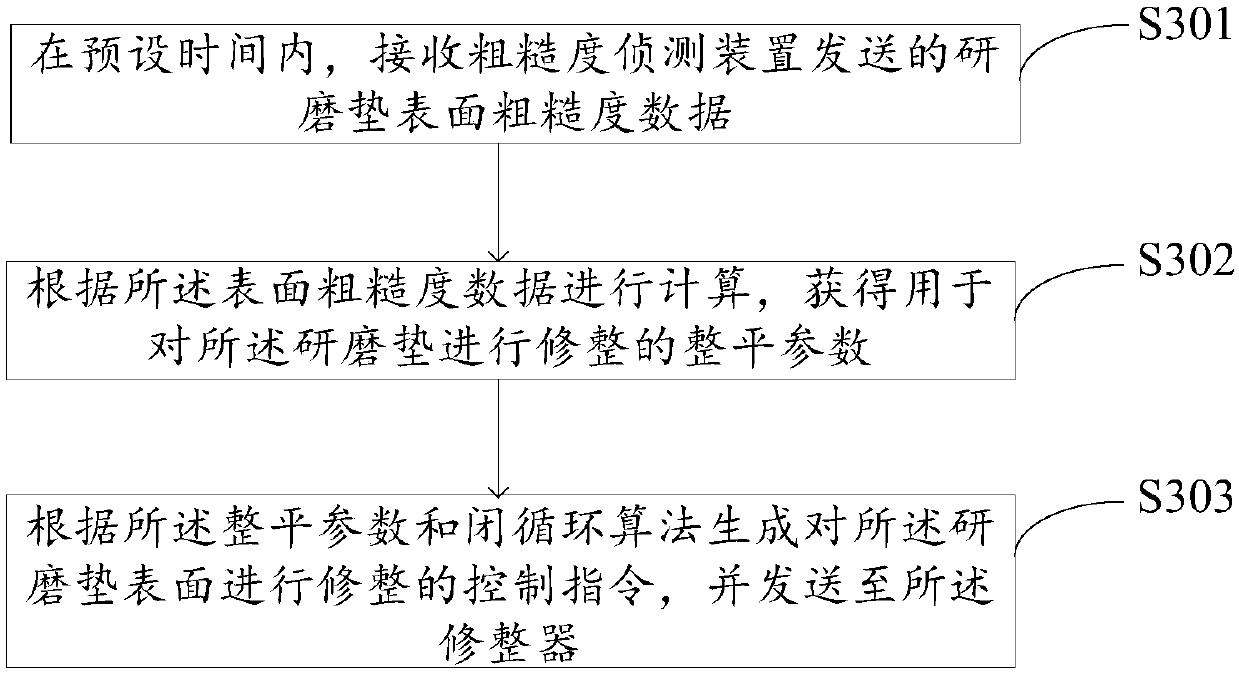

Conditioning method for polishing pad, and chemical-mechanical polishing method and device

InactiveCN109702650AGet roughness data in real timeMeet grinding requirementsLapping machinesAbrasive surface conditioning devicesSurface roughnessEngineering

The invention provides a conditioning method for a polishing pad, and a chemical-mechanical polishing method and device. The conditioning method for the polishing pad comprises the steps of receivingsurface roughness data of the polishing pad sent by a roughness detecting device within a preset time, wherein the surface roughness data is obtained by using the roughness detecting device to measurethe surface of the polishing pad; performing calculation conversion according to the surface roughness data to obtain leveling parameters for conditioning of the polishing pad, wherein the leveling parameters include conditioning pressure, conditioning time and rotation speed; and sending a control command based on the leveling parameters to a conditioner to enable the conditioner to condition the polishing pad in a real-time dynamic adjustment way according to the control command. The conditioning method adopting the technical scheme has the following advantages that the roughness data of the surface of the polishing pad can be obtained in real time, and the surface of the polishing pad is conditioned in real time according to the roughness data so that the surface roughness of the polishing pad can meet the polishing requirement, and thus the polishing performance can be improved.

Owner:CHANGXIN MEMORY TECH INC

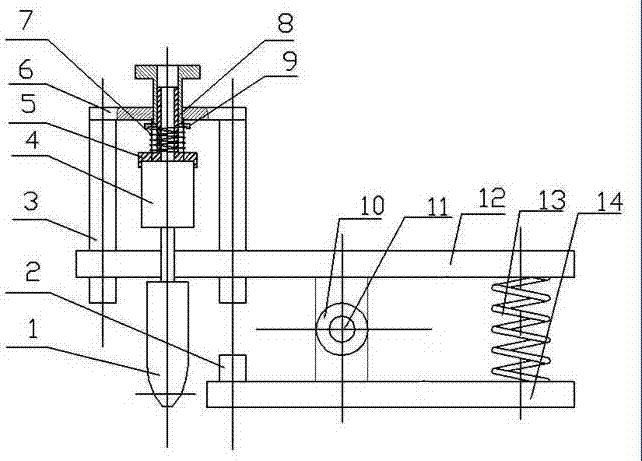

Steel belt scraper grinding machine

ActiveCN105538056AMeet the grinding requirementsReliable clampingGrinding carriagesGrinding drivesPrinting inkSteel belt

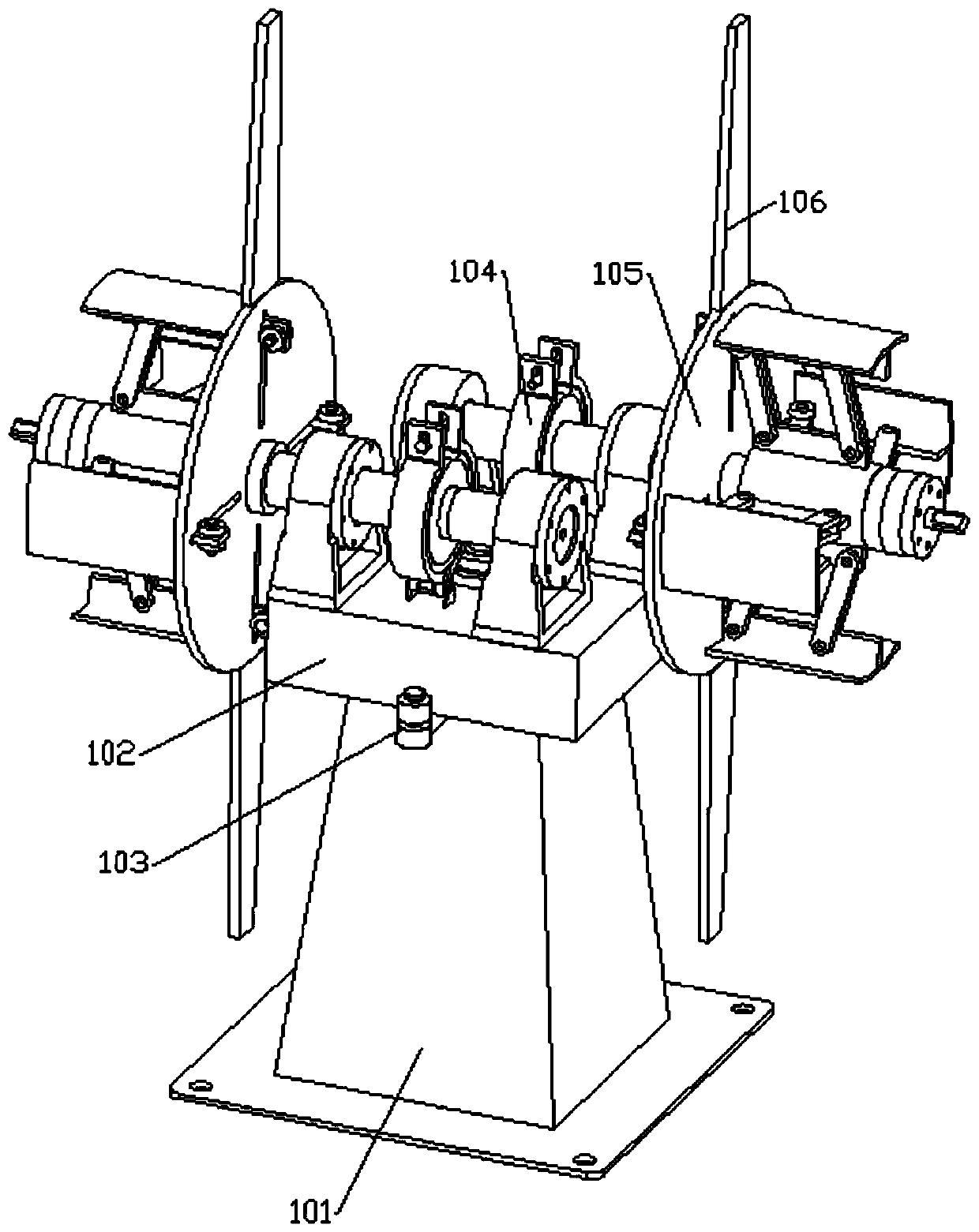

The invention discloses a steel belt scraper grinding machine which comprises a rack and a grinding head supported on the rack, wherein the two ends of the rack are respectively provided with steel belt scraper roll grinding drive mechanisms; each steel belt scraper roll grinding drive mechanism comprises a steel belt roll mounting shaft and a drive device; one end of each steel belt roll mounting shaft is in transmission connection to each drive device through a clutch; a tension control device is further mounted on each steel belt roll mounting shaft; the other end of each steel belt roll mounting shaft is provided with a steel belt roll clamping device; a pedestal is arranged on the rack; a workbench is arranged on the pedestal; a pressure plate is arranged above the workbench; the pressure plate is arranged in an adjustable mode relative to the workbench; a steel belt guide wheel is further arranged on the pedestal; and the working position of the grinding head corresponds to the position of the pressure plate. The steel belt scraper grinding machine disclosed by the invention can be adopted to efficiently complete grinding of a cutting edge of a steel belt roll type printing ink scraper, is simple and compact in structure, and is small in occupied space.

Owner:江苏贝斯特数控机械有限公司

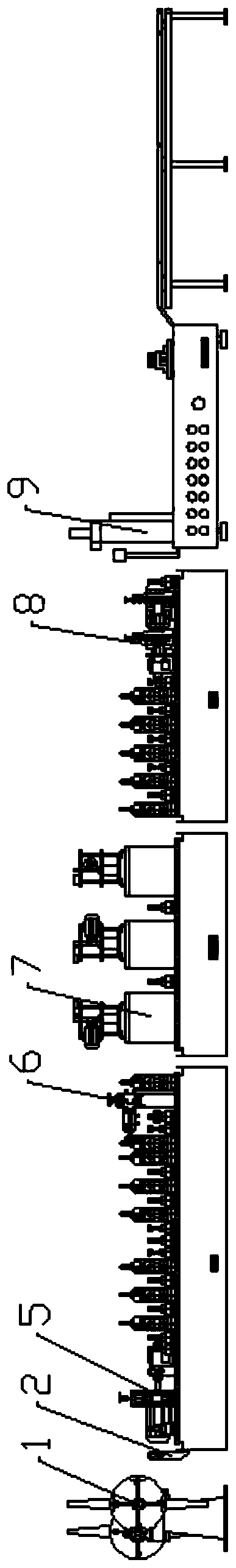

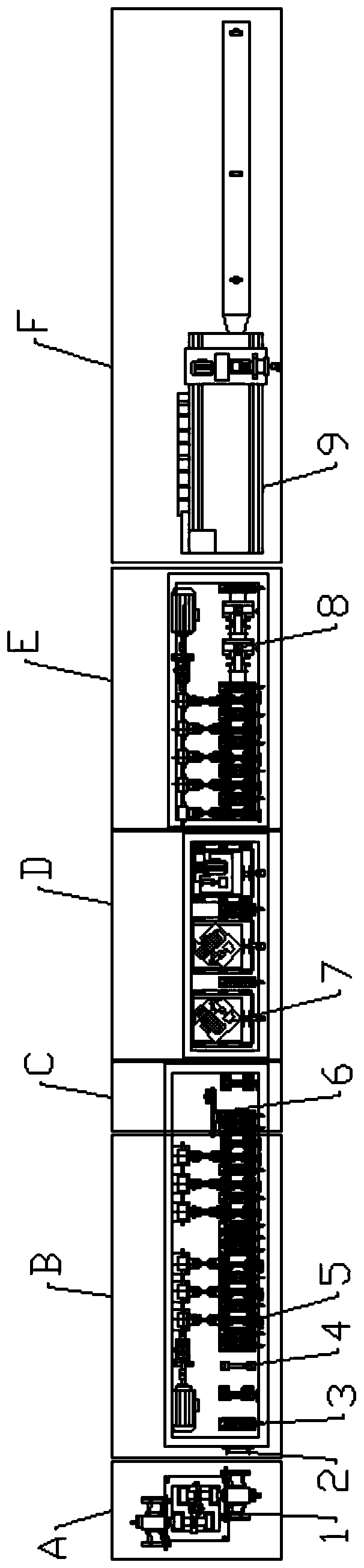

Pipe making machine

PendingCN109909756AEasy to unloadHigh unwinding efficiencyOther manufacturing equipments/toolsSheet steelPipe fitting

The invention discloses a pipe making machine which comprises an unwinding area, a forming area, a welding area, a polishing area, a straightening area and a cutting area. The unwinding area, the forming area, the welding area, the polishing area, the straightening area and the cutting area are sequentially arranged along a roll material steel plate conveying direction. An unwinding shelf is placed in the unwinding area and is used for placing roll material steel plates; multiple groups of pipe fitting forming mechanisms are placed in the forming area and are used for gradually forming the steel plates into round pipes; and a welding mechanism is placed in the welding area and is used for welding gaps on the round pipes. The pipe making machine has the beneficial effects that (1) by applying the unwinding shelf to the pipe making machine, materials can be conveniently unwinded and winded, so that the material unwinding and winding efficiency is high, and the 'zero' time for replacementcan be realized by adopting double-station unwinding; and (2) by adopting the side wheel seat forming mechanism, a right-and-left threaded screw rod drives two slide block nuts to gather together toward the middle or be separated toward two sides at the same time, so that the position of a forming mould is quickly adjusted; and the positions of the upper ends of two fixed shafts are adjusted andlimited through an adjusting assembly, so that the position stability of the forming mould in production engineering is ensured.

Owner:全南阳城机械制造有限公司

Production device for ductile iron pipe fittings

ActiveCN110695825AIncrease costEasy to grind separatelyEdge grinding machinesRevolution surface grinding machinesHydraulic cylinderPipe fitting

The invention discloses a production device for ductile iron pipe fittings, relates to the technical field of production of ductile iron pipe fittings, and solves the problems that the cost of grinding devices is increased, the time spent on installing the pipe fittings twice is long, and the grinding efficiency of the pipe fittings is reduced as the surface and the mouth of the ductile iron pipefittings are ground by two types of grinding devices respectively. A first sealing strip is fixedly connected to the mouth of a grinding box, and a first driving motor and a control panel are sequentially arranged on the other side of the grinding box from top to bottom. A supporting column is fixedly connected to the side of the lower end of the grinding box. A dust collector is fixedly connectedto the lower end of a collecting cover. Outer clamping mechanisms are arranged at both ends of a mounting rod, and an inner clamping mechanism is arranged in the middle of the mounting rod. A first grinding mechanism is arranged at the lower end of a first hydraulic cylinder, an electric slider is arranged at the upper end of an electric slide rail, and a second grinding mechanism is arranged atthe upper end of the electric slider.

Owner:HUBEI ZHENGXIN TUBE

Medium-speed vertical mill for milling petroleum coke

ActiveCN103801431AGuaranteed running stabilityMeet grinding requirementsGrain treatmentsPulp and paper industryMoisture

The invention relates to a medium-speed vertical mill for milling petroleum coke. The medium-speed vertical mill comprises a milling device including a milling roll assembly and a milling disc assembly, wherein the milling roll assembly comprises a milling roll and a milling roll sleeve, and a lining plate is arranged in the milling disc assembly; the width of the milling roll sleeve is at least increased by 10mm on the original basis, the thickness of the lining plate is at least increased by 20mm, and an wrap angle of the milling roll is at least reduced by 38.45 degrees. Compared with the prior art, the medium-speed vertical mill has the beneficial effects that on the basis of a conventional ZGM medium-speed coal mill, the milling curve is optimized, the milling efficiency is improved, and the service life of the improved complete machine is substantially prolonged; by utilizing a hydraulic variable loading system, a hydraulic oil pipeline system and a rotary separator are optimized, and by arranging a water injector, the operation stability of the medium-speed vertical mill for milling the petroleum coke is guaranteed; the technical scheme can completely meet the milling requirement of the petroleum coke, and indexes of a ground product are that the fineness R90 is less than 1.5% and the moisture Mpc is less than 1%.

Owner:BEIJING POWER EQUIP GRP

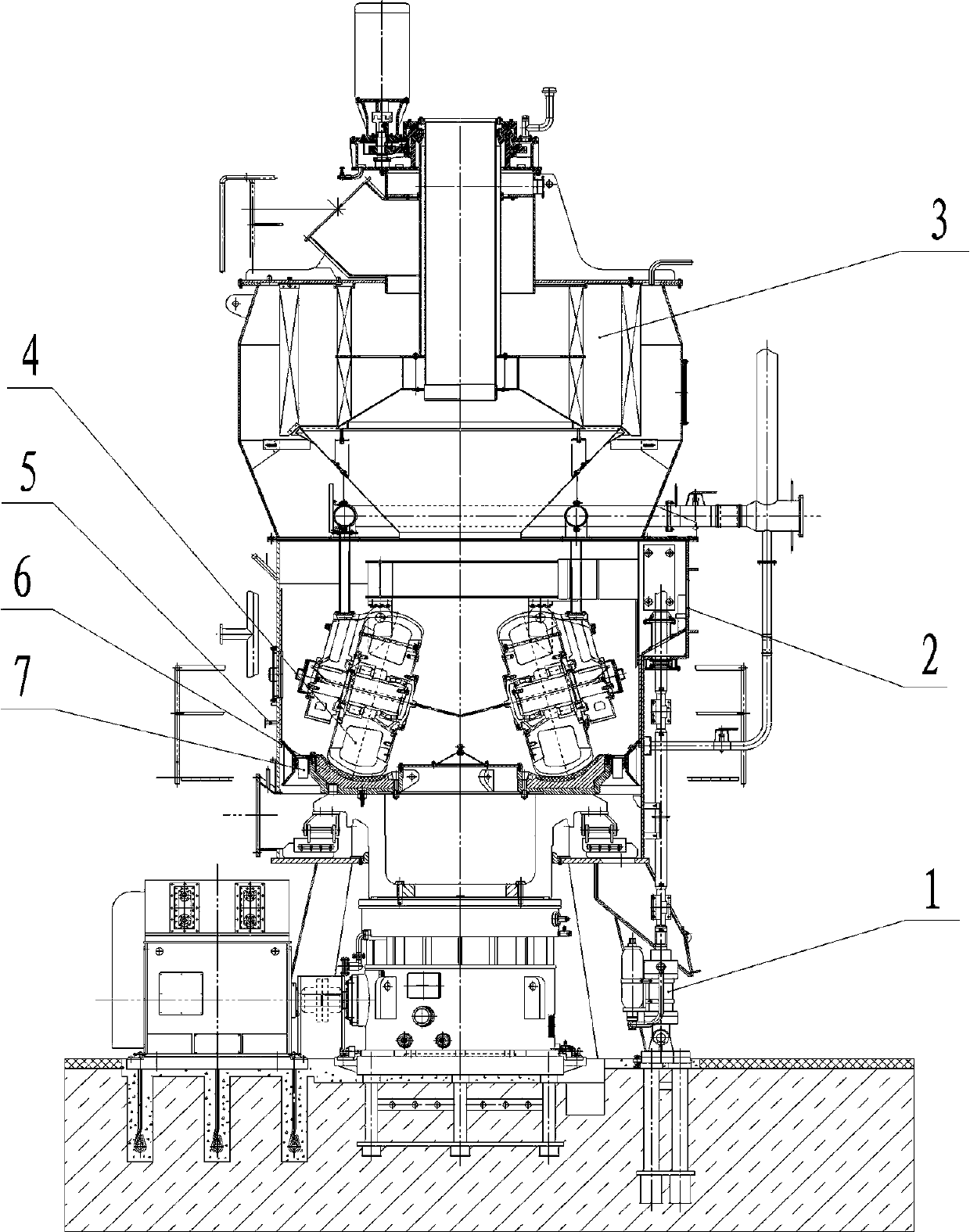

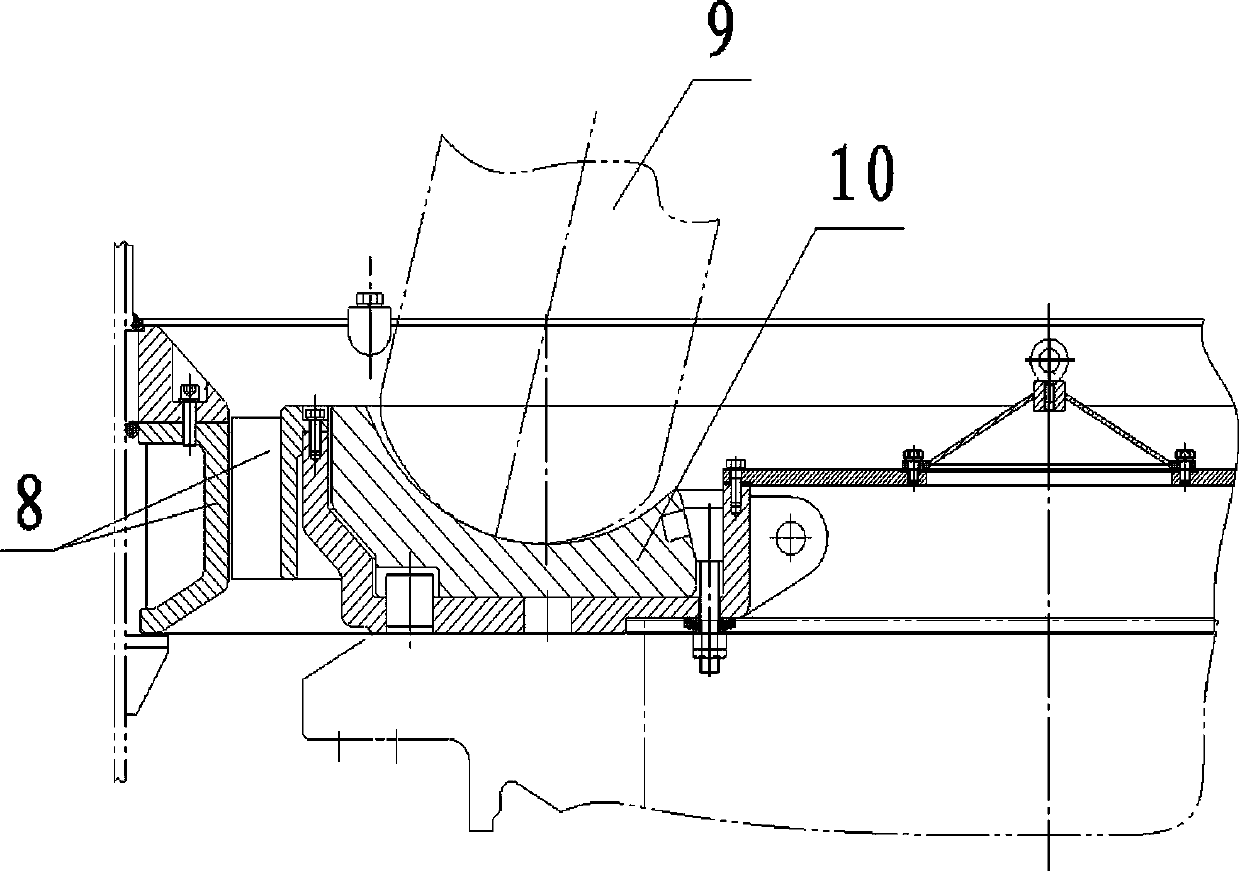

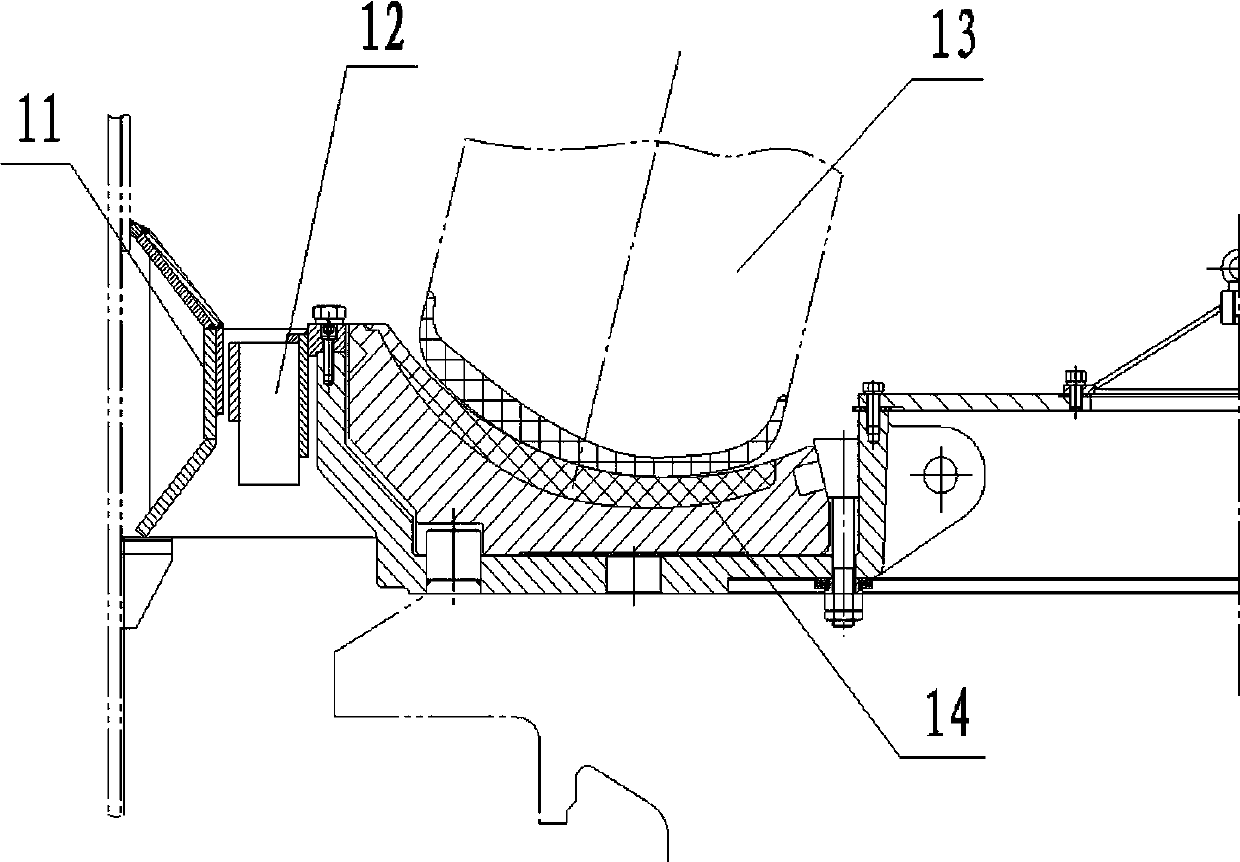

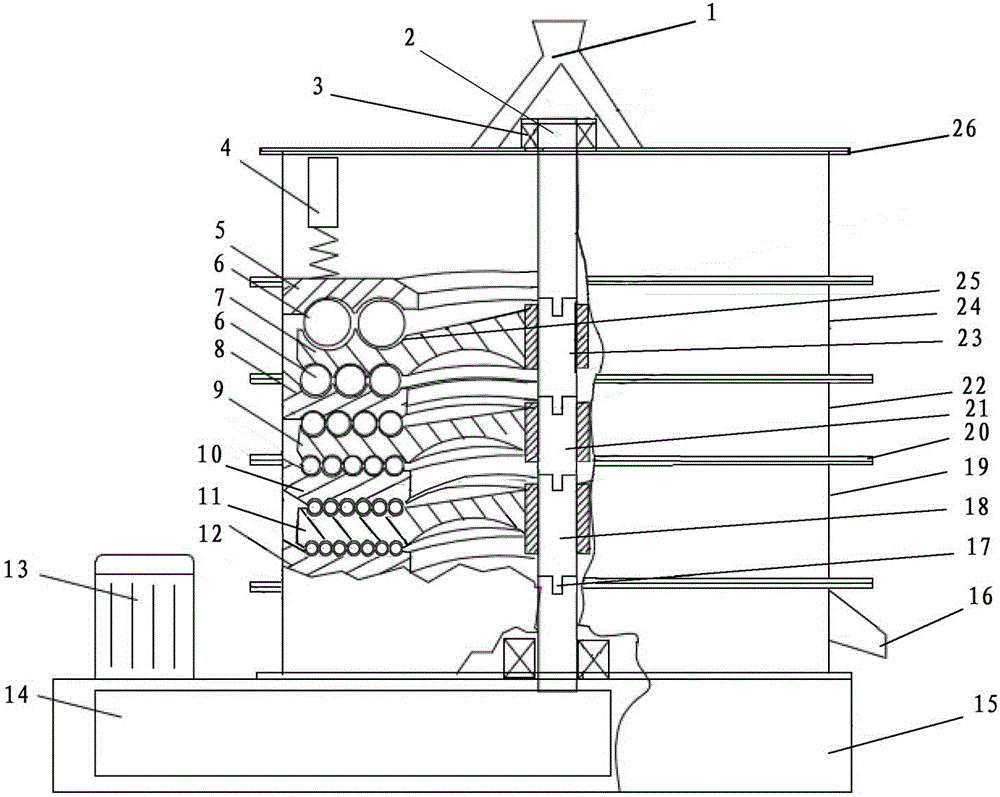

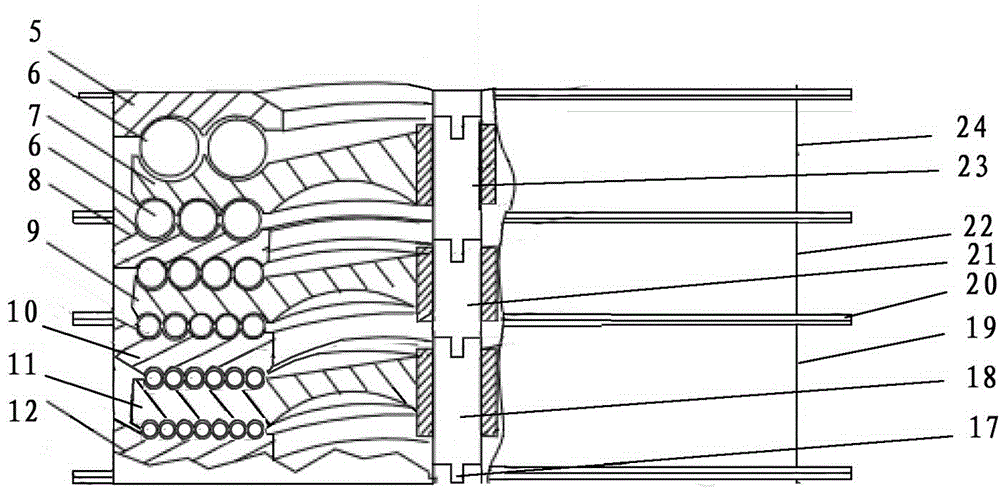

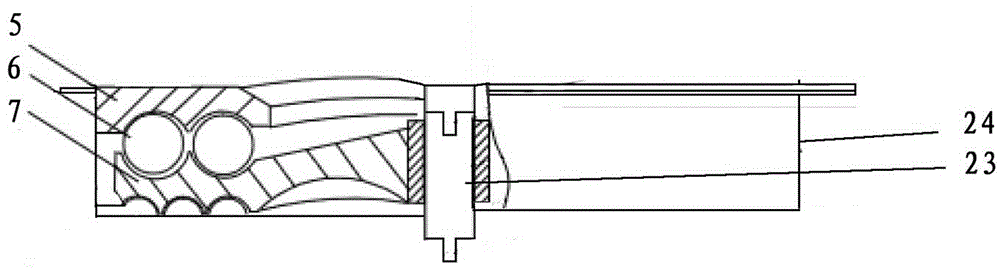

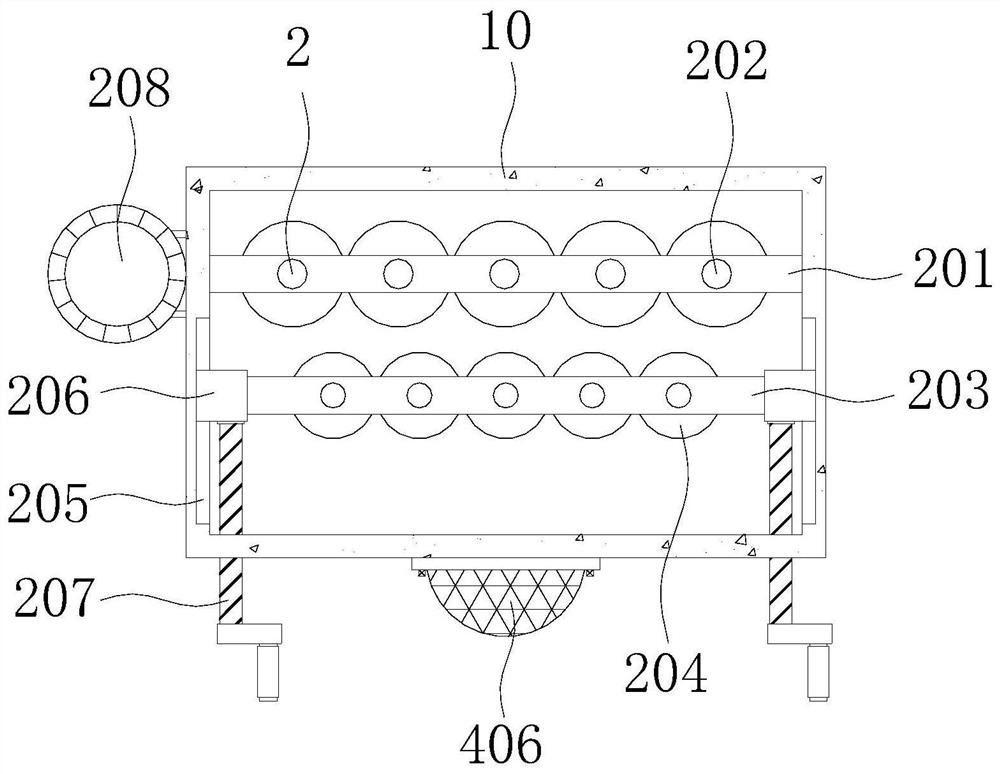

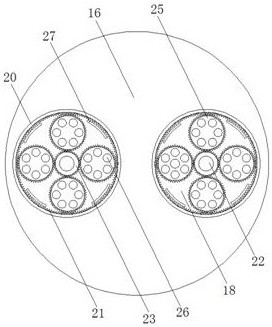

Combined ordered multi-pass internal-classification screening vertical type ball mill

The invention provides a combined ordered multi-pass internal-classification screening vertical type ball mill which is used for solving the technical problems that the existing vertical type ball mill is time-wasting and labor-wasting in repairing and dismounting the grinding mechanism, exchanging millstones of different rails and different-diameter grinding balls as well as the integral working efficiency is low due to repeated grinding of coarse-granule mineral aggregates. A grinding mechanism of the ball mill consists of a plurality of layers of connected grinding units, wherein each grinding unit comprises a millstone set, grinding balls, a unit main shaft and a unit shell, wherein at least two groove-shaped peripheral rails are arranged on opposite surfaces of a fixed millstone and a rotary millstone which are alternatively arranged along the radial direction; a plurality of channels for screening material granules are formed in the edges of the peripheral rails bearing the grinding balls along the radial direction; openings in the inner sides of the channels are gradually magnified towards the openings in the outer sides along the side walls of the channels. The combined ordered multi-pass internal-classification screening vertical type ball mill can be used for combining and assembling grinding balls with different diameters and millstones of different rails, and quickly classifying and screening material granules, so that the working noises are lowered, the ore-grinding working efficiency is greatly improved, and the energy consumption is reduced.

Owner:李广勋

Water-base grinding fluid for on-line electrolytic grinding

InactiveCN101020810AMeet grinding requirementsStrong adhesionOther chemical processesSodium molybdateWater based

The present invention discloses one kind of water-base grinding fluid for on-line electrolytic grinding, and belongs to the field of precise grinding fluid technology. The water-base grinding fluid consists of sodium molybdate 0.2-0.6 wt%, sodium carbonate 0.1-0.5 wt%, sodium silicate 0.3-0.8 wt%, borax 0.1-0.4 wt%, sodium benzoate 0.2-1.2 wt%, sodium chloride 0.01-0.1 wt%, water for the rest and boric acid ester in 0.7-1.2 vol% of water. The present invention has the advantages of environment friendship, low cost, high use performance and simple preparation process.

Owner:TIANJIN UNIV

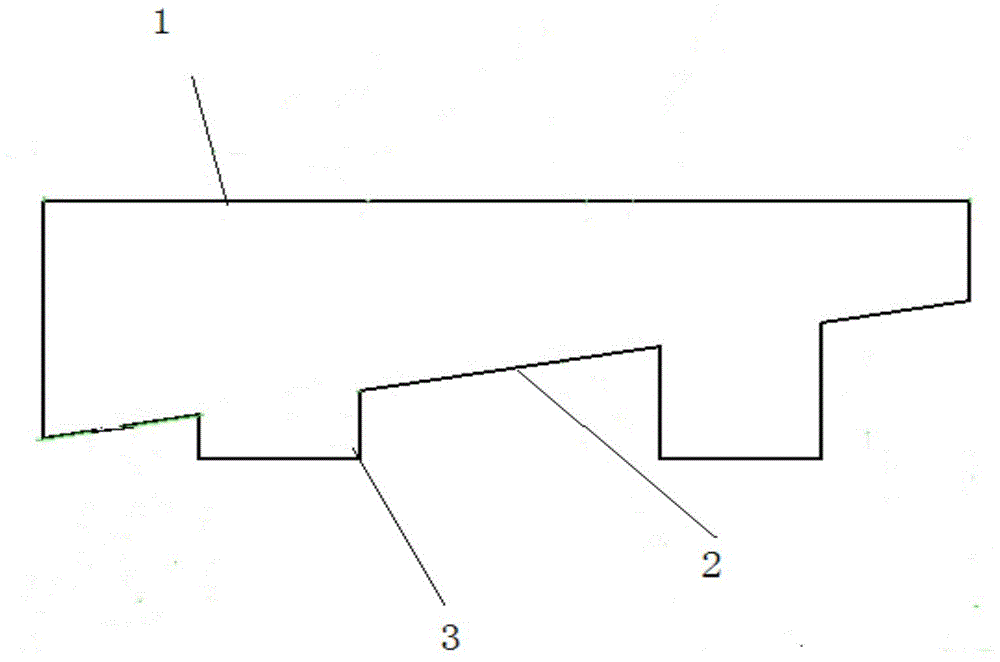

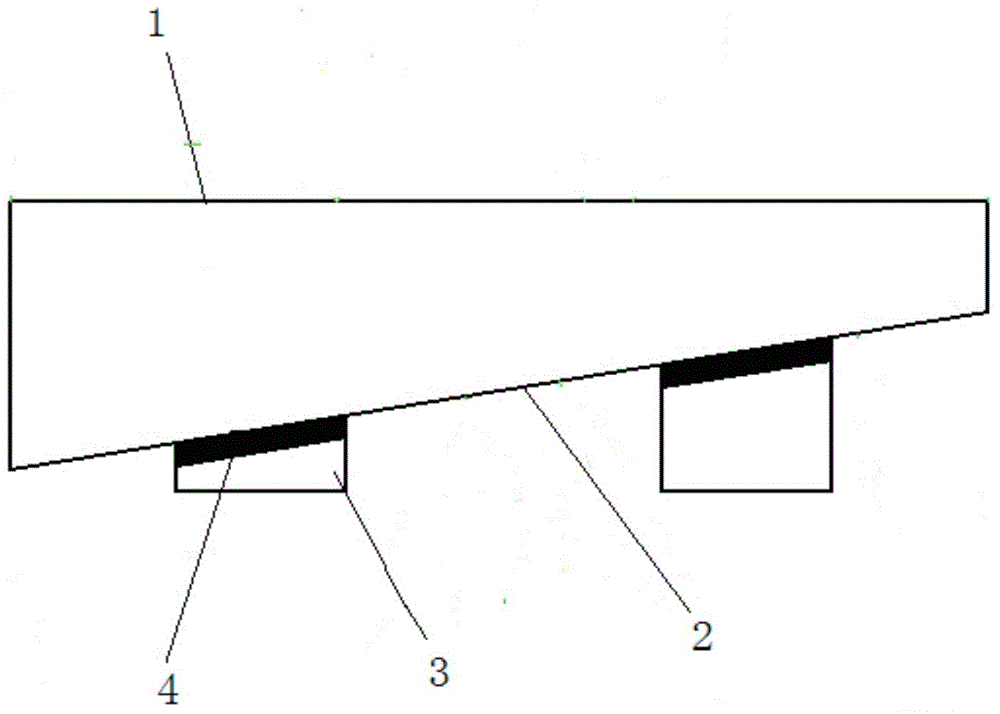

Machining process method of large-size single degree face wedge-shaped workpiece

The invention discloses a machining process method of a large-size single degree face wedge-shaped workpiece. The method comprises the process steps that (1) a reference plane of a workpiece is machined by milling; (2) the reference plane obtained after milling is used as the machining reference for machining a workpiece oblique plane, and the oblique plane of the workpiece is machined by milling and grinding; (3) a mounting process boss for workpiece reference plane grinding adheres to the workpiece oblique plane through metal adhering agents; (4) a process boss on the oblique plane is used as the mounting reference of machining reference plane by grinding, and the reference plane is machined by grinding; and (5) after the reference plane is machined by grinding, the process boss is taken off from the workpiece oblique plane, the metal adhering agents on the workpiece oblique plane are removed, and single-face wedge-shaped workpiece machining is completed. Compared with a machining method in the prior art, the process of machining method is simplified, machining efficiency is improved, and the machining accuracy of the workpiece is improved.

Owner:AECC AERO SCI & TECH CO LTD

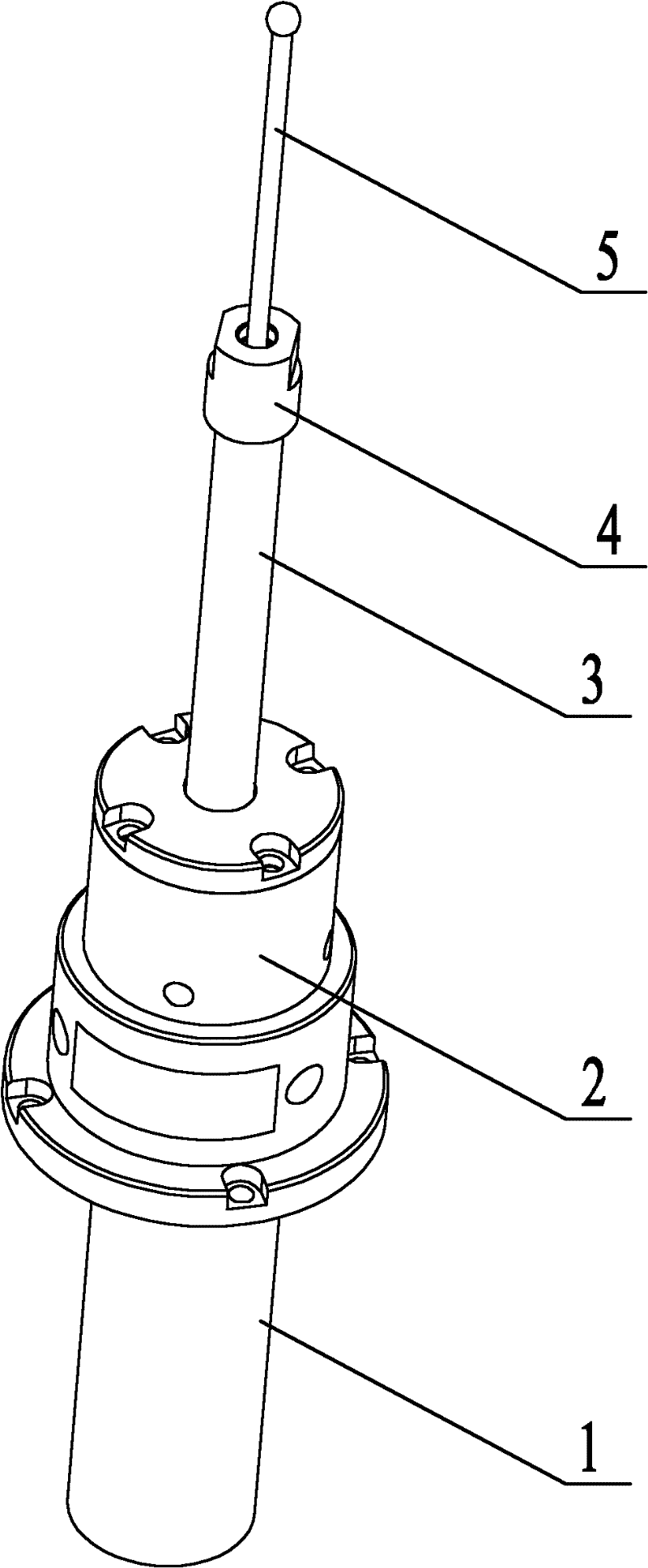

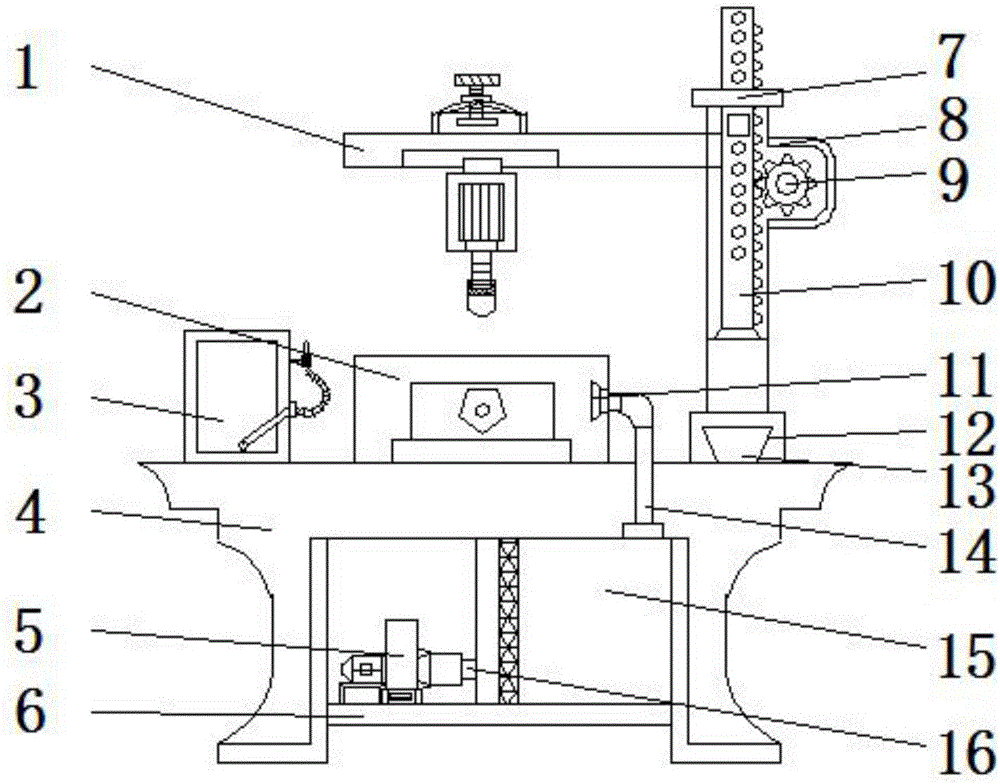

Special grinding machine for pipeline inner hole

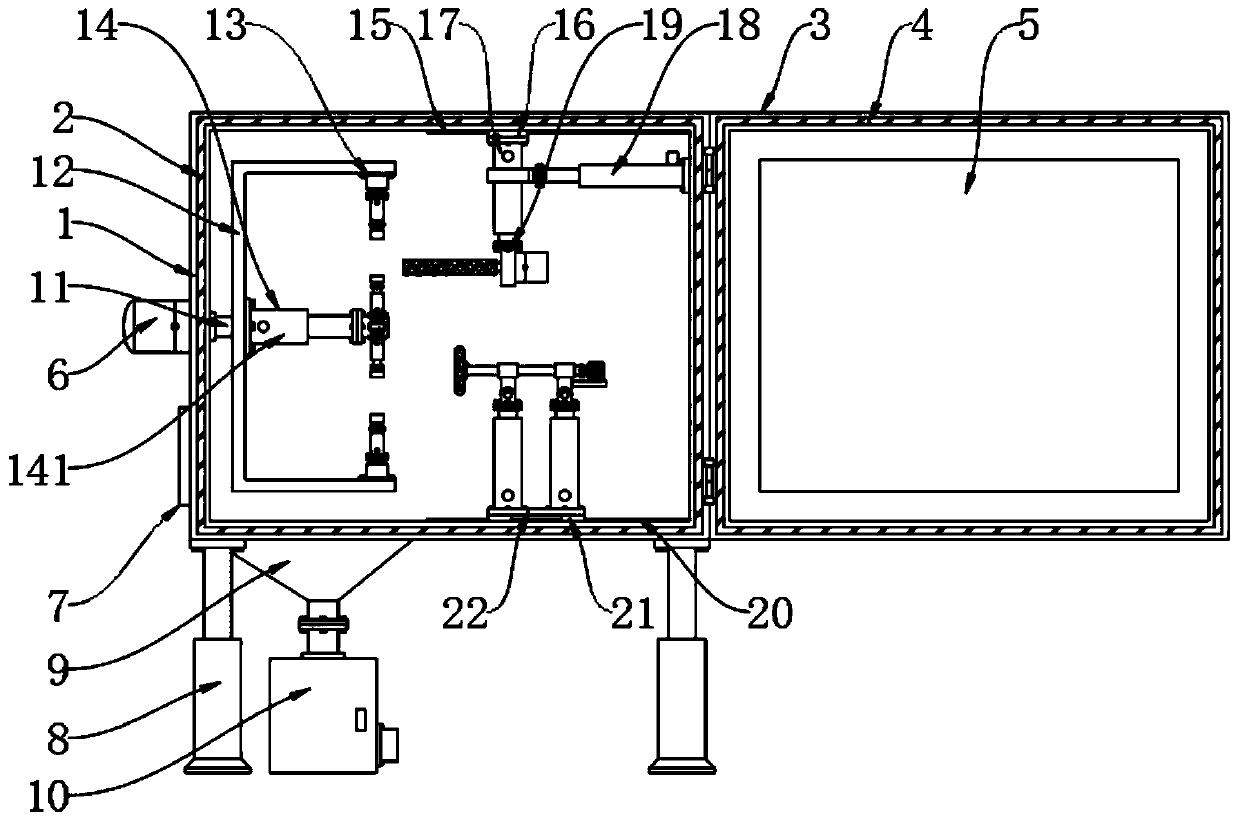

InactiveCN102407469ALow skill level requiredHigh degree of automationRevolution surface grinding machinesQuality controlEngineering

The invention discloses a special grinding machine for a pipeline inner hole, which comprises a spring clamp, a limiting plate (6), a manual grinding machine (4) and a grinding head (1); the limiting plate (6) is fixed to the spring clamp; the manual grinding machine (4) is located in the limiting plate (6); a compact spring (7) is arranged between the manual grinding machine (4) and the limiting plate (6); and the grinding head (1) is connected with the manual grinding machine (4) after passing through the spring clamp. The special grinding machine for the pipeline inner hole provided by the invention has the advantages of high efficiency, easy quality control, lower requirements on labor force and technique, and the like, and the grinding operation can be finished by clamping and dismounting the special grinding machine and starting and stopping power only in the whole working process.

Owner:杨春

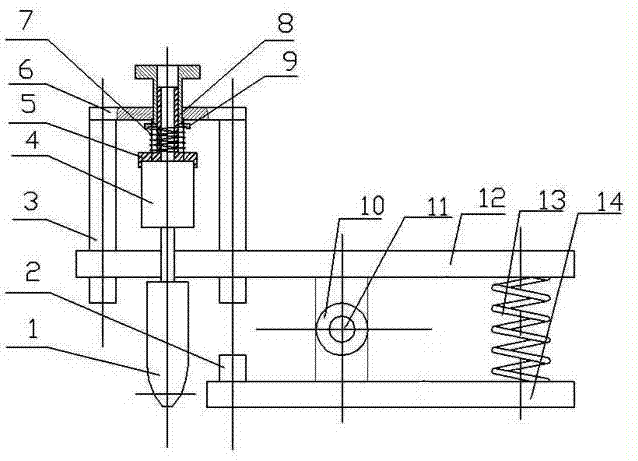

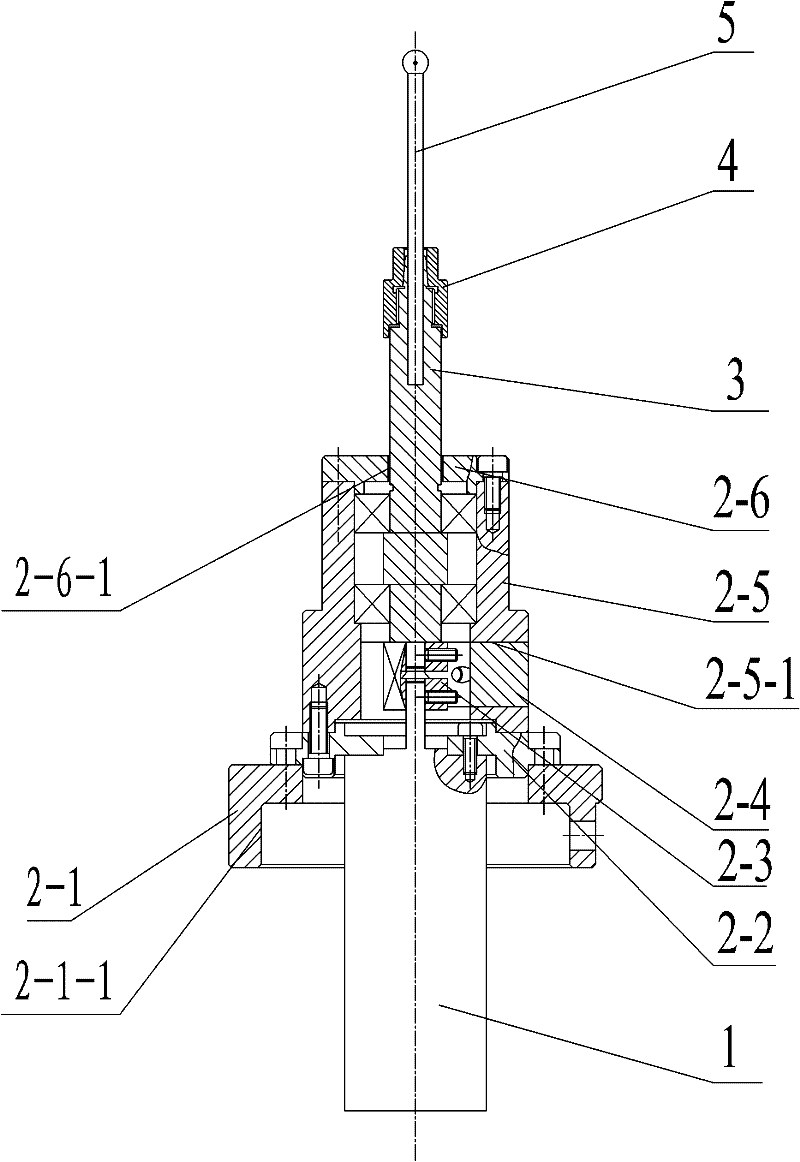

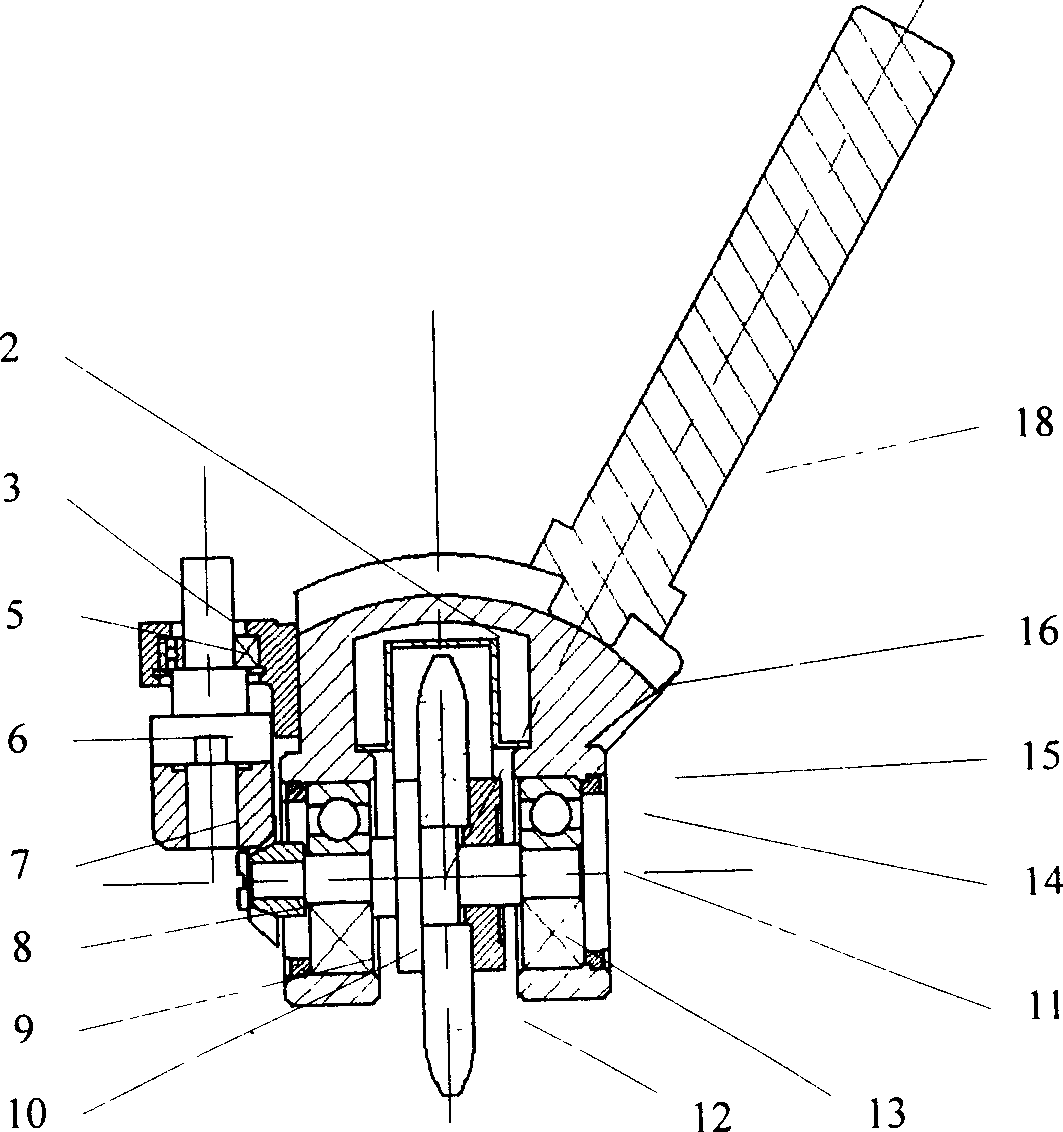

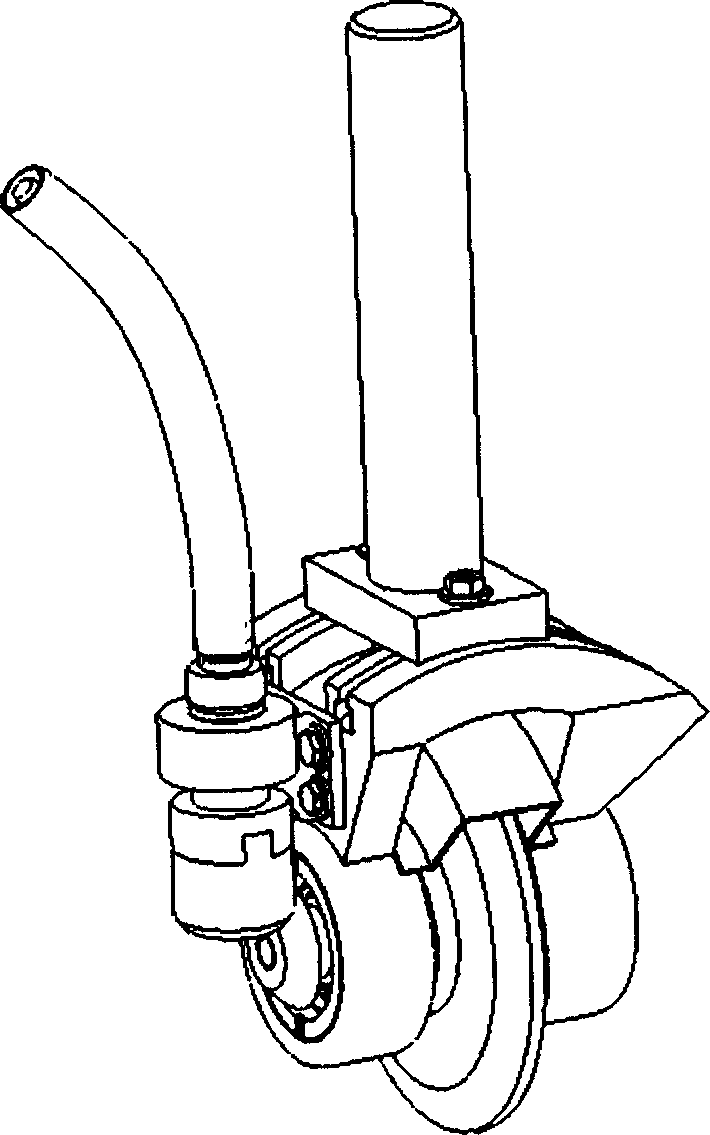

Grinding Drill for Robotic Assisted Cervical Disc Replacement Surgery System

A burr used in a robot-assisted cervical intervertebral disc replacement surgery system relates to a burr. The present invention solves the problem that there is no dedicated grinding drill for robot-assisted cervical intervertebral disc replacement surgery system at present. One end of the fixed ring passes through the output shaft of the high-speed DC motor and is fixed on the end face of the output shaft end of the high-speed DC motor, and the other end of the fixed ring is fixed on an end face of the housing. One end of the drive shaft is installed in the housing through a bearing, one end of the drive shaft of the grinder is fixedly connected to the output shaft of the high-speed DC motor through a coupling, the grinding head is fixed on the other end of the drive shaft of the grinder, and the end The cover is machined with a first central through hole in the axial direction, the end cover is fixed on the other end surface of the housing through the drive shaft of the mill drill, and the connecting platform is machined with a second central through hole in the axial direction, so The connecting platform passes through the high-speed DC motor and is fixedly connected with the fixed ring. The invention is a burr used in a robot-assisted cervical intervertebral disc replacement operation system.

Owner:HARBIN INST OF TECH

Machining device for aluminum alloy wind wheels for wall-mounted air conditioners

InactiveCN107433504AQuality improvementMinimize contamination of the working environmentGrinding wheel securing apparatusGrinding carriagesPhysical healthFixed frame

The invention relates to a processing device for an aluminum alloy wind wheel for a wall-mounted air conditioner, which includes a cross bar, a frame, a support rod and a dripper, an oil tank is installed on one side of the top of the frame, and the other The first slide rail is installed on the side, and a support rod is installed above the first slide rail, a cross bar is installed horizontally on one side of the chain rod, a transmission shaft is vertically installed on the output end of the motor, and the transmission shaft A grinding head is installed at the bottom end, a first casing is installed at the top of the frame between the fuel tank and the support rod, and fixing frames are installed at both ends of the top of the frame inside the first casing. The present invention is provided with a suction cup, an exhaust fan and a dust collection box, and the exhaust fan operates to collect the dust inside the first casing through the suction cup, reducing the occurrence of dust diffused and polluting the working environment, and at the same time reducing the dust concentration and reducing the impact on the working environment. Injury to the health of workers.

Owner:饶丽琼

Airtight pulverizer and application thereof

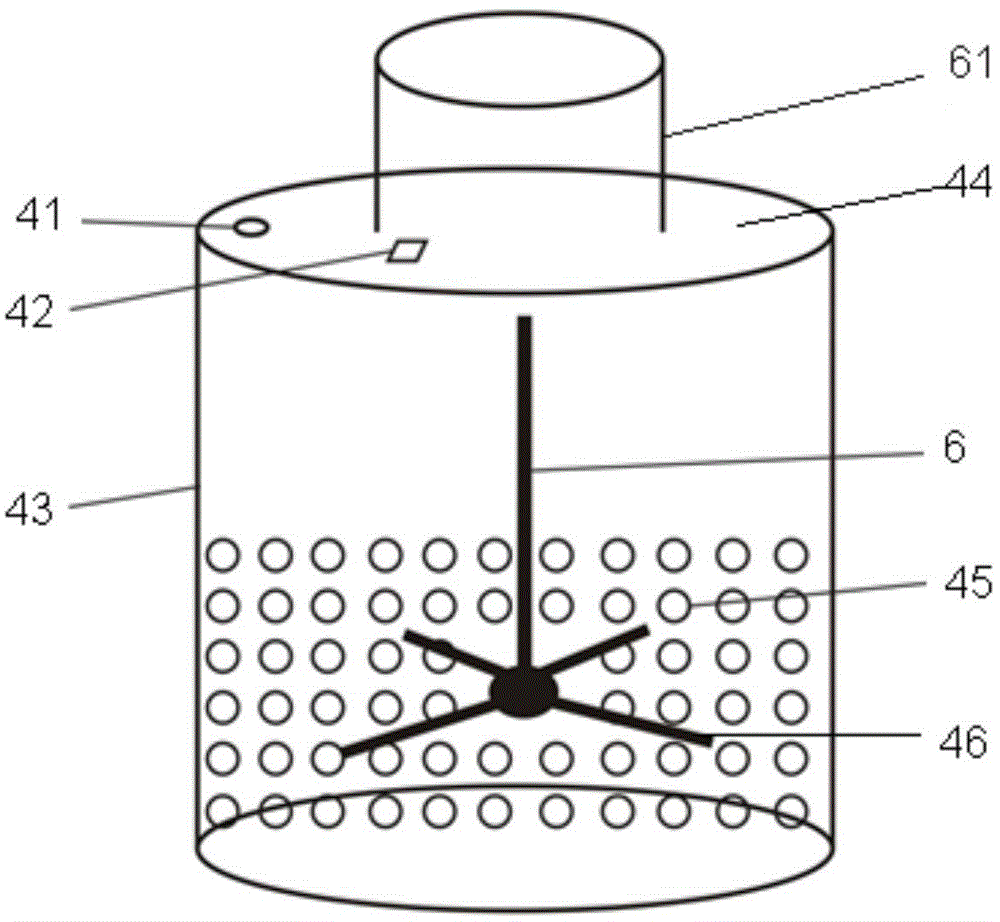

ActiveCN104923352AAchieve airtightnessImprove experimental test accuracyGrain treatmentsMagnetic rotationCoupling

The invention discloses an airtight pulverizer and application thereof. The pulverizer comprises a sample smashing tank and a non-contact type torque transmission system. The non-contact type torque transmission system comprises a motor, a magnetic rotation shaft and a magnetic transmission coupler. The motor is connected with the magnetic rotation shaft and drives the magnetic rotation shaft to rotate through the magnetic transmission coupler. A shell is arranged outside the magnetic rotation shaft. The lower end of the magnetic rotation shaft extends out of the bottom of the shell and extends into the sample smashing tank. A stirring piece is arranged in the sample smashing tank. The magnetic rotation shaft is connected with the stirring piece and drives the stirring piece to act. The sample smashing tank is connected with the shell of the magnetic rotation shaft in a sealed mode. According to the pulverizer, through the magnetic transmission technology, the external torque transmission efficiency is kept, good sealing, enough power, high efficiency and good effects are achieved when a sample is smashed, operation is easy and convenient, and the airtight pulverizer is suitable for practical use. The gas content of a rock sample can be measured through the pulverizer.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

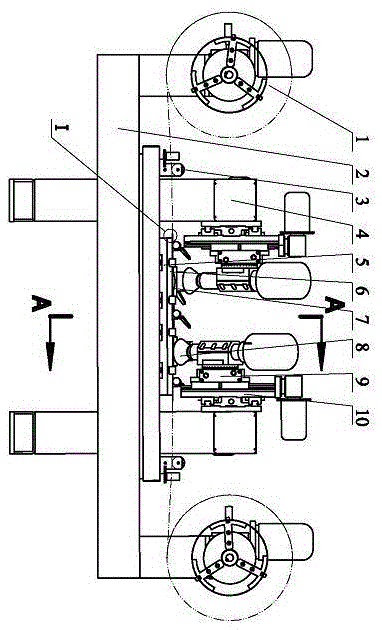

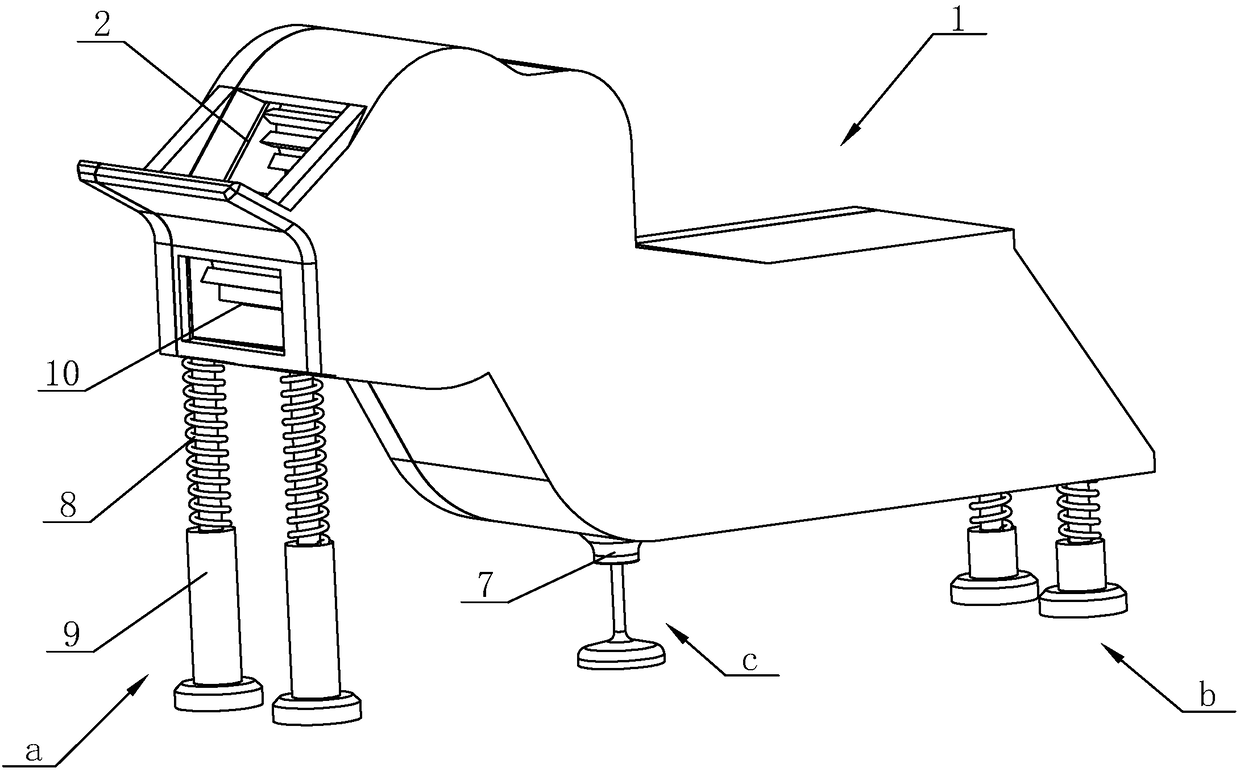

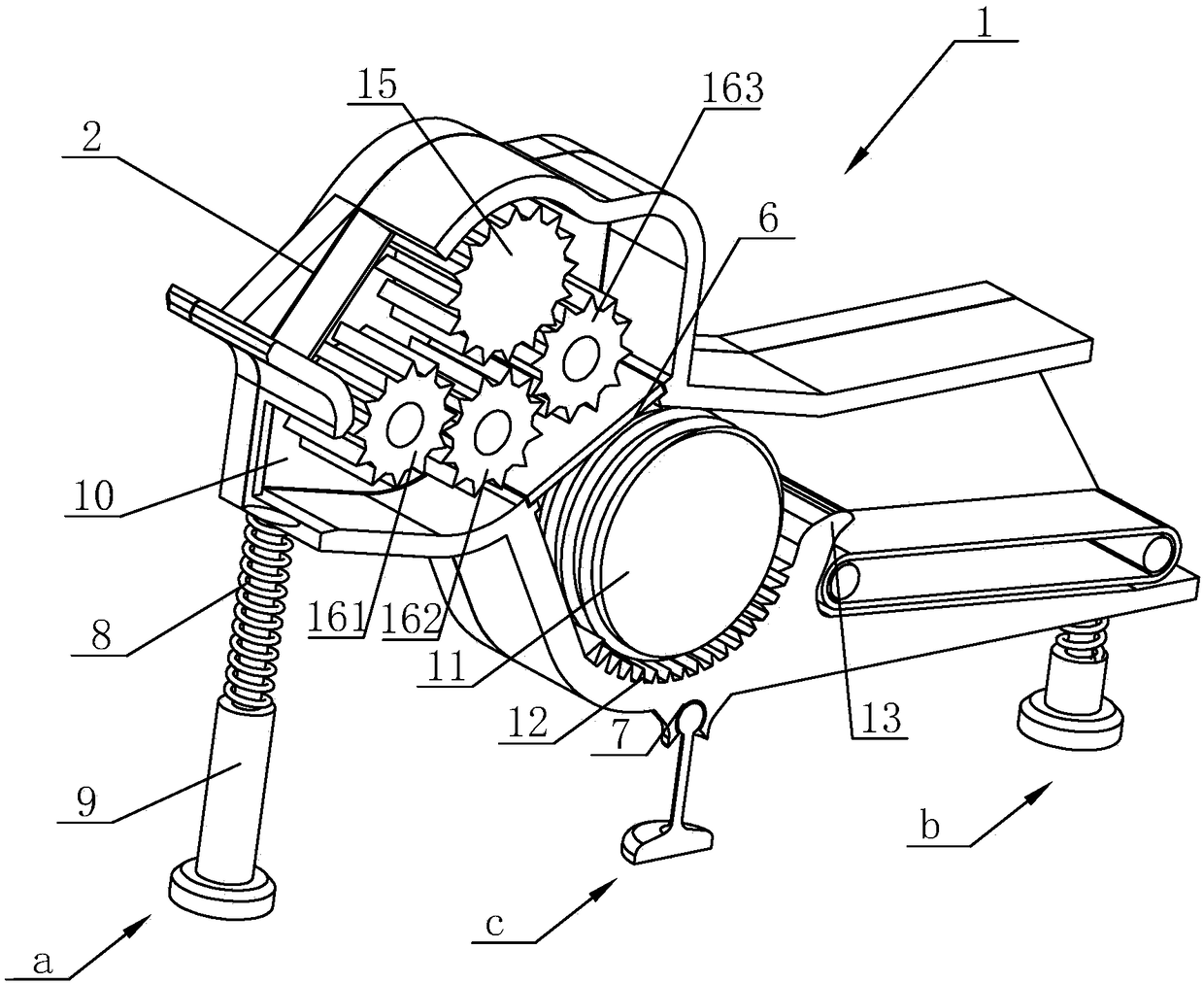

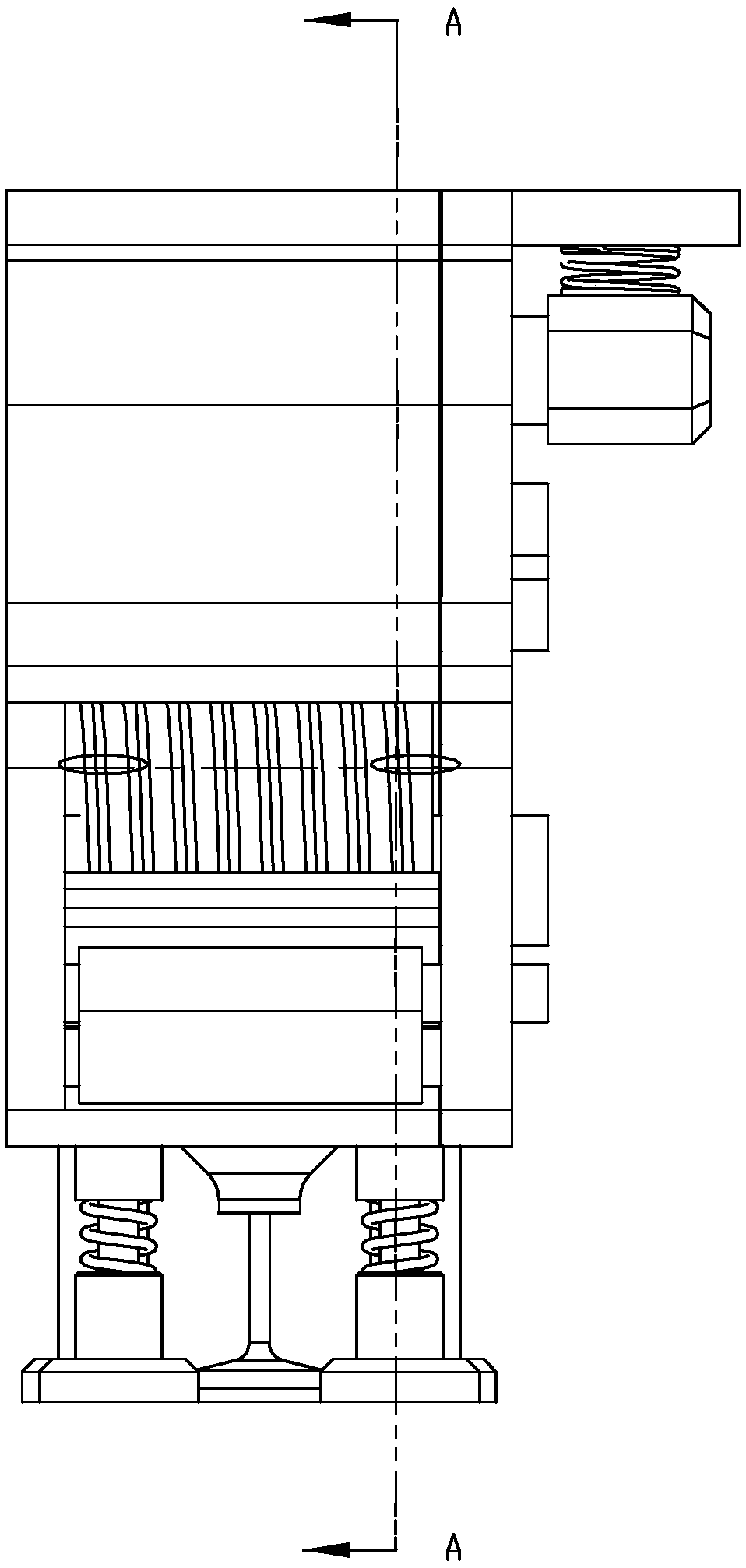

Subway steel rail grinding wagon

PendingCN111139698AMeet the grinding requirementsImprove running stabilityRailway track constructionEngineeringStructural engineering

The invention discloses a subway steel rail grinding wagon which comprises a wagon body and a steel rail grinding trolley hung on the lower portion of the wagon body through a lifting mechanism, and the steel rail grinding trolley comprises two grinding trolleys hinged to each other. The steel rail grinding trolley further comprises an elastic traction rod and a rigid traction rod, one grinding trolley is connected with the trolley body through the elastic traction rod, and the other grinding trolley is connected with the trolley body through the rigid traction rod. Traction of the steel railgrinding trolley is achieved through the elastic traction rod and the rigid traction rod. The technical problems that an existing subway steel rail grinding wagon is limited in application occasion, poor in operation stability and poor in grinding quality and effect can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

Automatic quercus sclerophylla fruit processing robot

ActiveCN106983117AImprove efficiencyNo manual operationSievingScreeningAgricultural engineeringRobot

The invention relates to an automatic quercus sclerophylla fruit processing robot which comprises a bottom plate. Two vertical plates are symmetrically mounted on two sides of the middle of the bottom plate, a separation device is mounted at the upper end of the two vertical plates, a screening device is mounted in the middle of the bottom plate and positioned below the separation device, a crushing and grinding device is mounted at the rear end of the bottom plate and positioned on the rear lower side of the screening device, and the separation device, the screening device and the crushing and grinding device are mutually matched to finish automatic quercus sclerophylla fruit processing technology. The processing robot can solve the problems that quercus sclerophylla fruits need to be manually separated, the manual screening efficiency of the quercus sclerophylla fruits is low, manually crushed and grinded quercus sclerophylla fruits are large in particle and need to be repeatedly made, labor intensity is high, consumed time is long, the making efficiency of the quercus sclerophylla fruits is low and the like in the existing processing course of the quercus sclerophylla fruits, and the quercus sclerophylla fruits can be automatically processed.

Owner:泰州亿丰达电器有限公司

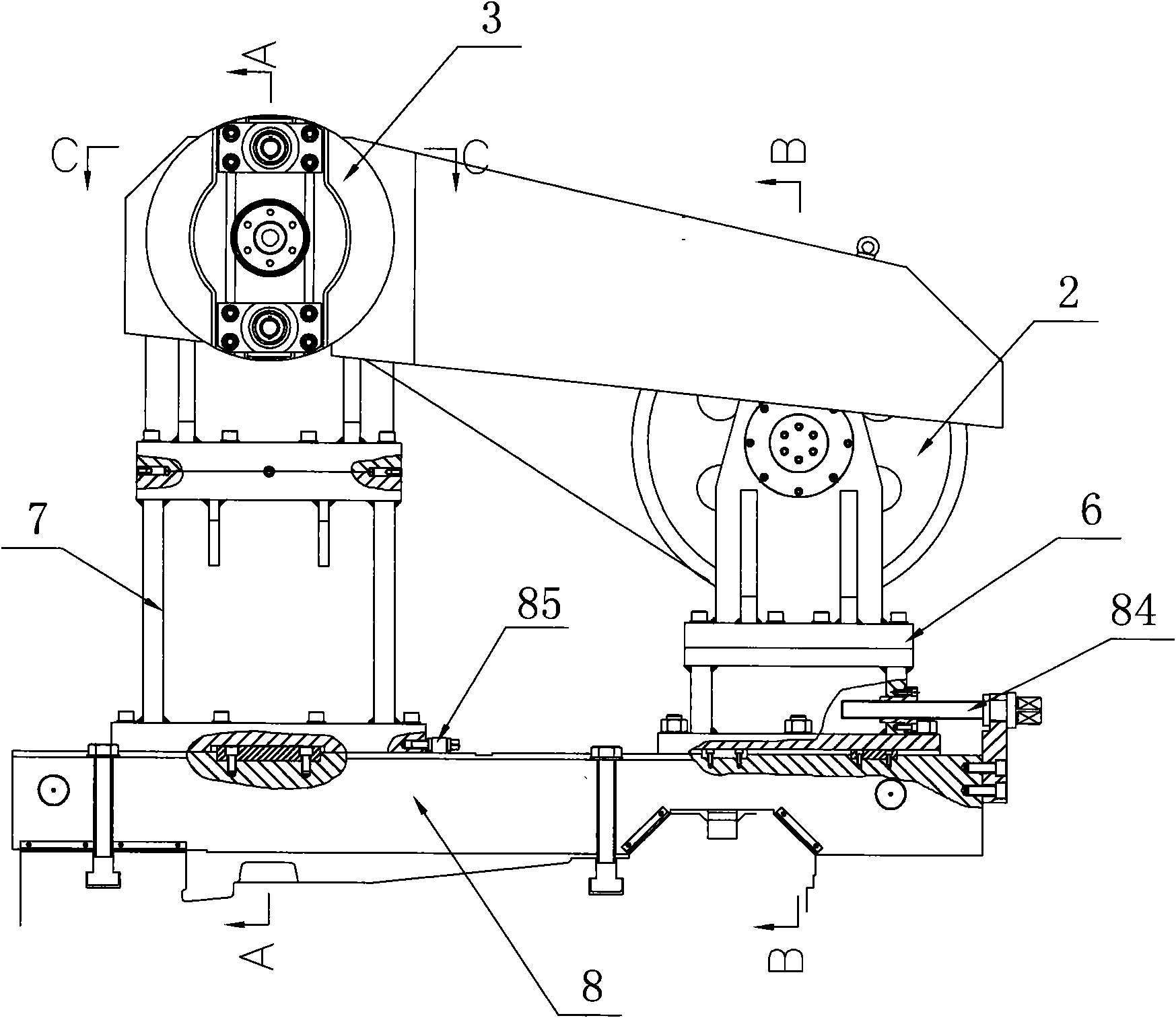

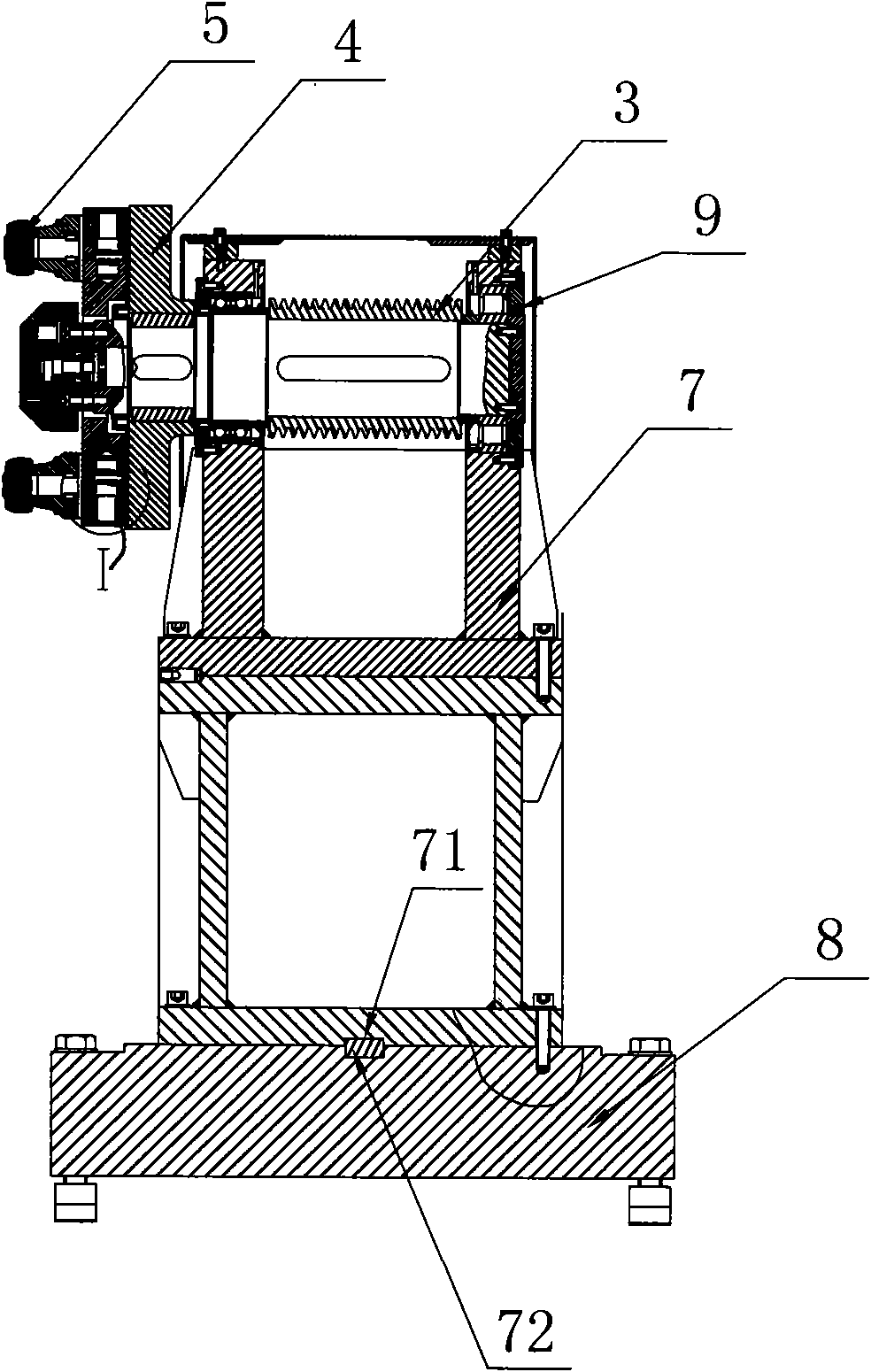

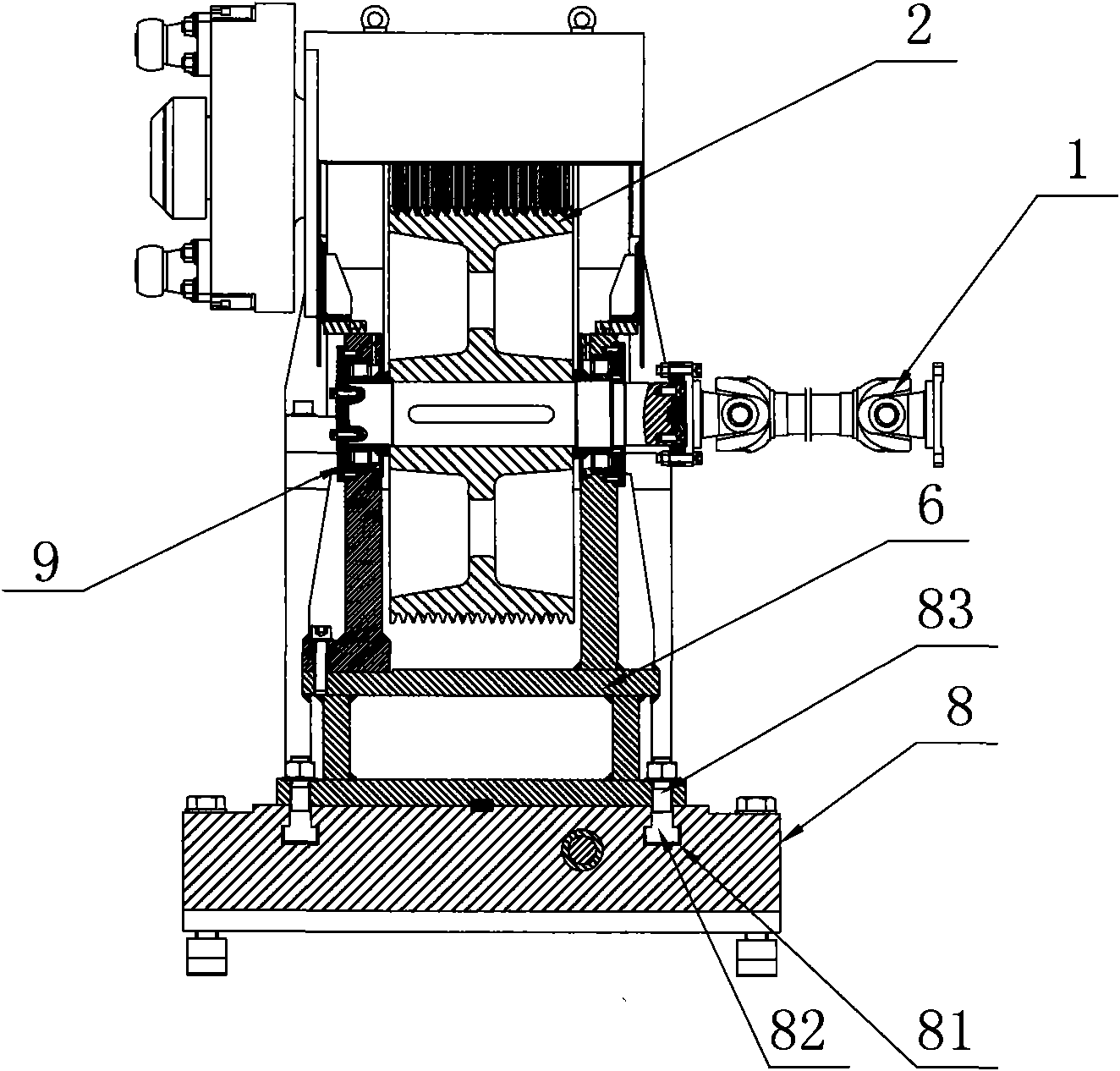

Secondary driving device for heavy numerical control roller grinder

ActiveCN101890662AIncrease speedIncrease line speedRevolution surface grinding machinesGrinding drivesNumerical controlCoupling

The invention discloses a secondary driving device for a heavy numerical control roller grinder. A driving mechanism of the roller grinder can drive a roller to rotate through first, second, and third belt pulleys; one end of a universal coupling can be detachably and fixedly positioned on a rotating shaft of the second belt pulley, while the other end is fixedly positioned on a rotating shaft of a fourth belt pulley; the fourth belt pulley drives a fifth belt pulley; the other end of a rotating shaft of the fifth belt pulley is connected with one end of a connecting disc; the other end of the connecting disc is flexibly and fixedly connected with two shifting blocks; the diameter of the fourth belt pulley is greater than that of the fifth belt pulley; the fourth and fifth belt pulleys can be rotationally and axially positioned on first and second supports in a locking way respectively; the lower ends of the first and second supports can be positioned on a pedestal in a radially-sliding and axially-fixed manner respectively; and the pedestal can be detachably and fixedly arranged on the body of the roller grinder. Thus, the rotating speed of the roller is increased and the aim of grinding rollers with various diameters can be fulfilled. The secondary driving device has the advantages of improving production efficiency, saving capital and plant space, along with small occupied space, convenient assembly and disassembly.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

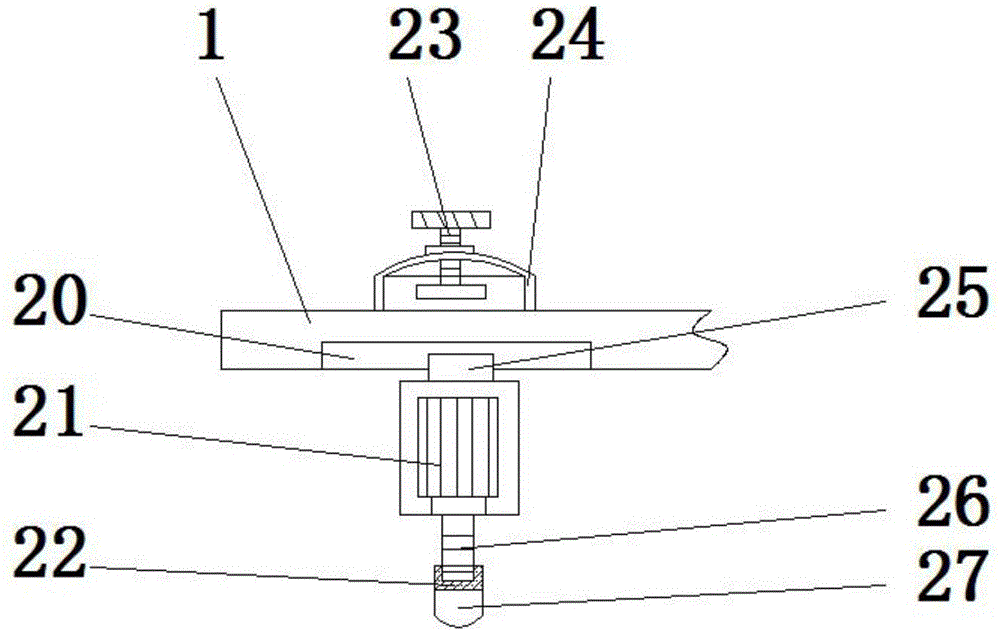

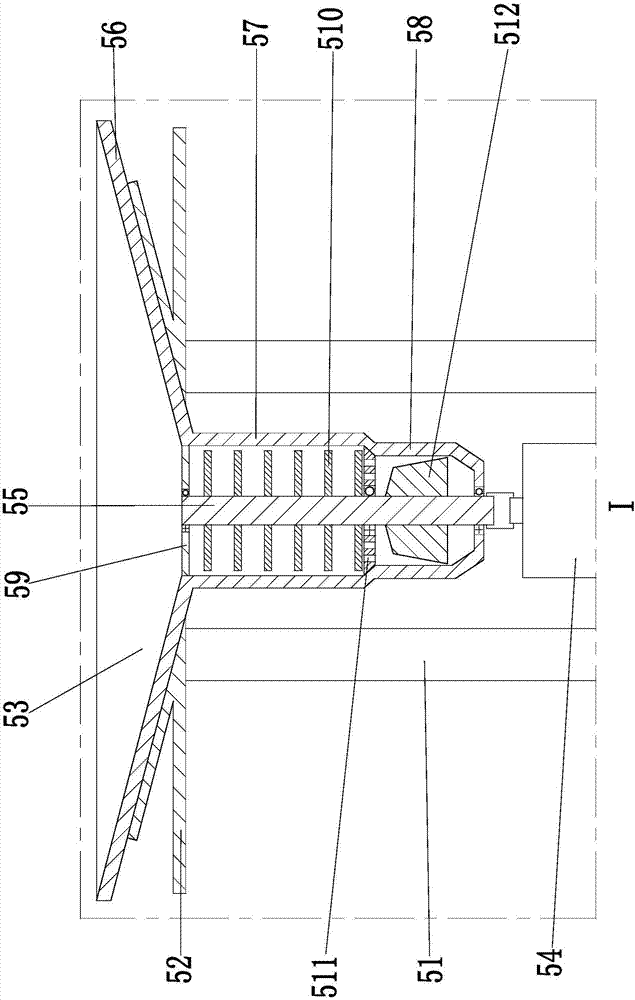

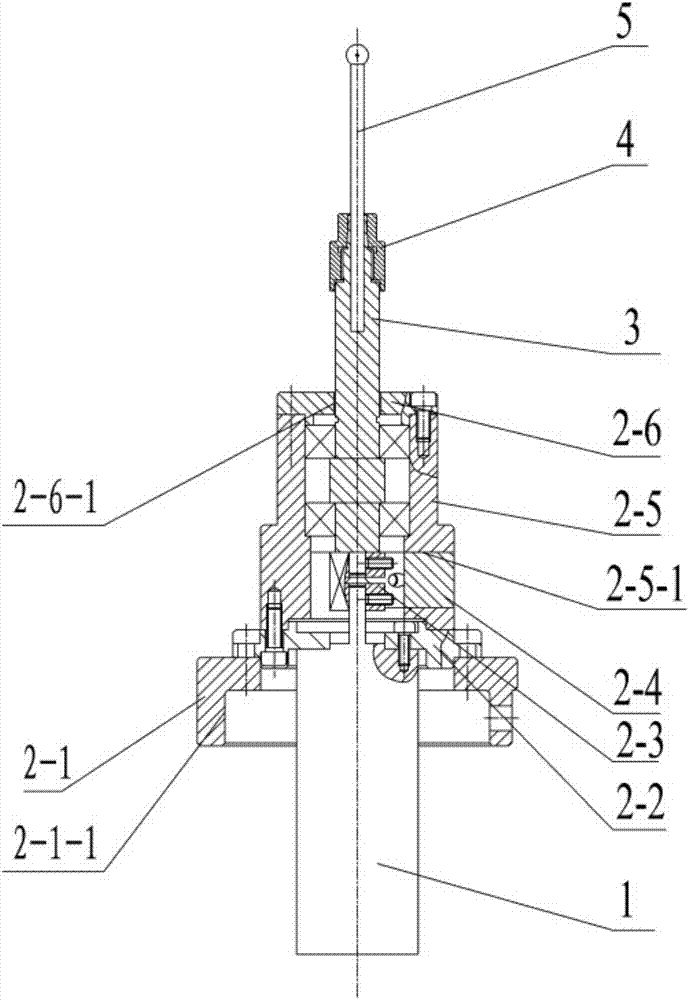

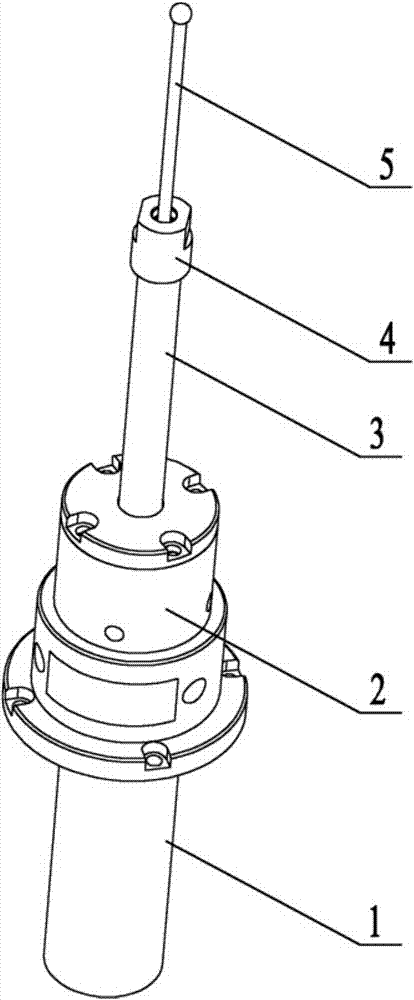

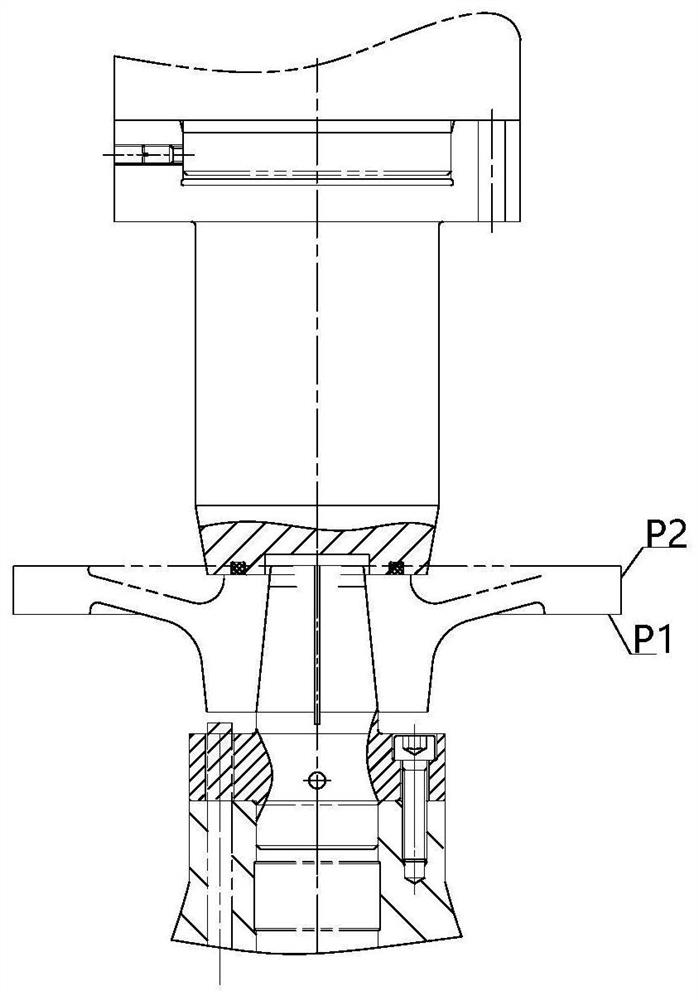

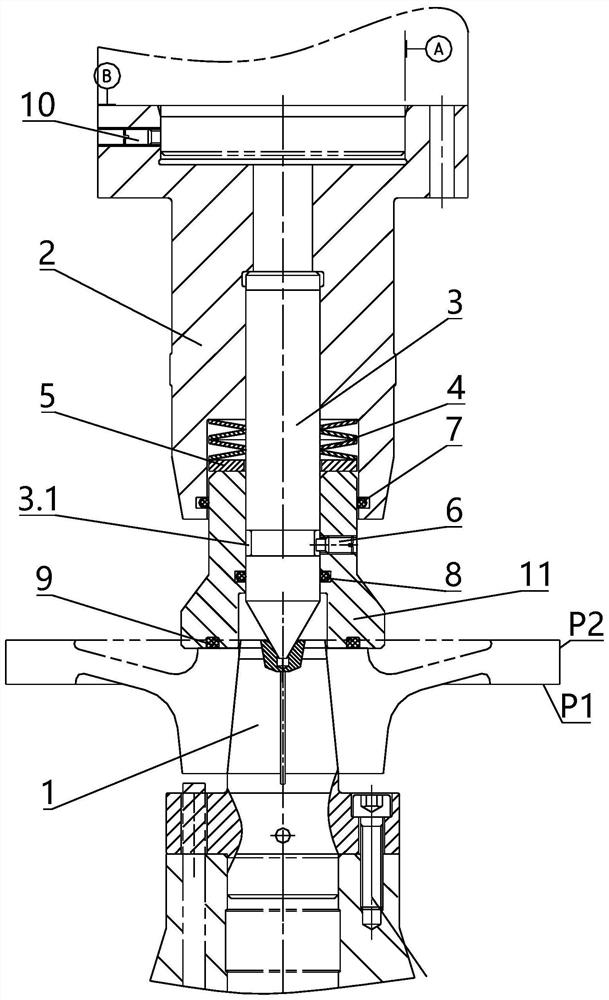

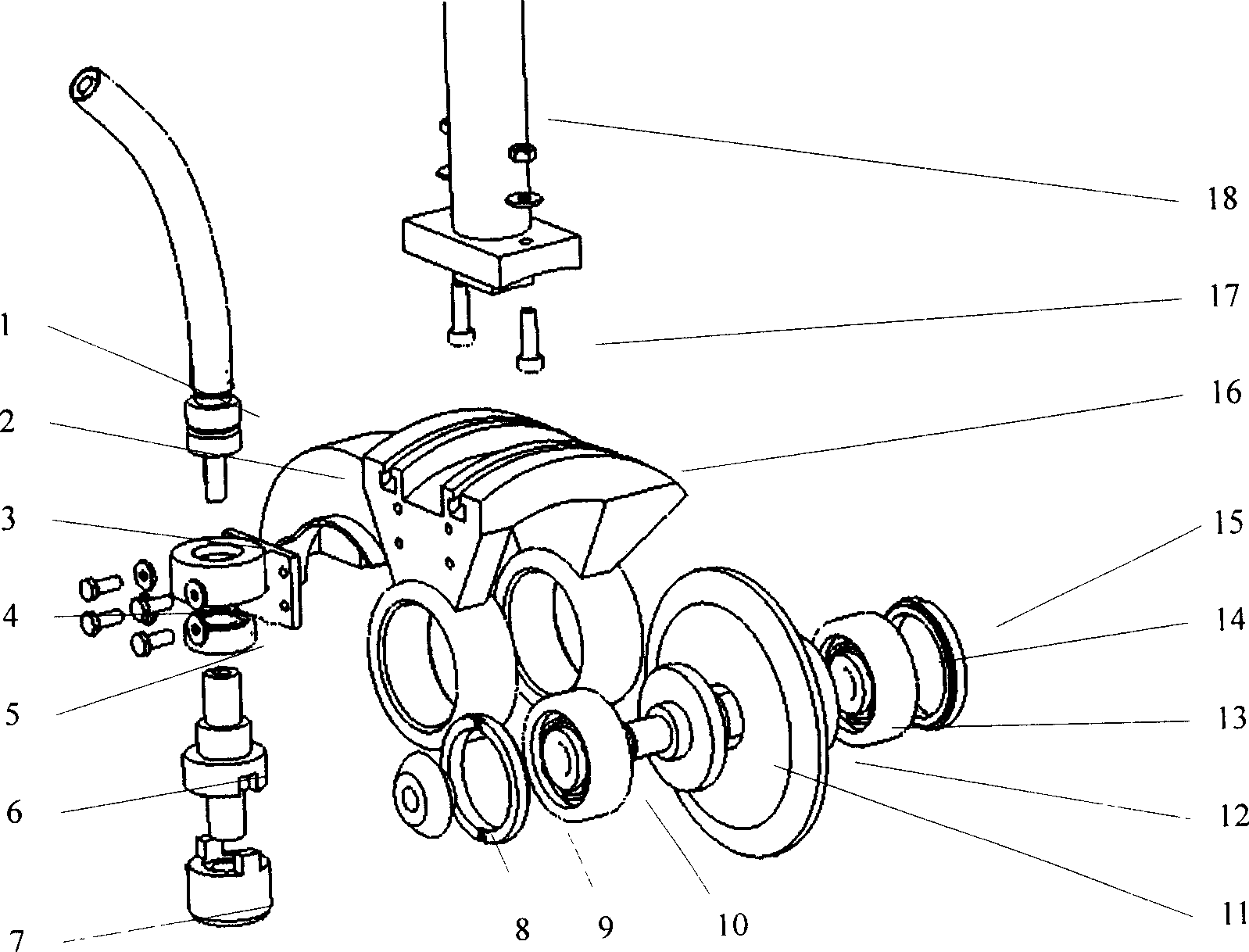

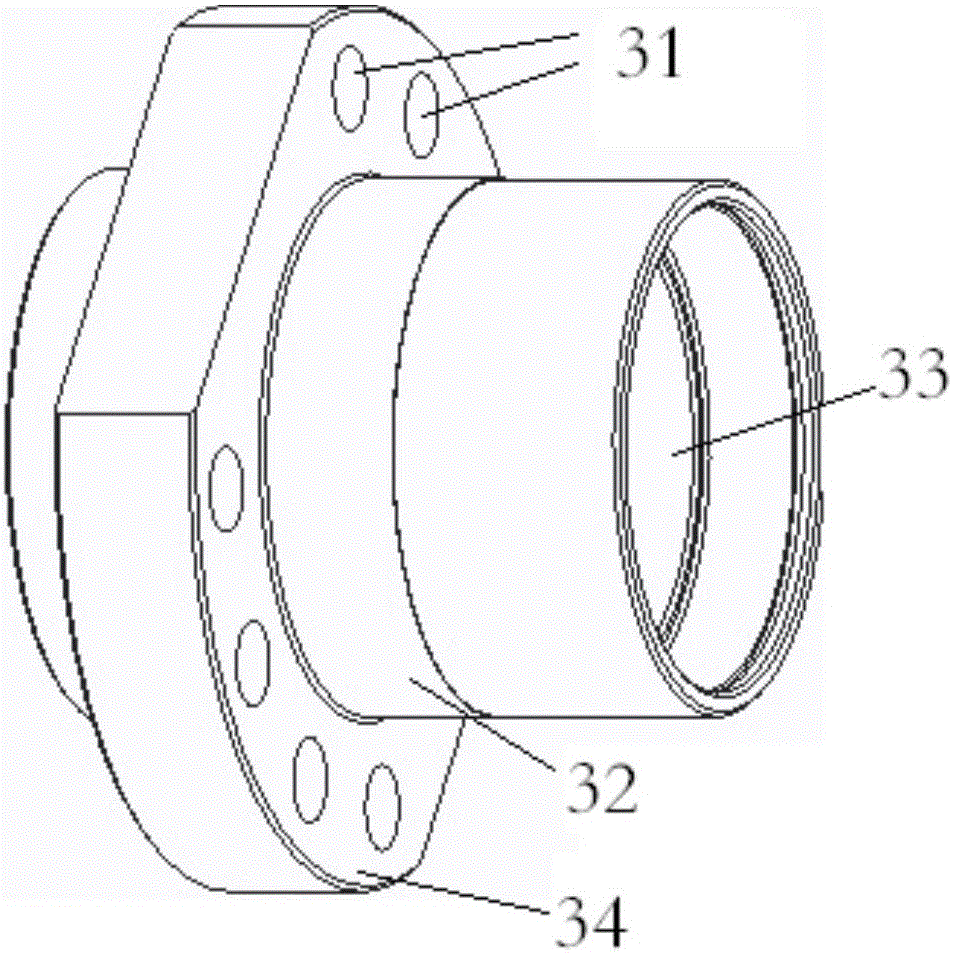

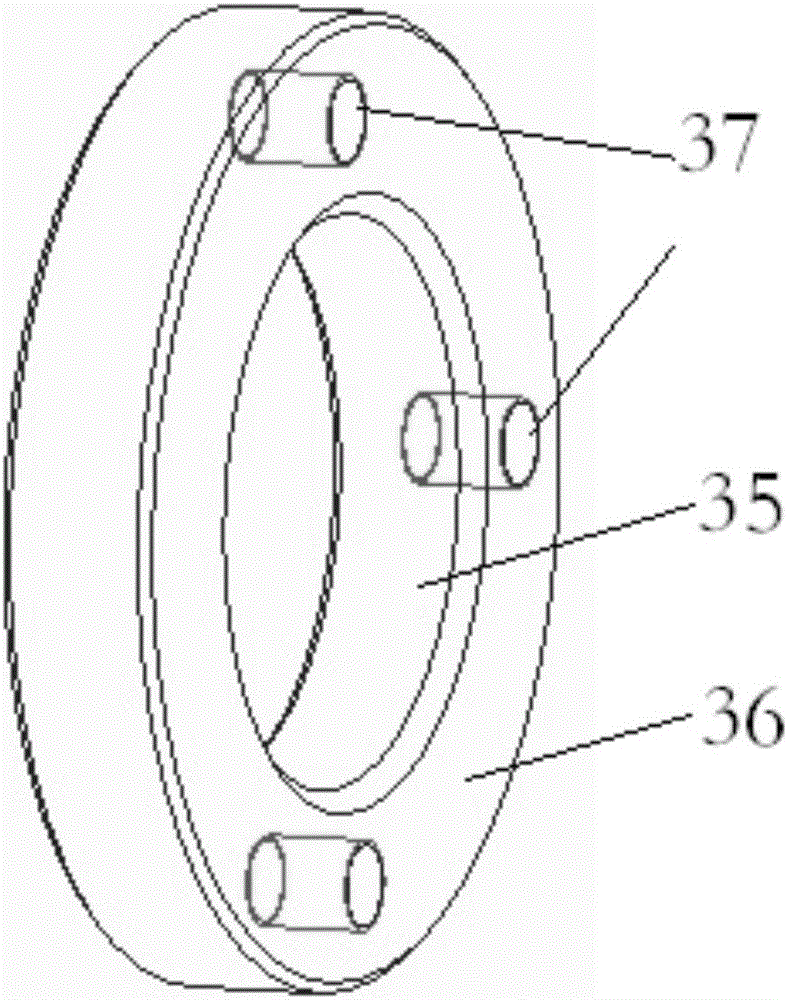

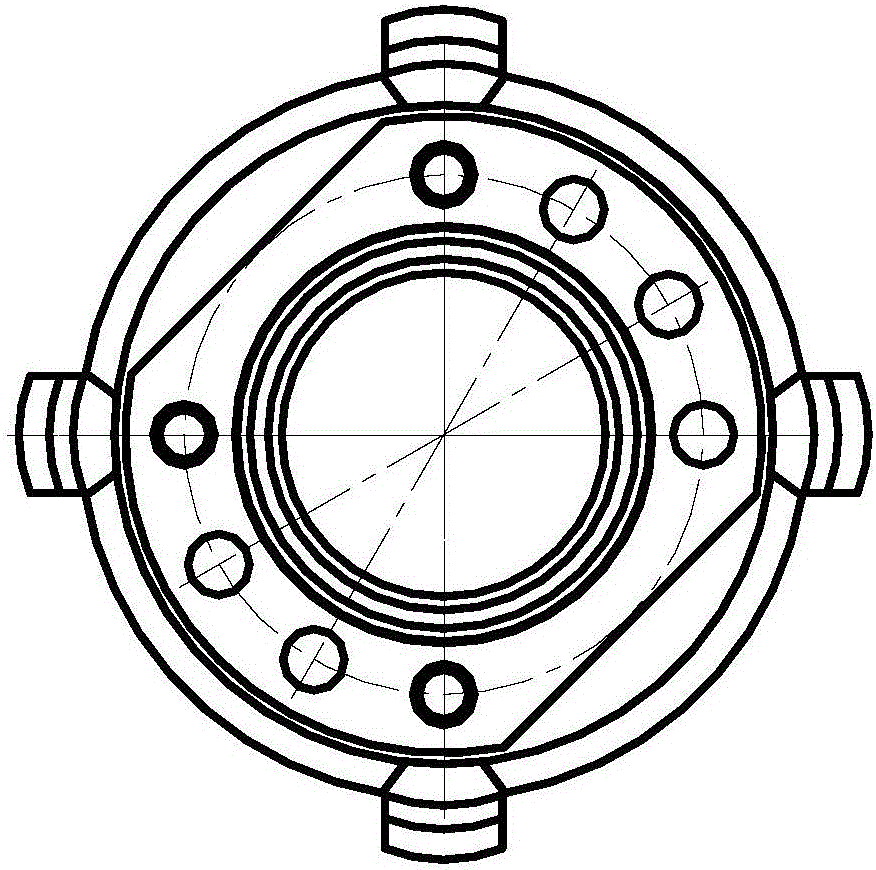

Abrasive drill for robot-assisted cervical intervertebral disc replacement surgery system

InactiveCN107496004AReduce deformationMeet grinding requirementsJoint implantsSurgical manipulatorsMedicineCoupling

The invention provides an abrasive drill for a robot-assisted cervical intervertebral disc replacement surgery system, relates to the abrasive drill, and aims to solve the problem that at present, no special abrasive drill for the robot-assisted cervical intervertebral disc replacement surgery system exists. One end of a fixing circular ring penetrates through an output shaft of a high-speed DC motor and is fixedly mounted on the end surface of the output shaft end of the high-speed DC motor; the other end of the fixing circular ring is fixedly mounted on one end surface of a shell; one end of an abrasive drill transmission shaft is mounted inside the shell through a bearing; one end of the abrasive drill transmission shaft is fixedly connected with the output shaft of the high-speed DC motor through a shaft coupler; an abrasive head is fixedly mounted at the other end of the abrasive drill transmission shaft; a first central through hole is axially formed in an end cover; the end cover penetrates through the abrasive drill transmission shaft and is fixedly mounted on the other end surface of the shell; a second central through hole is axially formed in a connecting platform; the connecting platform penetrates through the high-speed DC motor and is fixedly connected with the fixing circular ring. The abrasive drill is applied to the for the robot-assisted cervical intervertebral disc replacement surgery system.

Owner:CHANGSHA ZHANSHUO XUANXING INFORMATION TECH CO LTD

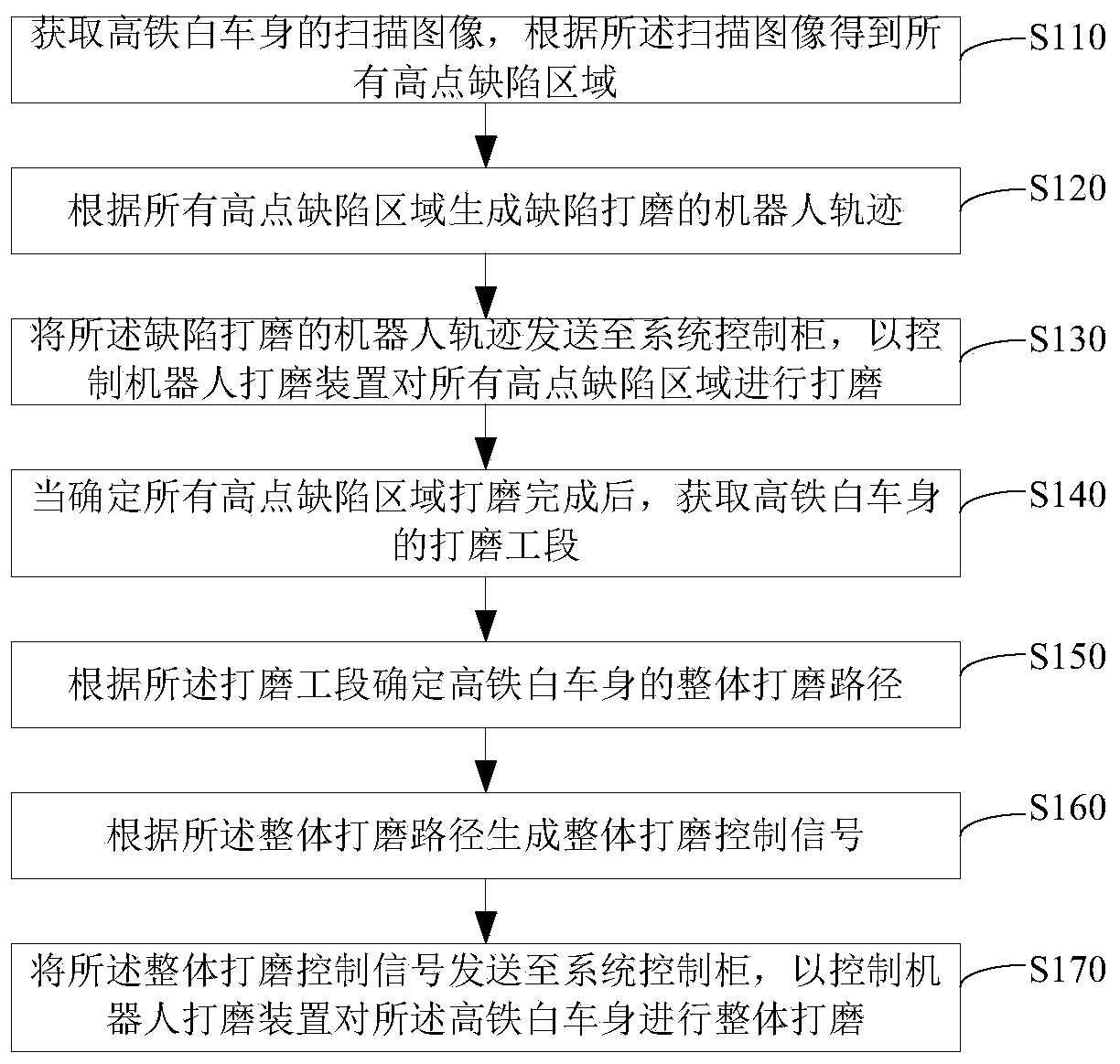

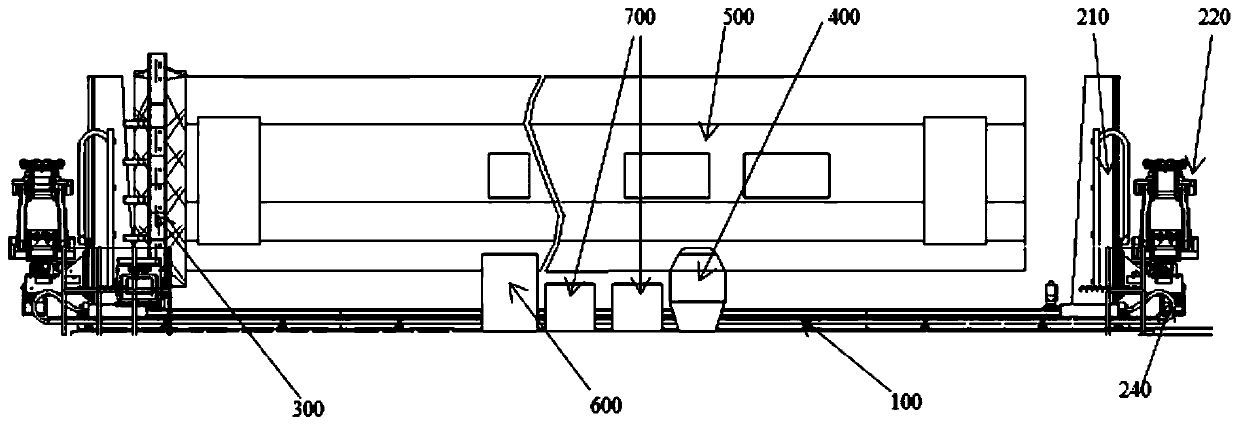

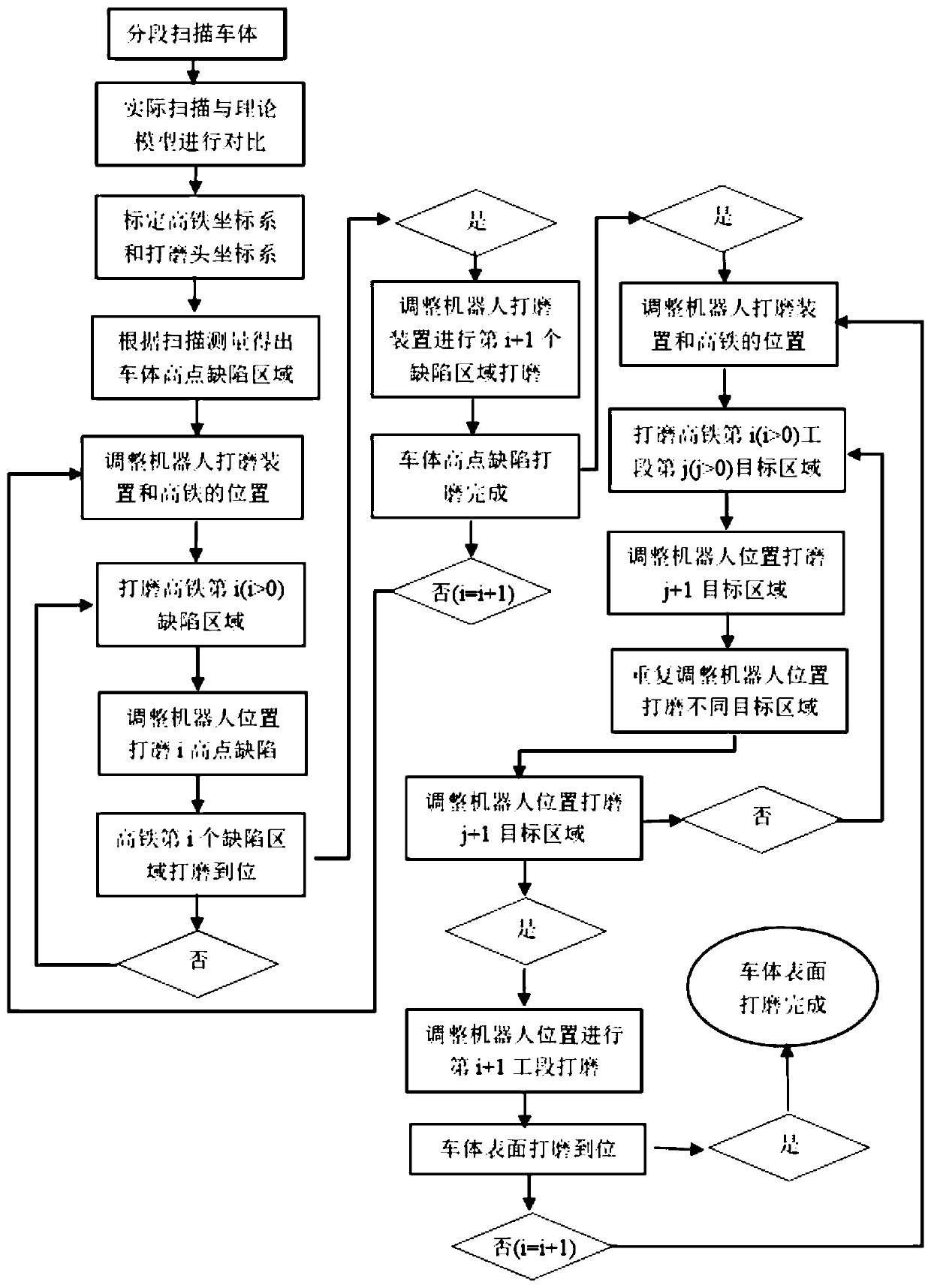

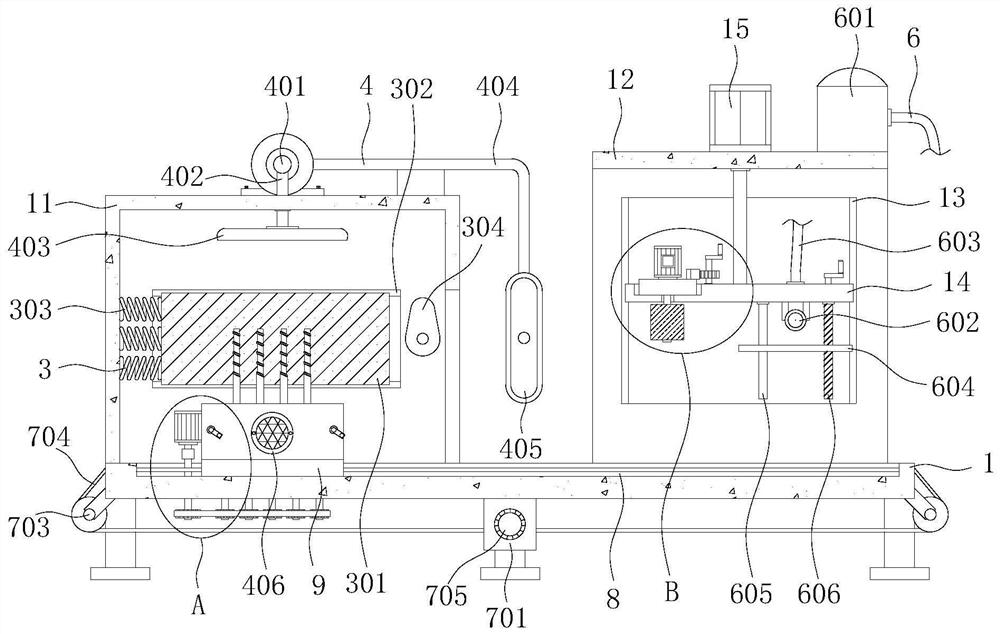

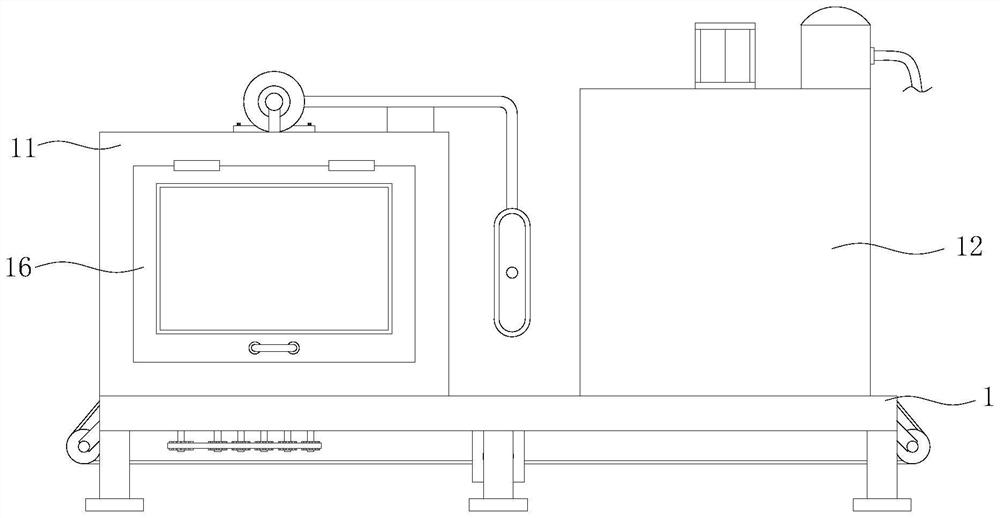

G-series high-speed train white body multi-robot cooperative grinding control method, device and system

ActiveCN111571612AEnsure consistencyMeet the grinding requirementsProgramme-controlled manipulatorGrinding feed controlControl signalControl engineering

The invention relates to the technical field of industrial robot grinding machining and specifically discloses a G-series high-speed train white body multi-robot cooperative grinding control method. The method comprises the steps that a scanning image of a G-series high-speed train white body is obtained, and all high point defect areas are obtained according to the scanning image; robot trajectories for defect grinding are generated according to all the high point defect areas; the robot trajectories for defect grinding are sent to a system control cabinet; grinding workshop sections of the G-series high-speed train white body are obtained; overall grinding paths of the G-series high-speed train white body are determined according to the grinding workshop sections; overall grinding control signals are generated according to the overall grinding paths; and the overall grinding control signals are sent to the system control cabinet. The invention further discloses a G-series high-speedtrain white body multi-robot cooperative grinding control device and system. According to the G-series high-speed train white body multi-robot cooperative grinding control method provided by the invention, grinding units and the grinding workshop sections of robots are determined by reasonably planning the grinding paths, and it is guaranteed that putty on the G-series high-speed train white bodyis ground in place and grinding requirements are met.

Owner:无锡中车时代智能装备研究院有限公司

Grinding device for production of threaded cutter for woodworking

InactiveCN111958048AIntegrity guaranteedImprove practicalityGrinding drivesFiling/rasping devicesScrew threadWorkbench

The invention discloses a grinding device for production of a threaded cutter for woodworking, and relates to the technical field of woodworking cutter machining. The grinding device for production ofthe threaded cutter for woodworking comprises a workbench. A clamping and rotating mechanism, a shell peeling mechanism, a cleaning and cooling mechanism, a grinding mechanism, a spraying mechanism and a transmission mechanism are arranged on the workbench. A third sliding groove is formed on the outer surface of the top of the workbench. A third sliding block is mounted on the third sliding groove in a sliding manner. A work box is welded and mounted on the outer surface of the top of the third sliding block. According to the grinding device for production of the threaded cutter for woodworking, the threaded cutter can rotate while being clamped and fixed, integrity of subsequent grinding work is guaranteed, and meanwhile the device can grind four sets of threaded cutters at the same time; and compared with a device adopting cutters which cannot rotate and a device only capable of grinding one set of cutter at a time, the device has the advantages of being efficient and practical andis convenient to use and popularize.

Owner:湖州南浔博锐木工刀具有限公司

TFT touch screen grinding rod and preparation method thereof

ActiveCN111041262ASolve the problem of edging and light leakageImprove qualityTurbinesOther manufacturing equipments/toolsDiamondGreen body

The invention discloses a TFT touch screen grinding rod and a preparation method thereof. The preparation method comprises the steps that copper powder, tin powder, cobalt powder, silver powder and cerium powder are mixed and then subjected to ball milling, a metal matrix is obtained, the metal matrix is mixed with diamond, and a material is obtained; and cold pressing is performed on the materialto obtain a green body, and hot pressing sintering is performed on the green body to obtain the TFT touch screen grinding rod. The TFT touch screen grinding rod prepared by the method has the characteristics of strong holding force, high exposure degree, long service life and the like, the grinding requirement of the TFT touch screen can be met and the speed can be increased from conventional 250mm / min to 350 mm / min, the working efficiency is improved by 140% and the batch use quality is stable without the sparking phenomenon. The preparation method is simple, wide in raw material source andsuitable for modern industrial production.

Owner:苏州赛尔科技有限公司

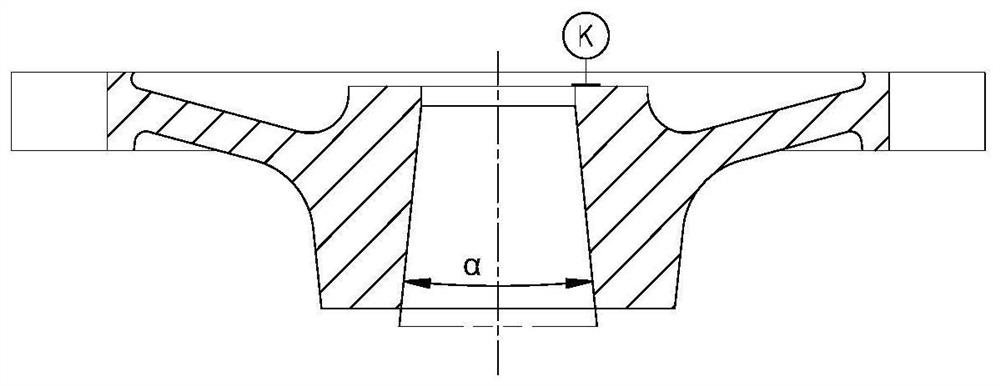

Gear grinding fixture for bevel gear

ActiveCN111975133AEliminate damageGuaranteed rigidityGear-cutting machinesGear teethGear grindingGear wheel

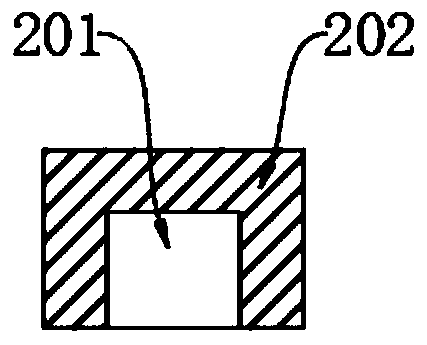

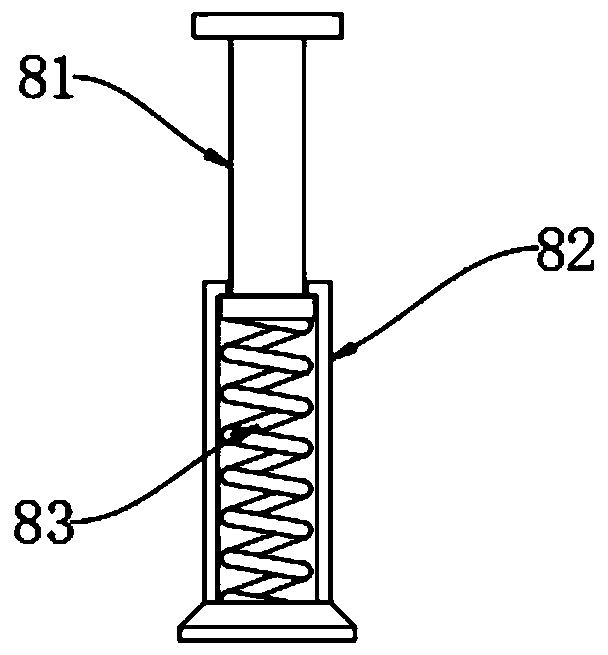

The invention discloses a gear grinding fixture for a bevel gear. The gear grinding fixture comprises a positioning shaft connected with a fixed part of a machine tool and a center seat connected witha movable part of the machine tool. The center seat is provided with a center and an upper indenter coaxial with the center seat. One end of the upper indenter is located in the center seat, and theother end extends out of the center seat and the end face can abut against a gear to be processed. A spring is arranged between the top surface of the upper indenter and the center seat. One end of the center is located in the center seat. The other end of the center penetrates from the spring and the upper indenter and the contact surface between the end and a central hole of the positioning shaft is a cone surface. The top of the cone surface is a flat surface and the flat surface is flush with the end surface of the upper indenter. The gear grinding fixture eliminates the random out-of-tolerance phenomenon of products during gear grinding and satisfies the requirements of gear grinding.

Owner:东风汽车零部件集团有限公司刃量具分公司

Double-station full-automatic double-sided grinding machine integrated with robot

PendingCN113199391AImprove stabilityImprove grinding efficiencyLapping machinesGrinding machinesGear wheelElectric machinery

The invention discloses a double-station full-automatic double-sided grinding machine integrated with a robot. The double-station full-automatic double-sided grinding machine integrated with the robot comprises a box body, a transferring device, a lower grinding structure, a clamping robot and an upper grinding structure. The double-station full-automatic double-sided grinding machine is characterized in that the box body is arranged on a bracket, a stand column is arranged on the box body, and a top plate is arranged at the top of the stand column; and the transferring device comprises a cross beam, a first motor, a rotating roller and a conveying belt, one end of the cross beam is arranged on the outer wall of the box body, the other end of the cross beam is arranged on the bracket, a bearing is arranged on the cross beam, the first motor is arranged on the cross beam, and the two ends of the rotating roller are arranged on a connecting shaft. According to the double-station full-automatic double-sided grinding machine, a ground workpiece can be transferred to the conveying belt through the clamping robot, and a workpiece needing to be ground on another conveying belt is transferred into a bearing hole in a planetary gear to be ground, so that automatic feeding and discharging of the ground workpiece are realized, the labor intensity and the safety of operators are reduced, and the feeding and discharging efficiency of the workpiece is improved.

Owner:ANHUI GENAN MULLERS

Numerically controlled inner tooth grinding head

InactiveCN1672846ALow costNo interferenceGear teeth manufacturing toolsGear teethEngineeringGrinding wheel

The present invention relates to gear machining equipment, and is especially numerically controlled inner tooth grinding head. The numerically controlled inner tooth grinding head consists of cutter shaft, grinding wheel installing angle regulating mechanism, grinding wheel bearing mechanism and driving force transmission mechanism. The grinding wheel installing angle regulating mechanism consists of the lower arced surface of cutter shaft and the upper arced surface of the grinding wheel support; and the driving force transmission mechanism consists of spring soft shaft and bevel gears. The present invention has the advantages of small grinding error, high grinding precision and smooth running.

Owner:SOUTH CHINA UNIV OF TECH

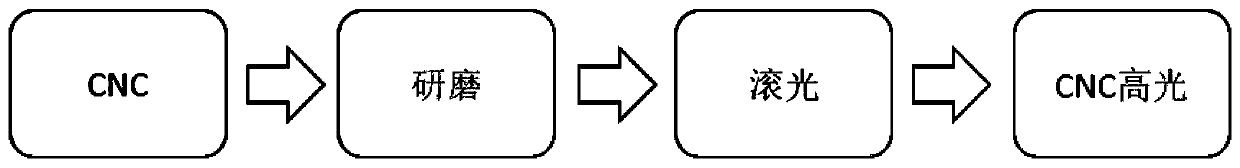

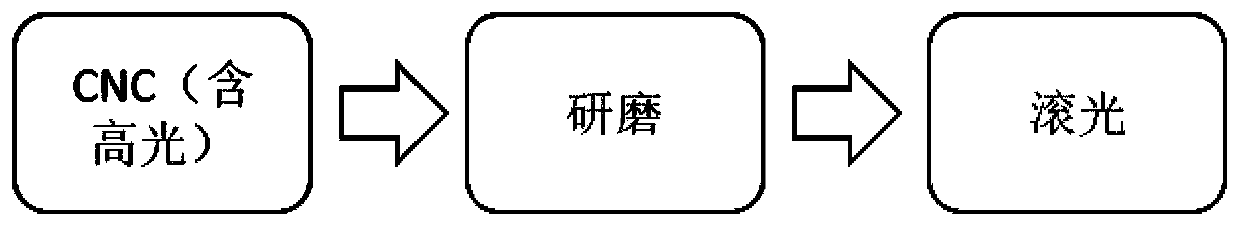

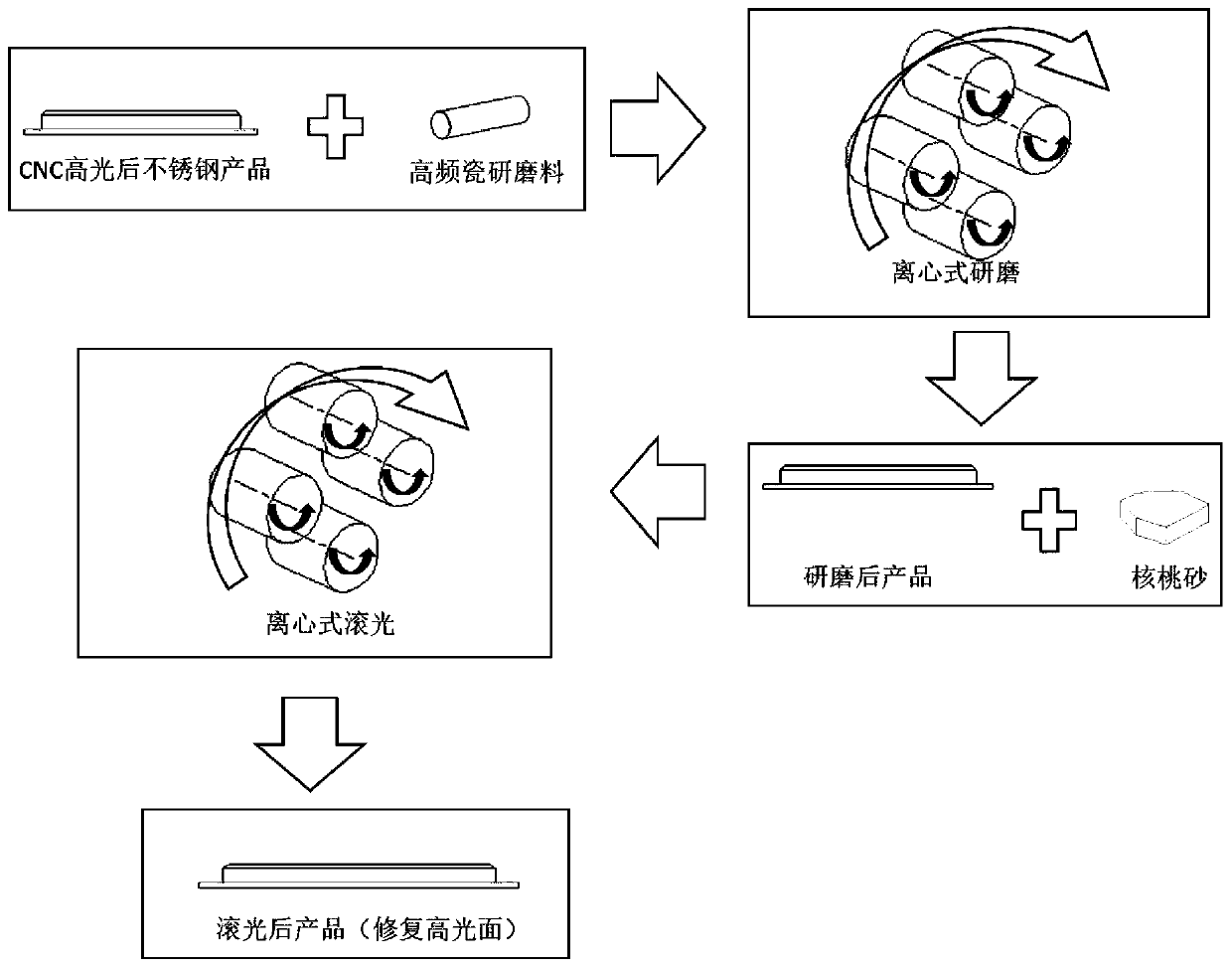

Stainless steel highly-polished surface nondestructive grinding and roll finish repairing method

The invention discloses a stainless steel highly-polished surface nondestructive grinding and roll finish repairing method. The method comprises the steps that A, CNC machining and CNC highly-polishedtreatment are conducted on a stainless steel product; B, grinding is conducted, specifically, the stainless steel product is placed in a roller of a centrifugal grinding machine, centrifugal grindingis conducted on the stainless steel product through a high-frequency ceramic grinding material, and the grinding time is 5-10 min; and C, roll finish is conducted, specifically, the ground stainlesssteel product is placed in a roller of a centrifugal roll finish mill, roll finish treatment is conducted with walnut sand as a grinding material, and the roll finish grinding time is 22-25 h. According to the method, as for the stainless steel highly-polished surface product needing to be machined and with the weight smaller than 30 g, the manufacturing procedures are reduced, the yield is increased, and the cost is reduced. By the adoption of the method, CNC machining is only needed once, the problem of damage to the highly-polished surface is solved through new technical schemes of grindingand roll finish, CNC secondary machining is reduced, cost is greatly saved, and the machining efficiency is improved.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

Building material smashing and damping device

InactiveCN108097371AAvoid damageUniform particle sizeNon-rotating vibration suppressionGrain treatmentsMotor driveEngineering

The invention discloses a building material smashing and damping device. The building material smashing and damping device is provided with a smashing chamber, a grinding chamber and a feeding chamber; building materials are extruded and smashed in the smashing chamber through a gear group and then are further grinded through the grinding chamber; a sieve plate is slantly arranged between the smashing chamber and the grinding chamber; by arranging a front elastic base, a rear elastic base and a universal rotating shaft bracket on the lower portion of a machine body and by utilizing vibration generated when a motor drives the gear group to rotate so as to drive the machine body, the sieve plate is made to vibrate, so that the smashed building materials are better sieved; and according to the design, a sieve plate vibration device is not required to be arranged, the equipment mechanism is more simplified, meanwhile, buffering can exist between the machine body and a supporting frame, andnoise during working of the equipment is reduced.

Owner:余成鹏

Resin binder concrete grinding and polishing wafer and preparing method thereof

ActiveCN106346376AImprove sharpnessMeet grinding requirementsAbrasion apparatusGrinding devicesHeat resistanceAdhesive glue

The invention discloses a resin binder concrete grinding and polishing wafer and a preparing method thereof. The grinding or polishing wafer is comprised of a diamond, a binder, fillers and a SiC, and is prepared from a raw material processing, a mixing, a molding process, a hardening process, an adhesive gluing tape cloth, a printing mesh number and a packaging storage step. The prepared product has sharp and durable, good heat resistance, grinding keeping a good sharpness from beginning to end, no ablation of the ground, no smell and in line with the requirements of concrete sealing solid ground grinding as well as suitable for heavy grinding equipment for curing concrete floor requirements. The preparating method is simple and safe, the method not only improves the efficiency and reduces the labor cost but also has the high economic efficiency, and the method has been widely recognized by the user.

Owner:NANAN BURKE DECORATION ENG CO LTD

Sequential grinding tool, machining mechanism and grinding method for planetary lead screw nut

ActiveCN106112145AImprove processing efficiencyLoading and unloadingThread cutting machinesBall screw driveEngineering

The invention provides a sequential grinding tool, a machining mechanism and a grinding method for a planetary lead screw nut. The machining mechanism comprises a workpiece headstock, a spindle transmission and a grinding wheel headstock and further comprises a first-stage guide rail and a second-stage guide rail. The second-stage guide rail is driven by a trapezoid lead screw or a ball lead screw and used for coarse grinding. The first-stage guide rail is a linear guide rail or is driven by a precision ball lead screw and used for accurate grinding. The second-stage guide rail is installed on a mounting base of the whole machining mechanism, and the second-stage guide rail can be fixedly connected with or separated from the mounting base through a second-stage clamping mechanism. The first-stage guide rail is installed on the second-stage guide rail. The first-stage guide rail can be fixedly connected with or separated from the second-stage guide rail through a first clamping mechanism. The spindle transmission is fixedly installed on the first-stage guide rail. An output shaft of the spindle transmission is connected with the workpiece headstock. The workpiece headstock and the grinding wheel headstock which is located on the same axis as the workpiece headstock are used for clamping a workpiece to be ground and a grinding wheel correspondingly.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com